Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Experiment

2.2. Laboratory Analyses

2.3. Statistical Analysis

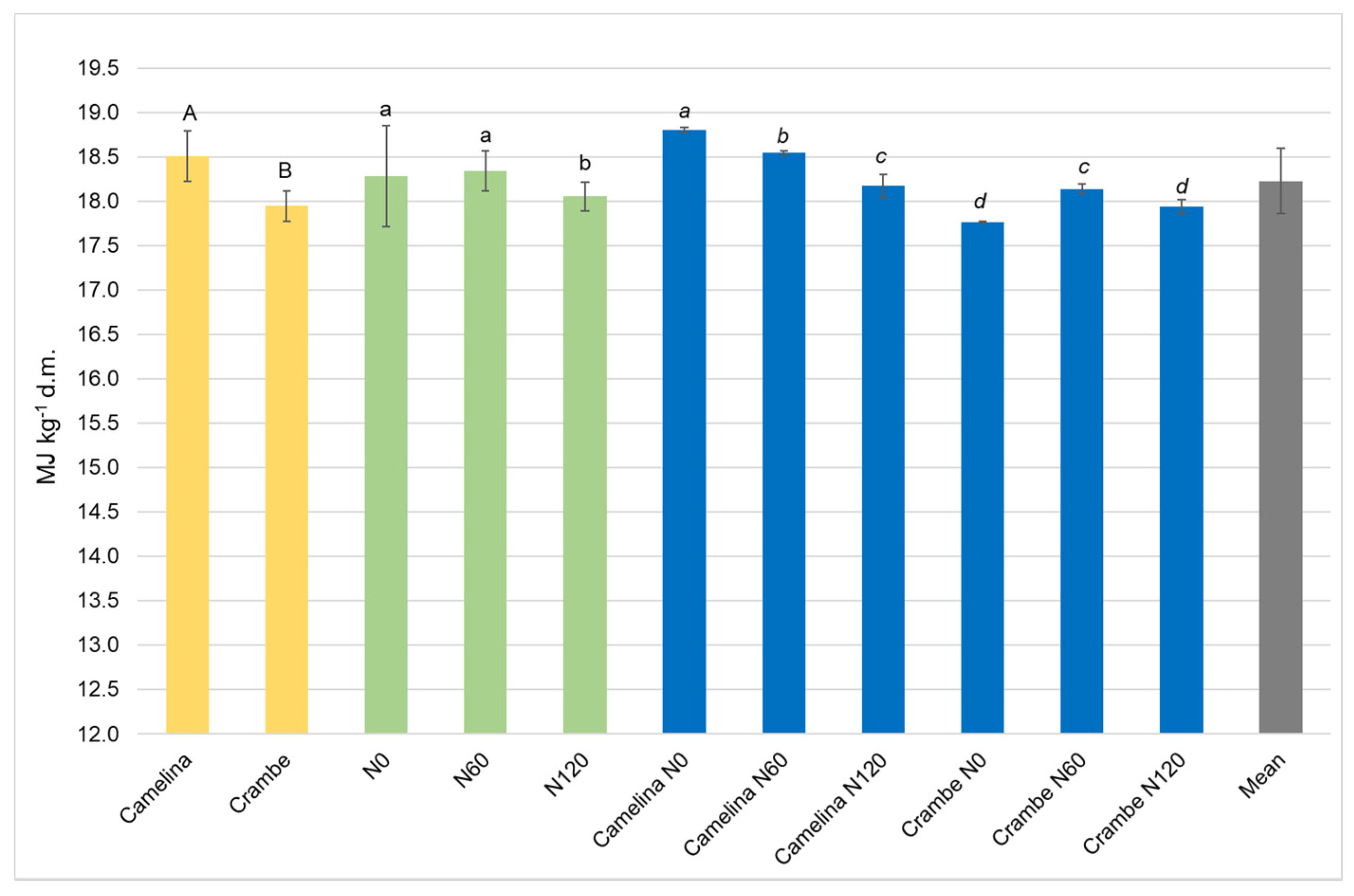

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Golembiewski, B.; Siccck, N.; Bröring, S. The emerging research landscape on bioeconomy: What has been done so far and what is essential from a technology and innovation management perspective? Innov. Food Sci. Emerg. Technol. 2015, 29, 308–317. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- European Commission. Communicationfrom the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 328, 82–209. [Google Scholar]

