Abstract

This paper presents current research trends and prospects of utilizing additive manufacturing (AM) techniques to manufacture electrical machines. Modern-day machine applications require extraordinary performance parameters such as high power-density, integrated functionalities, improved thermal, mechanical & electromagnetic properties. AM offers a higher degree of design flexibility to achieve these performance parameters, which is impossible to realize through conventional manufacturing techniques. AM has a lot to offer in every aspect of machine fabrication, such that from size/weight reduction to the realization of complex geometric designs. However, some practical limitations of existing AM techniques restrict their utilization in large scale production industry. The introduction of three-dimensional asymmetry in machine design is an aspect that can be exploited most with the prevalent level of research in AM. In order to take one step further towards the enablement of large-scale production of AM-built electrical machines, this paper also discusses some machine types which can best utilize existing developments in the field of AM.

1. Introduction

Additive manufacturing (AM) or 3D-printing is an all-encompassing terminology used for the processes where the manufacturing is done in layers, rendered from the digital model of a specific item or assembly. Recently, there has been a growing interest in the field of AM as it has emerged as an alternative manufacturing process, offering virtually unlimited potential for a wide range of industrial and special-purpose applications [1]. The AM offers various benefits over other conventional manufacturing processes, such as realizing complex/special purpose geometries, a wide range of multi-material usage possibilities, and rapid prototyping. There is also a potential for large in-volume production of complex mechanisms using AM, which is also evident from the fact that few aerospace companies have already announced the employment of AM in their manufacturing processes [2,3,4,5,6].

Due to the promising aspects of what it has to offer, AM has also attracted interest from the electrical machines’ manufacturing point of view. For electrical machines, as compared to the conventional manufacturing processes, the AM process has not yet progressed to an advanced stage. With the ongoing advances in the field of AM, it would soon find its place as the better alternative for electrical machines’ manufacturing. This is due to the fact that flexibility in design possibilities offered by employing AM, such as integration of structural and thermal management components with the active parts, make it the best solution for a wide range of applications such as special-purpose machines for aerospace, medical, robotics and automotive industry where high power-density, ruggedness, and compact structure is required. With the forecasted improvements in the field of AM, the manufacturability and performance of electrical machines could be significantly improved.

At present, research work has been done majorly on the AM of individual working parts for various electrical machines, like mechanical and thermal management assemblies, coils/windings, permanent magnets (PM), and stator/rotor packs, etc., but a complete AM-built and user-ready electrical machine, for large scale production and industrial applications, is a feat which is yet to be accomplished owing to a few challenges regarding slow manufacturing speed, internal constructional defects, limited multi-material printing capability and the need for post-processing of printed parts [7]. The flexibility in employing AM process for the manufacturing of electrical machines is dependent on the individual machine design, AM technique, post processing technique and its effects on machine properties. Another front for integration of AM into electrical machines’ manufacturing industry is the automation or minimization of post-processing procedures. Although it is currently on its initial stages of development, but it is another step forward towards the integration of AM in large-scale production industry [8].

This study investigates the current level of research and development, regarding employment of AM in manufacturing individual working parts of electrical machines and the potential of its employment for a completely AM-built electrical machine. This article also presents some candidates for AM-built electrical machines for the possibility of exploiting maximum benefits offered by AM at present stage, while keeping in view the limitations of currently available AM techniques.

2. Trends of AM in Construction of Electrical Machines

When considering AM for electrical machines, it offers virtually unlimited possibilities from prototyping to mass-personalized production. Employment of AM in production of electrical machines is a promising aspect offering various benefits over conventional manufacturing techniques, such as; realization of 3D-designs (including electrical, magnetic, mechanical and thermal considerations) [9], recyclable constructions [10] and optimal material utilization. Basic and standardized AM techniques for manufacturing processes have been described in [11,12] almost all of which have been used in manufacturing electrical machines or its parts, at various instances [13,14,15]. Among all the AM processes, selective laser melting (SLM), fused deposition modeling (FDM) and binder jet printing (BJP) technology are the ones shown to be most promising for the manufacturing of electrical machines [16].

2.1. Part-Wise Approach

From design and manufacturing point of view, any electrical machine can be subdivided into two basic subassemblies; active parts like core, coils/windings, PMs and the passive parts like thermal management components, mechanical assemblies. The research and development is progressing with a significant pace on both fronts with industrial implementations actually ahead of what is reflected in the research literature [13,17,18].

2.1.1. Active Parts

Active parts in electrical machines mainly comprise of core, windings/coils and PMs; responsible for the main functionality of the machine.

Core

Core in an electrical machine is the body with high magnetic permeability, used to confine and guide magnetic field. When considering its design and construction, magnetic properties such as, magnetic saturation, permeability, hysteresis losses, eddy current losses and mechanical properties are needed to be considered. Soft magnetic composite (SMC) and intermetallic alloys possess best of electromagnetic properties. Existing conventional methods employ these materials by molding, stacking or sintering them to achieve required geometry and electromagnetic properties [19]. But these materials are usually tricky to process using conventional methods, due to poor mechanical properties and limitation on the realization of complex geometries.

AM offers flexibility in various aspects; from selection of material composition and complex geometric shape realization to structural topology optimization. This gives a better control over electromagnetic and mechanical properties. Many researches have showcased promising results, highlighting the potential of AM utilization in manufacturing electrical machines. In addition to the flexibility in geometrical shape realization, [20,21] report high magnetic permeability of up-to 31,000, low hysteresis losses i.e., low coercivity of minimum 16 A/m and up-to 50% weight reduction in AM-built machine core. However increase in eddy currents, due to non-laminated dense structure was also reported [22,23], but this can be decreased significantly with the help of layered structure of different electrical resistivity. The layer-based manufacturing process of AM can also introduce a degree of anisotropy i.e., difference in electromagnetic properties, in build direction compared to other direction. This is a challenge that research in machine design and topology optimization has to address or account for, collectively [24]. Another issue associated with AM is the introduction of macroscopic faults in structure, which is also shown to decrease by using preheated print-bed [21]. In [25] the authors have shown that conventionally brittle Fe–Co and Fe–Si intermetallic alloys, at almost ideal compositions for electromagnetic applications, can be processed in bulk form by employing AM techniques without consequential macroscopic defects.

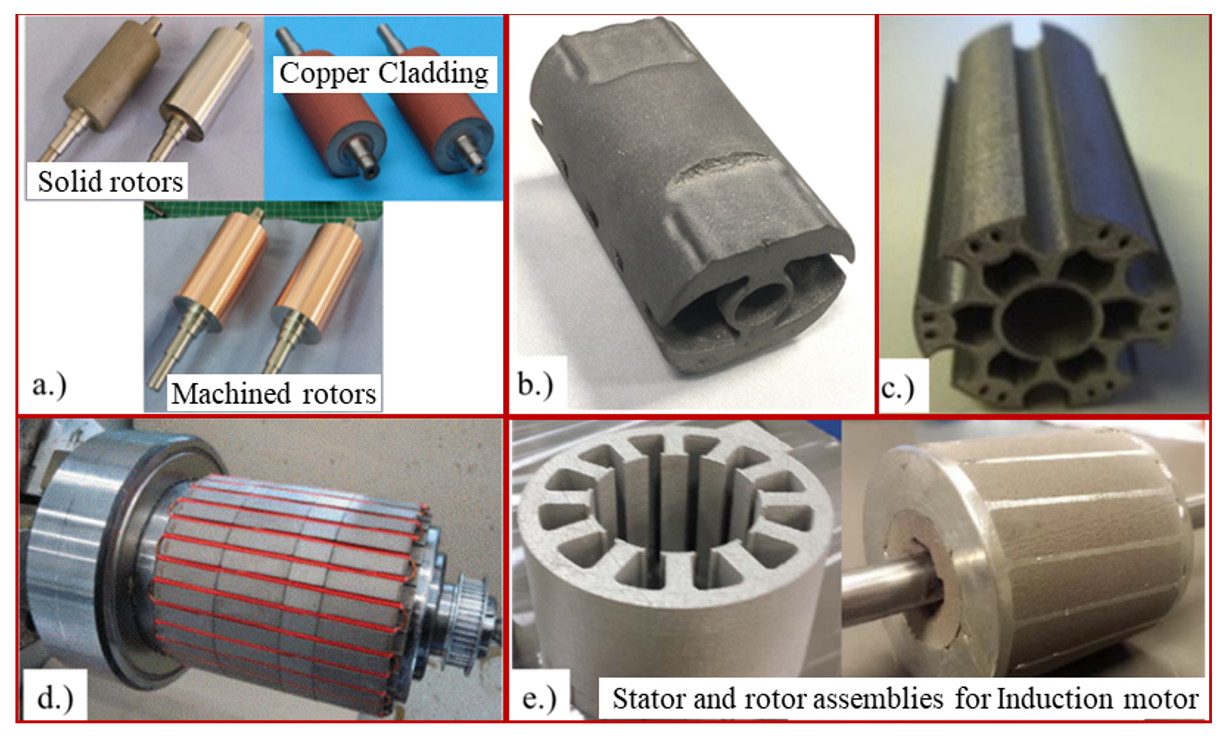

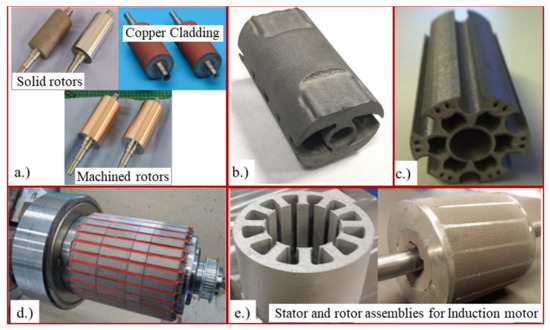

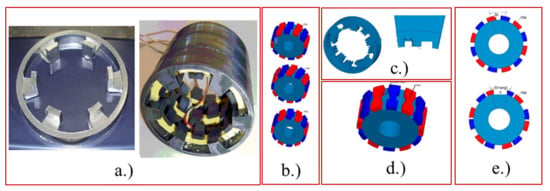

AM’s ability to realize different topology optimizations could be the means to produce high mechanical strength-low density, special purpose core geometries to optimally guide magnetic energy in electrical machines [20,26,27,28,29,30,31,32]. This also comes with the additional advantage of increased ductility due to enablement of multiscale microstructures. For major applications ranging from automotive to aerospace industries, the cores for rotating electrical machines need to have high torque-to weight ratio while keeping the structural integrity intact in conjunction with high permeability and low hysteresis and eddy current losses. Virtually, AM provides possibility for achieving maximum limits for this by providing opportunity to utilize topology optimizations in order to have appropriate geometry for electromagnetic energy guidance, optimal geometry for reduction in eddy current losses and cogging torque, optimal material composition for reduction in hysteresis losses and weight reduction due to low material usage while keeping the structural integrity. Figure 1 presents some of such examples for AM-built core structures.

Figure 1.

Examples of AM-built cores (a) solid steel rotor with copper cladding for usage in electric vehicles-Rolls Royce Central Technology [33] (b) PM rotor with optimized torque density [34] (c) prototype rotor for switched reluctance machine [16,26] (d) lightweight rotor utilizing lattice structure topology, for PM synchronous machine [35] (e) stator and rotor assemblies of an induction machine for automotive applications [36].

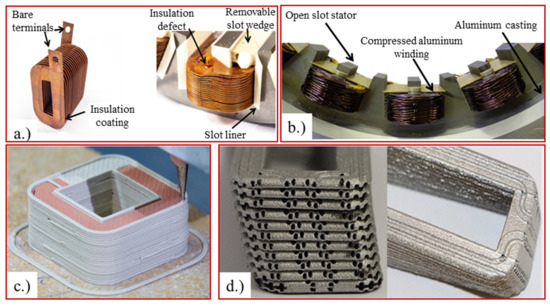

Coils/Windings

The winding assembly consisting of coils/windings, electrical insulation material and the holding assembly; is responsible to produce magnetic field in the electrical machine. From design and construction point-of-view, for electrical machines; the power losses are needed to be kept at minimum. Low electrical resistivity and high conductor fill-factor produces less power losses and indicates a good winding design. However, for modern machine applications requiring high speed and high frequency operation, the losses associated to skin and proximity effect dominate and hence complicate the design of winding assembly. With conventional design and manufacturing techniques, the balance between these important factors gets compromised.

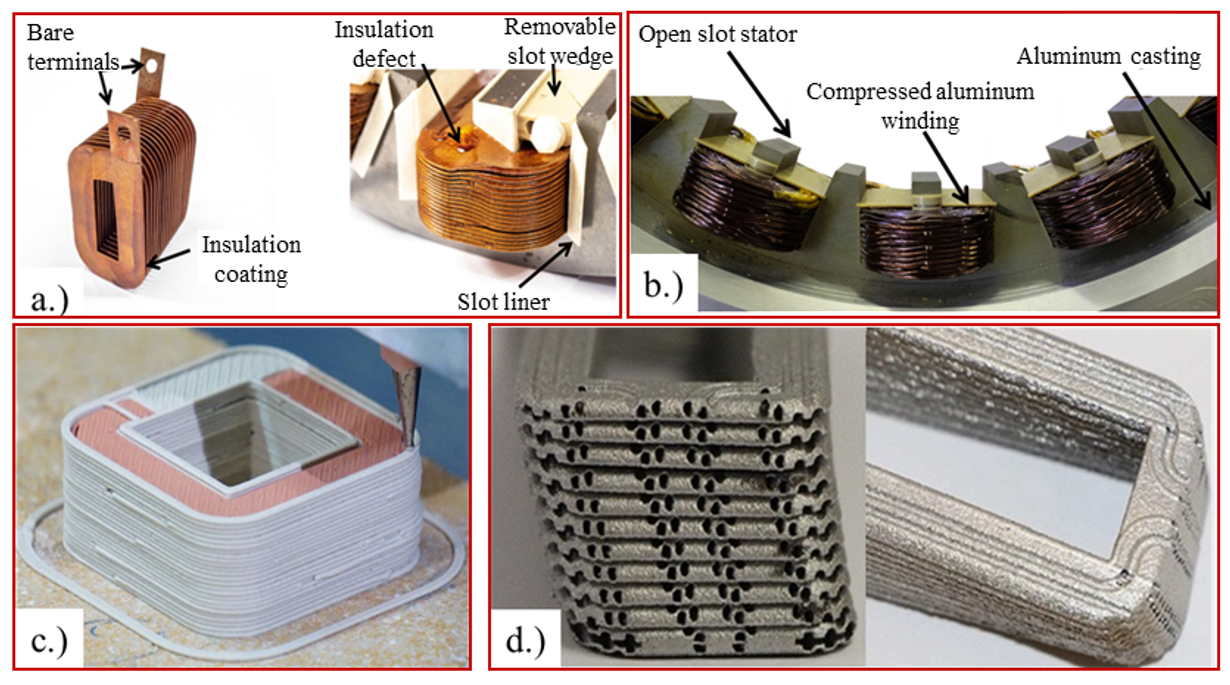

AM-built copper-alloy based coil, showed varied electrical properties for different heat treatments i.e., electrical conductivity from 51 to 75% international annealed copper standard-pure copper 100% (IACS) for the CuCr1Zr alloy [37,38]. Furthermore, it has been shown that specific profiling of the winding conductors, as shown in Figure 2a not only improved the slot area utilization (fill-factor) but also minimized the AC losses. Experimental results showed 20% improvement in continuous operation output [39].

