Empirical Studies on Biomass Briquette Production: A Literature Review

Abstract

:1. Introduction

2. Briquetting

2.1. Biomass and Pre-Treatments Used in the Production of Briquettes

| References | Raw-Material | Pre-Treatment | Briquetting Machine | Variables of Briquetting Equipment | Results and Conclusions of the Studies |

|---|---|---|---|---|---|

| [40] | Cassava waste | Drying, grinding and sieving | Hydraulic Press | Pressure | Briquettes produced without heating or binder achieved good results: relaxed density of 918 kg·m−3, compressive strength of 1.29 MPa, durability of 94.1%, expansion of 8.68 and energy density of 15.7 GJ·m−3 |

| [29] | Corncobs (CC) and oil palm trunk bark (OPTB) | Drying, grinding and sieving | Hydraulic Piston Press | Temperature and pressure | They were obtained: MC of 9.24–10.00%, density of 0.38–0.40 g·cm−3, water resistance of 87.60–92.00%, mechanical strength of 98.28–99.08%, compressive strength of 18.47 to 21.75 MPa and calorific value of 16.54 to 16.91 MJ·kg−1 |

| [8] | Olive mil solid waste (OMSW) | Drying, grinding and sieving | Hydraulic Press | Temperature and pressure | Briquettes with unit density: 2.04–3.03 g·cm−3 and bulk density: 0.84–1.20 g·cm−3. With 15% of binder, greater compressive strength (4581 kN), HHV (16.92 MJ·kg−1) and lower AC (6.72%) were obtained |

| [43] | Cashew nut shells (CNS) and areca nut shells (ANS) | Torrefaction (CNS), drying (ANS), grinding and sieving | Compacted screw motor-driven | Compressed screw speed | Average values: 18.9–21 MJ·kg−1 of calorific value, hardness 103–123 HB, porosity 52–65%, TU 3.5–4.5%, VM 71.2–73.2%, TC 3.3–5.2% and CF 18.8–20%. The “A” mixture is suitable for the production of briquettes, with a speed of 90 rpm and small CNS |

| [37] | Lantana camara e Prosopis juliflora | Drying, breaking, grinding, pulverizing and sieving | Industrial machine. Piston and ram | Not specified | The briquettes reached a density of 1200 kg·m−3, an energy density of 23.05 GJ·m−3. Ideal MC of 10–12% and lower AC of ≤2% |

| [38] | Palm Stem | Chopping, cleaning, carbonization and sieving | Hydraulic Press | Pressure | Through optimization, HHV of 306.704 MJ·kg−1 and compressive strength of 10.0608 kg·cm−2 were obtained, with the parameters of 120 mesh, ≈47% binder and ≈9.32 MPa |

| [27] | Wood Waste of Pinus spp. | Collects and sieving * | Manual mechanical device | Not specified | The biomass had an apparent density of 160 and 170 kg·m−3, TC of 0.38–1.78%, VM of 65.3–95.01% and FC of 4.49–34.3%. The briquettes had MC of 11.52–13.26%, HHV of 17.0–18.3 MJ·kg−1 and density of 930–1240 kg·m−3 |

| [28] | Corn husk (CH) e cassava peel (CP) | Drying, milling, torrefaction and humidification | Hydraulic piston press machine | Pressure | Briquettes torrefied at 300 °C with a mixture of 10/90 (CH/CP) showed good combustible characteristics. These showed increases of briquettes without thermal treatment of 18.19%; 2.98% and 32.25% in density, durability and compressive strength, respectively |

| [44] | Coal dust (C), sawdust (S) and post-consumer plastics (P) | Washing, drying, grinding and sieving | Manual Press | Not specified | They were obtained HHV from 26.5 to 33.8 MJ·kg−1. Impact resistance/break rate ≥ 90% in all briquettes and density from 1100 to 1300 kg·m−3. However, it had low resistance to compression, below 1 MPa |

| [13] | Coffee shrub residues and pinewood | Drying, grinding and sieving | Hydraulic Piston Press | Temperature and pressure | The coffee residue mixed with 75% of the pine wood yielded an apparent density of 1107–1163 kg·m−3, energy density of 19.13–19.89 GJ·m−3, tensile strength of 415–569 kgf and equilibrium moisture content of 9–11% by weight |

| [42] | Banana leaves and pseudostem, and rice husk | Chopping, milling, sieving, pressing and drying | Hydraulic Press | Pressure | The rice husk briquettes showed the highest compressive strength (19.8 MPa) and the highest HHV (18.1 MJ·kg−1), however they had a high AC value (25.4%) |

| [34] | Sugar bagasse and straw | Drying, grinding and sieving | Manual Hydraulic Press | Load measured in tonnes | Briquettes with a greater amount of sugarcane bagasse had greater resistance to compression, less generation of fines, moisture content of 11 to 12%. The use of straw is only feasible when associated with sugarcane bagasse |

| [45] | Palm kernel shell biochars (PKSB) | Uninformed | Compression cylindrical ram machine | Compaction speed and pressure | Average calorific value of 31.29 ± 1.44 MJ·kg−1. Impact resistant, preserving 95% of its initial weight. Poor performance for water resistance. Depending on the processing conditions, tensile strength > 800 kN·m−2 can be achieved. |

| [36] | Phyllostachys aurea | Drying, grinding, sieving and humidification | Laboratory press | Temperature and pressure | Biomass, briquettes produced from it and coal were evaluated. The briquettes showed higher energy density (21.47 GJ·m−3) than coal (11.38 GJ·m−3), but both have potential for energy applications |

| [30] | Sawdust (S) and date palm trunk (PT), plastic waste | Grinding and sieving | Laboratory hydraulic piston press | Temperature and pressure | Although the S70-W30 briquettes produced at 130 °C have a higher density (≈1190 kg·m−3) and durability (100%), almost all PT briquettes produced at room temperature showed high densities and durability, and the largest LHV with PT90-ASR10 |

| [39] | Charcoal thin waste and sanitary sewage sludge | Drying, grinding and sieving | Conical screw extruder | Pressure | The 50:50 mixture of charcoal and sludge was ideal for energy production with HHV of 17.47 MJ·kg−1, breaking strength of 41.19 MPa and apparent density of 913 kg·m−3 |

| [31] | Plastic waste, sawdust, maize husk and carbonized sub-bituminous coal | Drying, chopping, carbonization, grinding and sieving | Hydraulic Press | Load of up to 10 tons | HHV for briquettes with 0% and 90% coke was 13.8 and 21.45 MJ·kg−1, respectively. The raw material of 100% coke produces HHV of 23.86 MJ·kg−1. The highest VM (31.74%) and compressive strength (4.61 N·mm−3) were obtained in the briquette with 100% biomass and 0% coke |

| [46] | Coconut Fiber (FC) and sugarcane straw (PC) | Drying, grinding and sieving | Manual Hydraulic Press | Pressure | The briquettes made of PC e FC can be manufactured without heating or adding binder. The highest amount of FC was favorable for the compressive strength (0.37 MPa), HHV (18.24 MJ·kg−1), fixed carbon (22.28%) and AC (3.71%) |

| [26] | Wood of Eucalyptus spp. and Eucalyptus grandis | Drying, cutting, torrefaction, grinding and sieving | Hydraulic Piston Press | Temperature, pressing time and pressure | Values for E. spp. and E. grandis, respectively. Bulk density: 1.14 and 1.06 g·cm−3; energy density (Treatment at 200 °C): 24.79 and 21.70 GJ·m−3; lowest MC: 9.9 and 9.6%; lower hygroscopy: E. grandis at 200 °C and 10 MPa; greater compressive strength: relative |

| [47] | Banana Leave Waste | Milling and sizing | Hydraulic Press | Pressure | The compaction time of 0.6 and 1 s was negligible for density, with values of 999 and 1000 kg·m−3, respectively. Higher compressive strength (5.3 MPa) was achieved with 1 s. The calculation of the energy density was based on the density of 999 kg·m−3 |

| [48] | Corn stover | Drying, chopping and Milling | Laboratory piston press (Plunger) | Pressure | Given the different experiments, with different interactions of the input variables, better dry density and bulk density of 470 and 190 kg·m−3 are observed, respectively |

| [25] | Woody (timber) cutting waste (WCW) | Drying and sieving | Automatic hydraulic piston press | Clamping force and temperature | The 10:90 mass ratio of crude glycerol and WCW are suitable for forming briquettes. Its density is 798 kg·m−3, durability of 86.7%; 0.91 kN of stress resistance, HHV of 17.1 MJ·kg−1 and AC of 0.9% |

