MELCOR Analysis of a SPARC Experiment for Spray-PAR Interaction during a Hydrogen Release

Abstract

:1. Introduction

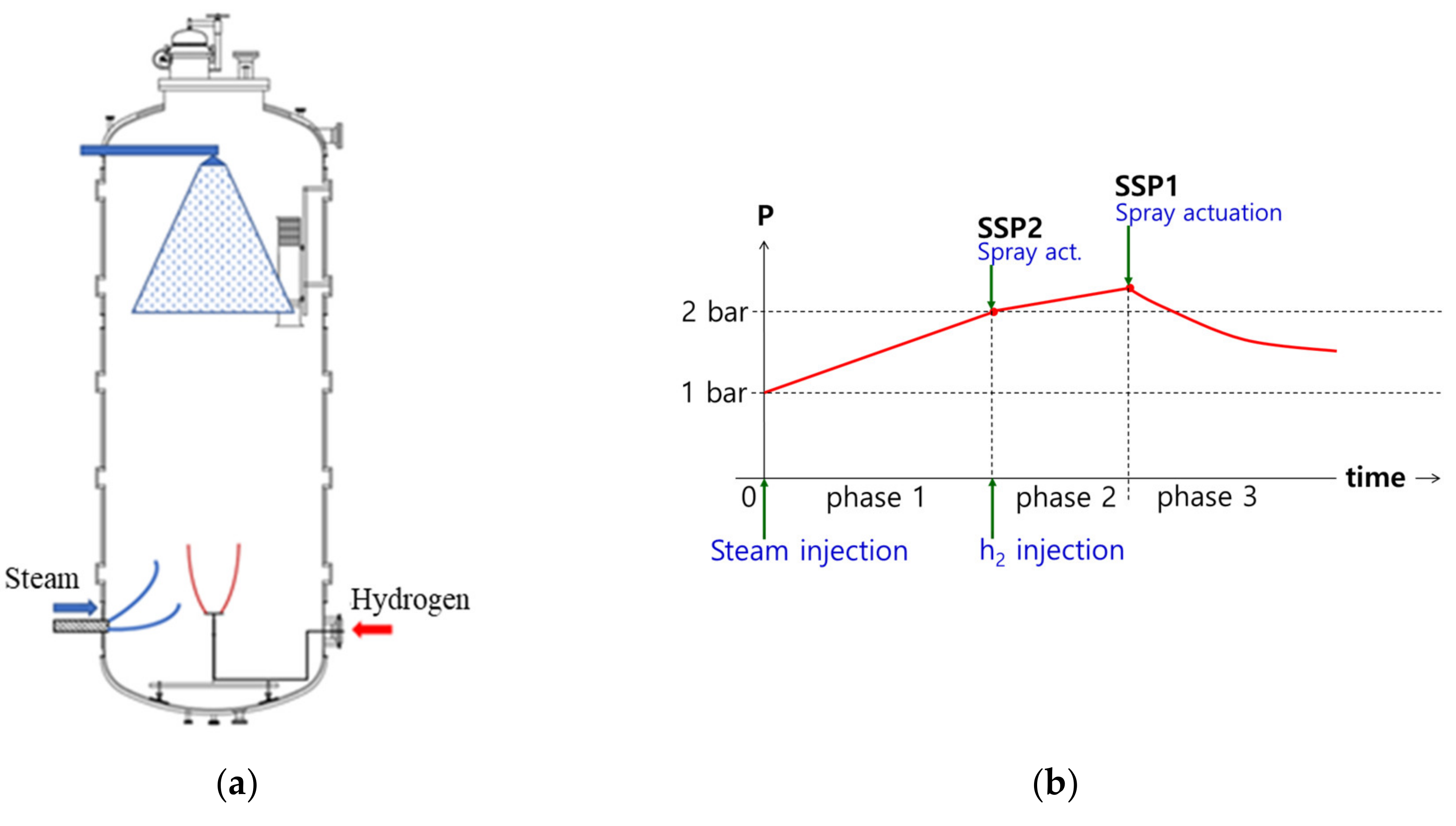

2. Facility and Test Description

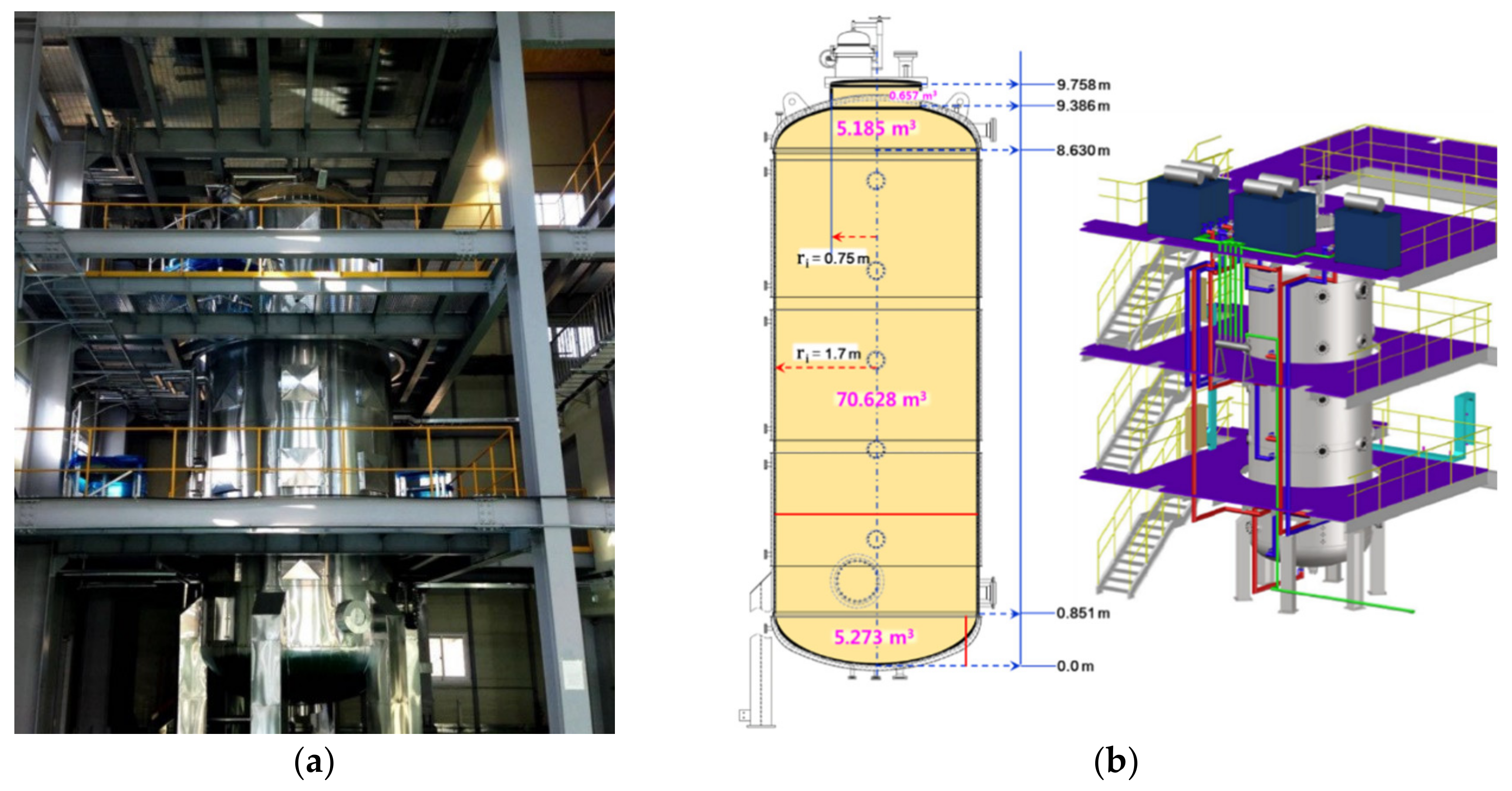

2.1. SPARC Test Facility

2.1.1. Test Vessel

2.1.2. Steam Supply System

2.1.3. Non Condensable Gas Supply System

- Air

- Hydrogen

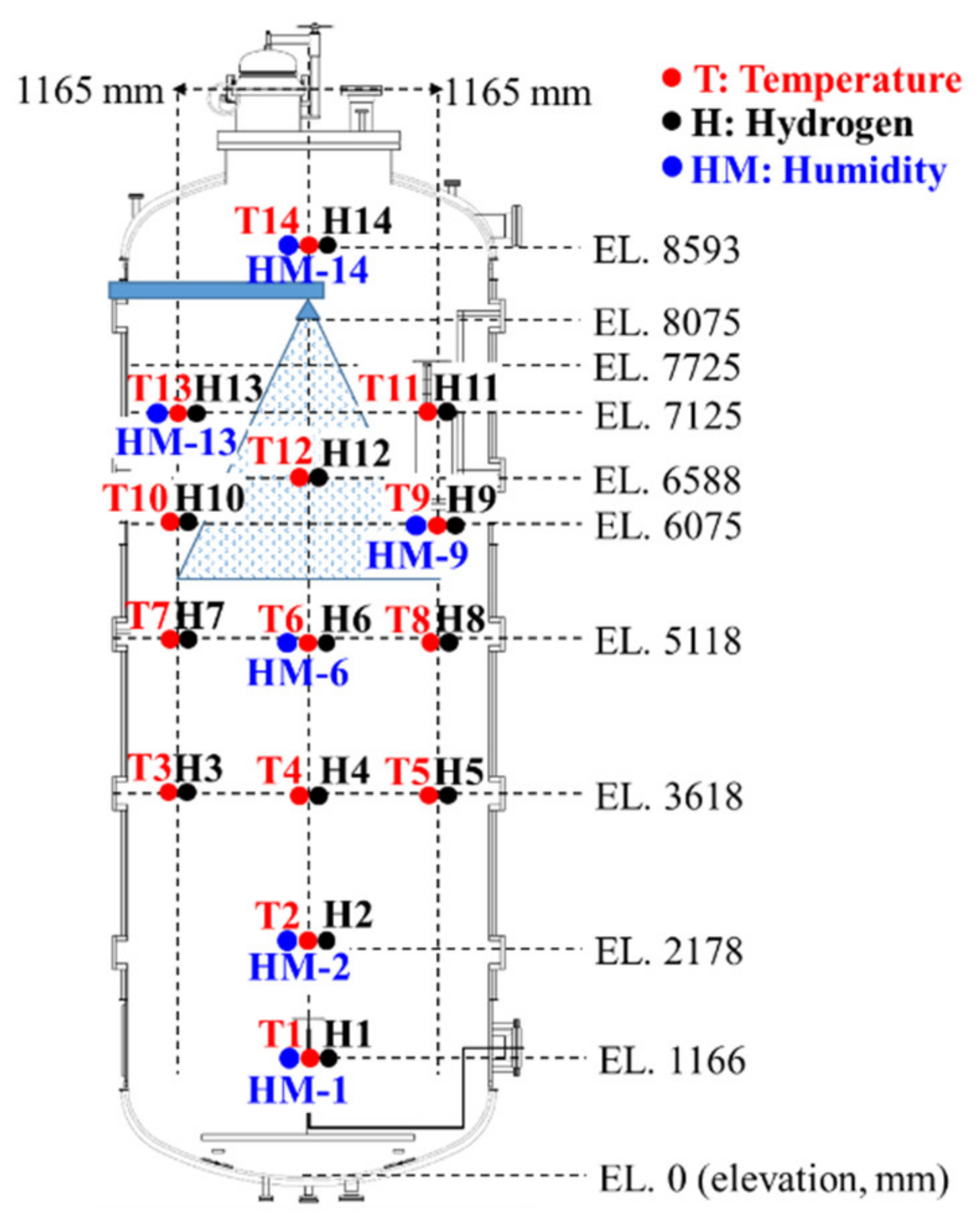

2.2. Measurements

2.2.1. Temperature

