Numerical and Experimental Study on Convective Heat Transfer Characteristics in Foam Materials

Abstract

1. Introduction

2. Experiment and Analysis

2.1. Experimental System

2.2. Experimental Results

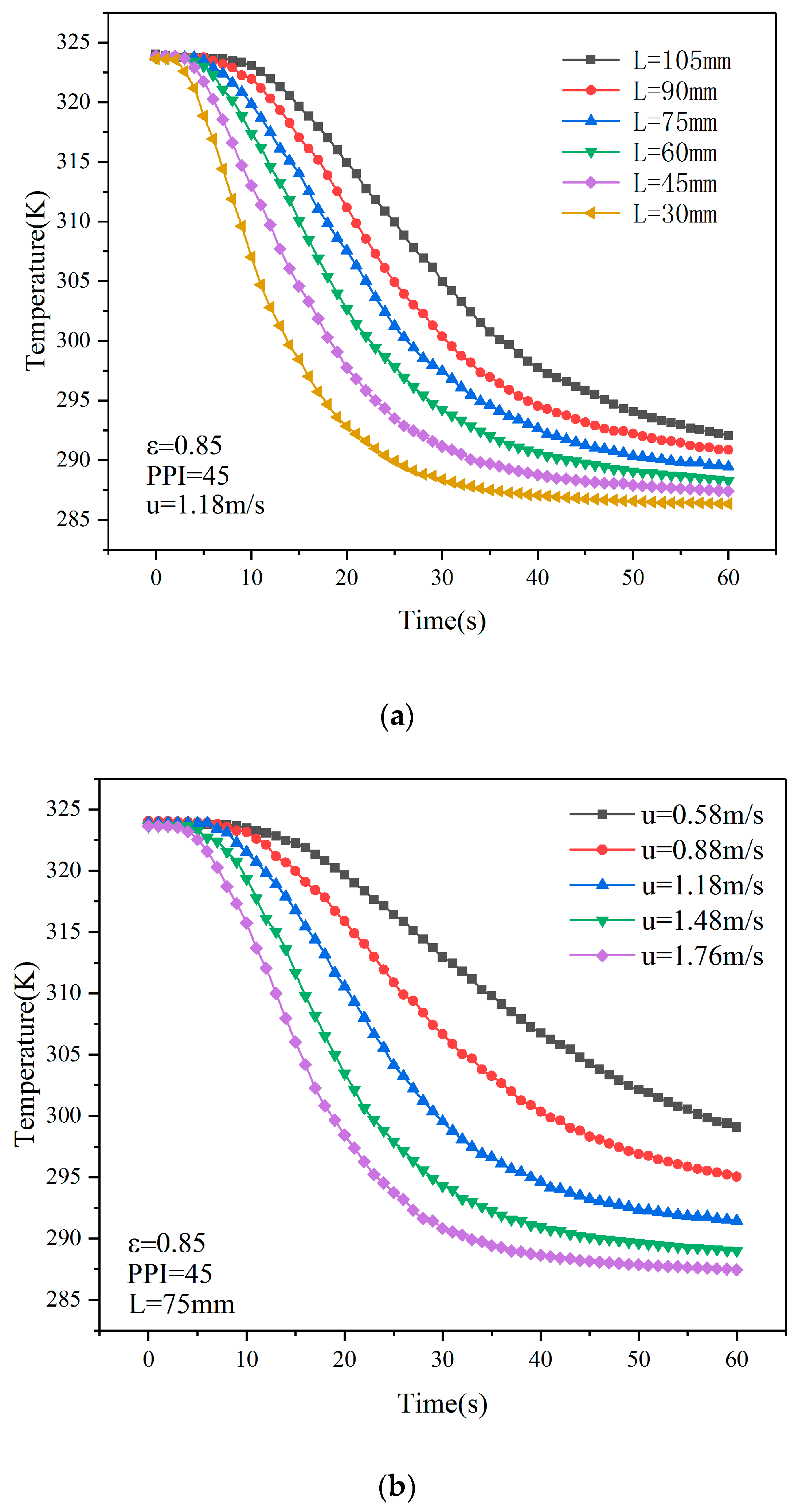

2.2.1. The Temperature Change in Foams

2.2.2. The Volumetric Heat Transfer Coefficient in Foams

3. Numerical Simulation

3.1. Geometric Model

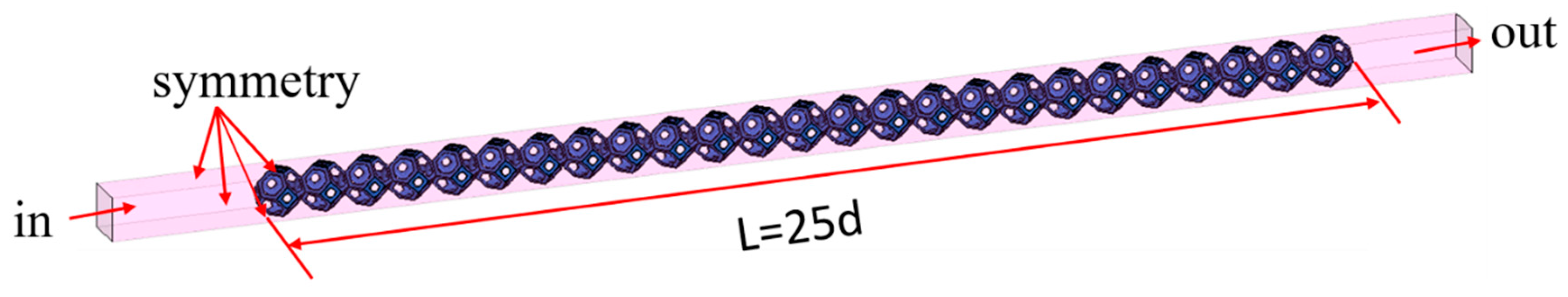

3.2. Computing Domain

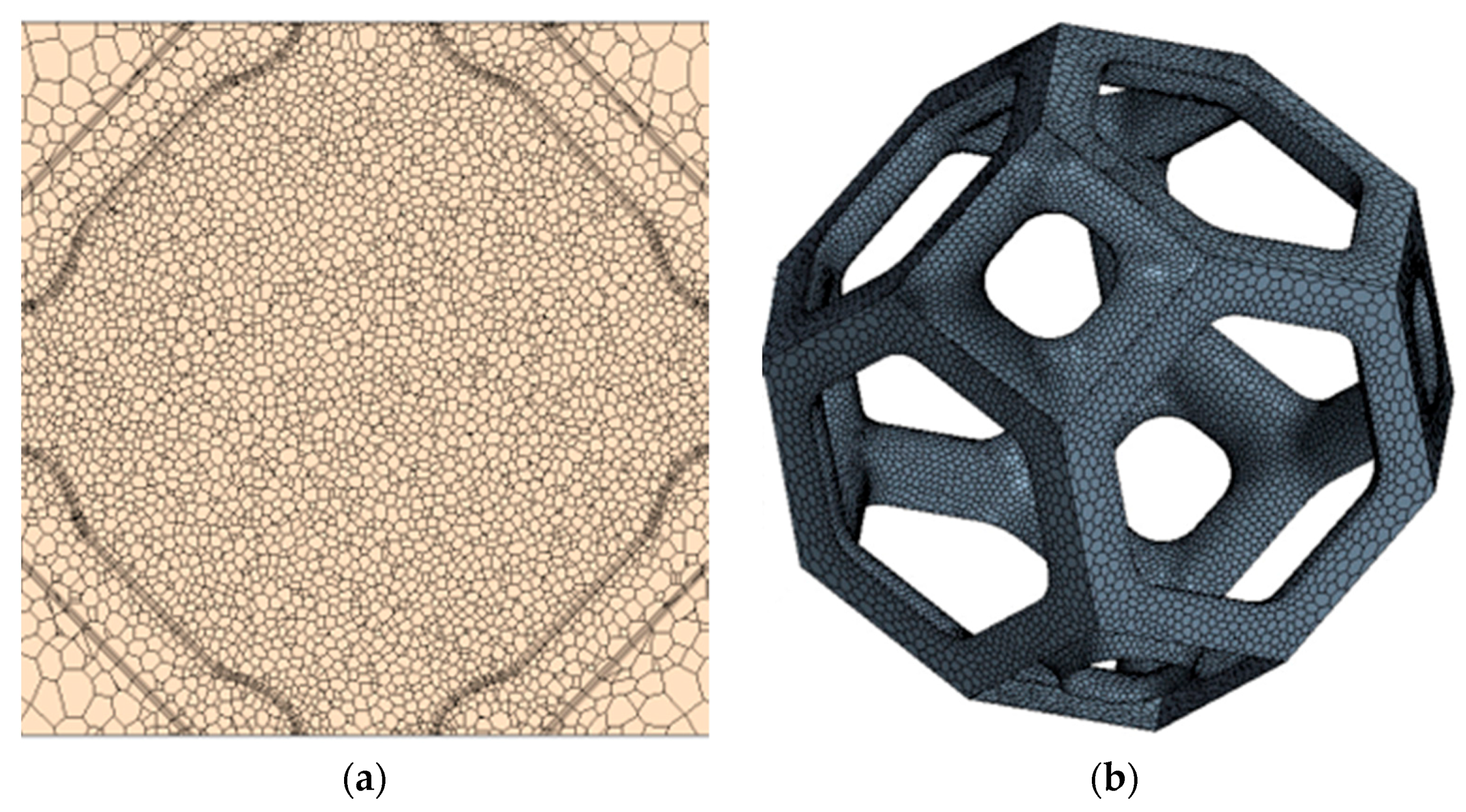

3.2.1. Grid Model and Physical Model

3.2.2. Grid Verification

4. Results and Discussion

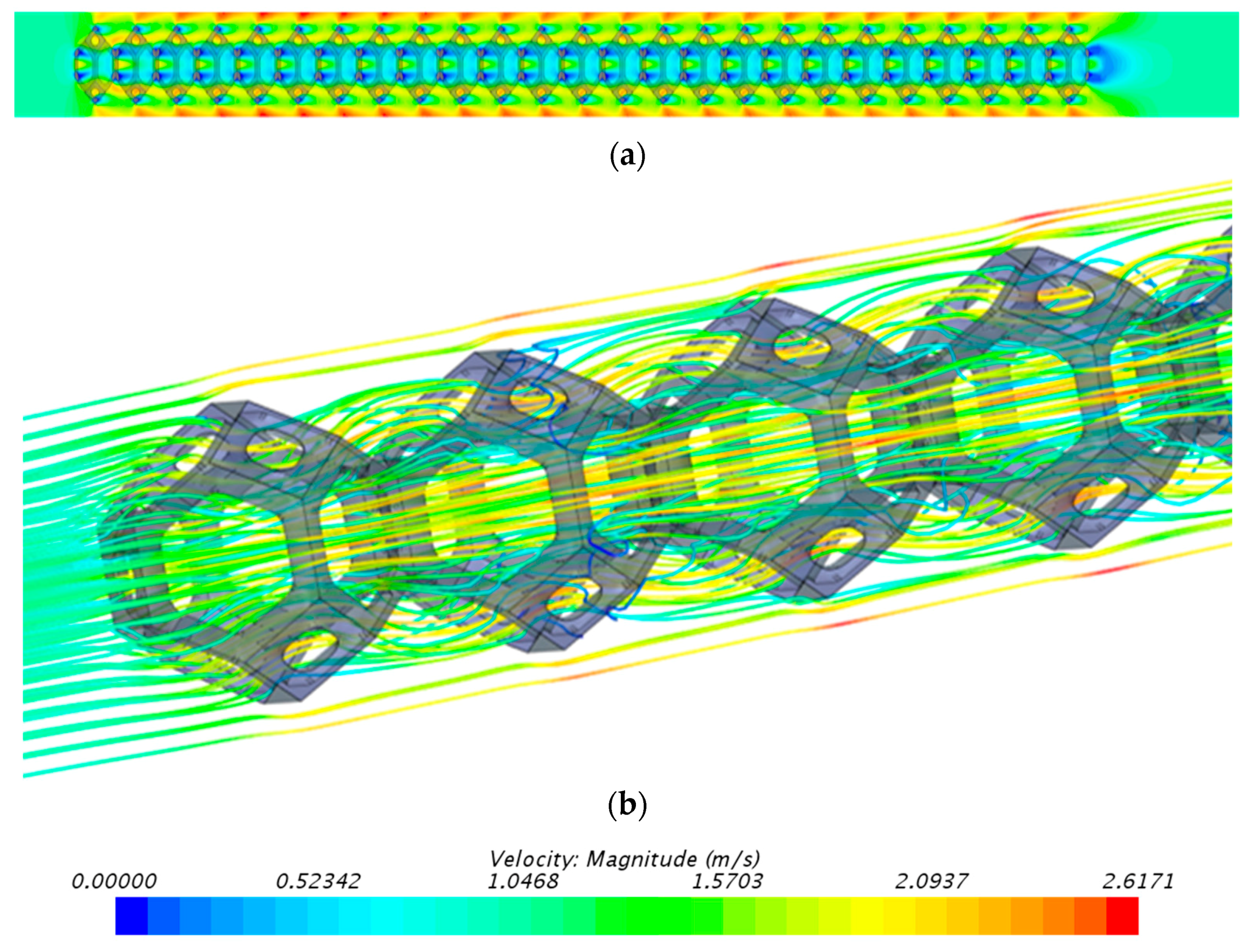

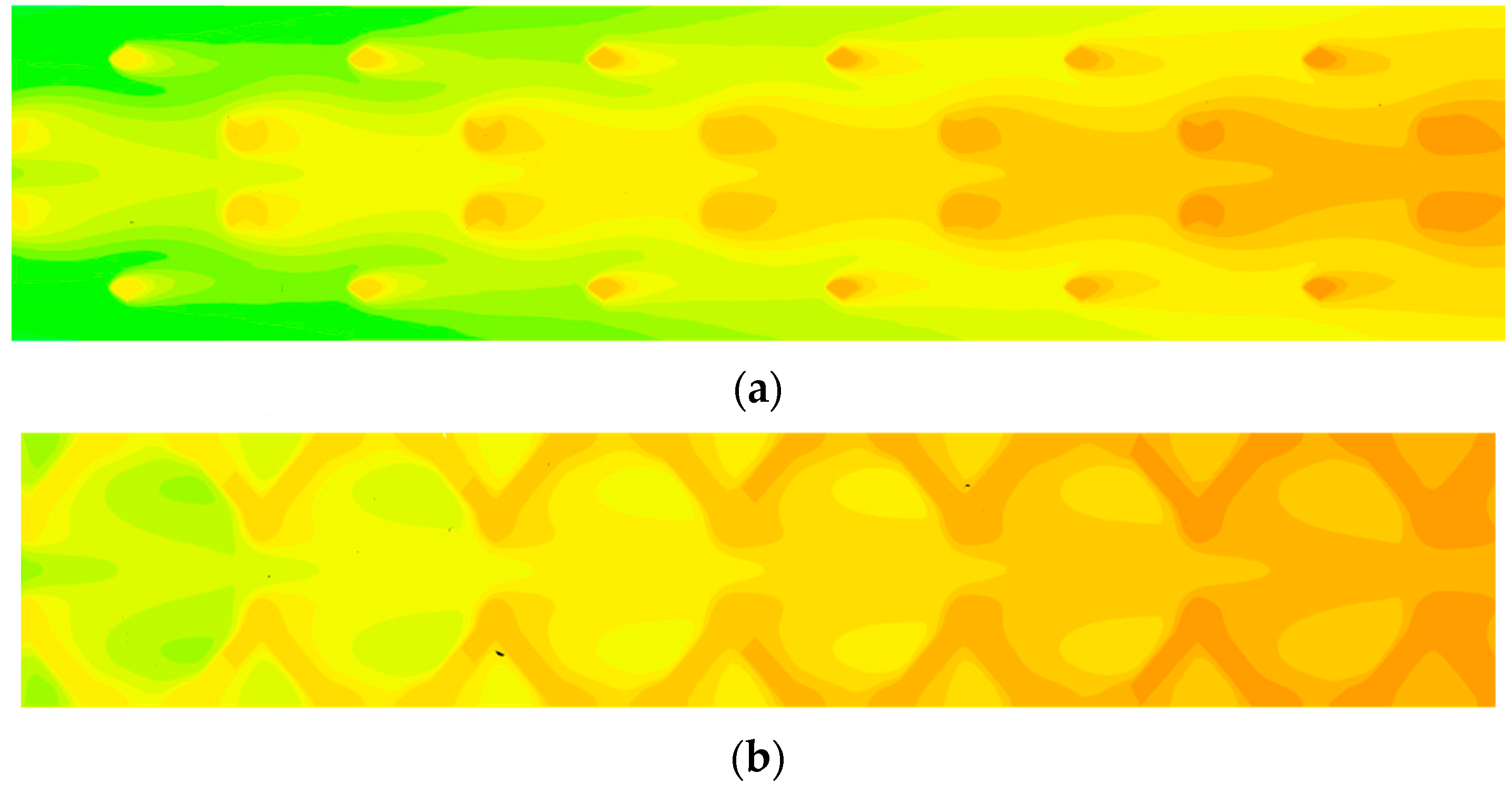

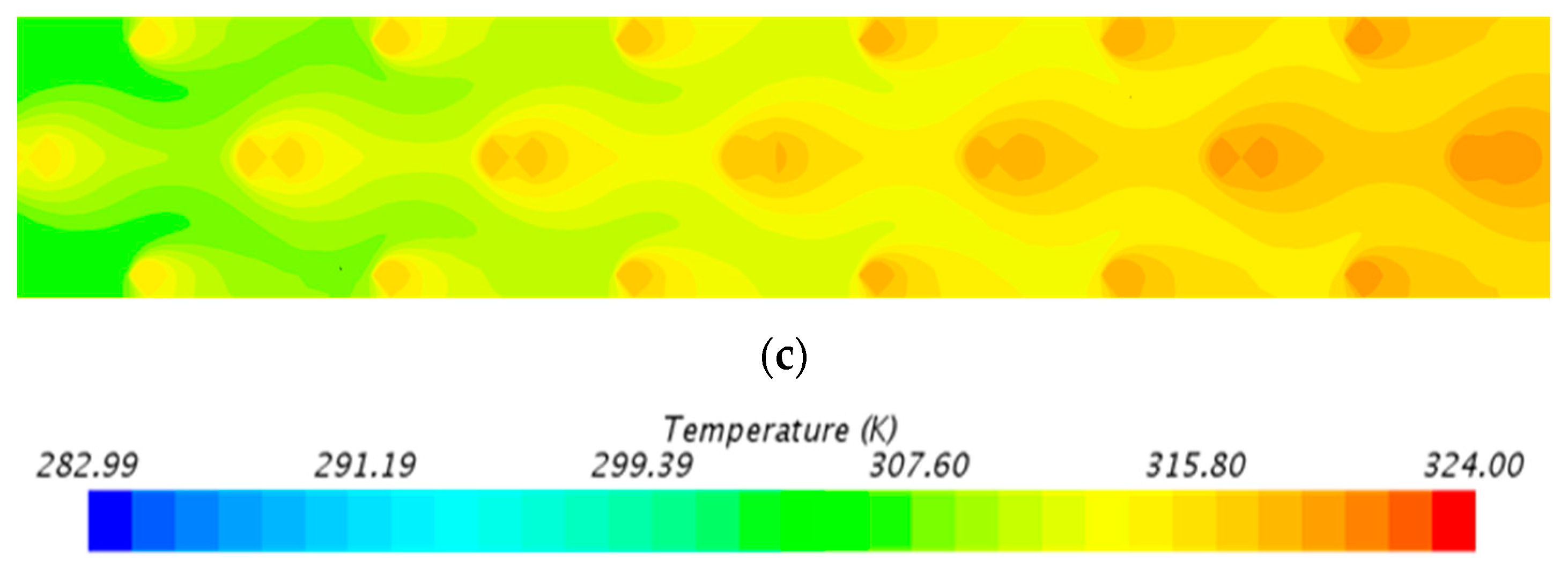

