1. Introduction

Interest has recently been focused on increasing energy demands and the issue of climate change as regards economic development/competition, ongoing deforestation and transportation needs. In Europe, 50% of final energy consumption is allocated for heating and cooling purposes, of which 80% is utilized inside buildings [

1,

2]. To appropriately address this issue, the 2009 Renewable Energy Directive (RED) assigned a renewable energy target to the building sector of 20% of final energy consumption by 2020; furthermore, EU Member States agreed to this promising target, as part of the EU’s energy and climate goals for 2030, that is, to achieve at least a 27% reduction in final energy consumption by 2030 [

1]. Defining an approach to charging and discharging thermal energy with a certain quantity in the form of passive and active storage methodology constitutes the key to successful renewable energy development.

PCMs have been used in various fields for thermal energy storage (TES), especially in the building envelope [

3]. Over a period of decades, many researchers have shown interest in integrating PCM as storage elements into the floor, dwelling wall, exterior wall, interior wall, as a partition wall, and so forth. Several works in the literature regarding PCMs and their building applications have thus been reviewed herein: PCM in cooling, heating and power generation [

4,

5,

6,

7]; PCM latent heat thermal energy storage (LHTES) systems towards improving building energy efficiency [

8]; a summary of 100 references relating to thermal energy storage with PCMs in building application encompassing impregnation methods, thermal performance analyses and numerical simulations [

9]; PCM applications in highly energy-efficient houses in relation to an analysis of the system, materials, switching temperatures, containments and design strategies [

10]; a review of PCMs integrated into building walls [

11]; and a review of PCM-based microencapsulation for building applications [

12]. PCMs have been studied by means of—(a) numerical methods: novel composite PCM panels incorporated into an external wall structure [

13]; numerical study of a PCM wall in evaluating several heat transfer correlations for natural, mixed and forced convection flows [

14]; a year-round simulation of a room integrating a new type of composite wall system embedded with various PCMs for cooling/heating energy savings, plus a PCM-enhanced envelope system providing the potential for thermal energy savings [

15,

16]; (b) experimental studies—thermal behavior and reduced energy consumption in two residential rooms embedded with a PCM layer in the inner face during heating periods [

17]; thermal performance improvement of a building envelope with and without PCM wall unit integration [

18]; investigation of a macro-encapsulated PCM position in the concrete walls of model rooms under actual conditions [

19]; PCMs incorporated into walls as thin layers to assess thermal performance and determine optimal PCM locations [

20]; assessment of residential building walls containing pipe-encapsulated PCMs for thermal performance in summer conditions [

21]; and (c) comparative studies of both these cases (i.e., numerical and experimental studies)—a wall composed of five layers of PCM placed on the back wall of the room set up to test thermal performance throughout the whole year in a cold climate [

22]; shape-stable nano-PCM composite incorporated into the gypsum wallboard as part of energy-efficient building construction [

23]; a study to investigate the effects of various parameters of PCM wallboard, such as phase change temperature, convective heat transfer coefficients and thickness [

24]; and gypsum wallboards incorporated with three different PCMs [

25]. Other research has applied PCM elements in actual in situ case studies [

26,

27]. Yannick et al. [

28] ran a simulation of the energy performance of a passive wall integrated into twin building zones located in the southern part of France. This passive wall, constituted from the exterior face by a 0.8-cm thick sheet of glass, a 4-cm thick layer of silica aerogel and glass bricks filled with PCM, was expected to simultaneously provide insulation, heat storage, and daylighting to the interior space. The results obtained indicated energy savings during the winter. Stephen et al. [

29] embedded PCM into the wallboard of a building in order to reduce the heating required to maintain the space comfortable. The numerical study was modeled by assuming that heat transfer through the building’s multi-layered envelopes was one-dimensional. Its authors stated that 21.38% of energy savings could be realized; consequently, they noted that using an optimized PCM in its optimal placement is fundamental to responding to the various climatic conditions. Alexander et al. [