Figure 2.

Examples of AM-built windings (a,b) AM-built shaped-profile, electrically insulated winding [39] (c) MM-AM built winding assembly with integrated ceramic insulation [13] (d) AM-built tooth-coil winding with integrated liquid-cooling channels [40].

Furthermore, processing of the coils/windings such as electrical insulation or coating can be done via Multi-Material (MM)-AM, rather than the conventional insulation technique such as enameling with resin, as illustrated in Figure 2b,c. This effectively eliminates the need for post processing of the AM produced part. The winding assembly along with insulation was tested thermally, by heating it 20 times up-to 300 °C, without showing any structural defects in insulation or change in electrical parameters of the coil.

Also, compared to conventional resin based insulation, good thermal characteristics of the resin based insulation from MM-AM provides for the attainability of higher current density in printed coil structures [13]. With the advent of AM in electrical machines, there’s a potential possibility for unique/novel/application-specific winding design with improved manufacturability and material utilization without compromising on the vital design factors. This shows the prospective improvements in electrical machine performance with the utilization of AM techniques.

Machines having efficiency, compactness and high torque-to-weight ratio as primary concerns, utilize permanent magnets (PMs) and therefore the manufacturing and consequent properties of PMs have significant importance. For such applications, PMs need to possess good functional magnetic, thermal and mechanical properties. For common applications, low energy-density PMs/soft magnets like Ferrites or MnAlC are used. But, for high energy-density/high specific-output applications, hard magnetic and high energy-product permanent magnets of materials like NdFeB/AlNiCo/SmCo are essential. Conventionally, PMs are either made by sintering or bonding which involve a large number of lengthy mechanical steps including pressing/molding and subsequent machining. This causes increase in production time and cost with the limitation on realization of complex/application-specific design possibilities.

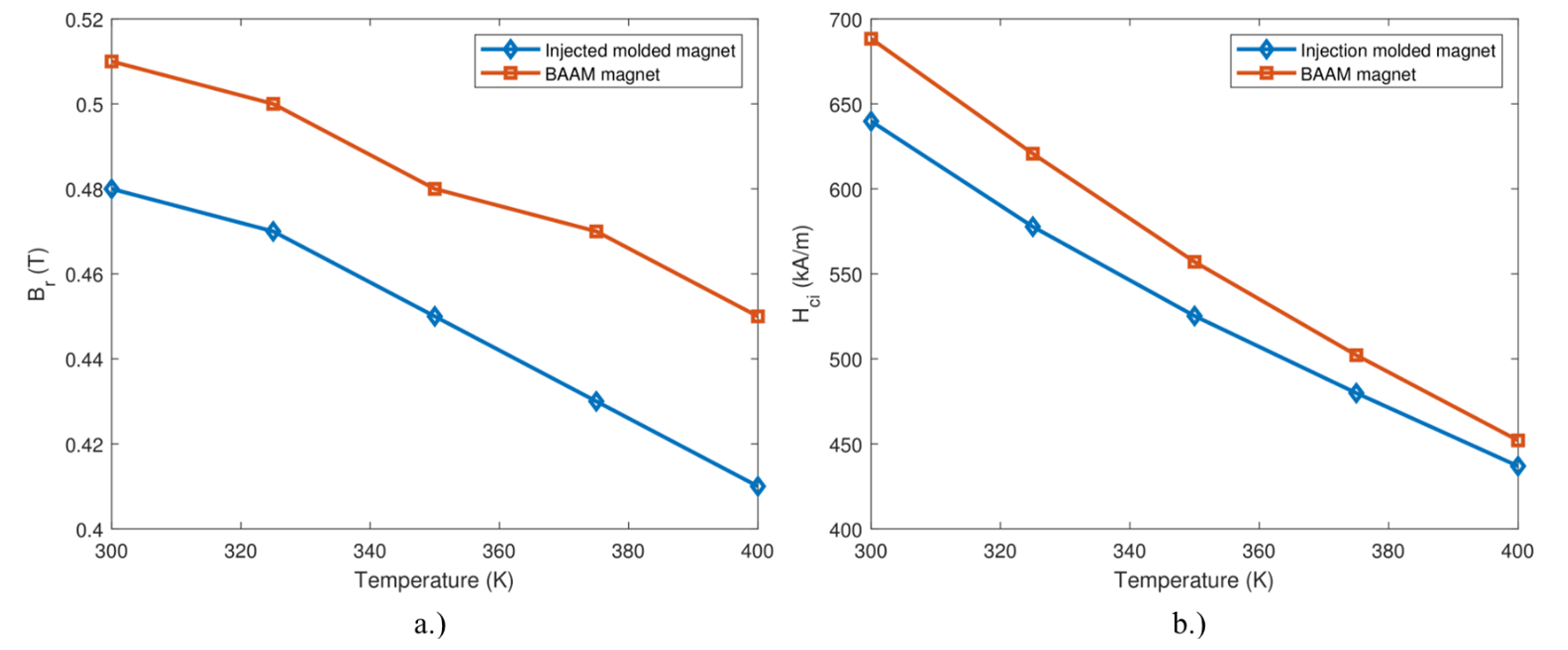

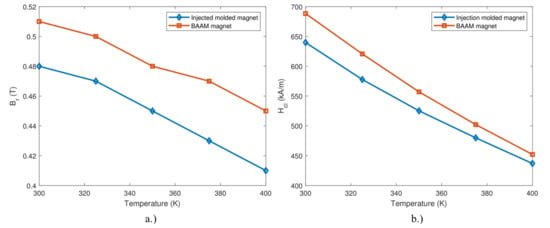

In [24] the authors have presented a comparison about effects of various AM techniques on the mechanical and magnetic properties of PMs. The PMs produced by SLM have shown to produce magnets with 90% density [41] but significant cracks and residual stresses are introduced in magnet which negatively impact its mechanical and magnetic properties. But this issue, as discussed earlier, can be suppressed to a large extent by pre & post-AM heat treatment [21]. The material extrusion and Binder Jet printing (BJP) produced NdFeB PMs have similar properties to that of fused deposition modelling (FDM) based PMs [42,43]. The challenge with BJP manufactured PMs is that the volume content needs to be increased which would in-turn increase the magnet density and residual flux density. This is shown to be done with the help of eutectic alloy infiltration with BJP technique [44]. Big area additive manufacturing (BAAM) is a special technology, NdFeB magnets manufactured through this technique have shown significantly enhanced performance as compared to other AM techniques. With material density and residual flux density being 20% higher and energy product (indicating of magnetic energy density) being 40% higher than that of other AM-PMs, BAAM magnet reflects competitiveness in terms of intrinsic coercive force and residual flux density. Thermal degradation performance of AM magnets is also better than its counterparts as also illustrated in Figure 3 [45,46,47].

Figure 3.

Comparison regarding the effect of thermal degradation on performance of conventional and AM-manufactured magnets (a) Remnant flux density as function of ambient temperature (b) Intrinsic coercive force as function of ambient temperature [24,45].

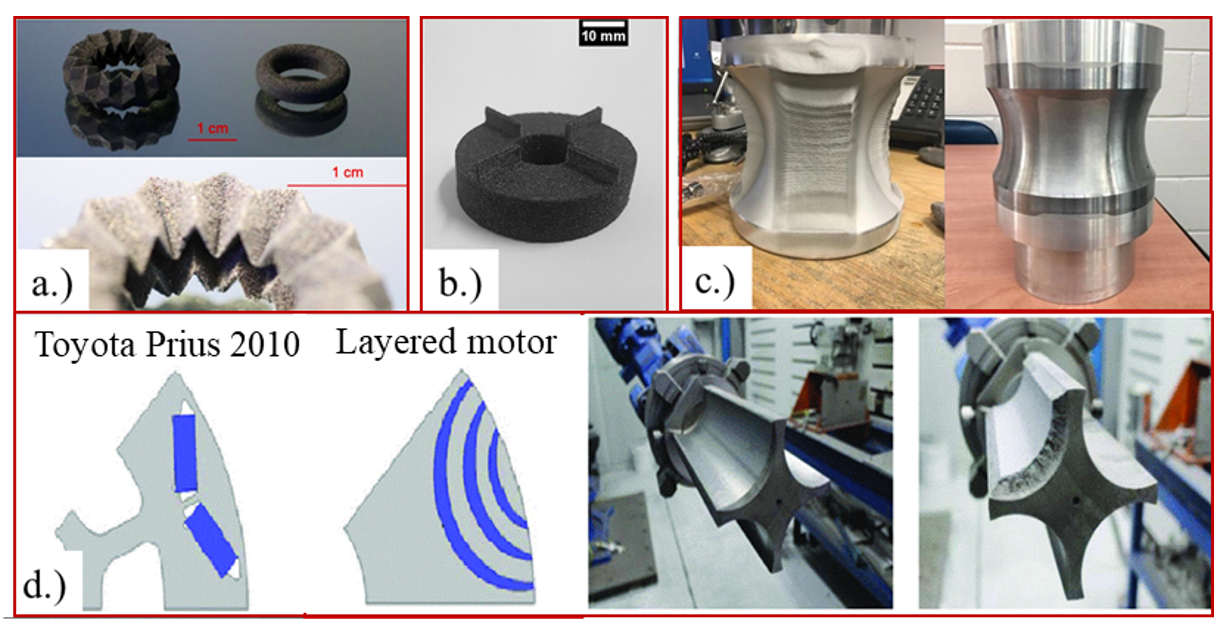

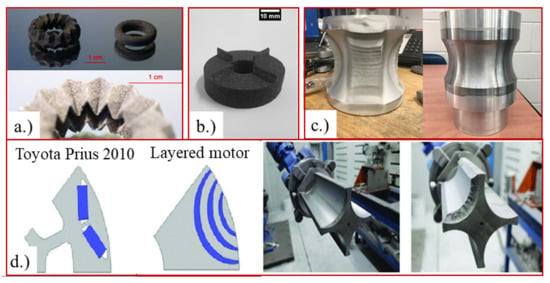

Furthermore, topology optimization (TO) enablement with almost all the AM techniques makes it easier to shape the PM geometry with relatively less analytical modelling. TO gives optimal distribution of multi-material within a specific, more complex or application-specific design space compared to conventional optimization techniques. This gives better magnetic energy delivery with the least of material waste [48,49,50]. Figure 4 presents various design concept realizations by utilizing AM.

Figure 4.

Examples of AM-built PMs (a) complex shaped PM realization [51] (b) NdFeB magnet produced by Selective Lase Sintering (SLS) [52] (c) bi-material hollow shape for electrical engines, with base material as iron and having NdFeB-Al composite at 0°,90°,180°,270° [53] (d) Enhanced interior PM motor for hybrid electric vehicle, with layered PM (left) design concept (right) fabrication process utilizing cold-spray AM [54].

Introduction of rare-earth elements in material composition is also used to enhance the magnetic properties such as intrinsic coercive force of the subject PM, even at high operating temperatures of 180 °C and higher. But this usually increases the cost of production which is less desirable in many applications [55,56]. Decreasing the use of rare-earth elements in magnet production has a positive effect on the cost and production diversity [57]. Through AM, isotropic or anisotropic properties can be modified/created by controlling the grain structure [15,58,59]. This yields better control over magnetic properties without relying much on rare-earth materials like Dy, Tb, Pr etc.

2.1.2. Passive Parts

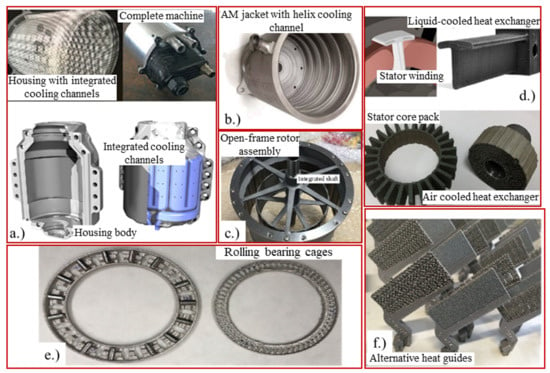

Passive parts in electrical machines include mechanical and thermal management assemblies comprising of machine frame, shaft, cooling structures and bearings, etc. These assemblies must have integrated functionalities in order to achieve compactness and improvement in performance parameters, vital for modern machine applications. Realizing the concept of integrated functionality is somewhat hindered due to limitations of conventional manufacturing techniques.

