A New Model for Environmental Assessment of the Comminution Process in the Chain of Biomass Energy Processing †

Abstract

1. Introduction

2. Materials and Methods

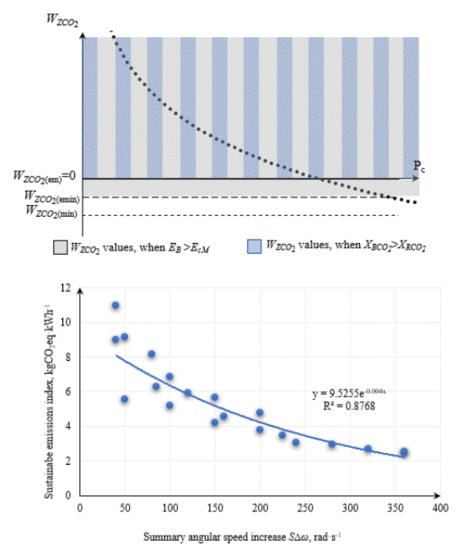

2.1. Model of a Sustainable CO2 Emissions Index

- ΔBCO2—environmental benefits—change in CO2 emissions,

- NCO2—environmental costs of grinding—energy consumption.

- XBCO2—CO2 emissions from the energy use (for example, combustion) of ground biomass, kgCO2eq,

- XRCO2—the amount of CO2 emissions associated with the use of electricity in the grinding process, kgCO2eq.

- mB—mass of ground biomass, kg,

- JACO2i—unit CO2 emissions for the i-th size class of biomass, kg·kWh−1,

- WBi—calorific value of the i-th size class of biomass, kWh·kg−1,

- qi—mass share of the i-th size class of biomass.

- EcM—total energy consumption of the grinding machine during the grinding of a mass of biomass mB, kWh,

- JKCO2—emissions of carbon dioxide for the production of electric energy from coal, kgCO2eq·kWh−1.

- Q—grinding efficiency, kg·h−1,

- t—time, h,

- Pi—power on the i-th grinding element,

- Pc—total power of the grinder.

- WBmin—minimal calorific value from the set of values of the i-th biomass fractions WBi,

- kk = 0.4—co-generation coefficient [59].

- if JACO2min/kk > JKCO2 then WZCO2 (e) > 0,

- if JACO2min/kk < JKCO2 then WZCO2 (e) < 0.

2.2. Conditions of Experimental Model Verification

- Choice and preparation of the test stand;

- Choice and preparation of the biomass to be tested;

- Determination of grinding conditions and the tests program;

- Comminution of the biomass while monitoring functional characteristics of grinding

- Determination of calorific values and emission values for given biomass fractions after comminution;

- Calculation of the value of the sustainable CO2 emissions index;

- Analysis of the relations between the emissions index and the angular speed of the working elements cutting edges.

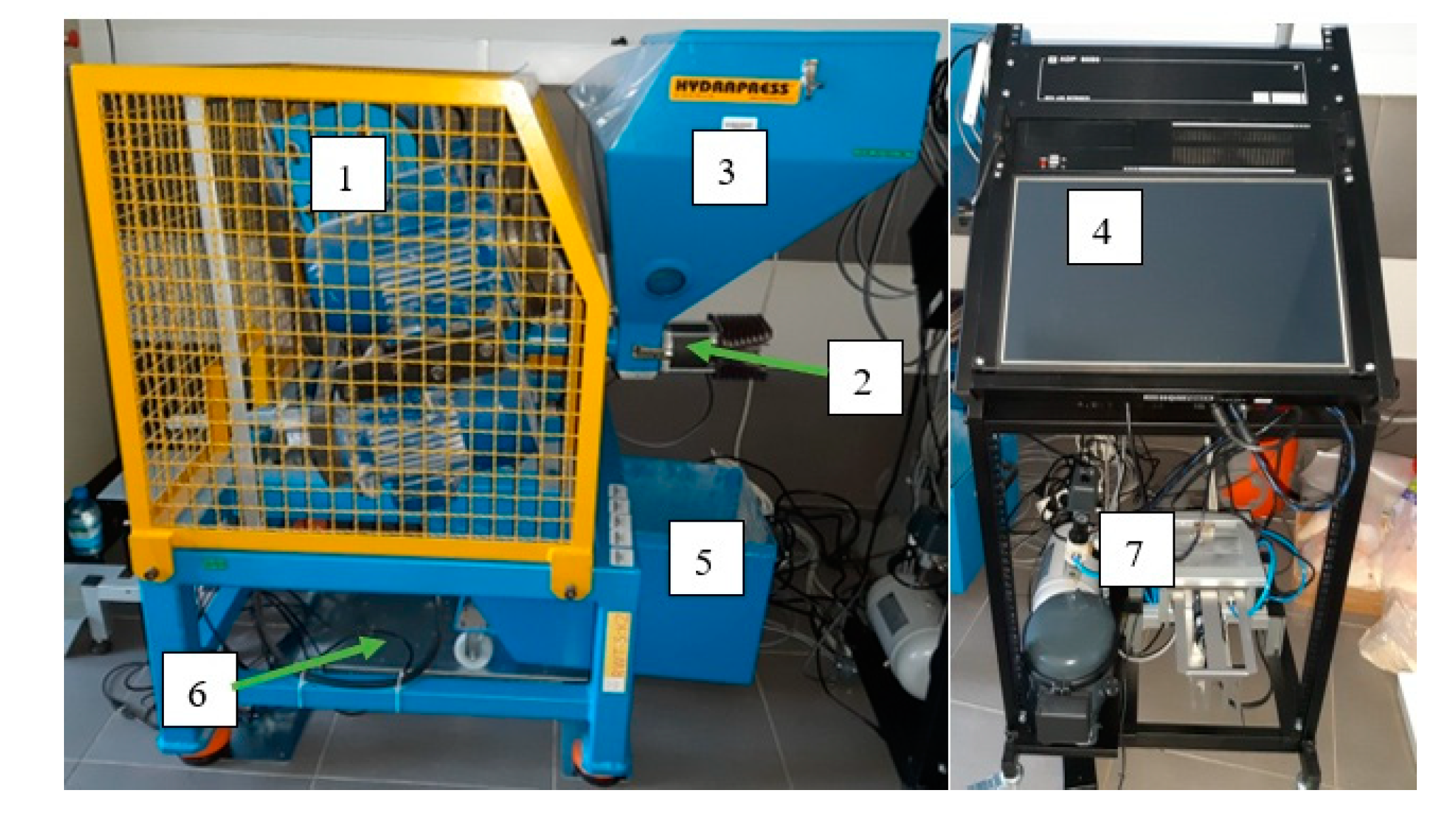

2.2.1. Test Stand

2.2.2. Comminuted Biomass

2.2.3. Comminution Process Conditions

2.2.4. Determination of Calorific and Emissions Values for Given Biomass Fractions after Comminution

2.2.5. Analytical Methods

3. Results and Discussion

3.1. Input Variables of the Sustainable CO2 Emissions Model

- CO2 emissions involved in the production of electric energy from coal is 0.812 kgCO2·kWh−1 [70].

- In the emissions analysis of this paper, only emissions from the grinding and energy-use processes were considered. Emissions relating to the pelletization process were excluded. The analysis was limited to energy use in the form of pellet combustion. No other methods were considered, such as gasification, fermentation, or digestion.

