Performance of Common Rail Direct Injection (CRDi) Engine Using Ceiba Pentandra Biodiesel and Hydrogen Fuel Combination

Abstract

:1. Introduction

2. Test Procedure Details

2.1. Combustion Fuels Used

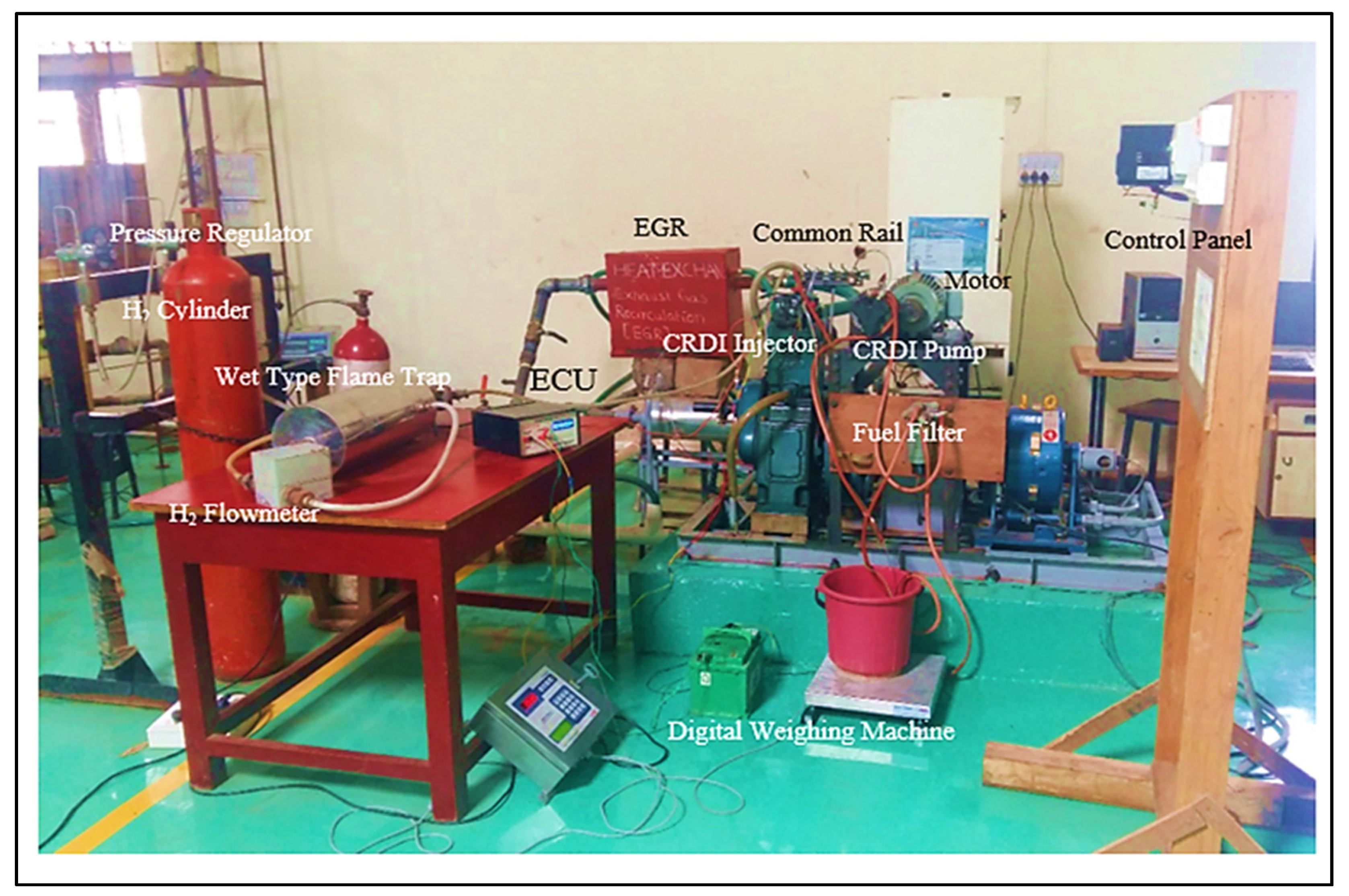

2.2. Test Set-Up

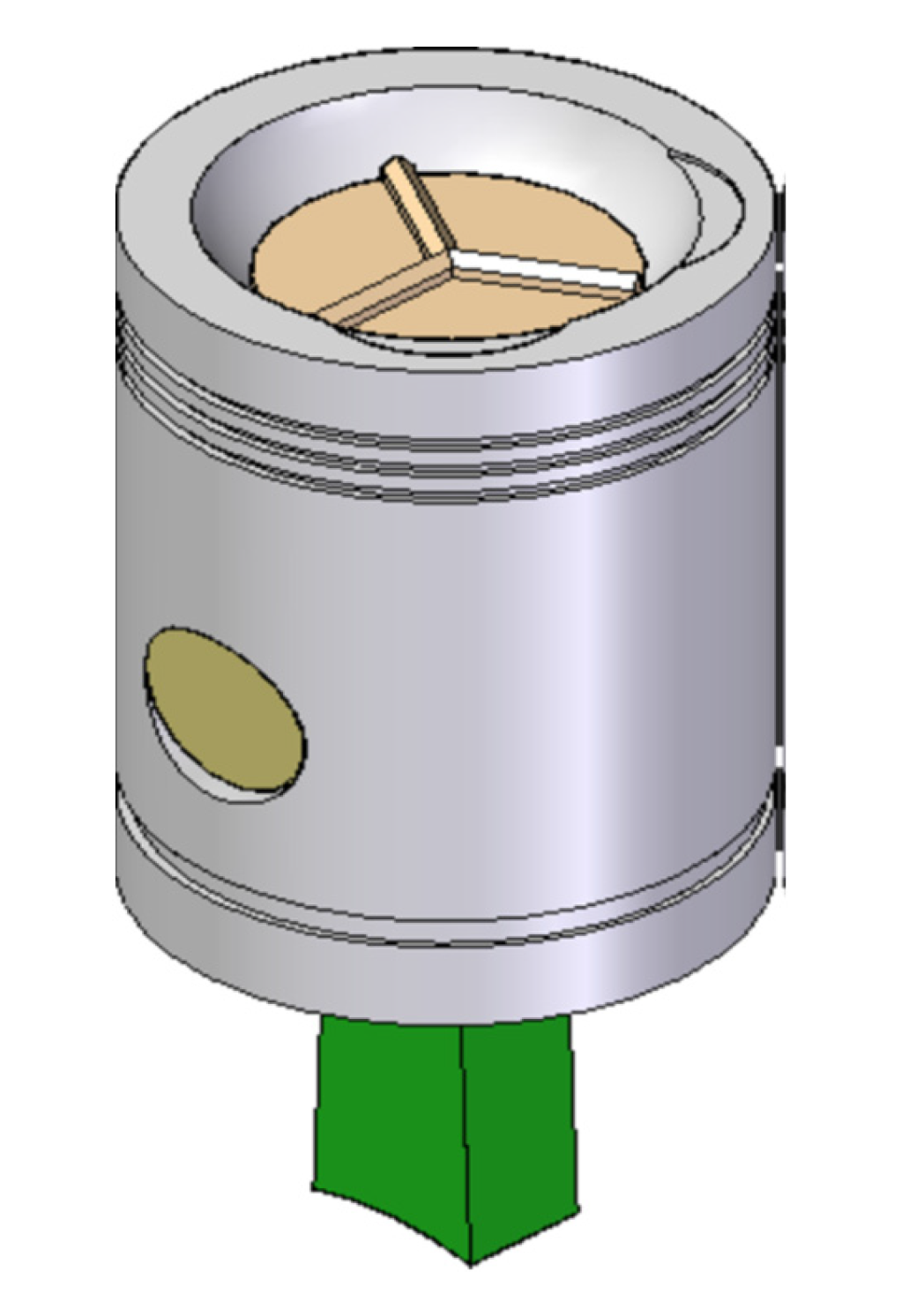