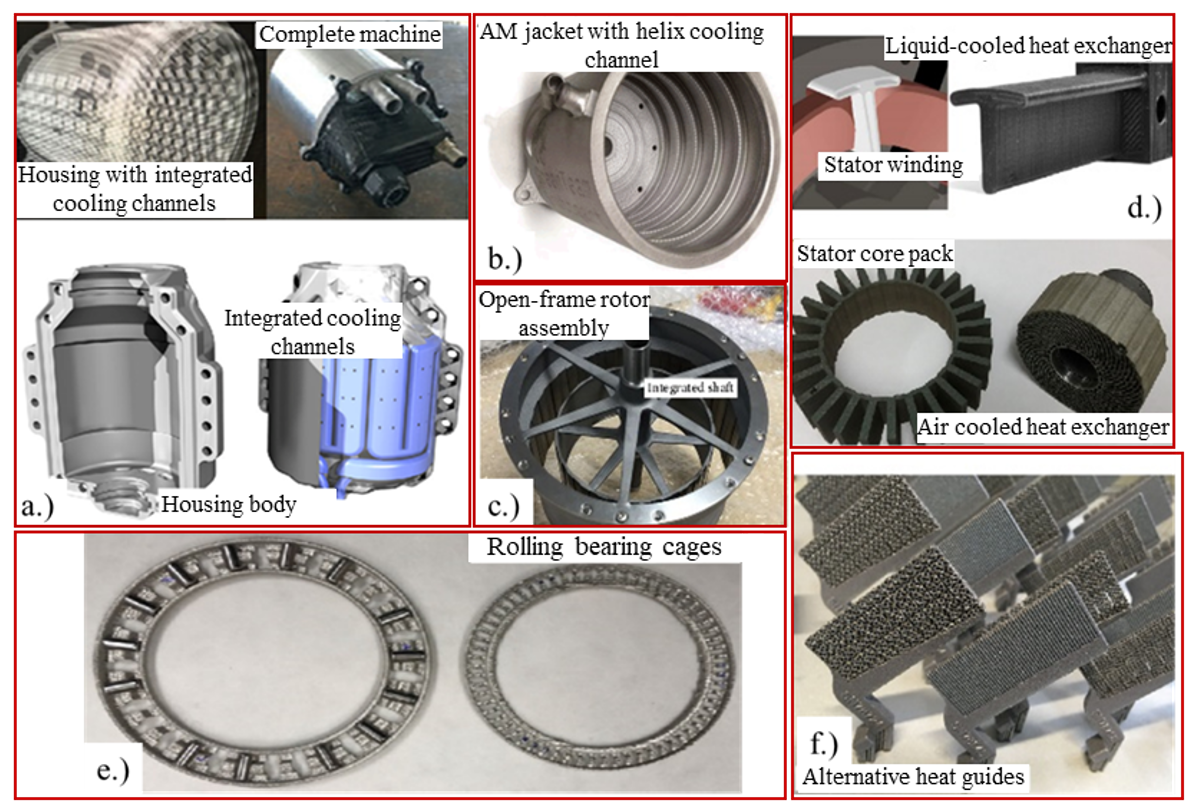

AM allows the machine designer/manufacturer to rethink the design of these assemblies by offering a wide range of material selection, reduction in the size/weight of structural parts due to enablement of various lattice structures and integration of various functionalities together, which cannot be realized with conventional manufacturing techniques. This means more compact, high power density and low-inertia electrical machines in an application-specific design space without compromising the operational performance. Figures below showcase some of the examples regarding employment of AM in mechanical and thermal management assemblies for electrical machines. In these examples [35,60,61,62,63,64] as shown in Figure 5, uniquely designed heat exchangers and various potential options for structural topologies have been presented. These include liquid and air-cooled rotor and stator assemblies, lattice structure assemblies, heat exchangers utilizing alternative plastics and ceramics, heat guides and rolling bearings etc. The integration of different functionalities, together in a structure, resulted in higher total mass flow for the heat exchange with consequent increase in cooling efficiency and reduction in overall weight. Due to increased mass flow for heat exchange, rapid cooling of peak loads also allowed for longer operation at peak loads.

Figure 5.

AM-built electrical machine parts (a) [60,61], (b) [65], (d) [62] integrated liquid cooled assemblies (c) air cooled rotor and stator assembly [66] (e) rolling bearing cages [63] (f) heat exchangers [67].

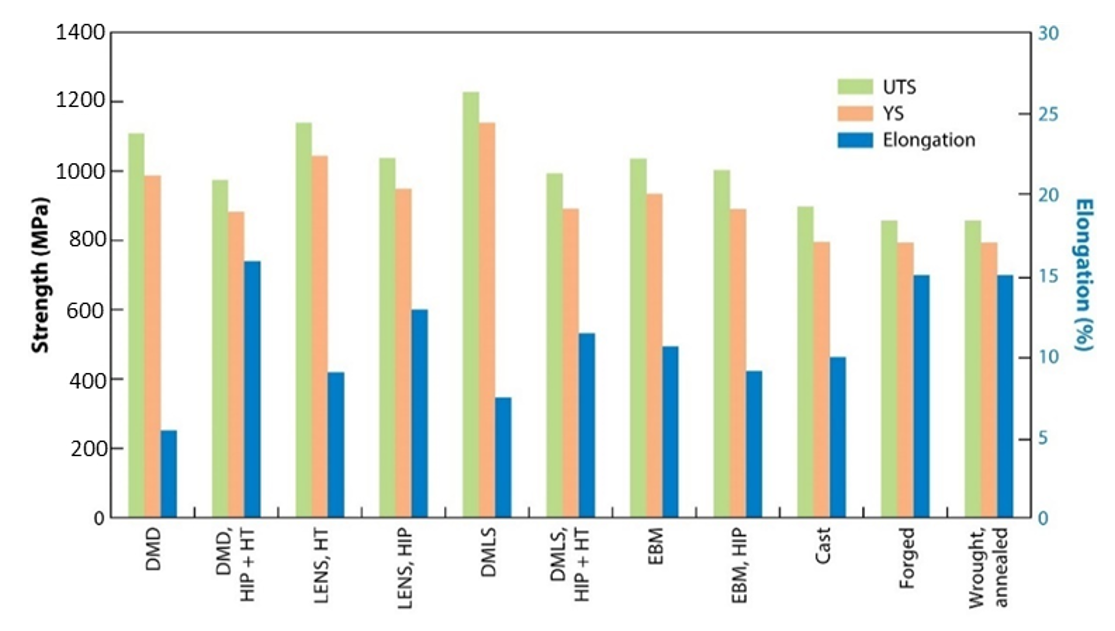

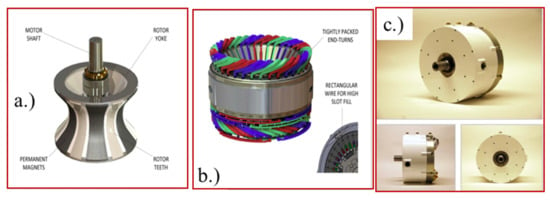

Research and development in this area of AM manufacturing is relatively on advanced stage with results comparable to the conventional techniques, as demonstrated by the comparison of mechanical properties for various conventional methods (wrought annealed, forging and casting) vs. AM techniques, as shown in Figure 6 [68,69,70,71].

Figure 6.

Comparison of mechanical properties for AM-built and Conventional built metallic material Ti-6Al-4V (UTS-ultimate tensile strength, YS-yield stress, DMD-direct metal deposition, LENS-laser engineered net shaping, DMLS-direct metal laser sintering, EBM-electron beam melting; HT-heat treated, HIP-hot isostatic pressing) [69].

In conclusion, AM has a lot to offer in almost every aspect of manufacturing process for electrical machines, such as:

- reduction in time and cost of production

- reduction in weight due to enablement of structural topology optimization

- better control over magnetic properties owing to the opportunity of varying the material composition

- less dependency on rare-earth elements due to control over isotropic/anisotropic properties through modification of grain structure

- enablement of complex/application-specific design realizations, by eliminating a lot of mechanical steps as well as the need of molds for almost any desired geometrical shape

- increase in power density, due to the opportunity of integrated functionalities within individual assemblies

2.2. Holistic Approach

It is only very recently that there has been emphasis on AM of electrical machines. That is why the technological developments and achievements in this field are relatively immature, however, research is progressing at a significant pace regarding the employment of AM in manufacturing electrical machines. Scientific research is a step-wise process so naturally, as a rule of thumb; research efforts were initially focused on the application of AM to produce individual machine components.

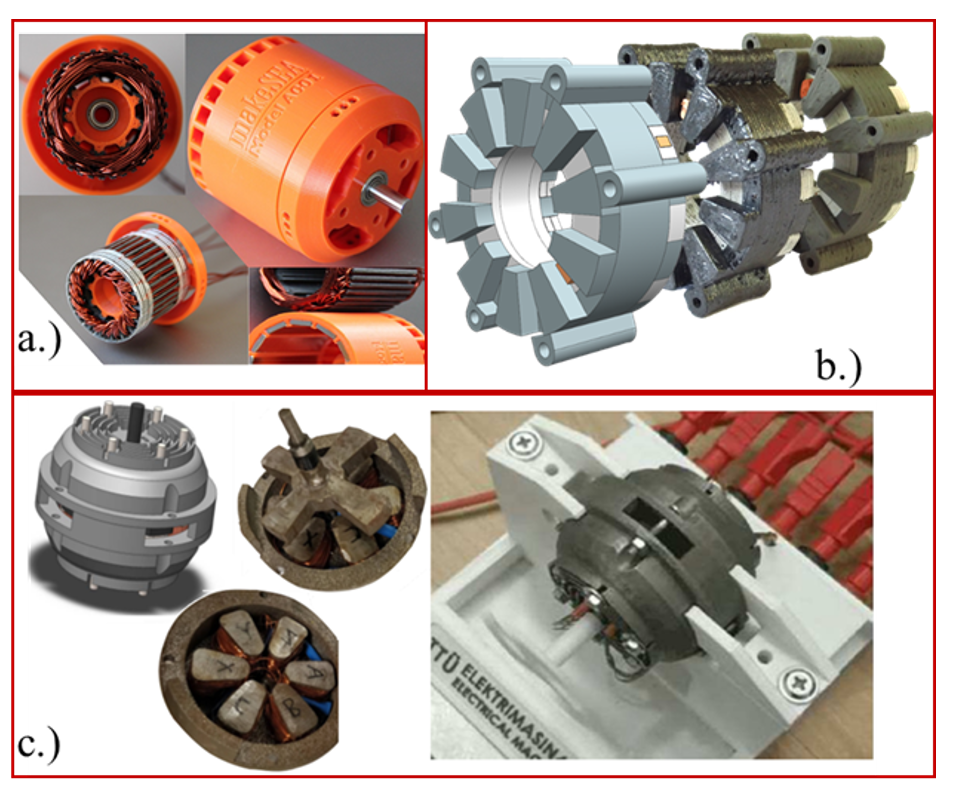

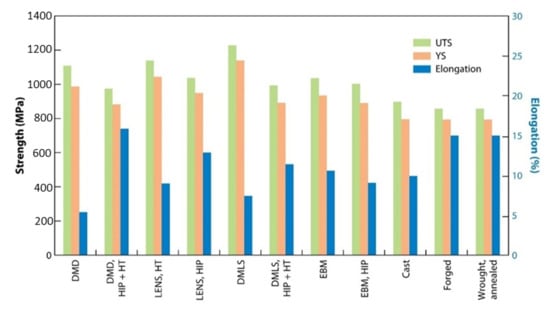

Various approaches by researchers are being adapted for the realization of completely AM built, self-replicating electrical machines; Figure 7a shows a simple brushless, Halbach array DC electric motor in which only the mechanical assembly is made using AM (from PLA plastic material), that houses its active parts like permanent magnets and coils/windings etc. This motor showcased efficiency of approximately 68% [72].

Figure 7.

Examples of AM-built electrical machines (a) halbach array DC motor [72] (b) stator of end-winding reluctance machine [17] (c) Prototype Axial-Flux SRM [73].

Researchers from Chemnitz University of Technology claimed to have produced a completely MM-AM built end-winding reluctance machine, functional machine using high viscosity metallic/ceramic pastes (Figure 7b). The machine is reported to have withstood operating temperatures of 300 °C due to the use of ceramic insulation which has high thermal conductivity but it needs extensive post-processing [17]. Figure 7c showcases an SLM printed prototype, fully functional axial-flux switched reluctance machine (SRM) but this prototype-production too, involved significant amount of post-processing [73].

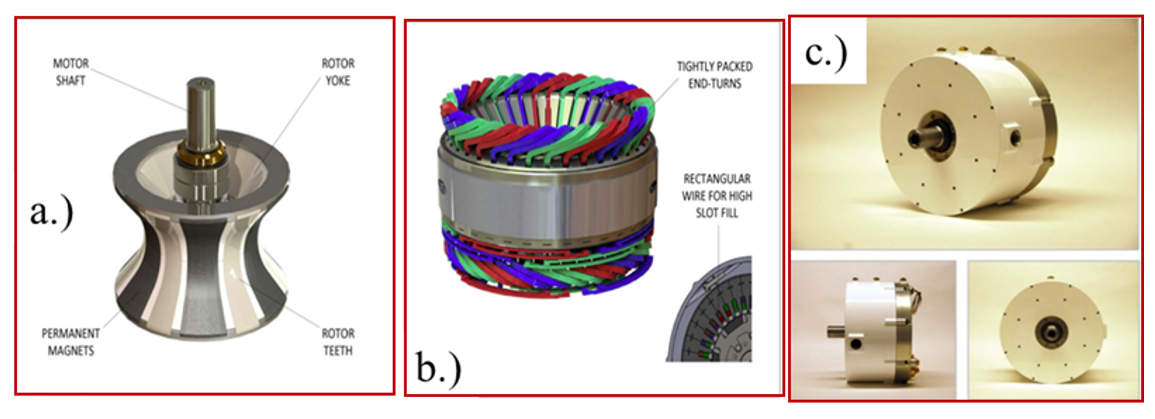

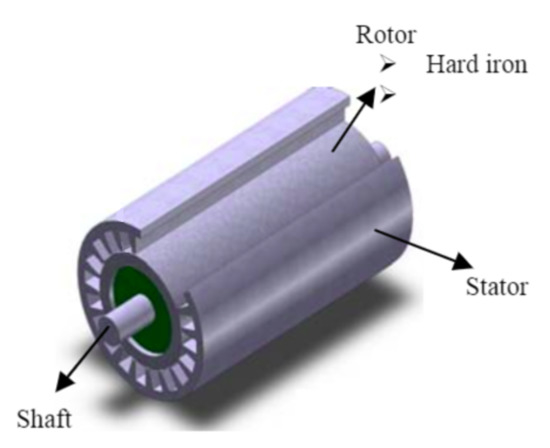

In [74,75] the authors have presented a prototype of an advanced electric motor design with hybrid field topology for automotive traction (Figure 8). The theoretical modelling shows promising performance characteristics of continuous power density at 2.8 kW/Kg or 8.6 kW/L and an above 90% efficiency in a broad operating region on torque-speed characteristics plot. This is a lot high relative to the commercially available traction motors. The authors report that the motor is currently under construction and after completion, results on the performance characteristics will be presented after third-party testing/validation.