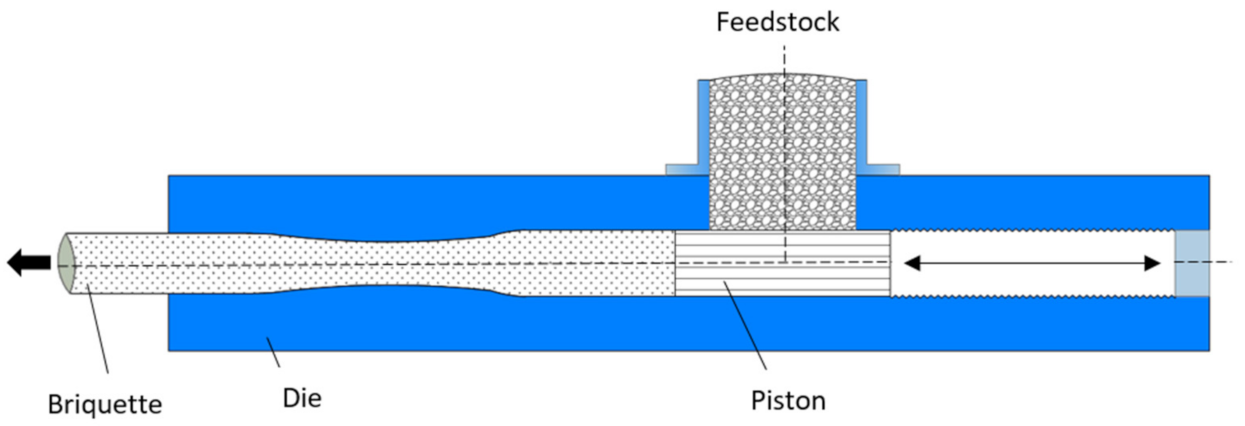

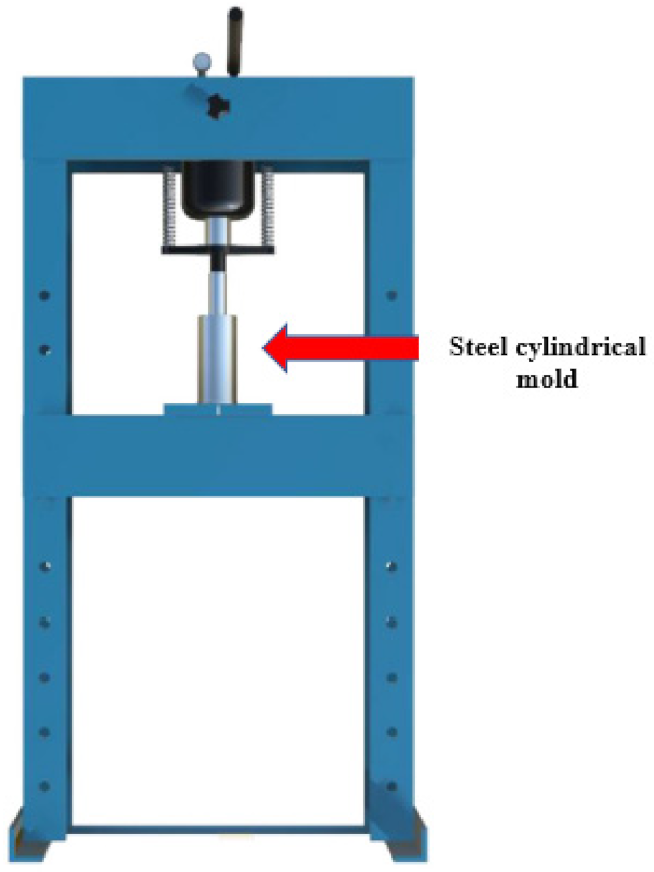

2.2. Main Briquette Production Processes

3. Main Parameters of Briquette Production in Academic Works

3.1. Levels of Briquette Production Parameters

3.1.1. Effect of Temperature on the Production of Briquettes

3.1.2. Variation in the Proportion of Biomass Mixed in the Production of Briquettes

3.1.3. Effect of the Addition of Binders on Biomass for the Production of Briquettes

3.1.4. Effect of Pressing Time on the Production of Briquettes

3.1.5. Effect of Biomass Moisture on the Production of Briquettes

3.1.6. Effect of Pressure on the Production of Biomass Briquettes

3.1.7. Effect of Particle Size on the Production of Biomass Briquettes

4. Main Response Parameters of Briquette Production

4.1. Thermal, Energetic and Moisture Content Response Variables