4.1. The Characteristics of Flow Field

The Local Thermal Equilibrium and Local Thermal Non-Equilibrium

5. Conclusions

- (1)

- The local thermal equilibrium easily occurs in a state when the thickness is larger or the flow velocity is smaller, which leads to a decrease in the volumetric heat transfer coefficient. Ignoring local thermal equilibrium leads to a significant deviation in evaluating volumetric heat transfer characteristics.

- (2)

- The foam structure such as pores and ligaments change the flow path, along with the disordered flow velocity, which affects the flow field and heat transfer characteristics, resulting in different degrees of local thermal equilibrium and local thermal non-equilibrium in the foams. Moreover, for foams with the same thickness and similar structure, the smaller porosity has obvious LTNE phenomenon and effective convective heat transfer effects.

- (3)

- For foams with a defined geometric structure, the larger the thickness, the thermal equilibrium phenomenon alternates with time and there is a large range for a long time, resulting in a reduction in the effective heat exchange area and a decrease in heat exchange efficiency.

- (4)

- The thickness and pore structure should be considered when using foam as the heat transfer medium to maintain a long local thermal non-equilibrium state and obtain a large heat exchange efficiency in designing products.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ε | porosity |

| PPI | pores per inch |

| ds | strut diameter |

| Ls | length of ligament |

| T | temperature |

| hv | volumetric heat transfer coefficient |

| u | velocity |

| d | cell diameter |

| L | thickness of foam |

| T0 | initial temperature |

| Tf,in | Inlet fluid temperature |

| TS | solid temperature |

References

- Zhao, C.Y. Review on thermal transport in high porosity cellular metal foams with open cells. Int. J. Heat Mass Transf. 2012, 55, 3618–3632. [Google Scholar] [CrossRef]

- Panse, S.S.; Singh, P.; Ekkad, S.V.; Patterson, M.W. Thermal hydraulic performance augmentation by high-porosity thin aluminum foams placed in high aspect ratio ducts. Appl. Therm. Eng. 2019, 161, 114162. [Google Scholar] [CrossRef]

