Thermal Performance and Energy Saving Analysis of Indoor Air–Water Heat Exchanger Based on Micro Heat Pipe Array for Data Center

Abstract

:1. Introduction

- –

- With regard to the theoretical calculation and actual design of MHPA-AWHE, there are several steps as follows: (a) The comprehensive performance based on heat transfer and pressure drop characteristics of serrated fins shows the best performance of different kinds of fins [19,20]. (b) The heat transfer equations are established from the air side to water side of MHPA-AWHE, and the optimal solution is obtained by simultaneous equations. Under the design condition of certain heat transfer rates, the size of the heat exchanger with the minimum number of MHPAs and the minimum length, width, height is obtained. (c) On this basis, the experimental platform is established, and the experimental results are verified with theoretical calculation values.

- –

- With regard to the structure aspect, there are several advantages: (a) The flat-plate appearance of MHPA facilitates the combination with the heat transfer enhancement structure. (b) On the water side, the parallel flow tube with tiny porous channels enlarges the heat transfer area, and the flat-plate appearance can easily fit with MHPA, (c) The serrated fins are used to increase the disturbance of air flow and enlarge the convective heat transfer area to enhance heat transfer.

- –

- With regard to the operating effect, (a) compared with traditional heat exchangers, the proposed configuration has a compact structure, small footprint, and low heat loss. (b) The MHPA-AWHE system is flexible and reliable and uses water or antifreeze as the circulating medium between indoor and outdoor sides instead of refrigerant pipelines.

- –

- With regard to the energy saving aspect, the most economical operation condition and matching number of modules are suggested in this work, and the critical environment temperature for the opening and closing of MHPA-AWHE system is obtained. The power consumption of DCs after the transformation is lower than that before the transformation.

