A Novel Assisted Gas–Oil Countercurrent EOR Technique for Attic Oil in Fault-Block Reservoirs

Abstract

:1. Introduction

2. Experimental Procedure and Materials

2.1. Experimental Model Design

2.2. Materials and Experimental Preparation

2.3. Experimental Design

2.3.1. Experimental Design of Water Flooding

2.3.2. Experimental Design of the Assisted GOC under Different Conditions

3. Results and Discussion

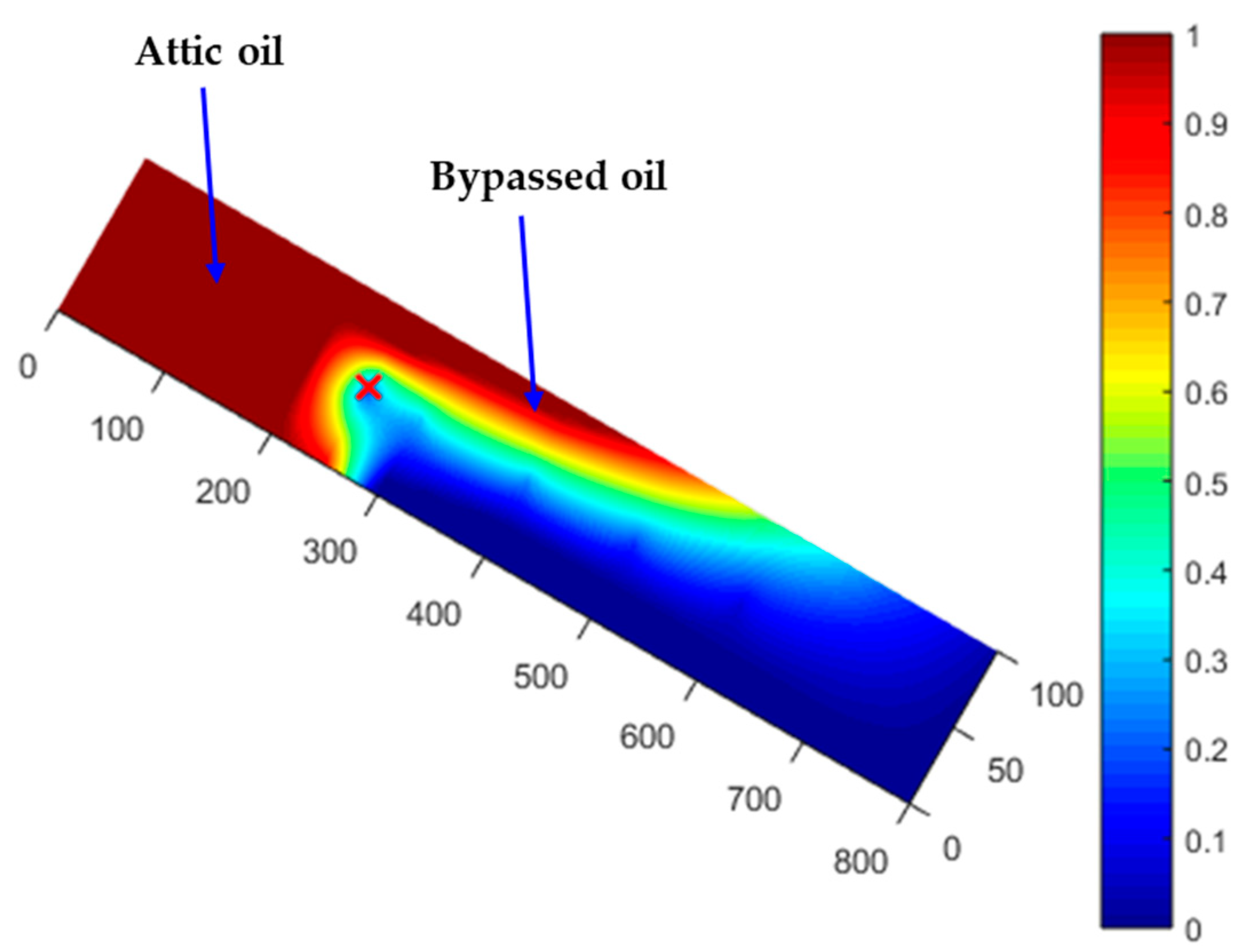

3.1. The Attic Oil Evaluation after Water Flooding