4.1.1. Volatile Matter and Fixed Carbon

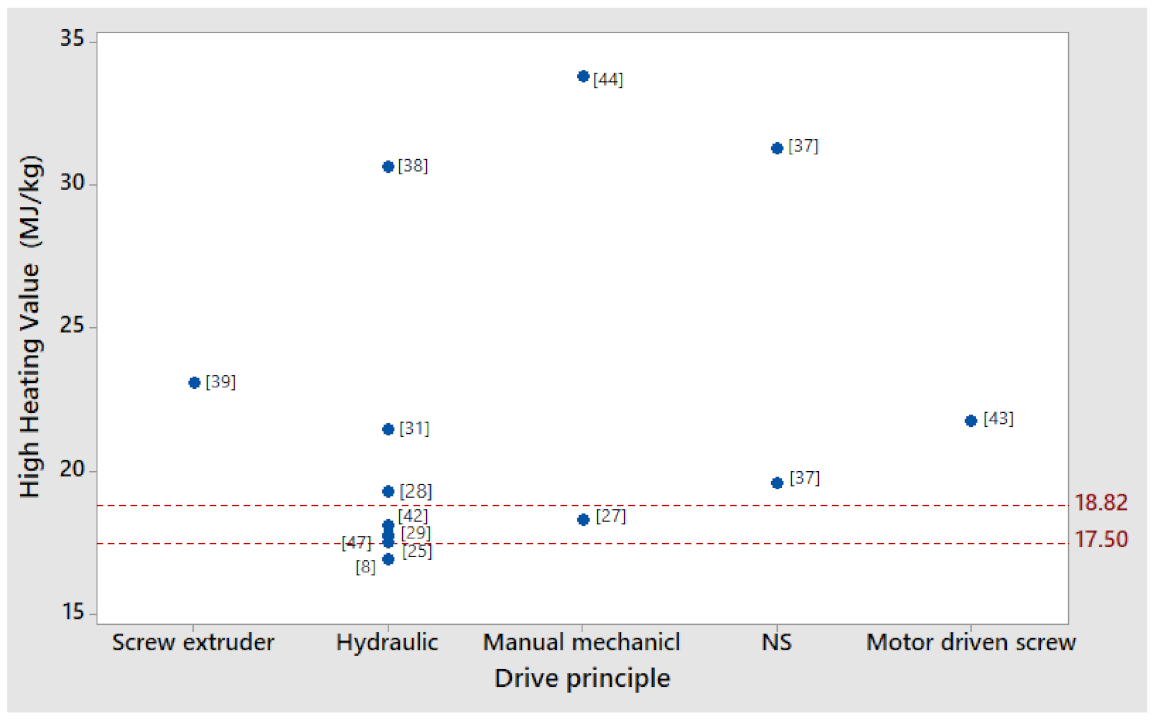

4.1.2. High Heating Value

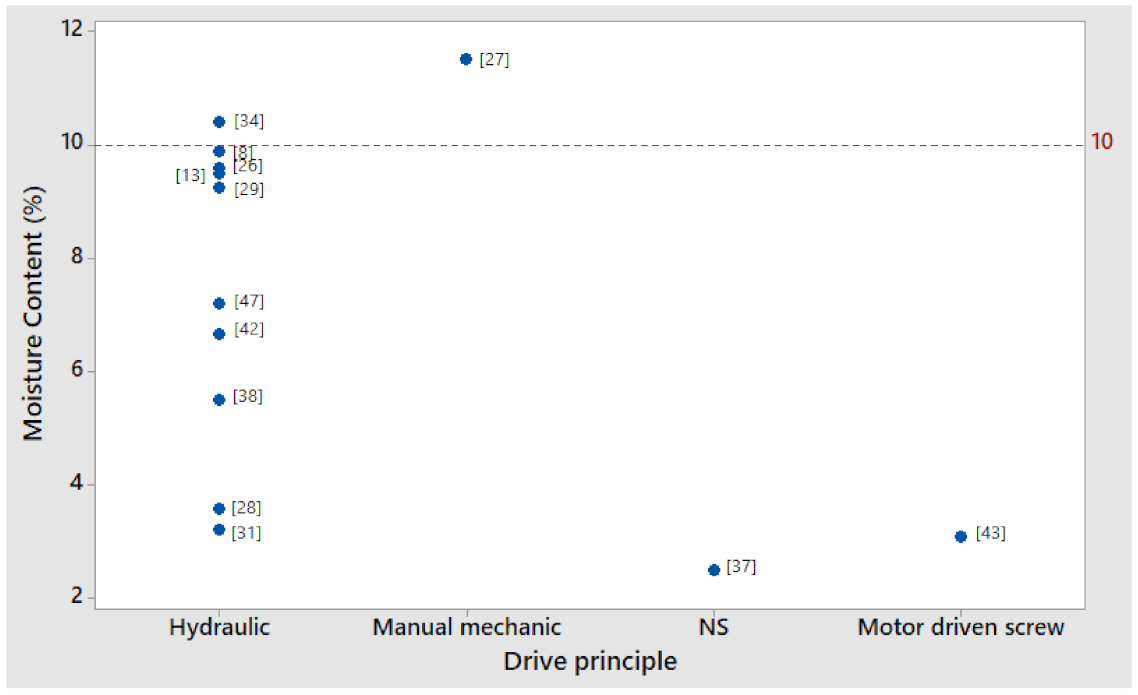

4.1.3. Moisture Content

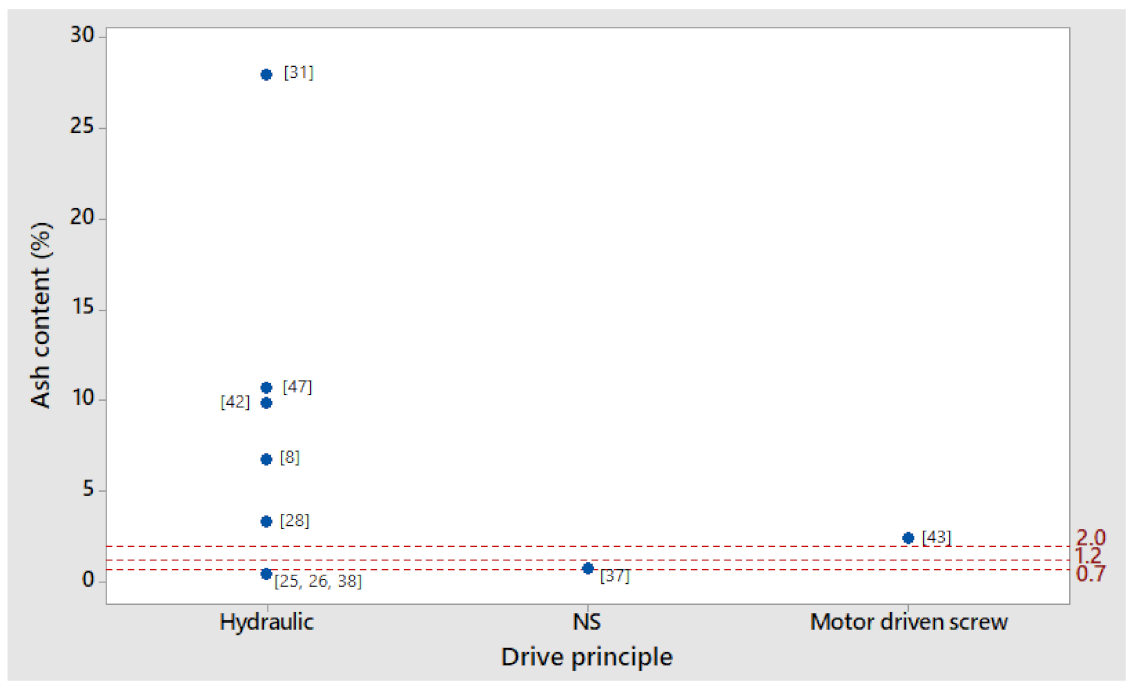

4.1.4. Ash Content

4.2. Physical-Mechanical Output Variables

4.2.1. Longitudinal Expansion

4.2.2. Generation of Fines

4.2.3. Water Absorption

4.2.4. Durability

4.2.5. Bulk Density

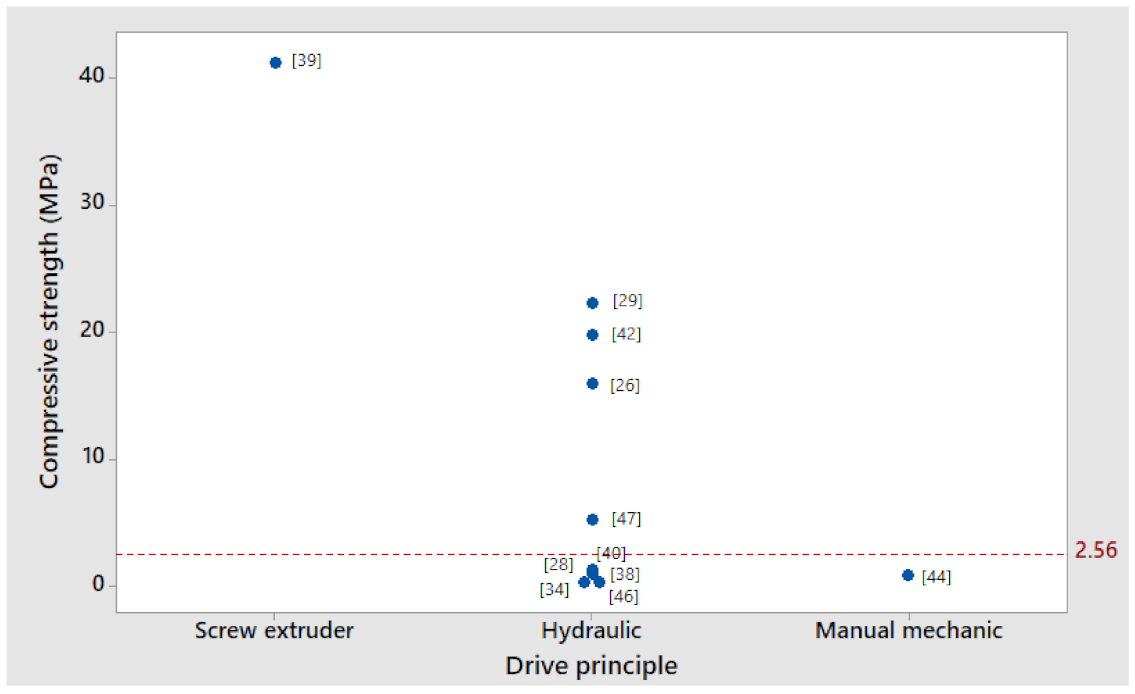

4.2.6. Compressive Strength

5. Modeling and Statistical Analysis of Experiments

6. Conclusions

- The input variables that were studied most often were: particle size of biomass (95%), compaction pressure (73%), moisture content of the raw material (68%), compaction time (59%), proportion of binder (50%), proportion of biomass to compose the briquettes (45%) and temperature (32%);