2. Experimental Investigation

2.1. MHPA-AWHE

2.2. Experimental System

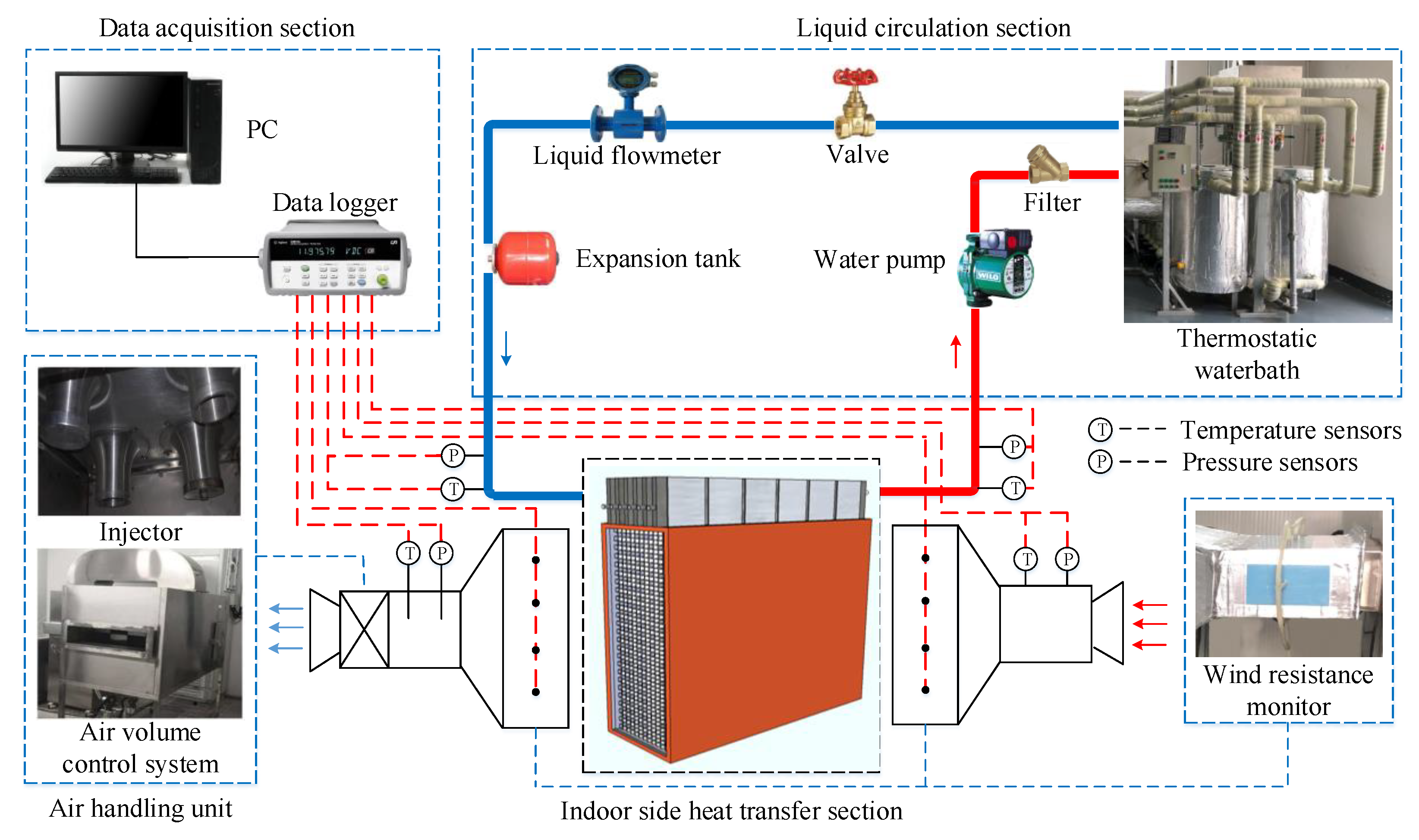

2.2.1. Experimental System of MHPA-AWHE

2.2.2. Distribution of Temperature Measurement Points

2.2.3. Experimental Method

2.3. Evaluation Index of Heat Exchanger System

2.3.1. Heat Transfer Rate and Heat Loss Rate

2.3.2. Efficiency of MHPA-AWHE System

2.3.3. Heat Flux and Thermal Conductivity of Core Components

2.3.4. Heat Transfer Process of MHPA-AWHE

2.3.5. Comprehensive Performance Evaluation Index (j/f1/2)

2.3.6. Energy Saving Evaluation Indexes

2.4. Uncertainty Analysis

3. Results and Discussion

3.1. Thermal Performance of MHPA-AWHE

3.1.1. Thermal Balance Performance of MHPA-AWHE

3.1.2. Heat Transfer Rate for Different Flow Rates and Inlet Water Temperatures

3.1.3. Efficiency of MHPA-AWHE

3.2. Heat Transfer Performance of MHPA-AWHE

3.2.1. Thermal Performance of Core Components

3.2.2. Thermal Resistance Analysis

3.3. Pressure Drop and Power Consumption

3.4. Comprehensive Performances of MHPA-AWHE

3.5. Energy Saving Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AWHE | air–water heat exchanger | D | equivalent diameter of fin: m |

| MHPA | micro-heat pipe array | l | length of single fin, m |

| EER | Energy efficiency ratio | Y | payback period, year |

| AC | air conditioner | I | initial investment |

| DC | data center | B1 | power consumption before the transformation, kWh |

| PFT | parallel flow tube | B2 | power consumption after the transformation, kWh |

| NTU | number of transfer units | Greek symbols | |

| P | power consumption, W | α | commercial electricity price, RMB/kWh |

| F | heat flux, W/cm2 | ||

| N | number | λ | thermal conductivity, W/(m·K) |

| cp | specific heat capacity, J/(kg·K) | ρ | density, kg/m3 |

| qv | volume flow rate, m3/s | Δβ | heat loss rate |

| t | temperature, °C | ε | heat exchanger efficiency |

| Q | heat transfer rate, W | δ | thickness, m |

| Q0 | cooling load, kW | ||

| A | area, m2 | Subscripts | |

| Pr | prandtl number | w | water side |

| ΔP | pressure drop, Pa | a | air side |

| C | quantity of specific heat capacity, W/K | i | inlet |

| o | outlet | ||

| j | Heat transfer factor | s | cross-section |

| f | Friction factor | min | minimum |

| R | thermal resistance, K/W | max | maximum |

| Re | Reynolds number | p | parallel flow tube |

| v | velocity, m/s | e | Evaporation section of MHPA |

| h | convective heat transfer coefficient, W/(m2·K) | c | Condensation section of MHPA |

| r | contact section | ||

| K | Heat transfer coefficient, W/(m2·K) | in | inner surface |

| out | outer surface | ||

References

- Hong, T.; Yang, L.; Hill, D.; Feng, W. Data and analytics to inform energy retrofit of high performance buildings. Appl. Energy 2014, 126, 90–106. [Google Scholar] [CrossRef] [Green Version]

