Uncertainty and Sensitivity Analysis of the In-Vessel Hydrogen Generation for Gen-III PWR and Phebus FPT-1 with MELCOR 2.2

Abstract

:1. Introduction

1.1. Hydrogen during a Severe Accident

1.2. Scope and Motivation

2. Methodology

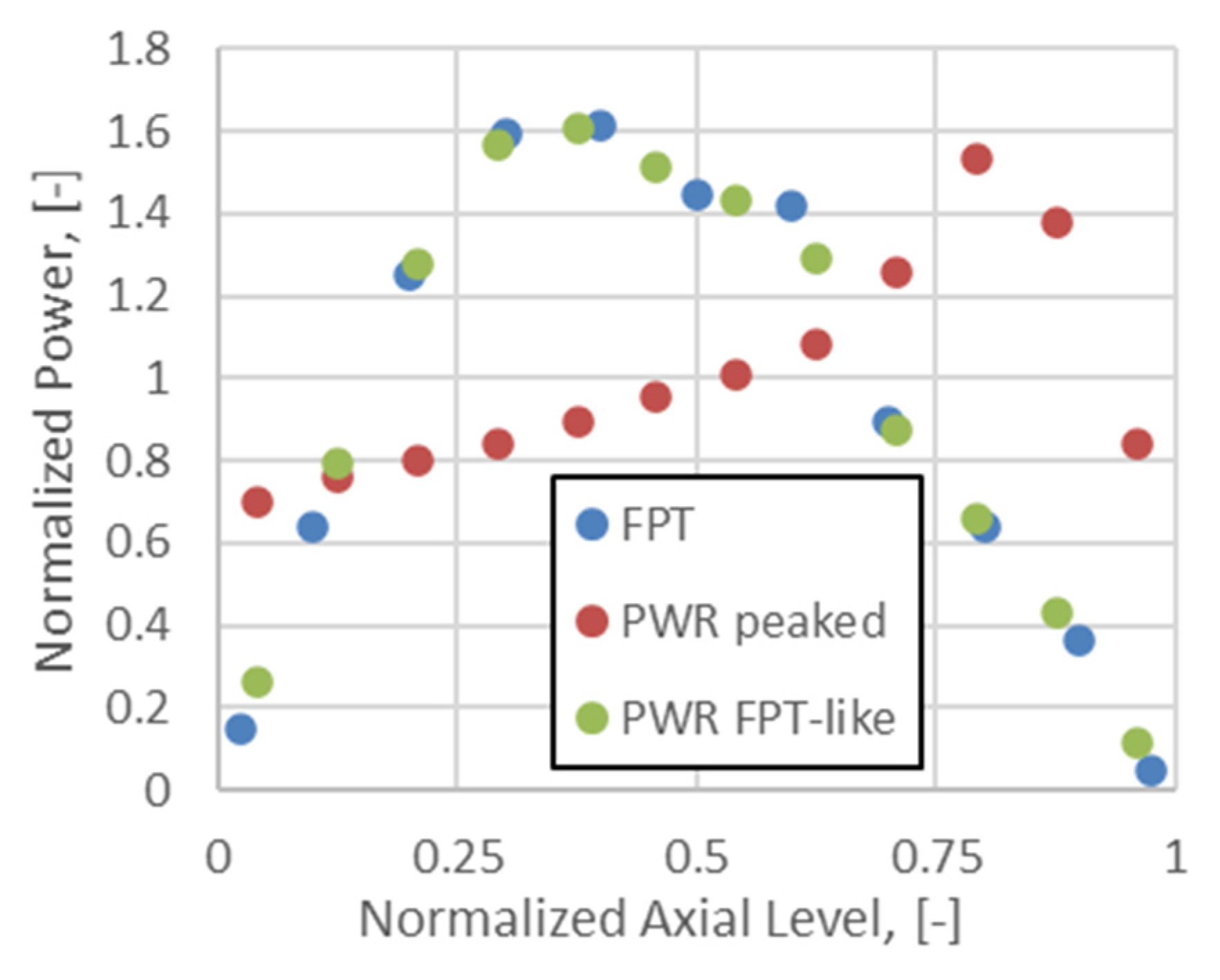

2.1. Phébus FPT-1 Model

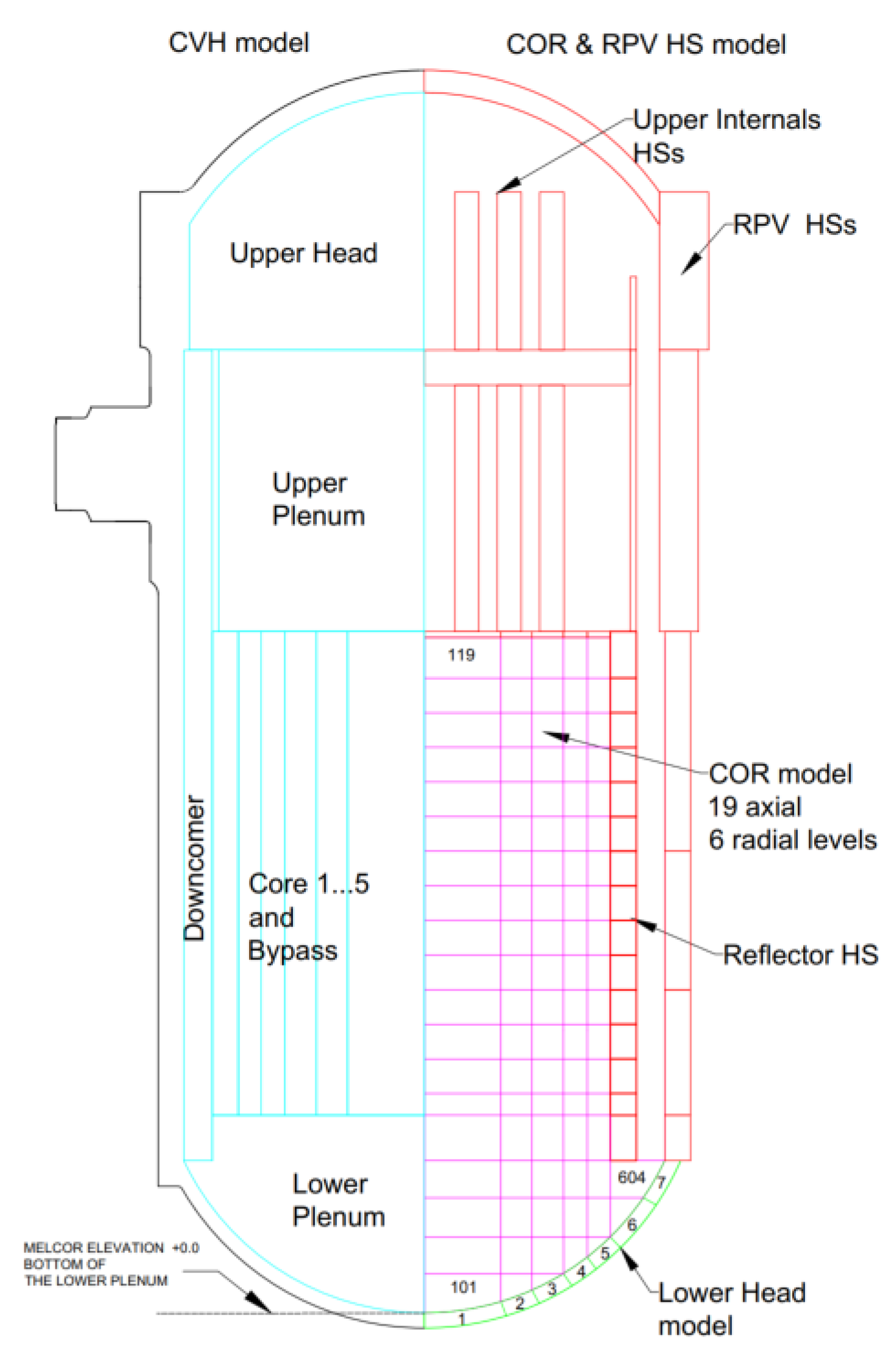

2.2. Gen-III PWR Model

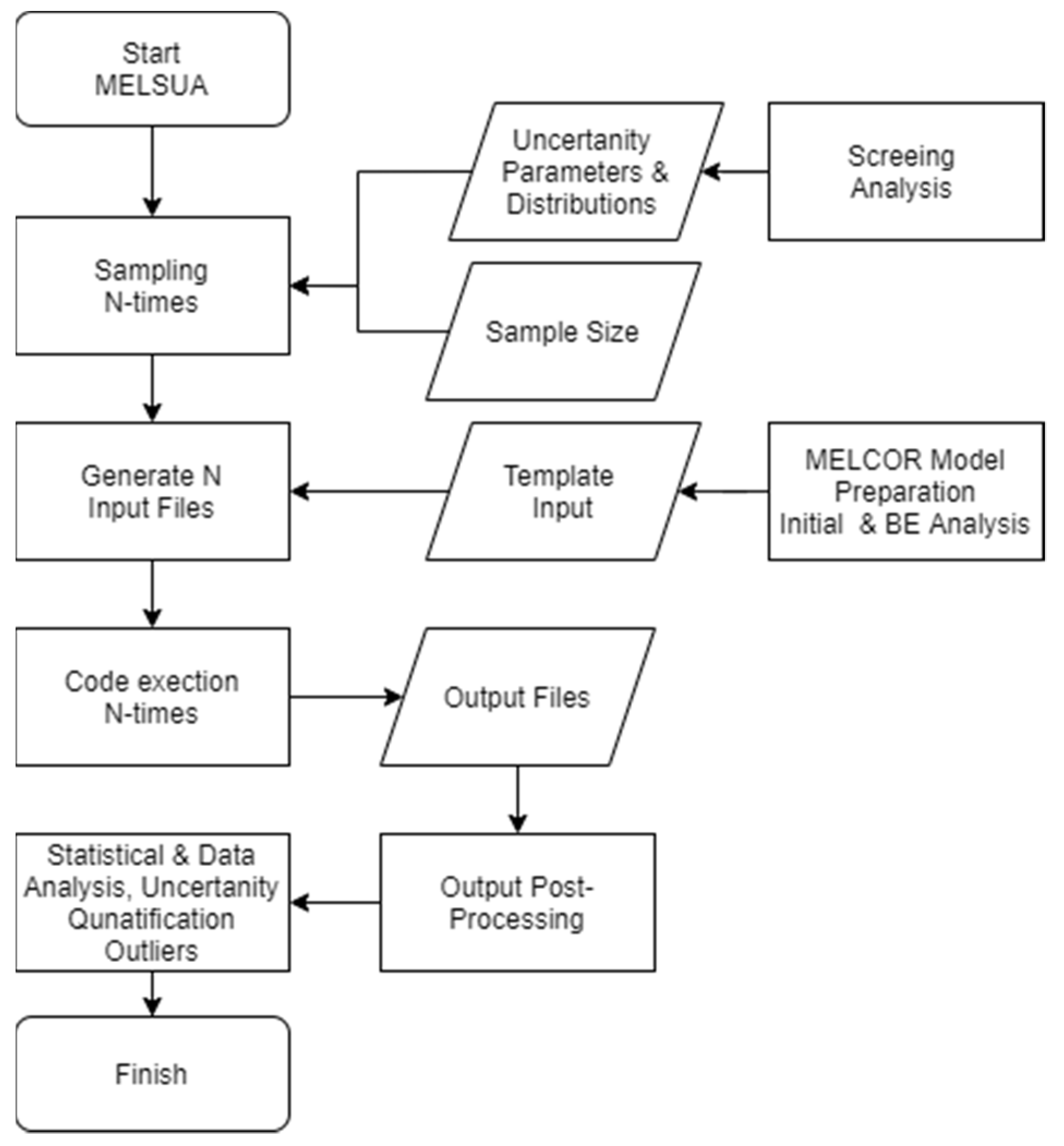

2.3. Uncertainty and Sensitivity Analysis Methodology

2.4. Studied Parameters and MELCOR Modelling

2.4.1. Studied Parameters

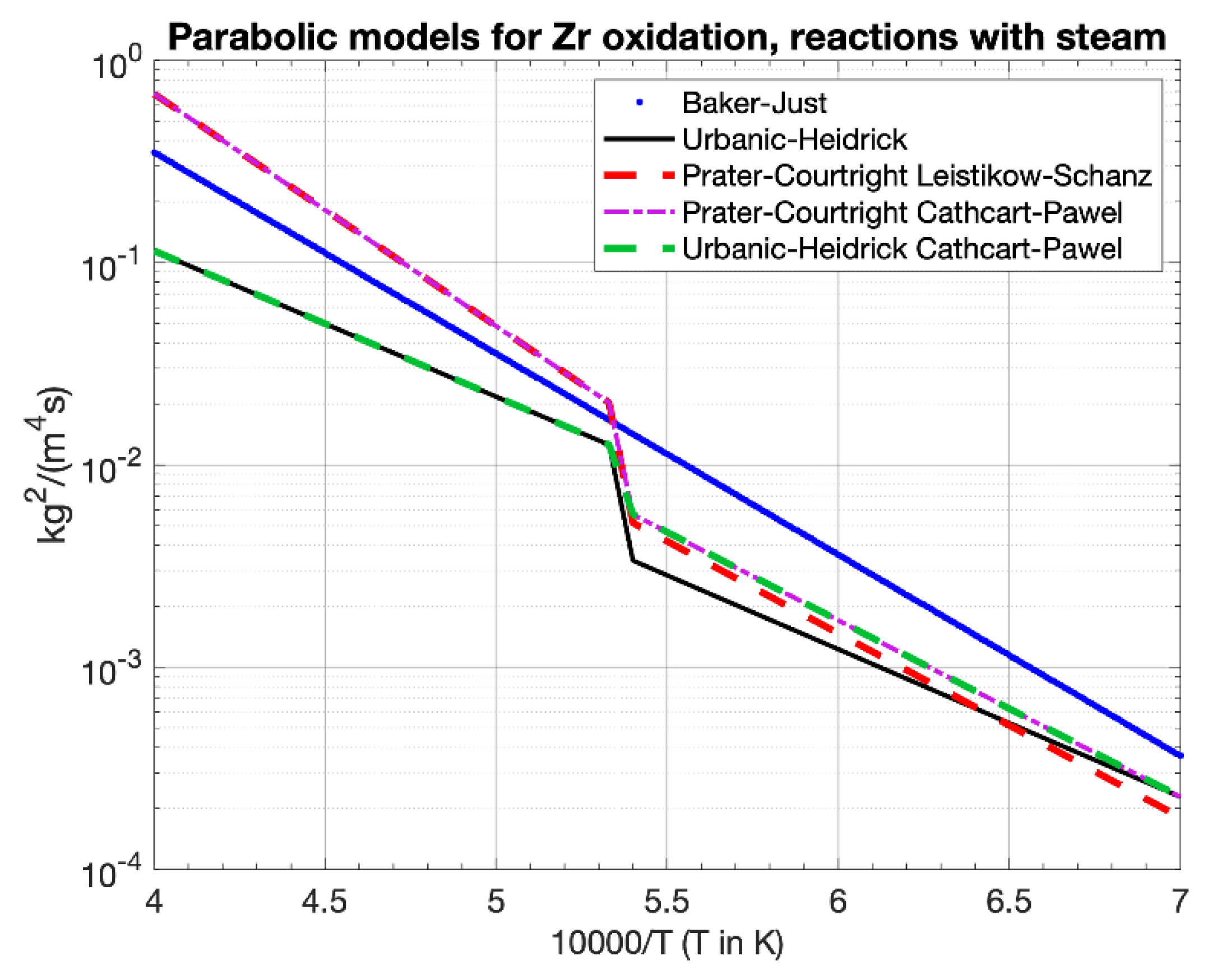

2.4.2. Zircaloy–Steam Oxidation Correlation—SC1001

2.4.3. Zircalloy Melt Breakout Temperature—SC1131 (2)