30] investigated a concrete wall integrating PCM in order to assess the annual energy and cost savings of an individual house subjected to two climate conditions, namely those of San Francisco and Los Angeles. They found that PCM integration can reduce the cooling load from 85% to 100% for San Francisco and from 53% to 82% for Los Angeles, while the effects of microencapsulated PCM on the reduction in annual heating demand and cost savings were small. Xu Wang et al. [

31] developed a PCM-brick wall (1.6 W × 2.4 H × 0.24 dm

3) in the aim of studying PCM efficiency (shape-stabilized phase change material made of high-density polyethylene, expanded graphite and paraffin) relative to the energy consumption performance inside the full-scale room sized 3.25 m (L) × 3.86 m (W) × 2.91 m (H) during three seasons—winter, summer, and midseason. Results showed that the PCM-brick wall can in winter reduce the heating load by 10% to 30%, while the cooling load could be reduced by 24.32% under summer conditions.

A review of the application of Trombe wall systems in buildings by Hu et al. [

32] described, for the past 15 years, the most pertinent contents of the solar Trombe walls installed by researchers; moreover, Saadatian et al. [

33] reviewed Trombe wall applications in building envelopes. A composite Trombe wall was originally built with element transparency as a glazing/double glazing configuration, with the addition of a few cm to allow for a non-ventilated air gap and a storage wall with/without PCM, as well as another few cm behind the storage wall with an insulating panel that creates a ventilated air gap between the two surfaces (storage and insulating wall) [

34]. This type of passive set-up has been studied for decades since its initial application with a storage wall and without PCM by F. Trombe and J. Michel [

35]. Subsequently, composite Trombe walls were renovated in the aim of incorporating PCMs to improve the quantity of thermal energy storage. A number of publications related to numerical and experimental studies of composite Trombe wall storage elements feature—(1) a storage wall without PCMs [

36,

37,

38,

39,

40]; (2) a storage wall with PCMs [

41,

42]; and (3) a comparison of both cases of storage walls with/without PCMs and another case of a passive wall [

43,

44,

45].

Simulation tools have been built to study the thermal behavior aspects of energy performance inside the building with respect to the heat transfer exchange—radiation, convection, and conduction. These tools further facilitate designers’ efforts in modeling different case studies of thermal energy performance through designing, drawing, inputting thermal properties of elements, connecting between model components (the Functional Mock-up Interface (or FMI)), and even coding or modifying the codes for specific interfaces (e.g., the PCM storage wall). Some of the more widespread programs have been utilized to model and simulate the energy performance of the designated buildings with respect to various configurations studied, namely—(a) EnergyPlus: a lightweight building simulation study [

46]; the effectiveness of PCM wallboards on partition walls [

47]; a PCM model for opaque walls [

48]; a study of building retrofitting based on the impact of PCMs [

49]; a simulation of microencapsulated PCM wallboards for summer thermal comfort in buildings [

50]; optimization of the PCM melting temperature applied to glass curtain walls for a retrofitted building system [

51]; a study of PCM impact on energy consumption and economic analysis [

52]; a study of PCM melting temperature to enhance thermal comfort [

53]; a study of PCMs in minimizing heating/cooling energy consumption [

54]; and a parametric analysis of PCM walls improving thermal comfort [

55]; (b) ESP-r: integration of microencapsulated PCMs into interior walls for energy savings [

56]; investigating a hybrid adaptable thermal storage (HATS) to reduce heating demands and enhance temperature comfort [

57]; a study of PCM-gypsum composites in buildings [

58]; and isothermal heat storage systems in buildings [

59]; (c) TRNSYS: a study of light wallboards containing PCMs [

60]; an approach to the energy simulation of PCM elements in building applications [

61]; a study of ceiling panels integrating PCM for lightweight applications in retrofitted buildings [

62]; a numerical model of external building walls containing PCM [

63]; a study of twin cells separated by a hollow glass brick wall filled with PCM [