Figure 8.

Hybrid-field Traction Motor (a) rotor (b) stator with integrated cooling (c) Partially assembled motor [74,75].

Another aspect in realization of complete additively manufactured electrical machine is the integration of power electronics, research in which has also been initiated. Efforts in micro-scale laser based AM to produce structures below 100 µm resolution may enable integration of power electronics with the electrical machines, that will enable production of integrated motor drives resulting in compact electrical machines for high performance demanding applications like in automotive and aerospace industry [76,77].

3. Future Prospects of Holistic Approach

As presented in previous sections, efforts have resulted in varied level of progress towards production of additively manufactured machine parts; with development in production/integration of thermal management and mechanical assemblies ahead from the production of active parts (core, coils/windings and the permanent magnets). However, to manufacture a fully additively manufactured electrical machine, very little has been done. It is now that the researchers are entertaining the idea of holistic manufacturing of electrical machines through AM and the most natural step forward seems to direct the efforts towards a comprehensive design approach, keeping in view the current state-of-the-art in this field.

3.1. Conventional/Symmetrical Electrical Machines

Conventional machines such as induction and synchronous machines have a widespread use for bulk energy conversion. Usually, they are simple/symmetrical in design and large in size. Industrial manufacturing of such machines, at present, is most feasible with conventional methods owing to the fact that resultant performance parameters obtained are very much mature and offer best results corresponding to operational requirement, cost and time for in-volume production. Employment of AM in industrial production of such machines is hindered, due to the following factors;

- limitation on the overall size which can be realized with AM at present i.e., relatively small print-bed size

- relatively less maturity regarding electromagnetic properties of AM materials

- associated production cost and time

Efforts are being put into these aspects, by researchers and various industries. Until this gap is filled-in, employment of AM in industrial manufacturing of conventional/symmetrical electrical machines is limited mostly to;

- rapid prototyping

- production of individual machine parts having application specific complex geometries which are impossible to manufacture otherwise

References [2,3,4,5,6,33,78,79,80,81] showcase various examples where renowned automotive, aerospace and satellite companies have utilized AM for production of complex machine parts. Despite the limitations and challenges associated with current state-of-the-art in AM, asymmetry in machine design is an area where benefits of AM can be exploited the most. In the next section, this aspect will be discussed in detail while exploring for machine types best suitable to be manufactured using current state-of-the-art in AM.

3.2. Non-Conventional/Asymmetrical Electrical Machines

Symmetry in design is a characteristic that has imposed major limitations on exploiting the full potential of electrical machines. Basically, the aim has been to reduce complexity and manufacturing costs in order to cater for the limitations of conventional manufacturing techniques. Since the advent of AM, this limitation is virtually no longer relevant. With the degree of freedom in design offered by AM, more stringent requirements of operating environment, power-density, reliability, compactness and performance parameters can be met easily.

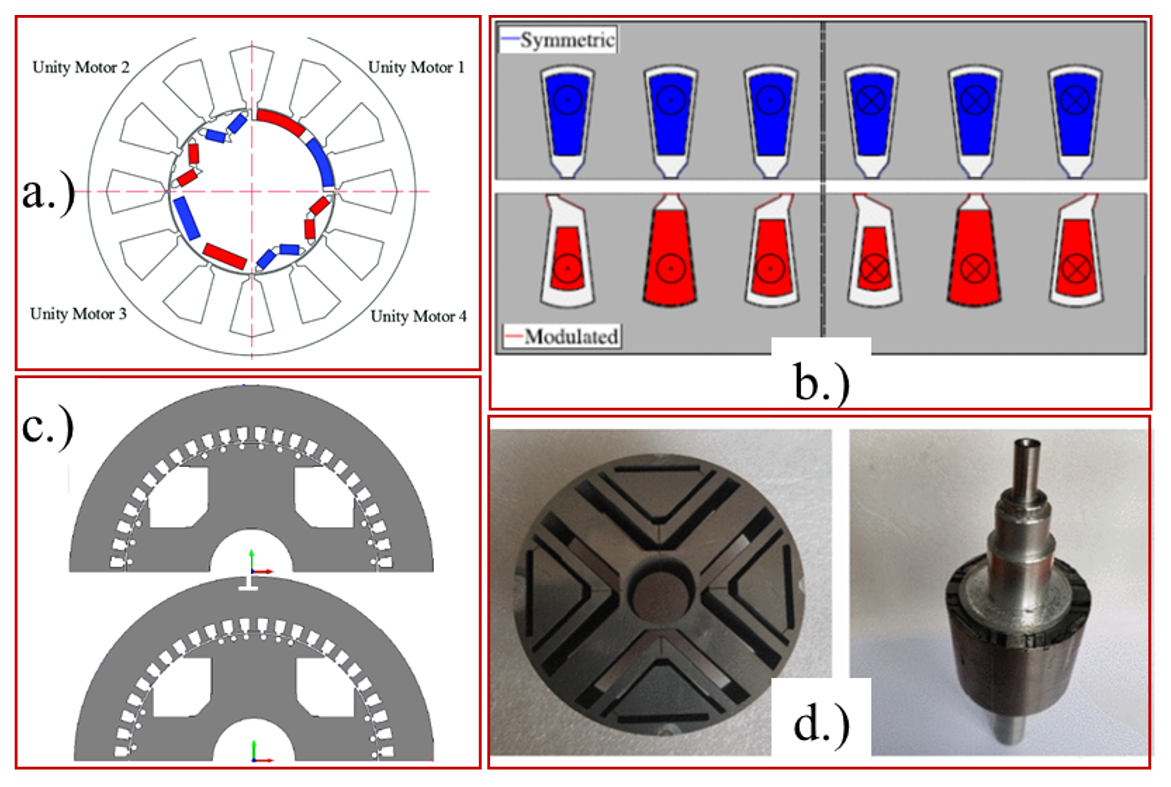

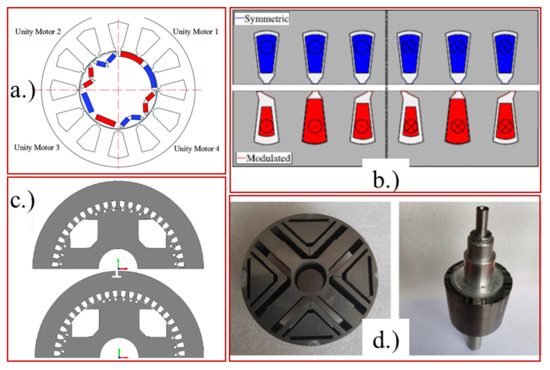

Research work to exploit alternative asymmetrical/non-conventional machine designs is under process by various researchers. Design examples such as those presented in [82,83,84,85,86,87,88,89,90,91] highlight the benefits of introducing asymmetry based on; unity motor asymmetry concept, repositioning of slot openings per-pole-per-phase, altering position of embedded bars on adjacent rotor poles and asymmetrical rotor configuration. Figure 9 presents pictorial representation for such examples and Table 1 showcases various benefits achieved from introduction of asymmetry in design. The associated disadvantages include unbalanced magnetic-pull and increased complexity in design which are needed to be considered during the design process.

Figure 9.

Concept of; (a) unity-motor asymmetry in rotor [83] (b) asymmetric slot-opening pattern (induction motor) [89] (c) asymmetric damper-cage topology (synchronous generator) [89] (d) hybrid-pole IPM machine with an asymmetrical magnet configuration in rotor [91].

Table 1.

Introduction of asymmetry in machine design with corresponding benefits.

Selective variation in electrical conductivity (EC) of coils/windings, enabled by AM, can contribute in managing winding losses. In [92] authors demonstrate this by employing conductors near slot opening with low EC to reduce winding AC losses and conductors near slot bottom with high EC to reduce DC losses. These results showcase the potential of improvement in performance parameters of various machines by employing targeted asymmetry in design. It equips the designers with more freedom to optimize machine performance.

4. Potential Candidate Machines for AM

In majority of examples and reference cited above, design asymmetry in order to improve performance characteristics of electrical machines, was introduced in 2-D (to remain within the limitations of conventional analysis and manufacturing techniques). With AM, the ability to introduce design asymmetry in 3-D enables a lot of flexibility in design and manufacturing of special purpose electrical machines. By special purpose electrical machine, it is meant for the machines which may be small in size, compact, application-specific and offering high energy density; having relatively complex design and manufacturing topology than the conventional Induction or Synchronous machines. The aim of this section is to investigate the candidate electrical machines from the standpoint of AM possibility and benefits of AM-utilization such as:

- Reduction in weight due to enablement of topology optimization

- Complex shape realization for optimal electromagnetic energy guidance

- High winding fill-factor for increased power density, etc.

- The target machine categories may include;

- Reluctance machines

- Hysteresis machines

- Brushless DC machines

These machines can be further classified into various types depending upon individual construction, application/utilization, performance characteristics and the control schemes involved. A no. of such machines with respect to their design, working principle, performance parameters and utilization will be discussed, in order to narrow down the machine selection for intended design of AM-built electrical machine. The selection of candidate machine types for AM is made while keeping in view following baselines:

- Least involvement of multi-material utilization

- Machine topology and design parameters falling within the constraints of present stage AM-capabilities

- Have the maximum chance of exploiting present stage AM capability to realize complex geometries, which is not possible otherwise.

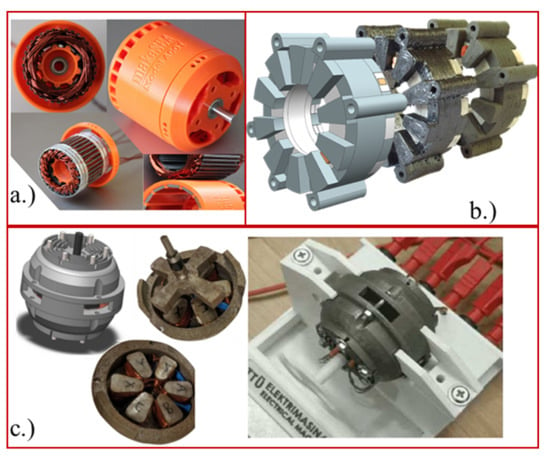

Another classification that offers potential benefits of AM-utilization is the axial flux topology in electrical machines. Axial flux machines have a few pros over radial flux machines, due to which they deliver significantly high power-density. First is the fact that in axial flux machines, the PMs are located relatively further from the central axis. This provides larger lever resulting in increased torque. Secondly, in radial flux machines, major portion of the winding in the form of coil overhang remains inactive i.e., it doesn’t serve any function other than just making loops. In addition to that, it causes electrical losses in the form of heat dissipation across electrical resistance that it offers. This effectively lowers the power/weight ratio and cooling efficiency. While in axial flux machines, there is less coil overhang and thus it provides high power/weight ratio and higher efficiency due to effective cooling as compared to the radial flux machines. Furthermore, in dual rotor topology of axial flux machines, the magnetic flux path is considerably short than in radial flux machines [93].

4.1. Switched Reluctance Machines (SRM)

These machines offer attractive qualities of high torque and a wide range of operating speed. By controlling switching sequence together with an appropriate electromagnetic design, the torque-speed characteristics of the SRMs can be made suitable for various traction applications in automotive industry. Furthermore, by simply changing the control parameter selection with torque and speed, a given machine design can offer different characteristics. On the other side, the complex control scheme due to on-line parameter variation, noise and vibration are some of its associated issues [94,95].

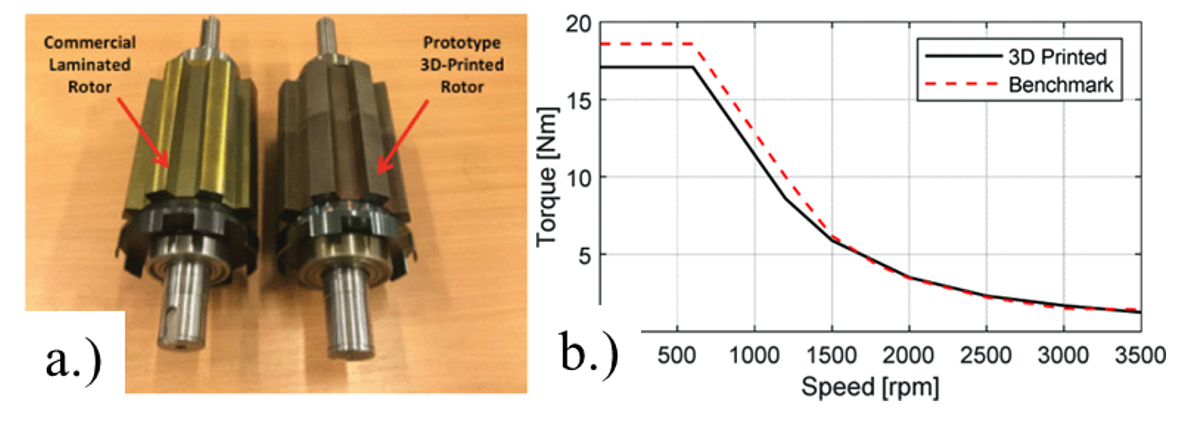

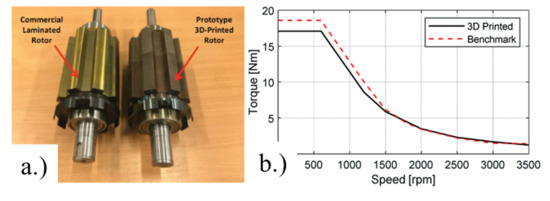

The readiness of metal AM for manufacturing of soft magnetic rotor for SRMs is demonstrated in [96] by comparing an additively manufactured rotor (Fe-5.0% w.t. Si) with that of a conventional laminated, non-oriented silicon steel rotor. Due to the absence of laminations, eddy current losses were significant; but at the rated speed, the output power was comparable to that of benchmark machine. The ratio of output power improved further, with increase in operating speed as presented Figure 10 and Table 2.