- Krzyżaniak, M.; Stolarski, J.M. Life cycle assessment of camelina and crambe production for biorefinery and energy purposes. J. Clean. Prod. 2019, 237, 117755. [Google Scholar] [CrossRef]

- Parajuli, R.; Knudsen, M.T.; Djomo, S.N.; Corona, A.; Birkved, M.; Dalgaard, T. Environmental life cycle assessment of producing willow, alfalfa and straw from spring barley as feedstocks for bioenergy or biorefinery systems. Sci. Total. Environ. 2017, 586, 226–240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dumeignil, F. A new concept of biorefi nery comes into operation: The EuroBioRef concept. In Biorefinery from Biomass to Chemicals and Fuels; Aresta, M., Dibenedetto, A., Dumeignil, F., Eds.; Walter de Gruyter GmbH & Co.: Berlin, Germany, 2012; pp. 1–17. [Google Scholar]

- Stolarski, M.J.; Śnieg, M.; Krzyżaniak, M.; Tworkowski, J.; Szczukowski, S.; Graban, L.; Lajszner, W. Short rotation coppices, grasses and other herbaceous crops: Biomass properties versus 26 genotypes and harvest time. Ind. Crop. Prod. 2018, 119, 22–32. [Google Scholar] [CrossRef]

- Von Cossel, M.; Lewandowski, I.; Elbersen, B.; Staritsky, I.; Van Eupen, M.; Iqbal, Y.; Mantel, S.; Scordia, D.; Testa, G.; Cosentino, S.L.; et al. Marginal agricultural land low-input systems for biomass production. Energies 2019, 12, 3123. [Google Scholar] [CrossRef] [Green Version]

- Berti, M.; Gesch, R.; Eynck, C.; Anderson, J.; Cermake, S. Camelina uses, genetics, genomics, production, and management. Ind. Crop. Prod. 2016, 94, 690–710. [Google Scholar] [CrossRef]

- Laghetti, G.; Piergiovanni, A.R.; Perrino, P. Yield and oil quality in selected lines of Crambe abyssinica Hochst. ex R.E. Fries and C. hispanica L. grown in Italy. Ind. Crop. Prod. 1995, 4, 203–212. [Google Scholar]

- Wang, Y.P.; Tang, J.S.; Chu, C.Q.; Tian, J. A preliminary study on the introduction and cultivation of Crambe abyssinica in China, an oil plant for industrial uses. Ind. Crop. Prod. 2000, 12, 47–52. [Google Scholar] [CrossRef]

- Kim, N.; Li, Y.; Sun, X.S. Epoxidation of Camelina sativa oil and peel adhesion properties. Ind. Crop. Prod. 2015, 64, 1–8. [Google Scholar] [CrossRef]

- Iłowska, J.; Chrobak, J.; Grabowski, R.; Szmatoła, M.; Woch, J.; Szwach, I.; Drabik, J.; Trzos, M.; Kozdrach, R.; Wrona, M. Designing Lubricating Properties of Vegetable Base Oils. Molecules 2018, 23, 2025. [Google Scholar] [CrossRef] [Green Version]

- Stolarski, M.J.; Krzyżaniak, M.; Tworkowski, J.; Załuski, D.; Kwiatkowski, J.; Szczukowski, S. Camelina and crambe production—Energy efficiency indices depending on nitrogen fertilizer application. Ind. Crop. Prod. 2019, 137, 386–395. [Google Scholar] [CrossRef]

- Gómez-Monedero, B.; Bimbela, F.; Arauzo, J.; Faria, J.; Ruiz, M.P. Pyrolysis of Red Eucalyptus, Camelina Straw, and Wheat Straw in an Ablative Reactor. Energy Fuels 2015, 29, 1766–1775. [Google Scholar] [CrossRef]

- Meyer, A.K.P.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Mohammad, B.T.; Al-Shannag, M.; Alnaief, M. Production of multiple biofuels from Whole Camelina Material: A renewable energy crop. BioResources 2019, 13, 4870–4883. [Google Scholar]

- Krzyżaniak, M.; Stolarski, M.J.; Tworkowski, J.; Puttick, D.; Eynck, C.; Załuski, D.; Kwiatkowskia, J. Yield and seed composition of 10 spring camelina genotypes cultivated in the temperate climate of Central Europe. Ind. Crop. Prod. 2019, 138, 111443. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Kwiatkowski, J.; Tworkowski, J.; Szczukowski, S. Energy and economic efficiency of camelina and crambe biomass production on a large-scale farm in north-eastern Poland. Energy 2018, 150, 770–780. [Google Scholar] [CrossRef]

