Comparison of Two Power Converter Topologies in Wind Turbine System

Abstract

:1. Introduction

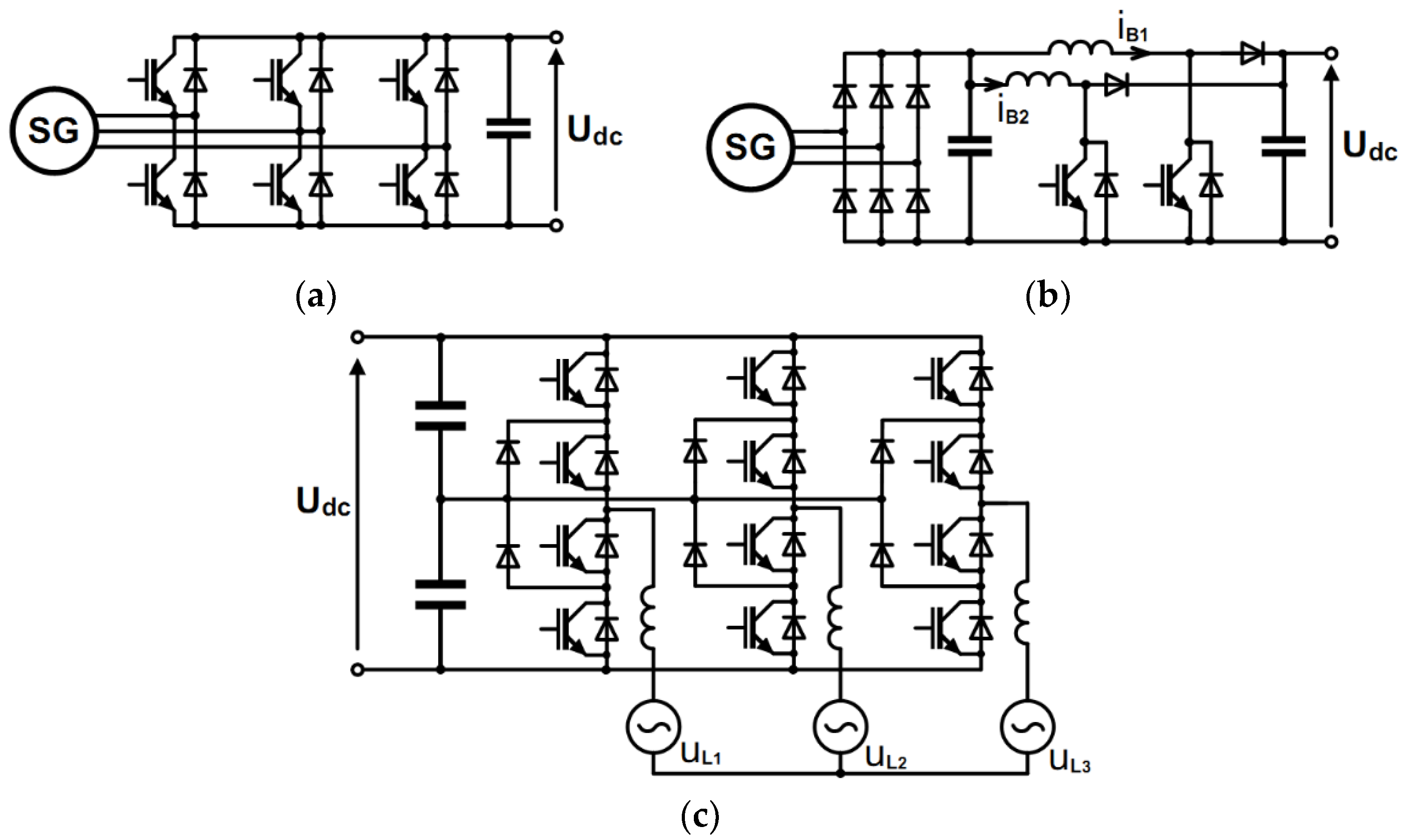

2. Generator and Grid Converter

- -

- efficiency of the grid converter;

- -

- efficiency of the generator converter;

- -

- efficiency of energy conversion in the generator.

