1. Introduction

The Earth is reported to have lost 28 trillion tons of ice since 1994 [

1]. This finding coincides with a worst-case scenario predicted by the United Nation’s Intergovernmental Panel on Climate Change (IPCC). This massive response to the rise in global temperatures only accentuates the immediate need for action. According to the Air Transport Action Group [

2], the global aviation industry produces around 2% of all human-induced CO

2 emissions, which constitutes approximately 12% of CO

2 emissions within the transport sector. These figures are bound to grow with projected increases in passenger demand for air travel. In approximately 10 years, the global fleet is expected to grow by 42% [

3].

In an attempt to curb greenhouse gas emissions and protect the environment, the Advisory Council for Aviation Research and Innovation in Europe (ACARE), through FlightPath2050 [

4], set up ambitious goals for the aviation industry for the year 2050. Specifically, a 75% reduction in CO

2 emissions per passenger km, 90% reduction in NOx emissions, and a 65% reduction in perceived noise compared to a typical new aircraft in 2000 are targeted. To achieve these goals, improvements at the system level are required, encompassing improvements to the airframe, engine, and operations in a synergistic manner.

Engine development is estimated to be capable of achieving a 20% reduction in fuel burn [

5]. For example, the UltraFan

® engine (Rolls Royce, West Sussex, UK), with an ultra-high bypass ratio design, should achieve a 25% improvement in fuel burn compared to Trent 772B engine, which is a representative year 2000 engine [

