3.1. Comparison of the CFD Analysis Results between the Pump Model without Balancing Holes and Type A and B Pump Models

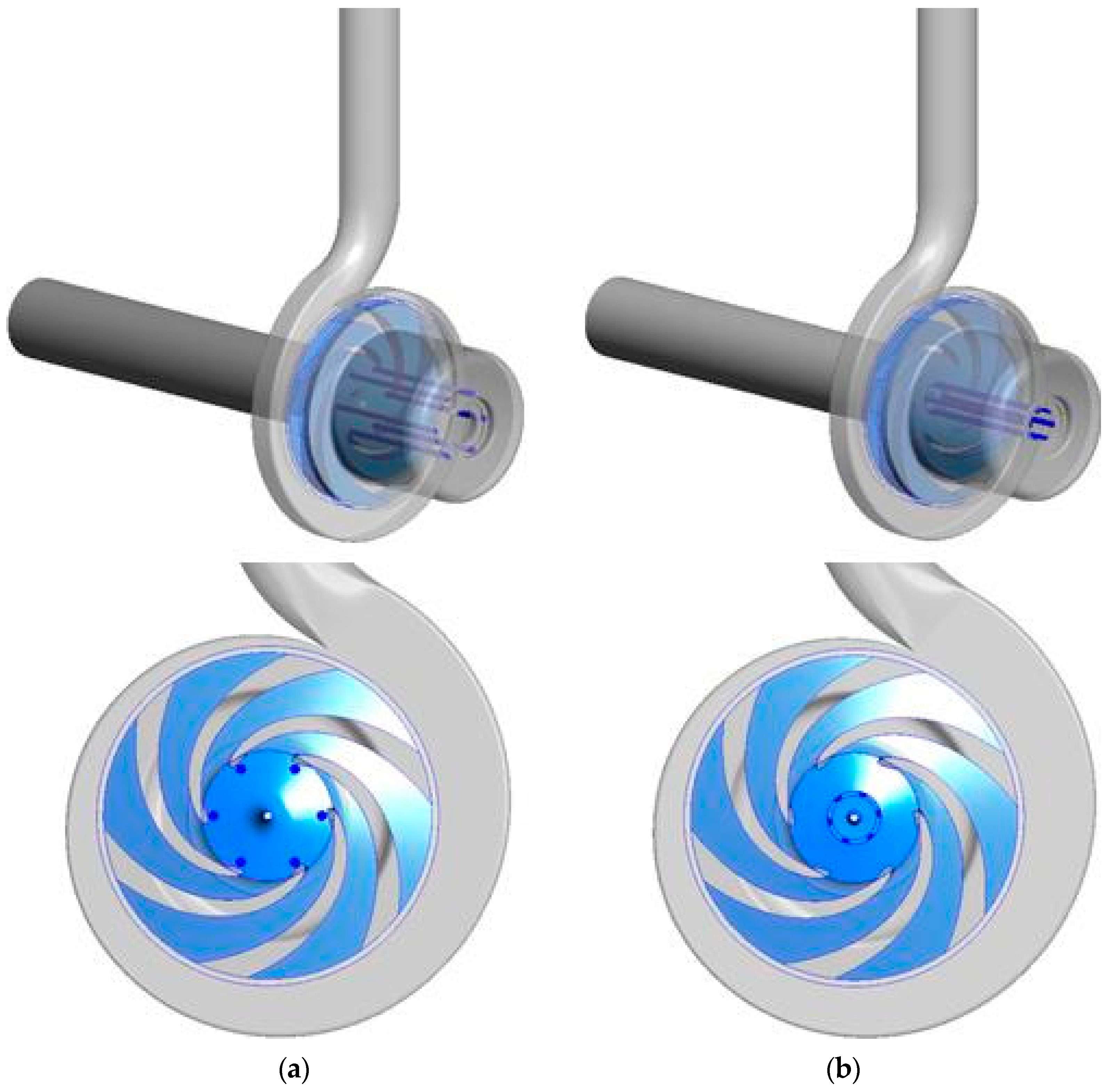

Figure 6 shows the comparison of the CFD analysis results between the pump model without balancing holes and Type A and B pump models with balancing holes. The Type A pump model was set with six balancing holes, 4 mm hole diameter, and hole position near the suction surface of the impeller blade, by referring to the general specifications of the centrifugal pump (see