- The response variables most used to classify the briquettes were: higher calorific value, moisture content, ash content, density and resistance to compression.

- The initial moisture content of the raw materials ranged from 8 to 12%;

- The most used briquetting temperature among the briquettes was 120 °C;

- Most works produce their briquettes at intermediate pressures. It is also noticed that higher pressure values are not necessarily ideal for maximizing the physical quality of briquettes;

- In order to obtain a higher final calorific value of the briquettes, it is preferable that they are composed mostly of the raw material with the greatest initial calorific value.;

- Generally speaking, particles of less granulometry promote stronger bonds between particles, resulting in more resistant briquettes. However, the ideal granulometry varies according to the raw material used and the briquetting process;

- The presence of a binder has an influence on the physical-mechanical and energetic properties of the briquettes. Its use is related to processes carried out at low temperatures and pressure. The most used binder was starch;

- Briquettes with apparent density above the limit of 750 kg·m−3, stipulated by the ENplus quality standard, can be produced in hydraulic driven machines;

- The lowest values of compressive strength were obtained in manual machines (hydraulic or mechanical).

Author Contributions

Funding

Conflicts of Interest

References

- Breyer, C.; Heinonen, S.; Ruotsalainen, J. New consciousness: A societal and energetic vision for rebalancing humankind within the limits of planet Earth. Technol. Forecast. Soc. Change 2017, 114, 7–15. [Google Scholar] [CrossRef]

- Onifade, S.T.; Alola, A.A.; Erdoğan, S.; Acet, H. Environmental aspect of energy transition and urbanization in the OPEC member states. Environ. Sci. Pollut. Res. 2021, 28, 17158–17169. [Google Scholar] [CrossRef]

- Quijera, J.A.; Alriols, M.G.; Labidi, J. Integration of a solar thermal system in a dairy process. Renew. Energy 2011, 36, 1843–1853. [Google Scholar] [CrossRef]

- Bridgwater, T. Biomass for energy. J. Sci. Food Agric. 2006, 86, 1755–1768. [Google Scholar] [CrossRef]

- Tchapda, A.H.; Pisupati, S.V. A Review of Thermal Co-Conversion of Coal and Biomass/Waste. Energies 2014, 7, 1098–1148. [Google Scholar] [CrossRef] [Green Version]

- Felfli, F.F.; Mesa, P.J.M.; Rocha, J.D.; Filippetto, D.; Luengo, C.A.; Pippo, W.A. Biomass briquetting and its perspectives in Brazil. Biomass-Bioenergy 2011, 35, 236–242. [Google Scholar] [CrossRef]

- Wongsiriamnuay, T.; Tippayawong, N. Effect of densification parameters on the properties of maize residue pellets. Biosyst. Eng. 2015, 139, 111–120. [Google Scholar] [CrossRef]

- Khlifi, S.; Lajili, M.; Belghith, S.; Mezlini, S.; Tabet, F.; Jeguirim, M. Briquettes Production from Olive Mill Waste under Optimal Temperature and Pressure Conditions: Physico-Chemical and Mechanical Characterizations. Energies 2020, 13, 1214. [Google Scholar] [CrossRef] [Green Version]

- Okwu, M.O.; Samuel, O.D. Adapted hyacinth briquetting machine for mass production of briquettes. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 2853–2866. [Google Scholar] [CrossRef]

- Panwar, V.; Prasad, B.; Wasewar, K.L. Biomass Residue Briquetting and Characterization. J. Energy Eng. 2011, 137, 108–114. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Effect of process parameters on pelletisation of herbaceous crops. Fuel 2009, 88, 1491–1497. [Google Scholar] [CrossRef]

- Verma, V.; Bram, S.; De Ruyck, J. Small scale biomass heating systems: Standards, quality labelling and market driving factors—An EU outlook. Biomass-Bioenergy 2009, 33, 1393–1402. [Google Scholar] [CrossRef]

- Martinez, C.L.M.; Sermyagina, E.; Carneiro, A.D.C.O.; Vakkilainen, E.; Cardoso, M. Production and characterization of coffee-pine wood residue briquettes as an alternative fuel for local firing systems in Brazil. Biomass-Bioenergy 2019, 123, 70–77. [Google Scholar] [CrossRef]

- Navalta, C.J.L.G.; Banaag, K.G.C.; Raboy, V.A.O.; Go, A.W.; Cabatingan, L.K.; Ju, Y.-H. Solid fuel from Co-briquetting of sugarcane bagasse and rice bran. Renew. Energy 2019, 147, 1941–1958. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Faizal, H.M.; Rahman, M.R.A.; Latiff, Z.A. Review on densification of palm residues as a technique for biomass energy utilization. J. Teknol. 2016, 78. [Google Scholar] [CrossRef] [Green Version]

- Tumuluru, J.S.; Wright, C.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technol. 2019, 7, 1801011. [Google Scholar] [CrossRef]

- Oladeji, J. Theoretical Aspects of Biomass Briquetting: A Review Study. J. Energy Technol. Policy 2015, 5, 72–82. [Google Scholar]

- El-Desouky, M.G.; Khalil, M.A.; El-Bindary, A.A.; El-Bindary, M.A. Biological, Biochemical and Thermochemical Techniques for Biofuel Production: An Updated Review. Biointerface Res. Appl. Chem. 2021, 12, 3034–3054. [Google Scholar] [CrossRef]

- Baeyens, J.; Kang, Q.; Appels, L.; Dewil, R.; Lv, Y.; Tan, T. Challenges and opportunities in improving the production of bio-ethanol. Prog. Energy Combust. Sci. 2015, 47, 60–88. [Google Scholar] [CrossRef]

- Mata, T.M.; Martins, A.; Caetano, N. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef] [Green Version]

- Naik, S.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Lü, J.; Sheahan, C.; Fu, P. Metabolic engineering of algae for fourth generation biofuels production. Energy Environ. Sci. 2011, 4, 2451–2466. [Google Scholar] [CrossRef]

- Raslavičius, L. Characterization of the woody cutting waste briquettes containing absorbed glycerol. Biomass-Bioenergy 2012, 45, 144–151. [Google Scholar] [CrossRef]

- Araújo, S.; Boas, M.A.V.; Neiva, D.M.; Carneiro, A.D.C.; Vital, B.; Breguez, M.; Pereira, H. Effect of a mild torrefaction for production of eucalypt wood briquettes under different compression pressures. Biomass-Bioenergy 2016, 90, 181–186. [Google Scholar] [CrossRef]