Figure 10.

(a) Benchmark and Prototype AM-Built SRM-rotor (b) Torque –Speed characteristics of Benchmark and AM-built-rotor SRM [96,97].

Table 2.

Variation in measured quantities of AM-built SRM from benchmark machine [96].

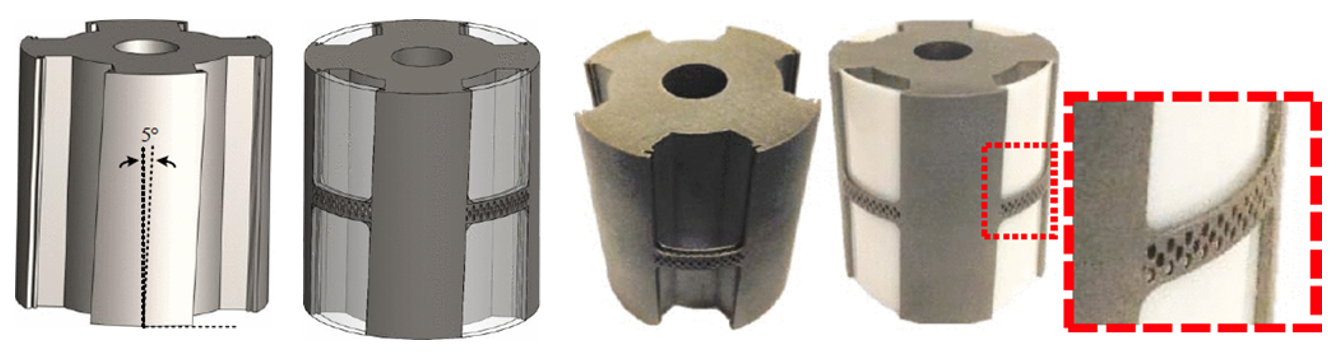

Another SLM fabricated asymmetric rotor for SRM is presented in Figure 11. This rotor is designed with skew and honeycomb structure, which is difficult to fabricate otherwise by conventional method. With this design, the reduction in torque ripple was analyzed by FEA simulation and then validated experimentally, giving approximately 45% reduced torque ripple [98].

Figure 11.

AM-built, Novel SRM-Rotor [98].

AM also enables application of topology optimization on machine design, Application of topology optimization on SRM design [99,100] and subsequent analysis, shows achievement of optimization goals i.e., high average torque and low torque ripple with low mass.

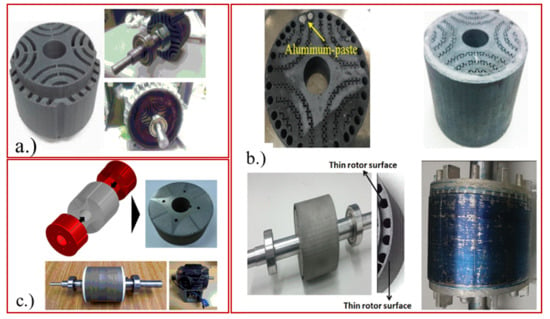

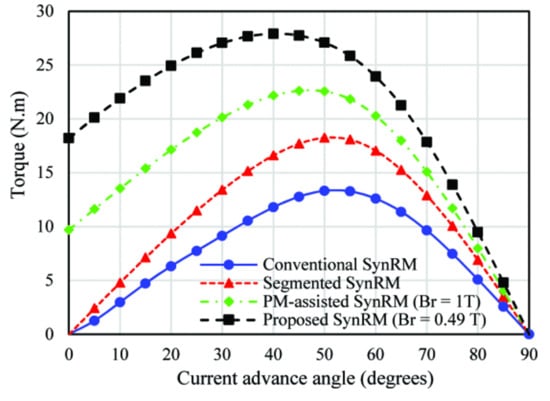

4.2. Synchronous Reluctance Machine (SynRM)

The synchronous reluctance machine (SynRM) has the advantage of relatively simple construction and low moment of inertia of rotor which gives fast response characteristic and high torque density but as the name suggests, it is essentially a constant-speed machine dependent on supply frequency. The speed control can be achieved over a wide range by employing frequency control scheme. These types of machines are widely used in proportioning devices, synthetic-fibre manufacturing industries, wrapping and folding machines, positioning of control rods in nuclear industries, industrial drive systems requiring synchronized and continuous processes. Potential use of such machines for traction purposes is also reported [101,102,103].

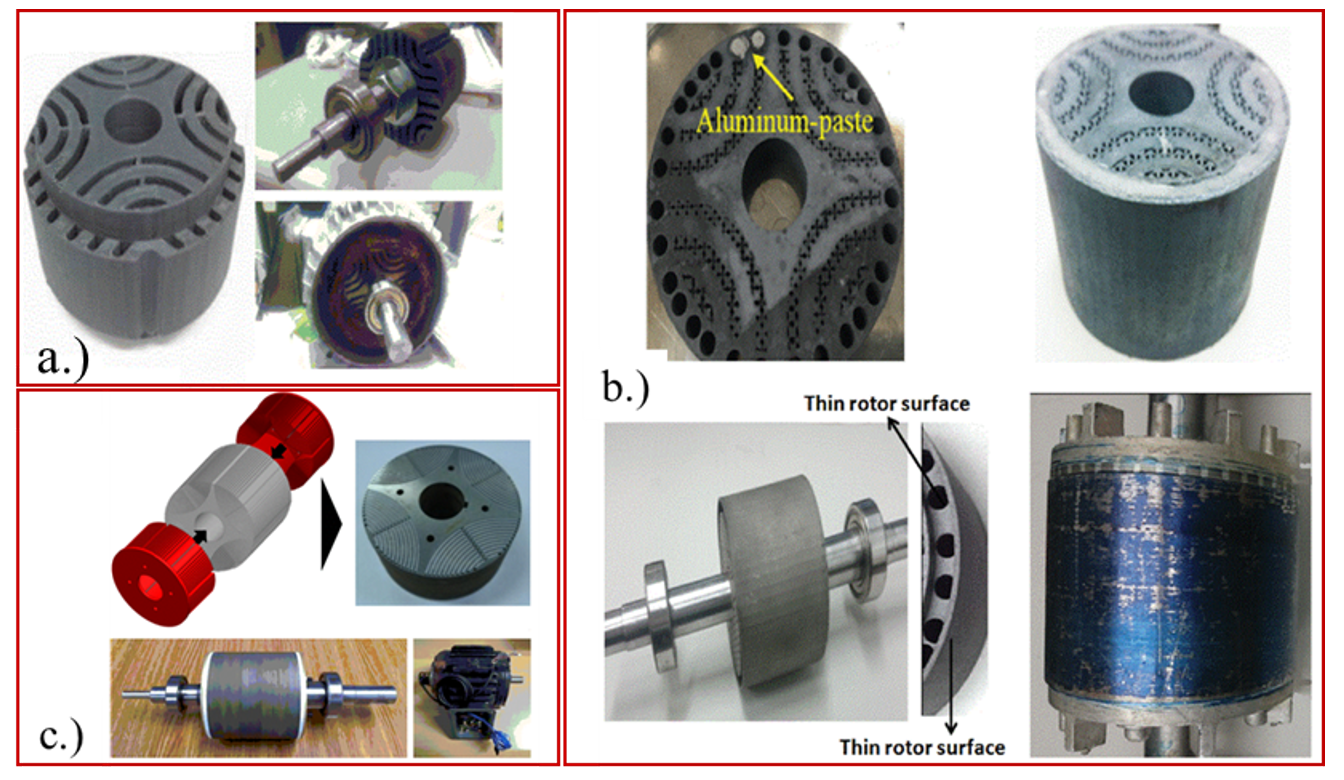

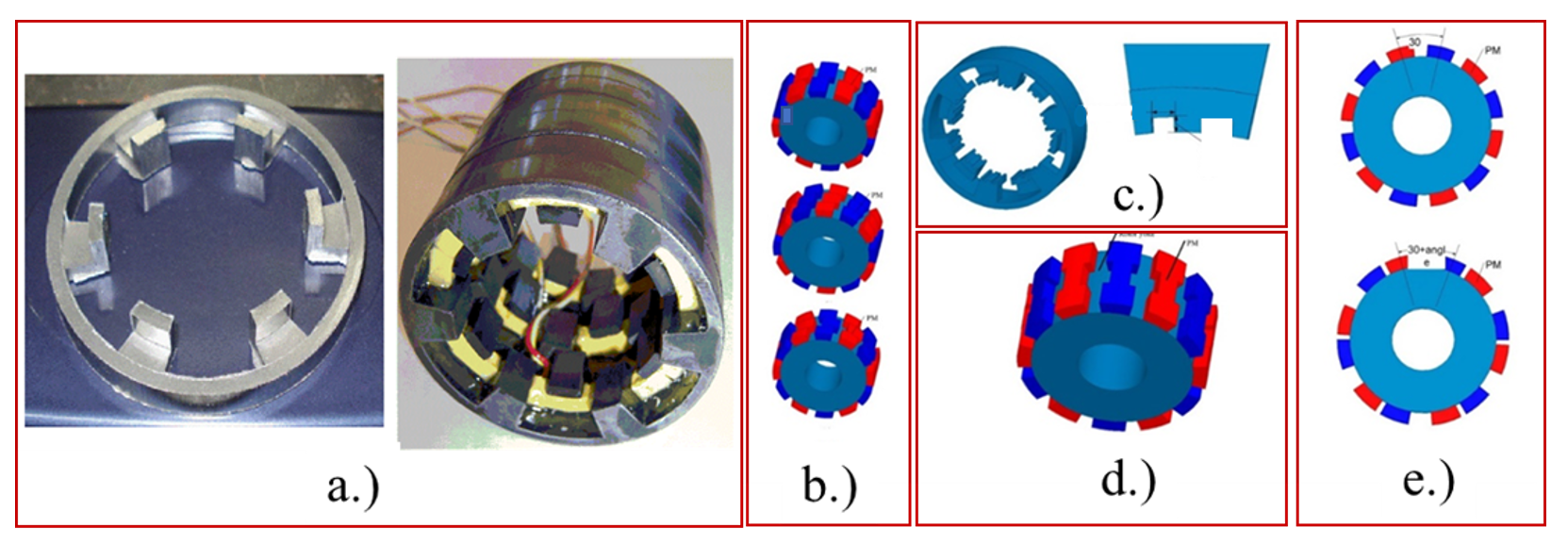

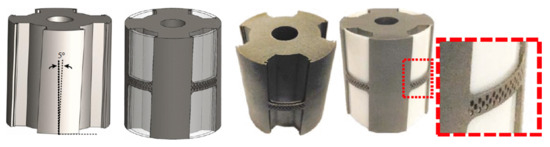

Considering the design prospects from AM point of view, the SynRM-rotor has three basic topologies namely; salient pole (SP), axially laminated anisotropy (ALA) structure and transversally laminated anisotropy (TLA) with ALA having the highest saliency ratio and maximum reported power factor of 0.8 [104]. ALA rotor has a complex structure and is relatively difficult to manufacture by conventional techniques. This is where AM comes-in. With the employment of AM, the SynRM rotor can be easily realized with the additional improvement and optimization of performance parameters by exploring new design topologies. In [105,106,107,108] the authors have presented different design topologies (as shown in Figure 12) for AM-built rotors with integration/enhancement of various functionalities.

Figure 12.

AM-built rotors for SynRM (a) 3D printed prototype [106] (b) Prototype Line Start-SynRM (LS-SynRM) with 3d-Net structure in rotor [107] (c) Prototype rotor design, assembled rotor and SynRM [108].

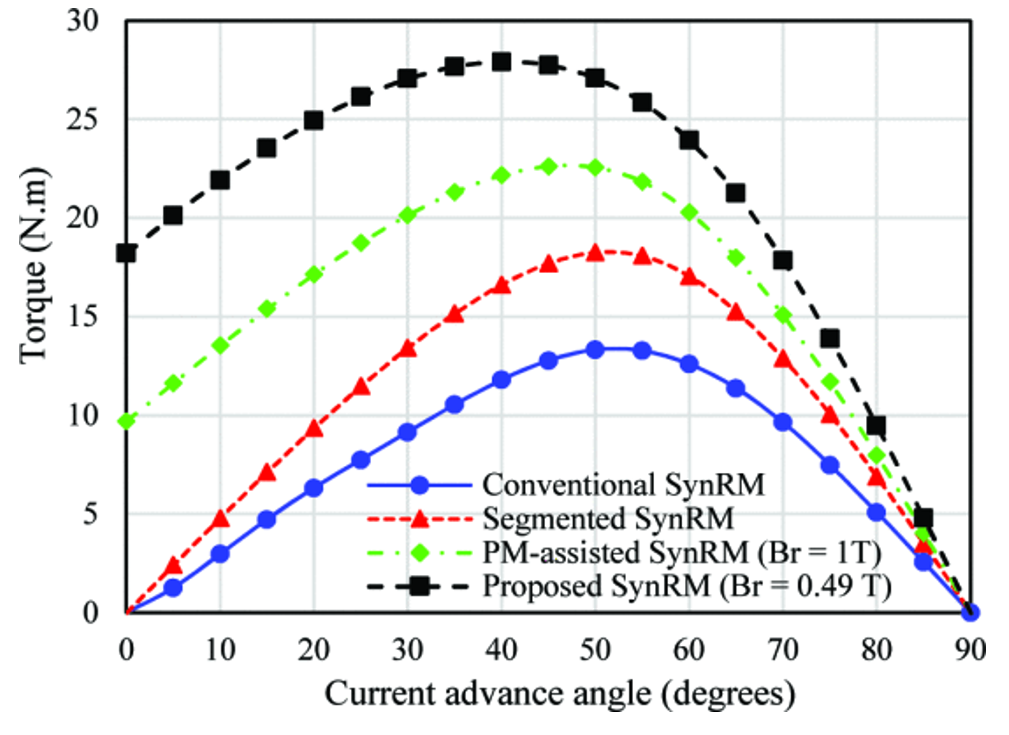

In [105] significant reduction in torque ripple i.e., one-fourth and 1.4% higher average torque, attributed to elimination of rotor bridges and center-posts (not possible with conventional manufacturing techniques), was achieved. The comparison of torque characteristics is shown in Figure 13.