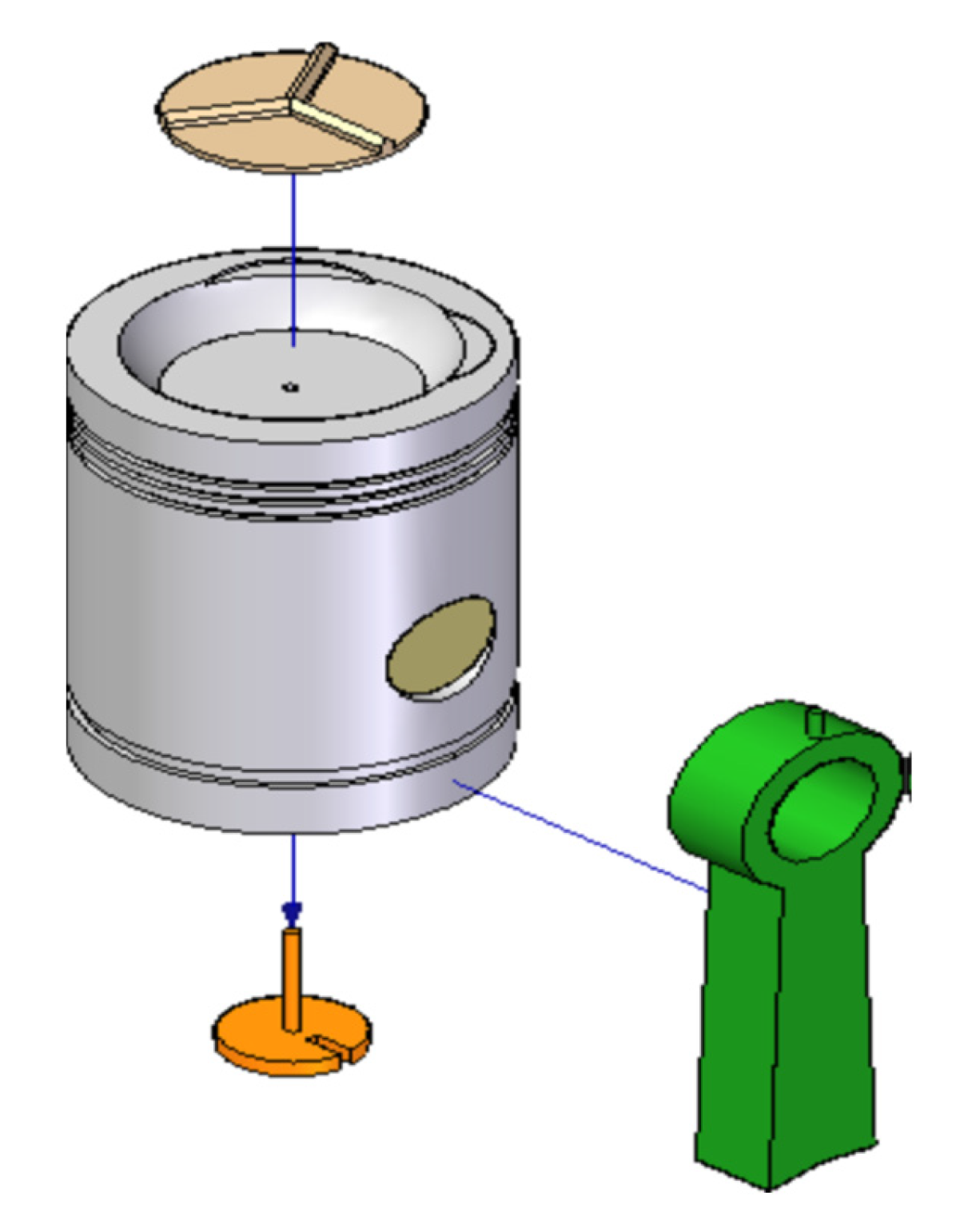

2.3. Modifications in Piston

3. Test Data Analysis

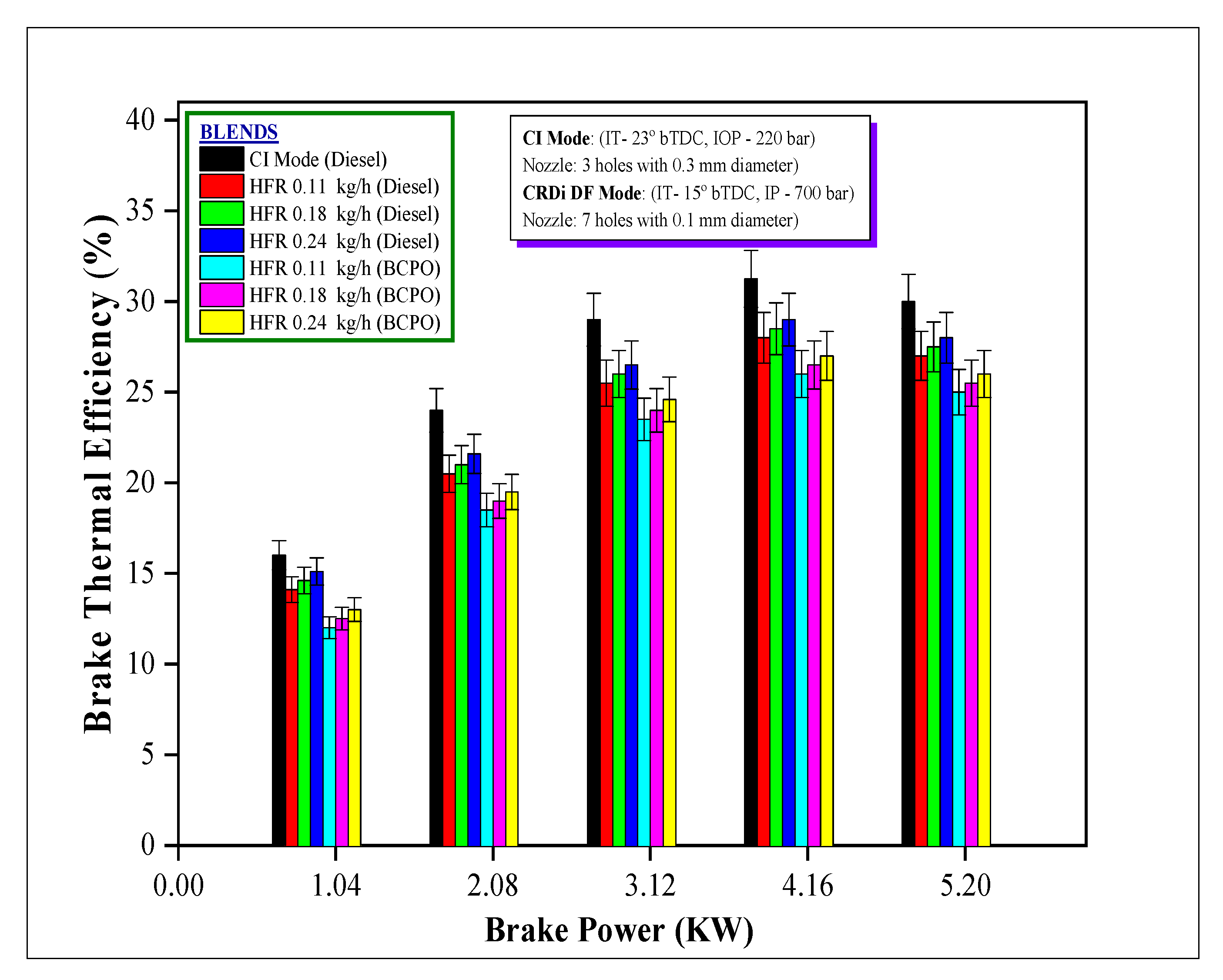

3.1. Influence of Flow Rate of Hydrogen

3.1.1. Brake Thermal Efficiency

- (mf xCv) fuel—Mass of fuel x Calorific value of fuel;

- (mgxCv)g—Mass of gas x Calorific value of gas;

- BP—Brake power.