- Beitelmal, A.H.; Patel, C.D. A steady–state model for the design and optimization of a centralized cooling system. Int. J. Energy Res. 2010, 34, 1239–1248. [Google Scholar] [CrossRef]

- Stein, J. Waterside economizing in data Centers: design and control considerations. ASHRAE Trans. 2009, 115, 192–200. [Google Scholar]

- Alanazi, S.; Dabbagh, M.; Hamdaoui, B.; Guizani, M.; Zorba, N. Reducing Data Center Energy Consumption Through Peak Shaving and Locked–In Energy Avoidance. IEEE Trans. Green Commun. Netw. 2017, 1, 551–562. [Google Scholar] [CrossRef]

- Zhang, X.; Lindberg, T.; Xiong, N.; Vyatkin, V.; Mousavi, A. Cooling Energy Consumption Investigation of Data Center IT Room with Vertical Placed Server. Energy Procedia 2017, 105, 2047–2052. [Google Scholar] [CrossRef]

- Tian, H.; He, Z.; Li, Z. A combined cooling solution for high heat density data centers using multi–stage heat pipe loops. Energy Build. 2015, 94, 177–188. [Google Scholar] [CrossRef]

- He, Z.; Ding, T.; Liu, Y.; Li, Z. Analysis of a district heating system using waste heat in a distributed cooling data center. Appl. Therm. Eng. 2018, 141, 1131–1140. [Google Scholar] [CrossRef]

- Oró, E.; Depoorter, V.; Pflugradt, N.; Salom, J. Overview of direct air free cooling and thermal energy storage potential energy savings in data centres. Appl. Therm. Eng. 2015, 85, 100–110. [Google Scholar] [CrossRef]

- Lee, K.P.; Chen, H.L. Analysis of energy saving potential of air–side free cooling for data centers in worldwide climate zones. Energy Build. 2013, 64, 103–112. [Google Scholar] [CrossRef]

- Ham, S.W.; Park, J.S.; Jeong, J.W. Optimum supply air temperature ranges of various air–side economizers in a modular data center. Appl. Therm. Eng. 2015, 77, 163–179. [Google Scholar] [CrossRef]

- Cho, J.; Lim, T.; Kim, B.S. Viability of datacenter cooling systems for energy efficiency in temperate or subtropical regions: Case study. Energy Build. 2012, 55, 189–197. [Google Scholar] [CrossRef]

- Deymi–Dashtebayaz, M.; Namanlo, S.V.; Arabkoohsar, A. Simultaneous use of air–side and water–side economizers with the air source heat pump in a data center for cooling and heating production. Appl. Therm. Eng. 2019, 161, 114–133. [Google Scholar] [CrossRef]

- Iyengar, M.; Kamath, V. Energy efficient economizer based data centers with air cooled servers. In Proceedings of the Thermal & Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2012. [Google Scholar]

- Fan, W.; Georgios, K.; Ma, Z. Integrative modelling and optimization of a desiccant cooling system coupled with a photovoltaic thermal–solar air heater. Sol. Energy 2019, 193, 929–947. [Google Scholar] [CrossRef]

- Kim, M.H.; Ham, S.W.; Park, J.S.; Jeong, J.W. Impact of integrated hot water cooling and desiccant assisted evaporative cooling systems on energy savings in a data center. Energy 2014, 78, 384–396. [Google Scholar] [CrossRef]

- Ren, H.; Ma, Z.; Stefan, G. Characterisation and evaluation of a new phase change enhanced working solution for liquid desiccant cooling systems. Appl. Therm. Eng. 2019, 150, 1197–1205. [Google Scholar] [CrossRef]

- Durand-Estebe, B.; Le Bot, C.; Mancos, J.N.; Arquis, E. Simulation of a temperature adaptive control strategy for an IWSE economizer in a data center. Appl. Energy 2014, 134, 45–56. [Google Scholar] [CrossRef]

- Wang, C.C.; Tao, W.H.; Chang, C.J. An investigation of the airside performance of the slit fin–and–tube heat exchangers. Int. J. Refrig. 1999, 22, 595–603. [Google Scholar] [CrossRef]

- Wang, C.C.; Lee, C.J.; Chang, C.T.; Lin, S.P. Heat transfer and friction correlation for compact louvered fin–and–tube heat exchangers. Int. J. Heat Mass Transf. 1998, 42, 1945–1956. [Google Scholar] [CrossRef]