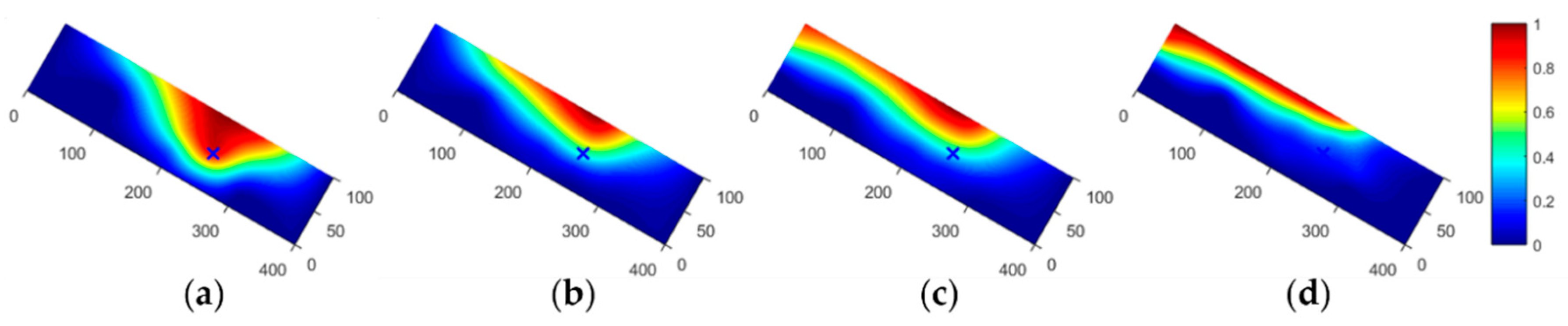

3.2. The Production Efficiency Evaluation of the Assisted GOC

3.3. The Production Performance Evaluation of the Assisted GOC

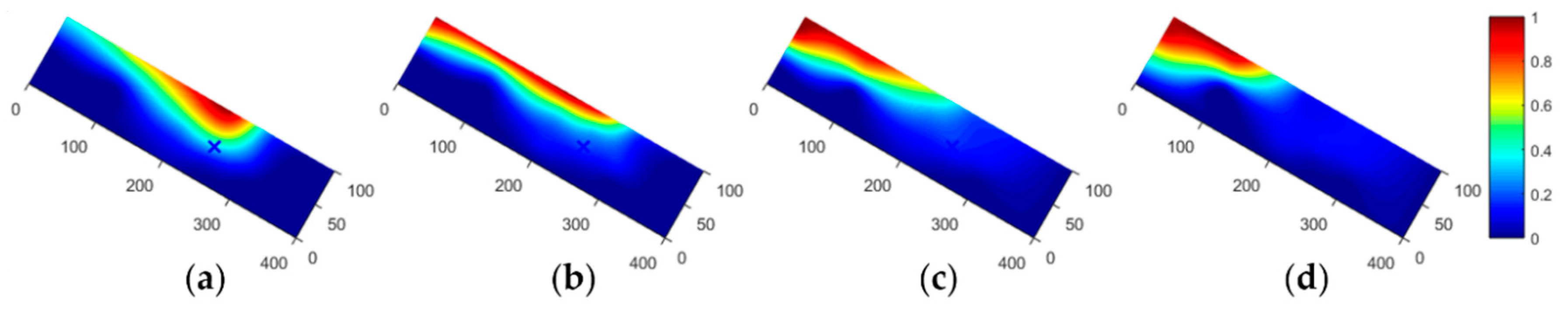

3.4. The Evaluation of Remaining Oil Distribution after the Assisted GOC Process

4. Conclusions

- The injected gas migrates upward to replace the attic oil which cannot be swept by the water flooding under the influence of GOC and WFA. The gas–oil countercurrent is the primary EOR mechanism of the proposed method.