- ISO. Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- ISO. Solid Biofuels—Sample Preparation; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- PKN. Solid Biofuels—Determination of the Content of Volatile Matter; Polski Komitet Normalizacyjny: Warsaw, Poland, 2016. [Google Scholar]

- PKN. Solid Biofuels—Determination of Calorific Value; Polski Komitet Normalizacyjny: Warsaw, Poland, 2017. [Google Scholar]

- PKN. Determination of Total Content of Carbon, Hydrogen and Nitrogen; Polski Komitet Normalizacyjny: Warsaw, Poland, 2015. [Google Scholar]

- PKN. Determination of Total Content of Sulphur and Chlorine; Polski Komitet Normalizacyjny: Warsaw, Poland, 2016. [Google Scholar]

- Sintim, H.Y.; Zheljazkov, V.D.; Obour, A.K.; Garciae, A.G.; Foulkef, T.K. Evaluating agronomic responses of camelina to seeding date under rain-fed conditions. Agron. J. 2016, 108, 349–357. [Google Scholar] [CrossRef] [Green Version]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash Deposition in Biomass Combustion or Co-Firing for Power/Heat Generation. Energies 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef] [Green Version]

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Krzyżaniak, M.; Gulczyński, P.; Mleczek, M. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew. Energy 2013, 57, 20–26. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Rybczyńska, B.; Krzyżaniak, M.; Lajszner, W.; Graban, Ł.; Peni, D.; Bordiean, A. Thermophysical properties and elemental composition of agricultural and forest solid biofuels versus fossil fuels. J. Elem. 2019, 24, 1215–1228. [Google Scholar] [CrossRef]

- Greenhalf, C.E.; Nowakowski, D.J.; Bridgwater, A.V.; Titiloye, J.; Yates, N.; Riche, A.; Shield, I. Thermochemical characterisation of straws and high yielding perennial grasses. Ind. Crop. Prod. 2012, 36, 449–459. [Google Scholar] [CrossRef]

- Osowski, S.; Fahlenkamp, H. Regenerative energy production using energy crops. Ind. Crop. Prod. 2006, 24, 196–203. [Google Scholar] [CrossRef]

| Source of Variation | Moisture | FC | Ash | VM | HHV | C | H | S | N | Cl |

|---|---|---|---|---|---|---|---|---|---|---|

| Species (A) | 0.06 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.06 | <0.001 |

| N rate (B) | <0.001 | 0.20 | <0.001 | 0.007 | <0.001 | 0.08 | 0.02 | 0.18 | <0.001 | <0.001 |

| A × B | <0.001 | 0.10 | <0.001 | <0.001 | <0.001 | 0.19 | 0.004 | <0.001 | <0.001 | <0.001 |

| Source of Variation | Moisture (%) | FC (% d.m.) | VM (% d.m.) | Ash (% d.m.) | |

|---|---|---|---|---|---|

| Species (A) | Camelina | 55.48 ± 2.8 | 20.90 ± 0.1 a | 74.32 ± 0.4 a | 4.79 ± 0.4 b |

| Crambe | 55.87 ± 0.5 | 19.56 ± 0.2 b | 73.47 ± 0.2 b | 6.97 ± 0.1 a | |

| N rate (B) | 0 | 53.72 ± 2.2 b | 20.32 ± 0.7 | 74.08 ± 0.7 a | 5.60 ± 1.4 c |

| 60 | 56.26 ± 1.0 b | 20.20 ± 0.7 | 73.73 ± 0.5 ab | 6.07 ± 1.1 a | |

| 120 | 57.06 ± 0.7 a | 20.16 ± 0.9 | 73.87 ± 0.2 b | 5.96 ± 1.0 b | |

| A × B | Camelina 0 | 51.75 ± 0.2 d | 20.97 ± 0.1 | 74.74 ± 0.1 a | 4.30 ± 0.01 d |

| Camelina 60 | 57.05 ± 0.7 ab | 20.78 ± 0.02 | 74.19 ± 0.1 b | 5.03 ± 0.1 c | |

| Camelina 120 | 57.64 ± 0.03 a | 20.94 ± 0.2 | 74.03 ± 0.2 bc | 5.03 ± 0.06 c | |