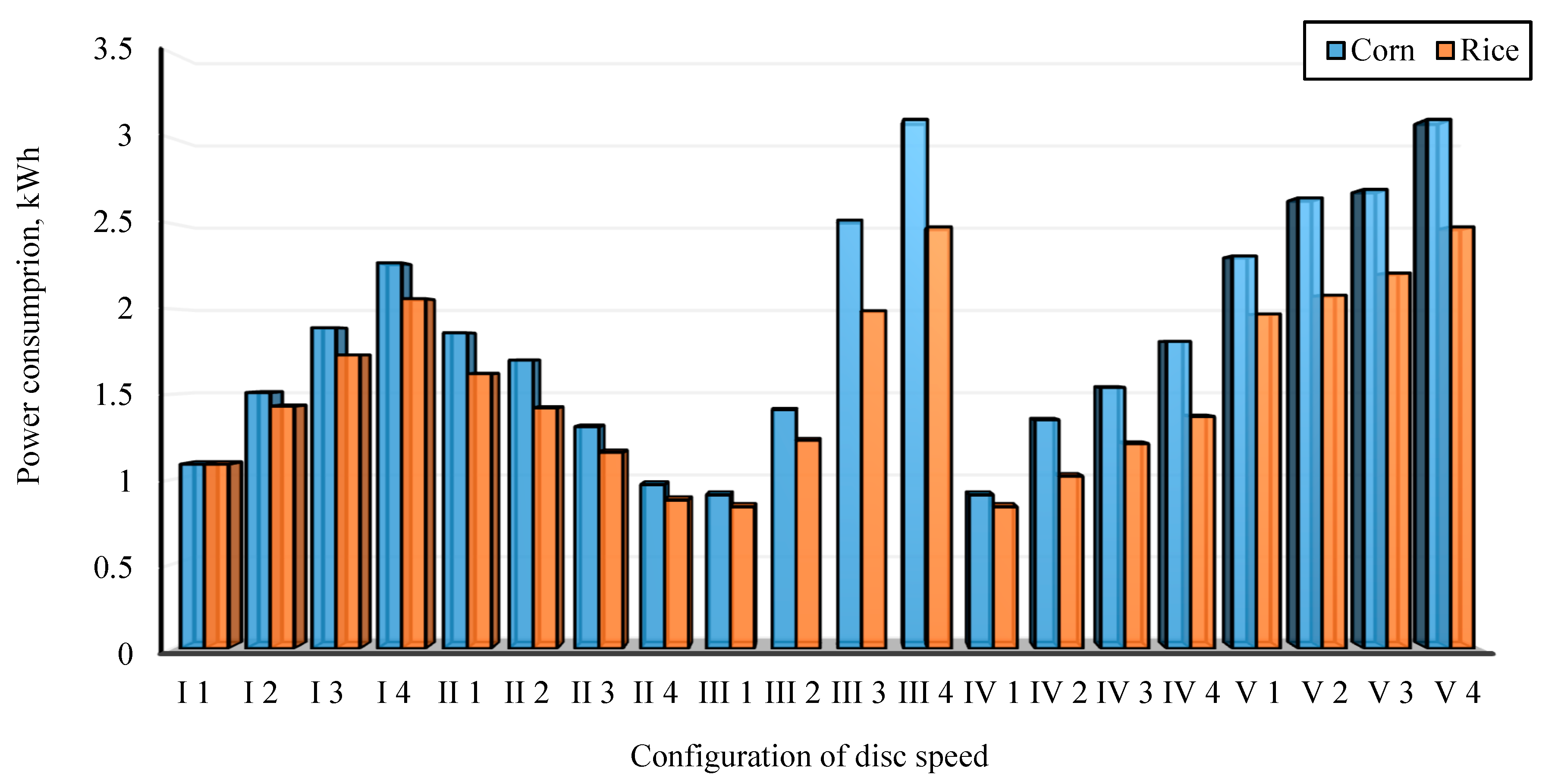

3.1.1. Power Consumption

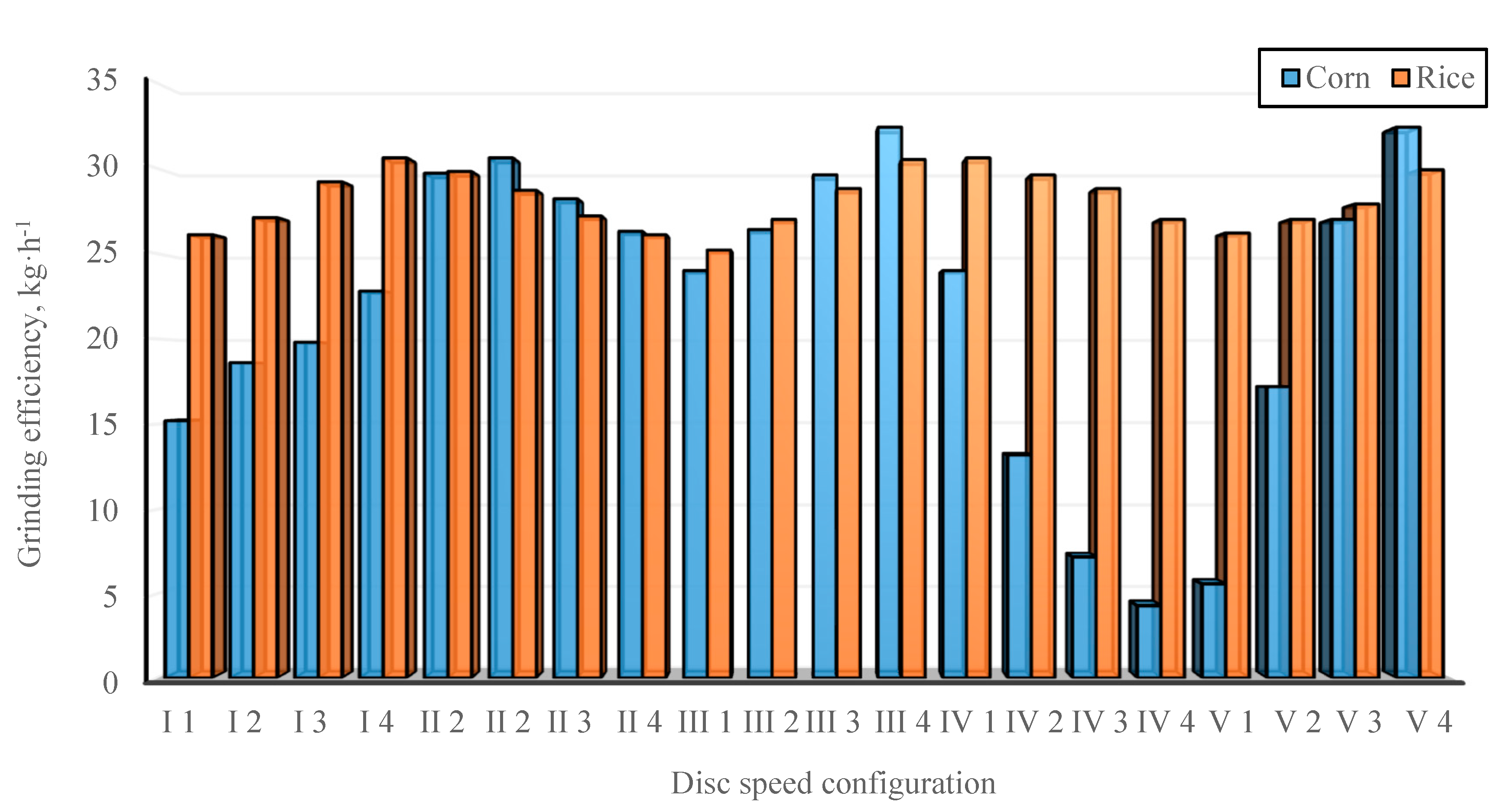

3.1.2. Grinding Efficiency

3.1.3. Granulometric Content of Biomaterial after Grinding

3.1.4. Unit Emissions Index JACO2i for the i-th Dimensional Fraction

3.1.5. Calorific Values

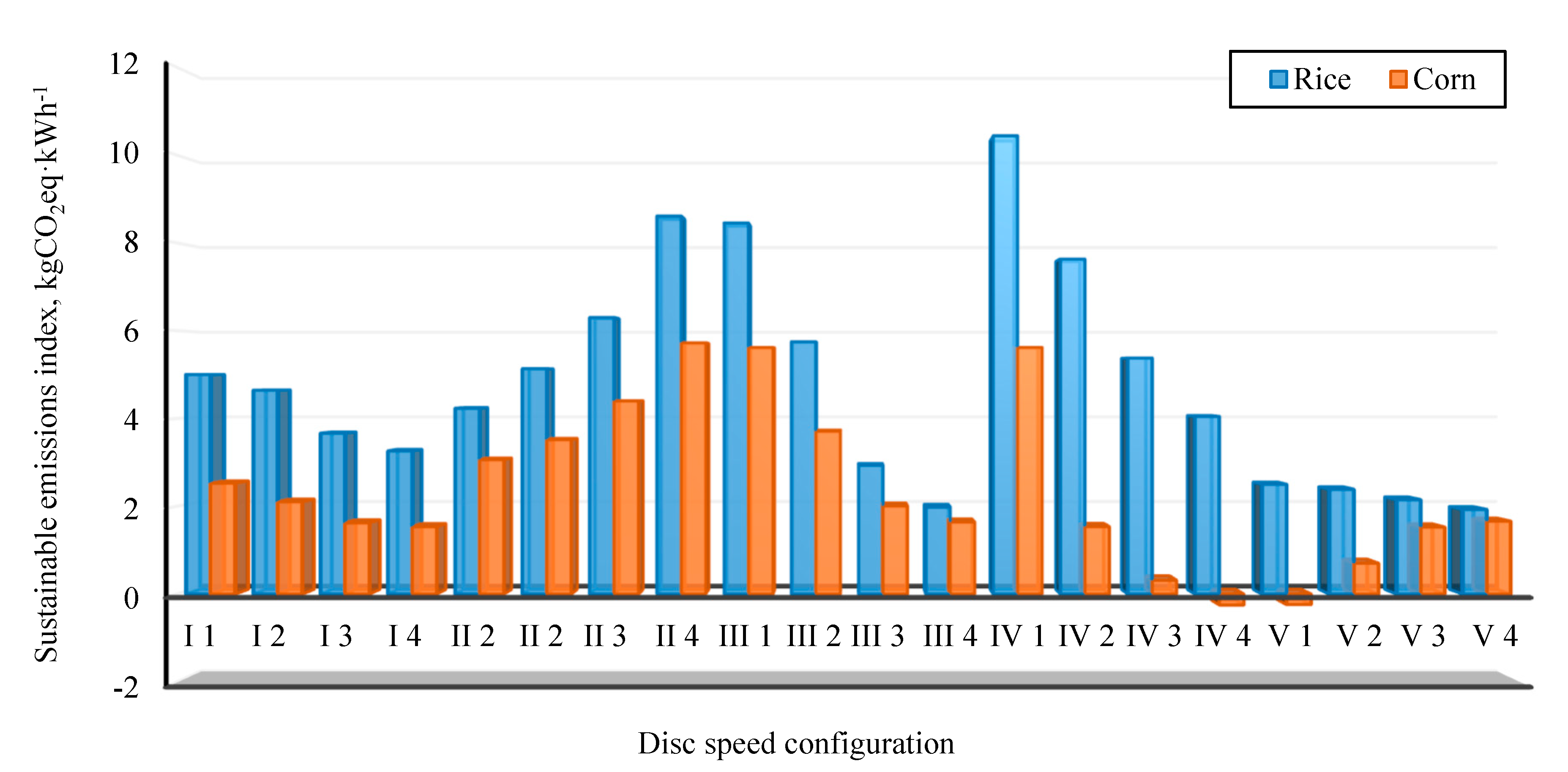

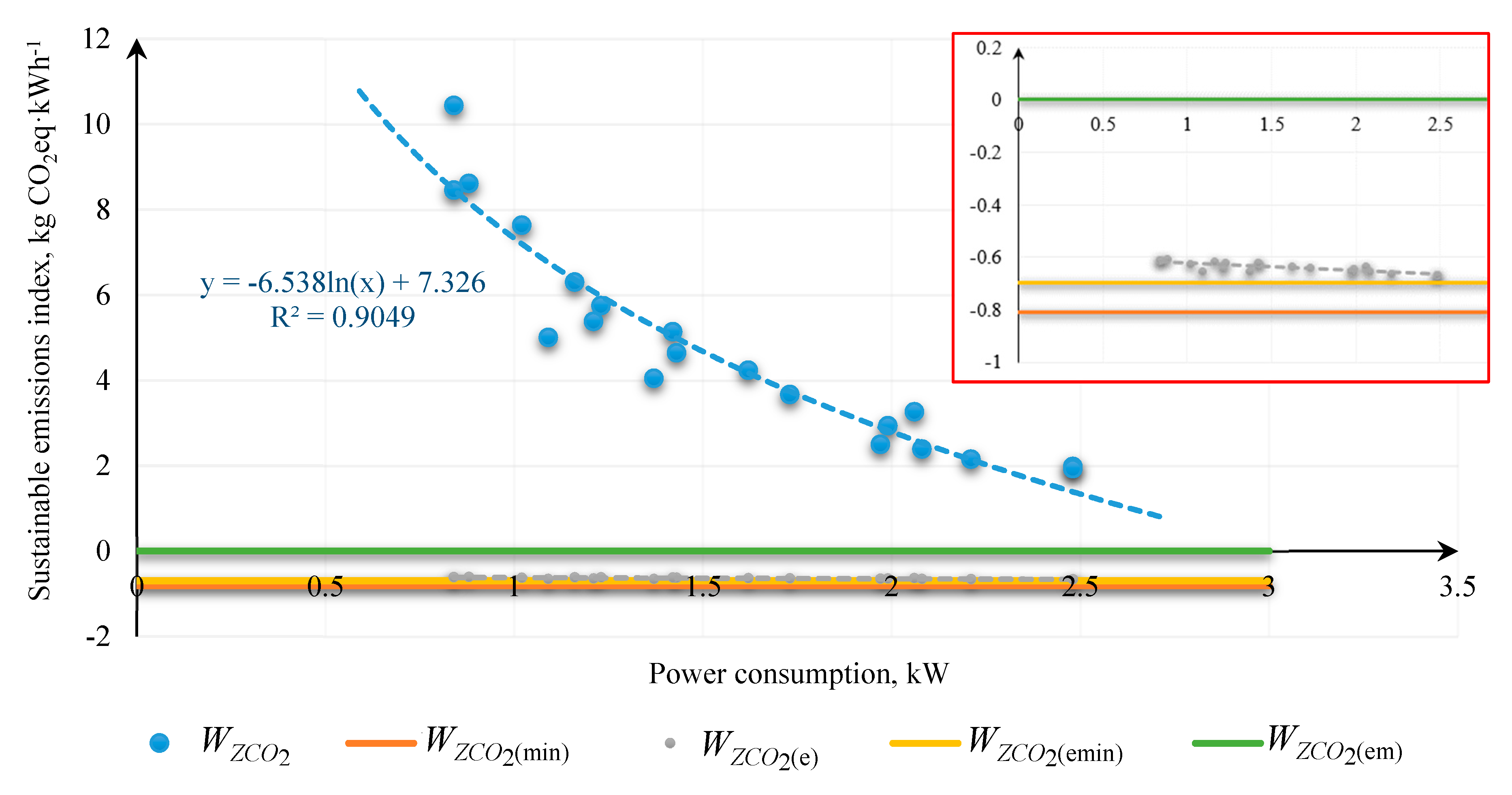

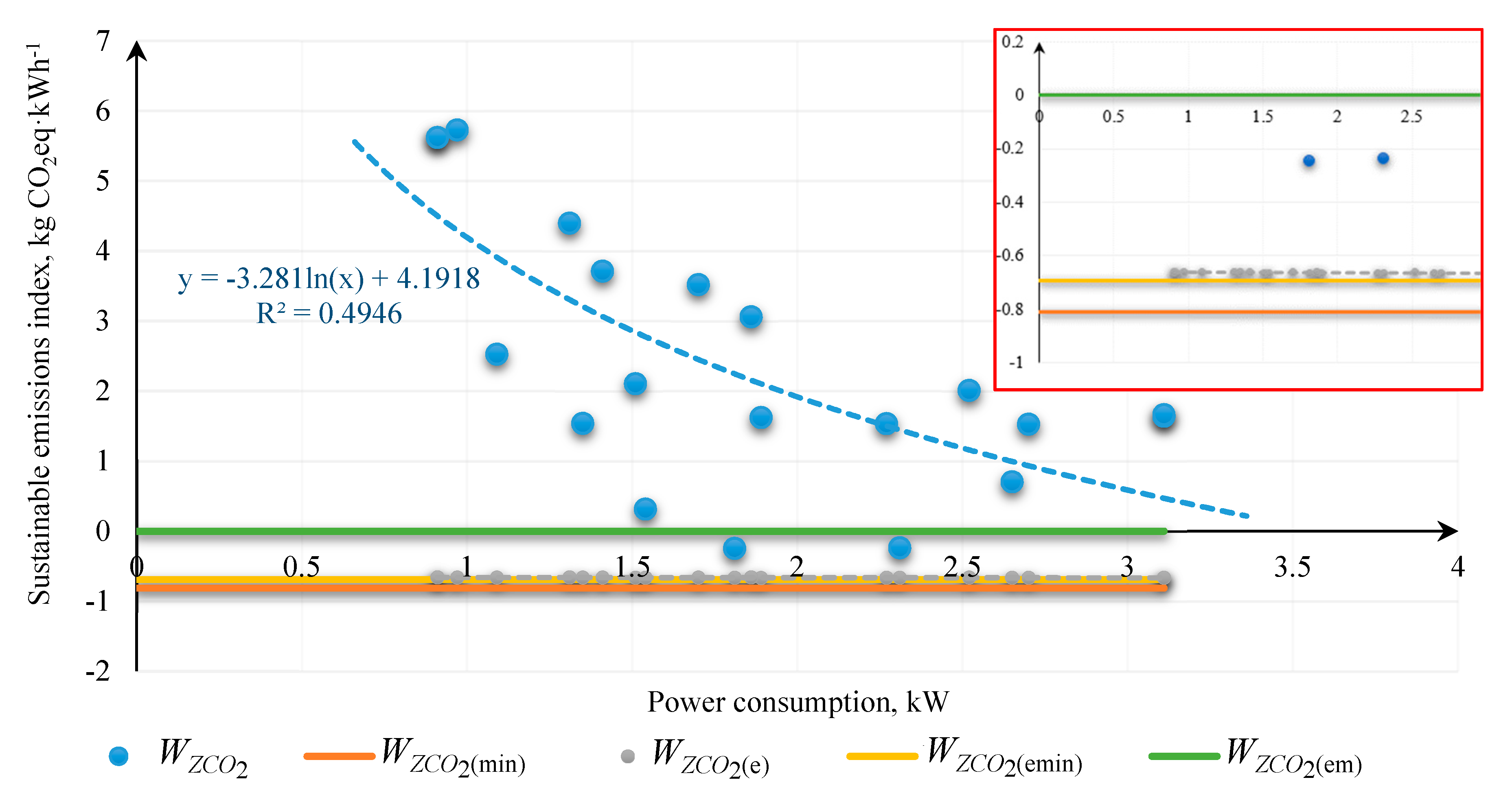

3.2. Carbon Dioxide Emissions Assessment of Grinding by Means of the Sustainable CO2 Emissions Index

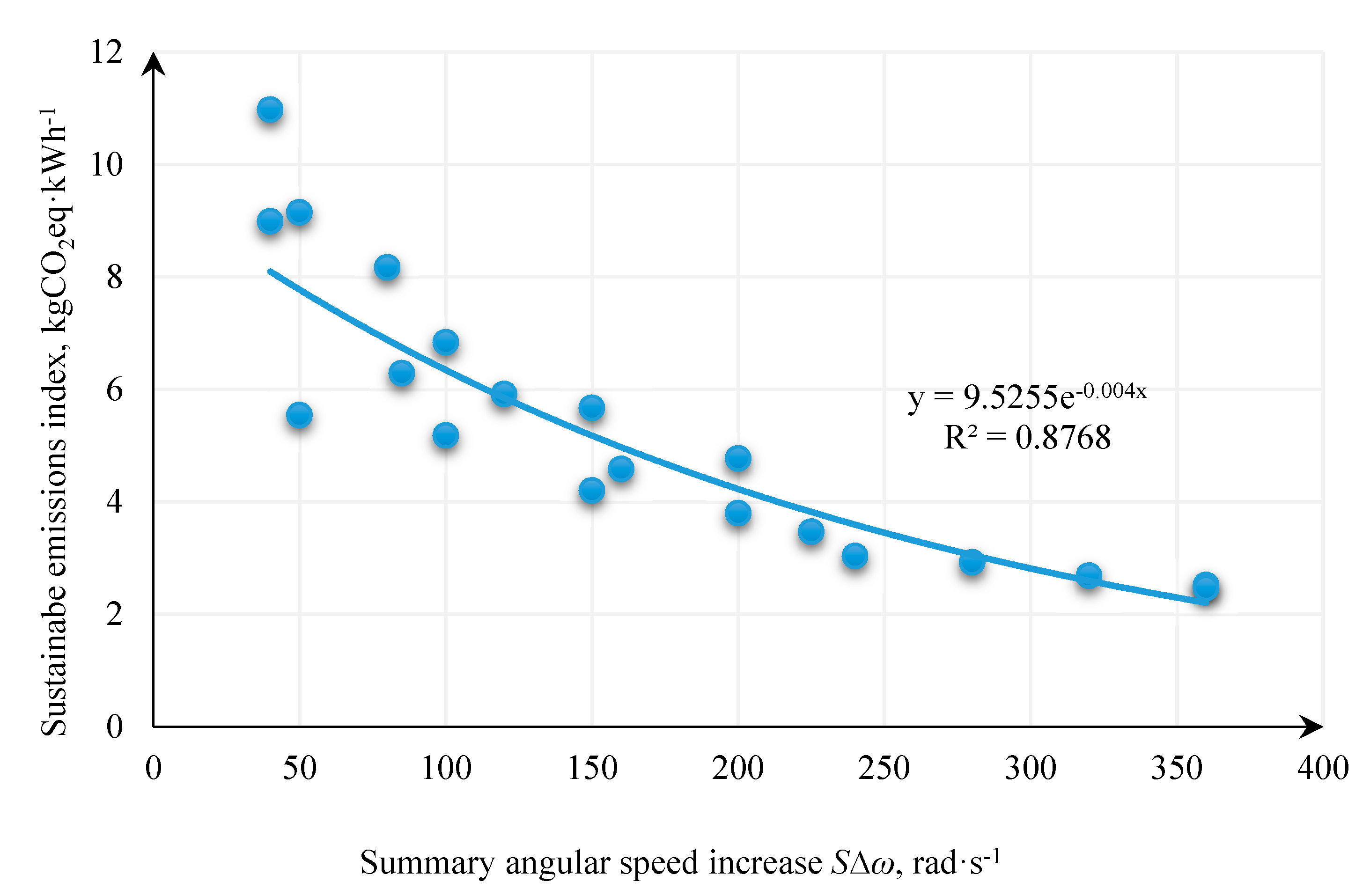

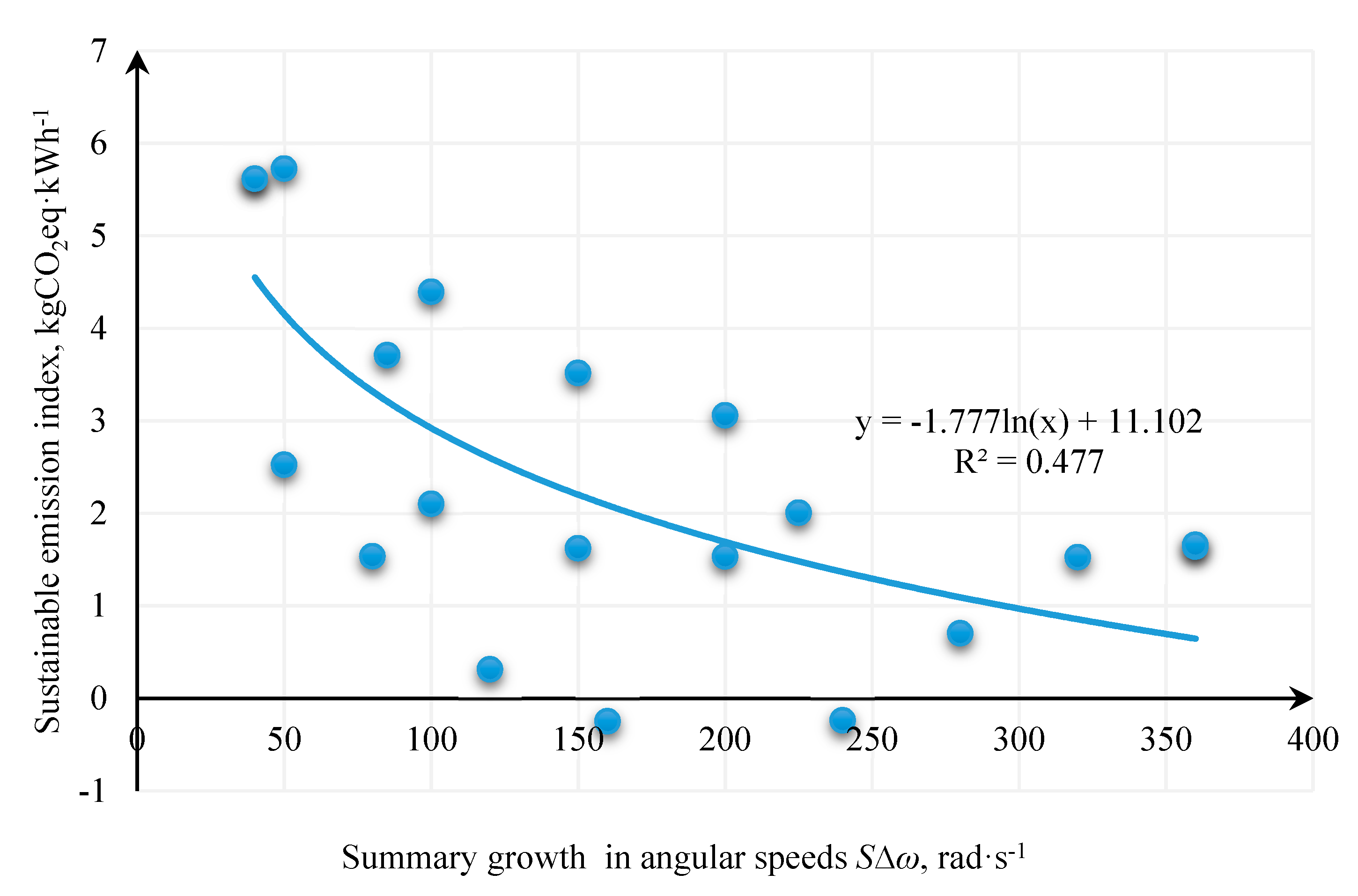

3.3. Analysis of the Relations between the Values of the Sustainable CO2 Emissions Index and the Angular Speed of the Working Elements of the Cutting Edges

4. Conclusions

- it was observed that the sustainable CO2 emissions index decreases with an increase in the value of SΔω;

- from the point of view of emissivity, it is better to grind at lower disc angular speeds;