- Wang, C.C.; Chi, K.Y.; Chang, Y.J.; Chang, Y.P. An experimental study of heat transfer and friction characteristics of typical louver fin–and–tube heat exchangers. Int. J. Heat Mass Transf. 1998, 41, 817–822. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Jang, J.Y. Parametric study and optimization of louver finned–tube heat exchangers by Taguchi method. Appl. Therm. Eng. 2012, 42, 101–110. [Google Scholar] [CrossRef]

- Tao, W.Q.; Cheng, Y.P.; Lee, T.S. 3D numerical simulation on fluid flow and heat transfer characteristics in multistage heat exchanger with slit fins. Heat Mass Transf. 2007, 44, 125–136. [Google Scholar] [CrossRef]

- Zhu, D.D.; Yan, D.; Li, Z. Modelling and applications of annual energy–using simulation module of separated heat pipe heat exchanger. Energy Build. 2013, 57, 26–33. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, Q.; Zhai, Z.; Ling, L. Numerical investigation on thermal characteristics and flow distribution of a parallel micro–channel separate heat pipe in data center. Int. J. Refrig. 2019, 98, 150–160. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, L.; Zhang, S.; Xie, N.; Chen, H. Heat transfer characteristics of a natural circulation separate heat pipe under various operating conditions. Int. J. Heat Mass Transf. 2018, 126, 191–200. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Liu, X.; Meng, X.; Guo, X.; Zhang, L. Experimental Investigation of Gravity Heat Pipe Exchanger Applied in Communication Base Station. Procedia Eng. 2015, 121, 1326–1333. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Tang, G.F.; Zhao, F.Y.; Wang, H.Q. Modeling and experimental investigation of looped separate heat pipe as waste heat recovery facility. Appl. Therm. Eng. 2006, 26, 2433–2441. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhang, K.R.; Diao, Y.H. Heat Pipe with Micro–Pore Tubes Array and Making Method Thereof and Heat Exchanging System. U.S. Patent No. 20,110,203,777, 25 August 2011. [Google Scholar]

- Zhang, J.; Diao, Y.H.; Zhao, Y.H.; Tang, X.; Yu, W.J.; Wang, S. Experimental study on the heat recovery characteristics of a new–type flat micro–heat pipe array heat exchanger using nano–fluid. Energy Convers. Manag. 2013, 75, 609–616. [Google Scholar] [CrossRef]

- Diao, Y.H.; Liu, J.R.; Wang, Y.; Zhao, Y.H. An Experimental Investigation on Heat Transfer Characteristics for Micro–Capillary Evaporator. J. Eng. Thermophys. 2009, 22, 87–98. [Google Scholar] [CrossRef]

- Ye, X.; Zhao, Y.; Quan, Z. Thermal management system of lithium–ion battery module based on micro heat pipe array. Int. J. Energy Res. 2018, 42, 648–655. [Google Scholar] [CrossRef]

- Wang, Z.; Diao, Y.; Zhao, Y.; Liang, L.; Wang, T. Experimental study on the new type of electrical storage heater based on flat micro–heat pipe arrays. Sci. China Technol. Sci. 2018, 61, 219–231. [Google Scholar] [CrossRef]

- Wang, G.; Quan, Z.; Zhao, Y.; Wang, H. Performance of a flat–plate micro heat pipe at different filling ratios and working fluids. Appl. Therm. Eng. 2019, 146, 459–468. [Google Scholar] [CrossRef]

- Diao, Y.H.; Liang, L.; Kang, Y.M.; Zhao, Y.H.; Wang, Z.Y.; Zhu, T.T. Experimental study on the heat recovery characteristic of a heat exchanger based on a flat micro–heat pipe array for the ventilation of residential buildings. Energy Build. 2017, 152, 448–457. [Google Scholar] [CrossRef]

- Yan, D.; Xie, X.N.; Song, F.T.; Jiang, Y. Building environment design simulation software DeST (1): An overview of developments and information of building simulation and DeST. HV AC 2004, 34, 48–56. [Google Scholar]

- Manglik, R.M.; Bergles, A.E. Heat transfer and pressure drop correlations for the rectangular offset strip fin compact heat exchanger. Exp. Therm. Fluid Sci. 1995, 10, 171–180. [Google Scholar] [CrossRef]