64]; integration of PCM technologies for net zero energy buildings [

65]; the energy performance of a Trombe wall in various building configurations [

66]; the effect of PCM in improving the thermal comfort in buildings [

67]; (d) Dymola/Modelica: a physical model of HVAC load prediction for urban building districts [

68]; an automated IFC (Industry Foundation Classes)-based workflow for building energy performance [

69]; a study of district energy demand based on the impact of building geometry [

70]; analysis of the impacts of typical envelope models for energy simulation at the district scale [

71]; energy saving potential of a two-pipe system in office buildings [

72]; a novel concept regarding bidirectional low temperature networks [

73]; the agent-based control of building energy systems [

74]; multi-floor building heating models [

75]; semantic inference-based control for building HVAC systems [

76]; equation-based, object-oriented Modelica modeling [

77]; energy performance of a PCM-based heat exchanger coupled with a novel HVAC system [

78]; a study of district heating and cooling systems [

79]; thermal processes in passive solar buildings using an object-oriented environment of Matlab-Simulink and Modelica [

80]; and a coupling of fast fluid dynamics and multi-zone airflow models to simulate the dynamics of HVAC systems [

81]; and (e) DesignBuilder: [

82]; an analysis of energy demands versus comfort levels for buildings integrating PCMs [

83], and so forth.

The Modelica language was designed as a non-proprietary, object-oriented and equation-based language for modeling purposes dedicated to complex physical systems, while Dymola uses the Modelica language as an open source, thus making it feasible to create its own model libraries or else extend the existing Modelica libraries. Dymola/Modelica has enabled us to accelerate development by using the Functional Mock-up Interface (FMI). Wetter and Haugstetter [

84] published a comparison between an equation-based and procedural modeling language for building energy simulation by two software applications. Modelica and TRNSYS were run for this comparison with respect to implementation of a multi-zone building energy simulation. Their results section stated that the model equation was executed with the Modelica language five to ten times faster than that executed with TRNSYS; moreover, it was easier to construct large models using Modelica rather than TRNSYS due to the fact that Modelica enables models to be built in a hierarchical manner in facilitating the debugging and reuse of sub-models. Moreover, these authors compared the balance of thermal energy performance relative to the annual cooling and heating output by these two software applications, which showed a difference ranging from 5% to 20%. Burhenne et al. [

85] studied a building performance simulation using Dymola/Modelica. The purpose of their research was to investigate an application of this tool for building performance simulation (BPS) problems. Their computational results from the Dymola/Modelica program highlighted this modeling language’s flexibility and suitability for tasks within the practical BPS. Gonzaléz and Yebra [

82] presented a comparison between Modelica, enabling use of both Dymola and SystemModeler, and DesignBuilder for their functionality as a building simulation tool. A simple building (7 m long, 4.6 m deep and 3 m high) was selected for modeling and simulation over a one-year period in the aim of observing how closely the obtained results could be approximated when the same building simulation systems were employed. The comparative results from these two building simulation tools led them to conclude that Modelica tools provide a real option for thermodynamic simulation modeling within the building sector and moreover are a key incentive for additional applications. Wetter [

86] presented a multi-zone building model for thermal building simulations in Dymola/Modelica. The modeled room was analyzed for its connection through airflow or heat exchange by means of conduction as regards both the thermal energy analysis and control analysis. It was specified in the conclusion that the room model for simulation leads to a shorter model development time. Tian et al. [

81] presented the integrative model of a building’s heating, ventilation and air conditioning (HVAC) systems, with the assistance of the Dymola/Modelica simulation platform for multi-zone models coupled with computational fluid dynamics (CFD) simulations for airflows. The coupling of three models (static coupling, dynamic coupling and quasi-dynamic coupling) based on Modelica’s “Buildings” library and CFD was studied under two scenarios—(1) implementation with a mass flow rate boundary condition for fast fluid dynamics (FFD); and (2) implementation with a total pressure boundary condition for FFD. Also examined were two case studies for validation—(1) isothermal flow with a non-uniform momentum distribution; and (2) non-isothermal flow with a non-uniform temperature distribution. The simulations results obtained, when compared to the results of measurement experiments, were found to be in good agreement and showed the ability of the coupled simulation models to capture the physics specific to the non-uniformity of a dynamic system.