Figure 2a and

Figure 3a). The Type B pump model was also set with six balancing holes and 4 mm hole diameter, and the hole position was set to the outer surface of the fixed shaft located at the same angle as the Type A pump model based on the impeller’s rotation axis (see

Figure 2b and

Figure 3b).

Figure 6a shows that the efficiency of the pump model without balancing holes is 71.6%. The efficiency of the Type A pump model is 46.9%, lower by approximately 25% than that of the pump model without balancing holes. However, the efficiency of the Type B pump model is 70.2%, only 1% lower than that of the pump model without balancing holes. Thus, in terms of efficiency, Type B balancing holes are much more advantageous than Type A balancing holes.

Figure 6b shows that the pump model without balancing holes has a head of 50.5 m, and the head of the Type A pump model is 41.1 m, lower by approximately 9 m than that of the pump model without balancing holes. However, the head of the Type B pump model is 50.4 m, which is not much different from that of the pump model without balancing holes. Therefore, Type B balancing holes are much more advantageous than Type A balancing holes in terms of the head size.

Figure 6c shows the calculation results of the axial thrust. First, the pump model without balancing holes has an axial thrust of approximately 1734.7 N. The pump with Type B balancing holes has an axial thrust of 1124.2 N, lower by 35% than the pump without balancing holes due to the balancing holes. However, the axial thrust of the pump with Type A balancing holes is −11071.0 N. This finding indicates that due to the balancing holes, an axial thrust of 1070.95 N acts in the opposite direction to that of the pump model without balancing holes. These results suggest that in the case of Type A balancing holes, an axial thrust acts in the opposite direction of the pump model without balancing holes due to the excessive reduction of the axial thrust, but in the case of Type B balancing holes, the axial thrust is lower by only a small amount.

Figure 7 and

Figure 8 show the velocity contour and vector on the X–Y and X–Z planes of the pump model without balancing holes and pump models with Type A and B balancing holes, respectively. First, in

Figure 7 and

Figure 8a, for the pump model without balancing holes, some of the high-pressure water that passed through the blades is recycled to the low-pressure inlet through the front flow path (see

Figure 1), but most water exits through the outlet via the volute. Furthermore, in the gap of the rear flow path (see

Figure 1), water from the high-pressure volute is supplied and remains (not recycled) and only the wall inside the rear flow path rotates.

Furthermore, for the pump models with balancing holes in

Figure 7 and

Figure 8b,c, the low-pressure water that entered through the impeller inlet must exit through the outlet via the volute as high-pressure water after receiving energy through the blades, but some of the high-pressure water passed through the blades flow through the front and rear flow paths instead of the volute, resulting in leakage. In particular, unlike the model without balancing holes in

Figure 7 and

Figure 8a, for the models in

Figure 7 and

Figure 8b,c, as the high-pressure volute and low-pressure inlet of the impeller are interconnected through the rear flow path, a recycling flow path of water is formed inside the impeller. This condition causes rapid changes in the pressure distribution around the impeller and the speed distribution at the impeller inlet that is hit by water. Particularly, in

Figure 7 and

Figure 8b, for the model with balancing holes installed in the rotating impeller, the flow through the rear flow path rapidly increases and flow energy loss occurs due to the effect of increasing flow velocity and the vortex flow caused by the complicated flow path shape. Consequently, the pressure of water in the back of the impeller sharply decreases compared to those shown in

Figure 7 and

Figure 8a,c. The same result is shown in

Figure 6.