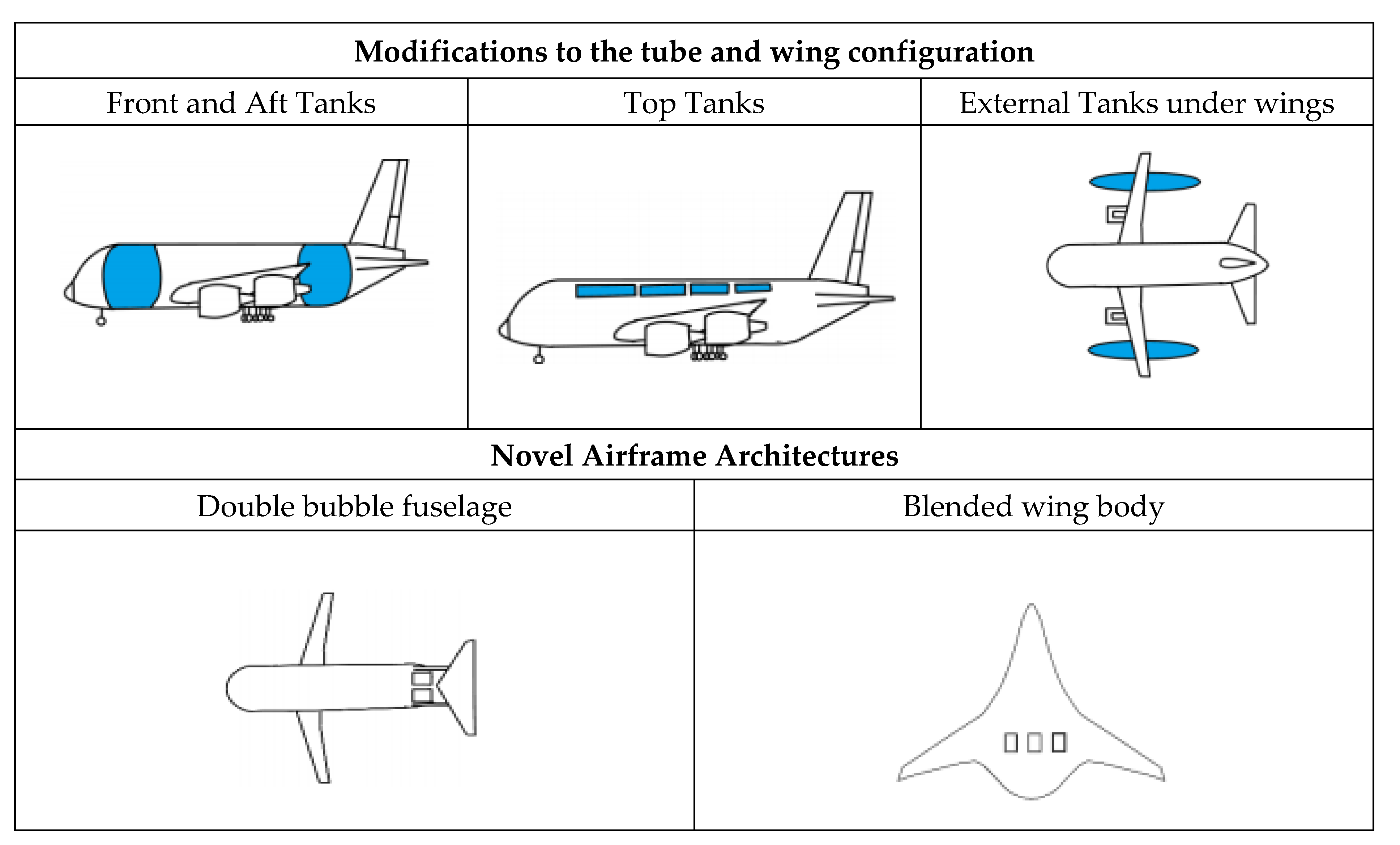

6]. However, the fan diameter is limited by the space available under the wing, installed drag, and weight. In terms of airframe development, a radically new configuration deviating away from the traditional tube-and-wing design is required to achieve a significant reduction in fuel consumption. The blended wing body is one such example developed by NASA, which achieves improved fuel benefits due to the superior lift-to-drag ratio, improved payload capability, and lower noise level. Additionally, superior air traffic management and operations, which could optimize flight trajectories and reduce ground idling times, could further decrease unnecessary fuel burn [

7]. However, these improvements can only cut fuel consumption to a certain extent, and only reduce the amount of CO

2 generated pro rata to the fuel burned. In order to achieve up to a 75% reduction in emission of carbon, alternative fuels may be required, as discussed in [

4].

The choice of an aviation fuel is dictated by various criteria, which are mainly dependent on availability, emissions, price, energy density, and safety. Kerosene has matched all those requirements, but the growing need to reduce greenhouse gas (GHG) emissions makes the continued use of this fossil fuel less viable for aviation.

Various alternatives are available—drop-in replacement fuels from vegetable oils and Syn-Jet can be blended with kerosene and used completely interchangeably with conventional fuel [

8]. They have generated significant interest from aviation stakeholders, but there are issues that need to be resolved. For instance, although vegetable oils are available in large quantities, their use as a fuel could lead to conflicts with food production. Syn-jet, having nearly identical properties to kerosene, would not solve environmental concerns due to its high carbon content. Significant investments in manufacturing are also required to produce drop-ins in sufficient quantities for the aviation sector. Additionally, the production of drop-in fuels can still contribute to net lifecycle CO

2 and pollutant emissions. Cryogenic fuels such as LNG, liquefied biomethane, and liquid hydrogen (LH

2) are attractive alternatives due to their high specific energy density, but they are at a disadvantage compared to other fuels in terms of their volumetric energy density, meaning that they require greater storage volume, a critical aspect for aviation.