The scientific gap encountered relates to the model study of a composite Trombe wall both with and without integration of a phase change material in Modelica’s Buildings Library, thus enabling us to study the energy performance of this type of passive wall regarding the heating requirements and comfort temperature available under various climatic conditions. This paper will investigate the impact of integrating PCM into the storage wall. The objectives of this study are twofold—producing results on heating energy, and observing temperature comfort inside the house. The previous study pertains to the model, using the Dymola/Modelica program and components from the Buildings [

87] and IDEAS [

88] libraries, along with the validation of a composite Trombe wall model compared to measurement data [

89]. Heat transfer in this model house is considered in 1D terms everywhere except in the ventilated air gap of the solar Trombe wall, where the vertical airflow is taken into account through enthalpic balances and correlations for the calculation of convective exchange coefficients [

90]. The model of the wall incorporating PCM has been compared with a small-scale experiment on a solar wall built in the laboratory. 17% by mass of BASF PCM Micronal

® were included in the mixture, generating a latent heat of 17,100 J/kg. The phase change temperature is 25.83 °C. Both the experiment and the method employed to characterize this composite material (mortar + PCM) are described in [

91,

92].

The purpose of this paper is to study the impact on the heating demands of integrating a solar wall in a single-family dwelling. Of special interest here is the fact that several types of composite solar walls are being considered—a solar wall integrating a cement mortar storage wall (thickness: 4 cm, sensible heat storage); a second wall integrating a cement mortar storage wall that incorporates a PCM (thickness: 4 cm, sensible and latent heat storage); and a third, more conventional, wall integrating a concrete storage wall (thickness: 15 cm, sensible heat storage). On the other hand, all these cases are compared to the reference case, whereby the house does not have a solar wall but instead a conventional opaque wall. The solar wall recovers free solar energy and transmits it to the room where it is located. To accomplish this, it is necessary to investigate the impact of the solar wall in the target room and possibly in the adjacent rooms. An underlying risk is that the solar wall brings too much energy into the room and causes overheating. One way to avoid this risk is to delay the solar gain until those times when heating is needed (especially at night). The phase shifts of the various solar wall configurations have been studied along with the temperatures in the house’s different rooms. To carry out this study, numerical thermal simulations at the scale of a house have been carried out. The studied house is an actual dwelling located in Croisilles (Pas-de-Calais, northern France), from which we recovered the layout drawings, resembling a standard rental house in France. The numerical simulations were run using a multi-zone model from the “Modelica Buildings Library” which includes the Trombe composite wall model.

2. Description of the Model House

The studied house has been awarded the Low Consumption Building (LCB) certification. The LCB level assesses a building’s energy consumption at less than 50 kWh of primary energy per m2 of usable floor area per year (in terms of conventional consumption for heating, cooling, ventilation, domestic hot water production and lighting systems).