- Morales-Máximo, M.; Ruíz-García, V.; López-Sosa, L.B.; Rutiaga-Quiñones, J.G. Exploitation of Wood Waste of Pinus spp for Briquette Production: A Case Study in the Community of San Francisco Pichátaro, Michoacán, Mexico. Appl. Sci. 2020, 10, 2933. [Google Scholar] [CrossRef]

- Waheed, M.A.; Akogun, O.A. Quality enhancement of fuel briquette from cornhusk and cassava peel blends for cofiring in coal thermal plant. Int. J. Energy Res. 2020, 45, 1867–1878. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique. Sustainability 2020, 12, 2468. [Google Scholar] [CrossRef] [Green Version]

- Garrido, M.A.; Conesa, J.A.; Garcia, M.D. Characterization and Production of Fuel Briquettes Made from Biomass and Plastic Wastes. Energies 2017, 10, 850. [Google Scholar] [CrossRef] [Green Version]

- Nwabue, F.; Unah, U.; Itumoh, E. Production and characterization of smokeless bio-coal briquettes incorporating plastic waste materials. Environ. Technol. Innov. 2017, 8, 233–245. [Google Scholar] [CrossRef]

- Iftikhar, M.; Asghar, A.; Ramzan, N.; Sajjadi, B.; Chen, W.-Y. Biomass densification: Effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biomass-Bioenergy 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Fillerup, E. Briquetting characteristics of woody and herbaceous biomass blends: Impact on physical properties, chemical composition, and calorific value. Biofuels Bioprod. Biorefin. 2020, 14, 1105–1124. [Google Scholar] [CrossRef]

- Masullo, L.S.; Alesi, L.S.; Quadros, T.M.C.; Silva, D.; De Pádua, F.A.; Yamaji, F.M. Use of Blends Containing Different Proportions of Straw and Sugarcane Bagasse for the Production of Briquettes. Rev. Virtual Quím. 2018, 10, 641–654. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass-Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Junior, C.R.S.; Lima, P.A.F.; Lopes, D.M.M.; Barbosa, P.V.G.; Coneglian, A.; Almeida, R.D.A. Characterization of biomass, charcoal and briquette of Phyllostachys aurea Carr. ex A. & C. Rivière. Sci. For. 2017, 45, 619–628. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Chandrashekar, N. Production and characterization of briquettes from invasive forest weeds: Lantana camara and Prosopis juliflora. J. Indian Acad. Wood Sci. 2020, 17, 158–164. [Google Scholar] [CrossRef]

- Helwani, Z.; Ramli, M.; Rusyana, A.; Marlina, M.; Fatra, W.; Idroes, G.M.; Suhendra, R.; Ashwie, V.; Mahlia, T.M.I.; Idroes, R. Alternative Briquette Material Made from Palm Stem Biomass Mediated by Glycerol Crude of Biodiesel Byproducts as a Natural Adhesive. Processes 2020, 8, 777. [Google Scholar] [CrossRef]

- de Oliveira, R.S.; Palácio, S.M.; da Silva, E.A.; Mariani, F.Q.; Reinehr, T.O. Briquettes production for use as power source for combustion using charcoal thin waste and sanitary sewage sludge. Environ. Sci. Pollut. Res. 2017, 24, 10778–10785. [Google Scholar] [CrossRef]

- Granado, M.P.P.; Suhogusoff, Y.V.M.; Santos, L.R.O.; Yamaji, F.M.; De Conti, A.C. Effects of pressure densification on strength and properties of cassava waste briquettes. Renew. Energy 2020, 167, 306–312. [Google Scholar] [CrossRef]

- Francik, S.; Knapczyk, A.; Knapczyk, A.; Francik, R. Decision Support System for the Production of Miscanthus and Willow Briquettes. Energies 2020, 13, 1364. [Google Scholar] [CrossRef] [Green Version]

- Maia, B.G.D.O.; De Oliveira, A.P.N.; De Oliveira, T.M.N.; Marangoni, C.; Souza, O.; Sellin, N. Characterization and production of banana crop and rice processing waste briquettes. Environ. Prog. Sustain. Energy 2017, 37, 1266–1273. [Google Scholar] [CrossRef]

- Chungcharoen, T.; Srisang, N. Preparation and characterization of fuel briquettes made from dual agricultural waste: Cashew nut shells and areca nuts. J. Clean. Prod. 2020, 256, 120434. [Google Scholar] [CrossRef]

- Gwenzi, W.; Ncube, R.S.; Rukuni, T. Development, properties and potential applications of high-energy fuel briquettes incorporating coal dust, biowastes and post-consumer plastics. SN Appl. Sci. 2020, 2, 1–14. [Google Scholar] [CrossRef]

- Bazargan, A.; Rough, S.L.; McKay, G. Fine tuning of process parameters for improving briquette production from palm kernel shell gasification waste. Environ. Technol. 2017, 39, 931–938. [Google Scholar] [CrossRef]

- Padilla, E.R.D.; Pires, I.C.S.A.; Yamaji, F.M.; Fandiño, J.M.M. Production and Physical-Mechanical Characterization of Briquettes from Coconut Fiber and Sugarcane Straw. Rev. Virtual Quím. 2016, 8, 1334–1346. [Google Scholar] [CrossRef]

- De Oliveira Maia, B.G.; Souza, O.; Marangoni, C.; Hotza, D.; De Oliveira, A.P.N.; Sellin, N. Production and characterization of fuel briquettes from banana leaves waste. Chem. Eng. Trans. 2014, 37, 439–444. [Google Scholar] [CrossRef]

- Thoreson, C.P.; Webster, K.E.; Darr, M.J.; Kapler, E.J. Investigation of Process Variables in the Densification of Corn Stover Briquettes. Energies 2014, 7, 4019–4032. [Google Scholar] [CrossRef] [Green Version]

- Aransiola, E.; Oyewusi, T.; Osunbitan, J.; Ogunjimi, L. Effect of binder type, binder concentration and compacting pressure on some physical properties of carbonized corncob briquette. Energy Rep. 2019, 5, 909–918. [Google Scholar] [CrossRef]

- Gado, I.H.; Ouiminga, S.K.; Daho, T.; Yonli, A.H.; Sougoti, M.; Koulidiati, J. Characterization of Briquettes Coming from Compaction of Paper and Cardboard Waste at Low and Medium Pressures. Waste Biomass-Valoriz. 2013, 5, 725–731. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Acheampong, B. Strength properties and calorific values of sawdust-briquettes as wood-residue energy generation source from tropical hardwoods of different densities. Biomass-Bioenergy 2016, 85, 144–152. [Google Scholar] [CrossRef]

- Seco, A.; Espuelas, S.; Marcelino-Sádaba, S.; Echeverría, A.M.; Prieto, E. Characterization of Biomass Briquettes from Spent Coffee Grounds and Xanthan Gum Using Low Pressure and Temperature. BioEnergy Res. 2019, 13, 369–377. [Google Scholar] [CrossRef]

- Lela, B.; Barišić, M.; Nižetić, S. Cardboard/sawdust briquettes as biomass fuel: Physical–mechanical and thermal characteristics. Waste Manag. 2016, 47, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Rejdak, M.; Robak, J.; Czardybon, A.; Ignasiak, K.; Fudała, P. Research on the Production of Composite Fuel on the Basis of Fine-Grained Coal Fractions and Biomass—The Impact of Process Parameters and the Type of Binder on the Quality of Briquettes Produced. Minerals 2019, 10, 31. [Google Scholar] [CrossRef] [Green Version]

- Grover, P.D.; Mishra, S.K. Biomass Briquetting: Technology and Pratices. In Regional Wood Energy Development Program in Asia, Field Document No. 46; Food and Agriculture Organization of the United Nations: Bangkok, Thailand, 1996; p. 46. [Google Scholar]