- Lv, J.X.; Wang, T.J.; Zhao, L.; Wang, J.H.; Hu, L.W.; Liu, G.H.; Zhao, S.B. Energy saving analysis of data center air conditioning system based on application of natural cooling technology. J. Refrig. 2018, 37, 113–118. [Google Scholar]

| Instrument | Model | Working Scale | Accuracy | Number |

|---|---|---|---|---|

| Frequency conversion pump | CHL2-30 | 6–15 m | – | 1 |

| Centrifugal fan | Popular9-1.5 kW | 0–3200 m3/h | – | 1 |

| Flow meter | MFM-15 | 0–3 m3/h | 0.5% | 1 |

| Data logger | Agilent 34970A | 0–300 V | – | 1 |

| Thermal resistor | PT100 | 0–150 °C | ±0.1 °C | 2 |

| Thermocouple | T-Dot contact | −35–105 °C | ±0.1 °C | 60 |

| Differential pressure Transmitter (air side) | 3351DP5SM3 | 0–30 kPa | 0.5% | 1 |

| Different pressure Transmitter (water side) | 3351DP5SM5 | 0–50 kPa | 0.5% | 1 |

| Power Monitor | HY-001 | 0–10 A | 1% | 1 |

| Physical Quantity | Numerical Range | Relative Uncertainty |

|---|---|---|

| Qa | 632–9298 W | ±3.16–6.61% |

| Qw | 695–8738 W | ±3.13–6.30% |

| Δβ | 2.6–13.8% | ±2.17–6.11% |

| ε | 51.1–90.0% | ±2.87–6.36% |

| γ | 6.65–24.42 | ±3.01–5.71% |

| j | 0.014–0.037 | ±2.32–5.18% |

| f | 0.206–0.079 | ±2.23–4.72% |

| Curves | Cmin/Cmax | Fitting Equation of ε-NTU | Variance/R2 |

|---|---|---|---|

| Curve 1 | 0.25 | 0.9698 | |

| Curve 2 | 0.5 | 0.99658 | |

| Curve 3 | 0.75 | 0.99956 | |

| Curve 4 | 1 | 0.99995 |

| Type of Heat Exchanger | Velocity of Air Flow (m/s) | Inlet Temperature Difference (°C) | Heat Flux (W/cm2) | Equivalent Thermal Conductivity (W/(m·K)) |

|---|---|---|---|---|

| Air–air heat exchanger based on MHPA | 0.95 | 8 | 4.79 | 5.98 × 103 |

| 13 | 7.97 | 7.59 × 103 | ||

| MHPA-AWHE | 0.96 | 8 | 8.48 | 3.42 × 104 |

| 13 | 13.03 | 5.01 × 104 |

| Environment Temperature | AC | MHPA-AWHE System | Hours (Total: 8760 h) |

|---|---|---|---|

| ≤0.72 °C | Off | On | 1723 h (19.7%) |

| 0.72–18.4 °C | On | On | 3803 h (43.4%) |

| ≥18.4 °C | On | Off | 3234 h (36.9%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, H.; Quan, Z.; Zhao, Y.; Wang, L.; Ren, R.; Liu, Z. Thermal Performance and Energy Saving Analysis of Indoor Air–Water Heat Exchanger Based on Micro Heat Pipe Array for Data Center. Energies 2020, 13, 393. https://doi.org/10.3390/en13020393

Jing H, Quan Z, Zhao Y, Wang L, Ren R, Liu Z. Thermal Performance and Energy Saving Analysis of Indoor Air–Water Heat Exchanger Based on Micro Heat Pipe Array for Data Center. Energies. 2020; 13(2):393. https://doi.org/10.3390/en13020393

Chicago/Turabian StyleJing, Heran, Zhenhua Quan, Yaohua Zhao, Lincheng Wang, Ruyang Ren, and Zichu Liu. 2020. "Thermal Performance and Energy Saving Analysis of Indoor Air–Water Heat Exchanger Based on Micro Heat Pipe Array for Data Center" Energies 13, no. 2: 393. https://doi.org/10.3390/en13020393

APA StyleJing, H., Quan, Z., Zhao, Y., Wang, L., Ren, R., & Liu, Z. (2020). Thermal Performance and Energy Saving Analysis of Indoor Air–Water Heat Exchanger Based on Micro Heat Pipe Array for Data Center. Energies, 13(2), 393. https://doi.org/10.3390/en13020393