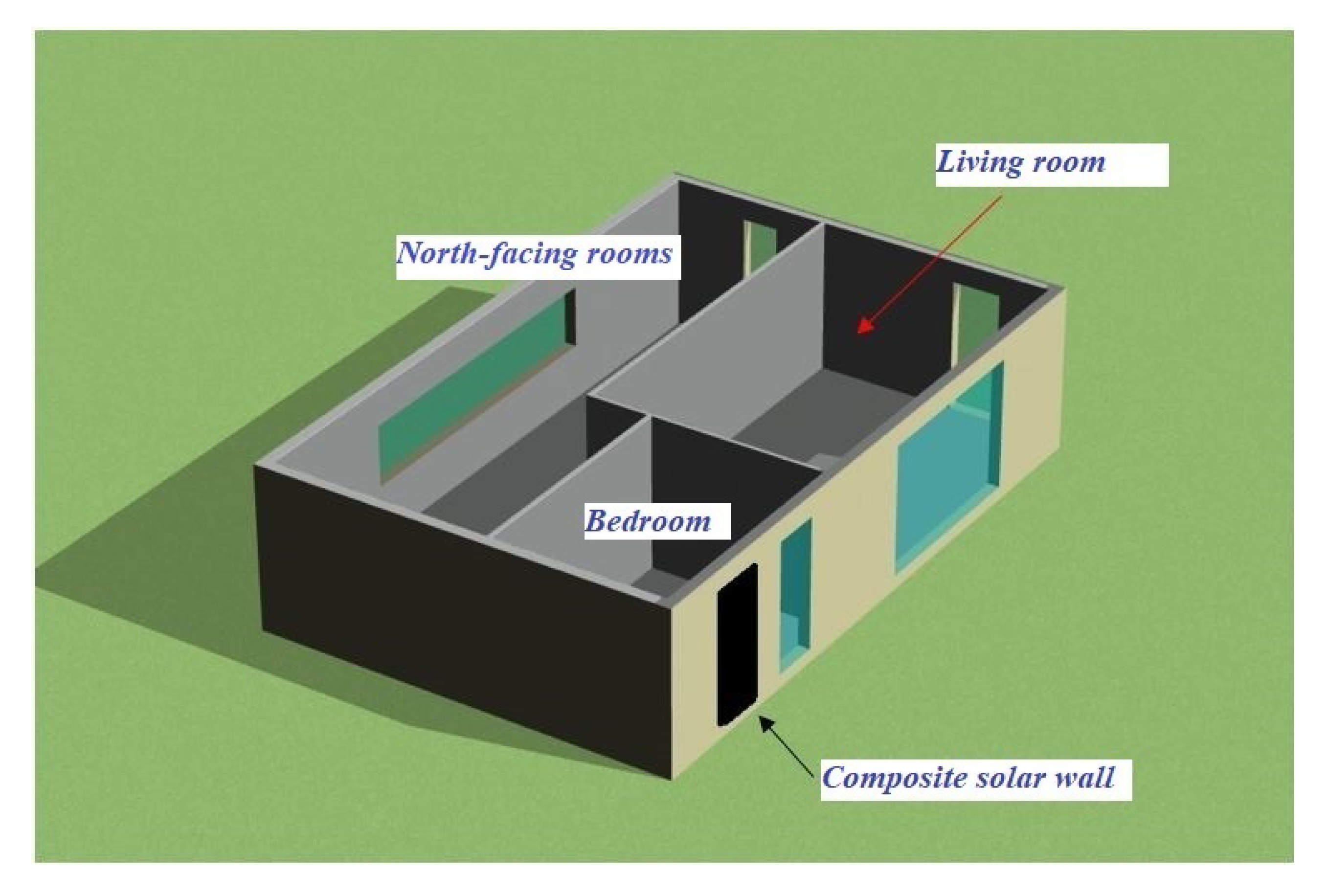

This house is a single-story dwelling whose layout is shown in

Figure 1. This type of residential building was considered for the study since its layout is aligned with the objectives of the study, namely—a heating demand comparison, a comparison of the number of thermal comfort hours, an impact assessment of one room equipped with a solar wall on the adjacent rooms, and an array of results related to the changing solar Trombe wall position. Given that the thermal behavior of the bedroom is being studied more specifically, the zoning has been limited to 3 zones, one of which groups all rooms on the north side of the house, with a total floor area of 30.39 m

2, while the other zones are limited to just one room (11.13-m

2 bedroom, 24.25-m

2 living room). The constructive features of the house are reported in

Table 1.

The thermophysical characteristics of these components are listed in

Table 2.

The windows used in the bedroom, living room and north-facing rooms are double glazed with a 12-mm air gap between 4-mm thick glass panes and a low-emissivity thin coating to minimize the transmission of infrared and ultraviolet light permeating through the glass. The frame area relative to the total window area is 38% (Ufr = 0.38). The dimensions of the windows are indicated in

Table 3.

