The CPV “Toolbox”: New Approaches to Maximizing Solar Resource Utilization with Application-Oriented Concentrator Photovoltaics

Abstract

:1. Introduction: The Promise and Pitfalls of PV and CPV

2. Light-Splitting and Hybrid Solar Energy Collection

3. Micro-Concentrators and Micro-Tracking

4. Light-Splitting and Microtracking CPV: Predicting Performance and Application Potential

4.1. The Challenge of Rooftop CPV

4.2. Rooftop CPV with Partial Transparency: Adding Value from Unconcentrated Light

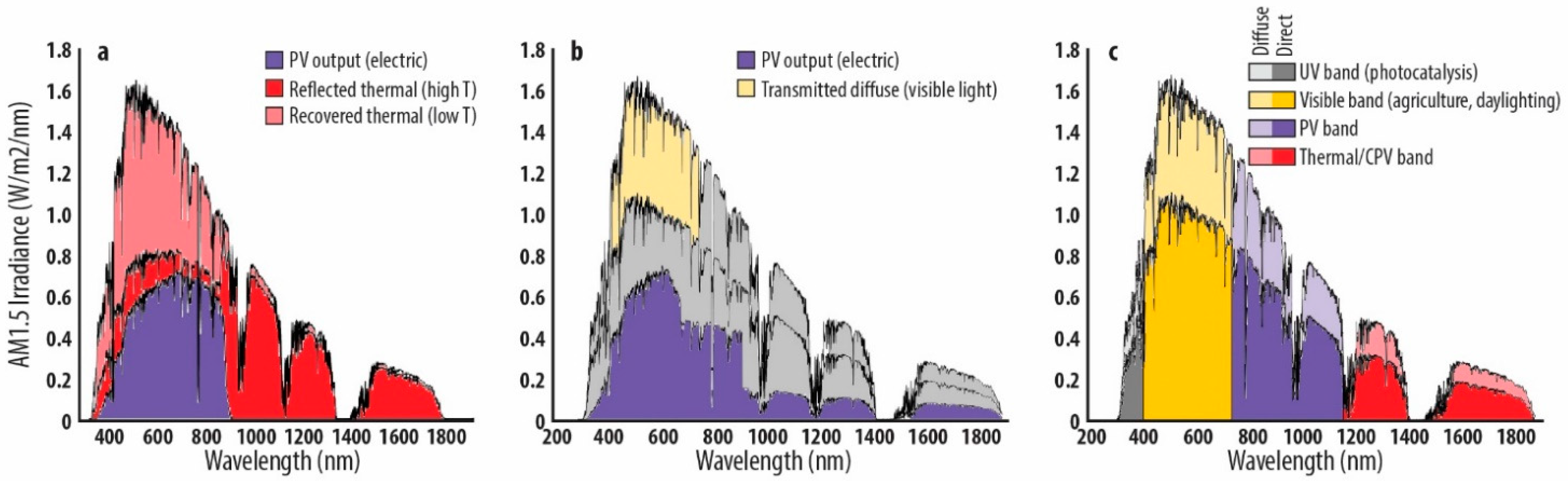

4.3. Spectrum Splitting: New Applications for an Old Concept?

5. PV-Thermal Applications

6. Remarks and Conclusions: A Future Path for CPV?

- −

- Miniaturization of cells and optics to create micro-CPV modules with low mass, improved form factors and superior heat dissipation performance compared to conventional CPV designs;

- −

- Integration of sun tracking into the module to enable fixed, trackerless installation; and

- −

- Development of hybrid collectors which capture parts of the solar resource that are unused by the PV cells as heat or light, boosting the overall solar resource utilization substantially.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Apostoleris, H.; Sgouridis, S.; Stefancich, M.; Chiesa, M. Utility solar prices will continue to drop all over the world even without subsidies. Nat. Energy 2019, 4, 833–834. [Google Scholar] [CrossRef] [Green Version]

- Shah, V.; Booream-Phelps, J. Crossing the Chasm Solar Grid Parity in a Low Oil Price Era; Deutsche Bank, February, 2015. Available online: https://www.db.com/cr/en/docs/solar_report_full_length.pdf (accessed on 2 February 2016).