2.2.2. Gas Concentration

2.2.3. Humidity

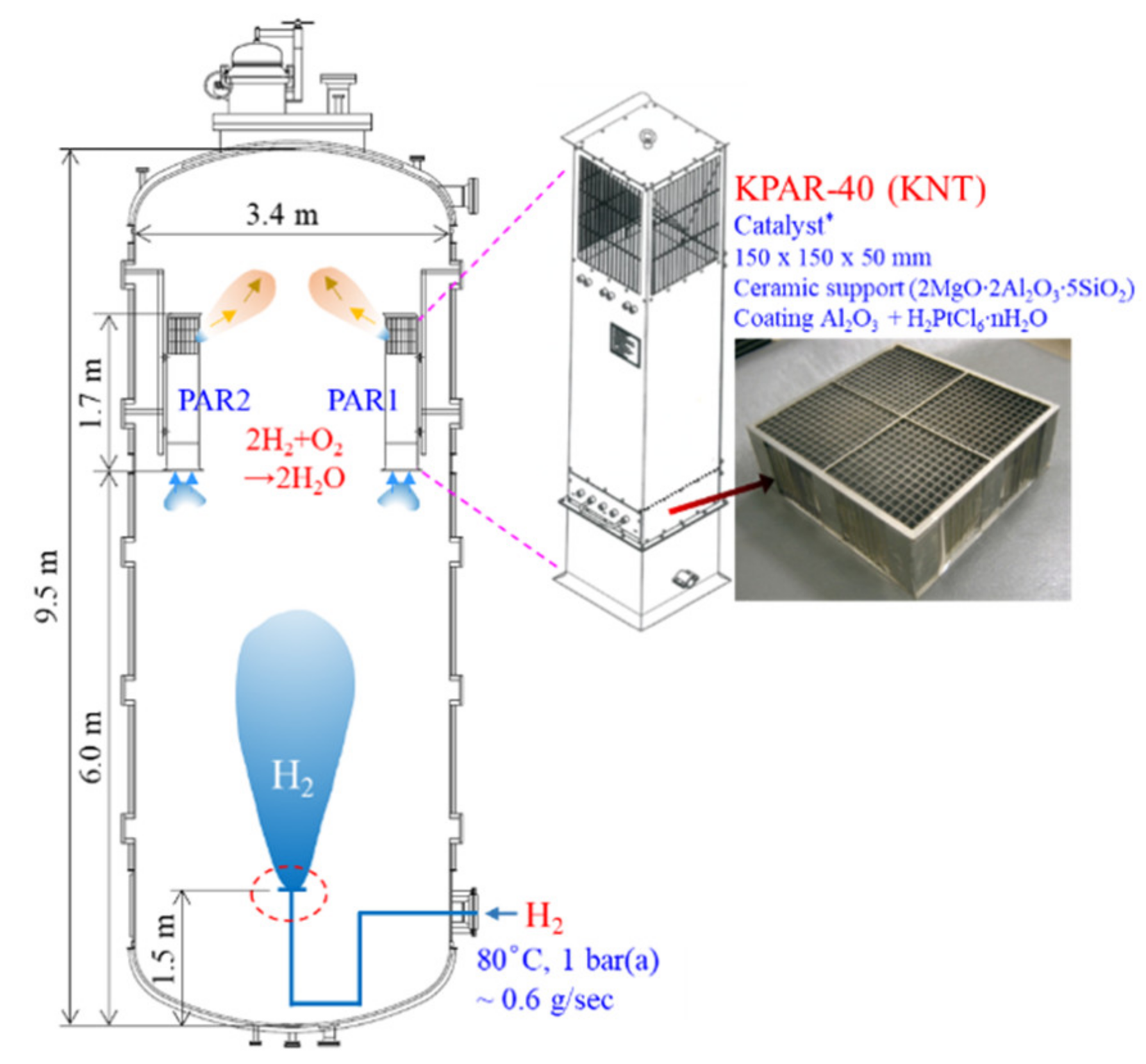

2.3. PAR

2.4. Spray System

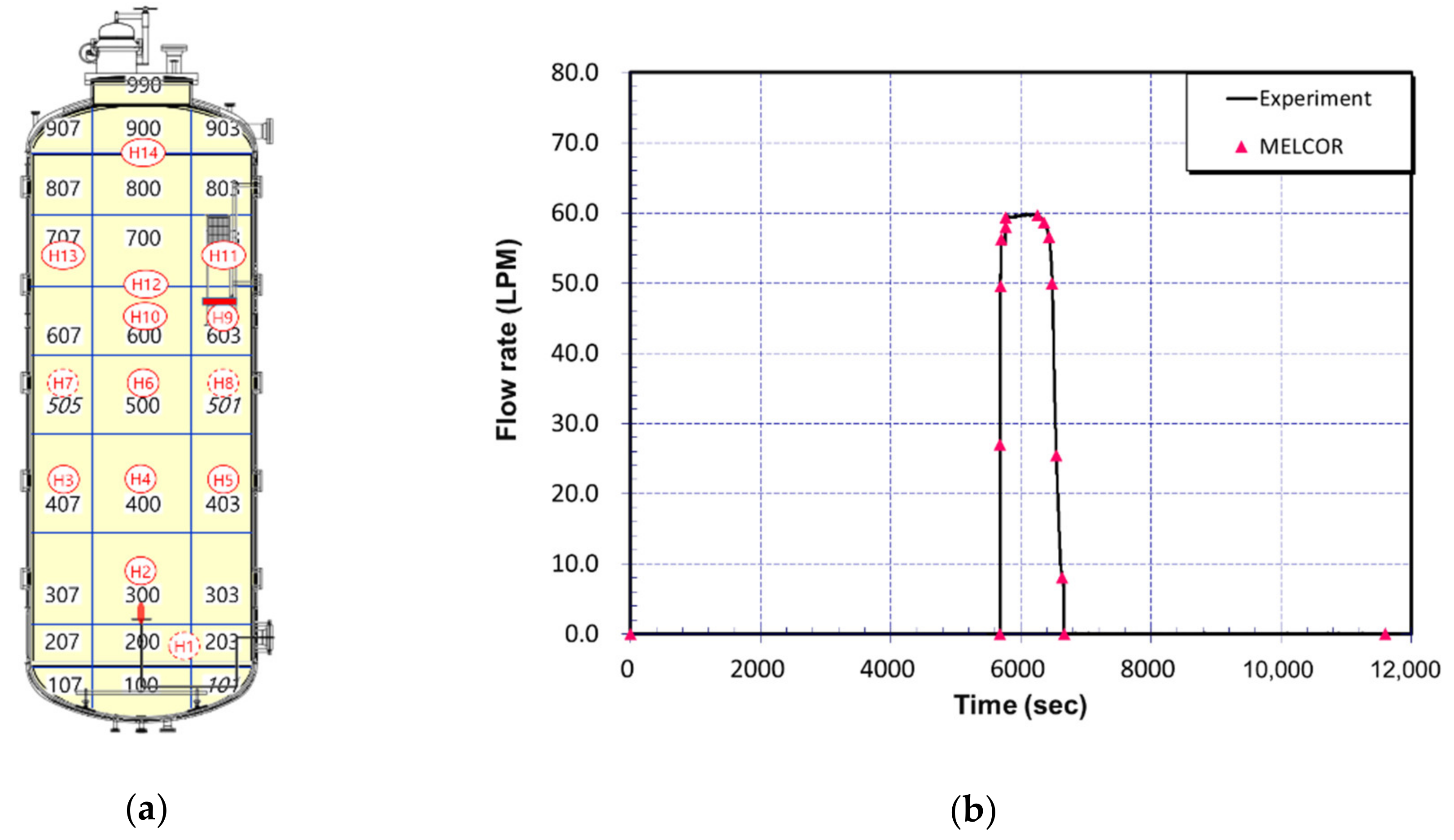

3. MELCOR Input Model

3.1. Preparation of Base Input Model

3.2. Verification Test for Base Input

3.3. Implementation of PAR Correlations

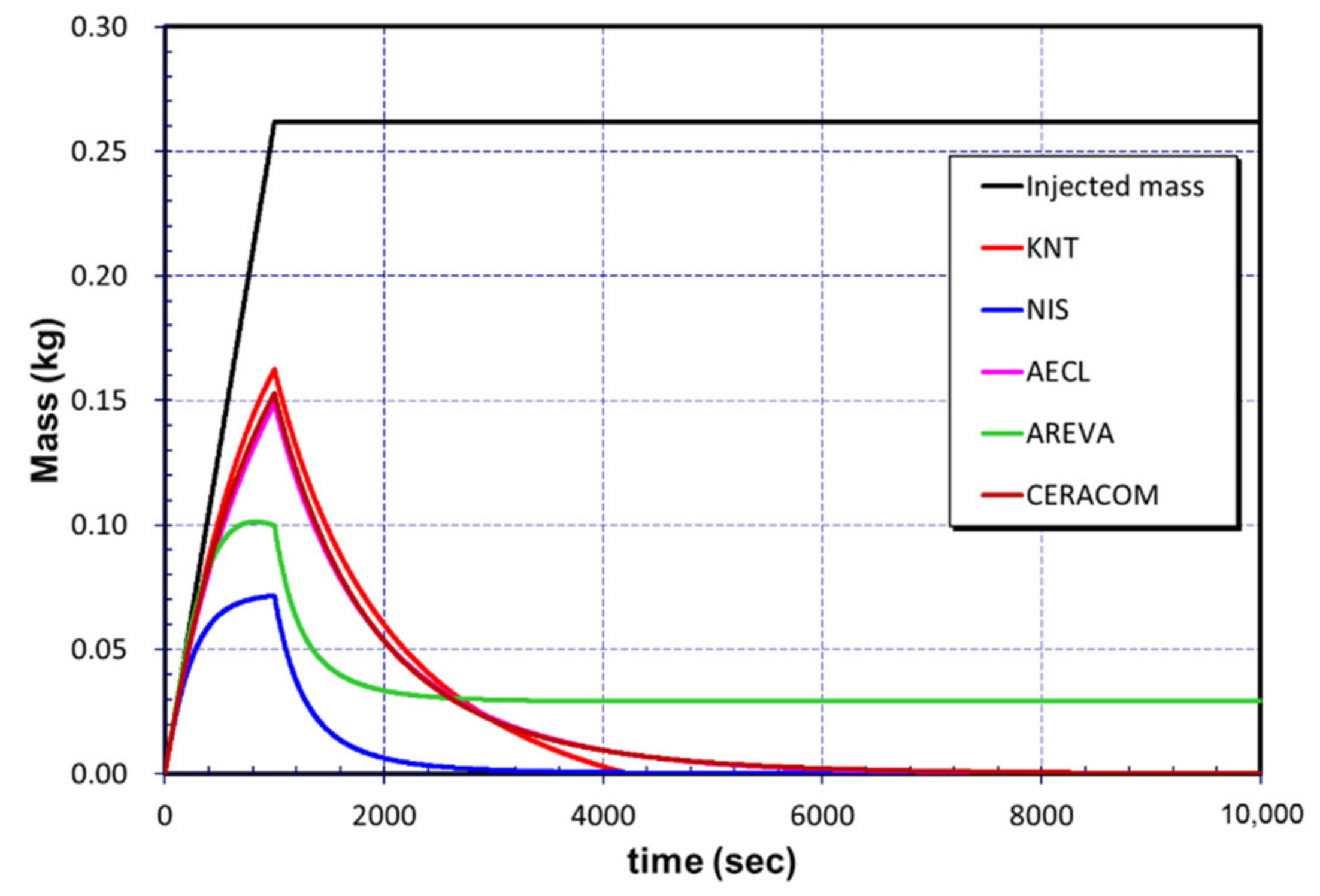

3.3.1. KNT PAR

- n: multification factor for the size of PAR in Table 2

- Values of constant parameters:

- = 2.9193, = 9.0852, = 2.3392

- : hydrogen concentration (vol. %)

- p: pressure (bar)

- T: temperature (K)

3.3.2. CERACOM PAR

- : multification factor for the size of PAR in Table 3

- : hydrogen concentration (vol. %)

- p: pressure (bar)

3.3.3. AECL PAR

- : hydrogen concentration (vol. %)

- p: pressure (bar)

- T: temperature (K)

3.3.4. AREVA PAR

- : hydrogen concentration (–)

- : oxygen concentration (–)

- : min (: max (

- p: pressure (bar)

3.3.5. NIS PAR

- : hydrogen density (kg/m3)

- : hydrogen volume concentration (–)

- p: pressure (kg/m2-s2)

- : universal gas constant = 8314 (J/kmol-K)

3.4. Verification Tests for Implementation of PAR Correlations

4. MELCOR Analysis of a SPARC-SPRAY-PAR Experiment

4.1. SPARC-SPRAY-PAR Experiments

4.2. MELCOR Modeling of SSP1 Test

- m = droplet mass (kg),

- T, Tcv = droplet, control volume atmosphere temperatures (K),

- z = droplet fall height (m),

- , = droplet, atmosphere densities (kg/m3),

- cpl = droplet specific heat capacity (J/kg-K),

- cpv = control volume atmosphere specific heat capacity (J/kg-K),

- hfg = latent heat of vaporization (J/kg),

- D = droplet diameter (m),

- Re = Reynolds number,

- Sc = Schmidt number,

- Le = Lewis number,

- Dc = diffusion coefficient (m2/s),

- Cd = drag coefficient, and

- B = the mass transfer driving force (n)