- Lei, T.; Wang, Z.; Li, Z.; Xu, J.; He, X.; Zhu, J. A biomass briquetting fuel machine and its large-scale operation system. J. Renew. Sustain. Energy 2013, 5, 013107. [Google Scholar] [CrossRef]

- Chaloupková, V.; Ivanova, T.; Ekrt, O.; Kabutey, A.; Herák, D. Determination of Particle Size and Distribution through Image-Based Macroscopic Analysis of the Structure of Biomass Briquettes. Energies 2018, 11, 331. [Google Scholar] [CrossRef] [Green Version]

- Križan, P.; Matú, M.; Soos, L.; Beniak, J.; Matúš, M. Behavior of Beech Sawdust during Densification into a Solid Biofuel. Energies 2015, 8, 6382–6398. [Google Scholar] [CrossRef] [Green Version]

- Chung, F.H. Unified theory and guidelines on adhesion. J. Appl. Polym. Sci. 1991, 42, 1319–1331. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Briquetting characteristics of bean straw-maize cob blend. Biomass-Bioenergy 2019, 126, 150–158. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass-Bioenergy 2019, 130, 105368. [Google Scholar] [CrossRef]

- Obi, O.F. Effect of briquetting temperature on the properties of biomass briquettes. Afr. J. Sci. Technol. Innov. Dev. 2015, 7, 386–394. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process. Technol. 2015, 133, 137–145. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Niño, A.; Arzola, N.; Araque, O. Experimental Study on the Mechanical Properties of Biomass Briquettes from a Mixture of Rice Husk and Pine Sawdust. Energies 2020, 13, 1060. [Google Scholar] [CrossRef] [Green Version]

- Nunes, E.Z.; De Andrade, A.M.; Júnior, A.F.D. Production of briquettes using coconut and eucalyptus wastes. Rev. Bras. Eng. Agrícola Ambient. 2019, 23, 883–888. [Google Scholar] [CrossRef]

- Song, X.; Zhang, S.; Wu, Y.; Cao, Z. Investigation on the properties of the bio-briquette fuel prepared from hydrothermal pretreated cotton stalk and wood sawdust. Renew. Energy 2019, 151, 184–191. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass-Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Febbi, P.; Menesatti, P.; Costa, C.; Pari, L.; Cecchini, M. Automated determination of poplar chip size distribution based on combined image and multivariate analyses. Biomass-Bioenergy 2015, 73, 1–10. [Google Scholar] [CrossRef]

- Nati, C.; Spinelli, R.; Fabbri, P. Wood chips size distribution in relation to blade wear and screen use. Biomass-Bioenergy 2010, 34, 583–587. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, X.; Liu, H. Experimental research on shape and size distribution of biomass particle. Fuel 2012, 94, 551–555. [Google Scholar] [CrossRef]

- Sette, C.R., Jr.; Hansted, A.L.S.; Novaes, E.; e Lima, P.A.F.; Rodrigues, A.C.; de Souza Santos, D.R.; Yamaji, F.M. Energy enhancement of the eucalyptus bark by briquette production. Ind. Crop. Prod. 2018, 122, 209–213. [Google Scholar] [CrossRef]

- Pang, L.; Yang, Y.; Wu, L.; Wang, F.; Meng, H. Effect of Particle Sizes on the Physical and Mechanical Properties of Briquettes. Energies 2019, 12, 3618. [Google Scholar] [CrossRef] [Green Version]

- Setter, C.; Ataíde, C.H.; Mendes, R.F.; de Oliveira, T.J.P. Influence of particle size on the physico-mechanical and energy properties of briquettes produced with coffee husks. Environ. Sci. Pollut. Res. 2020, 28, 8215–8223. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, Y. Physical properties of solid fuel briquettes made from Caragana korshinskii Kom. Powder Technol. 2014, 256, 293–299. [Google Scholar] [CrossRef]

- Martín-Ramos, P.; Martín-Gil, J.; Gómez-García, D.; Cuchí-Oterino, J.A. On the Physicochemical Characteristics and Applications of an “Undesirable” Pyrenean Thorny Cushion Dwarf: Echinospartum horridum (Vahl) Roth. Plants 2020, 9, 1180. [Google Scholar] [CrossRef] [PubMed]

- Faizal, H.M.; Nazri, M.S.M.; Rahman, M.; Syahrullail, S.; Latiff, Z.A. Development of palm biomass briquettes with polyethylene plastic waste addition. J. Teknol. 2016, 78, 69–75. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, E.R.K.; Marangoni, C.; Souza, O.; Sellin, N. Thermochemical characterization of banana leaves as a potential energy source. Energy Convers. Manag. 2013, 75, 603–608. [Google Scholar] [CrossRef]

- Antmen, Z.F. Exploitation of peanut and hazelnut shells as agricultural industrial wastes for solid biofuel production. Fresenius Environ. Bull. 2019, 28, 2340–2347. [Google Scholar]

- ENplus. ENplus For Wood Pellets EN plus Handbook Part 6: Schedule of Fees; European Pellet Council (EPC): Brussels, Belgium, 2015. [Google Scholar]

- Ahmad, K.K.; Sazali, K.; Kamarolzaman, A. Characterization of fuel briquettes from banana tree waste. Mater. Today Proc. 2018, 5, 21744–21752. [Google Scholar] [CrossRef]

- Duca, D.; Riva, G.; Pedretti, E.F.; Toscano, G. Wood pellet quality with respect to EN 14961-2 standard and certifications. Fuel 2014, 135, 9–14. [Google Scholar] [CrossRef]

- Ivanova, T.; Muntean, A.; Lhavrland, B.; Hutla, P. Quality assessment of solid biofuel made of sweet sorghum biomass. BIO Web Conf. 2018, 10, 02007. [Google Scholar] [CrossRef] [Green Version]

- Prvulovic, S.; Gluvakov, Z.; Tolmac, J.; Tolmac, D.; Matic, M.; Brkic, M. Methods for Determination of Biomass Energy Pellet Quality. Energy Fuels 2014, 28, 2013–2018. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Effects of operating parameters on maize COB briquette quality. Biomass-Bioenergy 2018, 112, 61–72. [Google Scholar] [CrossRef] [Green Version]

- Setter, C.; Costa, K.L.S.; de Oliveira, T.J.P.; Mendes, R.F. The effects of kraft lignin on the physicomechanical quality of briquettes produced with sugarcane bagasse and on the characteristics of the bio-oil obtained via slow pyrolysis. Fuel Process. Technol. 2020, 210, 106561. [Google Scholar] [CrossRef]

- Gilvari, H.; de Jong, W.; Schott, D.L. Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors—A review. Biomass-Bioenergy 2018, 120, 117–134. [Google Scholar] [CrossRef]

| Researchers | Temperature | Compaction Time | Cooling Time | Pressure | Granulometry | % Biomass | Type of Biomass | Binder | Compaction Speed | Moisture Content |