2.4.4. Fuel Rod Collapse Temperature—SC1132 (1)

2.4.5. Fractional Dissolution of materials—FUOZR and FSXSS

2.4.6. Candling/Refreezing HTC—HFRZZR and HFRZSS

2.4.7. Debris Diameter—DHYPD and DHYPDLP

2.4.8. Debris Porosity—PORDP

2.4.9. Radiation Exchange Factors—FCELA and FCELR

2.4.10. In-Vessel Falling Debris HTC—HDBH2O

2.4.11. Time-at-Temperature Model—IRODDAMAGE

2.4.12. Interactive Model Melting/Eutectic Temperature—TMLT

2.4.13. Maximum Melt Flow Rate after Breakthrough—SC1141 (2)

3. Results and Discussion

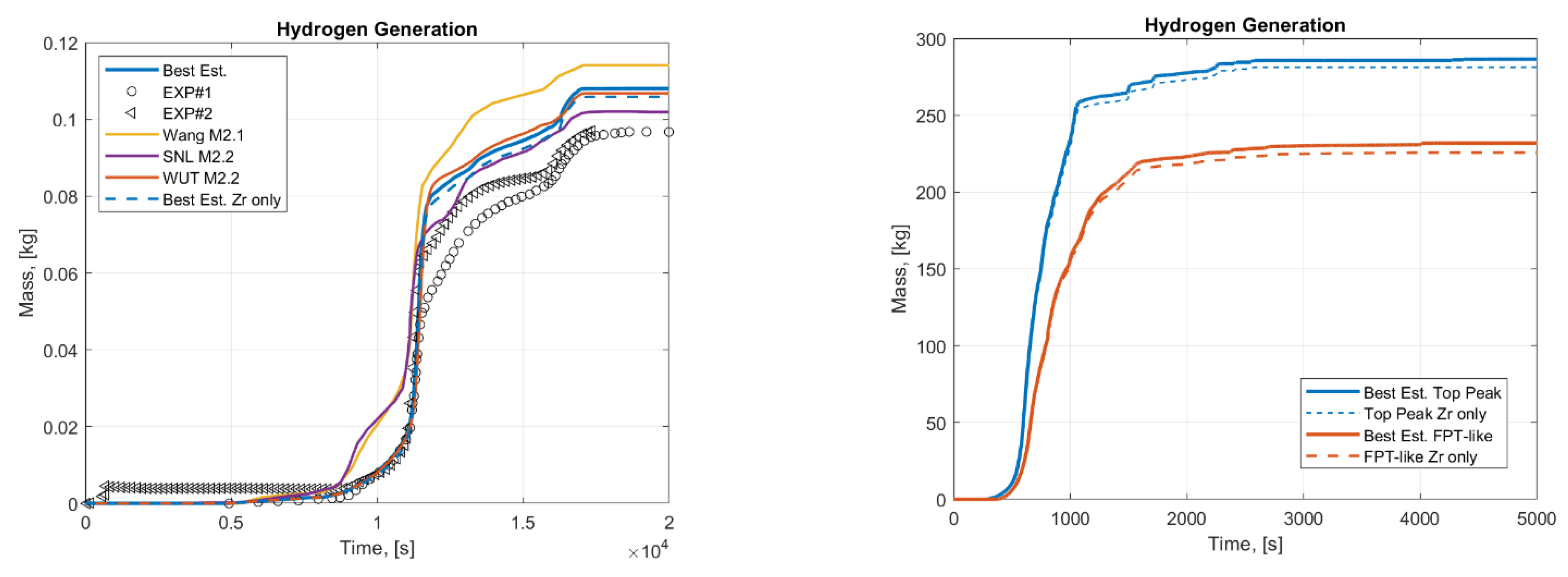

3.1. Best Estimate Results

3.1.1. BE Results for FPT-1

3.1.2. BE Results for PWR