- The gas upward migration speed is low, and the distribution of the gas phase is dispersive when only utilizing GOC to produce the attic oil. In this case, gas channeling can form easily in the production process, which can cause great loss of the gas cap energy. The production performance is very poor with only limited oil production.

- The function of WFA varies during different stages of the process. In the gas injection stage, the water flooding can block access to the downward migration and accelerate the migration speed which can improve production efficiency. The wells shut-in time shortens by 50% approximately. At the production stage, combining the expansion of the secondary gas cap, the bi-directional flooding forms. The water flooding can inhibit the gas channeling during the gas cap expansion and decrease the pressure decline rate. The water flooding can also displace the attic oil replaced under the production well and the resembled bypassed oil which cannot be swept by gas expansion.

- With the higher assisted effect in Exp4, the production duration can be extended four times with 223.86 mL more oil produced compared to the basic GOC production process in Exp1. However, excessive WFA can also cause water breakthrough which reduces oil production.

- Even for the best assisted GOC performance in Exp4, there is still production potential after one cycle of the process. This is caused by the limitation of the volume of injected gas. In practical production, more cycles are needed to achieve better production performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, S.; Wang, W.; Zhang, A.; Zhou, W. Genetic mechanism and evolution of the covert fault zone and its oil-controlling mode in qikou sag, eastern China. Energies 2019, 12, 98. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Cao, Y.; Liu, K.; Costanzo, A.; Feely, M. Diagenesis and evolution of the lower Eocene red-bed sandstone reservoirs in the Dongying Depression, China. Mar. Pet. Geol. 2018, 94, 230–245. [Google Scholar] [CrossRef]

- Yuan, S.; Wang, Q. New progress and prospect of oilfields development technologies in China. Pet. Explor. Dev. 2018, 45, 698–711. [Google Scholar] [CrossRef]

- Ma, K.; Jiang, H.Q.; Li, J.J.; Chang, Y.H.; Zhao, L.; Yang, H.X.; Yan, Q. A New Method of Bidirectional Displacement to Enhance Oil Recovery in Fault-block Reservoirs at High Water Cut Stage. In Proceedings of the IOR 2017—19th European Symposium Improved Oil Recovery, Stavanger, Norway, 24 April 2017. [Google Scholar]

- Yahong, W.; Xingfang, W.; Mengya, X.; Shengtao, G. Study of early dynamic evaluation methods in complex small fault-block reservoirs. Energy Procedia 2012, 14, 689–694. [Google Scholar] [CrossRef] [Green Version]

- Strickland, R.F.; Morse, R.A. Gas Injection for Upstructure Oil Drainage. J. Pet. Technol. 1979, 31, 1323–1331. [Google Scholar] [CrossRef]

- Yuan, D.; Hou, J.; Song, Z.; Wang, Y.; Luo, M.; Zheng, Z. Residual oil distribution characteristic of fractured-cavity carbonate reservoir after water flooding and enhanced oil recovery by N2 flooding of fractured-cavity carbonate reservoir. J. Pet. Sci. Eng. 2015, 129, 15–22. [Google Scholar] [CrossRef]

- Van der Poel, C.; Killian, J.W. Attic Oil. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Society of Petroleum Engineers, Dallas, TX, USA, 28 September 1975. [Google Scholar]

- Combs, G.D.; Knezek, R.B. Gas Injection for Upstructure Oil Drainage. J. Pet. Technol. 1971, 23, 361–372. [Google Scholar] [CrossRef]

- Richardson, J.G.; Blackwell, R.J. Use of Simple Mathematical Models for Predicting Reservoir Behavior. J. Pet. Technol. 2007, 23, 1145–1154. [Google Scholar] [CrossRef]