|---|---|---|---|---|---|---|---|---|---|---|

| [40] | X | X | X | X | ||||||

| [29] | X | X | X | X | X | X | ||||

| [8] | X | X | X | X | X | |||||

| [43] | X | X | X | X | X | |||||

| [37] | X | X | X | |||||||

| [38] | X | X | X | X | ||||||

| [27] | X | X | ||||||||

| [28] | X | X | X | X | X | |||||

| [44] | X | X | X | |||||||

| [13] | X | X | X | X | X | X | X | X | ||

| [42] | X | X | X | X | X | |||||

| [34] | X | X | X | X | ||||||

| [45] | X | X | X | X | ||||||

| [36] | X | X | X | X | X | X | ||||

| [30] | X | X | X | X | X | |||||

| [39] | X | X | X | X | X | |||||

| [31] | X | X | X | X | ||||||

| [46] | X | X | X | X | X | |||||

| [26] | X | X | X | X | X | X | X | |||

| [47] | X | X | X | X | ||||||

| [48] | X | X | X | |||||||

| [25] | X | X | X | X | X | |||||

| Occurrence | 7 | 13 | 3 | 16 | 21 | 10 | 4 | 11 | 2 | 15 |

| Percentage | 32% | 59% | 14% | 73% | 95% | 45% | 18% | 50% | 9% | 68% |

| Researchers | 28 | 30 | 38 | 60 | 90 | 110 | 120 | 130 | 200 |

|---|---|---|---|---|---|---|---|---|---|

| (°C) | |||||||||

| [29] | |||||||||

| [8] | |||||||||

| [13] | |||||||||

| [36] | |||||||||

| [30] | 120 | 130 | |||||||

| [26] | |||||||||

| [25] | |||||||||

| Researchers | 0 | 10 | 22 | 25 | 46.66 | 50 | 65 | 70 | 75 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | ||||||||||||

| [29] | 100 | |||||||||||

| [43] | 65 | |||||||||||

| [28] | 10 * | 90 | ||||||||||

| [44] | 10 | |||||||||||

| [13] | 75 | 100 | ||||||||||

| [34] | 75 | |||||||||||

| [30] | 90 | |||||||||||

| [39] | 50 * | 100 | ||||||||||

| [31] | 90 | |||||||||||

| [46] | 100 | |||||||||||

| Researchers | 0 | 0.5 | 1 | 4 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | 47 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | ||||||||||||

| [38] | 40 | ≈47 * | ||||||||||

| [29] | ||||||||||||

| [8] | 15 | |||||||||||

| [43] | 10 | |||||||||||

| [27] | ||||||||||||

| [28] | ||||||||||||

| [44] | 25 | |||||||||||

| [45] | 3–5 | |||||||||||

| [39] | ||||||||||||

| [31] | 10 | |||||||||||

| [25] | 10 | |||||||||||

| Researchers | 0 | 0.6 | 1 | 2 | 10 | 30 | 60 | 120 | 240 | 300 | 420 | 900 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (s) | ||||||||||||

| [40] | 120 | |||||||||||

| [8] | ||||||||||||

| [38] | ||||||||||||

| [28] | ||||||||||||

| [13] | ||||||||||||

| [42] | ||||||||||||

| [45] | 0 | |||||||||||

| [34] | ||||||||||||

| [36] | ||||||||||||

| [30] | ||||||||||||

| [46] | ||||||||||||

| [26] | ||||||||||||

| [47] | 1 | |||||||||||

| Researchers | 4 | 5 | 8 | 9 | 10 | 11 | 12 | 14 | 55 |

|---|---|---|---|---|---|---|---|---|---|

| (%) | |||||||||

| [40] | |||||||||

| [29] | 9.27 | ||||||||

| [43] | |||||||||

| [37] | 10–12 | ||||||||

| [13] | |||||||||

| [42] | |||||||||

| [34] | |||||||||

| [36] | |||||||||

| [39] | |||||||||

| [31] | 10.62 | ||||||||

| [46] | |||||||||

| [26] | 10.54–12.86 | ||||||||

| [47] | |||||||||

| [48] | 8.3 | ||||||||

| [25] | |||||||||

| Researchers | 7 | 8.27 | 10 | 12 | 14 | 15 | 18 | 22 | 27.6 | 40 | 50 | 60 | 67 | 80 | 100 | 125 | 150 | 204 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (MPa) | ||||||||||||||||||

| [40] | 102 | 204 | ||||||||||||||||

| [29] | ||||||||||||||||||

| [8] | 150 | |||||||||||||||||

| [38] | ≈ 9.3 * | ≈11–12 | ||||||||||||||||

| [28] | ||||||||||||||||||

| [13] | ||||||||||||||||||

| [42] | ||||||||||||||||||

| [45] | 40 | 60 | ||||||||||||||||

| [36] | 13.73 | |||||||||||||||||

| [30] | 44 | |||||||||||||||||

| [39] | ||||||||||||||||||

| [46] | 14 | 122.31 | ||||||||||||||||

| [26] | Not significant | |||||||||||||||||

| [47] | ||||||||||||||||||

| [25] | ||||||||||||||||||

| Researchers | 0.10 | 0.125 | 0.149 | 0.25 | 0.297 | 0.31 | 0.5 | 0.84 | 1 | 1.19 | 2 | 2.38 | 3 | 5 | 6 | 19 | 40 | 42 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | ||||||||||||||||||

| [40] | >1.19 | |||||||||||||||||

| [29] | ||||||||||||||||||

| [8] | ||||||||||||||||||

| [43] | 4.76 | |||||||||||||||||

| [37] | Mixture | |||||||||||||||||

| [38] | 0.125 * | 0.149 | ||||||||||||||||

| [27] | Mixture | |||||||||||||||||

| [28] | <1.18 | |||||||||||||||||

| [44] | ||||||||||||||||||

| [13] | Mixture | |||||||||||||||||

| [42] | Mixture | |||||||||||||||||

| [34] | Mixture | |||||||||||||||||

| [36] | ||||||||||||||||||

| [30] | ||||||||||||||||||

| [39] | Mixture | |||||||||||||||||

| [31] | ||||||||||||||||||

| [46] | Mixture | |||||||||||||||||

| [26] | 0.42 | |||||||||||||||||

| [47] | 2.5 | |||||||||||||||||

| [48] | 40–42 | |||||||||||||||||

| [25] | ||||||||||||||||||

| Researchers | Heating Value (MJ/kg) | Ash Content (%) | Moisture Content (%) | Volatile Material (%) | Fixed Carbon (%) | Energy Density (GJ·m−3) | Heat Pretreatment | Principle of Briquetting Drive | |

|---|---|---|---|---|---|---|---|---|---|

| Higher | Lower | ||||||||

| [40] | 15.7 | Hydraulic | |||||||

| [29] | 17.78 | 9.24 | Hydraulic | ||||||

| [8] | 16.92 | 6.72 | 9.88 | 61.86 | 18.75 | Hydraulic | |||

| [43] | 21.78 | 2.40 | 3.10 | 70.00 | 20.62 | Torrefaction of CNS (300°) | Motor driven screw | ||

| [37] | 19.60 | 17.80 | 0.70 | 2.50 | 73.20 | 18.60 | 23.3 | NS | |

| [38] | 30.67 | 0.45 | 5.50 | 19.73 | 71.40 | Carbonization (400 °C and 2 h) | Hydraulic | ||

| [27] | 18.30 | 11.52 | Manual mechanic | ||||||

| [28] | 19.31 | 3.30 | 3.60 | 40.10 | 36.80 | Torrefaction of CH and CP (200, 250 and 300 °C) | Hydraulic | ||

| [44] | 33.80 | Manual mechanic | |||||||

| [13] | 9.50 | 19.90 | Hydraulic | ||||||

| [42] | 18.10 | 9.85 | 6.68 | 69.40 | 18.70 | 17.52 | Hydraulic | ||

| [34] | 10.40 | Hydraulic | |||||||

| [45] | 31.29 | NS | |||||||

| [36] | 21.47 | NS | |||||||

| [30] | 20.80 | Hydraulic | |||||||

| [39] | 23.10 | Screw extruder | |||||||

| [31] | 21.45 | 27.93 | 3.23 | 17.23 | 42.41 | Carbonization: biomass (300–500 °C) and plastic waste (200 e 250 °C) | Hydraulic | ||

| [26] | 0.42 | 9.60 | 83.39 | 15.92 | 24.79 | Torrefaction (180, 200 and 220 °C, 1 h) | Hydraulic | ||