- Swanson, R.M. The promise of concentrators. Prog. Photovolt. Res. Appl. 2000, 8, 93–111. [Google Scholar] [CrossRef]

- Wiesenfarth, M.; Philipps, S.; Bett, A.; Horowitz, K.; Kurtz, S. Current Status of Concentrator Photovoltaic (CPV) Technology V1.3; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2017; Available online: https://www.ise.fraunhofer.de/de/veroeffentlichungen/veroeffentlichungen-pdf-dateien/studien-und-konzeptpapiere/current-status-of-concentrator-photovoltaic-cpv-technology-in-englischer-sprache.pdf (accessed on 23 April 2018).

- Green, M.A. How did solar cells get so cheap? Joule 2019, 3, 631–633. [Google Scholar] [CrossRef] [Green Version]

- Kavlak, G.; McNerney, J.; Trancik, J.E. Evaluating the causes of cost reduction in photovoltaic modules. Energy Policy 2018, 123, 700–710. [Google Scholar] [CrossRef] [Green Version]

- Swanson, R.M. A vision for crystalline silicon photovoltaics. Prog. Photovolt. Res. Appl. 2006, 14, 443–453. [Google Scholar] [CrossRef]

- Apostoleris, H.; Sgouridis, S.; Stefancich, M.; Chiesa, M. Evaluating the factors that led to low-priced solar electricity projects in the Middle East. Nat. Energy 2018, 3, 1. [Google Scholar] [CrossRef]

- Apostoleris, H.C.; Stefancich, M.; Chiesa, M. Concentrating Photovoltaics (CPV): The Path Ahead (Green Energy and Technology); Springer International Publishing: Manhattan, NY, USA, 2018. [Google Scholar]

- Kayes, B.M.; Nie, H.; Twist, R.; Spruytte, S.G.; Reinhardt, F.; Kizilyalli, I.C.; Higashi, G.S. 27.6% Conversion efficiency, a new record for single-junction solar cells under 1 sun illumination. In Proceedings of the Photovoltaic Specialists Conference (PVSC), 37th IEEE, Seattle, WA, USA, 13 June 2011; pp. 000004–000008. [Google Scholar]

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D.; Levi, D.H.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (version 49). Prog. Photovolt. Res. Appl. 2017, 25, 3–13. [Google Scholar] [CrossRef]

- Winston, R.; Yablonovitch, E.; Jiang, L.; Widyolar, B.K.; Abdelhamid, M.; Scranton, G.; Cygan, D.; Kozlov, A. Hybrid solar collector using nonimaging optics and photovoltaic components. In Proceedings of the SPIE Optical Engineering+ Applications, San Diego, CA, USA, 9–13 August 2015; p. 957208. [Google Scholar]

- Abdelhamid, M.; Widyolar, B.K.; Jiang, L.; Winston, R.; Yablonovitch, E.; Scranton, G.; Cygan, D.; Abbasi, H.; Kozlov, A. Novel double-stage high-concentrated solar hybrid photovoltaic/thermal (PV/T) collector with nonimaging optics and GaAs solar cells reflector. Appl. Energy 2016, 182, 68–79. [Google Scholar] [CrossRef] [Green Version]

- Spectrolab. Datasheet: CPV Point Focus Solar Cells: C4MJ Metamorphic Fourth Generation CPV Technology. Available online: https://www.spectrolab.com/DataSheets/PV/CPV/C3MJ_PLUS_2011.pdf (accessed on 12 December 2020).