Figure 13.

Comparison of torque characteristics [105].

In [106] the authors focused on efficiency and the starting ability of SynRM, by designing a 1-HP LS-SynRM and subsequently manufacturing it using AM. For the same design topology, the authors also presented a LS-SynRM [107] having flux barriers with 3D-net structure (only realizable with AM). The control over silicon content and machine’s geometry optimization permitted lower iron losses and higher efficiency for same operating conditions. For another example of AM-built Syn-RM [108] the reduction of eddy-currents, while retaining the mechanical integrity, was achieved by addressing the multi-material printing limitation of metal-AM in an innovative way. A polycarbonate resin-based, separately printed insulation structure was assembled with the metal-AM produced rotor core. The performance analysis at rated-speed showed 6% increase in output density and 1% increase in efficiency as compared to existing model being applied in industry. In [109], the authors showcase potential degree of freedom offered by AM in terms of parameter selection for FEM basedshape optimization. The paper presents substantial improvement in performance parameters such as torque ripple and average torque output by the means of optimizing the reluctance motor’s rotor shape. These results, how small in terms of improvement they may be, prove the case for potential of utilizing AM in manufacturing SynRMs.

4.3. Claw-Pole Machines

Claw-pole machines (CPM) having electrically excited claw-pole DC fields, yield higher torque density of up-to three times higher than conventional machines. This is mainly due to their ability to produce 3D-hetropolar magnetic field from single-coil excitation within claw-pole halves. The benefit of higher torque density, makes CPM an ideal candidate for a wide range of applications requiring size compactness like in automobile alternators, medium-sized household appliances etc. These machines have a complex design that is not easily realizable using conventional electrical-steel lamination construction and the use of SMCs has shown to be most advantageous regarding the manufacturing purposes [110,111].

Various topologies for rotor/stator-claw construction have been proposed over-time for industrial applications. A prototype CPM is shown in Figure 14a for illustration purpose. This machine was designed, manufactured with SMC-core of low mass density, analyzed and successfully tested for key performance and production parameters against a benchmark induction motor which is bulk-produced in industry for medium-sized household applications [112].

Figure 14.

(a) Molded stator of three phase CPM [112] (b) Magnet Skewing [115] (c) Claw-pole shaping & stator tooth notching [113] (d) Magnet axial pairing [113] (e) Magnet Shifting [113].

The torque coefficient of a CPM is dependent on the number of pole pairs but with increase in pole number, leakage flux also increases resulting in decreased power factor and efficiency. This necessitates for an optimization of pole pair quantity. Then comes the issue of cogging torque which is best dealt with magnet skewing, claw pole shape optimization, stator tooth notching, magnet axial pairing and magnet shift. The authors of [113,114] investigated these design topologies for a CPM, against the performance parameters. The basic design model consists of claw-pole stator cores encapsulating a global winding and a rotor core mounted with magnets. Figure 14b–e illustrate these topologies. With these design changes and optimizations, the CPM achieves higher output torque density but the design gets extremely complex. This complexity in design limits the usage of conventional manufacturing techniques but with the flexibility in design realization offered by AM, CPM becomes a strong candidate for AM-built electrical machine of future.

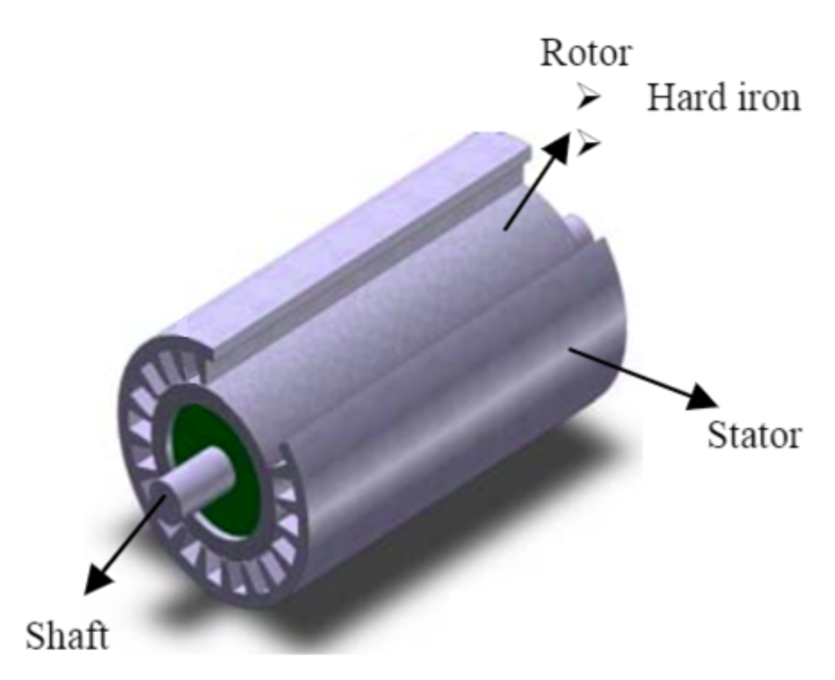

4.4. Hysteresis Motors

A hysteresis motor is essentially a synchronous motor without the DC excitation. The interaction of rotating stator flux with that of remnant flux (due to hysteresis effect which is normally not desirable in other machines), produces torque. These machines offer constant torque from initial to synchronous speed with the ability to accelerate and synchronize high-inertia loads. However, due to its operation being mainly based on the hysteresis losses, its power factor and torque/volume ratio is low [115]. Still, these machines are useful in low power applications where constant speed and low torque ripple are the main required characteristics such as; precision equipment, clocks, hard disks and gyroscopes etc. [116]. Their construction is relatively simple with a solid rotor of hard-magnetic material. The stator is of slotted construction; to house single or poly-phase windings that produce rotating flux. Figure 15 illustrates the hysteresis motor construction concept [117].

Figure 15.

Illustration of hysteresis motor construction [117].

With the rising demand of high speed and low torque-ripple machines for special-purpose and precision demanding applications; hysteresis motors with solid rotor have a promising utilization scenario, over other electrical machines with sintered PMs or laminated sheet configurations. This is due to a number of factors, such as:

- Mechanical strength is affected with laminated sheet configuration of conventional motors, which limits the maximum attainable speed.

- Solid rotor of hysteresis motor provides high stiffness during critical speed transitions

- Thermal behavior of conventional induction motors, where eddy currents cause overheating of rotor and in the case of synchronous PM motors, where excessive heating can cause demagnetization

- Hysteresis motor’s ability to improve its torque performance due to magnetization of rotor in response to impulsive electrical over-excitation [115,118,119,120]

Recent research works such as in [118,119,121] have showcased potential of various design topologies for hysteresis motors, regarding their application in high-speed context.

The authors of [51,122] also presented the attributes in terms of density and coercivity for magnetic material with various compositions, manufactured through cold spray (CS) and fused filament fabrication (FFF) techniques. The magnetic material was manufactured from readily available commercial powders. Table 3 provides attributes for hard magnetic materials from various techniques and different printing parameters.

Table 3.

Attributes of various AM produced magnetic materials [51,123,124].

A wide range of variation in coercivity value with various AM-techniques and associated printing parameters, establishes the prospect of utilizing AM in manufacturing hysteresis motor with magnetic characteristics optimized for application-specific requirements. Other than the section where AM of permanent magnets was discussed, this article was mostly aimed at finding and highlighting the techniques to mitigate the generic issues of hysteresis and eddy current losses in printed machine parts. Manufacturing of hysteresis motor can significantly utilize the benefits offered by AM in the form of efficient mechanical and thermal management assemblies, without investing much effort in avoiding the associated hysteresis and eddy current losses.

5. Conclusions

Existing research and the future potential of utilizing AM in the fabrication of electrical machines are investigated in this paper. Prevalent studies show that the efforts have been majorly focused on utilizing AM to produce individual machine parts or subassemblies. In that respect too, a varied level of progress is observed. The research level is relatively mature for passive parts such as mechanical and thermal management assemblies compared to active parts such as coils/windings, cores, and PMs. Due to this varied level of progress and minimal effort towards producing complete electrical machines, AM has not yet progressed to a level where it can replace conventional manufacturing techniques for large-scale production.

Virtually, AM offers a broad range of benefits over conventional manufacturing techniques such as:

- Optimal material utilization

- Structural topology optimization resulting in improved thermal and mechanical performance

- Optimal electromagnetic energy guidance through complex geometric shape realization

- Size and weight reduction due to enablement of integrated functionalities

- Control over material composition and hence its physical properties

With this much to offer, AM virtually has the potential to replace conventional manufacturing techniques completely. However, in reality, it lacks in some aspects such as the maximum size of print-bed, associated time & cost of production, the need for post-processing, and a relatively lesser level of research maturity in electromagnetic properties of printed parts. Due to these reasons, the utilization of AM in the industry is currently hindered.

With AM being utilized at its full potential, the production of mass-personalized or application-specific electrical machines will be enabled. With efforts in the right direction, it is just a matter of time before AM will be equivalent/competitive to conventional manufacturing techniques. The most natural step forward is to explore application-specific/complex machine designs which are not realizable otherwise. These may include customized machines for various industries like robotics, automotive, aerospace and medium-sized appliances, etc. These applications require compact and high power-density electrical machines. The candidate machines presented in this text offer such qualities with a lot of potential for improvement in their performance parameters by introducing asymmetry in their design. Asymmetry in design is a feature that is most difficult to realize using conventional manufacturing methods and that is where AM comes-in, as the only potential enabling technique for this feature.

Another thing evident from the examples cited in this article is that a number of many industries like General Electric (GE), Boeing and Rolls Royce are already utilizing AM in producing high-performance parts for applications ranging from vehicle traction to satellite and aerospace purposes. All of this necessitates the direction of research efforts towards the upcoming future of entirely AM-built electrical machines, and the most natural step-forward is the development of a comprehensive design scheme, keeping in view the latest state-of-the-art.

Author Contributions

Conceptualization, M.U.N., and A.K.; methodology, M.U.N. and A.K.; validation, A.K., and B.A.; Writing—Original draft preparation, M.U.N.; Writing—Review and editing, M.U.N., A.K., T.V. and A.R.; visualization, A.K., M.U.N.; supervision, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Estonian Research Council grant (PSG-137).

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Metal Additive Manufacturing. GE to Install First Metal Additively Manufactured Part on GEnx Commercial Airline Engines; Metal Additive Manufacturing: Shrewsbury, UK, 2018; Volume 4, p. 10. [Google Scholar]

- Ridge, O. GE Research Launches Project to Develop Metal Additively Manufactured Heat Exchanger. 2019. Available online: https://www.metal-am.com/ge-research-launches-project-to-develop-metal-additively-manufactured-heat-exchanger/ (accessed on 25 January 2021).

- Metal, A.M. Boeing 777X Takes Flight with Reported 300 Additively Manufactured Parts in each GE9X Engine. 2020. Available online: https://www.metal-am.com/boeing-777x-takes-flight-with-reported-300-additively-manufactured-parts-in-each-ge9x-engine/ (accessed on 25 January 2021).

- ESA Awards Dawn Aerospace €385K Contract for Additively Manufactured Rocket Engines. Available online: https://www.metal-am.com/esa-awards-dawn-aerospace-e385k-contract-for-additively-manufactured-rocket-engines/ (accessed on 25 January 2021).

- Metal Additive Manufacturing. Airbus Helicopters Begins Large-Scale Metal Additive Manufacturing of A350 Components; Metal Additive Manufacturing: Shrewsbury, UK, 2018; Volume 4, p. 36. [Google Scholar]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Rassolkin, A.; Vaimann, T. Challenges of Additive Manufacturing of Electrical Machines. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; pp. 44–48. [Google Scholar] [CrossRef]

- Project to Automate Post-Processing of Additively Manufactured Parts. Available online: https://www.metal-am.com/project-to-automate-post-processing-of-additively-manufactured-parts/ (accessed on 25 January 2021).

- Aguilera, E.; Ramos, J.; Espalin, D.; Cedillos, F.; Muse, D.; Wicker, R.; MacDonald, E. 3D Printing of Electro Mechanical Systems. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Hiller, J.D.; Lipson, H. Fully Recyclable Multi-Material Printing. In Proceedings of the Solid Freeform Fabrication, Austin, TX, USA, 3–5 August 2009. [Google Scholar]

- Wrobel, R.; Mecrow, B.C. A Comprehensive Review of Additive Manufacturing in Construction of Electrical Machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassolkin, A.; Belahcen, A. Technologies for Additive Manufacturing of Electrical Machines. In Proceedings of the 2019 20th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices (EDM), Erlagol, Russia, 29 June–3 July 2019; Volume 2019, pp. 651–655. [Google Scholar] [CrossRef]

- Lorenz, F.; Rudolph, J.; Wemer, R. Design of 3D Printed High Performance Windings for Switched Reluctance Machines. In Proceedings of the 2018 23rd International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2451–2457. [Google Scholar] [CrossRef]

- Wu, F.; El-Refaie, A.M. toward Additively Manufactured Electrical Machines: Opportunities and Challenges. IEEE Trans. Ind. Appl. 2020, 56, 1306–1320. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Yildirim, V.; Lamichhane, T.N.; Begley, B.A.; Post, B.K.; Hassen, A.A.; Sales, B.C.; Gandha, K.; Nlebedim, I.C. Additive Manufacturing of Isotropic NdFeB PPS Bonded Permanent Magnets. Materials 2020, 13, 3319. [Google Scholar] [CrossRef]

- Lamichhane, T.N.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M.P. Additive manufacturing of soft magnets for electrical machines—A review. Mater. Today Phys. 2020, 15, 100255. [Google Scholar] [CrossRef]

- 3D-Multimaterialdruck | Professur Elektrische Energiewandlungssystem und Antriebe | Fakultät für Elektrotechnik und I… | TU Chemnitz. Available online: https://www.tu-chemnitz.de/etit/ema/AMMM/ (accessed on 25 January 2021).