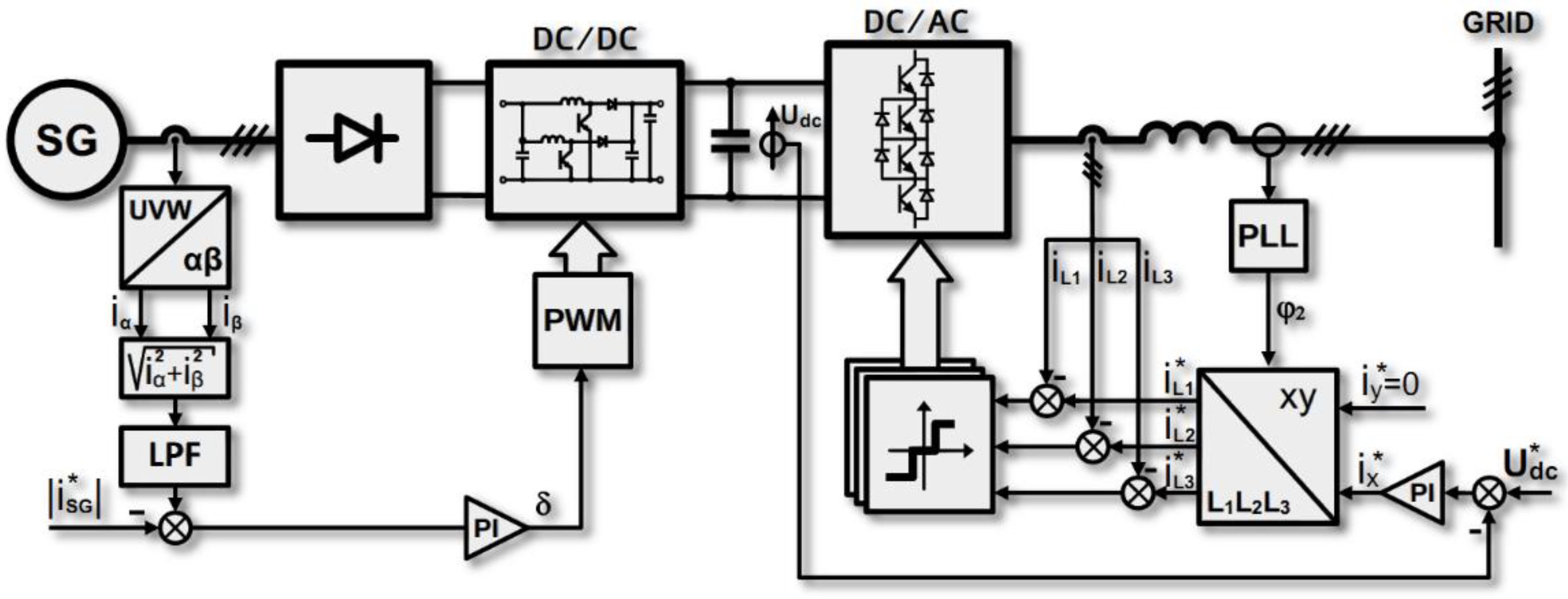

3. Control of Converters

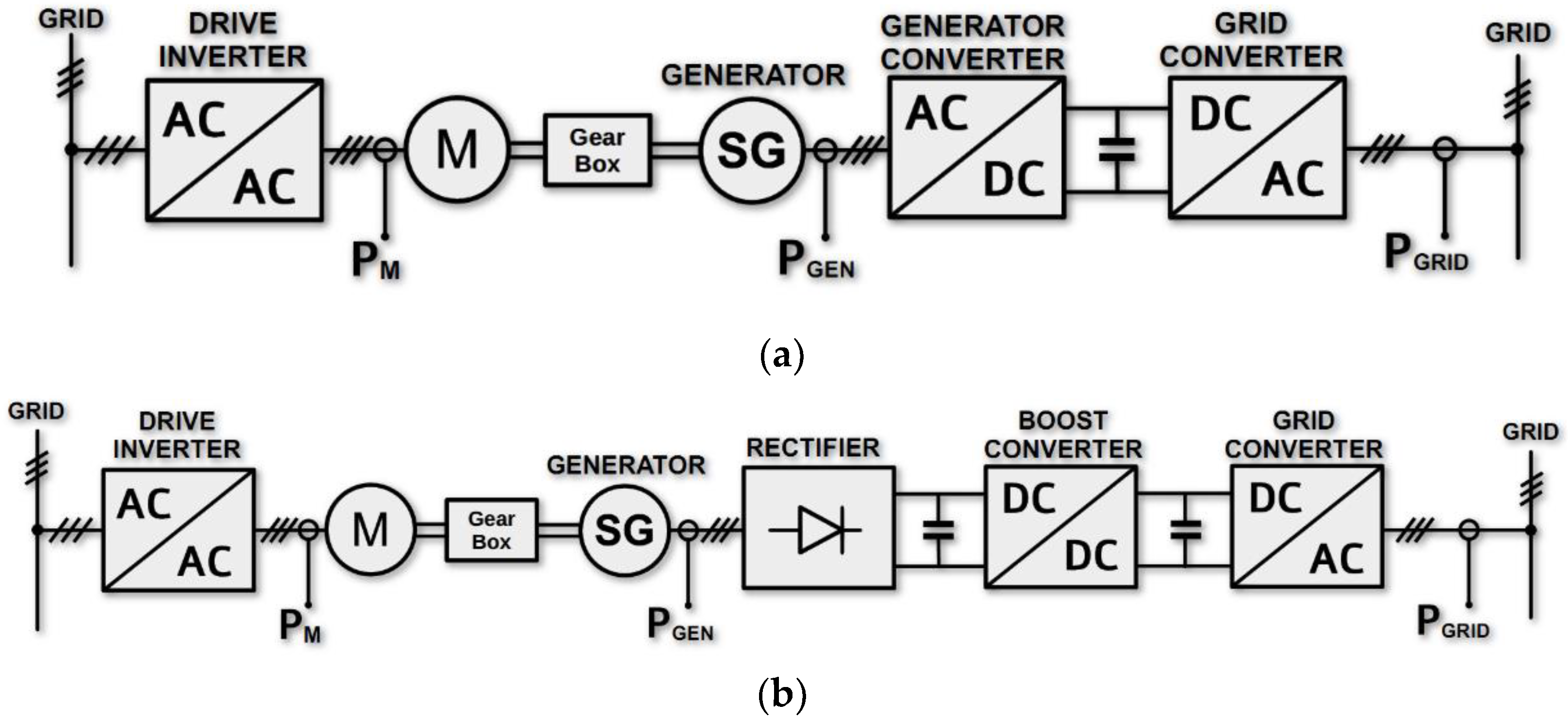

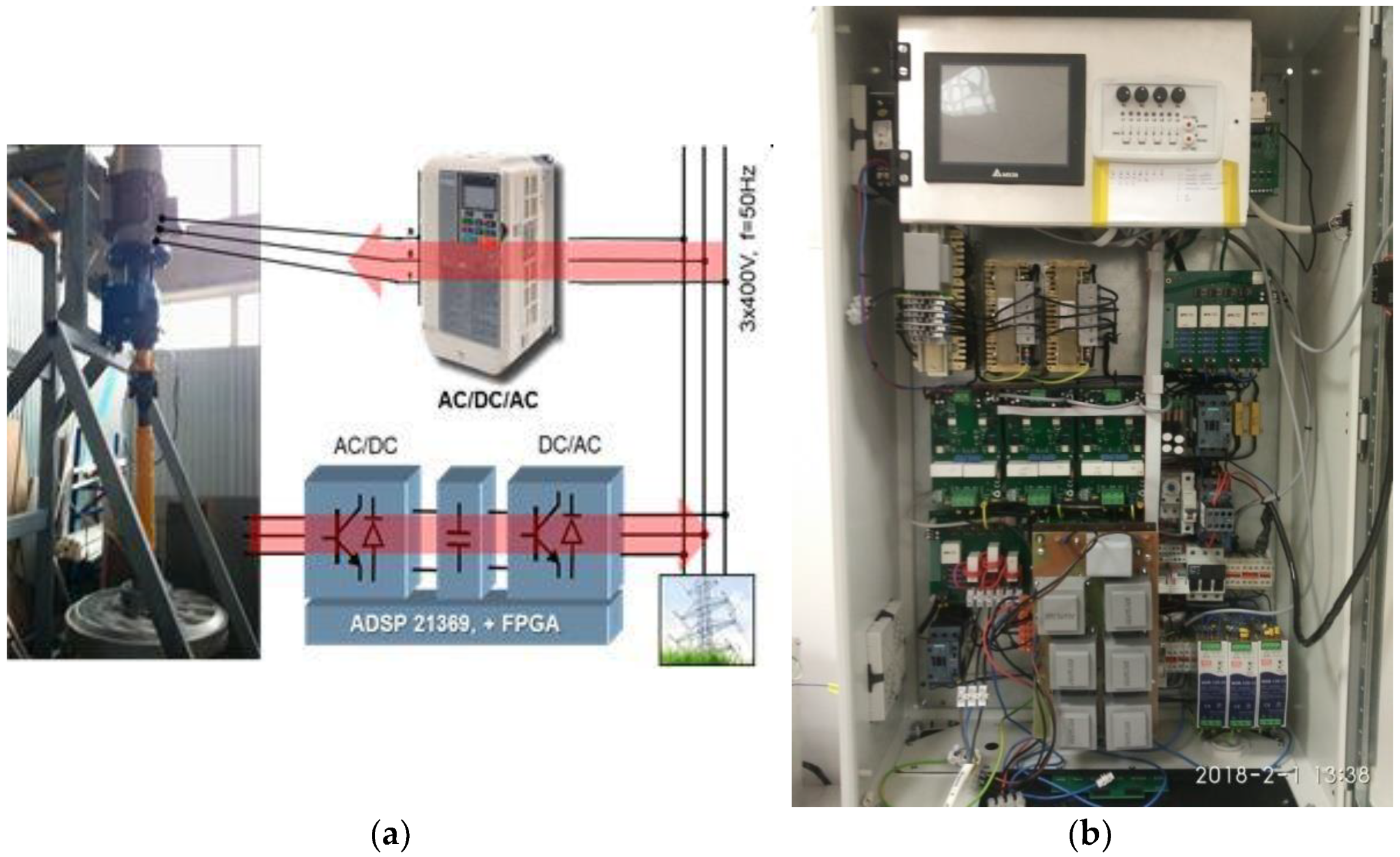

4. Laboratory Tests

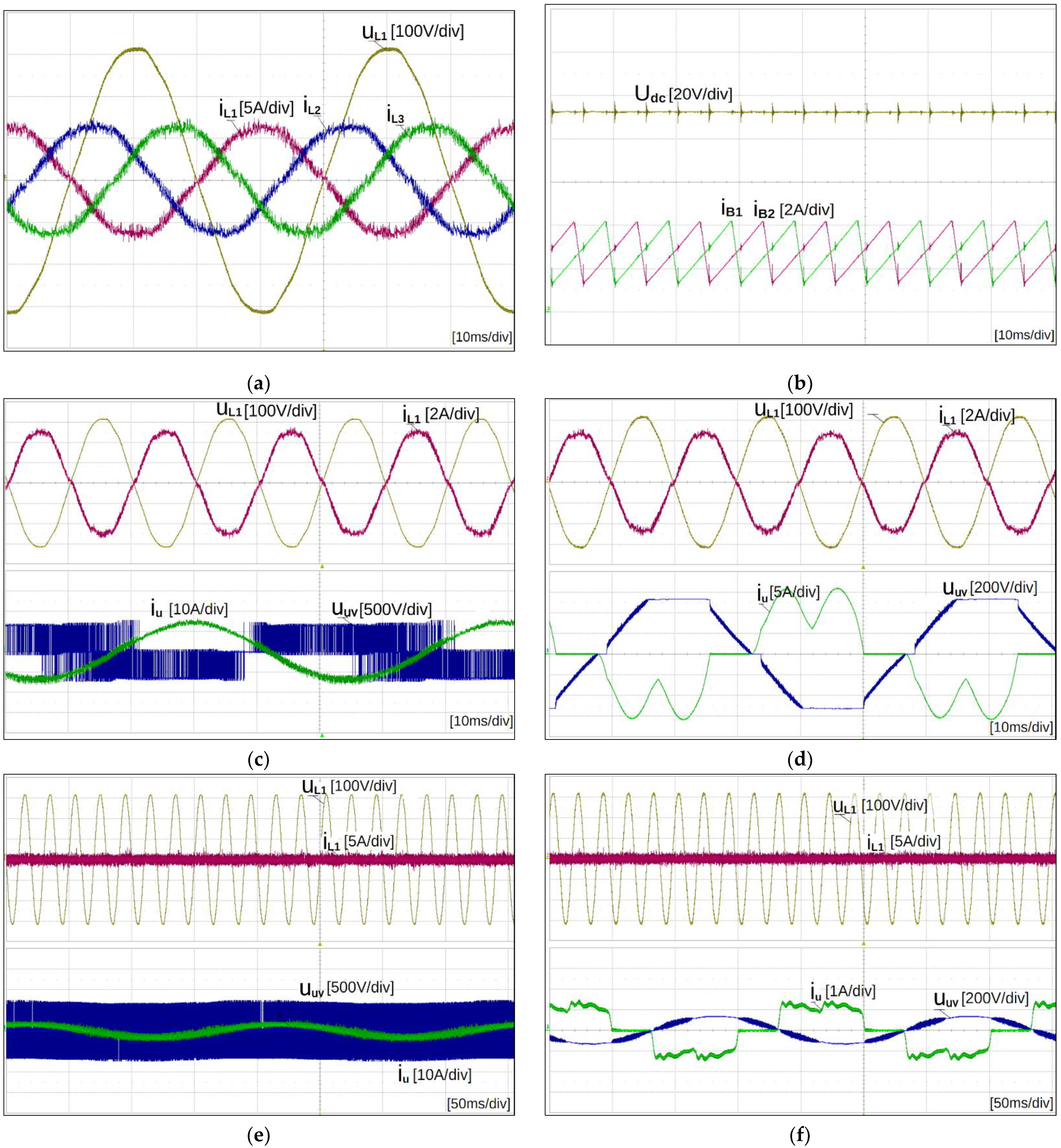

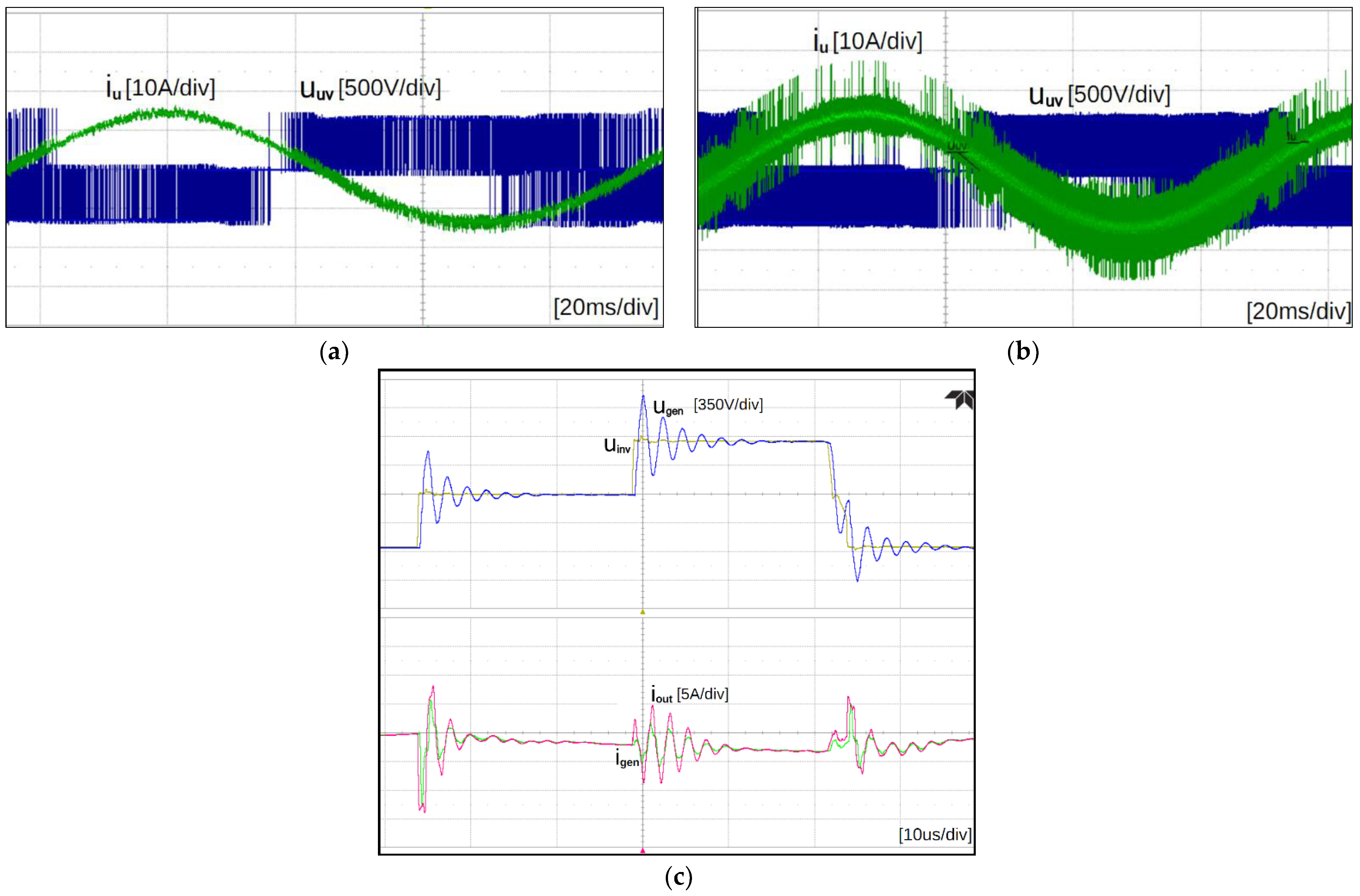

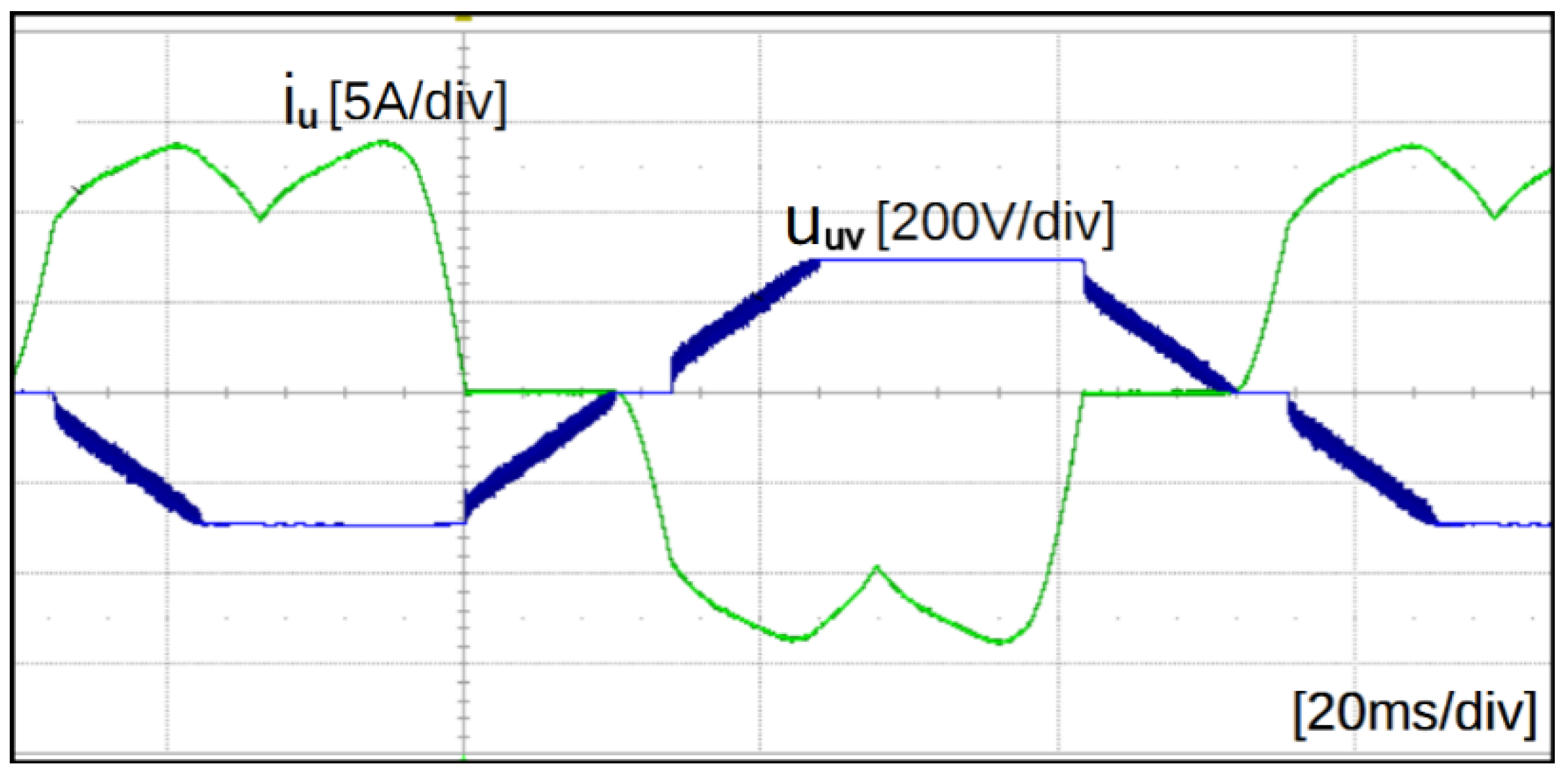

4.1. Converter Operation with T1 and T2 Topologies

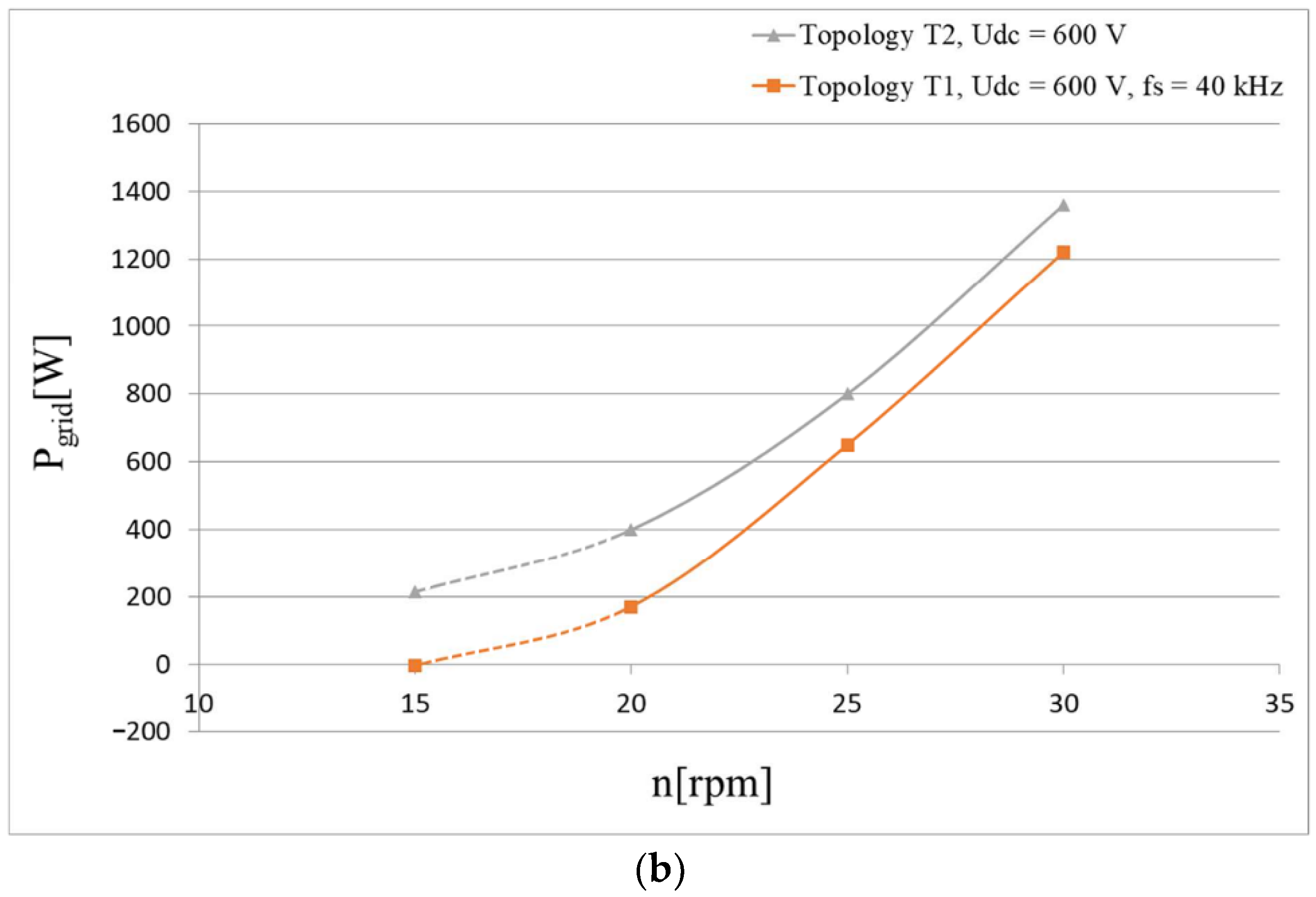

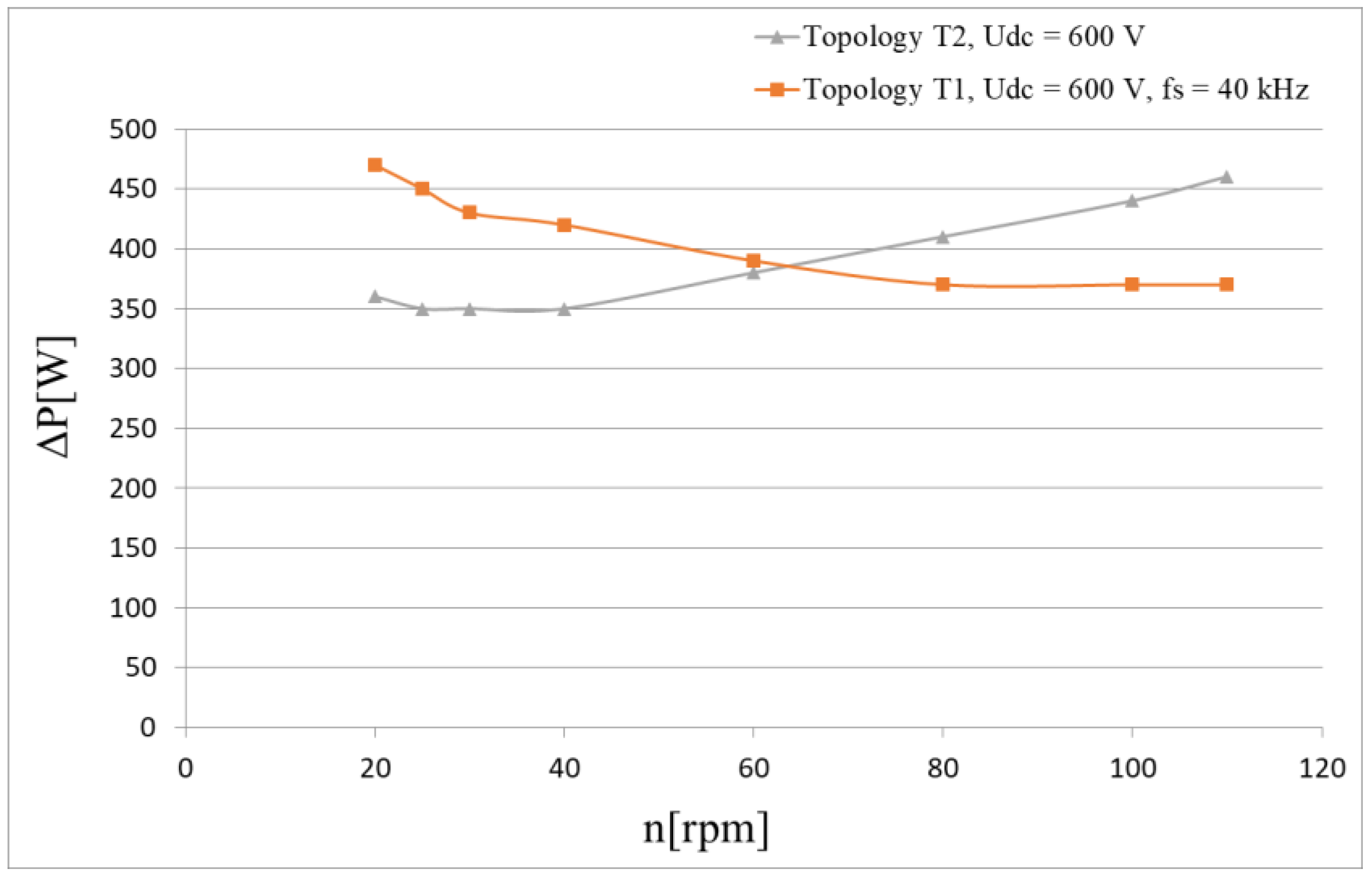

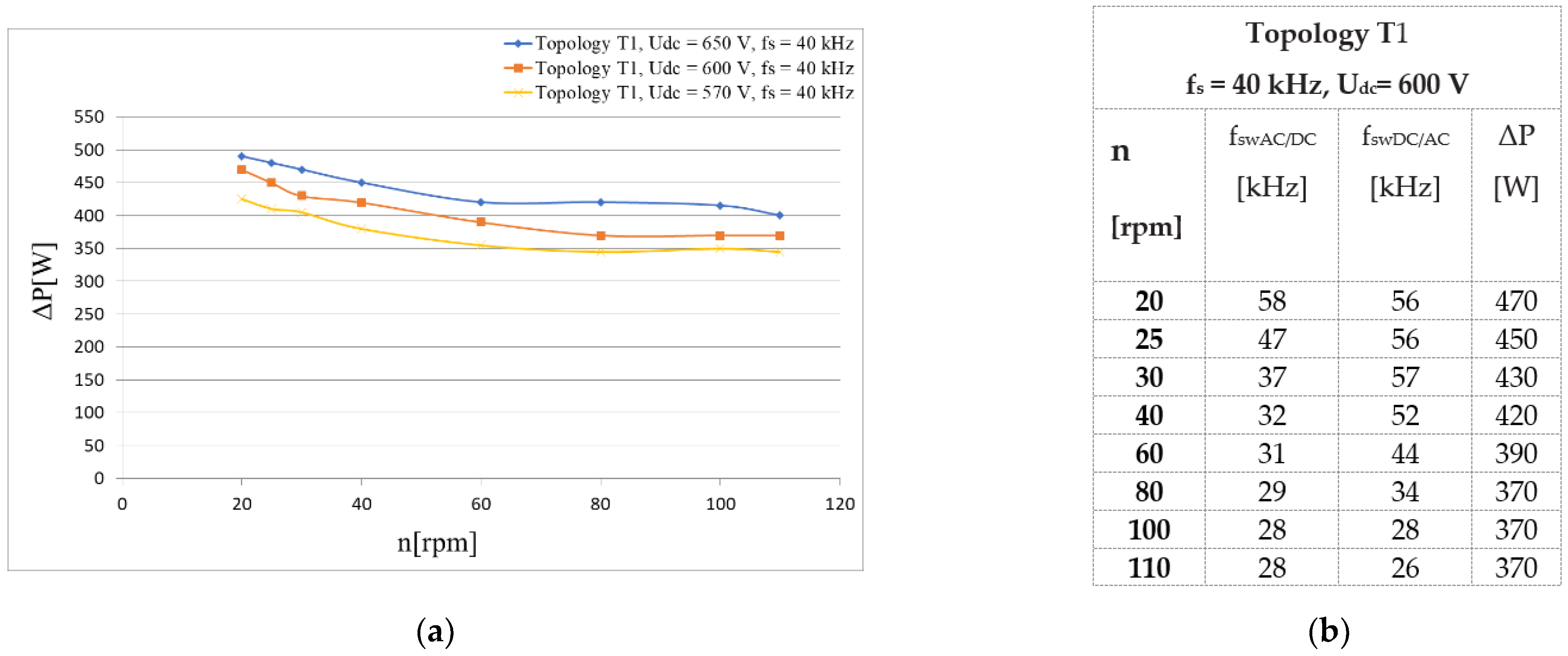

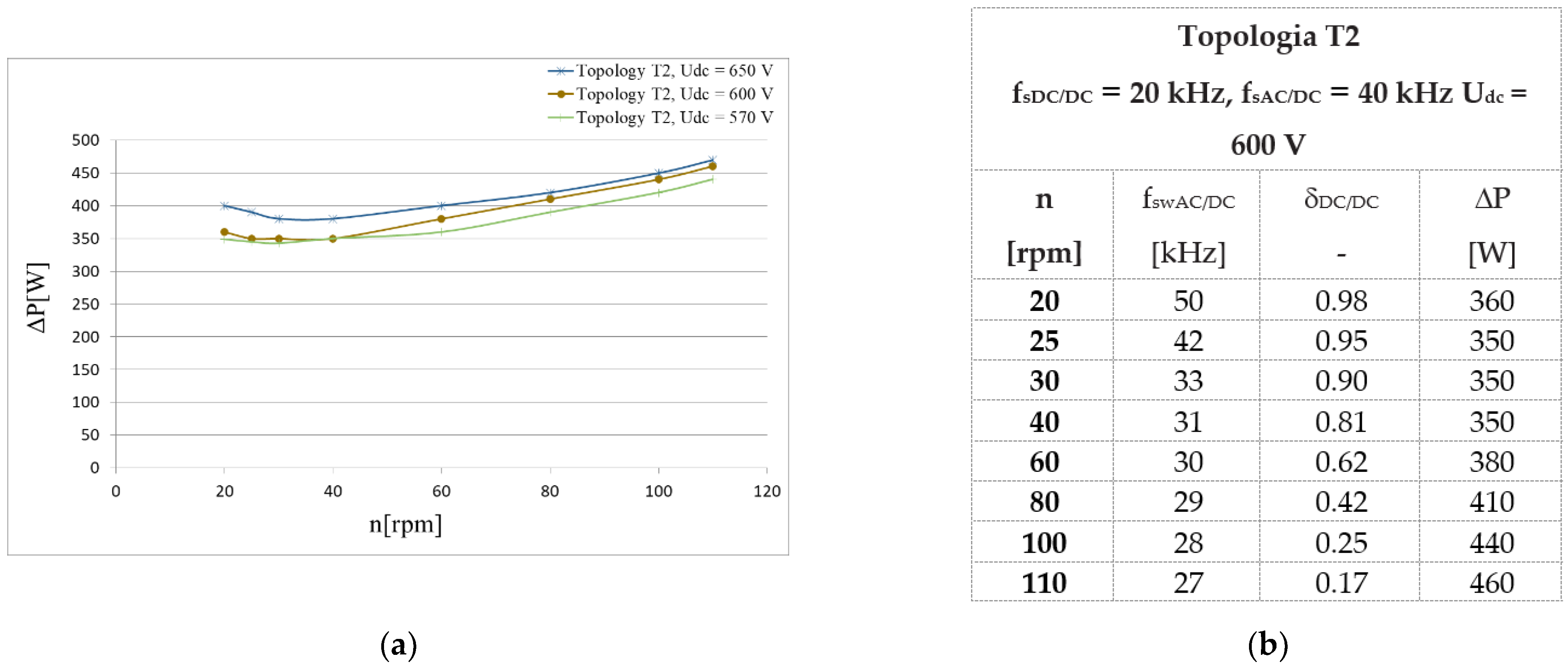