Figure 9 and

Figure 10 show the comparison of the distribution of entropy production on the X–Y and X–Z planes of the pump model without balancing holes and pump models with Types A and B balancing holes. Entropy production means the loss of viscous and turbulence dissipation by flow, and the flow loss distribution can be easily predicted by the distribution of entropy production [

15,

16].

The distribution of entropy production in

Figure 9 shows that, first, at the impeller inlet, the entropy production has a large value due to the surface shear force by the rotation of the blade leading edge. At the impeller outlet, the closer to the outlet, the faster the flow velocity becomes due to the rotation of the impeller, and the larger the loss due to flow instability resulting from the increasing flow path area. In particular,

Figure 9b,c for models with balancing holes show that the entropy production is large in the flow path area where recycling occurs due to the holes.

The distribution of entropy production on the X–Z plane in

Figure 10 shows more clearly that the entropy production is large in the area where recycling increases due to the holes. In particular, for the model with balancing holes installed in the rotating impeller,

Figure 9b shows an increase in the entropy production (loss of flow energy) due to the vortex flow near the back of the impeller constituting the rear flow path. It can be inferred that the result in

Figure 6 was caused by this condition.

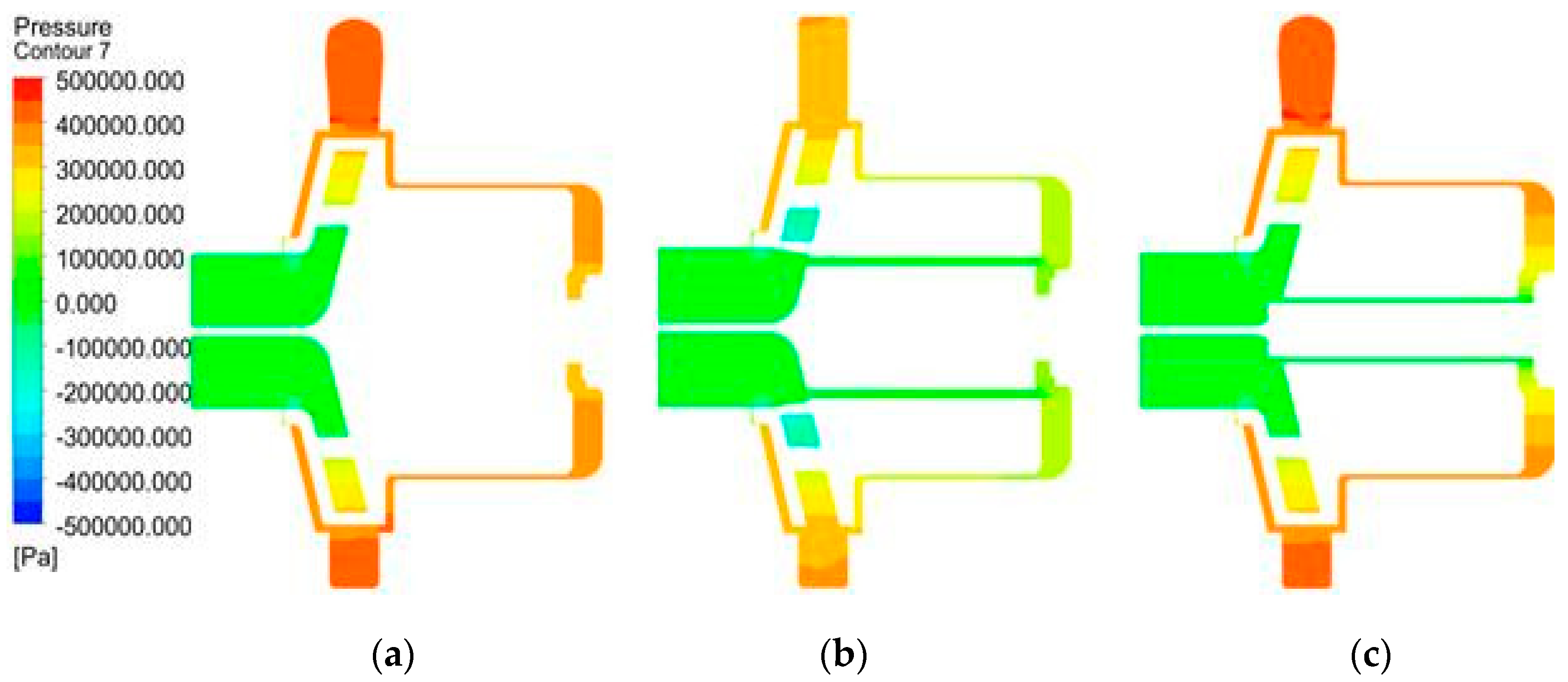

Figure 11 and

Figure 12 show the pressure contours on the X–Y and X–Z planes of the pump model without balancing holes and the pump models with Type A and B balancing holes.

The pressure contour in

Figure 11 shows that the pressure gradually increases as the low-pressure water, which was supplied from every pump through atmospheric pressure, and moves toward the outlet by receiving energy from the rotating impeller. For the pump model with balancing holes installed in the impeller,

Figure 11b shows that the pressure at the outlet is the lowest compared to those shown in

Figure 11a,c (see

Figure 6b). The reason for this is that, as shown in the above figures, the largest flow loss occurs in the flow path where the water is recycled after passing through the rear flow path and the balancing holes, as shown in

Figure 11b.

Figure 12 clearly shows the distribution of pressures in the recycling flow path created by the front flow path, balancing holes, and rear flow path. In the front flow path interconnecting the high-pressure volute and impeller inlet, a high-pressure flow is generated regardless of the balancing holes. However, the pressure distribution in the rear flow path is influenced by the existence or absence of balancing holes and the position of the shape. In