- Silbernagel, C. Submitted: Investigation of the Design, Manufacture and Testing of Additively Manufactured Coils for Electric Motor Applications. 2019. Available online: https://www.researchgate.net/publication/336922428_Investigation_of_the_design_manufacture_and_testing_of_additively_manufactured_coils_for_electric_motor_applications (accessed on 25 January 2021).

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Garibaldi, M. Laser Additive Manufacturing of Soft Magnetic Cores for Rotating Electrical Machinery: Materials Development and Part Design. 2018. Available online: https://www.researchgate.net/publication/329610071_Laser_additive_manufacturing_of_soft_magnetic_cores_for_rotating_electrical_machinery_materials_development_and_part_design#fullTextFileContent (accessed on 25 January 2021).

- Goll, D.; Schuller, D.; Martinek, G.; Kunert, T.; Schurr, J.; Sinz, C.; Schubert, T.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive manufacturing of soft magnetic materials and components. Addit. Manuf. 2019, 27, 428–439. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Rassolkin, A.; Vaimann, T. Hysteresis Loss Evaluation of Additively Manufactured Soft Magnetic Core. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 1657–1661. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Vaimann, T.; Rassõlkin, A.; Lukichev, D. Hysteresis Measurements and Numerical Losses Segregation of Additively Manufactured Silicon Steel for 3D Printing Electrical Machines. Appl. Sci. 2020, 10, 6515. [Google Scholar] [CrossRef]

- Pham, T.; Kwon, P.; Foster, S. Additive Manufacturing and Topology Optimization of Magnetic Materials for Electrical Machines—A Review. Energies 2021, 14, 283. [Google Scholar] [CrossRef]

- Babuska, T.F.; Wilson, M.A.; Johnson, K.L.; Whetten, S.R.; Curry, J.F.; Rodelas, J.M.; Atkinson, C.; Lu, P.; Chandross, M.; Krick, B.A.; et al. Achieving high strength and ductility in traditionally brittle soft magnetic intermetallics via additive manufacturing. Acta Mater. 2019, 180, 149–157. [Google Scholar] [CrossRef]

- Metsä-Kortelainen, S.; Lindroos, T.; Savolainen, M.; Jokinen, A.; Revuelta, A.; Pasanen, A.; Ruusuvuori, K.; Pippuri, J. Manufacturing of Topology Optimized Soft Magnetic Core through 3D Printing. 2016. Available online: https://cris.vtt.fi/en/publications/manufacturing-of-topology-optimized-soft-magnetic-core-through-3d (accessed on 26 January 2021).

- Freeman, F.S.; Lincoln, A.; Sharp, J.; Lambourne, A.; Todd, I. Exploiting thermal strain to achieve an in-situ magnetically graded material. Mater. Des. 2019, 161, 14–21. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Jhong, K.J.; Cheng, C.-W.; Huang, P.-W.; Tsai, M.-C.; Lee, W.-H. Metal 3D printing of synchronous reluctance motor. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; Volume 2016, pp. 1125–1128. [Google Scholar] [CrossRef]

- Yan, Y.; Lu, G.-Q.; Ngo, K.D.T.; Guido, L.J.; Aning, A.O.; Reynolds, W.T. Design Methodology and Materials for Additive Manufacturing of Magnetic Components; Virginia Tech: Blacksburg, VA, USA, April 2017; Available online: https://vtechworks.lib.vt.edu/handle/10919/77394 (accessed on 26 January 2021).

- Yan, Y.; Ding, C.; Ngo, K.D.T.; Mei, Y.; Lu, G.-Q. Additive manufacturing of planar inductor for Power Electronics applications. In Proceedings of the 2016 International Symposium on 3D Power Electronics Integration and Manufacturing (3D-PEIM), Raleigh, NC, USA, 13–15 June 2016. [Google Scholar] [CrossRef]

- Mikler, C.V.; Chaudhary, V.; Borkar, T.; Soni, V.; Jaeger, D.; Chen, X.; Contieri, R.; Ramanujan, R.V.; Banerjee, R. Laser Additive Manufacturing of Magnetic Materials. JOM 2017, 69, 532–543. [Google Scholar] [CrossRef]

- Benack, N.C.; Wang, T.; Matthews, K.; Taheri, M.L. Additive Manufacturing Methods for Soft Magnetic Composites (SMCs). Microsc. Microanal. 2018, 24, 1066–1067. [Google Scholar] [CrossRef]

- Lambourne, A. Opportunities and Challenges of ALM in Electrical Machines. In Proceedings of the Advanced Propulsion Centre UK Seminar, Birmingham, UK, 11–12 November 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; Volume 35. [Google Scholar]

- Garibaldi, M.; Gerada, C.; Ashcroft, I.A.; Hague, R.J. Free-Form Design of Electrical Machine Rotor Cores for Production Using Additive Manufacturing. J. Mech. Des. Trans. 2019, 141, 1–27. [Google Scholar] [CrossRef]

- Lammers, S.; Adam, G.; Schmid, H.J.; Mrozek, R.; Oberacker, R.; Hoffmann, M.J.; Quattrone, F.; Ponick, B. Additive Manufacturing of a lightweight rotor for a permanent magnet synchronous machine. In Proceedings of the 2016 6th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 November–1 December 2016; pp. 41–45. [Google Scholar] [CrossRef]

- Chinthavali, M. 3D printing technology for automotive applications. In Proceedings of the 2016 International Symposium on 3D Power Electronics Integration and Manufacturing (3D-PEIM), Raleigh, NC, USA, 13–15 June 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Simpson, N.; Mellor, P.H. Additive manufacturing of shaped profile windings for minimal AC loss in gapped inductors. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017. [Google Scholar] [CrossRef]

- Simpson, N.; Mellor, P.H. Additive Manufacturing of Shaped Profile Windings for Minimal AC Loss in Electrical Machines. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 5765–5772. [Google Scholar] [CrossRef]

- Simpson, N.; North, D.J.; Collins, S.M.; Mellor, P.H. Additive Manufacturing of Shaped Profile Windings for Minimal AC Loss in Electrical Machines. IEEE Trans. Ind. Appl. 2020, 56, 2510–2519. [Google Scholar] [CrossRef]

- Wohlers, C.; Juris, P.; Kabelac, S.; Ponick, B. Design and direct liquid cooling of tooth-coil windings. Electr. Eng. 2018, 100, 2299–2308. [Google Scholar] [CrossRef]

- Urban, N.; Huber, F.; Franke, J. Influences of process parameters on rare earth magnets produced by laser beam melting. In Proceedings of the 2017 7th International Electric Drives Production Conference (EDPC), Wuerzburg, Germany, 5–6 December 2017; Volume 2017, pp. 1–5. [Google Scholar] [CrossRef]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-write 3D printing of NdFeB bonded magnets. Mater. Manuf. Process. 2018, 33, 109–113. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Shafer, C.S.; Elliott, A.M.; Siddel, D.H.; McGuire, M.A.; Springfield, R.M.; Martin, J.; Fredette, R.; Ormerod, J. Binder Jetting: A Novel NdFeB Bonded Magnet Fabrication Process. JOM 2016, 68, 1978–1982. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Conner, B.; Chi, M.; Elliott, A.M.; Rios, O.; Zhou, H.; Paranthaman, M.P. A novel method combining additive manufacturing and alloy infiltration for NdFeB bonded magnet fabrication. J. Magn. Magn. Mater. 2017, 438, 163–167. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 1–7. [Google Scholar] [CrossRef]

- Li, L.; Post, B.; Kunc, V.; Elliott, A.M.; Paranthaman, M.P. Additive manufacturing of near-net-shape bonded magnets: Prospects and challenges. Scr. Mater. 2017, 135, 100–104. [Google Scholar] [CrossRef]

- Li, L.; Jones, K.; Sales, B.; Pries, J.L.; Nlebedim, I.; Jin, K.; Bei, H.; Post, B.K.; Kesler, M.S.; Rios, O.; et al. Fabrication of highly dense isotropic Nd-Fe-B nylon bonded magnets via extrusion-based additive manufacturing. Addit. Manuf. 2018, 21, 495–500. [Google Scholar] [CrossRef]

- Wang, S.; Kang, J. Topology optimization of nonlinear magnetostatics. IEEE Trans. Magn. 2002, 38, 1029–1032. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Pfaff, C.; Kriwet, J.; Groenefeld, M.; Teliban, I.; Vogler, C.; Suess, D. Topology optimized and 3D printed polymer-bonded permanent magnets for a predefined external field. J. Appl. Phys. 2017, 122, 053904. [Google Scholar] [CrossRef]

- Wu, F.; El-Refaie, A.M. Towards Fully Additively-Manufactured Permanent Magnet Synchronous Machines: Opportunities and Challenges. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 2225–2232. [Google Scholar] [CrossRef]

- Jaćimović, J.; Binda, F.; Herrmann, L.G.; Greuter, F.; Genta, J.; Calvo, M.; Tomše, T.; Simon, R.A. Net Shape 3D Printed NdFeB Permanent Magnet. Adv. Eng. Mater. 2017, 19, 1700098. [Google Scholar] [CrossRef]

- Mapley, M.; Pauls, J.P.; Tansley, G.; Busch, A.; Gregory, S.D. Selective laser sintering of bonded magnets from flake and spherical powders. Scr. Mater. 2019, 172, 154–158. [Google Scholar] [CrossRef]

- Lamarre, J.-M.; Bernier, F. Permanent Magnets Produced by Cold Spray Additive Manufacturing for Electric Engines. J. Therm. Spray Technol. 2019, 28, 1709–1717. [Google Scholar] [CrossRef]

- Ibrahim, M.; Bernier, F.; Lamarre, J.-M. Novel Multi-layer Design and Additive Manufacturing Fabrication of a High Power Density and Efficiency Interior PM Motor. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 3601–3606. [Google Scholar] [CrossRef]

- Sagawa, M.; Fujimura, S.; Yamamoto, H.; Matsuura, Y.; Hiraga, K. Permanent magnet materials based on the rare earth-iron-boron tetragonal compounds. IEEE Trans. Magn. 1984, 20, 1584–1589. [Google Scholar] [CrossRef]

- Tenaud, P.; Vial, F.; Sagawa, M. Improved corrosion and temperature behaviour of modified Nd-Fe-B magnets. IEEE Trans. Magn. 1990, 26, 1930–1932. [Google Scholar] [CrossRef]

- Kramer, M.J.; McCallum, R.W.; Anderson, I.A.; Constantinides, S. Prospects for Non-Rare Earth Permanent Magnets for Traction Motors and Generators. JOM 2012, 64, 752–763. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Sridharan, N.; List, F.A.; Babu, S.S.; Dehoff, R.R.; Constantinides, S. Additive Manufacturing of Near-net Shaped Permanent Magnets; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016. [Google Scholar] [CrossRef]

- Sridharan, N.; Cakmak, E.; List, F.A.; Uçar, H.; Constantinides, S.; Babu, S.S.; McCall, S.K.; Paranthaman, M.P. Rationalization of solidification mechanism of Nd–Fe–B magnets during laser directed-energy deposition. J. Mater. Sci. 2018, 53, 8619–8626. [Google Scholar] [CrossRef]

- Additive Manufacturing Moves TUfast. Available online: https://additivenews.com/additive-manufacturing-moves-tufast/ (accessed on 28 January 2021).

- Nottingham PhD Student Wins Additive World Design Challenge Award. Available online: https://exchange.nottingham.ac.uk/blog/phd-student-wins-additive-world-design-challenge-award/ (accessed on 28 January 2021).

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Cooling of Windings in Electric Machines via 3D Printed Heat Exchanger. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 229–235. [Google Scholar] [CrossRef]

- Tate, J.G.; Richardson, B.S.; Love, L.J. Additive Manufacturing for Low Volume Bearings; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2017. [Google Scholar] [CrossRef]

- Carriero, A.; Locatelli, M.; Ramakrishnan, K.; Mastinu, G.; Gobbi, M. A Review of the State of the Art of Electric Traction Motors Cooling Techniques. SAE Tech. Pap. Ser. 2018. [Google Scholar] [CrossRef]

- European Powder Metallurgy Association (EPMA)—Cooling Jacket with Internal Helix Structure. Available online: https://www.epma.com/spotlight-on-pm/cooling-jacket-with-internal-helix-structure (accessed on 27 March 2021).

- Wrobel, R.; Mecrow, B. Additive Manufacturing in Construction of Electrical Machines—A Review. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019; pp. 15–22. [Google Scholar] [CrossRef]

- Wrobel, R.; Hussein, A. Design Considerations of Heat Guides Fabricated Using Additive Manufacturing for Enhanced Heat Transfer in Electrical Machines. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 6506–6513. [Google Scholar] [CrossRef]

- Isaza, J.F.; Aumund-Kopp, C. Additive Manufacturing with metal powders: Design for manufacture evolves into design for function. Powder Metall. Rev. 2014, 3, 41–50. [Google Scholar]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The additive manufacturing (AM) of titanium alloys. In Titanium Powder Metallurgy: Science, Technology and Applications; Elsevier: Amsterdam, The Netherlands, 2015; pp. 447–468. [Google Scholar]

- Laimer, C. Brushless Motor—makeSEA. Available online: https://www.makesea.com/web/claimer/brushless-motor (accessed on 28 January 2021).

