Experimental Performance Evaluation of an Integrated Solar-Driven Adsorption System in Terms of Thermal Storage and Cooling Capacity

Abstract

:1. Introduction

- Increase of carbon dioxide (CO2) emissions since the largest percentage of electrical energy is produced by non-renewable energy sources. Carbon dioxide emissions accentuate the greenhouse effect and by extension global warming.

- Contribute to the depletion of fossil fuels. Estimates about the depletion of fossil fuels indicate 107 years for coal, 37 year for gas and only 35 years for oil [1].

- Their extensive and simultaneous use during summer months causes serious problems to the power plants and electrical network, increasing the danger of power outages and black outs [2].

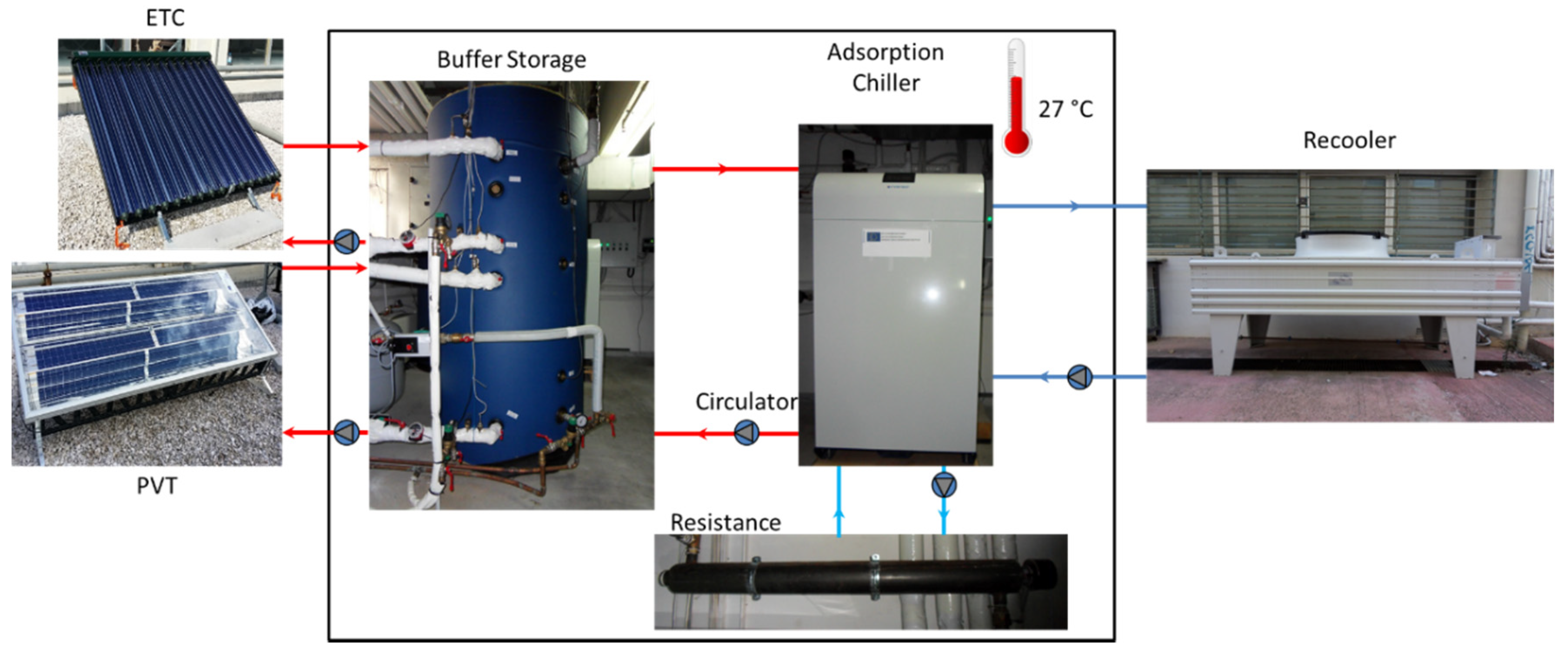