- higher values of the emissions index were obtained for rice, and from the point of view of emissivity, rice is better than corn in energy applications.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Miao, Z.; Grift, T.E.; Hansen, A.C.; Ting, K.C. Energy requirement for comminution of biomass in relation to particle physical properties. Ind. Crop. Prod. 2011, 33, 504–513. [Google Scholar] [CrossRef]

- Tomporowski, A.; Flizikowski, J. Motion characteristics of a multi-disc grinder of biomass grain. Przem. Chem. 2013, 92, 498–503. [Google Scholar]

- Abo El-Khair, B.E.-S.; Manal, G.M.; Shimaa, R.H. Complementary production of biofuels by the green alga Chlorella vulgaris. Int. J. Renew. Energy Res. 2015, 5, 936–943. [Google Scholar]

- Adapa, P.K.; Tabil, L.G.; Schoenau, G.J. Factors affecting the quality of biomass pellet for biofuel and energy analysis of pelleting process. Int. J. Agric. Biol. Eng. 2013, 6, 1–12. [Google Scholar]

- Aguado, R.; Cuevas, M.; Pérez-Villarejo, L.; Martínez-Cartas, M.L.; Sánchez, S. Upgrading almond-tree pruning as a biofuel via wet torrefaction. Renew. Energy 2020, 145, 2091–2100. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Che Kamarludin, S.N.; Jainal, M.S.; Azizan, A.; Safaai, N.S.M.; Daud, A.R.M. Mechanical pretreatment of lignocellulosic biomass for biofuel production. Appl. Mech. Mater. 2014, 625, 838–841. [Google Scholar] [CrossRef]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef] [PubMed]

- Poudel, J.; Ohm, T.-I.; Lee, S.-H.; Oh, S.C. A study on torrefaction of sewage sludge to enhance solid fuel qualities. Waste Manag. 2015, 40, 112–118. [Google Scholar] [CrossRef]

- Ware, A.; Power, N. Biogas from cattle slaughterhouse waste: Energy recovery towards an energy self-sufficient industry in Ireland. Renew. Energy 2016, 97, 541–549. [Google Scholar] [CrossRef]

- Abelha, P.; Vilela, C.M.; Nanou, P.; Carbo, M.; Janssen, A.; Leiser, S. Combustion improvements of upgraded biomass by washing and torrefaction. Fuel 2019, 253, 1018–1033. [Google Scholar] [CrossRef]

- Basu, P. Chapter 11—Biomass Combustion and Cofiring. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Basu, P., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 393–413. ISBN 978-0-12-812992-0. [Google Scholar]

- Eisenlauer, M.; Teipel, U. Comminution of biogenic materials. Can. J. Chem. Eng. 2017, 95, 1236–1244. [Google Scholar] [CrossRef]

- Hu, J.; Chen, Y.; Ni, D. Effect of superfine grinding on quality and antioxidant property of fine green tea powders. LWT Food Sci. Technol. 2012, 45, 8–12. [Google Scholar] [CrossRef]

- Salman, A.D.; Ghadiri, M.; Hounslow, M. Particle Breakage; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 978-0-08-055346-7. [Google Scholar]

- Mannheim, V. Examination of Thermic Treatment and Biogas Processes by Lca. Ann. Fac. Eng. Hunedoara Int. J. Eng. 2014, 12, 225–234. [Google Scholar]

- Mannheim, V.; Siménfalvi, Z. Determining a Priority Order between Thermic Utilization Processes for Organic Industrial Waste with LCA.; WIT Press: Southampton, UK, 2012; pp. 153–166. [Google Scholar]

- Johnson, N.W. Review of Existing Eco-efficient Comminution Devices. Unpublished work. 2013. Available online: http://www.ceecthefuture.org/wp-content/uploads/2013/02/Bills-review-of-Eco-eff-devices.pdf (accessed on 5 November 2019).