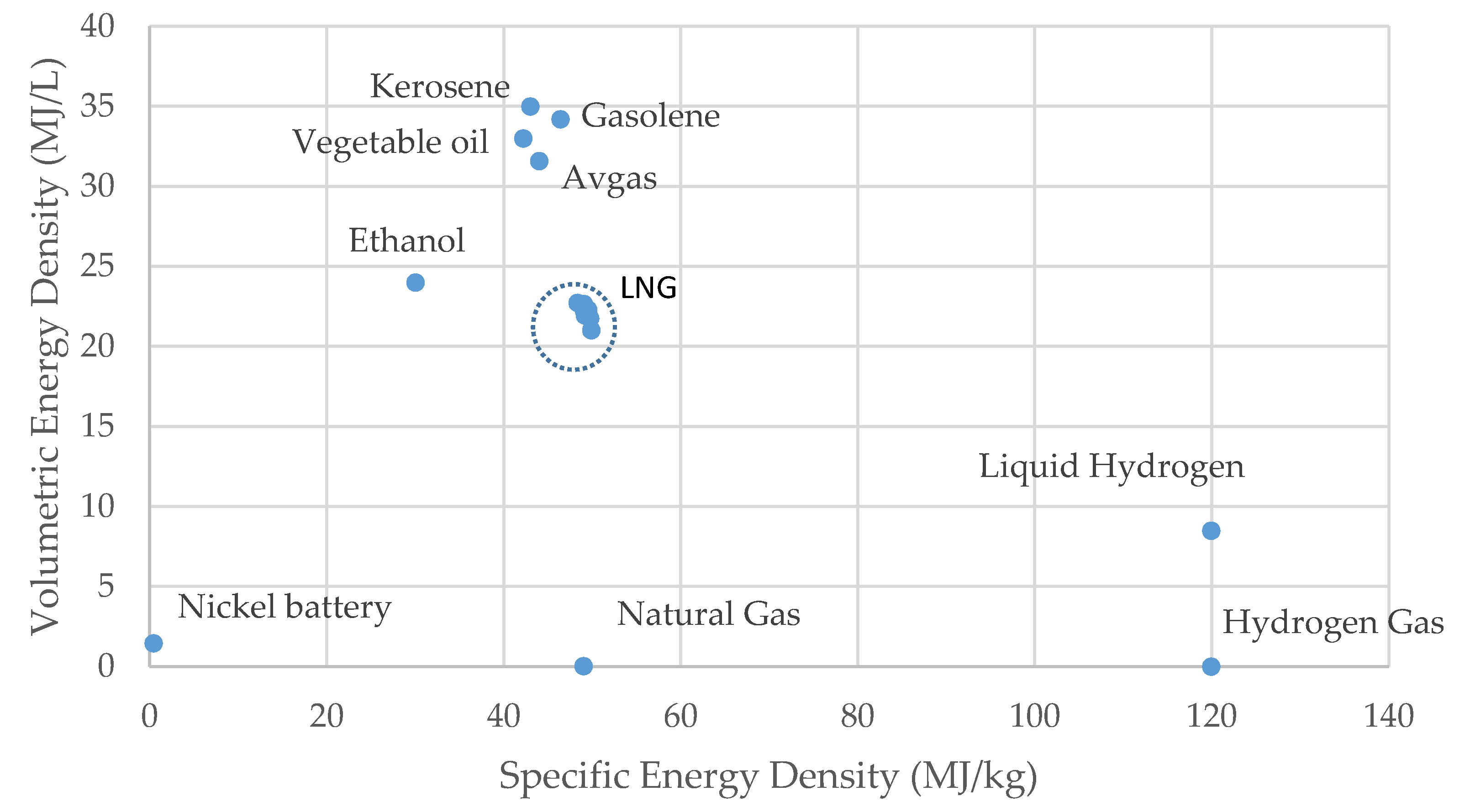

Figure 1 summarizes the differences between potential alternative fuels for aviation with regard to energy density, including both specific energy density (SED) and volumetric energy density (VED) [

9].

Kerosene is at the top of the chart, which makes it an ideal candidate for aviation. Just below are other fuels with high carbon contents and which are naturally in liquid states. With a decrease in the carbon-to-hydrogen ratio, there is a reduction in CO2 emissions after combustion. This makes the fuel more attractive from an environmental point of view. However, this is accompanied by a decrease in the volumetric energy density, which implies that for a fixed specific energy density, more storage space is required in the fuel tanks to store the same amount of energy. Even in its cryogenically cooled liquid state, the volumetric energy density of natural gas is 35% less than for kerosene, while the volumetric energy density of hydrogen is reduced by 75% compared to kerosene. Although LH2 has approximately 170% higher specific energy density compared to kerosene and has the potential for zero carbon emissions if produced cleanly, its implementation would require a complete redesign of the aircraft and propulsion systems. Furthermore, scaling-up green hydrogen production is still a significant challenge.

Natural gas, which is mostly methane, has been suggested as an alternative fuel for aviation, and liquefying it minimizes the fuel tank weight and volume. Several prior studies have been conducted to assess LNG use for subsonic aircrafts.

In 1980, the Beech Sundowner, a two-seater turboprop, was the first aircraft to operate on liquid methane [

10]. Around the same time, Lockheed performed a thorough analysis on the prospects of LNG in civil aviation. They concluded that the modifications required to implement the use of a cryogenic fuel were too extensive to make sense economically, given the low price of kerosene at that time [

8]. In 1988, a modified Tupolev TU-154, the TU-155, had its first flight, with one of its three engines operating on LNG. The aircraft performed several demonstration flights to international airports in Moscow, Bratislava, Nice, Berlin, and Hannover, which totaled more than 100 flight hours [

10]; the project was discontinued after the fall of the Soviet Union.

NASA came to the conclusion that the use of methane had the potential to be competitive in all major areas, reducing the direct operating cost, gross weight, initial cost, and energy utilization if appropriate standards of handling and safety were maintained [

11]. Following this, a similar study was performed by AIR-LNG, who instead inserted the tanks in LD6 containers within the cargo bay, whereby the only modification to the aircraft fuel system was the addition of LNG equipment. Through the partial or full replacement of kerosene, they estimated the possibility of implementing LNG for air transport within a timeframe of 3–6 years [

12]. Although this configuration can be implemented with little redesign, which makes its implementation feasible in such a short timeframe, less space is available for the storage of LNG which reduces the range capability of LNG-flown aircraft. More recently, the start-up company Savion Aerospace proposed a business turboprop aircraft design cruising at Mach 0.55 and powered using LNG. Specifically, the founder, Jonathan Gibbs, claims that by using existing engines and retrofitting the combustor to burn natural gas, 75% of the development cost can be reduced, with the added benefit of a 15% reduction in maintenance costs due to the lower sulfur content [

13].