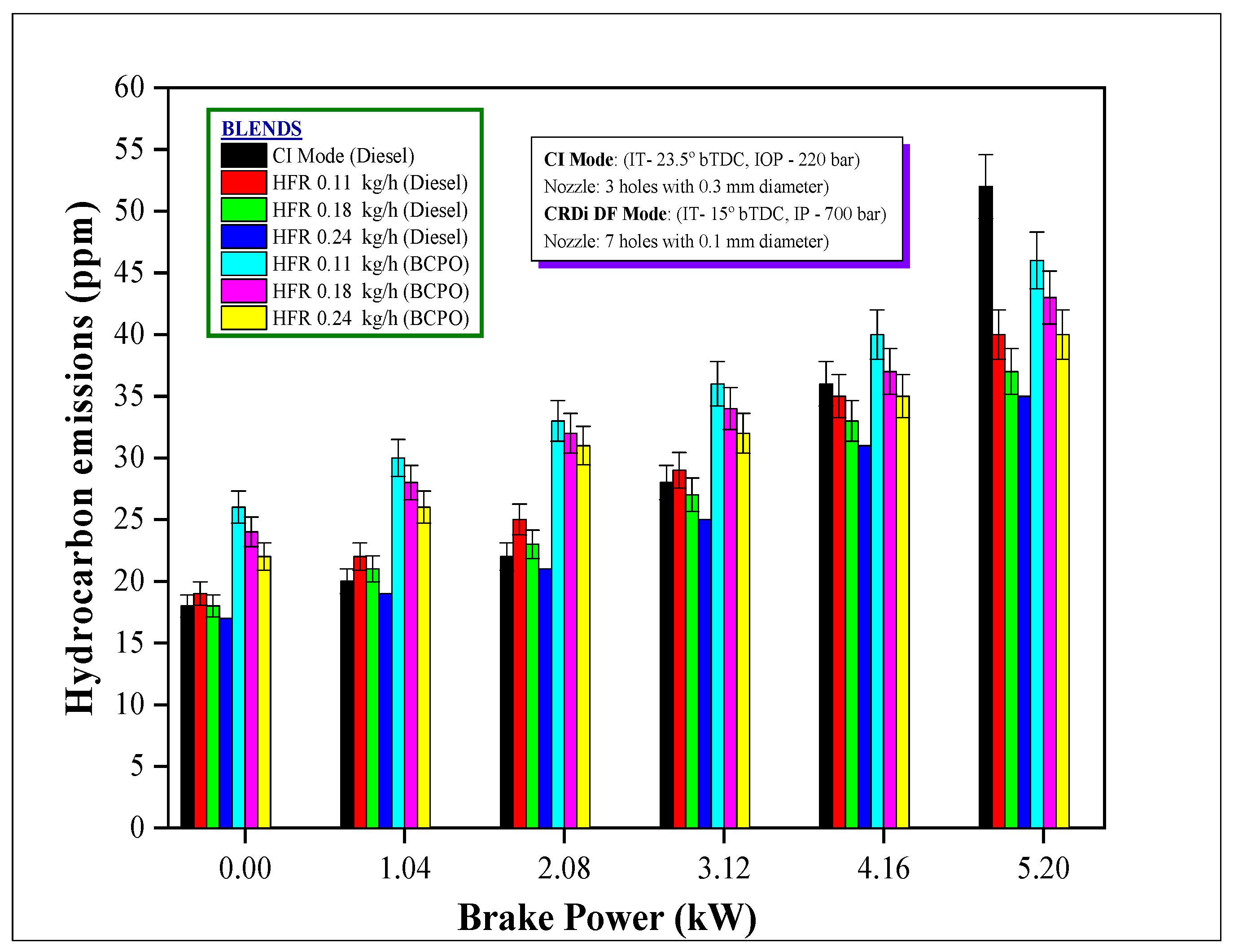

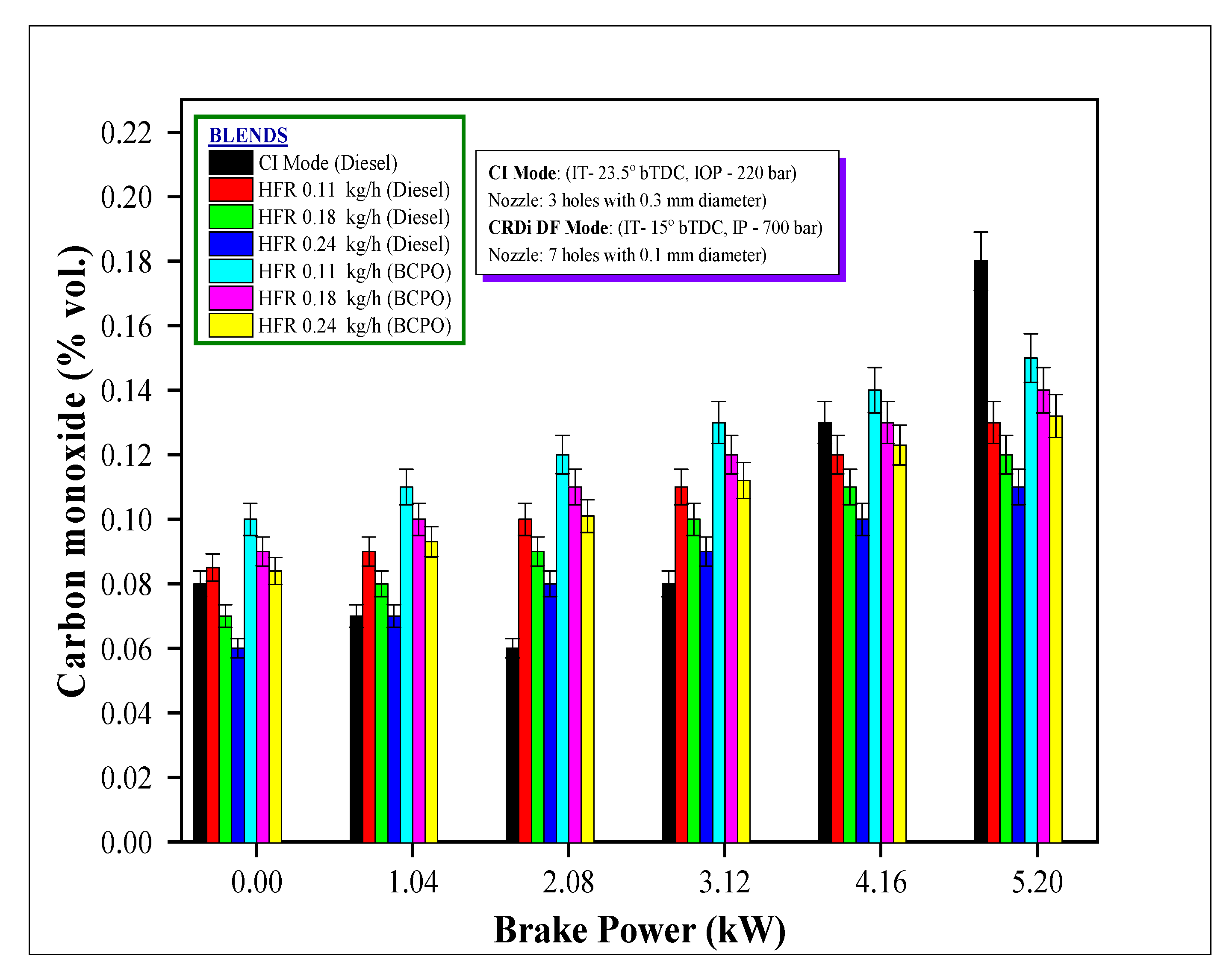

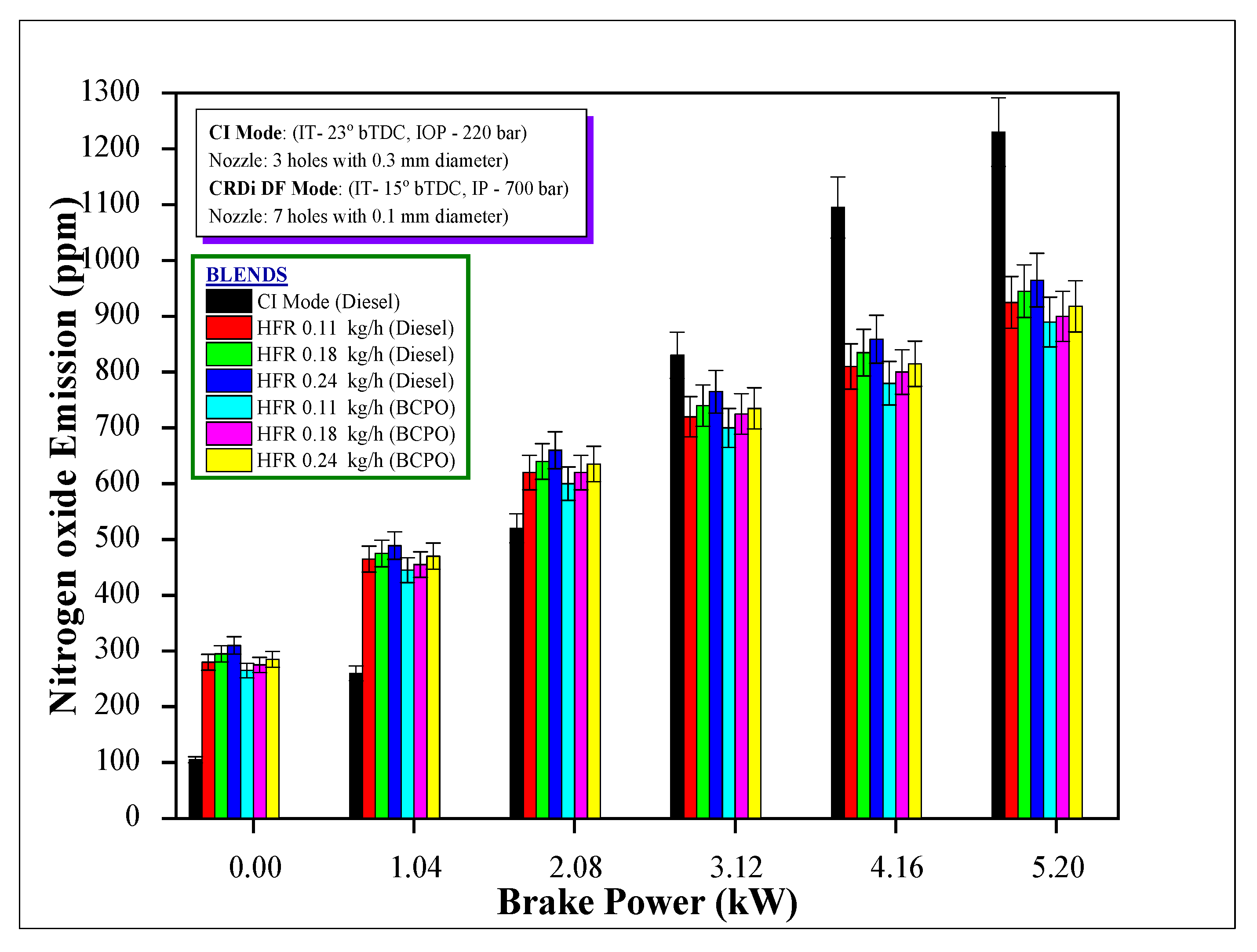

3.1.2. Emission Component Data

3.2. IP Variation Influence on CRDi Engine Performance

3.2.1. Brake Thermal Efficiency

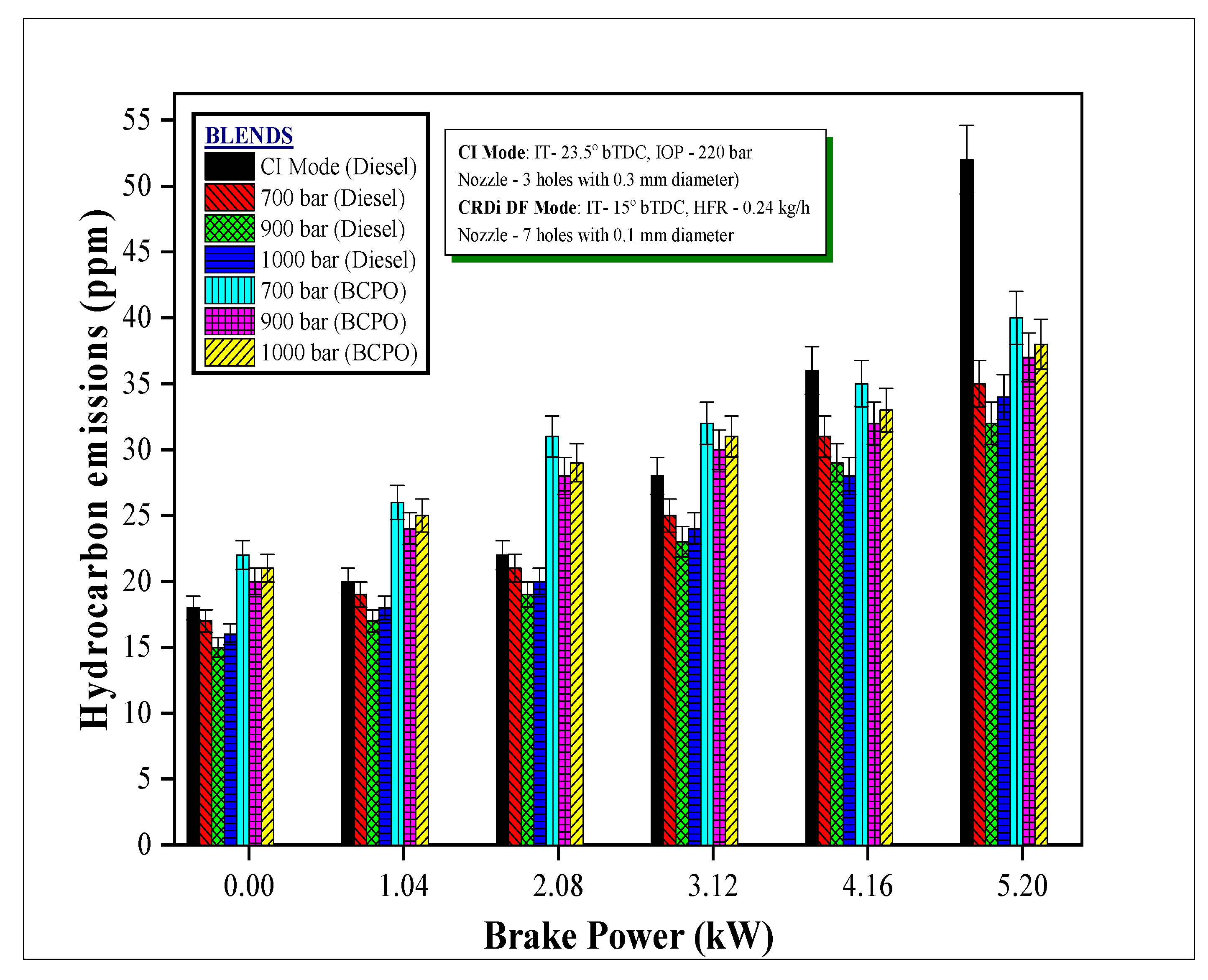

3.2.2. Emission Component Data

3.3. EGR Influence on CRDi Engine Performance

3.3.1. Performance: Brake Thermal Efficiency

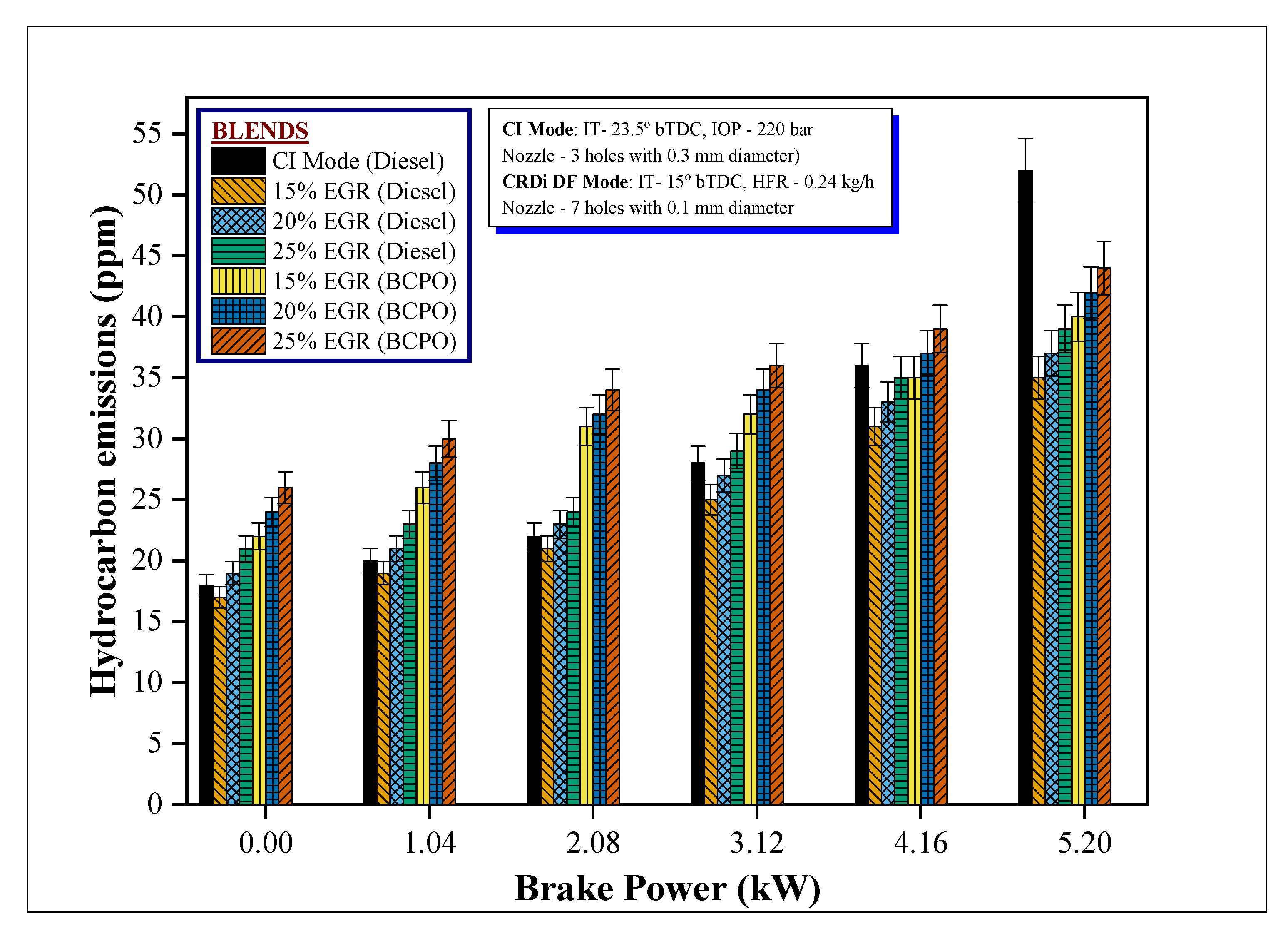

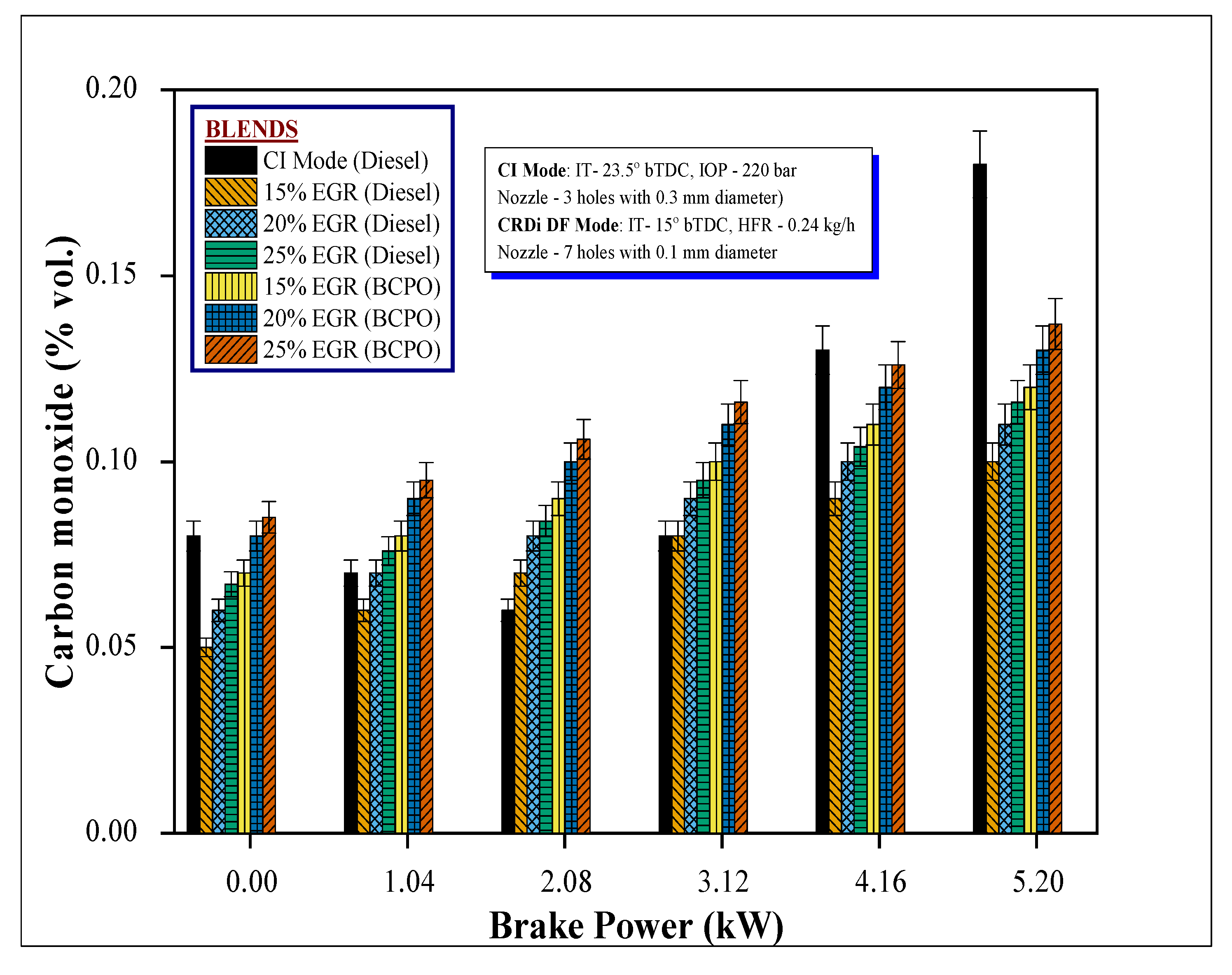

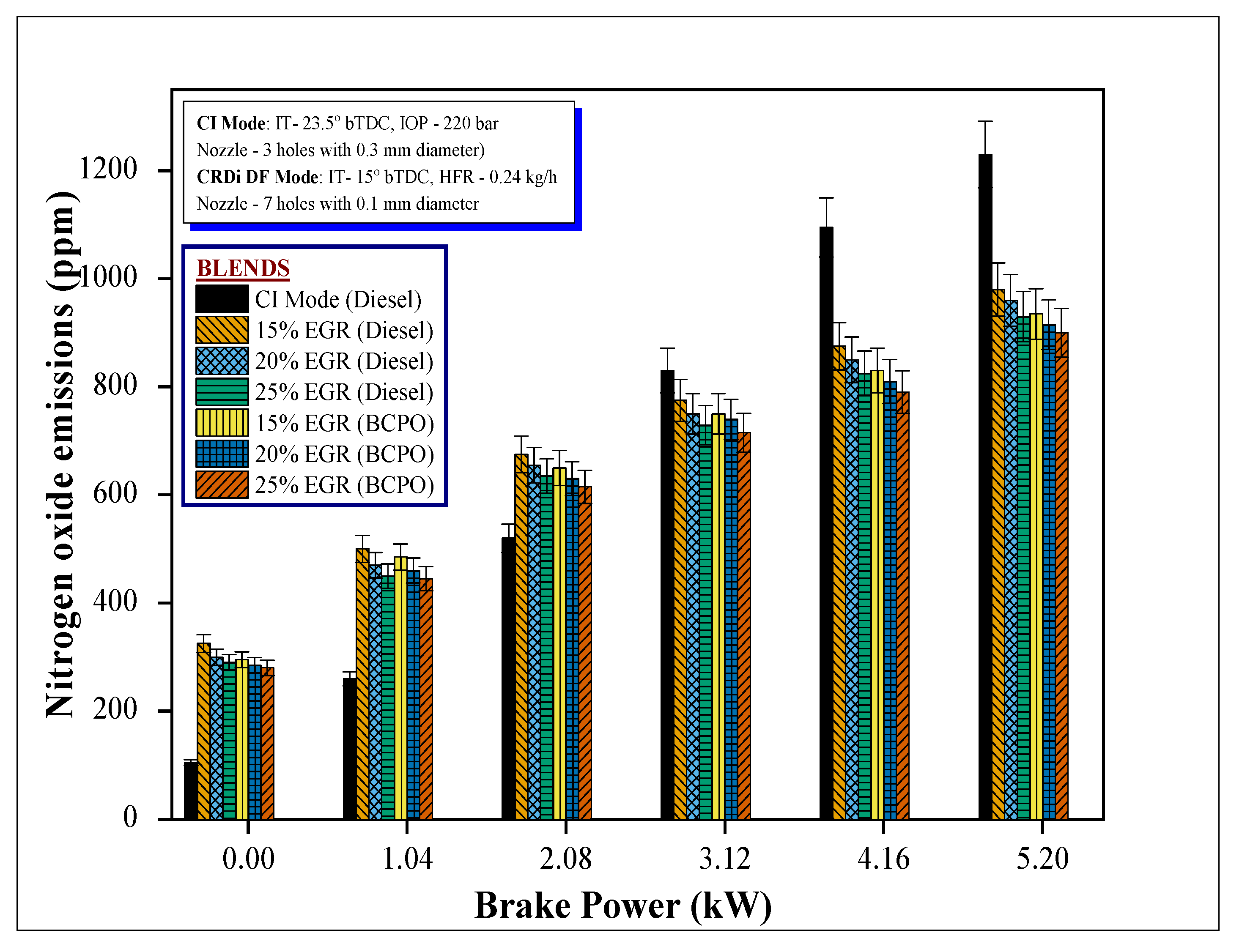

3.3.2. Emission Component Data

4. Conclusions

- Hydrogen infusion reduced the pilot fuel content. At operating parameters of 0.24 kg/h HFR, 900 bar IP with combustion chamber modifications collaborated to give CRDi engine a better performance with lower emissions.

- At 0.24 kg/h HFR, the CRDi engine provided 7.8% reduced BTE and redesigned combustion chamber relative to diesel-operated CI mode.

- At optimum operating conditions, HC emissions in CRDi engine were reduced by 18.5%, and CO emissions were decreased by 17% relative to the CI mode. NOx emissions in CRDi engine were decreased by 28% relative to the CI mode.