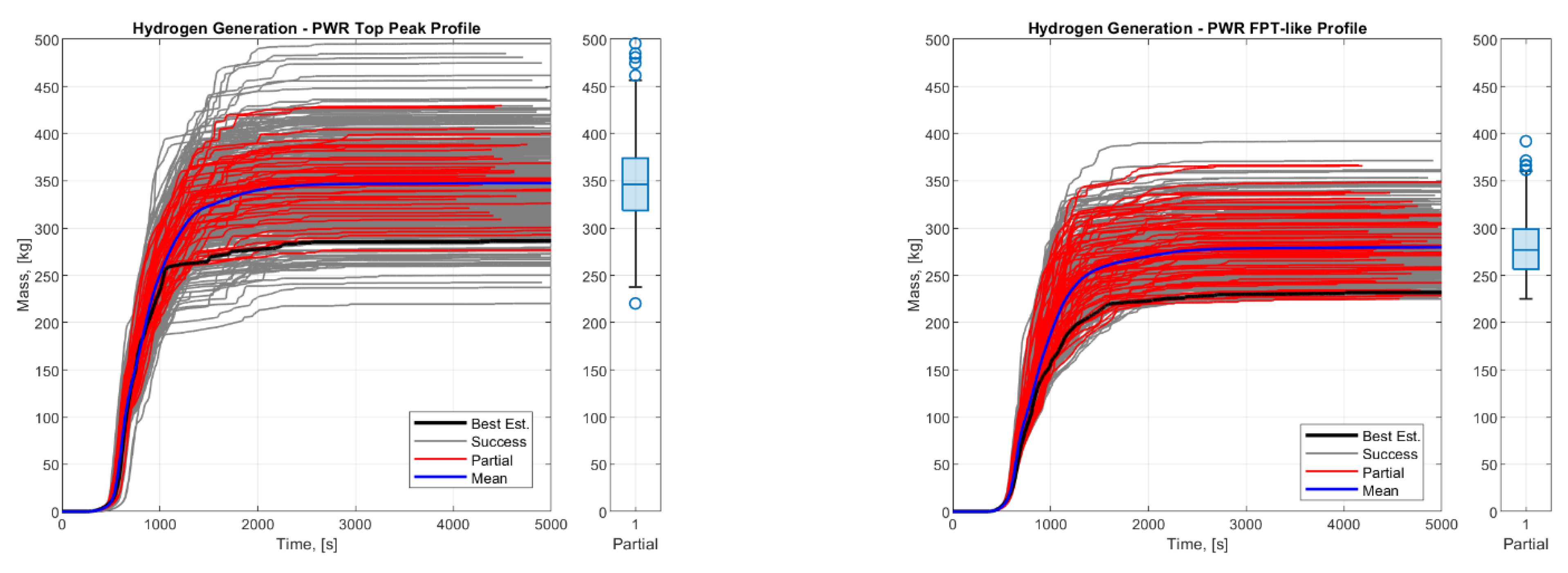

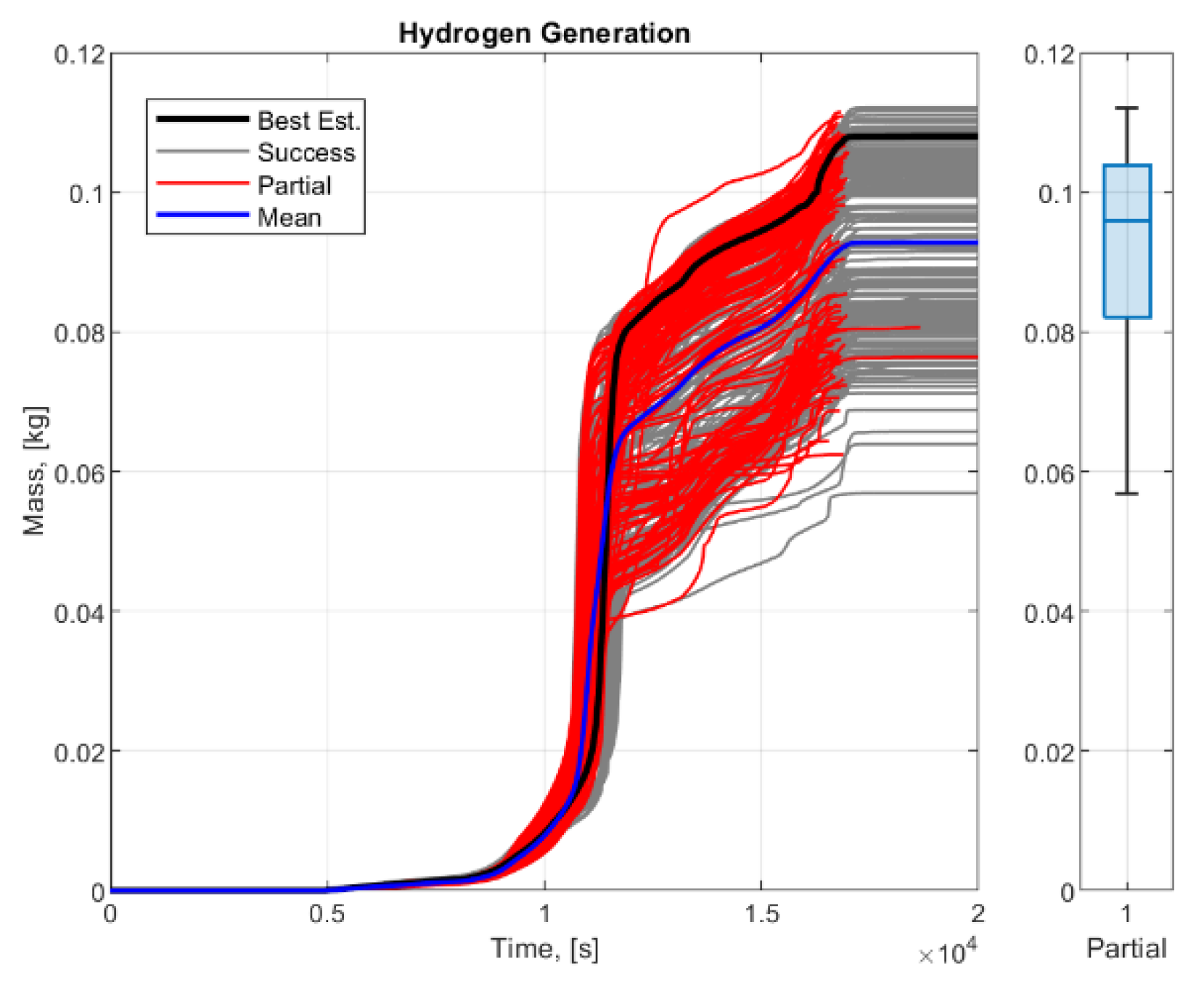

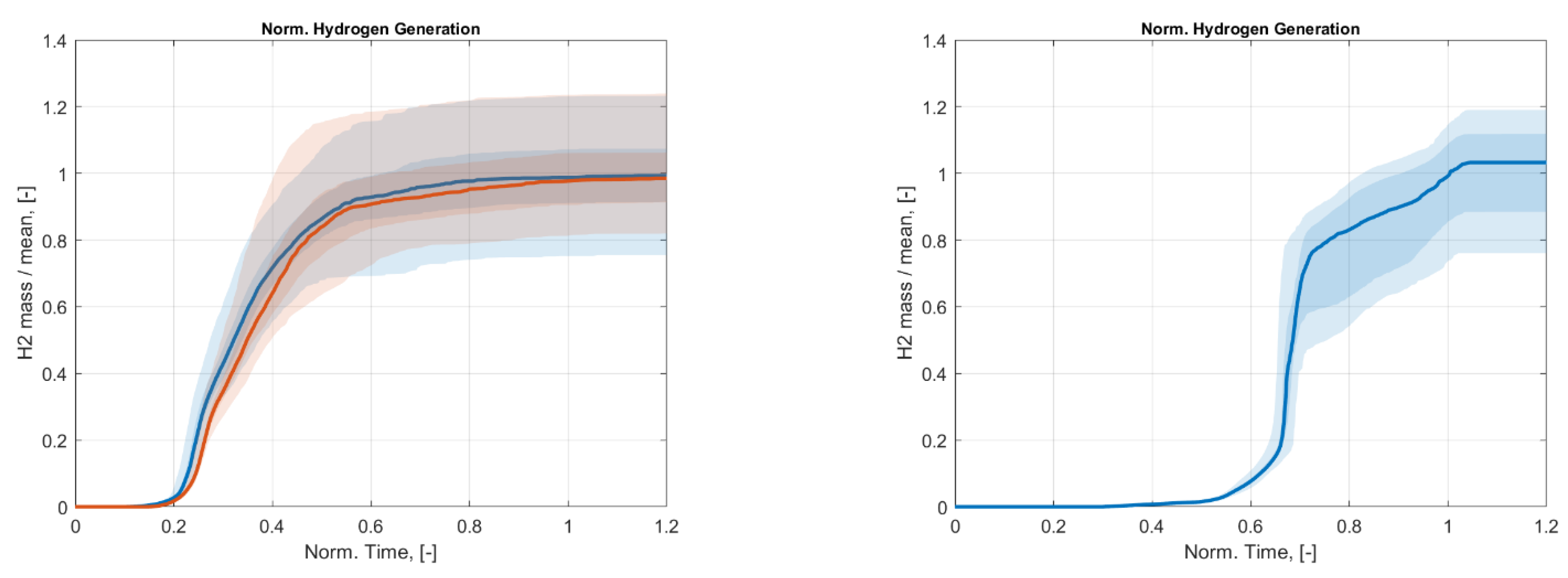

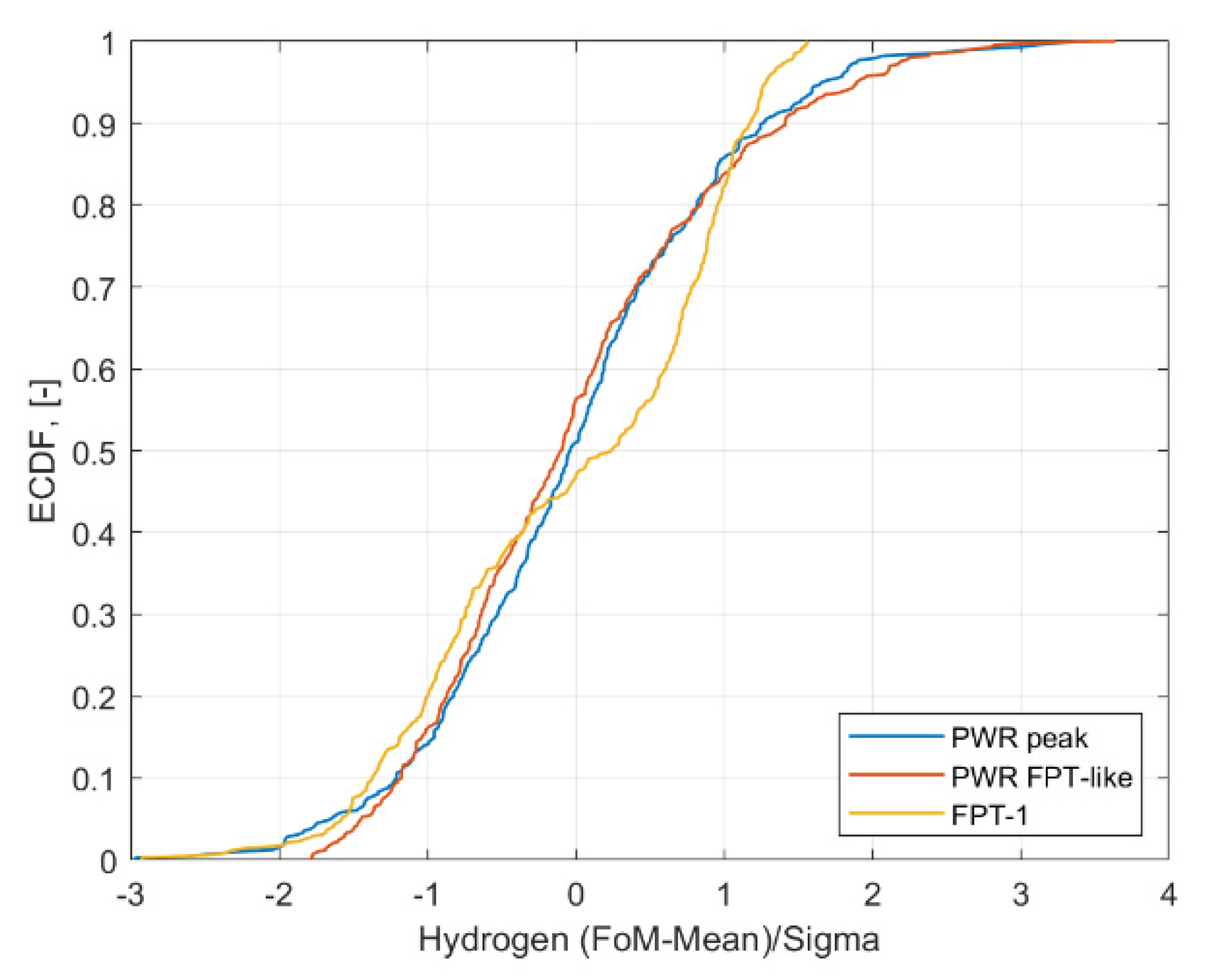

3.2. Uncertainty Analysis

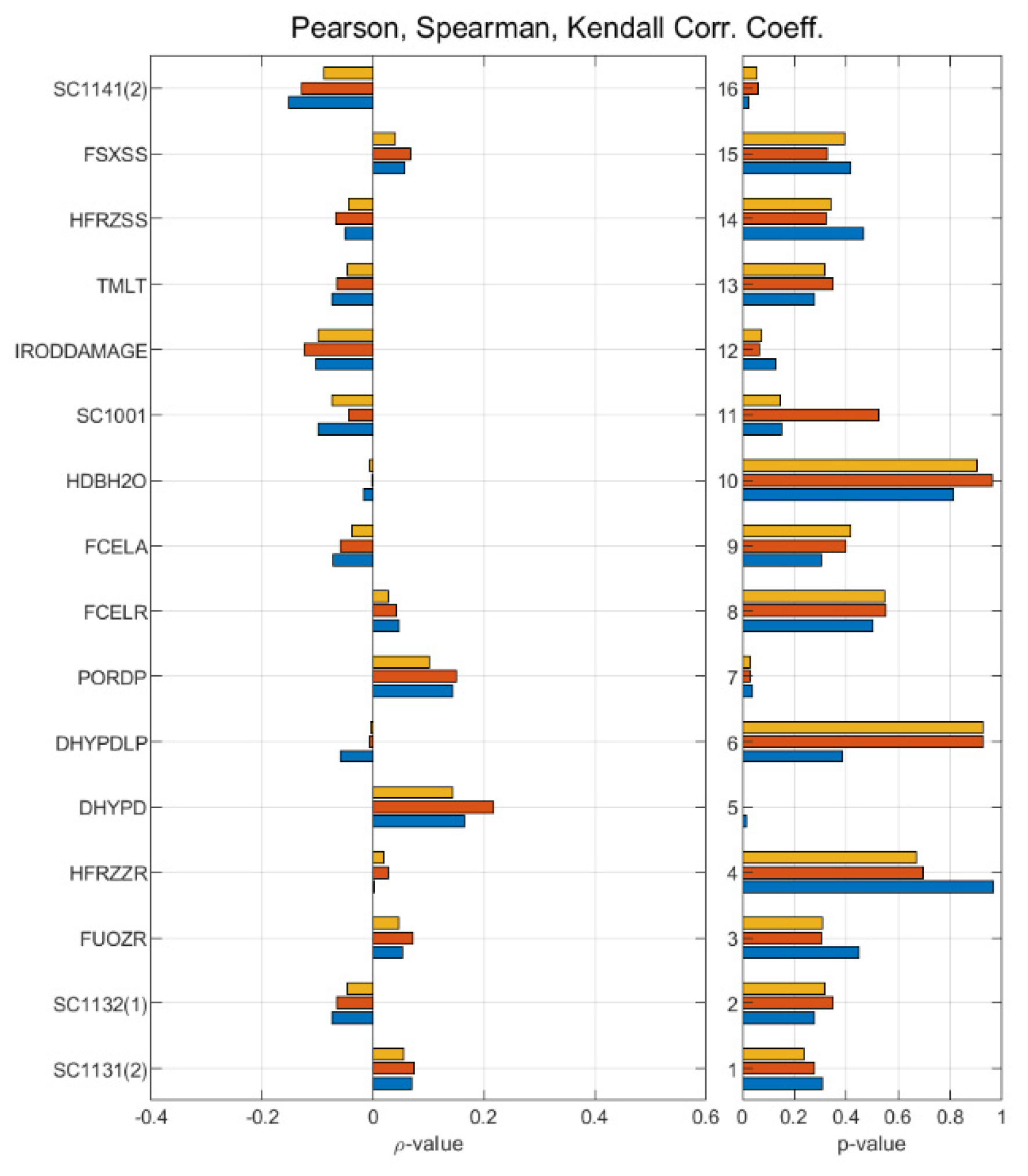

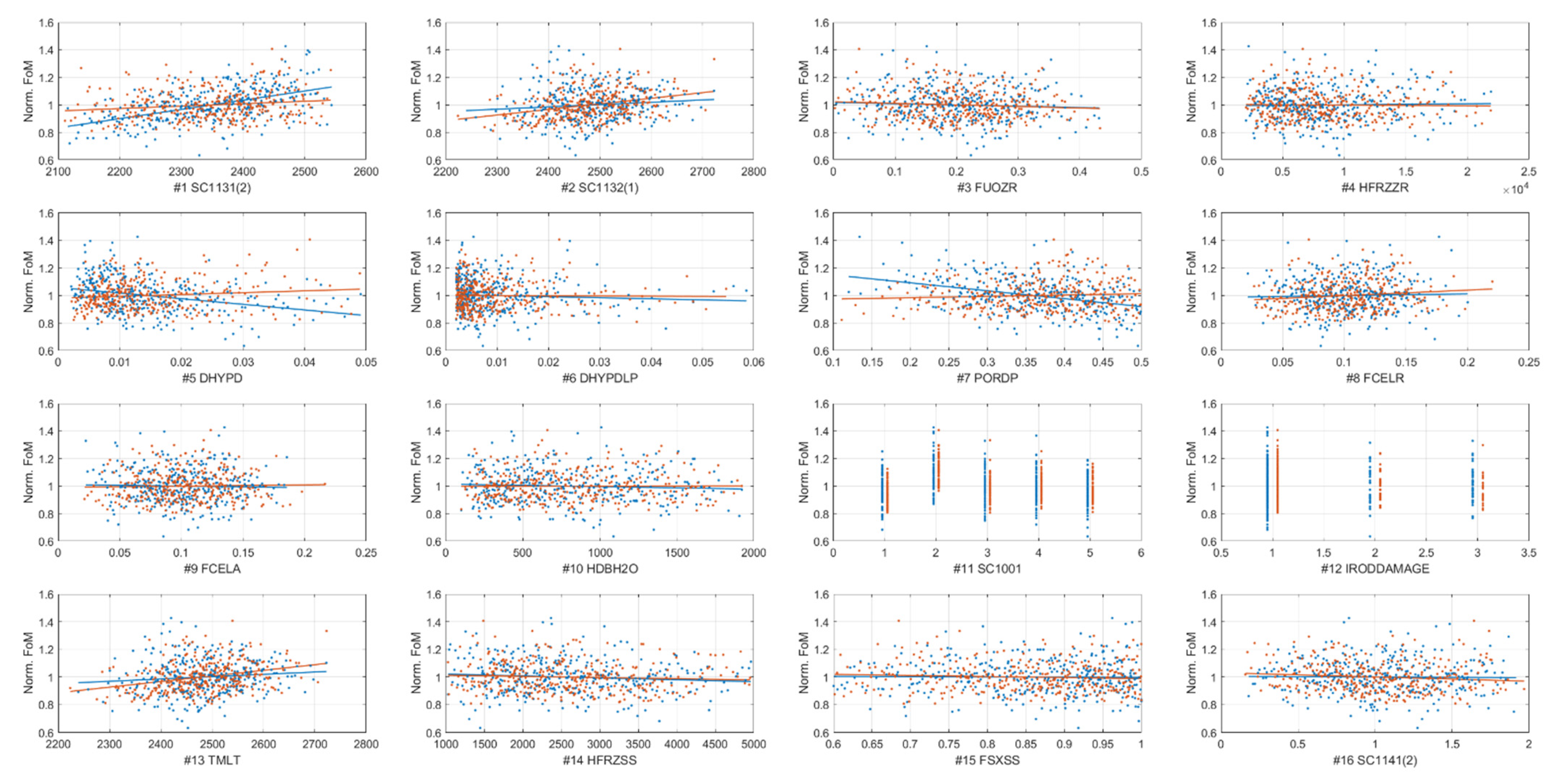

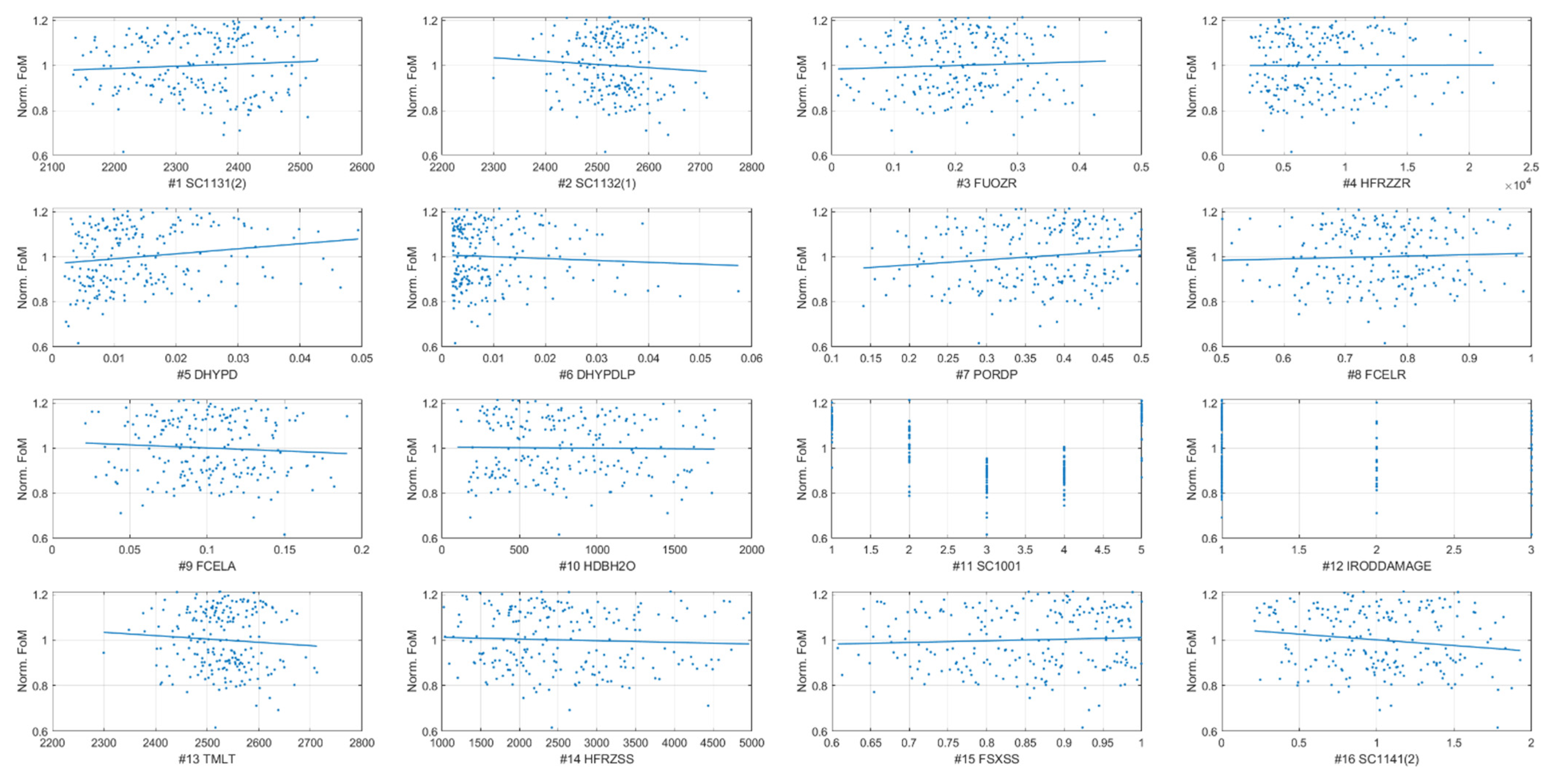

3.3. Sensitivity Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Sehgal, B.R. Nuclear Safety in Light Water Reactors Severe Accident Phenomenology; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- IRSN. Nuclear Power Reactor Core Melt Accidents; EDP Sciences: Paris, France, 2015.