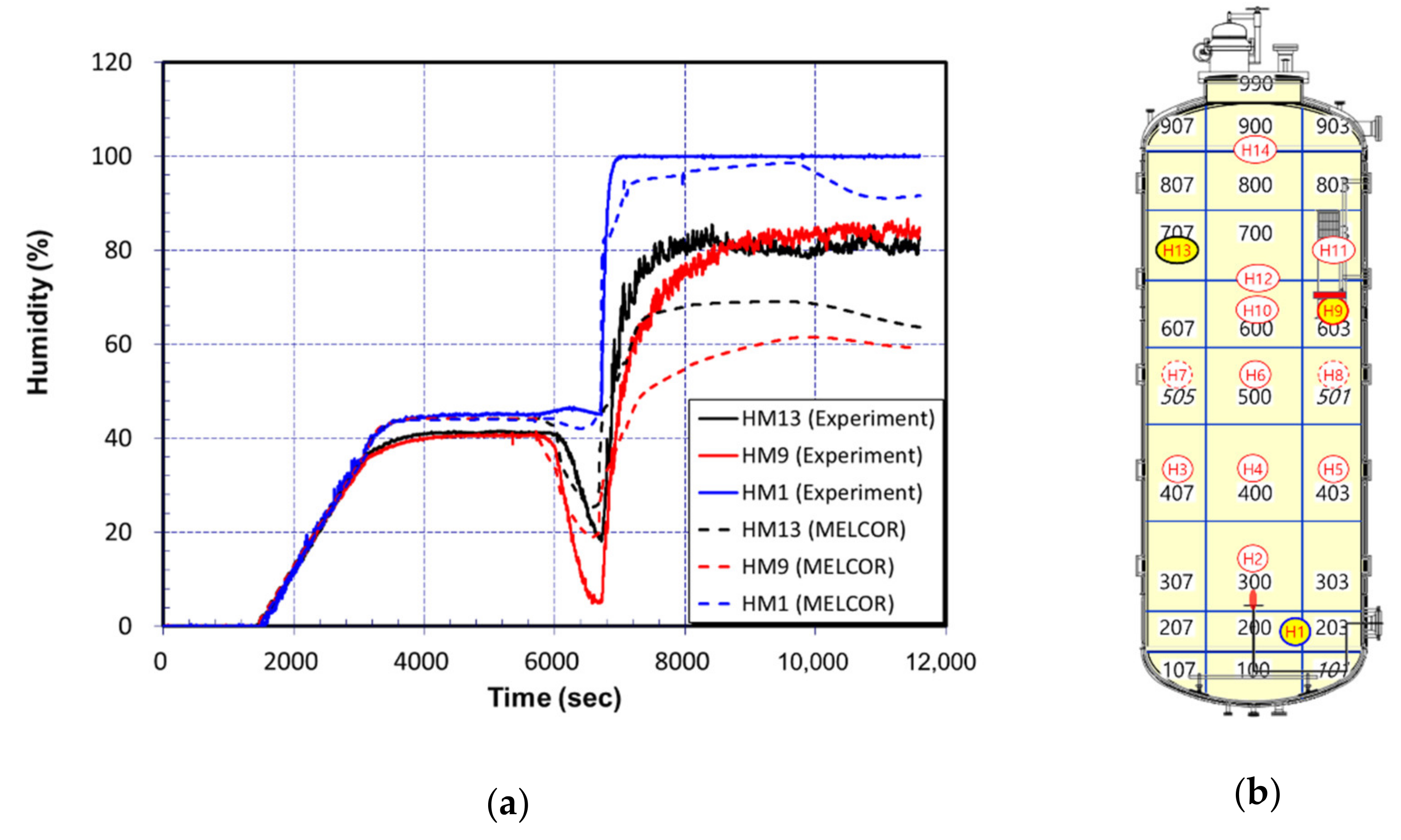

4.3. MELCOR Analysis Results of SSP1 Test

- Linear pressure increase due to constant water vapor injection (1.0 bar → 2.0 bar)

- Variation of pressure increase due to hydrogen injection (with an appropriate heat loss and accurate data fitting for injection flow rate)

- Rapid de-pressurization as soon as spray injection starts, and subsequent re-rising and moderate decrease of pressure.

- Characteristic of rapid increase in inflow velocity following the start of the PAR operation after hydrogen injection.

- Temporal increase of the natural circulation flow due to rapid cooling of upper gas field at the beginning of spray injection.

- Gradual reduction of PAR inlet flow rate due to reduction of hydrogen/PAR reaction and internal temperature differences during the spray injection.

- Increase of gas temperature in the SPARC vessel by injection of steam and recover of temperature (126 °C) during stabilization period.

- Rapid increase of gas temperature inside of the vessel due to PAR operation with hydrogen injection started.

- Rapid temperature decrease immediately after spraying and subsequent behavior of mild temperature decrease.

- Due to the presence of spraying droplet, local humidity measurements are higher than the MELCOR predictions (especially in areas where the liquid droplet falling down).

- As spraying droplet is accumulated at low bottom elevation (CV100) of the SPARC vessel after about 10,000 s, MELCOR code predicts that water vapor partial pressure is decreasing, while the saturation vapor temperature rarely changes. Therefore, humidity calculation values drop, although the humidity measurement (HM1) is still 100%.

- The measurement of high hydrogen concentration due to the presence of strong hydrogen jets at the elevation near the hydrogen injection tube (H2) is under-predicted by the volume-averaged values of MELCOR prediction as shown in Figure 14a.

- From the test results the hydrogen concentration measurement (H1) at the bottom of the SPARC container (CV 200 area) begins to increase later than other areas because hydrogen fills the upper space first at the time of hydrogen injection. It is approximately after 7400 s that all hydrogen concentrations are uniformly distributed throughout the internal region of the vessel. However, the lumped approach by MELCOR cannot resolve the local distributions in detail.

- The distribution of maximum hydrogen concentration values at each measurement position is not accurately predicted, as shown in Figure 14b,c.

5. Conclusions

- The linearly increasing rate of pressure by compressing the vessel with steam injection.

- Variation of pressure increase due to hydrogen injection and a PAR actuation.

- Rapid de-pressurization as soon as spray injection starts, and subsequent re-rising and moderate decrease of pressure.

- The locally high steam jet cannot be captured by the volume-average calculation of MELCOR.

- Resolution of the hydrogen concentration along different elevations.