However, the implementation of LNG in aviation has some underlying complexities that need to be addressed first. For instance, airports will need to accommodate large LNG storage tanks or liquefaction facilities in addition to pipelines to ensure safe and effective refueling. In addition, extra safety measures need to be taken due to the properties of this fuel. For instance, in case of a crash in water, water must not be allowed to enter the tanks due to the violent reaction of LNG with water.

Nevertheless, the world could significantly benefit both economically and environmentally from using LNG in aviation if those hurdles were addressed. Following the discovery and expansion of vast reserves of natural gas using shale fracking, the price of natural gas dropped significantly, and in 2020 reached its lowest level since 1995 [

14]. In addition to it having a 16% higher heating value and a higher hydrogen-to-carbon ratio molecule than Jet A, LNG presents itself as a competitive alternative aviation fuel. In this context, LNG could prove itself to be a clean alternative and act as a stepping stone towards the development of net-zero carbon emission alternatives, such as biomethane or hydrogen.

This paper aims to assess the performance benefits achieved in terms of CO2 emissions and energy-saving potential by replacing kerosene with LNG, in addition to discussing the challenges presented by the use of a cryogenic fuel for aircraft propulsion. In order to achieve this, an integrated design and simulation framework are developed and applied for the case of a single-aisle, short-range aircraft that is extensively used in civil aviation. The assessment is performed at the mission level, taking into consideration the effects of fuel synthesis on engine performance and accounting for the added weight and drag due to the necessary changes to the airframe. To the authors’ knowledge, such a holistic assessment addressing the multitude of factors affecting aircraft and engine performance and discussing the implications of the required modifications had not previously been published within the research community.

5. Conclusions

The potential benefits of introducing LNG in civil aviation were quantified by utilizing a simulation framework integrating aircraft engine performance models, a tank sizing module, and an aircraft weight estimation module. A case study based on the popular Boeing 737–800 aircraft was performed and the changes on the airframe weight and volume due to conversion to LNG were considered. The “above-the-passenger-cabin” tank configuration was selected, utilizing two cylindrical tanks with a frontal diameter of 2 m, leading to an increased fuselage wetted area and higher drag. The front tank has a length of 7.3 m and the rear tank has a length of 12.2 m, designed considering both safety issues and minimum impact on the aircraft’s center of gravity. The added weight of the fuel storage system is 4 tons, resulting in an increase in the aircraft maximum take-off weight of 4% (2.5 tons). The aircraft performance was assessed against the baseline case (Jet A-1) for three different LNG sources in terms of the payload range performance, mission energy and fuel consumption, CO2 emissions, and fuel cost. The LNG-converted aircraft had a slightly reduced range for the case of maximum payload. The decrease in range varied from 1.7% to 5.7% for the different LNG sources. For the ferry mission, LNG with increased energy density provided a benefit in terms of range of 0.9–4.8% for the different sources. For the maximum payload, the added weight resulted in a decrease of range when LNG was considered, while for the ferry mission it was the fuel specific energy that provided the benefit, since there was no limitation on fuel mass due to payload. These results indicate that when assessing LNG for aviation, it is important to consider the source and synthesis, since these factors affects both LHV and density, and hence the mission-available energy. These are also operational parameters that have to be assessed if LNG is used in aviation, since aircraft performance will change depending on the take-off airport.

It is apparent that the increases of aircraft weight and frontal area for the LNG cases will result in higher energy consumption per passenger. The results indicate that the increase in energy will be in the range of 10% for a typical flight (1000–2000 nmi). Of course considering the difference between the LHV of kerosene and LNG, this is translated to a fuel reduction of 4% (1.6–5.0%, depending on the source) for typical flights, and up to 6.7% (4.3–7.6%) reduction for the shortest flights that this aircraft operates (in the range of 250 nmi). This fuel reduction in conjunction with the lower CO2 index of LNG compared to kerosene offers a substantial CO2 emissions reduction in the range of 16% for typical missions and up to 18% for very short missions. The lower cost of LNG compared to kerosene offers a significant fuel cost per passenger reduction of approximately 16%. In this context, it is apparent that LNG has significant environmental and economic benefits compared to kerosene, even when accounting for weight and drag penalties. It is also important to consider that gas turbine engines operate without the need for a major redesign or retrofitting with NG, while if we consider future propulsion configurations (e.g., hybrid-electric, supersonic), LNG thermal management capabilities may act as technology enablers. Of course, the adoption of LNG in aviation will have to address the current lack of infrastructure and the need for a new logistic approach considering aspects such as the source and synthesis, fuel delivery, and fuel stability. The prospects for LNG utilization in other transport industries (e.g., marine) may offer experience that can support its application for aviation.