- Cotal, H.; Fetzer, C.; Boisvert, J.; Kinsey, G.; King, R.; Hebert, P.; Yoon, H.; Karam, N. III–V multijunction solar cells for concentrating photovoltaics. Energy Environ. Sci. 2009, 2, 174–192. [Google Scholar] [CrossRef]

- Hirai, D.; Okamoto, K.; Yamada, N. Fabrication of highly transparent concentrator photovoltaic module for efficient dual land use in middle DNI region. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–4. [Google Scholar]

- Domínguez, C.; Jost, N.; Askins, S.; Victoria, M.; Antón, I. A review of the promises and challenges of micro-concentrator photovoltaics. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2016; p. 080003. [Google Scholar]

- Apostoleris, H.; Stefancich, M.; Chiesa, M. Tracking-integrated systems for concentrating photovoltaics. Nat. Energy 2016, 16018. [Google Scholar] [CrossRef]

- Hallas, J.M.; Karp, J.H.; Tremblay, E.J.; Ford, J.E. Lateral Translation Micro-Tracking of Planar Micro-Optic Solar Concentrator. In SPIE Solar Energy+ Technology; International Society for Optics and Photonics: Bellingham, WA, USA, 2010; pp. 776904–776907. [Google Scholar]

- Baker, K.A.; Karp, J.H.; Tremblay, E.J.; Hallas, J.M.; Ford, J.E. Reactive self-tracking solar concentrators: Concept, design, and initial materials characterization. Appl. Opt. 2012, 51, 1086–1094. [Google Scholar] [CrossRef]

- Zagolla, V.; Tremblay, E.; Moser, C. Proof of principle demonstration of a self-tracking concentrator. Opt. Express 2014, 22, A498–A510. [Google Scholar] [CrossRef]

- Cheng, J.; Park, S.; Chen, C.-L. Optofluidic solar concentrators using electrowetting tracking: Concept, design, and characterization. Sol. Energy 2013, 89, 152–161. [Google Scholar] [CrossRef]

- Apostoleris, H.; Stefancich, M.; Lilliu, S.; Chiesa, M. Sun-tracking optical element realized using thermally activated transparency-switching material. Opt. Express 2015, 23, A930–A935. [Google Scholar] [CrossRef] [Green Version]

- Johnsen, H.J.; Torgersen, J.; Aksnes, A. Solar Tracking Using Beam-Steering Lens Arrays. In Nonimaging Optics: Efficient Design for Illumination and Solar Concentration XV; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10758, p. 1075805. [Google Scholar]

- Teng, T.-C.; Kuo, C.-H.; Li, Y.-J. Planar solar concentrator composed of stacked waveguides with arc-segment structures and movable receiving assemblies. Opt. Express 2020, 28, 34362–34377. [Google Scholar] [CrossRef]

- Price, J.S.; Grede, A.J.; Wang, B.; Lipski, M.V.; Fisher, B.; Lee, K.-T.; He, J.; Brulo, G.S.; Ma, X.; Burroughs, S. High-concentration planar microtracking photovoltaic system exceeding 30% efficiency. Nat. Energy 2017, 2, 17113. [Google Scholar] [CrossRef]

- Price, J.S.; Sheng, X.; Meulblok, B.M.; Rogers, J.A.; Giebink, N.C. Wide-angle planar microtracking for quasi-static microcell concentrating photovoltaics. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef]

- Nardin, G.; Domínguez, C.; Aguilar, Á.F.; Anglade, L.; Duchemin, M.; Schuppisser, D.; Gerlich, F.; Ackermann, M.; Coulot, L.; Cuénod, B. Industrialization of hybrid Si/III–V and translucent planar micro-tracking modules. Prog. Photovolt. Res. Appl. 2020. [Google Scholar] [CrossRef]

- Askins, S.; Jost, N.; Aguilar, A.; Anglade, L.; Nardin, G.; Duchemin, M.; Gerlich, F.; Ackerman, M.; Coulot, L.; Petri, D. Performance of Hybrid Micro-Concentrator Module with Integrated Planar Tracking and Diffuse Light Collection. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 2507–2512. [Google Scholar]

- Barbose, G.L.; Darghouth, N.R. Tracking the Sun IX: The Installed Price of Residential and Non-residential Photovalic Systems in the United States (Washington: US Department of Energy, 2016). Available Emp. Lbl. Gov. Publ. Trackin 2016. [Google Scholar] [CrossRef] [Green Version]