- Lee, J.C.; McCormick, N.J. Risk and Safety Analysis of Nuclear Systems; Wiley and Sons: New York, NY, USA, 2011. [Google Scholar]

- IAEA. IAEA-TECDOC-1797 Accident Tolerant Fuel Concepts for Light Water Reactors; International Atomic Energy Agency: Vienna, Austria, 2016. [Google Scholar]

- Dehjourian, M.; Sayareh, R.; Rahgoshay, M.; Jahanfarnia, G.; Shirani, A.S.; Sayyareh, R. Investigation of a Hydrogen Mitigation System During Large Break Loss-of-Coolant Accident for a Two-Loop Pressurized Water Reactor. Nucl. Eng. Technol. 2016, 48, 1174–1183. [Google Scholar] [CrossRef] [Green Version]

- Gharari, R.; Kazeminejad, H.; Kojouri, N.M.; Hedayat, A.; Vand, M.H. Application of a severe accident code to the sensitivity and uncertainty analysis of hydrogen production in the WWER1000/V. Ann. Nucl. Energy 2021, 152, 108018. [Google Scholar] [CrossRef]

- Gharari, R.; Kazeminejad, H.; Kojouri, N.M.; Hedayat, A. A review on hydrogen generation, explosion, and mitigation during severe accidents in light water nuclear reactors. Int. J. Hydrogen Energy 2018, 43, 1939–1965. [Google Scholar] [CrossRef]

- Gharari, R.; Kazeminejad, H.; Kojouri, N.M.; Hedayat, A.; Vand, M.H.; Abadi, M.N.A.; Safarzadeh, O. Study the effects of various parameters on hydrogen production in the WWER1000/V. Prog. Nucl. Energy 2020, 124, 103370. [Google Scholar] [CrossRef]