4.2. Efficiency of AC/DC/AC and DC/DC/AC Converters

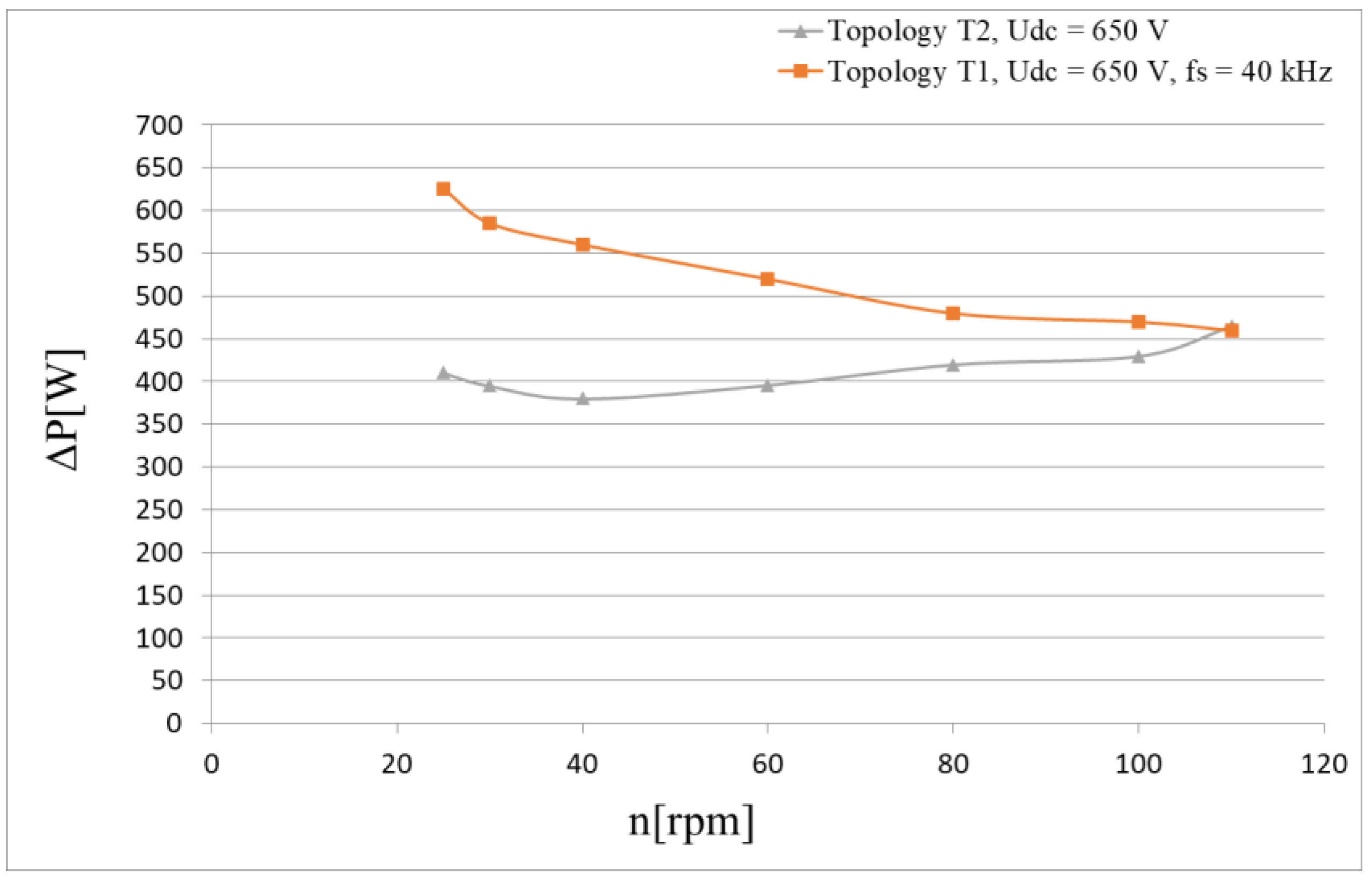

4.3. Efficiency of Converters Depending on DC Link Voltage

4.4. Effect of Switching Frequency on the Generator Converter Efficiency

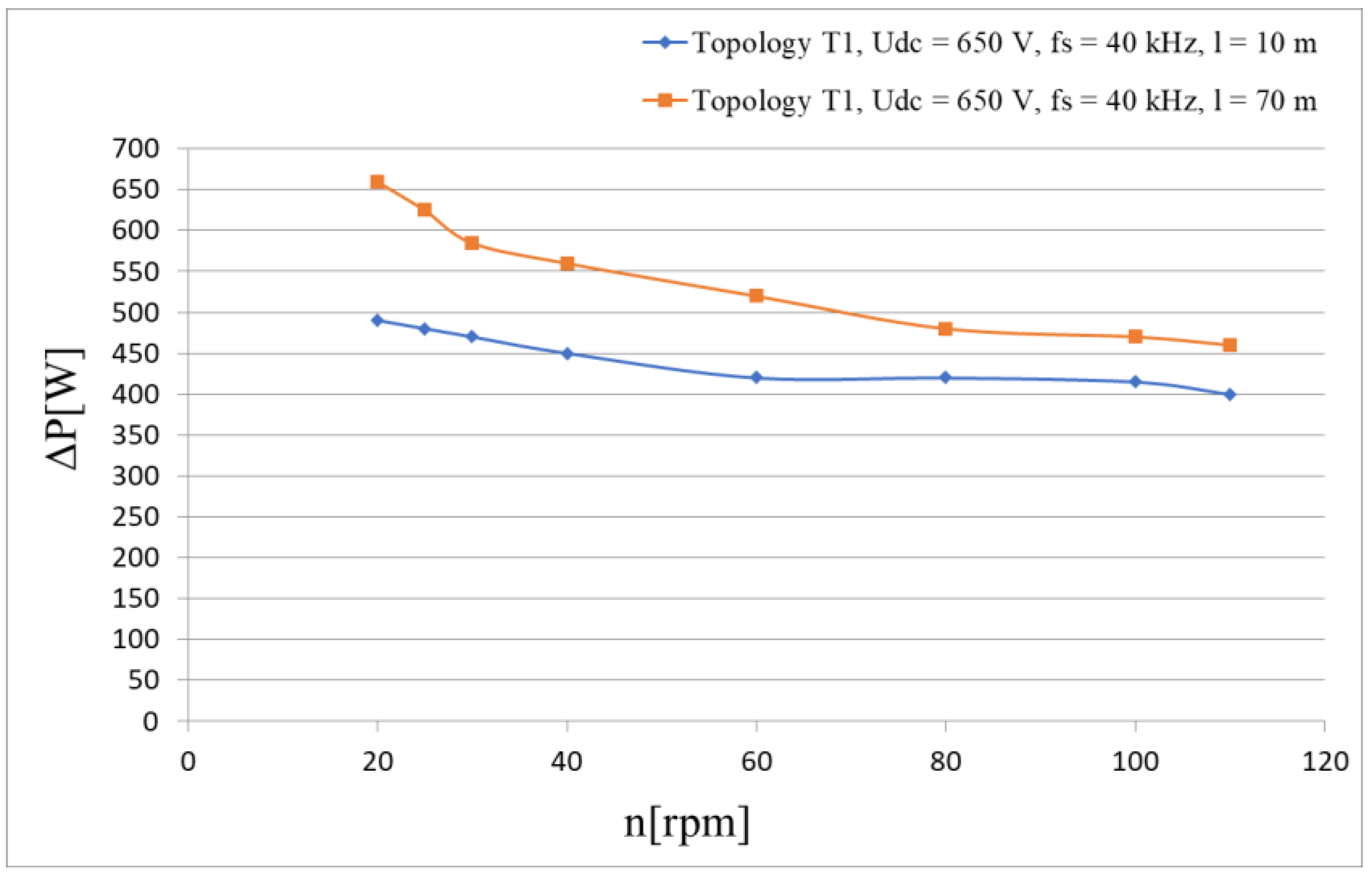

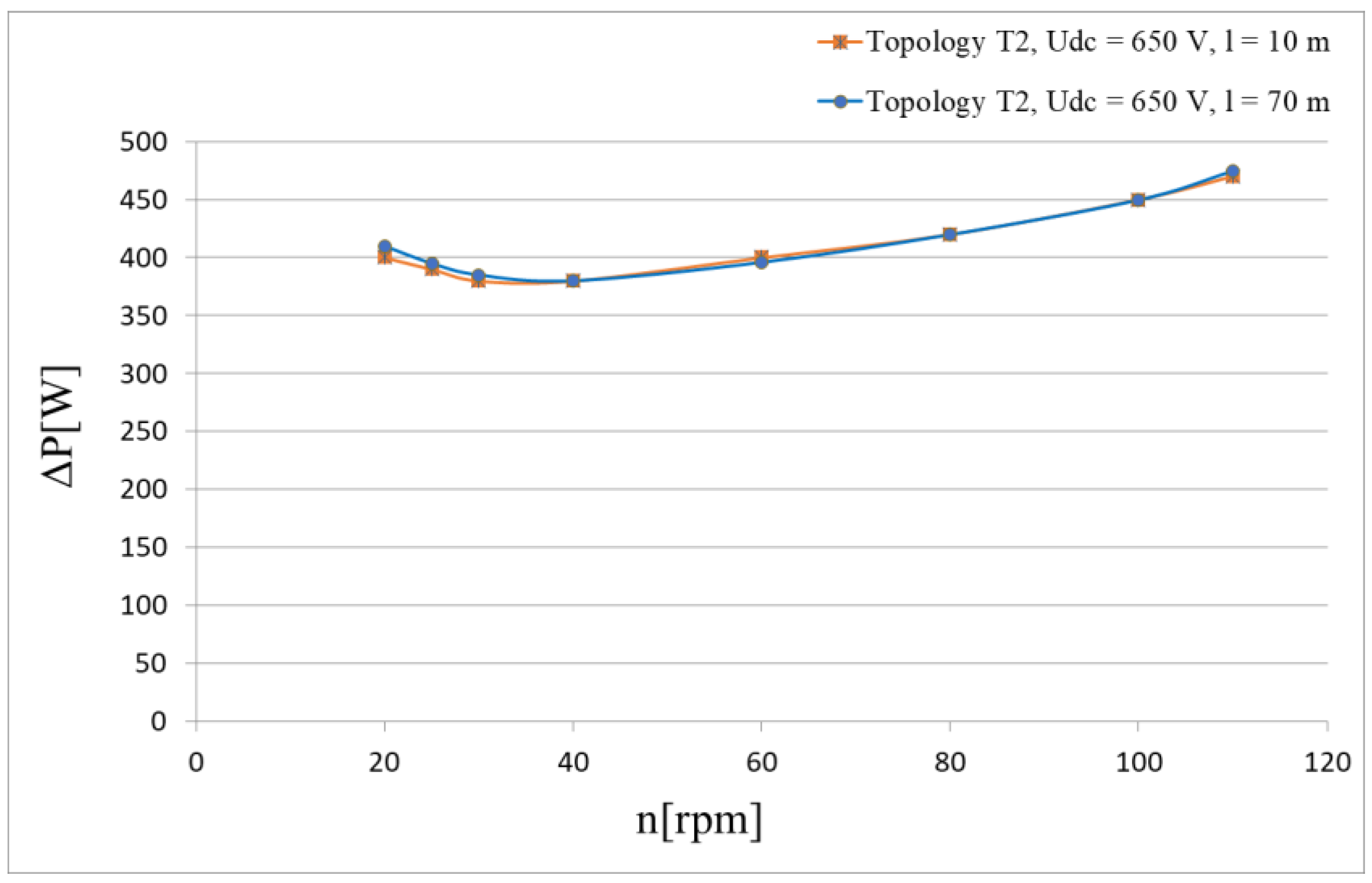

4.5. Effect of Generator-to-Converter Cable Length on Power Losses in Converters

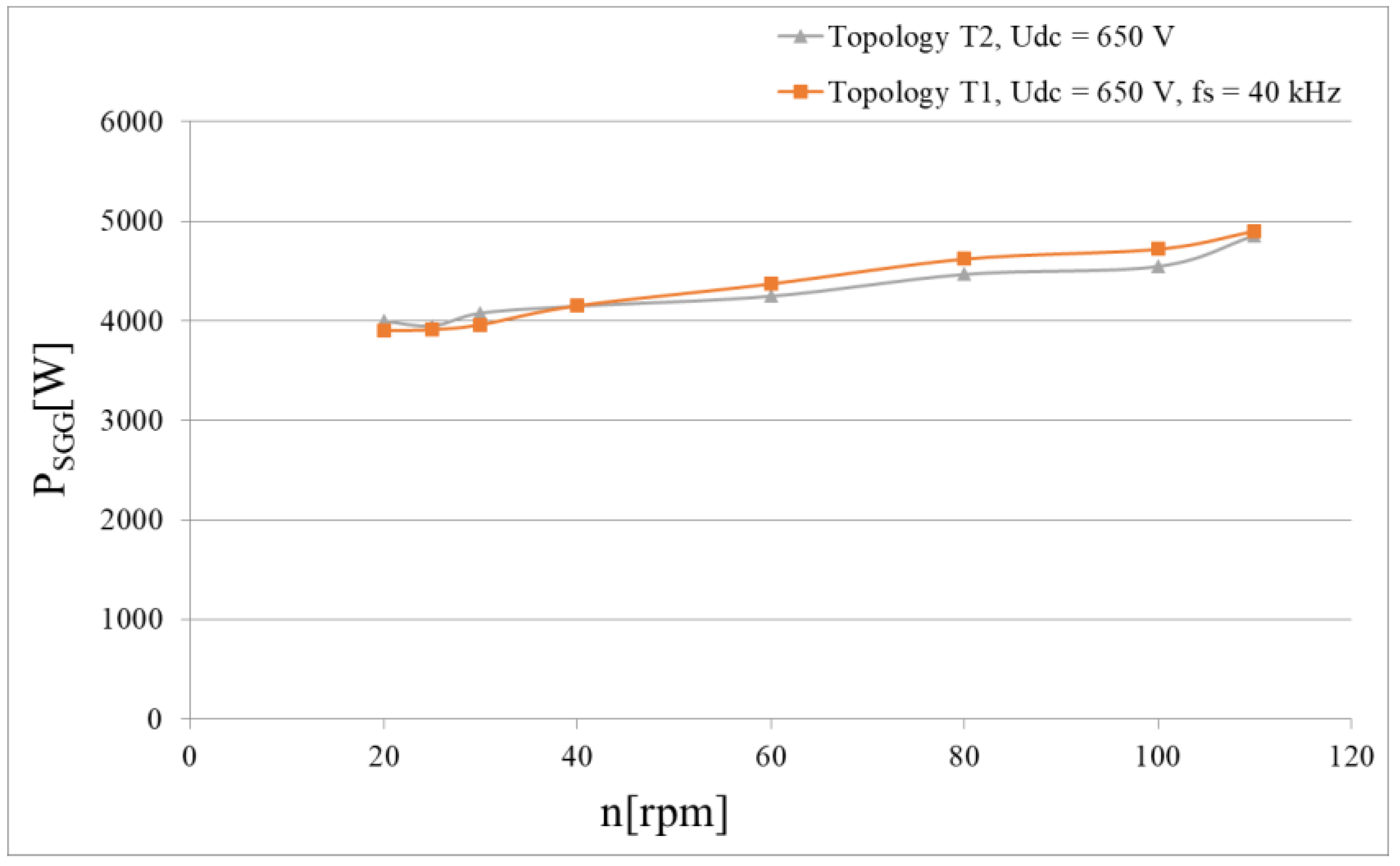

4.6. Losses in the Generator