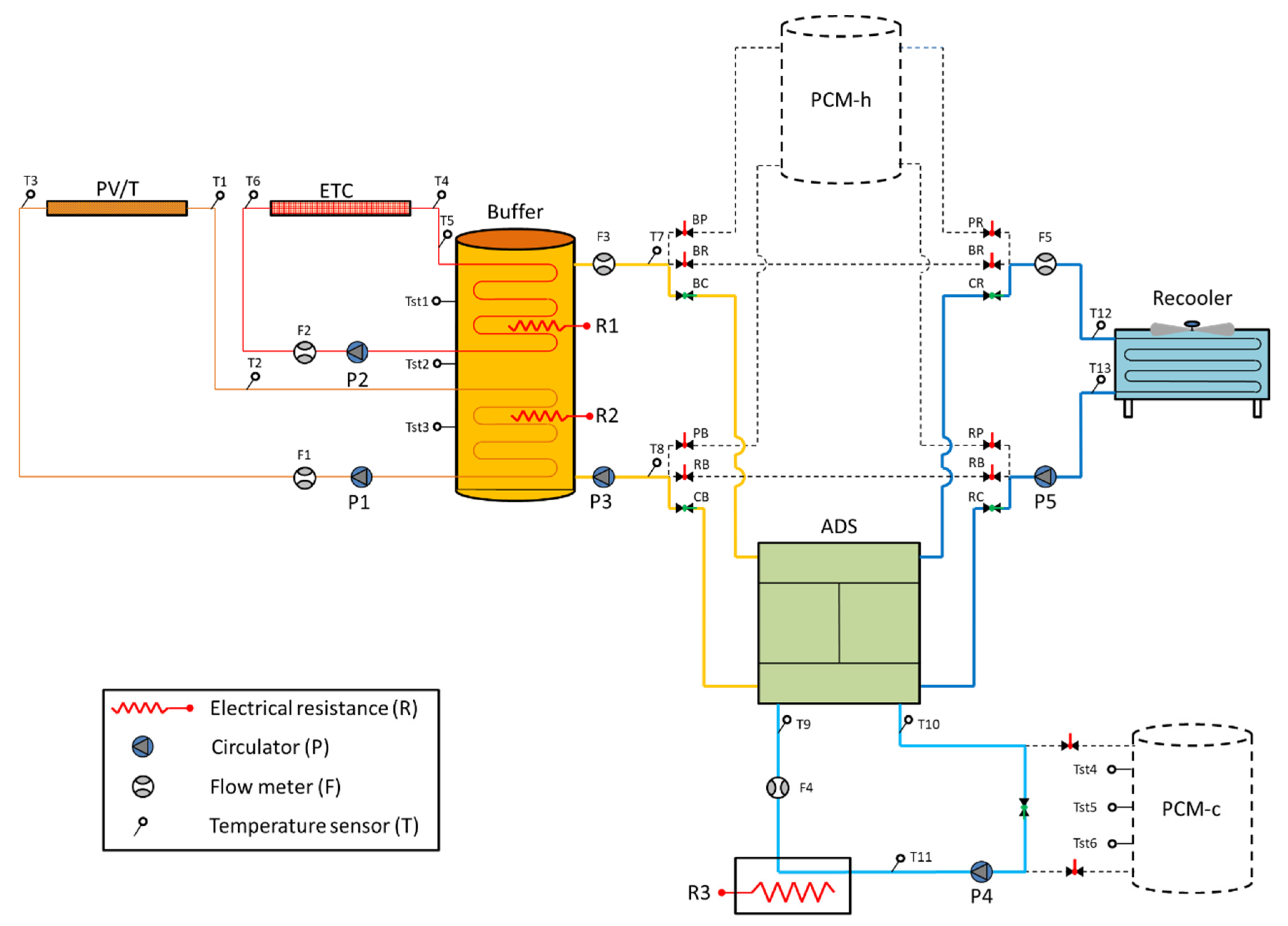

2. System Description and Experimental Process

3. Mathematical Background

4. Results and Discussion

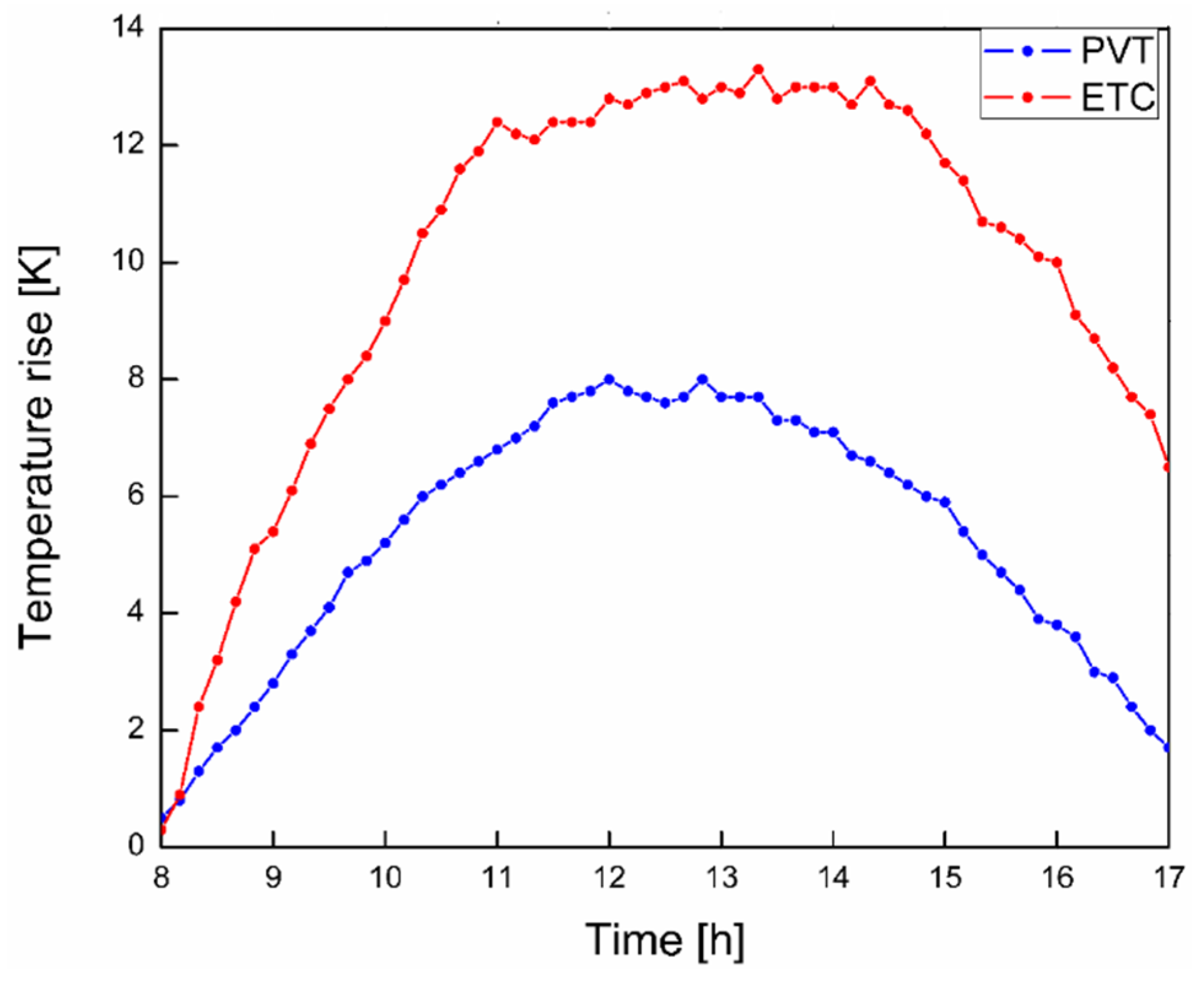

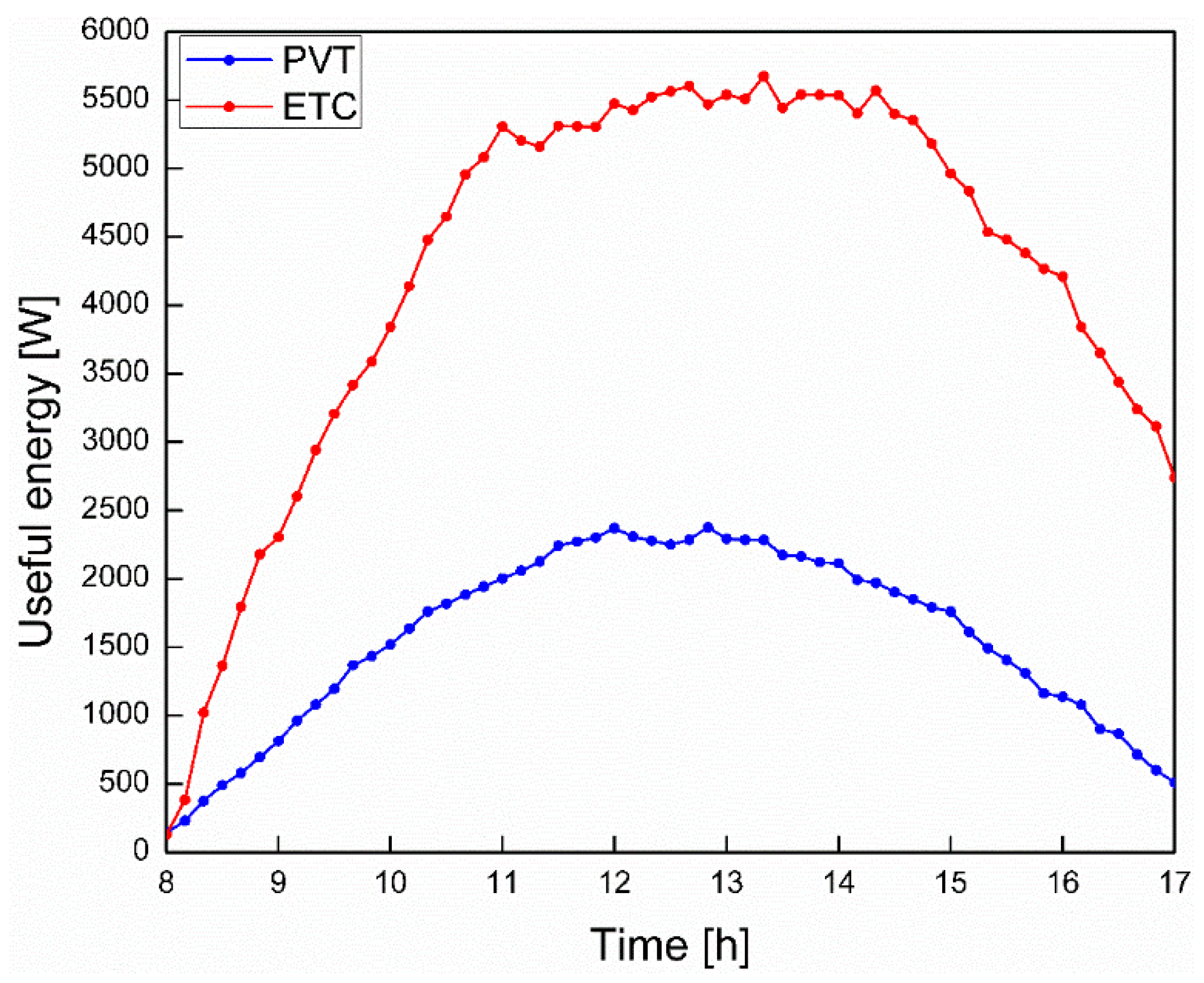

4.1. Ambient Conditions and Collector Performance

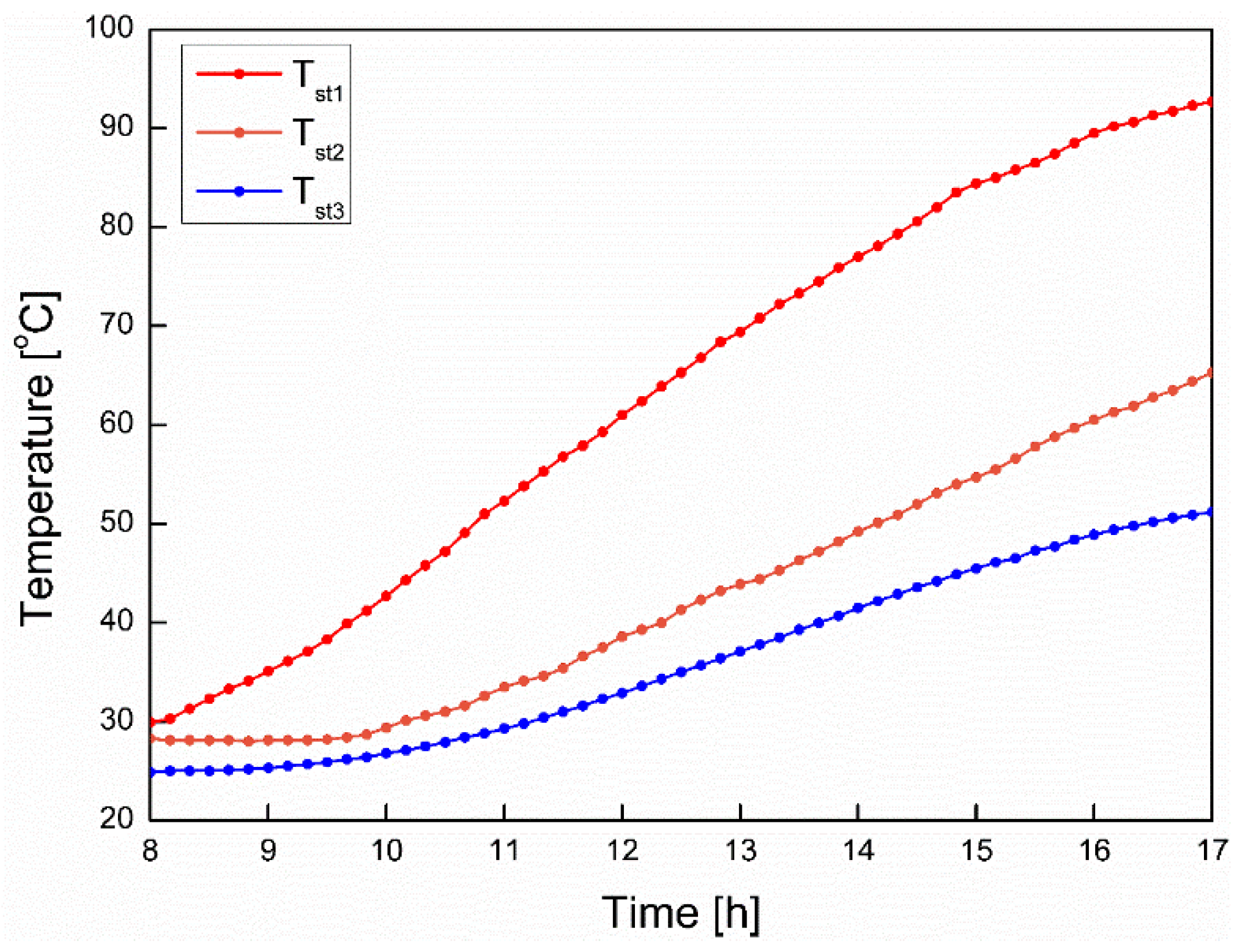

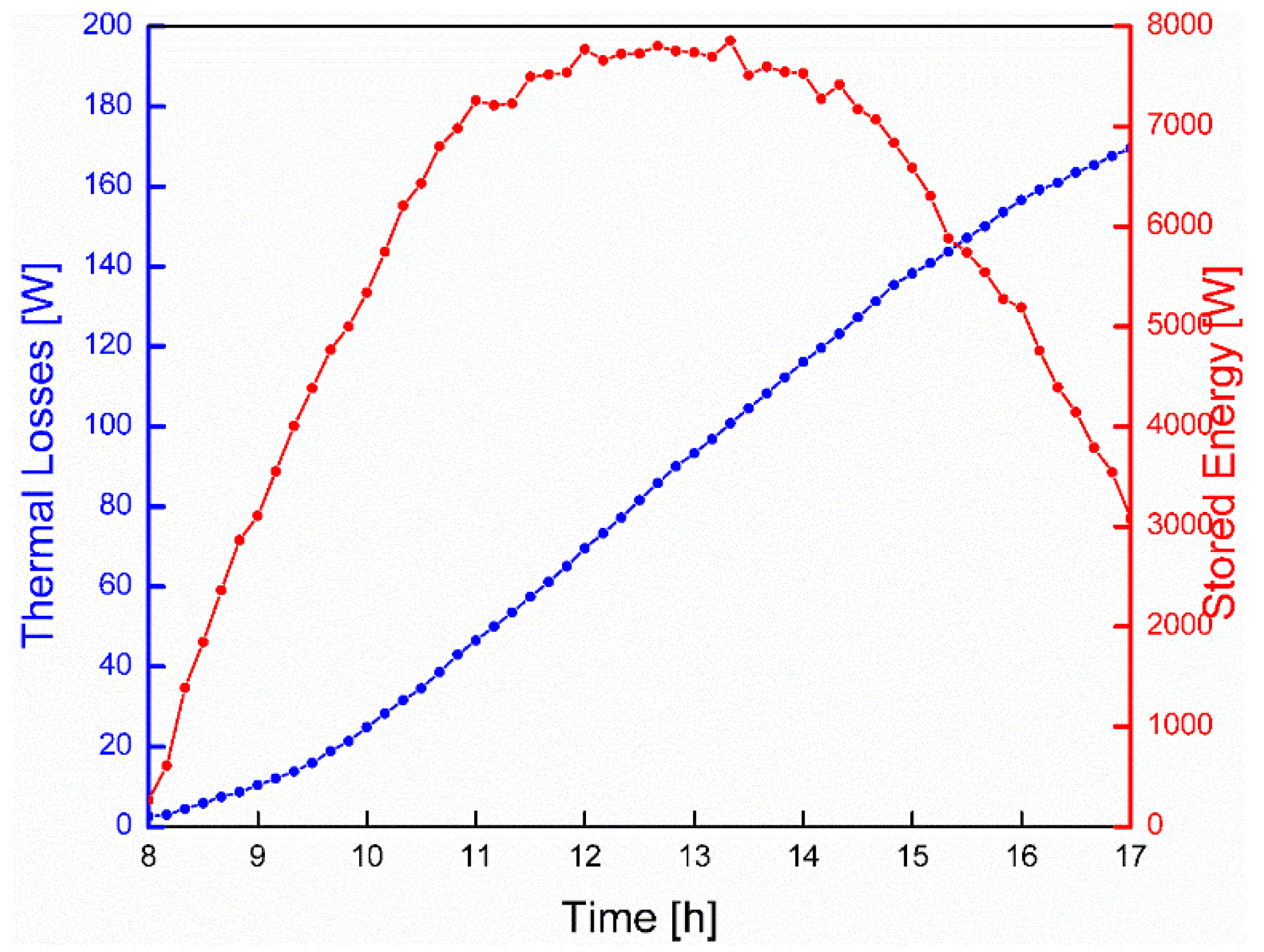

4.2. Thermal Energy Storage

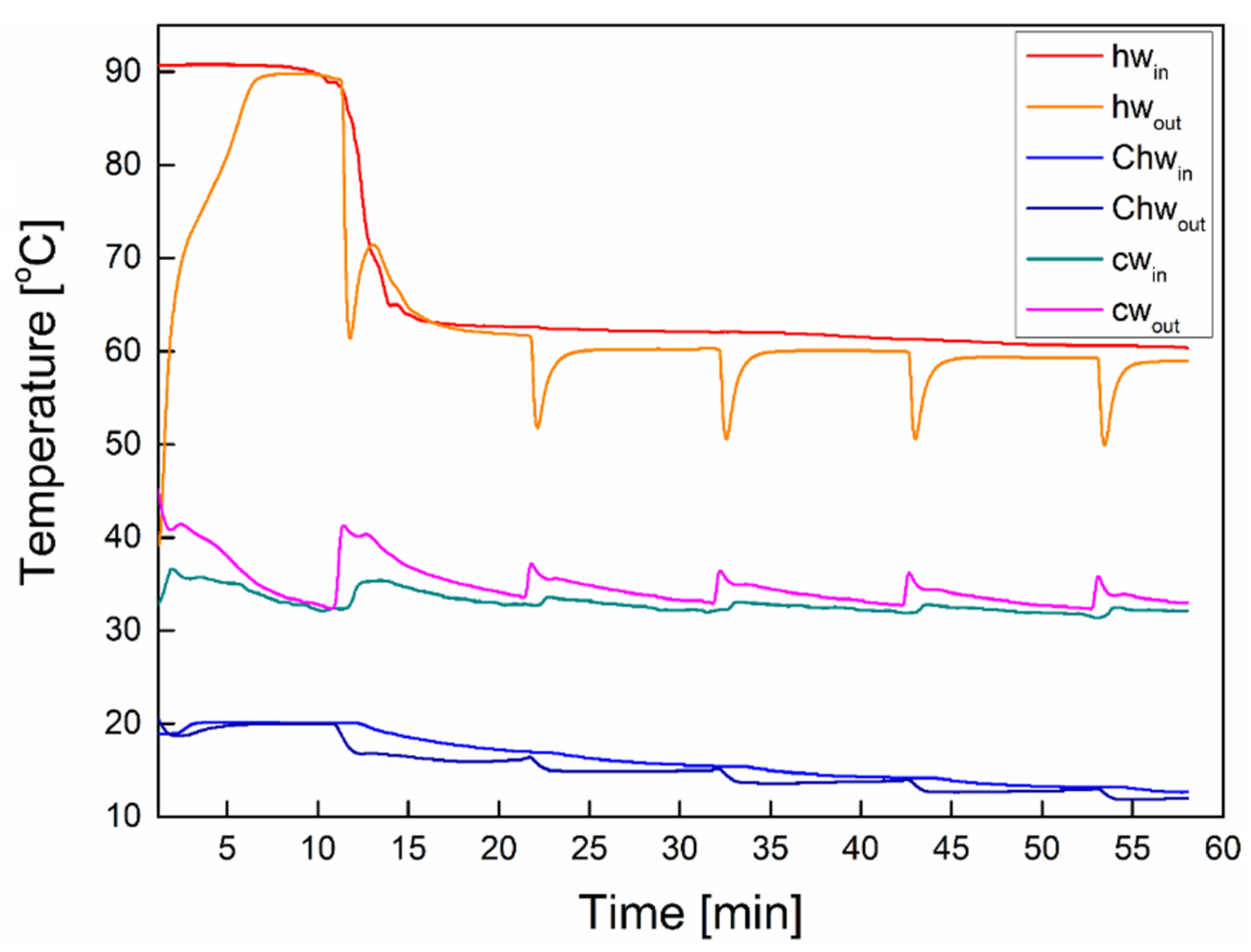

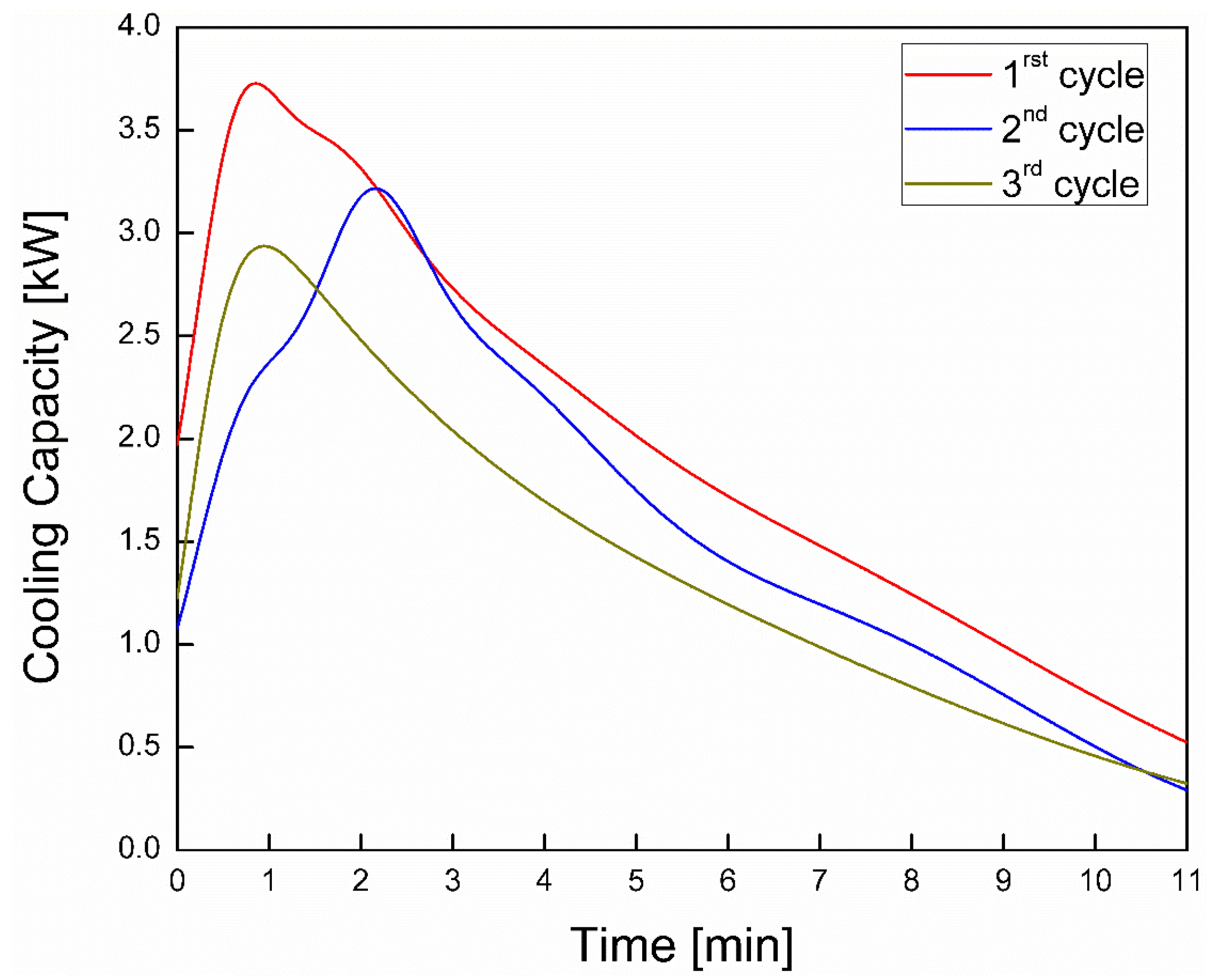

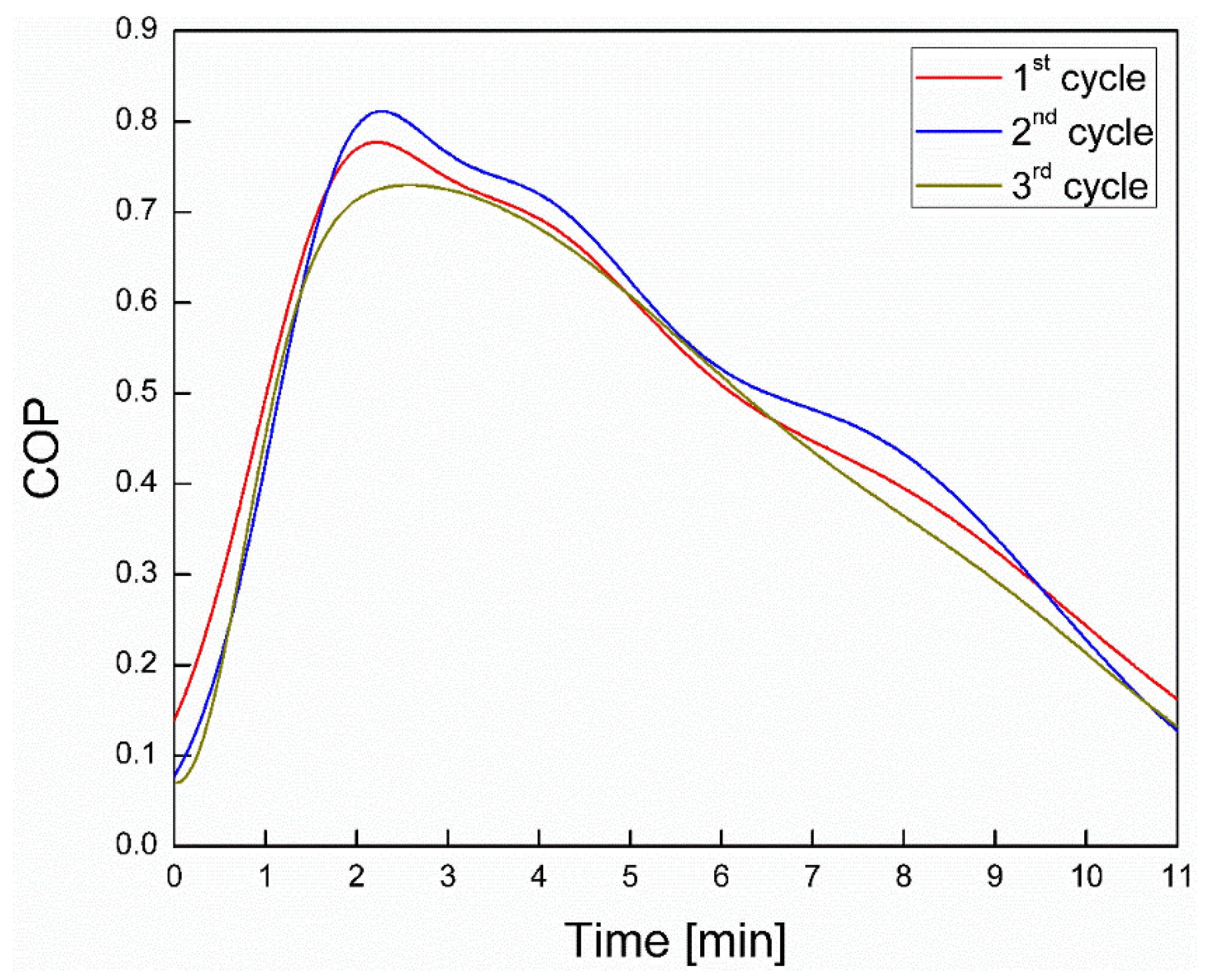

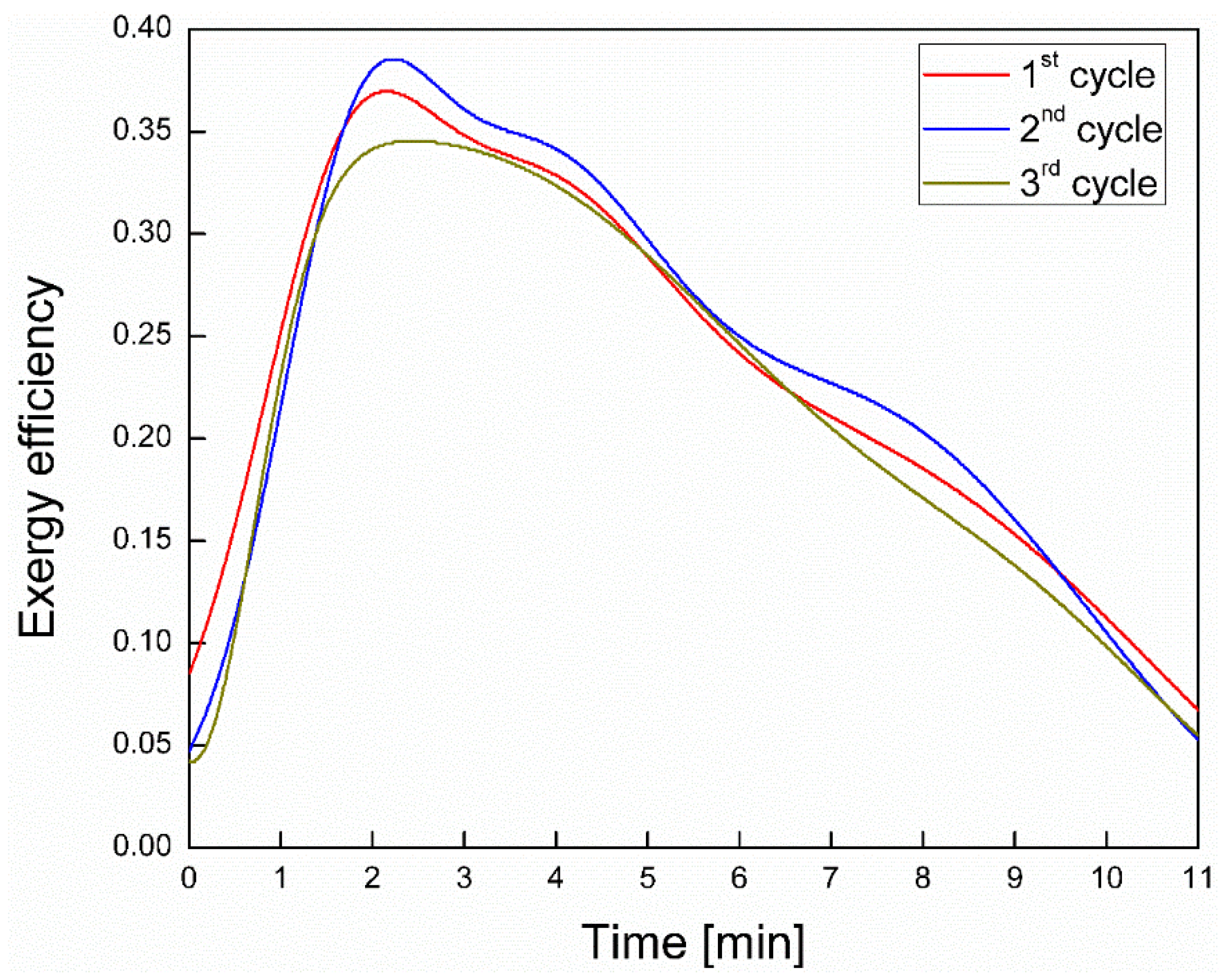

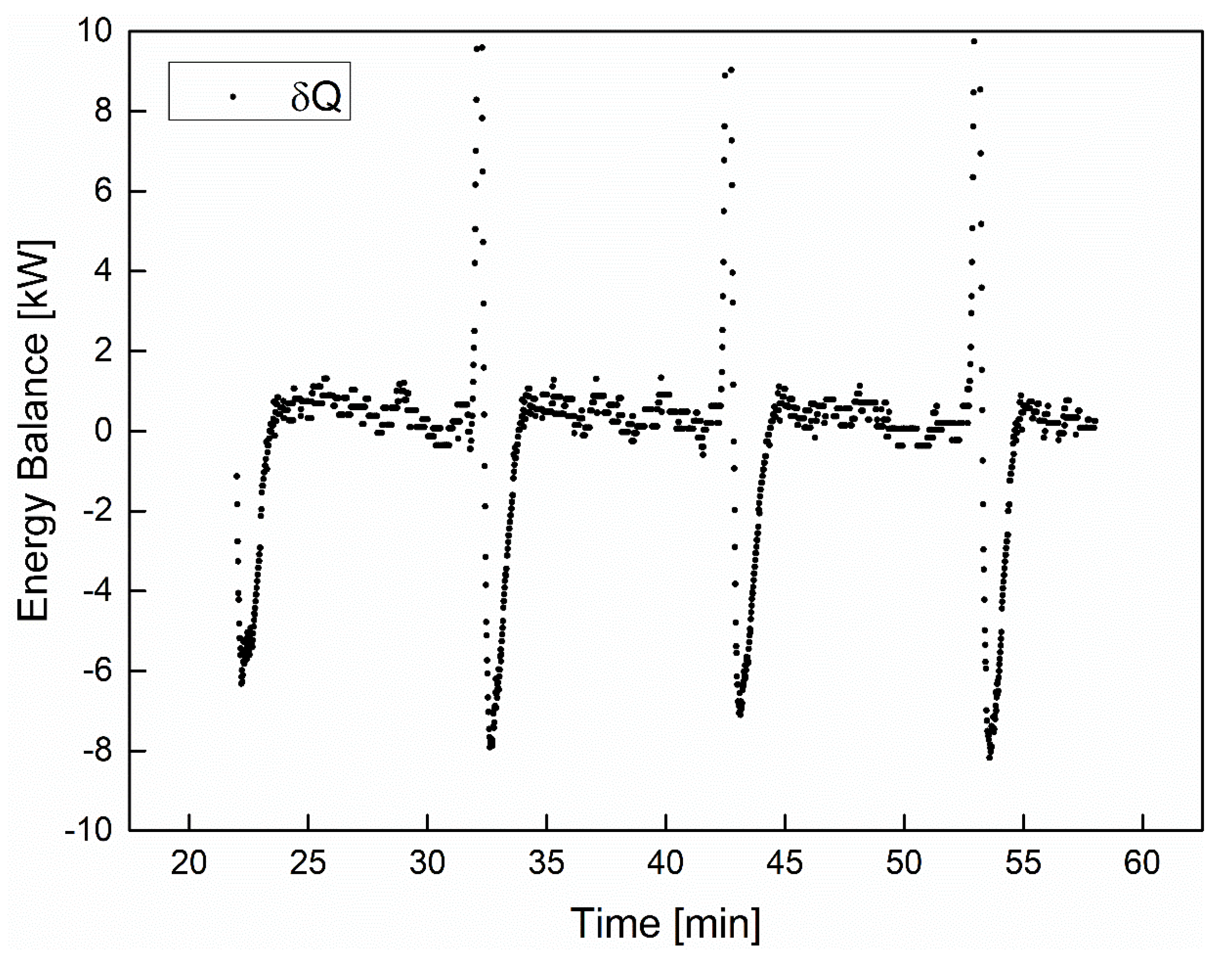

4.3. Adsorption Chiller Performance

5. Conclusions

- The combination of the examined solar collectors was efficient for driving the investigated solar cooling system during the whole year, serving both high and low cooling loads.