- Kruszelnicka, W.; Flizikowski, J.; Tomporowski, A. Auto-monitoring system of grainy biomass comminution technology. IOP Conf. Ser. Mater. Sci. Eng. 2018, 393, 012076. [Google Scholar] [CrossRef]

- Wołosiewicz-Głąb, M.; Foszcz, D.; Saramak, D.; Gawenda, T.; Krawczykowski, D. Analysis of a grinding efficiency in the electromagnetic mill for variable process and feed parameters. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 18, p. 01012. [Google Scholar]

- Jachimowski, R.; Szczepanski, E.; Klodawski, M.; Markowska, K.; Dabrowski, J. Selection of a Container Storage Strategy at the Rail-road Intermodal Terminal as a Function of Minimization of the Energy Expenditure of Transshipment Devices and CO2 Emissions. Rocz. Ochr. Sr. 2018, 20, 965–988. [Google Scholar]

- Tomporowski, A.; Flizikowski, J.; Kasner, R.; Kruszelnicka, W. Environmental Control of Wind Power Technology. Rocz. Ochr. Środowiska 2017, 19, 694–714. [Google Scholar]

- Kruszelnicka, W.; Tomporowski, A.; Flizikowski, J.; Kasner, R.; Cyganiuk, J. Basis of Biomass Grinders Sustainable Designing. Syst. Saf. Hum. Tech. Facil. Environ. 2019, 1, 542–549. [Google Scholar] [CrossRef]

- Marczuk, A.; Misztal, W.; Savinykh, P.; Turubanov, N.; Isupov, A.; Zyryanov, D. Improving Efficiency of Horizontal Ribbon Mixer by Optimizing Its Constructional and Operational Parameters. Eksploat. Niezawodn. 2019, 21, 220–225. [Google Scholar] [CrossRef]

- Tomporowski, A.; Flizikowski, J.; Kruszelnicka, W. A new concept of roller-plate mills. Przem. Chem. 2017, 96, 1750–1755. [Google Scholar]

- Szymańska, E. Efektywność przedsiębiorstwa-definiowanie i pomiar. Rocz. Nauk Rol. 2010, 97, 152–164. [Google Scholar]

- Kleiber, M.; Czaplicka-Kolarz, K. Ekoefektywność Technologii: Praca Zbiorowa; Wydawnictwo Naukowe Instytutu Technologii Eksploatacji—Państwowego Instytutu Badawczego: Radom, Poland, 2011; ISBN 978-83-7789-050-9.

- Aoe, T. Eco-efficiency and ecodesign in electrical and electronic products. J. Clean. Prod. 2007, 15, 1406–1414. [Google Scholar] [CrossRef]

- Huppes, G.; Ishikawa, M. Eco-efficiency and Its xsTerminology. J. Ind. Ecol. 2005, 9, 43–46. [Google Scholar] [CrossRef]

- Schneider, L.; Finkbeiner, M. Life Cycle Assessment of EU Oilseed Crushing and Vegetable Oil Refining; Technische Universitat Berlin: Berlin, Germany, 2013; p. 59. [Google Scholar]

- Homagain, K.; Shahi, C.; Luckai, N.; Sharma, M. Life cycle cost and economic assessment of biochar-based bioenergy production and biochar land application in Northwestern Ontario, Canada. For. Ecosyst. 2016, 3, 21. [Google Scholar] [CrossRef]

- Fontes, J. Handbook for Product Social Impact Assessment; PRe Sustainability: Amersfoort, The Netherlands, 2016. [Google Scholar]

- Pierobon, F.; Eastin, I.L.; Ganguly, I. Life cycle assessment of residual lignocellulosic biomass-based jet fuel with activated carbon and lignosulfonate as co-products. Biotechnol. Biofuels 2018, 11, 139. [Google Scholar] [CrossRef]

- Liu, W.; Wang, J.; Richard, T.L.; Hartley, D.S.; Spatari, S.; Volk, T.A. Economic and life cycle assessments of biomass utilization for bioenergy products. Biofuels Bioprod. Biorefining 2017, 11, 633–647. [Google Scholar] [CrossRef]

- Johnson, L.; Lippke, B.; Oneil, E. Modeling biomass collection and woods processing life-cycle analysis. Prod. J. 2012, 62, 258–272. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis. In Advanced Methods in Resource and Waste Management; CRC/Lewis: Boca Raton, FL, USA, 2004; ISBN 978-1-56670-604-9. [Google Scholar]

- Liedtke, C.; Bienge, K.; Wiesen, K.; Teubler, J.; Greiff, K.; Lettenmeier, M.; Rohn, H. Resource Use in the Production and Consumption System—The MIPS Approach. Resources 2014, 3, 544–574. [Google Scholar] [CrossRef]

- Ściążko, M.; Czaplicka-Kolarz, K. Model Ekologicznego i Ekonomicznego Prognozowania Wydobycia i Użytkowania Czystego Węgla. T. 2, Ekoefektywność Technologii Czystego Spalania Węgla; Główny Instytu Górnictwa: Katowice, Poland, 2004. [Google Scholar]

- Tahara, K.; Sagisaka, M.; Ozawa, T.; Yamaguchi, K.; Inaba, A. Comparison of “CO2 efficiency” between company and industry. J. Clean. Prod. 2005, 13, 1301–1308. [Google Scholar] [CrossRef]

- Bennett, M.; James, P.; Klinkers, L. Sustainable Measures—Evaluation and Reporting of Environmental and Social Performance; Greenleaf Publishing Ltd.: Sheffield, UK, 1999. [Google Scholar]

- Kasner, R. Ocena Korzyści i Nakładów Cyklu Życia Elektrowni Wiatrowej; Politechnika Poznańska: Poznań, Poland, 2016; p. 186. [Google Scholar]

- Tomporowski, A.; Flizikowski, J.; Opielak, M.; Kasner, R.; Kruszelnicka, W. Assessment of Energy Use and Elimination of Co2 Emissions in the Life Cycle of an Offshore Wind Power Plant Farm. Pol. Marit. Res. 2017, 24, 93–101. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Kruczek, M.; Czaplicka-Kolarz, K. Wykorzystanie ekoefektywności w ocenie poziomu ekoinnowacyjności. In Innowacje w Zarządzaniu i Inżynierii Produkcji; Oficyna Wydawnicza Polskiego Towarzystwa Zarządzania Produkcją: Opole, Poland, 2013. [Google Scholar]

- Flizikowski, J.; Wełnowski, J.; Dudziak, P. Analysis end eco-technological evaluation of micro-grain supersonic milling. Part I. Models and indicators. Inżynieria I Apar. Chem. 2017, 56, 161–163. [Google Scholar]

- Mroziński, A.; Flizikowski, J.; Macko, M. Inżynieria Rozdrabniania Biomasy; Grafpol: Wrocław, Poland, 2016; ISBN 978-83-64423-35-2. [Google Scholar]

- Kruszelnicka, W. Analiza Procesu Wielotarczowego Rozdrabniania Biomasy w Ujęciu Energochlonności i Emisji CO2. Ph.D. Thesis, Uniwersytet Technologiczno-Przyrodniczy im. Jana i Jędrzeja Śniadeckich w Bydgoszczy, Bydgoszcz, Poland, 2019. [Google Scholar]

- Kruszelnicka, W.; Bałdowska-Witos, P.; Flizikowski, J.; Tomporowski, A.; Kasner, R. Energy balance of wood biomass utilization. Part I—Characteristics of the problem and research methodology. TEKA Kom. Mot. Energ. Roln 2017, 17, 55–60. [Google Scholar]

- Kruszelnicka, W.; Bałdowska-Witos, P.; Kasner, R.; Flizikowski, J.; Tomporowski, A.; Rudnicki, J. Evaluation of emissivity and environmental safety of biomass grinders drive. Przem. Chem. 2019, 98, 1494–1498. [Google Scholar]

- Fuerstenau, D.W.; Abouzeid, A.-Z.M. The energy efficiency of ball milling in comminution. Int. J. Miner. Process. 2002, 67, 161–185. [Google Scholar] [CrossRef]

- Kawatra, S.K. Advances in Comminution; Society for Mining, Metallurgy, and Exploration: Littleton, CO, USA, 2006; ISBN 978-0-87335-246-8. [Google Scholar]

- Tomporowski, A.; Flizikowski, J.; Wełnowski, J.; Najzarek, Z.; Topoliński, T.; Kruszelnicka, W.; Piasecka, I.; Śmigiel, S. Regeneration of rubber waste using an intelligent grinding system. Przem. Chem. 2018, 97, 1659–1665. [Google Scholar]

- Naimi, L.J.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Womac, A.R.; Lau, A.K.; Melin, S. Development of Size Reduction Equations for Calculating Energy Input for Grinding Lignocellulosic Particles. Appl. Eng. Agric. 2013, 29, 93–100. [Google Scholar] [CrossRef]