| Crambe 0 | 55.68 ± 0.2 c | 19.67 ± 0.2 | 73.42 ± 0.2 cd | 6.91 ± 0.003 b | |

| Crambe 60 | 55.47 ± 0.2 c | 19.62 ± 0.2 | 73.27 ± 0.05 d | 7.11 ± 0.1 a | |

| Crambe 120 | 56.47 ± 0.5 b | 19.39 ± 0.07 | 73.72 ± 0.07 c | 6.90 ± 0.02 b | |

| Mean | - | 55.68 ± 2.0 | 20.23 ± 0.7 | 73.89 ± 0.5 | 5.88 ± 1.2 |

| Source of Variation | C (% d.m.) | H (% d.m.) | S (% d.m.) | N (% d.m.) | Cl (% d.m.) | |

|---|---|---|---|---|---|---|

| Species (A) | Camelina | 51.70 ± 0.7 a | 6.50 ± 0.1 a | 0.284 ± 0.013 a | 1.27 ± 0.03 | 0.097 ± 0.01 b |

| Crambe | 49.73 ± 0.4 b | 6.32 ± 0.05 b | 0.216 ± 0.006 b | 1.27 ± 0.14 | 0.531 ± 0.06 a | |

| N rate (B) | 0 | 51.03 ± 1.4 | 6.44 ± 0.1 a | 0.249 ± 0.038 | 1.19 ± 0.1 a | 0.312 ± 0.3 b |

| 60 | 50.34 ± 0.9 | 6.34 ± 0.04 b | 0.254 ± 0.048 | 1.29 ± 0.06 b | 0.343 ± 0.3 a | |

| 120 | 50.79 ± 1.2 | 6.44 ± 0.2 a | 0.246 ± 0.028 | 1.33 ± 0.04 c | 0.288 ± 0.2 c | |

| A × B | Camelina N0 | 52.21 ± 0.6 | 6.56 ± 0.02 a | 0.284 ± 0.008 ab | 1.29 ± 0.01 b | 0.083 ± 0.006 d |

| Camelina N60 | 51.02 ± 0.6 | 6.34 ± 0.01 b | 0.297 ± 0.008 a | 1.23 ± 0.01 c | 0.095 ± 0.006 d | |

| Camelina N120 | 51.88 ± 0.02 | 6.59 ± 0.1 a | 0.271 ± 0.008 b | 1.29 ± 0.01 b | 0.112 ± 0.006 b | |

| Crambe N0 | 49.85 ± 0.2 | 6.33 ± 0.02 b | 0.215 ± 0.003 c | 1.09 ± 0.01 d | 0.540 ± 0.006 b | |

| Crambe N60 | 49.67 ± 0.7 | 6.33 ± 0.06 b | 0.210 ± 0.002 c | 1.35 ± 0.01 a | 0.590 ± 0.006 a | |

| Crambe N120 | 49.69 ± 0.5 | 6.29 ± 0.05 b | 0.222 ± 0.004 c | 1.36 ± 0.01 a | 0.463 ± 0.006 b | |

| Mean | - | 50.72 ± 1.2 | 6.41 ± 0.1 | 0.250 ± 0.037 | 1.27 ± 0.10 | 0.314 ± 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krzyżaniak, M.; Stolarski, M.J.; Graban, Ł.; Lajszner, W.; Kuriata, T. Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy. Energies 2020, 13, 1503. https://doi.org/10.3390/en13061503

Krzyżaniak M, Stolarski MJ, Graban Ł, Lajszner W, Kuriata T. Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy. Energies. 2020; 13(6):1503. https://doi.org/10.3390/en13061503

Chicago/Turabian StyleKrzyżaniak, Michał, Mariusz J. Stolarski, Łukasz Graban, Waldemar Lajszner, and Tomasz Kuriata. 2020. "Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy" Energies 13, no. 6: 1503. https://doi.org/10.3390/en13061503

APA StyleKrzyżaniak, M., Stolarski, M. J., Graban, Ł., Lajszner, W., & Kuriata, T. (2020). Camelina and Crambe Oil Crops for Bioeconomy—Straw Utilisation for Energy. Energies, 13(6), 1503. https://doi.org/10.3390/en13061503