- The steady-state period of the ETC series lasted longer than that of the PVT series.

- During this period, the working fluid in PVT collectors exhibited a 7.8 K rise in temperature, thus producing 2.3 kW of useful thermal power, while in ETC series the temperature rise was 12.8 K, with a production of useful power equal to 5.6 K.

- The storage tank can be divided into three zones. The temperature of each zone increased almost linearly (constant rate).

- The heat losses of the storage tank exhibited a linear variation, as they followed the behavior of the storage tank temperatures.

- The maximum storage rate was nearly 7.7 kW, observed during the collectors’ steady-state phase.

- The total thermal energy stored in the tank during the 9 h experiment was equal to 24.70 kWh or 88.94 MJ.

- A transient phase of nearly 20 min was observed, after which three cycles of 11 min each were formatted and used for the present analysis.

- After the end of third cycle, a minimum temperature of 12 °C was observed at the outlet of the evaporator.

- The average cooling capacity of each cycle varied between 1.4–2.0 kW, while the average COP was almost constant at around 0.49.

- The adsorption chiller approached the ideal Carnot cycle at a level varying between 36–43%. The average exergetic efficiency was about 23% for all cycles.

- The switching process substantially affected the energy balance. However, during most of the cycle period, the energy balance was satisfactorily fulfilled.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Area (m2) | |

| Specific heat capacity (J kg−1 K−1) | |