- At 20% EGR lowered the BTE by 14.2% and reduced hydrocarbons, nitrogen oxide and carbon monoxide by 6.3%, 30.5% and 9%, respectively, compared to the CI mode of operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CRDi | Common rail direct injection |

| DF | Dual fuel |

| H2 | Hydrogen |

| CI | Compression ignition |

| IC | Internal combustion |

| ID | Ignition delay |

| IOP | Injector opening pressure |

| IP | Injection pressure |

| IT | Injection timing |

| EGR | Exhaust gas recirculation |

| CA | Crank angle |

| CR | Compression ratior |

| bTDC | Before top dead centre |

| IT | Injection timing |

| BCPO | Biodiesel of ceiba pentandra oil |

| HFR | Hydrogen fuel flow rate |

| BSFC | Brake specific fuel consumption |

| HRR | Heat release rate |

| PP | Peak pressure |

| NOx | Oxides of nitrogen |

| HC | Hydrocarbon |

| CO | Carbon monoxide |

| NG | Natural gas |

References

- Abedin, M.J.; Imran, A.; Masjuki, H.H.; Kalam, M.A.; Shahir, S.A.; Varman, M.; Ruhul, A.M. An overview on comparative engine performance and emission characteristics of different techniques involved in diesel engine as dual-fuel engine oper-ation. Renew. Sustain. Energy Rev. 2016, 60, 306–316. [Google Scholar] [CrossRef]

- Bora, B.J.; Saha, U.K. Experimental evaluation of a rice bran biodiesel—Biogas run dual fuel diesel engine at varying compression ratios. Renew. Energy 2016, 87, 782–790. [Google Scholar] [CrossRef]

- Kumar, M.S.; Nataraj, G.; Selvan, S.A. A comprehensive assessment on the effect of high octane fuels induction on engine’s combustion behaviour of a Mahua oil based dual fuel engine. Fuel 2017, 199, 176–184. [Google Scholar] [CrossRef]

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and emission characteristics of a hydrogen-diesel du-al-fuel engine. Int. J. Hydrog. Energy 2018, 43, 13605–13617. [Google Scholar] [CrossRef]

- Sharma, P.; Dhar, A. Compression ratio influence on combustion and emissions characteristic of hydrogen diesel dual fuel CI engine: Numerical Study. Fuel 2018, 222, 852–858. [Google Scholar] [CrossRef]