Figure 12a, there is no recycling flow through the rear flow path because there are no balancing holes, but a high pressure occurs in the large space behind the rear flow path because it is connected to the volute through which high-pressure water flows. As a result, the pump without balancing holes receives a large axial thrust toward the front of the impeller during operation. However, in

Figure 12b, for the pump model with balancing holes installed in the rotating impeller, there is a pressure reduction effect due to the increase in flow velocity as the flow through the rear flow path rapidly increases. Furthermore, the pressure of water at the rear of the impeller is rapidly reduced due to the loss of flow energy from the vortex flow, which is caused by the complicated flow path shape. Consequently, as shown in

Figure 6c, a large axial thrust occurs toward the back of the impeller opposite to the direction in

Figure 12a,c.

The above results show that the axial thrust in the pump impeller during operation can be removed with minimal efficiency reduction and head loss if the balancing holes of appropriate sizes are installed at proper positions in the impeller.

3.2. Pump Performance and Axial Thrust with Different Positions of Balancing Holes

Figure 13 shows the calculation results of the axial thrust and performance according to the diameter of balancing holes and the cooling water flow rate through the balancing hole flow path for Type A and B pump models.

The left graph in

Figure 13a, comparing the axial thrust of each model when there are no balancing holes in the pump with Type A balancing holes, shows that an axial thrust of 1734.7 N is generated, but when there are balancing holes of 2 mm diameter, the axial thrust decreases to 395 N. Then, the axial thrust rapidly decreases with an increasing diameter, and the axial thrust becomes zero when the diameter is 2.9 mm (flow rate 0.4 kg/s). When the diameter increases to 7 mm, the axial thrust decreases further, showing a reverse axial thrust of −1868 N before gradually becoming constant. The right graph in

Figure 13a shows the calculation results with the flow rate through the balancing holes instead of the diameter of the balancing holes. While the diameter of balancing holes changes from 2 to 12 mm, the flow rate through the balancing holes increases from 0.146 to 3.819 kg/s in proportion to the diameter of the balancing holes. This finding indicates that the axial thrust rapidly decreases due to the pressure relief at the back of the pump, according to the increase in the flow rate.