2.1. Numerical Model

Figure 2 shows the model of the studied house, which has been divided into three thermal zones. The model of the solar wall is connected to the bedroom. This model was validated by comparing the data measured from a small experimental solar wall with the simulated data. The differences between energy balances and temperatures were all within 10% [

89]. The weather data are stored in the ’weaBus’ component. The defined materials for both the building envelope and solar Trombe wall are stored in the yellow tables on the top left-hand side of the schematic model.

The numerical thermal model of each zone in the individual house (bedroom, living room, north-facing rooms) originates mainly from the ’MixedAir’ component of the ’Building Library’. This component can be used to model a single room with an unlimited number of opaque elements or simulate a multi-zone building model. A strong underlying assumption is that the air circulating inside the room is completely mixed, thus taking into account heat transfer through walls, floors, ceilings and windows. The three models are connected in order to simulate the three zones of the house.

Concerning ventilation, the airflow corresponds to the number of main rooms, including the minimal airflow in the kitchen, 150 m

3/h in the present case and fixed in all three zones; moreover, air circulation between zones has not been taken into account [

93].

For this study, all results stem from numerical calculations using the same model. It will be assumed that the errors occurring in each case studied are of the same order of magnitude.

2.2. Composite Trombe Wall Description

The composite Trombe wall (

Figure 3) has been integrated into the south sidewall of the bedroom, which was originally an opaque wall, 1.34 m wide and 2.15 m high (surface area: 2.88 m

2). The operating mode and primary characteristics of this solar wall have been described in a previous study [

89]. The thermal properties of the defined storage walls, as well as the double glazing and insulating panel, are all given in

Table 4.

2.3. Meteorological Data

The meteorological data used were extracted from the ‘EnergyPlus’ software website [

94]. Outdoor temperature, outdoor relative humidity, wind speed and direction, and annual solar radiation were all input into the Dymola model using the ‘ReaderTMY3’ reader in the ‘Modelica Building Library’. Three different climates were considered in this study—Paris-Orly, Lyon, and Nice.

Figure 4 and

Figure 5 show the monthly maximum values of global solar flux and the monthly average outdoor temperatures for these three regions. It can be observed that the Nice region is hotter since it supplies a solar flux and outdoor temperature higher than those of the other two regions.

2.4. Configuration Studied

Three configurations will be implemented for the thermal model house simulation, as reported in

Table 5. Configuration 1 serves as the reference, whereby the model house simulation does not include the solar Trombe wall (composite Trombe wall), but instead an opaque wall similar to the other unglazed walls. The Configuration 2 simulation includes a solar Trombe wall, whose storage wall is made from a 15-cm thick concrete. Lastly, according to Configuration 3, the simulation will be run once again, this time by replacing the concrete storage wall with a 4-cm thick storage wall produced from combining cement mortar and microencapsulated PCM. Three distinct climatic conditions will be utilized to simulate these three configurations—Paris, Lyon, and Nice. Also, two setpoint temperatures will be introduced—(a) a constant setpoint of 20 °C, and (b) a variable setpoint of 19 °C (for 14 h, from 7:00 a.m. to 9:00 p.m.) and 16 °C (for 10 h from 9:00 p.m. to 7:00 a.m.).

2.5. Criteria for Interpreting the Results

To evaluate the benefit of installing a solar wall in terms of energy savings, the main criterion will focus on the heating energy demands recorded based on simulation results compared to the heating energy demands of the reference house. On the other hand, a solar Trombe wall can cause overheating; therefore, it is important to consider thermal comfort in the various thermal zones of the house.

Heating energy demands are calculated based on an integration as a function of both time and power, as follows:

where

Q is the heating energy demands (J),

P the power (W), and

dt the time (s).