- Foad, B.; Hassan, M.; Takeda, T. Uncertainty & sensitivity analyses for LOCA simulation of PHEBUS experiment FPT-1 using a modified SUNSET code. Ann. Nucl. Energy 2020, 144, 107575. [Google Scholar] [CrossRef]

- Galushin, S.; Kudinov, P. Sensitivity and uncertainty analysis of the vessel lower head failure mode and melt release conditions in Nordic BWR using MELCOR code. Ann. Nucl. Energy 2020, 135, 106976. [Google Scholar] [CrossRef]

- Itoh, H.; Zheng, X.; Tamaki, H.; Maruyama, Y. Influence of In-Vessel Melt Progression on Uncertainty of Source Term during a Severe Accident. In Proceedings of the ICONE22-2014 22nd International Conference on Nuclear Engineering, Prague, Czech Republic, 7–11 July 2014. [Google Scholar] [CrossRef]

- Saghafi, M.; Yousefpour, F.; Karimi, K.; Hoseyni, S.M. Determination of PAR configuration for PWR containment design: A hydrogen mitigation strategy. Int. J. Hydrogen Energy 2017, 42, 7104–7119. [Google Scholar] [CrossRef]

- Di Giuli, M.; Malicki, M.; Dejardin, P.; Corda, V.; Swaidan, A. MELCOR 2.2-ASTEC V2.2 crosswalk study reproducing SBLOCA and CSBO scenarios in a PWR1000-like reactor part I: Analysis of RCS thermal-hydraulics and in-vessel phenomena. Nucl. Eng. Des. 2021, 111248. [Google Scholar] [CrossRef]

- Darnowski, P.; Skrzypek, E.; Mazgaj, P.; Świrski, K.; Gandrille, P. Total loss of AC power analysis for EPR reactor. Nucl. Eng. Des. 2015, 289, 8–18. [Google Scholar] [CrossRef]

- EPRI. Modular Accident Analysis Program (MAAP)—MELCOR Crosswalk—Phase 1 Study; EPRI Report 3002004449; Electric Power Research Institute: Palo Alto, CA, USA, 2014. [Google Scholar]

- Luxat, D.L.; Kalanich, D.A.; Hanophy, J.T.; Gauntt, R.O.; Wachowiak, R.M. MAAP-MELCOR Crosswalk Phase 1 Study. Nucl. Technol. 2016, 196, 684–697. [Google Scholar] [CrossRef]

- De Luze, O.; Haste, T.; Barrachin, M.; Repetto, G. Early phase fuel degradation in Phébus FP: Initiating phenomena of degradation in fuel bundle tests. Ann. Nucl. Energy 2013, 61, 23–35. [Google Scholar] [CrossRef]

- Clement, B.; Haste, T.; Krausmann, E.; Dickinson, S.; Gyenes, G.; Duspiva, J.; De Rosa, F.; Paci, S.; Martín-Fuertes, F.; Scholytssek, W.; et al. Thematic network for a Phebus FPT1 international standard problem (THENPHEBISP). Nucl. Eng. Des. 2005, 235, 347–357. [Google Scholar] [CrossRef]

- Grégoire, A.-C.; Haste, T. Material release from the bundle in Phébus FP. Ann. Nucl. Energy 2013, 61, 63–74. [Google Scholar] [CrossRef]

- Dubourg, R.; Faure-Geors, H.; Nicaise, G.; Barrachin, M. Fission product release in the first two PHEBUS tests FPT0 and FPT. Nucl. Eng. Des. 2005, 235, 2183–2208. [Google Scholar] [CrossRef]

- Shwarz, C. Foreword—Final Seminar Phebus Project. Ann. Nucl. Energy 2013, 61, 1–3. [Google Scholar] [CrossRef]

- Clément, B.; Zeyen, R. The objectives of the Phébus FP experimental programme and main findings. Ann. Nucl. Energy 2013, 61, 4–10. [Google Scholar] [CrossRef]

- Spirzewski, M.; Domitr, P.; Darnowski, P. Global uncertainty and sensitivity analysis of MELCOR and TRACE critical flow models against MARVIKEN tests. Nucl. Eng. Des. 2021, 378, 111150. [Google Scholar] [CrossRef]

- Domitr, P.; Darnowski, P.; Spirzewski, M. The Assessment of Critical Flow Models of MELCOR2.2 and TRACE V5.0 Patch 5 against Marviken Critical Flow Tests. In Proceedings of the 18th International Topical Meeting on Nuclear Reactor Thermal Hydraulics NURETH 2019, Portland, OR, USA, 18–23 August 2019. [Google Scholar]

- Stano, P.M.; Spirzewski, M. Modular global uncertainty analysis of event-driven indicators of system’s availability. In Proceedings of the ESREL 2018, Trondheim, Norway, 17–21 June 2018. [Google Scholar] [CrossRef]

- Spirzewski, M.; Anglart, H.; Stano, P.M. Uncertainty and sensitivity analysis of a phenomenological dryout model implemented in DARIA system code. Nucl. Eng. Des. 2019, 355, 110281. [Google Scholar] [CrossRef]

- NARSIS. NARSIS Project. 2021. Available online: www.narsis.eu (accessed on 5 July 2021).

- Mazgaj, P.; Darnowski, P.; Niewinski, G. Uncertainty Analysis of the Hydrogen Production in the PHEBUS FPT-1. In Proceedings of the 28th International Conference Nuclear Energy for New Europe, Portoroz, Slovenia, 9–12 September 2019; pp. 1–8. [Google Scholar]

- Darnowski, P.; Włostowski, M.; Stępień, M.; Niewiński, G. Study of the material release during PHÉBUS FPT-1 bundle phase with MELCOR 2.2. Ann. Nucl. Energy 2020, 148, 107700. [Google Scholar] [CrossRef]

- Clement, B.; Haste, T. Thematic Network for a Phebus FPT-1 International Standard Problem—Comparison Report on International Standard Problem ISP-46; OECD/NEA Report; OECD Nuclear Energy Agency: Issy-les-Moulineaux, France, 2003. [Google Scholar]

- Bruneliere, H.; Barry, T.; Brandelet, J.Y.; Perrichon, L.; Duflot, N.; Guigeno, Y.; Darnowski, P.; Mazgaj, P.; Stępień, M. NARSIS WP4.1: Definition of a Simplified Theoretical NPP Representative of the European Fleet; Horizon 2020 Project Report; European Commission: Brussels, 2018. [Google Scholar]

- Darnowski, P.; Mazgaj, P.; Skrzypek, E. MELCOR Simulations of the SBO in Gen III PWR with EVMR. In Proceedings of the 28th International Conference Nuclear Energy for New Europe, Portoroz, Slovenia, 9–12 September 2019; pp. 1–8. [Google Scholar]

- Darnowski, P.; Skrzypek, E.; Mazgaj, P.; Gatkowski, M. Simulations of Large Break Loss of Coolant Accident without Safety Injection for EPR Reactor using MELCOR Computer Code. In Proceedings of the European Review Meeting on Severe Accident Research ERSMAR-2015, Marsille, France, 24–26 March 2015; pp. 24–26. [Google Scholar]

- Darnowski, P. MelSUA—MELCOR Senstivity and Uncertanity Toolbox, GitLab Repository. 2021. Available online: https://gitlab.com/darczu/x-core/-/tree/master/Modules/MLC_package/SenstivityUncertanityAnalysis (accessed on 6 July 2021).

- Gauntt, R.O.; Bixler, N.E.; Wagner, K.C. An Uncertainty Analysis of the Hydrogen Source Term for A Station Blackout Accident in Sequoyah using MELCOR 1.8.5; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 2014. [CrossRef]

- Glaeser, H. GRS Method for Uncertainty and Sensitivity Evaluation of Code Results and Applications. Sci. Technol. Nucl. Install. 2008, 2008, 798901. [Google Scholar] [CrossRef] [Green Version]

- Perez, M.; Reventos, F.; Batet, L.; Guba, A.; Tóth, I.; Mieusset, T.; Bazin, P.; de Crécy, A.; Borisov, S.; Skorek, T.; et al. Uncertainty and sensitivity analysis of a LBLOCA in a PWR Nuclear Power Plant: Results of the Phase V of the BEMUSE programme. Nucl. Eng. Des. 2011, 241, 4206–4222. [Google Scholar] [CrossRef]

- Wilks, S.S. Determination of Sample Sizes for Setting Tolerance Limits. Ann. Math. Stat. 1941, 12, 91–96. [Google Scholar] [CrossRef]

- U.S. NRC. State-of-the-Art Reactor Consequence Analyses Project Volume 1: Peach Bottom Integrated Analysis; NUREG/CR-7110; SOARCA: Washington, DC, USA, 2013; Volume 1.

- Saltelli, A.; Ratto, M.; Andres, T.; Campolongo, F.; Cariboni, J.; Gatelli, D.; Saisana, M.; Tarantola, S. Global Sensitivity Analysis: The Primer; Wiley and Sons: New York, NY, USA, 2007. [Google Scholar] [CrossRef] [Green Version]

- CSNI. OECD/CSNI Workshop on Best Estimate Methods and Uncertainty Evaluations. 2013. Available online: https://www.oecd-nea.org/nsd/docs/2013/csni-r2013-8-part2.pdf (accessed on 10 May 2021).

- Sandia National Laboratories. MELCOR 2.2 Computer Code Manual—Volume 1: Primer and Users’ Guide; Sandia National Laboratories Report; Sandia National Laboratories: Albuquerque, NM, USA, 2017.