- Littlefair, P.J. The luminous efficacy of daylight: A review. Lighting Res. Technol. 1985, 17, 162–182. [Google Scholar] [CrossRef]

- Inada, K. Action spectra for photosynthesis in higher plants. Plant Cell Physiol. 1976, 17, 355–365. [Google Scholar]

- Song, X.P.; Tan, H.T.; Tan, P.Y. Assessment of light adequacy for vertical farming in a tropical city. Urban For. Urban Green. 2018, 29, 49–57. [Google Scholar] [CrossRef]

- Apostoleris, H.; Chiesa, M. High-concentration photovoltaics for dual-use with agriculture. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2019; p. 050002. [Google Scholar]

- Maragliano, C.; Apostoleris, H.; Bronzoni, M.; Rampino, S.; Stefancich, M.; Chiesa, M. Efficiency enhancement in two-cell CIGS photovoltaic system with low-cost optical spectral splitter. Opt. Express 2016, 24, A222–A233. [Google Scholar] [CrossRef]

- Keevers, M.J.; Lau, C.F.J.; Green, M.A.; Thomas, I.; Lasich, J.B.; King, R.R.; Emery, K.A. High Efficiency Spectrum Splitting Prototype Submodule Using Commercial CPV Cells. Prog. Photovolt. Res. Appl. 2015. [Google Scholar] [CrossRef]

- Crisostomo, F.; Taylor, R.A.; Surjadi, D.; Mojiri, A.; Rosengarten, G.; Hawkes, E.R. Spectral splitting strategy and optical model for the development of a concentrating hybrid PV/T collector. Appl. Energy 2015, 141, 238–246. [Google Scholar] [CrossRef]

- Goetzberger, A.; Goldschmidt, J.; Peters, M.; Löper, P. Light trapping, a new approach to spectrum splitting. Sol. Energy Mater. Sol. Cells 2008, 92, 1570–1578. [Google Scholar] [CrossRef]

- Kosten, E.D.; Warmann, E.C.; Lloyd, J.; Atwater, H.A. Spectrum splitting photovoltaics: Light trapping filtered concentrator for ultrahigh photovoltaic efficiency. In Proceedings of the SPIE Solar Energy+ Technology, San Diego, CA, USA, 26–29 August 2013; pp. 882109-1–882109-3. [Google Scholar]

- Escarra, M.D.; Darbe, S.; Warmann, E.C.; Atwater, H. Spectrum-splitting photovoltaics: Holographic spectrum splitting in eight-junction, ultra-high efficiency module. In Proceedings of the 2013 IEEE 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 1852–1855. [Google Scholar]

- Stefancich, M.; Zayan, A.; Chiesa, M.; Rampino, S.; Roncati, D.; Kimerling, L.; Michel, J. Single element spectral splitting solar concentrator for multiple cells CPV system. Opt. Express 2012, 20, 9004–9018. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Ferry, J.; Winston, R.; Kirk, A.; Osowski, M.; Cygan, D.; Abbasi, H. Theoretical and experimental performance of a two-stage (50X) hybrid spectrum splitting solar collector tested to 600 °C. Appl. Energy 2019, 239, 514–525. [Google Scholar] [CrossRef]

- Kim, Y.; Cruz, S.S.; Lee, K.; Alawode, B.O.; Choi, C.; Song, Y.; Johnson, J.M.; Heidelberger, C.; Kong, W.; Choi, S. Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 2017, 544, 340–343. [Google Scholar] [CrossRef]

- Meinen, E.; van Ieperen, W.; Hogewoning, S.; Trouwborst, G. Finding the Optimal Growth-Light Spectrum for Greenhouse Crops. In Proceedings of the VII International Symposium on Light in Horticultural Systems 956, Wageningen, The Netherlands, 12–25 October 2012; pp. 357–363. [Google Scholar]

- Liu, W.; Liu, L.; Guan, C.; Zhang, F.; Li, M.; Lv, H.; Yao, P.; Ingenhoff, J. A novel agricultural photovoltaic system based on solar spectrum separation. Sol. Energy 2018, 162, 84–94. [Google Scholar] [CrossRef]