- Early prediction of uniform gas mixing.

Author Contributions

Funding

Conflicts of Interest

References

- IAEA. Mitigation of Hydrogen Hazards in Severe Accidents in Nuclear Power Plants; IAEA-TECDOC-1661; International Atomic Energy Agency: Vienna, Austria, 2011. [Google Scholar]

- Hong, S.-W.; Kim, H.T.; Kim, J. PAR Experiments in the World and KAERI PAR Experiment; KAERI/TR-7478/2018; KAERI: Daejeon, Korea, 2018. [Google Scholar]

- Bentaib, A.; Meynet, N.; Bleyer, A. Overview on Hydrogen Risk Research and Development Activities: Methodology and Open Issues. Nucl. Eng. Technol. 2015, 47, 26–32. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Hong, S.-H.; Park, K.-H.; Kim, J.-H.; Oh, J.-Y.; Kim, H.T.; Kim, S.B.; Hong, S.-W.; Na, Y.S. Experimental Study of Hydrogen Behaviors Affected by Pressure Control Systems in a Reactor Containment; KAERI/TR-7991/2019; KAERI: Daejeon, Korea, 2019. [Google Scholar]

- Kim, J.; Kim, H.T. Research on a Hydrogen Stratification Induced by PARs Installed in a Containment. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Yeosu, Korea, 24–26 October 2018. [Google Scholar]

- Gauntt, R.O.; Cash, J.E.; Cole, R.K.; Erickson, C.M.; Humphries, L.L.; Rodríguez, S.B.; Young, M.F. MELCOR Computer Code Manuals, Version 1.8.6, Vol. 1: Primer and Users’ Guide; NUREG/CR-6119, Volume 1, Rev. 3, SAND 2005-5713; Sandia National Laboratories: Albuquerque, NM, USA, 2005. [Google Scholar]

- Humphries, L.L.; Beeny, B.A.; Gelbard, F.; Louie, D.L.; Phillips, J. MELCOR Computer Code Manuals, Vol. 2: Reference Manual, Version 2.2.9541; SAND 2018-13560; Sandia National Laboratories: Albuquerque, NM, USA, 2018. [Google Scholar]

- Kim, H.T.; Kim, J. Development of a MELCOR Input for Hydrogen Experiments in the SPARC Test Facility. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Yeosu, Korea, 24–26 October 2018. [Google Scholar]

- Fischer, K. Qualification of Passive Catalytic Module for Hydrogen Mitigation. Nucl. Technol. 1995, 112, 58–62. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.T.; Hong, S.; Park, K.-H.; Kim, J.-H.; Oh, J.-Y. Experimental Study of Hydrogen Behaviors Affected by Pressure Control Systems in a Reactor Containment. In Proceedings of the Transactions of the Korean Nuclear Society Virtual Spring Meeting, Daejeon, Korea, 9–10 July 2020. [Google Scholar]

- SOAR on Containment Thermalhydraulics and Hydrogen Distribution. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:41041086 (accessed on 7 September 2020).

- OECD/NEA Experts. OECD/SETH-2 Project PANDA and MISTRA Experiments Final Summary Report; NEA-CSNI-R-2012-5; OECD/NEA: Paris, France, 2012. [Google Scholar]

- Paranjape, S.; Mignot, G.; Paladino, D. Effect of thermal stratification on full-cone spray performance in reactor containment for a scaled scenario. In Proceedings of the 22nd International Conference on Nuclear Engineering (ICONE22), Prague, Czech Republic, 7–11 July 2014. [Google Scholar]

- Paranjape, S.; Kapulla, R.; Mignot, G.; Paladino, D.; Zboray, R. Light water reactor hollow cone containment spray performance tests in the presence of light non-condensible gas. In Proceedings of the 15th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics (NURETH-15), Pisa, Italy, 12–17 May 2013. [Google Scholar]

- Gupta, S.; Langer, G.; Freitag, M.; Colombet, M.; Schmidt, E.; Laufenberg, B. Hydrogen Combustion during Spray Operation: Tests HD-30 to HD-35; Technical Report of OECD/NEA THAI-2 Project; 1501420-TR-HD-30–35; Becker Technologies GmbH: Eschborn, Germany, 2014. [Google Scholar]

- Kim, J.; Lee, U.; Hong, S.-W.; Kim, S.-B.; Kim, H.-D. Spray effect on the behavior of hydrogen during severe accidents by a loss-of-coolant in the APR1400 containment. Int. Commun. Heat Mass Transf. 2006, 33, 1207–1216. [Google Scholar] [CrossRef]

- Mimouni, S.; Lamy, J.-S.; Lavieville, J.; Guieu, S.; Martin, M. Modelling of sprays in containment applications with a CMFD code. Nucl. Eng. Des. 2010, 240, 2260–2270. [Google Scholar] [CrossRef] [Green Version]

- Malet, J.; Blumenfeld, L.; Arndt, S.; Babic, M.; Bentaib, A.; Dabbene, F.; Kostka, P.; Mimouni, S.; Movahed, M.; Paci, S.; et al. Sprays in containment: Final results of the SARNET spray benchmark. Nucl. Eng. Des. 2011, 241, 2162–2171. [Google Scholar] [CrossRef]

- KNT. PAR. Available online: http://gbs.gobizkorea.com/catalog/product_view.jsp?blogId=kntcom&objId=1102591 (accessed on 7 September 2020).