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Y.; Wei, C.; Zhang, Z.; Qiao, W. Review on position/speed sensorless control for permanent-magnet synchronous machine-based wind energy conversion systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 203–216. [Google Scholar] [CrossRef]

- Beainy, A.; Maatouk, C.; Moubayed, N.; Kaddah, F. Comparison of different types of generator for wind energy conversion system topologies. In Proceedings of the 3rd International Conference on Renewable Energies for Developing Countries, Zouk Mosbeh, Lebanon, 13–15 July 2016. [Google Scholar]

- Hansen, A.D.; Iov, F.; Blaabjerg, F. Review of contemporary wind turbine concepts and their market penetration. Wind Eng. 2004, 28, 247–263. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B.; Sen, P.C.; Kouro, S.; Narimani, M. High-power wind energy conversion systems: State-of-the-art and emerging technologies. Proc. IEEE 2015, 103, 740–788. [Google Scholar] [CrossRef]

- Honrubia-Escribano, A.; Jiménez-Buendía, F.; Sosa-Avendaño, J.; Gartmann, P.; Frahm, S.; Fortmann, J.; Sørensen, P.; Gómez-Lázaro, E. Fault-Ride Trough validation of IEC 61400-27-1 type 3 and type 4 models of different wind turbine manufacturers. Energies 2019, 12, 3039. [Google Scholar] [CrossRef] [Green Version]

- Sekhar, K.R.; Barot, R.; Patel, P.; Kumar, N.V. R.; Barot, R.; Patel, P.; Kumar, N.V. A novel topology for improved DC bus utilization in PMSG based wind energy generation system. In Proceedings of the 4th International Conference on Renewable Energy Research and Applicationc, Palermo, Italy, 27–30 August 2015. [Google Scholar]

- Arthishri, K.; Kumaresan, N.; Gounden, N.A. Analysis and application of three-phase SEIG with power converters for supplying single-phase grid from wind energy. IEEE Syst. J. 2019, 13, 1813–1822. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B.; Rivera, M.; Rodriguez, J. A new power conversion system for megawatt PMSG wind turbines using four-level converters and a simple control scheme based on two-step model predictive strategy—part II. J. Emerg. Sel. Top. Power Electron. 2014, 2, 14–25. [Google Scholar] [CrossRef]