| Solar irradiance (W m−2) | |

| Mass flow rate (kg s−1) | |

| Energy rate (W) | |

| Temperature (K) | |

| Heat loss coefficient (W m−2 K−1) | |

| Efficiency (-) | |

| Condenser | |

| Chilled water | |

| Cooling water | |

| Evaporator | |

| Exergy | |

| Heat transfer fluid | |

| Generator | |

| Hot water | |

| Mix-zone number | |

| Inlet | |

| Losses | |

| Laboratory | |

| Ambient temperature | |

| Outlet | |

| Storage tank | |

| Useful | |

| water | |

| COP | Coefficient of performance |

| CPC | Compound parabolic collector |

| ETC | Evacuated tube collectors |

| PCM | Phase change material |

| PVT | Photovoltaic thermal collectors |

References

- Shafiee, S.; Topal, E. When will fossil fuel reserves be diminished? Energy Policy 2009, 37, 181–189. [Google Scholar] [CrossRef]

- Huang, L.; Zheng, R. Energy and Economic Performance of Solar Cooling Systems in the Hot-Summer and Cold-Winter Zone. Buildings 2018, 8, 37. [Google Scholar] [CrossRef] [Green Version]

- Akahira, A.; Alam, K.C.A.; Hamamoto, Y.; Akisawa, A.; Kashiwagi, T. Mass recovery adsorption refrigeration cycle—Improving cooling capacity. Int. J. Refrig. 2004, 27, 225–234. [Google Scholar] [CrossRef]

- Chorowski, M.; Pyrka, P. Modelling and experimental investigation of an adsorption chiller using low-temperature heat from cogeneration. Energy 2015, 92, 221–229. [Google Scholar] [CrossRef]

- Farid, S.K.; Billah, M.M.; Khan, M.Z.I.; Rahman, M.M.; Sharif, U.M. A numerical analysis of cooling water temperature of two-stage adsorption chiller along with different mass ratios. Int. Commun. Heat Mass Transf. 2011, 38, 1086–1092. [Google Scholar] [CrossRef]

- Bataineh, K.; Taamneh, Y. Review and recent improvements of solar sorption cooling systems. Energy Build. 2016, 128, 22–37. [Google Scholar] [CrossRef]

- Alobaid, M.; Hughes, B.; Calautit, J.K.; O’Connor, D.; Heyes, A. A review of solar driven absorption cooling with photovoltaic thermal systems. Renew. Sustain. Energy Rev. 2017, 76, 728–742. [Google Scholar] [CrossRef] [Green Version]

- Hassan, H.Z.; Mohamad, A.A. A review on solar-powered closed physisorption cooling systems. Renew. Sustain. Energy Rev. 2012, 16, 2516–2538. [Google Scholar] [CrossRef]

- Alam, K.C.A.; Saha, B.B.; Akisawa, A. Adsorption cooling driven by solar collector: A case study for Tokyo solar data. Appl. Therm. Eng. 2013, 50, 1603–1609. [Google Scholar] [CrossRef]