- Hashemi, S.M.H.; Choi, J.-W.; Psaltis, D. Solar thermal harvesting for enhanced photocatalytic reactions. Phys. Chem. Chem. Phys. 2014, 16, 5137–5141. [Google Scholar] [CrossRef]

- Nakata, K.; Fujishima, A. TiO2 photocatalysis: Design and applications. J. Photochem. Photobiol. C Photochem. Rev. 2012, 13, 169–189. [Google Scholar] [CrossRef]

- Ozer, L.Y.; Apostoleris, H.; Ravaux, F.; Shylin, S.I.; Mamedov, F.; Lindblad, A.; Johansson, F.O.; Chiesa, M.; Sá, J.; Palmisano, G. Long-Lasting Non-hydrogenated Dark Titanium Dioxide: Medium Vacuum Anneal for Enhanced Visible Activity of Modified Multiphase Photocatalysts. ChemCatChem 2018, 10, 2949–2954. [Google Scholar] [CrossRef]

- Nair, V.; Muñoz-Batista, M.J.; Fernández-García, M.; Luque, R.; Colmenares, J.C. Thermo-Photocatalysis: Environmental and Energy Applications. ChemSusChem 2019, 12, 2098–2116. [Google Scholar] [CrossRef]

- Ibrahim, A.; Othman, M.Y.; Ruslan, M.H.; Mat, S.; Sopian, K. Recent advances in flat plate photovoltaic/thermal (PV/T) solar collectors. Renew. Sustain. Energy Rev. 2011, 15, 352–365. [Google Scholar] [CrossRef]

- Cox Iii, C.; Raghuraman, P. Design considerations for flat-plate-photovoltaic/thermal collectors. Sol. Energy 1985, 35, 227–241. [Google Scholar] [CrossRef]

- Coventry, J.S. Performance of a concentrating photovoltaic/thermal solar collector. Sol. Energy 2005, 78, 211–222. [Google Scholar] [CrossRef]

- Daneshazarian, R.; Cuce, E.; Cuce, P.M.; Sher, F. Concentrating photovoltaic thermal (CPVT) collectors and systems: Theory, performance assessment and applications. Renew. Sustain. Energy Rev. 2018, 81, 473–492. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Brinkley, J.; Hota, S.K.; Ferry, J.; Diaz, G.; Winston, R. Experimental performance of an ultra-low-cost solar photovoltaic-thermal (PVT) collector using aluminum minichannels and nonimaging optics. Appl. Energy 2020, 268, 114894. [Google Scholar] [CrossRef]

- ALTA DEVICES Technolgy Brief: Single Solar Cell; Alta Devices: Sunnyvale, CA, USA, 2014; Available online: http://dukeofdrones.com/wp-content/uploads/2015/02/single_cell.pdf (accessed on 29 December 2020).

- Panasonic. Photovoltaic Module HIT VBHN3-series Datasheet. Available online: https://panasonic.net/lifesolutions/solar/download/pdf/N330_325_320SJ47Datasheet_190226.pdf (accessed on 29 December 2020).

- Johnsen, H.J.; Aksnes, A.; Torgersen, J. Beyond the 2D limit: Étendue-squeezing line-focus solar concentrators. Opt. Lett. 2020, 46, 42–45. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Ferry, J.; Winston, R. Non-tracking East-West XCPC solar thermal collector for 200 celsius applications. Appl. Energy 2018, 216, 521–533. [Google Scholar] [CrossRef]

- Mittelman, G.; Kribus, A.; Mouchtar, O.; Dayan, A. Water desalination with concentrating photovoltaic/thermal (CPVT) systems. Sol. Energy 2009, 83, 1322–1334. [Google Scholar] [CrossRef]

- Brinkley, J.; Jiang, L.; Widyolar, B.; Hota, S.K.; Bhusal, Y.; Diaz, G.; Winston, R. Thermal, electrical, and cost study of advanced optical photovoltaic thermal system (ADOPTS). Appl. Energy 2020, 269, 115105. [Google Scholar] [CrossRef]