- Rashidi, S.; Kashefi, M.H.; Kim, K.C.; Samimi-Abianeh, O. Potentials of porous materials for energy management in heat exchangers—A comprehensive review. Appl. Energy 2019, 243, 206–232. [Google Scholar] [CrossRef]

- Feng, S.S.; Kuang, J.J.; Wen, T.; Lu, T.J.; Ichimiya, K. An experimental and numerical study of finned metal foam heat sinks under impinging air jet cooling. Int. J. Heat Mass Transf. 2014, 77, 1063–1074. [Google Scholar] [CrossRef]

- Rehman, T.-u.; Ali, H.M. Experimental investigation on paraffin wax integrated with copper foam based heat sinks for electronic components thermal cooling. Int. Commun. Heat Mass Transf. 2018, 98, 155–162. [Google Scholar] [CrossRef]

- Al-Athel, K.S. A computational methodology for assessing the thermal behavior of metal foam heat sinks. Appl. Therm. Eng. 2017, 111, 884–893. [Google Scholar] [CrossRef]

- Bayomy, A.M.; Saghir, M.Z.; Yousefi, T. Electronic cooling using water flow in aluminum metal foam heat sink: Experimental and numerical approach. Int. J. Therm. Sci. 2016, 109, 182–200. [Google Scholar] [CrossRef]

- Pozzobon, J.C.; Mantelli, M.B.H.; Silva, A.K.D. Experimental study of unstructured porous media inserts for water recovery in a reduced scale, crossflow cooling tower. Appl. Therm. Eng. 2015, 96, 632–639. [Google Scholar] [CrossRef]