- Dawande, M.S.; Dubey, G.K. Programmable input power factor correction method for switch-mode rectifiers. Trans. Power Electron. 1996, 11, 585–590. [Google Scholar] [CrossRef]

- Echchaachouail, A.; El Hanil, S.; Hammouch, A.; Guedira, S.; Dahil, K. Low-cost maximum power point tracking structure of a grid connected wind conversion chain based on a PMSG. In Proceedings of the 2nd International Conference on Electrical and Information Technologies, Tangier, Morocco, 4–7 May 2016. [Google Scholar]

- Mouli, G.R.C.; Schijffelen, J.H.; Bauer, P.; Zeman, M. Design and comparison of a 10-kW interleaved Boost Converter for PV application using Si and SiC devices. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 610–623. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Soong, W.L.; Pathmanathan, M.; Ertugrul, N. Comparison of AC/DC converters and the principles of a new control strategy in small-scale wind turbine systems. In Proceedings of the 22nd Australasian Universities Power Engineering Conference, Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Zhang, Z.; Wang, F.; Acikgoz, M.; Caiand, X.; Kennel, R. FPGA HiL simulation of back-to-back converter PMSG by wind turbine systems. In Proceedings of the 9th International Conference on Power Electronics-ECCE Asia, Seoul, Korea, 1–5 June 2015. [Google Scholar]

- Davari, M.Y.; Mohamed, Y.A.I. Robust DC-Link voltage control of a full-scale PMSG wind turbine for effective integration in DC grids. IEEE Trans. Power Electron. 2017, 32, 4021–4035. [Google Scholar] [CrossRef]

- Dey, P.; Datta, M.; Fernando, N. Comparisons of PI and PR current controllers based flux weakening to limit DC-link capacitor overvoltage in PMSG based wind energy system. In Proceedings of the IEEE Innovative Smart Grid Technologies–Asia, Melbourne, Australia, 28 November–1 December 2016. [Google Scholar]

- Xu, Y.; Nian, H.; Chen, L. Small-Signal Modeling and Analysis of DC-Link Dynamics in Type-IV Wind Turbine System. IEEE Trans. Ind. Electron. 2021, 68, 1423–1433. [Google Scholar] [CrossRef]

- Karaagac, U.; Mahseredjian, J.; Gagnon, R.; Gras, H.; Saad, H.; Cai, L.; Kocar, I.; Haddad, A.; Farantatos, E.; Bu, S.; et al. A Generic EMT-type model for wind Parks with permanent magnet synchronous generator full size converter wind turbines. IEEE Power Energy Technol. Syst. 2019, 6, 131–141. [Google Scholar] [CrossRef]

- Radwan, A.A.A.; Mohamed, Y.A.I. Grid-connected wind-solar cogeneration using back-to-back voltage-source converters. IEEE Trans. Sustain. Energy 2020, 11, 315–325. [Google Scholar] [CrossRef]

- Campos-Gaona, D.; Stock, A.; Anaya-Lara, O.; Leithead, W. Dynamic wind power plant control for system integration using the generator response following concept. Energies 2020, 13, 1804. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Yang, X.; Zhou, X.; Yang, L.; Zhou, Y. Dual closed-loop linear active disturbance rejection control of grid-side converter of permanent magnet direct-drive wind turbine. Energies 2020, 13, 1090. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Li, Z.; Kazmierkowski, M.P.; Rodrıguez, J.; Kennel, R. Robust predictive control of three-level NPC back-to-back power converter PMSG wind turbine systems with revised predictions. IEEE Trans. Power Electron. 2018, 33, 9588–9598. [Google Scholar] [CrossRef]

- Kim, N.; Kim, G.-H.; Kim, K.-M.; Park, M.; Yu, I.-K.; Lee, S.; Song, E.; Kim, T.-W. Comparative analysis of 10 MW class gearedand gearless type superconducting synchronous generators for a wind power generation system. IEEE Trans. Appl. Supercond. 2012, 22, 5202004. [Google Scholar]

- Chu, J.; Yuan, L.; Hu, Y.; Pan, C.; Pan, L. Comparative analysis of identification methods for mechanical dynamics of large-scale wind turbine. Energies 2019, 12, 3429. [Google Scholar] [CrossRef] [Green Version]

- Sun, P.; Yao, J.; Liu, R.; Pei, J.; Zhang, H.; Liu, Y. Virtual capacitance control for improving dynamic stability of the DFIG-based wind turbines during a symmetrical fault in a weak AC grid. IEEE Trans. Ind. Electron. 2021, 68, 333–346. [Google Scholar] [CrossRef]

- Kavousi, A.; Fathi, S.H.; Milimonfared, J.; Soltani, M.N. Application of boost converter to increase the speed range of dual-stator winding induction generator in wind power systems. IEEE Trans. Power Electron. 2018, 33, 9599–9610. [Google Scholar] [CrossRef] [Green Version]

- Brando, G.; Dannier, A.; Spina, I. Performance analysis of a full order sensorless control adaptive observer for doubly-fed induction generator in grid connected operation. Energies 2021, 14, 1254. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, G.; Blaabjerg, F. Optimal selection of power converter in DFIG wind turbine with enhanced system-level reliability. IEEE Trans. Ind. Appl. 2018, 54, 3637–3644. [Google Scholar] [CrossRef] [Green Version]

- Vernica, I.; Ma, K.; Blaabjerg, F. Optimal derating strategy of power electronics converter for maximum wind energy production with lifetime information of power devices. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 267–276. [Google Scholar] [CrossRef]

- Blaschke, F. The principle of field orientation as applied to the new transvector closed-loop control system for rotating field machines. Siemens Rev. 1972, 34, 217–220. [Google Scholar]

- Kheralnwala, H.; Divan, D.M. Delta modulation strategies for resonant link inverters. IEEE Trans. Power Electron. 1990, 5, 220–228. [Google Scholar] [CrossRef]

- Steele, R. Delta Modulation Systems; Pentech Press &Halsted Press: London, UK, 1975. [Google Scholar]

- Sikorski, A.; Kuzma, A. Cooperation of induction squirrel-cage generator with grid connected AC/DC/AC converter. Bull. Pol. Acad. Sci. Tech. Sci. 2009, 57, 317–322. [Google Scholar] [CrossRef] [Green Version]

| Device | Parameter | Units | Data |

|---|---|---|---|

| Synchronous Generator | Rated output power PN | kW | 10 |

| Rated speed n | rpm | 100 | |

| Rated output voltage (ph-ph) | V | 380 | |

| Rated current | A | 15.3 | |

| Number of pole pairs | - | 12 | |

| Efficiency at rated speed | % | >85 | |

| Frequency at rated speed | Hz | 23.3 | |

| Gear box | Gear ratio | - | 12 |

| Drive Motor | Rated output power | kW | 12 |

| Rated speed | rpm | 1440 | |

| Rated output voltage (ph-ph) | V | 400 | |

| Rated current | A | 21 | |

| Drives Inverter Yaskawa | Rated output power | kW | 18.6 |

| Rated output voltage (ph-ph) | V | 400 | |

| Rated current | A | 27 |

| Characteristic | Topology T1 | Topology T2 |

|---|---|---|

| Speed range when power is transferred to the grid | Smaller | Larger |

| Losses in the range of (1.0–0.5) n | Low | High |

| Losses in the range of (0.5–0.15) n | High | Low |

| Dependence of losses on Udc | High | Low |

| Power losses in the generator | High | Low |

| Mechanical vibration and noise | None | High |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikorski, A.; Falkowski, P.; Korzeniewski, M. Comparison of Two Power Converter Topologies in Wind Turbine System. Energies 2021, 14, 6574. https://doi.org/10.3390/en14206574

Sikorski A, Falkowski P, Korzeniewski M. Comparison of Two Power Converter Topologies in Wind Turbine System. Energies. 2021; 14(20):6574. https://doi.org/10.3390/en14206574

Chicago/Turabian StyleSikorski, Andrzej, Piotr Falkowski, and Marek Korzeniewski. 2021. "Comparison of Two Power Converter Topologies in Wind Turbine System" Energies 14, no. 20: 6574. https://doi.org/10.3390/en14206574

APA StyleSikorski, A., Falkowski, P., & Korzeniewski, M. (2021). Comparison of Two Power Converter Topologies in Wind Turbine System. Energies, 14(20), 6574. https://doi.org/10.3390/en14206574