Once the solar Trombe wall has performed during the heating period, we are able to observe the comfort criteria within the thermal zone. In summer, a reflective shield placed in front of the glazing blocks the solar gains directed towards the solar Trombe wall. To evaluate the comfort temperature, the notion behind the adaptive comfort method is to be applied. According to this method, for the case when outdoor temperature changes, the perception of comfort in the building also changes because the building’s occupants, as well as their clothing insulation, tend to adapt to climatic conditions.

Standard EN 15251 [

95] takes into account this notion of adaptive comfort; it proposes a comfort temperature calculation that depends on a daily temperature calculated as a moving average. The problem with this method is its failure to consider the case of evaluating comfort temperature with low outdoor temperatures (in winter). McCartney and Nicol [

96] proposed an adaptive comfort temperature calculation based on measurements conducted in France; it is based on a running mean temperature

TRM, which is assessed daily according to its value on the previous day and the value of the daily mean temperature of the day preceding

TDM:

These authors then proposed calculating the comfort temperature as a piecewise affine function of

TRM:

It can be thus be considered that 80% of people are satisfied with a temperature within a zone ±3.5 °C on either side of this comfort temperature. For the study on winter comfort, it is therefore stipulated to define an upper limit temperature Tcmax of 3.5 °C above Tc (Tcmax = Tc + 3.5 °C) as a comfort criterion. In this case, such a limit allows calculating, during the heating period with a solar Trombe wall in operation, the number of hours of temperature discomfort, that is, when temperature fluctuations exceed this comfort criterion. For Paris weather, during the heating period, this Tcmax temperature varies from 26 °C during the coldest part of the winter to roughly 28 °C.

4. Conclusions

This study has conducted the dynamic thermal simulations of a French Low Consumption Building (LCB) house. The objective was to demonstrate the benefit of a solar Trombe wall installation on the annual heating energy demands. The other aspect examined herein consisted of comparing simulation results of the model house with the PCM integrated into the solar Trombe wall; this comparison focused on heating energy demands, energy savings and the number of hours of temperature discomfort. The design house was modeled with the thermal simulation software Dymola/Modelica. Moreover, the numerical model of the solar Trombe wall was developed and validated using experimental data from previous studies [

38,

89].

To carry out the study, a detached single-family house was divided into three thermal zones, and various configurations were applied. Three distinct climatic conditions were chosen in this study to simulate and analyze energy performance—Paris in the north, Lyon the center, and Nice the south of France. The three specified configurations are as follows:

Simulation of the house without a solar Trombe wall—Configuration 1;

Simulation of the house with a solar Trombe wall yet PCM (either concrete or mortar storage wall)—Configuration 2;

Simulation of the house with a solar Trombe wall integrating the PCM storage wall—Configuration 3.

An analysis of the results has indicated that the installation of a solar Trombe wall, regardless of the configuration (concrete, mortar with or without PCM) makes it feasible to reduce the heating energy demands in the bedroom on the order of 20 to 30% depending on the climate zone. PCM introduction into the mortar has, however, a rather weak effect on heating energy demands (reduction on the order of 2% compared to mortar alone), but the energy heating demands are closely replicated with installation of a concrete storage wall.

For a storage wall with 4 cm of mortar, the overheating generated in the zone containing the solar Trombe wall is very pronounced. It abates somewhat if air is circulating between the rooms of the house. This finding is also valid when integrating PCM microcapsules into the mortar, even though the temperature varies slightly less. The 4-cm thick PCM storage wall does not yield a thermal behavior in the room close to that of the 15-cm thick concrete storage wall. The concrete solar Trombe wall releases and extends the thermal energy much later into the room; therefore, it allows limiting the periods of discomfort while offering the same energy efficiency.

It is important to highlight from the various results reported that the solar wall should not be expected to deliver maximum energy, but instead serve as an energy source when heating is required. It is thus possible to prevent overheating and delay switching on the heating system in order to save energy.

Moreover, it is interesting to note that even if the variable setpoint temperature with night and day reductions were to be applied, the solar Trombe wall would retain its potential to reduce heating energy demands, regardless of the climate zone.