- Juan, C. Hernandez Oil Bypassing By Water Invasion to Wells: Mechanisms and Remediation. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2007. [Google Scholar]

- Luo, H.; Delshad, M.; Pope, G.A.; Mohanty, K.K. Scaling up the interplay of fingering and channeling for unstable water/polymer floods in viscous-oil reservoirs. J. Pet. Sci. Eng. 2018, 165, 332–346. [Google Scholar] [CrossRef]

- Loro, R.; Hill, R.; Jackson, M.; Slate, T. Technologies that have transformed the Exmouth into Australia. APPEA J. 2017, 55, 233. [Google Scholar] [CrossRef]

- Martins, E.J.; Larez, N.J.; Lesso, W.G., Jr. Recovery of Attic Oil Through Horizontal Drilling. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers, Houston, CA, USA, 8–10 November 1993; pp. 1–11. [Google Scholar]

- Vo, D.T.; Marsh, E.L.; Sienkiewicz, L.J.; Mueller, M.D.; May, R.S. Gulf of Mexico Horizontal Well Improves Attic-Oil Recovery in Active Waterdrive Reservoir. SPE Reserv. Eng. 2007, 12, 163–168. [Google Scholar] [CrossRef]

- Lyngra, S.; Al-Sofi, A.; Al-Otaibi, U.; Al-Shakhs, M.; Al-Alawi, A. New Technology Applications For Improved Attic Oil Recovery: The World’s First Slim Smart Completions. In Proceedings of the International Petroleum Technology Conference, Society of Petroleum Engineers, Kuala Lumpur, Malaysia, 3–5 December 2008; pp. 1–6. [Google Scholar]

- Sun, Z.; Espinoza, D.N.; Balhoff, M.T.; Dewers, T.A. Discrete Element Modeling of Micro-scratch Tests: Investigation of Mechanisms of CO2 Alteration in Reservoir Rocks. Rock Mech. Rock Eng. 2017, 50, 3337–3348. [Google Scholar] [CrossRef]

- De Loubens, R.; Ramakrishnan, T.S. Analysis and computation of gravity-induced migration in porous media. J. Fluid Mech. 2011, 675, 60–86. [Google Scholar] [CrossRef]

- Jadhawar, P.S.; Sarma, H.K. Effect of well pattern and injection well type on the CO2-assisted gravity drainage enhanced oil recovery. J. Pet. Sci. Eng. 2012, 98–99, 83–94. [Google Scholar] [CrossRef]

- Nordbotten, J.M.; Celia, M.A.; Bachu, S.; Dahle, H.K. Semianalytical solution for CO2 leakage through an abandoned well. Environ. Sci. Technol. 2005, 39, 602–611. [Google Scholar] [CrossRef]

- Sherafati, M.; Jessen, K. Dynamic Relative Permeability and Simulation of WAG Injection Processes. Transp. Porous Media 2017, 117, 125–147. [Google Scholar] [CrossRef]

- Al-Mudhafar, W.J.; Rao, D.N.; Srinivasan, S. Robust Optimization of Cyclic CO2 flooding through the Gas-Assisted Gravity Drainage process under geological uncertainties. J. Pet. Sci. Eng. 2018, 166, 490–509. [Google Scholar] [CrossRef]

- Templeton, E.E.; Nielsen, R.F.; Stahl, C.D. A Study of Gravity Counterflow Segregation. Soc. Pet. Eng. J. 1961, 2, 185–193. [Google Scholar] [CrossRef]

- Briggs, J.E.; Katz, D.L. Drainage of Water from Sand in Developing Aquifer Storage. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Society of Petroleum Engineers, Dallas, TX, USA, 2–5 October 1966. [Google Scholar]

- Karpyn, Z.T.; Li, G.; Grader, A.S.; Halleck, P.M. Experimental conditions favoring the formation of fluid banks during counter-current flow in porous media. Transp. Porous Media 2006, 62, 109–124. [Google Scholar] [CrossRef]