- Darnowski, P. X-Core Nuclear Engineering Matlab Toolbox, GitLab Repostory. 2021. Available online: https://gitlab.com/darczu/x-core (accessed on 6 July 2021).

- Gauntt, R.O. Uncertainty Analyses Using the MELCOR Severe Accident Analysis Code. In Proceedings of the OECD Workshop Evaluation of Uncertainties in Relation to Severe Accidents and Level-2 Probabilistic Safety Analysis, Aix-En-Provence, France, 7–9 November 2005. [Google Scholar]

- U.S. NRC. State-of-the-Art Reactor Consequence Analyses Project—Uncertainty Analysis of the Unmitigated Long-Term Station Blackout of the Peach Bottom Atomic Power Station; NUREG/CR-7155; SOARCA: Washington, DC, USA, 2018.

- Esmaili, H. NRC Severe Accident & MELCOR Activities, 10th Eur. MELCOR User Gr. Meet. 2018. Available online: https://www.psi.ch/emug/Emug2018EN/EMUG_2018_02.pdf (accessed on 10 May 2021).

- Urbanic, V.; Heidrick, T. High-temperature oxidation of zircaloy-2 and zircaloy-4 in steam. J. Nucl. Mater. 1978, 75, 251–261. [Google Scholar] [CrossRef]

- Baker, L.; Just, L.C. Studies of Metal-Water Reactions at High Temperatures, III. Experimental-and Theoretical Studies of the Zirconium-Water Reaction—Argonne National Laboratory Report ANL-6548; Argonne National Laboratory: Argonne, IL, USA, 1962.

- Prater, J.T.; Courtright, E.L. NUREG/CR-4889—Zircaloy-4 oxidation at 1300 to 2400 °C; Nuclear Regulatory Commission: Washington, DC, USA, 1987.

- Leistikow, S.; Schanz, G. Oxidation kinetics and related phenomena of zircaloy-4 fuel cladding exposed to high temperature steam and hydrogen-steam mixtures under PWR accident conditions. Nucl. Eng. Des. 1987, 103, 65–84. [Google Scholar] [CrossRef]

- Cathcart, J.; Pawel, R.E.; McKee, R.A.; Druschel, R.E.; Yurek, G.J.; Campbell, J.J.; Jury, S.H. ORNL/NUREG-17—Zirconium Metal-Water Oxidation kinetics IV; Reaction Rate Studies; Nuclear Regulatory Commission: Washington, DC, USA, 1977.

- SNL. MELCOR Best Practices as Applied in the State-of-the-Art Reactor Consequence Analyses; NUREG/CR-7008; Nuclear Regulatory Commission: Washington, DC, USA, 2014.

- Sandia National Laboratories. Draft State-of-the-Art Reactor Consequence Analyses Project—Uncertainty Analysis of the Unmitigated Short-Term Station Blackout of the Surry Power Station; Sandia National Laboratories Report; Sandia National Laboratories: Albuquerque, NM, USA, 2015.

- Galushin, S.; Kudinov, P. Sensitivity Analysis of the Vessel Lower Head Failure in Nordic BWR Using MELCOR Code. In Proceedings of the Probabilistic Safety Assessment and Management PSAM 14, Los Angeles, CA, USA, 16–21 September 2018. [Google Scholar]

- SNL. MELCOR 2.1 Computer Code Manual—Volume 3: MELCOR Assessment Problems; Sandia National Laboratories: Albuquerque, MN, USA, 2015.

- Tina Ghosh, S.; Mattie, P.D.; Gauntt, R.O.; Bixler, N.E.; Ross, K.W.; Sallaberry, C.J.; Osborn, D.M. SOARCA Peach Bottom Atomic Power Station Long-Term Station Blackout Uncertainty Analysis: Overview. In Proceedings of the Probabilistic Safety Assessment and Management PSAM 12, Honolulu, HI, USA, 22–27 June 2014. [Google Scholar]

- Humphries, L.L. MELCOR Code Development Status EMUG 2018—International Use of MELCOR, Presented by Larry Humphries during European MELCOR User Group Meeting (EMUG-2018), Zagreb, Croatia, April 25–27, 2018. Available online: https://www.psi.ch/sites/default/files/import/emug/Emug2018EN/EMUG_2018_01.pdf (accessed on 5 August 2021).

- Humphries, L.L. QUICKLOOK OVERVIEW OF CHANGES IN MELCOR 2.2: Rev 9496 to Rev 11932; Sandia National Laboratories: Albuquerque, NM, USA, 2018.

- Wang, J.; Wang, C.; Corradini, M.L.; Haskin, T.; Tian, W.; Su, G.; Qiu, S. PHEBUS FPT-1 simulation by using MELCOR and primary blockage model exploration. Nucl. Eng. Des. 2016, 307, 119–129. [Google Scholar] [CrossRef]

- Wang, J.; Corradini, M.L.; Fu, W.; Haskin, T.; Zhang, Y.; Tian, W.; Su, G.; Qiu, S. Simulation of the PHEBUS FPT-1 experiment using MELCOR and exploration of the primary core degradation mechanism. Ann. Nucl. Energy 2015, 85, 193–204. [Google Scholar] [CrossRef]

- Humphries, L.L. QUICKLOOK OVERVIEW OF CHANGES IN MELCOR 2.2: Rev 6342 to Rev 9496; Sandia National Laboratories: Albuquerque, NM, USA, 2018.

- Leonard, M.T.; Ashbaugh, S.G.; Cole, R.K.; Bergeron, K.D.; Nagashima, K. A direct comparison of MELCOR 1.8.3 and MAAP4 results for several PWR & BWR accident sequences. In Proceedings of the International Topical Meeting on Probabilistic Safety Assessment—Moving toward Risk Based Regulation, Park City, UT, USA, 29 September–3 October 1996; Available online: https://www.osti.gov/biblio/288425 (accessed on 1 May 2021).

- Ahn, K.-I.; Park, S.-Y.; Cho, S.-W. MELCOR 1.8.4 sensitivity analysis of the severe accident evolution during the APR 1400 LOCA. Ann. Nucl. Energy 2006, 33, 71–83. [Google Scholar] [CrossRef]

- Vierow, K.; Liao, Y.; Johnson, J.; Kenton, M.; Gauntt, R. Severe accident analysis of a PWR station blackout with the MELCOR, MAAP4 and SCDAP/RELAP5 codes. Nucl. Eng. Des. 2004, 234, 129–145. [Google Scholar] [CrossRef]

- SNL. MELCOR 1.8.5 Computer Code Manuals—Vol. 3: Demonstration Problems; Sandia National Laboratories: Albuquerque, NM, USA, 2000.

- Haste, T.; Birchley, J.; Cazzoli, E.; Vitazkova, J. Analysis of TMI-2 with MELCOR and SCDAPSIM. In Proceedings of the International Congress on Advances in Nuclear Power Plants 2005 ICAPP-05, Seoul, Korea, 15–19 May 2005. [Google Scholar]

- Šadek, D.; Grgi, Č.; Nikola, S. Analysis of In-Vessel Severe Accident Phenomena in NPP Krško Analysis of In-Vessel Severe Accident Phenomena in NPP Krško. In Proceedings of the 7th International Conference on Nuclear Option in Countries with Small and Medium Electricity Grids, Dubrovnik, Croatia, 25–29 May 2008. [Google Scholar]

- Zhao, N.; Chen, Y.; Ma, W.; Bechta, S.; Isaksson, P. A nodal sensitivity study of MELCOR simulation for severe accidents in a pressurized water reactor. Ann. Nucl. Energy 2021, 160, 108373. [Google Scholar] [CrossRef]

- Alexandra, A.E.; Gertman, E.; George, D.G.L.; Mesina, L. Uncertainty Analysis of RELAP5-3D. 2012. Available online: http://www.osti.gov/servlets/purl/1056002/ (accessed on 10 July 2021).

- Guo, Z.; Dailey, R.; Feng, T.; Zhou, Y.; Sun, Z.; Corradini, M.L.; Wang, J. Uncertainty analysis of ATF Cr-coated-Zircaloy on BWR in-vessel accident progression during a station blackout. Reliab. Eng. Syst. Saf. 2021, 213, 107770. [Google Scholar] [CrossRef]

- Joo, H.Y.; Kim, J.W.; Moon, J.H. Use of big data analysis to investigate the relationship between natural radiation dose rates and cancer incidences in Republic of Korea. Nucl. Eng. Technol. 2020, 52, 1798–1806. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation Coefficients. Anesthesia Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- Akoglu, H. User’s guide to correlation coefficients. Turk. J. Emerg. Med. 2018, 18, 91–93. [Google Scholar] [CrossRef] [PubMed]

- Freixa, J.; Kim, T.-W.; Manera, A. Post-test thermal-hydraulic analysis of two intermediate LOCA tests at the ROSA facility including uncertainty evaluation. Nucl. Eng. Des. 2013, 264, 153–160. [Google Scholar] [CrossRef]

- Zheng, X.; Itoh, H.; Tamaki, H.; Maruyama, Y. Source term uncertainty analysis: Probabilistic approaches and applications to a BWR severe accident. Mech. Eng. J. 2015, 2, 15-00032. [Google Scholar] [CrossRef] [Green Version]