By contrast, when the diameter of the balancing holes was 2 mm, the pump with Type B balancing holes generated a forward axial thrust of 1238 N, which is larger than that of the pump with Type A balancing holes. Furthermore, as the diameter increased to 8.3 mm, the change in flow rate through the balancing holes was very small. Then, the flow rate sharply increased for a very small diameter change of 0.2 mm, which also rapidly decreased the axial thrust, showing a discontinuous trend of the flow rate. Due to the pump with Type B balancing holes, the flowing fluid does not receive the kinetic energy by motor rotation, unlike the pump with Type A balancing holes because the balancing holes are located on the outer wall of the inner shaft. As a result, a transient flow phenomenon occurs in the discontinuous section where the fluid flowing through the balancing hole flow path located on the fixed axis moves to the rotating impeller.

Figure 14a shows the changes of the total pressure distribution at section A-A including the kinetic energy of the fluid according to the changes in the diameter of balancing holes for the pump with Type B balancing holes.

Figure 14b shows the static pressure distribution at section A-A. In this figure, when the diameter of balancing holes is 8.3 mm or less, the flow rate is low because the energy is insufficient for the fluid to move to the front of the impeller by overcoming the resistance of the flow path only by the pressure of the fluid at the back of the impeller. Consequently, there is no significant change in the total pressure of the fluid flowing to the rotating impeller from the fixed balancing hole. However, when the hole diameter becomes larger than 8.5 mm, the high-pressure fluid at the back of the impeller can sufficiently overcome the resistance of the fixed flow path. Thus, the flow rate suddenly increases, and the total pressure inside the balancing holes increases. This phenomenon can be seen more clearly in

Figure 14c. As shown in this figure, when the diameter of balancing holes is 8.3 mm or less, the fluid flowing through the fixed balancing hole flow path has insufficient energy to break through the main flow around the rotating impeller, but when it becomes larger than 8.5 mm, the fluid breaks through the main flow around the rotating impeller. Furthermore, as the flow path gradually expands, the surrounding pressure distribution becomes stabilized. Then, the axial thrust also decreases with an increasing diameter of the pump with Type B balancing holes, and the axial thrust becomes zero when the diameter becomes 10.5 mm (flow rate: 4 kg/s), as shown in

Figure 13a.

Figure 13b,c show the calculation results of the changes in efficiency and head according to the diameter of the balancing holes and flow rate through the balancing holes for pumps with Type A and B balancing holes. In the balanced flow rate (Type A: 0.4 kg/s, Type B: 4 kg/s) or balanced hole diameter size (Type A: 2.9 mm, Type B: 10.5 mm), the efficiency of the Type A pump model is 55.1% and that of the Type B pump model is 52%. Thus, the efficiency of Type A is approximately 3.1% higher than that of Type B. Furthermore, the heads of the Type A and B pump models are 45.6 and 44.4 m, respectively. Thus, the head of Type A is higher by approximately 1.2 m. For this reason, Type A is often adopted for the balancing holes of general pumps. However, the magnetic drive centrifugal pump requires a sufficient amount of coolant unlike the general pump to prevent low efficiency (low torque transmission power) of the magnetic drive due to high heat around the magnetic drive during operation. Considering this structural characteristic, Type B balancing holes can be more appropriate for the design of balancing holes for magnetic drive centrifugal pumps, which can achieve a coolant with 10 times higher flow rate even if there is a small loss (efficiency 3.1%, head 1.2 m) in terms of efficiency and head. In particular, Type B balancing holes also have an advantage as the margin of the coolant flow design is relatively large because it has a smaller change in efficiency and head according to the change of the flow rate around the balanced position compared to Type A balancing holes, as shown in

Figure 13.