- Park, J.-W.; Koh, B.-R.; Suh, K.Y. Demonstrative testing of honeycomb passive autocatalytic recombiner for nuclear power plant. Nucl. Eng. Des. 2011, 241, 4280–4288. [Google Scholar] [CrossRef]

- Kim, I.; Kim, D.-S. APR1400: Evolutionary Korean Next Generation Reactor. In Proceedings of the 10th International Conference on Nuclear Engineering (ICONE-10), Arlington, TX, USA, 14–18 April 2002. [Google Scholar]

- Kim, C.H.; Sung, J.J.; Ha, S.J.; Seo, P.W. Operational Experience of Ceramic Honeycomb Passive Autocatalytic Recombiner as a Hydrogen Mitigation System. In Proceedings of the 16th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics (NURETH-16), Chicago, IL, USA, 30 August–4 September 2015. [Google Scholar]

- Kelm, S.; Jahn, W.; Rinecke, E. Operational Behaviour of Catalytic Recombiners—Experimental Results and Modelling Approaches. In Proceedings of the workshop on Experiments and CFD Code Application to Nuclear Reactor Safety (XCFD4NRS), Grenoble, France, 10–12 September 2008. [Google Scholar]

- Bachellerie, E.; Arnould, F.; Auglaire, M.; Boeck, B.; Braillard, O.; Eckardt, B.; Ferroni, F.; Moffett, R. Generic Approach for Designing and Implementing a Passive Autocatalytic Recombiner PAR-System in nuclear power plant containments. Nucl. Eng. Des. 2003, 221, 151–165. [Google Scholar] [CrossRef]

- AREVA Passive Autocatalytic Recombiner. Available online: http://us.areva.com/home/liblocal/docs/Solutions/liteature/G-008-V1PB-2011-ENG_PAR_reader.pdf (accessed on 7 September 2020).

- Dewit, W.A.; Koroll, G.W.; Sitar, L.; Graham, W.R.C. Hydrogen Recombiner Development at AECL; AECL-1172 NEA/CSNI(96)8; AECL: Chalk River, ON, Canada, 1996. [Google Scholar]

- Jeon, J.; Choi, W.; Kim, N.K.; Jeun, G.; Kim, S.J. MELCOR Simulation of Containment Spray for Potential Regulation of 100TBq Cesium-137 Release from OPR1000. In Proceedings of the Transactions of the Korean Nuclear Society Spring Meeting, Jeju, Korea, 12–13 May 2016. [Google Scholar]

| Design Parameter | Value, Specification |

|---|---|

| Pressure | 15 bar (at 180 °C) |

| Height | 9.76 m |

| Diameter | 3.4 m |

| Free volume | 82 m3 |

| Wall heating | Oil heating (partly electrical heating) |

| No. of measurements | 14 (H2), 4 (O2), 4 (H2O), 112 (wall temperature) |

| KNT Model | n Value |

|---|---|

| KPAR-40 | 1 |

| KPAR-80 | 2 |

| KPAR-160 | 4 |

| CERACOM Model | k Value |

|---|---|

| NP400 (small) | 0.05 |

| NP800 (medium) | 0.106 |

| NP1600 (large) | 0.255 |

| AREVA Model | A | B |

|---|---|---|

| FR1-380T | 3.1 | 3.7 |

| FR1-750T | 6.1 | 7.4 |

| FR1-1500T | 13.7 | 16.7 |

| Time (s) | Test Procedures | Test Conditions/MECOR Input |

|---|---|---|

| 1420 | Steam injection starts | pressure: 1.0 bar temperature: 126 °C mass flow: 0.0264 kg/s |

| 3130 | End of steam injection | |

| - | Steady conditions | |

| 5675 | H2 injection starts | temperature: 27 °C flow: ~60 LPM |

| 6680 | End of H2 injection | |

| 6709 | Spray starts | temperature: 52.7 °C flow: 0.197 × 10−3 m3/s |

| 11,609 | End of spray actuation |

| Parameter | Value |

|---|---|

| Thickness (mm) | 25 |

| Cp (heat capacity of wall, J/Kg/K) | 510 |

| (wall density, J/kg/K) | 7970 |

| k (conductivity, W/m/K) | 15 |

| Heat transfer rate on the inner surface (W/m2/K) | 1. Steam injection: 8.0 2. H2 injection: 100.0 3. Steady state: 20.0 4. Spray actuation: 100.0 |

| Outer wall temperature (K) | 399.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.T.; Kim, J. MELCOR Analysis of a SPARC Experiment for Spray-PAR Interaction during a Hydrogen Release. Energies 2020, 13, 5696. https://doi.org/10.3390/en13215696

Kim HT, Kim J. MELCOR Analysis of a SPARC Experiment for Spray-PAR Interaction during a Hydrogen Release. Energies. 2020; 13(21):5696. https://doi.org/10.3390/en13215696

Chicago/Turabian StyleKim, Hyoung Tae, and Jongtae Kim. 2020. "MELCOR Analysis of a SPARC Experiment for Spray-PAR Interaction during a Hydrogen Release" Energies 13, no. 21: 5696. https://doi.org/10.3390/en13215696

APA StyleKim, H. T., & Kim, J. (2020). MELCOR Analysis of a SPARC Experiment for Spray-PAR Interaction during a Hydrogen Release. Energies, 13(21), 5696. https://doi.org/10.3390/en13215696