- Gomez-Garcia, F.; González-Aguilar, J.; Olalde, G.; Romero, M. Thermal and hydrodynamic behavior of ceramic volumetric absorbers for central receiver solar power plants: A review. Renew. Sustain. Energy Rev. 2016, 57, 648–658. [Google Scholar] [CrossRef]

- Barreto, G.; Canhoto, P.; Collares-Pereira, M. Three-dimensional CFD modelling and thermal performance analysis of porous volumetric receivers coupled to solar concentration systems. Appl. Energy 2019, 252, 113433. [Google Scholar] [CrossRef]

- Zaversky, F.; Aldaz, L.; Sánchez, M.; Ávila-Marín, A.L.; IsabelRoldán, M. Numerical and experimental evaluation and optimization of ceramic foam as solar absorber—Single-layer vs multi-layer configurations. Appl. Energy 2018, 210, 351–375. [Google Scholar] [CrossRef]

- Frey, M.; Romero, T.; Roger, A.C.; Edouard, D. An intensification of the CO2 methanation reaction: Effect of carbon nanofiber network on the hydrodynamic, thermal and catalytic properties of reactors filled with open cell foams. Chem. Eng. Sci. 2019, 195, 271–280. [Google Scholar] [CrossRef]

- Chueh, W.C.; Falter, C.; Abbott, M.; Scipio, D.; Furler, P.; Haile, S.M.; Steinfeld, A. High-Flux Solar-Driven Thermochemical Dissociation of CO2 and H2O Using Nonstoichiometric Ceria. Science 2015, 330, 1797–1801. [Google Scholar] [CrossRef] [PubMed]

- Ranut, P.; Nobile, E.; Mancini, L. High resolution microtomography-based CFD simulation of flow and heat transfer in aluminum metal foams. Appl. Therm. Eng. 2014, 69, 230–240. [Google Scholar] [CrossRef]

- Xu, H.J.; Xing, Z.B.; Wang, F.Q.; Cheng, Z.M. Review on Heat Conduction, Heat Convection, Thermal Radiation and Phase Change Heat Transfer of Nanofluids in Porous Media: Fundamentals and Applications. Chem. Eng. Sci. 2018, 195, 462–483. [Google Scholar] [CrossRef]

- Dukhan, N.; Al-Rammahi, M.A.; Suleiman, A.S. Fluid temperature measurements inside metal foam and comparison to Brinkman–Darcy flow convection analysis. Int. J. Heat Mass Transf. 2013, 67, 877–884. [Google Scholar] [CrossRef]

- Dukhan, N.; Bağcı, Ö.; Özdemir, M. Thermal development in open-cell metal foam: An experiment with constant wall heat flux. Int. J. Heat Mass Transf. 2015, 85, 852–859. [Google Scholar] [CrossRef]

- Dietrich, B. Heat transfer coefficients for solid ceramic sponges—Experimental results and correlation. Int. J. Heat Mass Transf. 2013, 61, 627–637. [Google Scholar] [CrossRef]

- Xia, X.L.; Xue, C.; Sun, C.; Li, Z.H.; Bo, L. Experiment on the convective heat transfer from airflow to skeleton in open-cell porous foams. Int. J. Heat Mass Transf. 2017, 106, 83–90. [Google Scholar] [CrossRef]

- Vijay, D.; Goetze, P.; Wulf, R.; Gross, U. Forced convection through open cell foams based on homogenization approach: Transient analysis. Int. J. Therm. Sci. 2015, 98, 395–408. [Google Scholar] [CrossRef]

- Vijay, D.; Goetze, P.; Wulf, R.; Gross, U. Forced convection through open cell foams based on homogenization approach: Steady state analysis. Int. J. Therm. Sci. 2015, 98, 381–394. [Google Scholar] [CrossRef]