- Baker, R.O.; Yarranton, H.W.; Jensen, J.L. Practical Reservoir Engineering and Characterization; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 978-0-12-801811-8. [Google Scholar]

- Zhang, Y.; Hu, J.; Zhang, Q. Simulation study of CO2 Huff-n-Puff in tight oil reservoirs considering molecular diffusion and adsorption. Energies 2019, 12, 2136. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Lin, M.; Wang, S.; Chen, S.; Cheng, L. Impact of un-propped fracture conductivity on produced gas huff-n-puff performance in Montney liquid rich tight reservoirs. J. Pet. Sci. Eng. 2019, 181, 106234. [Google Scholar] [CrossRef]

- Bai, H.; Zhang, Q.; Li, Z.; Li, B.; Zhu, D.; Zhang, L.; Lv, G. Effect of fracture on production characteristics and oil distribution during CO2 huff-n-puff under tight and low-permeability conditions. Fuel 2019, 246, 117–125. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, Q.; Rui, Z.; Wang, H.; Feng, J.; Zhang, L.; Zeng, F. Feasibility study of CO2 huff ‘n’ puff process to enhance heavy oil recovery via long core experiments. Appl. Energy 2019, 236, 526–539. [Google Scholar] [CrossRef]

- Kimbrell, W.C.; Allison, E.C. Improved Recovery from Gulf of Mexico Reservoirs: Comparison of Methane, Nitrogen and Flue Gas for Attic Oil. Final Report; Louisiana State University: Baton Rouge, LA, USA, 1996; Volume IV. [Google Scholar]

- Bai, B.; Hu, Q.; Li, Z.; Lü, G.; Li, X. Evaluating the sealing effectiveness of a caprock-fault system for CO2-EOR storage: A case study of the Shengli oilfield. Geofluids 2017, 2017, 17. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Sun, J. The Control Theory and Application for Well Pattern Optimization of Heterogeneous Sandstone Reservoirs; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 978-3-662-53285-0. [Google Scholar]

- Akkurt, R.; Bowcock, M.; Davies, J.; Del Campo, C.; Hill, B.; Joshi, S.; Kundu, D.; Kumar, S.; O’Keefe, M.; Samir, M.; et al. Focusing on downhole fluid sampling and analysis. Oilf. Rev. 2006, 18, 4–19. [Google Scholar]

- Zuo, J.Y.; Zhang, D.; Dubost, F.X.; Dong, C.; Mullins, O.; O’Keefe, M.; Betancourt, S. Equation-of-State-Based Downhole Fluid Characterization. SPE J. 2011, 16, 115–124. [Google Scholar] [CrossRef]

- Mayerhofer, M.; Oduba, O.; Agarwal, K.; Melcher, H.; Lolon, E.; Bartell, J.; Weijers, L. A Cost/Benefit Review of Completion Choices in the Williston Basin Using a Hybrid Physics-Based-Modeling/Multivariate-Analysis Approach. SPE Prod. Oper. 2018, 34, 024–040. [Google Scholar] [CrossRef]

- Donaldson, E.C.; Chilingarian, G.V.; Yen, T.F. Enhanced Oil Recovery, II: Processes and Operations; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Melrose, J.C. Role of Capillary Forces In Detennining Microscopic Displacement Efficiency For Oil Recovery By Waterflooding. J. Can. Pet. Technol. 1974, 13, 12. [Google Scholar] [CrossRef]