- Tarabet, L.; Lounici, M.; Loubar, K.; Khiari, K.; Bouguessa, R.; Tazerout, M. Hydrogen supplemented natural gas effect on a DI diesel engine operating under dual fuel mode with a biodiesel pilot fuel. Int. J. Hydrog. Energy 2018, 43, 5961–5971. [Google Scholar] [CrossRef]

- Dhole, A.; Lata, D.; Yarasu, R. Effect of hydrogen and producer gas as secondary fuels on combustion parameters of a dual fuel diesel engine. Appl. Therm. Eng. 2016, 108, 764–773. [Google Scholar] [CrossRef]

- Kumar, M.; Tsujimura, T.; Suzuki, Y. NOx model development and validation with diesel and hydrogen/diesel dual-fuel system on diesel engine. Energy 2018, 145, 496–506. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Liew, C.; Li, Y.; Wayne, S.; Clark, N. An investigation on the mechanism of the increased NO2 emissions from H2-diesel dual fuel engine. Int. J. Hydrog. Energy 2018, 43, 3837–3844. [Google Scholar] [CrossRef]

- Tsujimura, T.; Suzuki, Y. The utilization of hydrogen in hydrogen/diesel dual fuel engine. Int. J. Hydrog. Energy 2017, 42, 14019–14029. [Google Scholar] [CrossRef]

- Verma, S.; Das, L.; Kaushik, S.; Tyagi, S. An experimental investigation of exergetic performance and emission characteristics of hydrogen supplemented biogas-diesel dual fuel engine. Int. J. Hydrog. Energy 2018, 43, 2452–2468. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G.; Dhanasekaran, C.; Kalaiselvan, K. Experimental investigation of hydrogen port fuel injection in DI diesel engine. Int. J. Hydrog. Energy 2007, 32, 4071–4080. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G. Performance and emission studies on port injection of hydrogen with varied flow rates with Diesel as an ignition source. Appl. Energy 2010, 87, 2218–2229. [Google Scholar] [CrossRef]

- Srinivasan, C.; Subramanian, R. Investigation of using hydrogen as an internal combustion engine fuel. Middle East J. Sci. Res. 2015, 23, 785–790. [Google Scholar]

- Khandal, S.; Banapurmath, N.; Gaitonde, V. Effect of hydrogen fuel flow rate, fuel injection timing and exhaust gas re-circulation on the performance of dual fuel engine powered with renewable fuels. Renew. Energy 2018, 126, 79–94. [Google Scholar] [CrossRef]