- Kruszelnicka, W. New model for ecological assessment of comminution process in energy biomass processing chain. In Proceedings of the Renewable Energy Sources-Engineering, Technology, Innovation, Krynica, Poland, 12–14 June 2019. [Google Scholar]

- Kruszelnicka, W. Study of Physical Properties of Rice and Corn Used for Energy Purposes. In Renewable Energy Sources: Engineering, Technology, Innovation; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer International Publishing: Manhattan, NY, USA, 2020; pp. 149–162. [Google Scholar]

- Szyszlak-Barglowicz, J.; Zajac, G.; Slowik, T. Research on Emissions from Combustion of Pellets in Agro Biomass Low Power Boiler. Rocz. Ochr. Sr. 2017, 19, 715–730. [Google Scholar]

- Kowalczyk-Juśko, A. Redukcja emisji zanieczyszczeń dzięki zastąpieniu węgla biomasą spartiny preriowej. Probl. Inżynierii Rol. 2010, 18, 69–77. [Google Scholar]

- Kruszelnicka, W.; Bałdowska-Witos, P.; Flizikowski, J.; Tomporowski, A. Investigation of grain biomass properties as an alternative fuel. Int. Sci. J. Trans Motauto World 2018, 3, 45–48. [Google Scholar]

- Dańko, R.; Szymała, K.; Holtzer, M.; Holtzer, G. Skojarzone wytwarzanie energii elektrycznej i ciepła w systemie kogeneracji. Arch. Foundry Eng. 2012, 12, 6. [Google Scholar]

- Buffington, D.E. Burning Shalled Corn—A Renewable Fuel Source. Agric. Biol. Eng. 2005, H, 78. [Google Scholar]

- Lizotte, P.-L.; Savoie, P.; De Champlain, A. Ash Content and Calorific Energy of Corn Stover Components in Eastern Canada. Energies 2015, 8, 4827–4838. [Google Scholar] [CrossRef]

- Pode, R. Potential applications of rice husk ash waste from rice husk biomass power plant. Renew. Sustain. Energy Rev. 2016, 53, 1468–1485. [Google Scholar] [CrossRef]

- Moe, P.W.; Tyell, H.F.; Hooven, N.W. Physical Form and Energy Value of Corn Grain. J. Dairy Sci. 1973, 56, 1298–1304. [Google Scholar] [CrossRef]

- Panzeri, D.; Cesari, V.; Toschi, I.; Pilu, R. Seed Calorific Value in Different Maize Genotypes. Energy Sour. Part A Recovery Util. Environ. Eff. 2011, 33, 1700–1705. [Google Scholar] [CrossRef]

- Shen, J.; Zhu, S.; Liu, X.; Zhang, H.; Tan, J. Measurement of Heating Value of Rice Husk by Using Oxygen Bomb Calorimeter with Benzoic Acid as Combustion Adjuvant. Energy Procedia 2012, 17, 208–213. [Google Scholar] [CrossRef]

- Determination of Moisture Content. Available online: http://www.ico.org/projects/Good-Hygiene-Practices/cnt/cnt_sp/sec_3/docs_3.2/Determine%20m%20c.pdf (accessed on 21 October 2019).

- International Organization for Standardization. Green Coffee—Determination of Water Content—Basic Reference Method; International Organization for Standardization: Geneva, Switzerland, 2001; ISO 1446:2001. [Google Scholar]

- International Organization for Standardization. Particle Size Analysis—Image Analysis Methods—Part 2: Dynamic Image Analysis Methods; International Organization for Standardization: Geneva, Switzerland, 2006; ISO 13322-2:2006. [Google Scholar]

- International Organization for Standardization. DIN DIN 66 165-1 and 2: Sieve Analysis, Fundamentals (1) and Procedure (2); International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- CO2 Emission Factors [Wskaźniki Emisji CO2]. Available online: https://prawomiejscowe.pl/api/file/GetZipxAttachment/155/1147170/preview (accessed on 22 October 2019).

- Tumuluru, J.S.; Tabil, L.G.; Song, Y.; Iroba, K.L.; Meda, V. Grinding energy and physical properties of chopped and hammer-milled barley, wheat, oat, and canola straws. Biomass Bioenergy 2014, 60, 58–67. [Google Scholar] [CrossRef]

- Warechowska, M. Some physical properties of cereal grain and energy consumption of grinding. Agric. Eng. 2014, 1, 239–249. [Google Scholar]

- Greffeuille, V.; Mabille, F.; Rousset, M.; Oury, F.-X.; Abecassis, J.; Lullien-Pellerin, V. Mechanical properties of outer layers from near-isogenic lines of common wheat differing in hardness. J. Cereal Sci. 2007, 45, 227–235. [Google Scholar] [CrossRef]

- Greffeuille, V.; Abecassis, J.; Barouh, N.; Villeneuve, P.; Mabille, F.; Bar L’Helgouac’h, C.; Lullien-Pellerin, V. Analysis of the milling reduction of bread wheat farina: Physical and biochemical characterisation. J. Cereal Sci. 2007, 45, 97–105. [Google Scholar] [CrossRef]

- Rogowska, D.; Lubowicz, J. Analiza możliwości obniżenia emisji gazów cieplarnianych w cyklu życia bioetanolu paliwowego. Naft. Gaz 2012, 68, 1044–1049. [Google Scholar]

- Smejtkova, A.; Vaculik, P. Comparison of power consumption of a two-roll mill and a disc mill. Agron. Res. 2018, 16, 1486–1492. [Google Scholar]

- Boehm, A.; Meissner, P.; Plochberger, T. An energy based comparison of vertical roller mills and tumbling mills. Int. J. Miner. Process. 2015, 136, 37–41. [Google Scholar] [CrossRef]

| Parameter | Disc 1 | Disc 2 | Disc 3 | Disc 4 | Disc 5 |

|---|---|---|---|---|---|

| Disc diameter Dn (mm) | 274 | 274 | 274 | 274 | 274 |

| Number of holes ln (psc.) | 14 | 22 | 27 | 33 | 39 |

| Diameter of holes dn (mm) | 30 | 23 | 21 | 17.5 | 17.5 |

| Radius of hole arrangement in a row 1 (mm) | 85 | 82.4 | 79.5 | 79.5 | 82 |

| Radius of hole arrangement in a row 2 (mm) | 101.5 | 107.4 | 95.5 | 99.5 | 102 |

| Radius of hole arrangement in a row 3 (mm) | - | - | 110.5 | 114.5 | 117 |

| Test Program | Configuration No. | S∆ω | ∆ω | ω1 | ω2 | ω3 | ω4 | ω5 |

|---|---|---|---|---|---|---|---|---|

| rad·s−1 | rad·s−1 | rad·s−1 | rad·s−1 | rad·s−1 | rad·s−1 | rad·s−1 | ||

| I | 1 | 50 | 5 | 20 | 25 | 30 | 35 | 40 |

| 2 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | |

| 3 | 150 | 15 | 20 | 35 | 50 | 65 | 80 | |

| 4 | 200 | 20 | 20 | 40 | 60 | 80 | 100 | |

| II | 1 | 200 | 20 | 100 | 80 | 60 | 40 | 20 |

| 2 | 150 | 15 | 80 | 65 | 50 | 35 | 20 | |

| 3 | 100 | 10 | 60 | 50 | 40 | 30 | 20 | |

| 4 | 50 | 5 | 40 | 35 | 30 | 25 | 20 | |

| III | 1 | 40 | 20 | 20 | 40 | 20 | 40 | 20 |

| 2 | 85 | 20 | 45 | 25 | 45 | 25 | 45 | |

| 3 | 225 | 25 | 75 | 50 | 75 | 50 | 75 | |

| 4 | 360 | 20 | 100 | 80 | 100 | 80 | 100 | |

| IV | 1 | 40 | 20 | 20 | 40 | 20 | 40 | 20 |

| 2 | 80 | 40 | 20 | 60 | 20 | 60 | 20 | |

| 3 | 120 | 60 | 20 | 80 | 20 | 80 | 20 | |

| 4 | 160 | 80 | 20 | 100 | 20 | 100 | 20 | |

| V | 1 | 240 | 80 | 100 | 20 | 100 | 20 | 100 |

| 2 | 280 | 60 | 100 | 40 | 100 | 40 | 100 | |

| 3 | 320 | 40 | 100 | 60 | 100 | 60 | 100 | |

| 4 | 360 | 20 | 100 | 80 | 100 | 80 | 100 |

| Fraction Dimension (µm) | ||||

|---|---|---|---|---|

| Rice | 0–630 | 630–1250 | 1250–2000 | >2000 |

| Corn | 0–500 | 500–1250 | 1250–2000 | >2000 |

| Fraction Percentage Share (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Config. | Rice | Corn | |||||||