| [47] | 17.70 | 10.70 | 7.20 | 75.30 | 14.00 | 17.52 | Hydraulic | ||

| [25] | 17.50 | 0.40 | Hydraulic | ||||||

| Arithmetic Average | 21.95 | 19.30 | 6.29 | 7.07 | 56.69 | 28.58 | 20.03 | ||

| SD | 5.52 | 1.50 | 8.12 | 3.06 | 23.32 | 17.71 | 3.09 | ||

| ENplus A1 | ≥16.50 | ≤0.70 | ≤10.0 | ||||||

| ENplus A2 | ≥16.50 | ≤1.20 | ≤10.0 | ||||||

| ENplus A3 | ≥16.50 | ≤2.00 | ≤10.0 | ||||||

| EN 14961-2 [76] | ≥18.82 | ||||||||

| DIN 51731 [77] | ≥17.50 | ||||||||

| Researchers | Densities (Kg·m−3) | Compressive Strength (MPa) | Impact Resistance (%) | Water Resistance (%) | Tensile Strength (kN·m−2) | Durability (%) | Generation of Fines (%) | Longitudinal Expansion (%) | Water Absorption (%) | Principle of Briquetting Drive | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Density [m/v] | Bulk | ||||||||||

| [40] | 918.00 | 1.29 | 94.10 | 8.68 | Hydraulic | ||||||

| [29] | 430.00 | 22.33 | 99.20 | 93.20 | Hydraulic | ||||||

| [8] | 3030.00 | 1200.00 | Hydraulic | ||||||||

| [37] | 1250.00 | NS | |||||||||

| [38] | 1060.00 | 0.99 | Hydraulic | ||||||||

| [27] | 1240.00 | Manual mechanic | |||||||||

| [28] | 590.00 | 1.23 | 99.30 | Hydraulic | |||||||

| [44] | 1300.00 | 0.86 | 99.00 | 3.00 | Manual mechanic | ||||||

| [13] | 1163.00 | Hydraulic | |||||||||

| [42] | 990.00 | 19.80 | Hydraulic | ||||||||

| [34] | 920.00 | 0.37 | 4.00 | 15.00 | Hydraulic | ||||||

| [45] | 95.00 | 50.00 | 830.00 | NS | |||||||

| [36] | 1170.00 | 2070.00 | 99.89 | NS | |||||||

| [30] | 1190.00 | 100.00 | Hydraulic | ||||||||

| [39] | 913.00 | 41.19 | Screw extruder | ||||||||

| [31] | 1524.00 | Hydraulic | |||||||||

| [46] | 0.37 | 6.62 | 13.47 | Hydraulic | |||||||

| [26] | 1140.00 | 16.00 | 3.00 | 1.00 | Hydraulic | ||||||

| [47] | 1000.00 | 5.30 | Hydraulic | ||||||||

| [48] | 500.00 | 190.00 | NS | ||||||||

| [25] | 861.00 | 95.60 | Hydraulic | ||||||||

| Arithmetic average | 1157.75 | 965.11 | 9.98 | 97.73 | 71.60 | 1450.00 | 97.78 | 5.31 | 10.49 | 2.00 | |

| SD | 652.92 | 293.31 | 12.73 | 1.93 | 21.60 | 620.00 | 2.45 | 1.31 | 4.68 | 1.00 | |

| ENplus A1 | 600 ≤ BD ≤ 750 | ≥98.00 | <1.00 | ||||||||

| ENplus A2 | 601 ≤ BD ≤ 750 | ≥97.50 | <1.00 | ||||||||

| ENplus A3 | 602 ≤ BD ≤ 750 | ≥97.50 | <1.00 | ||||||||

| Researchers | DOE | Statistical Analysis | Data Analyzed | Statistical Softwares |

|---|---|---|---|---|

| [40] | Uninformed | Analysis of variance (ANOVA) and Tukey’s test | The effects of densification pressure and pressing time on properties were evaluated. The data analyzed statistically were relaxed density, energy density, resistance to compression and durability. | R statistical software |

| [29] | Random sampling method | Analysis of Variance (ANOVA) and Fisher’s Least Significance Difference (LSD) | The 5 different briquette compositions and the properties of HHV, MC, density, compressive strength, water resistance and break index were randomly tested and replicated four times. | Uninformed |

| [43] | Full factorial design (2 × 6 × 2) | Analysis of variance (ANOVA) and Tukey’s HSD test | The influence of operational parameters (SNC sizes, mixed proportions and speed) and their interactions on mechanical and fuel properties and the production rate. | SPSS v.14 |

| [38] | Response Surface Methods (RSM) with Central Composite Design (CCD) | Analysis of variance (ANOVA), regression model and lack of fit. | The effect of the input variables (particle size, binder composition and pressing pressure) on the calorific value responses and the compressive strength of the briquettes. | Uninformed |

| [28] | D-optimal crossed design | Analysis of variance (ANOVA), regression analysis, R2, R2 adj, pareto analysis | The physical and combustion indices of the briquettes, namely density, durability, resistance to compression, calorific value, MC, VM, FC and AC, in addition to the fuel ratio, combustibility index and volatile flammability. | Design Expert v.6.0.8 |

| [44] | Factorial design | Kolmogorov-Smirnov e Levene tests; nonparametric Kruskal–Wallis test, Analysis of variance (ANOVA), least significant difference (LSD) and t test. | The breakage index/impact resistance, density, compressive strength, water absorption and calorific value were analyzed. | SPSS v.16 |

| [13] | Factorial design (5 × 5) | Analysis of variance (ANOVA) and Tukey’s test | Proportions of waste mix, five mixtures of biomass on the answers: equilibrium moisture content, tensile strength, apparent density and energy density. | Statistica v.8.0 and R program |

| [34] | Completely Randomized design (CRD) | Tests of Shapiro-Wilk and Box-cox. Analysis of variance (ANOVA) and Tukey’s test | The chemical characterization data of the biomasses (MC, VM, FC, AC) and the physical analysis data of the briquettes (MC and compressive strength) were analyzed. | R statistical software |

| [36] | Completely Randomized design (CRD) | Analysis of variance (ANOVA) | The means, standard deviation and coefficients of variation were made for all variables. ANOVA was used in the data of the immediate analysis and HHV, energy density of biomass and coal. | Uninformed |

| [46] | Uninformed | Bartlett’s test, analysis of variance (ANOVA) and Tukey’s test | HHV, dimensional stability (longitudinal expansion), resistance to compression and generation of fines (friability) were analyzed. | Statgraphics v.15.2.05 and Excel 2013 |

| [48] | Full factorial design | Analysis of variance (ANOVA) | Evaluate the main effects and interactions of input variables on dry particle density. | Minitab |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Rotella Junior, P. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. https://doi.org/10.3390/en14248320

Marreiro HMP, Peruchi RS, Lopes RMBP, Andersen SLF, Eliziário SA, Rotella Junior P. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies. 2021; 14(24):8320. https://doi.org/10.3390/en14248320

Chicago/Turabian StyleMarreiro, Hívila M. P., Rogério S. Peruchi, Riuzuani M. B. P. Lopes, Silvia L. F. Andersen, Sayonara A. Eliziário, and Paulo Rotella Junior. 2021. "Empirical Studies on Biomass Briquette Production: A Literature Review" Energies 14, no. 24: 8320. https://doi.org/10.3390/en14248320

APA StyleMarreiro, H. M. P., Peruchi, R. S., Lopes, R. M. B. P., Andersen, S. L. F., Eliziário, S. A., & Rotella Junior, P. (2021). Empirical Studies on Biomass Briquette Production: A Literature Review. Energies, 14(24), 8320. https://doi.org/10.3390/en14248320