- Zhou, D.; Fayers, F.J.; Orr, F.M. Scaling of multiphase flow in simple heterogeneous porous media. Proc. SPE Symp. Improv. Oil Recover. 1994, 2, 559–569. [Google Scholar] [CrossRef]

| Characteristic Parameters | Value | Characteristic Parameters | Value |

|---|---|---|---|

| Length (cm) | 80 | Number of sampling probes | 30 |

| Diameter (cm) | 10 | Dip angle (°) | 0–90 |

| Cross-sectional area (cm2) | 79 | Withstand pressure (MPa) | 30 |

| Model volume (mL) | 6283 | Withstand temperature (°C) | 150 |

| Fluid | Viscosity (cP) | Density (g/cm3) |

|---|---|---|

| Mineral oil | 10 | 0.8 |

| Water | 1 | 1 |

| Gas | 0.02 | 0.2 |

| NO. | Schematic Diagram of Experiment as Shown in Figure 3 | Injection Stage | Sampling Time during Wells Shut-in (Hours) | Production Stage | ||

|---|---|---|---|---|---|---|

| Gas Injection Rate (mL/min) | Water Injection Rate (mL/min) | Production Rate (mL/min) | Water Injection Rate (mL/min) | |||

| Exp1 | a2-b-c2 | 2 | 0 | 24, 48, 72, 96 | 0.5 | 0 |

| Exp2 | a1-b-c2 | 2 | 0.5 | 0.5 | 0 | |

| Exp3 | a1-b-c1 | 2 | 0.5 | 1 | 0.5 | |

| Exp4 | a1-b-c1 | 2 | 0.8 | 1 | 0.8 | |

| NO. | Sand Volume (cm3) | Permeability (mD) | Porosity (%) | Oil Reverses (mL) |

|---|---|---|---|---|

| Exp1 | 6205.30 | 1308.26 | 37.24 | 2025.62 |

| Exp2 | 6251.50 | 1272.73 | 36.73 | 1992.37 |

| Exp3 | 6242.10 | 1293.41 | 37.08 | 2013.46 |

| Exp4 | 6271.60 | 1246.55 | 36.61 | 1980.51 |

| NO. | Cumulative Water Injection (PV) | Oil Recovery Factor of Water Flooding (%) | Model Pressure after Water Flooding (MPa) | Remaining Reserves after Water Flooding (mL) |

|---|---|---|---|---|

| Exp1 | 0.58 | 46.73 | 10.10 | 1079.05 |

| Exp2 | 0.57 | 45.92 | 10.08 | 1077.47 |

| Exp3 | 0.58 | 46.11 | 10.03 | 1085.05 |

| Exp4 | 0.56 | 45.37 | 10.20 | 1081.95 |

| NO. | Gas Injection Volume (mL) | Oil Increment Volume (mL) | Water Production Volume (mL) |

|---|---|---|---|

| Exp1 | 65.45 | 32.55 | 5.47 |

| Exp2 | 56.74 | 63.38 | 8.63 |

| Exp3 | 55.82 | 174.34 | 12.15 |

| Exp4 | 49.37 | 256.41 | 44.31 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, K.; Jiang, H.; Li, J.; Zhang, R.; Shen, K.; Zhou, Y. A Novel Assisted Gas–Oil Countercurrent EOR Technique for Attic Oil in Fault-Block Reservoirs. Energies 2020, 13, 402. https://doi.org/10.3390/en13020402

Ma K, Jiang H, Li J, Zhang R, Shen K, Zhou Y. A Novel Assisted Gas–Oil Countercurrent EOR Technique for Attic Oil in Fault-Block Reservoirs. Energies. 2020; 13(2):402. https://doi.org/10.3390/en13020402

Chicago/Turabian StyleMa, Kang, Hanqiao Jiang, Junjian Li, Rongda Zhang, Kangqi Shen, and Yu Zhou. 2020. "A Novel Assisted Gas–Oil Countercurrent EOR Technique for Attic Oil in Fault-Block Reservoirs" Energies 13, no. 2: 402. https://doi.org/10.3390/en13020402

APA StyleMa, K., Jiang, H., Li, J., Zhang, R., Shen, K., & Zhou, Y. (2020). A Novel Assisted Gas–Oil Countercurrent EOR Technique for Attic Oil in Fault-Block Reservoirs. Energies, 13(2), 402. https://doi.org/10.3390/en13020402