- Khandal, S.; Banapurmath, N.; Gaitonde, V. Effect of exhaust gas recirculation, fuel injection pressure and injection timing on the performance of common rail direct injection engine powered with honge biodiesel (BHO). Energy 2017, 139, 828–841. [Google Scholar] [CrossRef]

- Duda, K.; Wierzbicki, S.; Smieja, M.; Mikulski, M. Comparison of performance and emissions of a CRDI diesel engine fuelled with biodiesel of different origin. Fuel 2018, 212, 202–222. [Google Scholar] [CrossRef]

- Roy, S.; Ghosh, A.; Das, A.K.; Banerjee, R. A comparative study of GEP and an ANN strategy to model engine performance and emission characteristics of a CRDI assisted single cylinder diesel engine under CNG dual-fuel operation. J. Nat. Gas Sci. Eng. 2014, 21, 814–828. [Google Scholar] [CrossRef]

- Kim, H.; Choi, B. The effect of biodiesel and bioethanol blended diesel fuel on nanoparticles and exhaust emissions from CRDI diesel engine. Renew. Energy 2010, 35, 157–163. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Saravanan, B.; Somasundaram, P.; Jegadheesan, C.; Chaturvedi, B.; Sharma, S.; Patni, G. A novel study on the effect lemon peel oil as a fuel in CRDI engine at various injection strategies. Energy Convers. Manag. 2018, 172, 517–528. [Google Scholar] [CrossRef]

- Hohenberg, G.F. Advanced Approaches for Heat Transfer Calculations; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1979; pp. 2788–2806. Available online: http://www.jstor.org/stable/44699090 (accessed on 7 July 2021).

- Hayes, T.K.; Savage, L.D.; Sorenson, S.C. Cylinder Pressure Data Acquisition and Heat Release Analysis on a Personal Computer; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1986. [Google Scholar]

- Manjunath, N.; Rajashekhar, C.; Khan, T.Y.; Badruddin, I.A.; Kamangar, S.; Khandal, S. Augmented Turbulence for Progressive and Efficient Combustion in Biodiesel–Diesel Engine. Arab. J. Sci. Eng. 2019, 44, 7957–7966. [Google Scholar] [CrossRef]

- Lee, C.S.; Park, S.W. An experimental and numerical study on fuel atomization characteristics of high-pressure diesel injection sprays. Fuel 2002, 81, 2417–2423. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Luo, Y.; Chan, T.L. Optimization of Exhaust Emissions of a Diesel Engine Fuelled with Biodiesel. Energy Fuels 2006, 20, 1015–1023. [Google Scholar] [CrossRef]

| Properties | Diesel Fuel | BCPO Fuel |

|---|---|---|

| Chemical composition Kinematic viscosity at 40 °C (cSt) | C12H23 2.5 | C9H18O2 5.1 |

| Calorific Fuel Value (kJ/kg) | 44,000 | 38,900 |

| Density at 15 °C (kg/m3) | 832 | 890 |

| Cloud Temperature Point (°C) | −2 | 4 |

| Pour Temperature Point (°C) | −5 | 5.5 |

| Flash Temperature Point (°C) | 66 | 205 |

| Properties | Hydrogen Fuel |

|---|---|

| Chemical composition | H2 |

| Temperature of auto ignition (K) | 858 |

| Minimum energy for ignition (mJ) | 0.02 |

| Flammable range (% volume in air) | 4–75 |

| Mass basis Stoichiometric air fuel ratio | 34.3 |

| Density at 1 bar and 15 °C | 0.0838 |

| Net value of heating (MJ/kg) | 119.93 |

| Velocity of flame (cm/s) | 265–325 |

| Octane grade number | 130 |

| Parameters | Specifications |

|---|---|

| Type of Engine | Cylinder: 1 Stroke: 4 |

| Injection pressure | 600–1000 bar |

| Cooling system | Water cooling |

| Type of fuel used | Diesel/Biodiesel |

| Rated power | 5.2 kW at 1500 RPM |

| Torque at full load Cubic capacity Bore diameter | 0.033 kg-m 0.661 L 0.0875 m |

| Stroke Length | 0.11 m |

| Ratio of Compression (RC) | 17.5:1 |

| Mode of Operation | Operating Conditions |

|---|---|

| CI | IT—23.5° bTDC, IOP—220 bar, CR—17.5, hemispherical combustion chamber, Fuel–Diesel, injector with 3 holes, 0.3 mm hole diameter |

| CRDi | |

| Case 1 | IT—15° bTDC, IP—700 bar, CR—17.5, modified combustion chamber, Fuel–Diesel/BCPO with HFR variable, injector with 7 holes, 0.1 mm hole diameter |

| Case 2 | IT—15° bTDC, IP—Variable, CR—17.5, modified combustion chamber, Fuel–Diesel/BCPO with HFR fixed, injector with 7 holes, 0.1 mm hole diameter |

| Case 3 | IT—15° bTDC, IP—900 bar, CR—17.5, modified combustion chamber, Fuel–Diesel/BCPO with HFR fixed, EGR—variable, injector with 7-holes, 0.1 mm hole diameter |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, T.M.Y.; Soudagar, M.E.M.; Khandal, S.V.; Javed, S.; Mokashi, I.; Baig, M.A.A.; Ismail, K.A.; Elfasakhany, A. Performance of Common Rail Direct Injection (CRDi) Engine Using Ceiba Pentandra Biodiesel and Hydrogen Fuel Combination. Energies 2021, 14, 7142. https://doi.org/10.3390/en14217142

Khan TMY, Soudagar MEM, Khandal SV, Javed S, Mokashi I, Baig MAA, Ismail KA, Elfasakhany A. Performance of Common Rail Direct Injection (CRDi) Engine Using Ceiba Pentandra Biodiesel and Hydrogen Fuel Combination. Energies. 2021; 14(21):7142. https://doi.org/10.3390/en14217142

Chicago/Turabian StyleKhan, T. M. Yunus, Manzoore Elahi M. Soudagar, S. V. Khandal, Syed Javed, Imran Mokashi, Maughal Ahmed Ali Baig, Khadiga Ahmed Ismail, and Ashraf Elfasakhany. 2021. "Performance of Common Rail Direct Injection (CRDi) Engine Using Ceiba Pentandra Biodiesel and Hydrogen Fuel Combination" Energies 14, no. 21: 7142. https://doi.org/10.3390/en14217142

APA StyleKhan, T. M. Y., Soudagar, M. E. M., Khandal, S. V., Javed, S., Mokashi, I., Baig, M. A. A., Ismail, K. A., & Elfasakhany, A. (2021). Performance of Common Rail Direct Injection (CRDi) Engine Using Ceiba Pentandra Biodiesel and Hydrogen Fuel Combination. Energies, 14(21), 7142. https://doi.org/10.3390/en14217142