| 0–630 μm | 630–1250 μm | 1250–2000 μm | >2000 μm | 0–500 μm | 500–1250 μm | 1250–2000 μm | >2000 μm | ||

| I | 1 | 9.4 | 29.3 | 56.4 | 4.9 | 2.4 | 32.2 | 42.3 | 23.1 |

| 2 | 3.4 | 13.8 | 67.8 | 15.0 | 2.9 | 38.2 | 40.1 | 18.8 | |

| 3 | 6.9 | 21.0 | 62.4 | 9.7 | 3.0 | 47.5 | 38.3 | 11.2 | |

| 4 | 5.8 | 18.4 | 63.5 | 12.3 | 2.9 | 44.7 | 39.4 | 13.0 | |

| II | 1 | 5.8 | 18.4 | 63.5 | 12.3 | 1.8 | 26.9 | 42.0 | 29.3 |

| 2 | 2.9 | 12.7 | 66.6 | 17.8 | 2.2 | 30.9 | 41.0 | 25.9 | |

| 3 | 2.3 | 10.1 | 66.8 | 20.8 | 2.0 | 30.8 | 37.0 | 30.2 | |

| 4 | 0.9 | 6.4 | 67.1 | 25.6 | 2.4 | 32.2 | 36.3 | 29.1 | |

| III | 1 | 1.7 | 9.0 | 66.4 | 22.9 | 1.9 | 27.9 | 35.8 | 34.4 |

| 2 | 2.8 | 11.7 | 65.7 | 19.8 | 2.1 | 31.1 | 37.8 | 29.0 | |

| 3 | 8.9 | 22.5 | 60.3 | 8.3 | 2.0 | 31.3 | 42.3 | 24.4 | |

| 4 | 13.3 | 35.0 | 48.7 | 3.0 | 2.3 | 39.2 | 44.4 | 14.1 | |

| IV | 1 | 1.7 | 9.0 | 66.4 | 22.9 | 1.9 | 27.9 | 35.8 | 34.4 |

| 2 | 2.4 | 13.7 | 67.7 | 16.2 | 2.4 | 33.2 | 38.0 | 26.4 | |

| 3 | 6.3 | 23.4 | 62.1 | 8.2 | 2.4 | 36.2 | 48.7 | 14.7 | |

| 4 | 8.4 | 28.1 | 58.1 | 5.4 | 2.2 | 33.0 | 48.1 | 16.7 | |

| V | 1 | 7.0 | 27.3 | 60.5 | 5.2 | 1.9 | 38.1 | 42.5 | 17.5 |

| 2 | 9.4 | 27.2 | 58.2 | 5.2 | 2.1 | 44.1 | 42.7 | 11.1 | |

| 3 | 12.4 | 30.8 | 53.7 | 3.1 | 2.2 | 42.2 | 44.4 | 11.2 | |

| 4 | 13.3 | 35.0 | 48.7 | 3.0 | 2.2 | 33.0 | 48.1 | 16.7 | |

| Rice | Corn | ||

|---|---|---|---|

| Fraction Dimension (μm) | Unit Emissions Index (kg·kWh−1) | Fraction Dimension (μm) | Unit Emissions Index (kg·kWh−1) |

| 0–630 | 0.0453 | 0–500 | 0.04859 |

| 630–1250 | 0.0356 | 60–1250 | 0.05432 |

| 1250–2000 | 0.0745 | 1250–2000 | 0.059701 |

| >2000 | 0.11428 | >2000 | 0.068181 |

| Rice | Corn | ||

|---|---|---|---|

| Fraction Dimension (μm) | Calorific Value (kWh·kg−1) | Fraction Dimension (μm) | Calorific Value (kWh·kg−1) |

| 0–630 | 3.97 | 0–500 | 3.91 |

| 630–1250 | 3.93 | 60–1250 | 4.05 |

| 1250–2000 | 3.89 | 1250–2000 | 4.02 |

| >2000 | 3.85 | >2000 | 3.96 |

| Rp | M | S | K | V | s | Min. | Max. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| WZCO2 | Corn | 5.96 | 1.83 | 0.54 | −0.53 | 76.31 | 2.42 | 1.84 | −0.24 | 5.72 |

| Rice | 8.51 | 4.14 | 0.8 | −0.08 | 50.73 | 4.82 | 2.45 | 1.93 | 10.44 | |

| S∆ω | 320 | 260 | 0.6 | −0.72 | 63.11 | 165.5 | 104.44 | 40 | 360 | |

| ω1 | 80 | 20 | 0.32 | −1.82 | 66.54 | 54.00 | 35.93 | 20 | 100 | |

| ω2 | 80 | 40 | 0.54 | −0.72 | 44.03 | 51.75 | 22.78 | 20 | 100 | |

| ω3 | 80 | 25 | 0.51 | −1.26 | 57.83 | 54.00 | 31.23 | 20 | 100 | |

| ω4 | 80 | 40 | 0.54 | −0.72 | 44.03 | 51.75 | 22.78 | 20 | 100 | |

| ω5 | 80 | 20 | 0.32 | −1.82 | 66.54 | 54.00 | 35.93 | 20 | 100 | |

| ω1 | ω2 | ω3 | ω4 | ω5 | SΔω | ||

|---|---|---|---|---|---|---|---|

| Corn | Rho Spearman’s | −0.107 | −0.258 | −0.307 | −0.557 | −0.480 | −0.617 * |

| p-value | 0.653 | 0.272 | 0.188 | 0.011 | 0.032 | 0.004 | |

| Rice | Rho Spearman’s | −0.609 * | −0.232 | −0.855 * | −0.434 | −0.853 * | −0.946 * |

| p-value | 0.004 | 0.325 | 0.000 | 0.056 | 0.000 | 0.000 | |

| Coefficients | t-stat. | p-Value * | F | Significance | R2 | ||

|---|---|---|---|---|---|---|---|

| Corn | Constant | 4.09 | 6.16 | 8.08 × 10−6 | 8.75 | 0.008 | 0.3271 |

| SΔω | −0.01 | −2.96 | 0.008 | ||||

| Rice | Constant | 8.17 | 15.13 | 1.11 × 10−11 | 53.00 | 9.13 × 10−7 | 0.7464 |

| SΔω | −0.02 | −7.28 | 9.13 × 10−7 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kruszelnicka, W. A New Model for Environmental Assessment of the Comminution Process in the Chain of Biomass Energy Processing †. Energies 2020, 13, 330. https://doi.org/10.3390/en13020330

Kruszelnicka W. A New Model for Environmental Assessment of the Comminution Process in the Chain of Biomass Energy Processing †. Energies. 2020; 13(2):330. https://doi.org/10.3390/en13020330

Chicago/Turabian StyleKruszelnicka, Weronika. 2020. "A New Model for Environmental Assessment of the Comminution Process in the Chain of Biomass Energy Processing †" Energies 13, no. 2: 330. https://doi.org/10.3390/en13020330

APA StyleKruszelnicka, W. (2020). A New Model for Environmental Assessment of the Comminution Process in the Chain of Biomass Energy Processing †. Energies, 13(2), 330. https://doi.org/10.3390/en13020330