- Krishnakumar, K.; John, A.K.; Venkatarathnam, G. A review on transient test techniques for obtaining heat transfer design data of compact heat exchanger surfaces. Exp. Therm. Fluid Sci. 2011, 35, 738–743. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Luo, X.; Kabelac, S. The single-blow transient testing technique for offset and wavy fins of compact plate-fin heat exchangers. Appl. Therm. Eng. 2017, 111, 1588–1595. [Google Scholar] [CrossRef]

- Chiappini, D. Numerical simulation of natural convection in open-cells metal foams. Int. J. Heat Mass Transf. 2018, 117, 527–537. [Google Scholar] [CrossRef]

- Ambrosio, G.; Bianco, N.; Chiu, W.K.S.; Iasiello, M.; Oliviero, M. The effect of open-cell metal foams strut shape on convection heat transfer and pressure drop. Appl. Therm. Eng. 2016, 103, 333–343. [Google Scholar] [CrossRef]

- Zafari, M.; Panjepour, M.; Davazdah Emami, M.; Meratian, M. Microtomography-based numerical simulation of fluid flow and heat transfer in open cell metal foams. Appl. Therm. Eng. 2015, 80, 347–354. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Caliot, C.; Flamant, G.; Wang, Z.F. Numerical simulation of convective heat transfer between air flow and ceramic foams to optimise volumetric solar air receiver performances. Int. J. Heat Mass Transf. 2011, 54, 1527–1537. [Google Scholar] [CrossRef]

- Du, S.; Tong, Z.X.; Zhang, H.H.; He, Y.L. Tomography-based determination of Nusselt number correlation for the porous volumetric solar receiver with different geometrical parameters. Renew. Energy 2018, 135, 711–718. [Google Scholar] [CrossRef]

- Das, S.; Sneijders, S.; Deen, N.G.; Kuipers, J.A.M. Drag and heat transfer closures for realistic numerically generated random open-cell solid foams using an immersed boundary method. Chem. Eng. Sci. 2018, 183, 260–274. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Q.N.; Qu, Z.G.; Yang, R.Z. Simulation and analytical validation of forced convection inside open-cell metal foams. Int. J. Therm. Sci. 2017, 111, 234–245. [Google Scholar] [CrossRef]

- Iasiello, M.; Cunsolo, S.; Bianco, N.; Chiu, W.K.S.; Naso, V. Developing thermal flow in open-cell foams. Int. J. Therm. Sci. 2016, 111, 129–137. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Diani, A.; Rossetto, L. Air forced convection through metal foams: Experimental results and modeling. Int. J. Heat Mass Transf. 2013, 62, 112–123. [Google Scholar] [CrossRef]

| Parameter | Case1 | Case2 | Case3 |

|---|---|---|---|

| Base size | 0.5 mm | 0.5 mm | 0.4 mm |

| Minimum face mesh size | 0.125 mm | 0.05 mm | 0.04 mm |

| Total number of grid cells | 1,072,595 | 3,942,086 | 5,466,177 |

| Number of mesh nodes | 4,798,145 | 19,797,049 | 27,577,773 |

| Pressure drop | 36.83 Pa | 35.18 Pa | 35.15 Pa |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Yang, L.; Wu, Z.; Xu, S. Numerical and Experimental Study on Convective Heat Transfer Characteristics in Foam Materials. Energies 2020, 13, 348. https://doi.org/10.3390/en13020348

Lu H, Yang L, Wu Z, Xu S. Numerical and Experimental Study on Convective Heat Transfer Characteristics in Foam Materials. Energies. 2020; 13(2):348. https://doi.org/10.3390/en13020348

Chicago/Turabian StyleLu, Hongyan, Lixin Yang, Zhiyong Wu, and Siqi Xu. 2020. "Numerical and Experimental Study on Convective Heat Transfer Characteristics in Foam Materials" Energies 13, no. 2: 348. https://doi.org/10.3390/en13020348

APA StyleLu, H., Yang, L., Wu, Z., & Xu, S. (2020). Numerical and Experimental Study on Convective Heat Transfer Characteristics in Foam Materials. Energies, 13(2), 348. https://doi.org/10.3390/en13020348