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassolkin, A.; Belahcen, A. Additive Manufacturing of Prototype Axial Flux Switched Reluctance Electrical Machine. In Proceedings of the 2021 28th International Workshop on Electric Drives: Improving Reliability of Electric Drives (IWED), Moscow, Russia, 27–29 January 2021. [Google Scholar]

- Hošek, M.; Krishnasamy, J.; Sah, S.; Bashaw, T. Spray-Formed Hybrid-Field Electric Motor. In Proceedings of the 2016 ASME Design Engineering Technical Conference, Vancouver, BC, Canada, 17–21 July 2016; Volume 3. [Google Scholar] [CrossRef]

- Krishnasamy, J.; Hosek, M. Spray-Formed Hybrid-Field Traction Motor. SAE Tech. Pap. Ser. 2017, 1. [Google Scholar] [CrossRef]

- Schniedenharn, M.; Belting, M.; Batista, R.J.S.; Meiners, W.; Weisheit, A. Micro scale laser based additive manufacturing for metals. In Proceedings of the ICALEO 2013—32nd International Congress on Applications of Lasers & Electro-Optics, Miami, FL, USA, 6–10 October 2013; Volume 2013, pp. 661–666. [Google Scholar] [CrossRef]

- Conrad, M.; De Doncker, R.W.; Schniedenharn, M.; Diatlov, A. Packaging for power semiconductors based on the 3D printing technology Selective Laser Melting. In Proceedings of the 2014 16th European Conference on Power Electronics and Applications, Lappeenranta, Finland, 26–28 August 2014. [Google Scholar] [CrossRef]

- Why Companies Steadily Embrace Additive Manufacturing|IE. Available online: https://interestingengineering.com/why-companies-steadily-embrace-additive-manufacturing (accessed on 1 February 2021).

- Formatec—Ceramic Injection Moulding. Available online: https://formateceurope.com/ceramic-injection-moulding (accessed on 22 February 2021).

- Australian Army Successfully Conducts Field Test of SPEE3D Metal 3D Printer—3D Printing Industry. Available online: https://3dprintingindustry.com/news/australian-army-successfully-conducts-field-test-of-spee3d-metal-3d-printer-172941/ (accessed on 22 February 2021).

- Marshall Aerospace Soars with 3D Printing|Stratasys. Available online: https://www.stratasys.com/explore/case-study/marshall-aerospace-and-defence-group (accessed on 20 February 2021).

- Nemec, M.; Makuc, D.; Ambrozic, V.; Fiser, R. Simplified model of induction machine with electrical rotor asymmetry. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010. [Google Scholar] [CrossRef]

- Sun, X.; Sizov, G.; Melfi, M. Asymmetrical Design in Electrical Machines. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 3786–3792. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, X.; Xu, G.; Zhao, W. Torque calculation of five-phase synchronous reluctance motors with shifted-asymmetrical-salient-poles under saturation condition. China Electrotech. Soc. Trans. Electr. Mach. Syst. 2020, 4, 105–113. [Google Scholar] [CrossRef]

- Caruso, M.; Cecconi, V.; Di Tommaso, A.O.; Miceli, R.; Nevoloso, C. Performance Comparison of Electrical Motors equipped with slightly Asymmetrical Windings. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 2–4 July 2019. [Google Scholar] [CrossRef]

- Ren, W.; Xu, Q.; Li, Q. Asymmetrical V-Shape Rotor Configuration of an Interior Permanent Magnet Machine for Improving Torque Characteristics. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Sanada, M.; Hiramoto, K.; Morimoto, S.; Takeda, Y. Torque Ripple Improvement for Synchronous Reluctance Motor Using an Asymmetric Flux Barrier Arrangement. IEEE Trans. Ind. Appl. 2004, 40, 1076–1082. [Google Scholar] [CrossRef]

- Wanjiku, J.; Khan, M.A.; Barendse, P.S.; Pillay, P. Influence of Slot Openings and Tooth Profile on Cogging Torque in Axial-Flux PM Machines. IEEE Trans. Ind. Electron. 2015, 62, 7578–7589. [Google Scholar] [CrossRef]

- Nuzzo, S.; Marfoli, A.; Papini, L.; Bolognesi, P.; Gerada, C.; Galea, M. The potential of exploiting non-symmetric structures in electrical machines. In Proceedings of the IECON 2019 45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 2019, pp. 1393–1398. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, D.; Lipo, T.A.; Kwon, B.-I. Performance Improvement of Ferrite-Assisted Synchronous Reluctance Machines Using Asymmetrical Rotor Configurations. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Lin, H.; Zhu, Z.Q.; Lyu, S.; Niu, S. A Novel Hybrid-Pole Interior PM Machine with Magnet-Axis-Shifting Effect. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 273–279. [Google Scholar] [CrossRef]

- Wu, F.; El-Refaie, A.M. Minimization of Winding AC Losses Using Inhomogeneous Electrical Conductivity Enabled by Additive Manufacturing. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 3607–3614. [Google Scholar] [CrossRef]

- Moreels, D.; Axial Flux vs. Radial Flux Machines. 31 January 2018. Available online: https://www.magnax.com/magnax-blog/axial-flux-vs-radial-flux.-4-reasons-why-does-axial-flux-machines-deliver-a-higher-power-density (accessed on 3 February 2021).

- Krishnamurthy, M.; Edrington, C.; Emadi, A.; Asadi, P.; Ehsani, M.; Fahimi, B. Making the case for applications of switched reluctance motor technology in automotive products. IEEE Trans. Power Electron. 2006, 21, 659–675. [Google Scholar] [CrossRef]

- Edvarrd. Characteristics and Work Principles of Switched Reluctance (SR) Motor. 8 December 2014. Available online: https://electrical-engineering-portal.com/characteristics-and-work-principles-of-switched-reluctance-sr-motor (accessed on 3 February 2021).

- Gargalis, L.; Madonna, V.; Giangrande, P.; Rocca, R.; Hardy, M.; Ashcroft, I.; Galea, M.; Hague, R. Additive Manufacturing and Testing of a Soft Magnetic Rotor for a Switched Reluctance Motor. IEEE Access 2020, 8, 206982–206991. [Google Scholar] [CrossRef]

- Gargalis, L.; Madonna, V.; Giangrande, P.; Rocca, R.; Ashcroft, I.; Hague, R.; Galea, M. Development and Testing of Soft Magnetic Rotor for a Switched Reluctance Motor Built Through Additive Manufacturing Technology. In Proceedings of the 2020 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamatsu, Japan, 24–27 November 2020; pp. 263–268. [Google Scholar] [CrossRef]

- Tseng, G.; Jhong, K.; Tsai, M.; Huang, P.; Lee, L. Application of Additive Manufacturing for Low Torque Ripple of 6/4 Switched Reluctance Motor—IEEE Conference Publication. In Proceedings of the 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–26 November 2016; Available online: https://ieeexplore.ieee.org/document/7837094 (accessed on 3 February 2021).

- Manninen, A.; Keranen, J.; Pippuri-Makelainen, J.; Riipinen, T.; Metsa-Kortelainen, S.; Lindroos, T. Impact of Topology Optimization Problem Setup on Switched Reluctance Machine Design. In Proceedings of the 2019 22nd International Conference on the Computation of Electromagnetic Fields (COMPUMAG), Paris, France, 15–19 July 2019. [Google Scholar] [CrossRef]

- Lee, J.; Seo, J.H.; Kikuchi, N. Topology optimization of switched reluctance motors for the desired torque profile. Struct. Multidiscip. Optim. 2010, 42, 783–796. [Google Scholar] [CrossRef]

- Ban, B.; Stipetic, S.; Klanac, M. Synchronous Reluctance Machines: Theory, Design and the Potential Use in Traction Applications. In Proceedings of the 2019 International Conference on Electrical Drives & Power Electronics (EDPE), The High Tatras, Slovakia, 24–26 September 2019; Volume 2019, pp. 177–188. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Carraro, E.; Castiello, M.; Fornasiero, E. Electric Vehicle Traction Based on Synchronous Reluctance Motors. IEEE Trans. Ind. Appl. 2016, 52, 4762–4769. [Google Scholar] [CrossRef]

- Jurca, F.N.; Mircea, R.; Martis, C.; Martis, R.; Florin, P.P. Synchronous reluctance motors for small electric traction vehicle. In Proceedings of the 2014 International Conference and Exposition on Electrical and Power Engineering (EPE), Brno, Czech Republic, 12–14 May 2014; pp. 317–321. [Google Scholar] [CrossRef]

- Cai, S.; Shen, J.; Hao, H.; Jin, M. Design methods of transversally laminated synchronous reluctance machines. China Electrotech. Soc. Trans. Electr. Mach. Syst. 2017, 1, 164–173. [Google Scholar] [CrossRef]

- Ibrahim, M.; Bernier, F.; Lamarre, J.-M. Design of a PM-Assisted Synchronous Reluctance Motor Utilizing Additive Manufacturing of Magnetic Materials. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 1663–1668. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Tsai, M.-C.; Huang, P.-W.; Cheng, C.-W.; Huang, J.-M. Characteristic comparison of transversally laminated anisotropic synchronous reluctance motor fabrication based on 2D lamination and 3D printing. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 894–897. [Google Scholar] [CrossRef]

- Huang, P.; Tsai, M.; Jiang, I. 3D Structure Line Start Synchronous Reluctance Motor Design Based on Selective Laser Melting of 3D Printing. In Proceedings of the 2018 IEEE International Magnetics Conference (INTERMAG), Singapore, 23–27 April 2018. [Google Scholar] [CrossRef]

- Hong, H.-S.; Liu, H.-C.; Cho, S.-Y.; Lee, J.; Jin, C.-S. Design of High-End Synchronous Reluctance Motor Using 3-D Printing Technology. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Kaska, J.; Orosz, T.; Karban, P.; Dolezel, I.; Pechanek, R.; Panek, D. Optimization of Reluctance Motor with Printed Rotor. In Proceedings of the 2019 22nd International Conference on the Computation of Electromagnetic Fields (COMPUMAG), Paris, France, 15–19 July 2019. [Google Scholar] [CrossRef]

- Jack, A.; Mecrow, B.; Maddison, C.; Wahab, N. Claw pole armature permanent magnet machines exploiting soft iron powder metallurgy. In Proceedings of the 1997 IEEE International Electric Machines and Drives Conference Record, Milwaukee, WI, USA, 18–21 May 2002. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.G.; Watterson, P.; Wu, W. Comparative study of 3-D flux electrical machines with soft magnetic composite cores. IEEE Trans. Ind. Appl. 2003, 39, 1696–1703. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.; Dorrell, D. Design and Analysis of a Claw Pole Permanent Magnet Motor With Molded Soft Magnetic Composite Core. IEEE Trans. Magn. 2009, 45, 4582–4585. [Google Scholar] [CrossRef]

- Liu, C.; Lu, J.; Wang, Y.; Lei, G.; Zhu, J.; Guo, Y. Techniques for Reduction of the Cogging Torque in Claw Pole Machines with SMC Cores. Energies 2017, 10, 1541. [Google Scholar] [CrossRef]

- Liu, C.; Lu, J.; Wang, Y.; Lei, G.; Zhu, J.; Guo, Y. Design Issues for Claw Pole Machines with Soft Magnetic Composite Cores. Energies 2018, 11, 1998. [Google Scholar] [CrossRef]

- Galluzzi, R.; Amati, N.; Tonoli, A. Modeling, Design, and Validation of Magnetic Hysteresis Motors. IEEE Trans. Ind. Electron. 2020, 67, 1171–1179. [Google Scholar] [CrossRef]

- Rajagopal, K. Design of a compact hysteresis motor used in a gyroscope. IEEE Trans. Magn. 2003, 39, 3013–3015. [Google Scholar] [CrossRef]

- Inácio, D.; Inácio, S.; Pina, J.M.; Gonçalves, A.; Neves, M.V.; Rodrigues, A.L.; Pronto, A. Numerical and experimental comparison of electromechanical properties and efficiency of HTS and ferromagnetic hysteresis motors. J. Phys. Conf. Ser. 2008, 97. [Google Scholar] [CrossRef]

- Galluzzi, R.; Tonoli, A.; Amati, N. Magnetic hysteresis machines for next-generation electric turbochargers. In Proceedings of the 2017 International Conference of Electrical and Electronic Technologies for Automotive, Torino, Italy, 15–16 June 2017. [Google Scholar] [CrossRef]

- Jagieła, M.; Bumby, J.; Spooner, E. Time-domain and frequency-domain finite element models of a solid-rotor induction/hysteresis motor. IET Electr. Power Appl. 2010, 4, 185. [Google Scholar] [CrossRef]

- O’Kelly, D. Hysteresis motor with overexcitation and solid-state control. Proc. Inst. Electr. Eng. 1978, 125, 288. [Google Scholar] [CrossRef]

- Jagiela, M.; Garbiec, T.; Kowol, M. Design of High-Speed Hybrid Hysteresis Motor Rotor Using Finite Element Model and Decision Process. IEEE Trans. Magn. 2014, 50, 861–864. [Google Scholar] [CrossRef]

- Goll, D.; Schurr, J.; Trauter, F.; Schanz, J.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive manufacturing of soft and hard magnetic materials. Procedia CIRP 2020, 94, 248–253. [Google Scholar] [CrossRef]

- Bernier, F.; Ibrahim, M.; Mihai, M.; Thomas, Y.; Lamarre, J.-M. Additive manufacturing of soft and hard magnetic materials used in electrical machines. Met. Powder Rep. 2020, 75, 334–343. [Google Scholar] [CrossRef]

- Popov, V.; Koptyug, A.; Radulov, I.; Maccari, F.; Muller, G. Prospects of additive manufacturing of rare-earth and non-rare-earth permanent magnets. Procedia Manuf. 2018, 21, 100–108. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).