- Dönitz, W.; Erdle, E. High-temperature electrolysis of water vapor—status of development and perspectives for application. Int. J. Hydrog. Energy 1985, 10, 291–295. [Google Scholar] [CrossRef]

- Doenitz, W.; Schmidberger, R.; Steinheil, E.; Streicher, R. Hydrogen production by high temperature electrolysis of water vapour. Int. J. Hydrog. Energy 1980, 5, 55–63. [Google Scholar] [CrossRef]

- Lin, M.; Haussener, S. Techno-economic modeling and optimization of solar-driven high-temperature electrolysis systems. Sol. Energy 2017, 155, 1389–1402. [Google Scholar] [CrossRef] [Green Version]

- Parvareh, F.; Sharma, M.; Qadir, A.; Milani, D.; Khalilpour, R.; Chiesa, M.; Abbas, A. Integration of solar energy in coal-fired power plants retrofitted with carbon capture: A review. Renew. Sustain. Energy Rev. 2014, 38, 1029–1044. [Google Scholar] [CrossRef]

| Location | Direct Fraction | High-Performance CPV Boost | Commercial CPV Boost | 50% Transmissive Commercial CPV Boost |

|---|---|---|---|---|

| Buenos Aires | 0.53 | 0.94 | 0.59 | 1.58 |

| Bogra | 0.50 | 1.03 | 0.86 | 1.70 |

| Calgary | 0.64 | 1.15 | 0.83 | 1.55 |

| Dagget | 0.79 | 1.56 | 1.24 | 1.74 |

| Aswan | 0.74 | 1.51 | 1.26 | 1.74 |

| Fargo | 0.59 | 1.08 | 0.83 | 1.53 |

| Berlin | 0.44 | 0.83 | 0.66 | 1.53 |

| Amapala Los Palonas | 0.68 | 1.39 | 1.14 | 1.76 |

| Reykjavik | 0.42 | 0.76 | 0.55 | 1.45 |

| Kagoshima | 0.49 | 0.96 | 0.79 | 1.60 |

| Semipalatinsk | 0.54 | 1.02 | 0.79 | 1.55 |

| Kaunas | 0.39 | 0.72 | 0.57 | 1.50 |

| Macau | 0.52 | 1.04 | 0.87 | 1.65 |

| Kathmandu | 0.57 | 1.16 | 0.96 | 1.70 |

| Arequipa | 0.68 | 1.30 | 0.85 | 1.64 |

| Kangnung | 0.53 | 1.01 | 0.82 | 1.58 |

| Dakar | 0.55 | 1.10 | 0.92 | 1.64 |

| Bangkok | 0.42 | 0.87 | 0.73 | 1.66 |

| Kiev | 0.45 | 0.84 | 0.67 | 1.53 |

| Tucson | 0.77 | 1.54 | 1.26 | 1.75 |

| Abu Dhabi | 0.73 | 1.48 | 1.22 | 1.76 |

| Harare | 0.48 | 0.89 | 0.51 | 1.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Apostoleris, H.; Stefancich, M.; Chiesa, M. The CPV “Toolbox”: New Approaches to Maximizing Solar Resource Utilization with Application-Oriented Concentrator Photovoltaics. Energies 2021, 14, 795. https://doi.org/10.3390/en14040795

Apostoleris H, Stefancich M, Chiesa M. The CPV “Toolbox”: New Approaches to Maximizing Solar Resource Utilization with Application-Oriented Concentrator Photovoltaics. Energies. 2021; 14(4):795. https://doi.org/10.3390/en14040795

Chicago/Turabian StyleApostoleris, Harry, Marco Stefancich, and Matteo Chiesa. 2021. "The CPV “Toolbox”: New Approaches to Maximizing Solar Resource Utilization with Application-Oriented Concentrator Photovoltaics" Energies 14, no. 4: 795. https://doi.org/10.3390/en14040795