- Clausse, M.; Alam, K.C.A.; Meunier, F. Residential air conditioning and heating by means of enhanced solar collectors coupled to an adsorption system. Sol. Energy 2008, 82, 885–892. [Google Scholar] [CrossRef] [Green Version]

- El-Sharkawy, I.I.; Abdelmeguid, H.; Saha, B.B. Potential application of solar powered adsorption cooling systems in the Middle East. Appl. Energy 2014, 126, 235–245. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A.; Vicidomini, M. Adsorption chiller operation by recovering low-temperature heat from building integrated photovoltaic thermal collectors: Modelling and simulation. Energy Convers. Manag. 2017, 149, 1019–1036. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A. Solar heating and cooling systems by absorption and adsorption chillers driven by stationary and concentrating photovoltaic/thermal solar. Renew. Sustain. Energy Rev. 2018, 82, 1874–1908. [Google Scholar] [CrossRef]

- Koronaki, I.P.; Papoutsis, E.G.; Papaefthimiou, V.D. Thermodynamic modeling and exergy analysis of a solar adsorption cooling system with cooling tower in Mediterranean conditions. Appl. Therm. Eng. 2016, 99, 1027–1038. [Google Scholar] [CrossRef]

- Alahmer, A.; Wang, X.; Alam, K.C.A. Dynamic and Economic Investigation of a Solar Thermal-Driven Two-Bed Adsorption Chiller under Perth Climatic Conditions. Energies 2020, 13, 1005. [Google Scholar] [CrossRef] [Green Version]

- Basdanis, T.; Tsimpoukis, A.; Valougeorgis, D. Performance optimization of a solar adsorption chiller by dynamically adjusting the half-cycle time. Renew. Energy 2021, 164, 362–374. [Google Scholar] [CrossRef]

- Zhai, X.Q.; Wang, R.Z.; Wu, J.Y.; Dai, Y.J.; Ma, Q. Design and performance of a solar-powered air-conditioning system in a green building. Appl. Energy 2008, 85, 297–311. [Google Scholar] [CrossRef]

- Fasfous, A.; Asfar, J.; Al-Salaymeh, A.; Sakhrieh, A.; Al-Hamamre, Z.; Al-Bawwab, A.; Hamdan, M. Potential of utilizing solar cooling in The University of Jordan. Energy Convers. Manag. 2013, 65, 729–735. [Google Scholar] [CrossRef]

- Lu, Z.S.; Wang, R.Z.; Xia, Z.Z.; Lu, X.R.; Yang, C.B.; Ma, Y.C.; Ma, G.B. Study of a novel solar adsorption cooling system and a solar absorption cooling system with new CPC collectors. Renew. Energy 2013, 50, 299–306. [Google Scholar] [CrossRef]

- Thomas, S.; Hennaut, S.; Maas, S.; Andre, P. Experimentation and Simulation of a Small-Scale Adsorption Cooling System in Temperate Climate. Energy Procedia 2012, 30, 704–714. [Google Scholar] [CrossRef] [Green Version]

- Roumpedakis, T.C.; Vasta, S.; Sapienza, A.; Kallis, G.; Karellas, S.; Wittstadt, U.; Tanne, M.; Harborth, N.; Sonnenfeld, U. Performance Results of a Solar Adsorption Cooling and Heating Unit. Energies 2020, 13, 1630. [Google Scholar] [CrossRef] [Green Version]

- Koronaki, I.P.; Nitsas, M.T. Experimental and theoretical performance investigation of asymmetric photovoltaic/thermal hybrid solar collectors connected in series. Renew. Energy 2018, 118, 654–672. [Google Scholar] [CrossRef]

- Saha, B.B.; Boelman, E.C.; Kashiwagi, T. Computer simulation of a silica gel-water adsorption refrigeration cycle-the influence of operating conditions on cooling output and COP. ASHRAE Trans. 1995, 101, 348–357. [Google Scholar]

- Boelman, E.C.; Saha, B.B.; Kashiwagi, T. Experimental investigation of a silica gel-water adsorption refrigeration cycle-the influence of operating conditions on cooling output and COP. ASHRAE Trans. 1995, 101, 358–366. [Google Scholar]

- Kalkan, N.; Young, E.A.; Celiktas, A. Solar thermal air conditioning technology reducing the footprint of solar thermal air conditioning. Renew. Sustain. Energy Rev. 2012, 16, 6352–6383. [Google Scholar] [CrossRef]

| PVT | Total area 11 m2 |

| ETC | Total area 9.76 m2 |

| Adsorption chiller | Nominal cooling capacity 10 kW |

| Buffer storage tank | Total volume 865 lt |

| Dry cooler | Nominal capacity 56.4 kW |

| Electrical resistance | Resistance electrical power 12 kW |

| Equipment | Accuracy | Relative Error |

|---|---|---|

| pyranometer | ±(4% |Gtot|) | 2.7% |

| HTF temperature sensors | ±(0.15 + 0.002 × |Temp|) | 0.8% |

| Ambient temperature sensor | ±(0.15 + 0.002 × |Temp|) | 1.1% |

| Flowmeter | ±1% | 0.7% |

| Wind meter | 1% ± 0.1 m/s | 1% |

| Heat Transfer Fluid (In Every Section of the Unit) | Water |

|---|---|

| PVT mass flow rate | 0.07 kg/s |

| ETC mass flow rate | 0.10 kg/s |

| Regenerator mass flow rate | 0.40 kg/s |

| Evaporator mass flow rate | 0.48 kg/s |

| Condenser mass flow rate | 1.02 kg/s |

| Laboratory temperature | 27 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nitsas, M.T.; Papoutsis, E.G.; Koronaki, I.P. Experimental Performance Evaluation of an Integrated Solar-Driven Adsorption System in Terms of Thermal Storage and Cooling Capacity. Energies 2020, 13, 5931. https://doi.org/10.3390/en13225931

Nitsas MT, Papoutsis EG, Koronaki IP. Experimental Performance Evaluation of an Integrated Solar-Driven Adsorption System in Terms of Thermal Storage and Cooling Capacity. Energies. 2020; 13(22):5931. https://doi.org/10.3390/en13225931

Chicago/Turabian StyleNitsas, M.T., E.G. Papoutsis, and I.P. Koronaki. 2020. "Experimental Performance Evaluation of an Integrated Solar-Driven Adsorption System in Terms of Thermal Storage and Cooling Capacity" Energies 13, no. 22: 5931. https://doi.org/10.3390/en13225931

APA StyleNitsas, M. T., Papoutsis, E. G., & Koronaki, I. P. (2020). Experimental Performance Evaluation of an Integrated Solar-Driven Adsorption System in Terms of Thermal Storage and Cooling Capacity. Energies, 13(22), 5931. https://doi.org/10.3390/en13225931