- Gauntt, K.W.; Ross, D.M.; Osborn, C.J.; Sallaberry, A.S.; Goldmann, J.N.; Cardoni, P.D.; Mattie, S.T.; Ghosh, E.; Fuller, S.; Andrew, J.N.; et al. SOARCA Peach Bottom Atomic Power Station long-term station blackout uncertainty analysis: MELCOR parameters and probabilistic results. In Proceedings of the International Topical Meeting on Probabilistic Safety Assessment and Analysis, Columbia, SC, USA, 22–26 September 2013; Volume 2, pp. 1310–1326. [Google Scholar]

| Parameter | Gen-III PWR | FPT-1 |

|---|---|---|

| Thermal power | 4500 MWth | Maximum 34 kWth |

| Mass of uranium dioxide | ~144 tons | 10.4241 kg |

| Mass of zirconium | ~39 tons | 3.50435 kg |

| Maximum H2 due to Zr oxidation | ~1.7 tons | 0.154 kg |

| No | MELCOR Field Name | Unit | Type | Best Est. Value | Distribution | Distribution Parameters | Distribution Values | Truncation Limits |

|---|---|---|---|---|---|---|---|---|

| 1 | SC1131 (2) | (K) | Continuous | 2400.0 | Triangular | a, b, c | (2100.0, 2400.0, 2550.0) | No |

| 2 | SC1132 (1) | (K) | Continuous | 2500.0 | Normal | mu, sigma | (2479.0, 83.0) | No |

| 3 | FUOZR | (-) | Continuous | 0.2 | Normal | mu, sigma | (0.2, 0.09) | (0.0, 0.5) |

| 4 | HFRZZR | (W∙m−2∙K−1) | Continuous | 7500.0 | Lognormal | mu, sigma | (8.9227, 0.55962) (ln(7500), ln(1.75)) | (2000, 22,000) |

| 5 | DHYPD | (m) | Continuous | 0.01 | Lognormal | mu, sigma | (−4.4228, 0.69315) (ln(0.012), ln(2.0)) | (0.002, 0.05) |

| 6 | DHYPDLP | (m) | Continuous | 0.002 | Lognormal | mu, sigma | (−5.2983, 1.0986) (ln(0.005), ln(3)) | (0.0020, 0.060) |

| 7 | PORDP | (-) | Continuous | 0.4 | Normal | mu, sigma | (0.38, 0.1) | (0.10, 0.50) |

| 8 | FCELR | (-) | Continuous | 0.1 | Normal | mu, sigma | (0.1, 0.035) | (0.020, 0.30) |

| 9a | FCELA for FPT-1 | (-) | Continuous | 0.75 | Normal | mu, sigma | (0.75, 0.1) | (0.5, 1.0) |

| 9b | FCELA for PWR | (-) | Continuous | 0.1 | Normal | mu, sigma | (0.1, 0.035) | (0.02, 0.3) |

| 10 | HDBH2O | (W∙m−2∙K−1) | Continuous | 100.0 | Triangular | a, b, c | (100.0, 250.0, 2000.0) | No |

| 11 | SC1001 | (-) | Discrete | 1.0 | Discrete | 1,2,3,4,5 | p = (0.2 0.2 0.2 0.2 0.2) | No |

| 12 | IRODDAMAGE | (-) | Discrete | 1.0 | Discrete | 1,2,3 | p = (0.8 0.1 0.1) | No |

| 13 | TMLT | (K) | Equal | 2500.0 | Normal | Same as 2 | Same as 2 | Same as 2 |

| 14 | HFRZSS | (W∙m−2∙K−1) | Continuous | 2500.0 | Lognormal | mu, sigma | (7.824, 0.40547) (ln(2500), ln(1.5)) | (1000, 5000) |

| 15 | FSXSS | (-) | Continuous | 1.0 | Normal | mu, sigma | (1.0, 0.2) | (0.6, 1) |

| 16 | SC1141 (2) | (kg∙m−1∙s−1) | Continuous | 1.0 | Triangular | a, b, c | (0.1, 1.0, 2.0) | No |

| No | Model | Reaction Constant, Kp (kg2/(m4s)) | Reference |

|---|---|---|---|

| 1 | Urbanic–Heidrick | 29.6 ∙ exp(−16,820/T), T < 1853 K | [47] |

| (Default) | 87.9 ∙ exp(−16,610/T), T > 1873 K | ||

| 2 | Baker–Just | 3330 ∙ exp(−22,897/T) | [48] |

| 3 | Prater–Courtright | 26,763.6 ∙ exp(−26,440/T), T > 1873 K | [49] |

| Leistikow–Schanz | 425.8 ∙ exp(−20,962/T), T < 1853 K | [50] | |

| 4 | Prater–Courtright | 26,763.6 ∙ exp(−26,440/T), T > 1873 K | [49] |

| Cathcart–Pawel | 294.2 ∙ exp(−20,100/T) < 1853 K | [51] | |

| 5 | Urbanic–Heidrick | 87.9 ∙ exp(−/T), T > 1873 K | [47] |

| Cathcart–Pawel | 294.2 ∙ exp(−20,100/T) < 1853 K | [51] |

| Model #0 | Probability = 0.8 | Model #1 | Probability = 0.1 | Model #2 | Probability = 0.1 |

|---|---|---|---|---|---|

| Temperature, (K) | Time, (s) | Temperature, (K) | Time, (s) | Temperature, (K) | Time, (s) |

| 2090.0 | 6.00 ∙ 1031 | 1990.0 | 6.00 ∙ 1031 | 2190.0 | 6.00 ∙ 1031 |

| 2100.0 | 3.60 ∙ 104 | 2000.0 | 1.80 ∙ 104 | 2200.0 | 7.20 ∙ 104 |

| 2500.0 | 3.60 ∙ 103 | 2400.0 | 1.80 ∙ 103 | 2600.0 | 7.20 ∙ 103 |

| 2600.0 | 3.00 ∙ 102 | 2500.0 | 1.50 ∙ 102 | 2700.0 | 6.00 ∙ 102 |

| Reactor | Code | Scenario | Thermal Power | In-Vessel Hydrogen Mass | H2-to-Power Ratio | Reference |

|---|---|---|---|---|---|---|

| PWR W-3 | M1.8.3 | SBO | 2686 | 600 | 0.22 | [62] |

| PWR APR1400 | M1.8.4 | LBLOCA | 4000 | 420 | 0.11 | [63] |

| PWR Zion | M1.8.5 | SBO | 3250 | 530 | 0.16 | [64] |

| PWR Sequoyah | M1.8.5 | SBO | 3411 | 456/718 | 0.13/0.21 | [35,44] |

| PWR Surry | M1.8.5 | LBLOCA | 2546 | 100 | 0.04 | [65] |

| PWR Zion | M1.8.5 | LBLOCA | 3250 | 265 | 0.08 | [65] |

| PWR TMI-2 | M1.8.5 | SBLOCA | 2772 | 330/425 | 0.12/0.15 | [66] |

| PWR TMI-2 | M1.8.5 | SBLOCA | 2772 | 350 | 0.13 | [65] |

| VVER | M1.8.6 | SBO | 3000 | 189/456 | 0.06/0.15 | [6] |

| PWR Krshko | M1.8.6 | SBO | 2000 | 160/200 | 0.08/0.1 | [67] |

| PWR Beznau | M1.8.6 | LBLOCA | 1130 | 128 | 0.11 | [5] |

| PWR | M2.1.5 | SBO | 4590 | 600 | 0.13 | [14] |

| PWR | M2.1.5 | LBLOCA | 4590 | 490 | 0.1 | [33] |

| PWR W-3 | M2.2 | LBLOCA | 3152 | 234/328 | 0.07/0.10 | [68] |

| PWR W-3 | M2.2 | SBLOCA | 3152 | 192/315 | 0.06/0.10 | [68] |

| PWR | M2.2.9 | SBO | 4500 | ~550 | 0.12 | [32] (*) |

| PWR | M2.2.15 | SBO | 3000 | 450/510 | 0.15/0.17 | [13] |

| PWR, top peak | M2.2.18 | LBLOCA | 4500 | BE 286 | 0.06 | This work |

| power profile | Min 220/Max 495 | 0.05/0.11 | ||||

| PWR, FPT-like | M2.2.18 | LBLOCA | 4500 | BE 232 | 0.05 | This work |

| power profile | Min 225/Max 392 | 0.05/0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darnowski, P.; Mazgaj, P.; Włostowski, M. Uncertainty and Sensitivity Analysis of the In-Vessel Hydrogen Generation for Gen-III PWR and Phebus FPT-1 with MELCOR 2.2. Energies 2021, 14, 4884. https://doi.org/10.3390/en14164884

Darnowski P, Mazgaj P, Włostowski M. Uncertainty and Sensitivity Analysis of the In-Vessel Hydrogen Generation for Gen-III PWR and Phebus FPT-1 with MELCOR 2.2. Energies. 2021; 14(16):4884. https://doi.org/10.3390/en14164884

Chicago/Turabian StyleDarnowski, Piotr, Piotr Mazgaj, and Mateusz Włostowski. 2021. "Uncertainty and Sensitivity Analysis of the In-Vessel Hydrogen Generation for Gen-III PWR and Phebus FPT-1 with MELCOR 2.2" Energies 14, no. 16: 4884. https://doi.org/10.3390/en14164884

APA StyleDarnowski, P., Mazgaj, P., & Włostowski, M. (2021). Uncertainty and Sensitivity Analysis of the In-Vessel Hydrogen Generation for Gen-III PWR and Phebus FPT-1 with MELCOR 2.2. Energies, 14(16), 4884. https://doi.org/10.3390/en14164884