Control of Transformerless Inverter-Based Two-Stage Grid-Connected Photovoltaic System Using Adaptive-PI and Adaptive Sliding Mode Controllers

Abstract

1. Introduction

- The design of a A-PI and A-SMC for DC-link voltage control, for both active and reactive power control;

- The current controller was designed with an RHC-based PR controller to mitigate third, fifth, and seventh harmonics;

- A SOGI-based PLL was employed that has harmonic immunity, fast-tracking accuracy, and a rapid dynamic response;

- Testing of the proposed system under two scenarios, i.e., with and without a feedforward PV power loop, to improve dynamics and control;

- A comparative assessment of the designed controllers with a conventionally well-tuned PI controller.

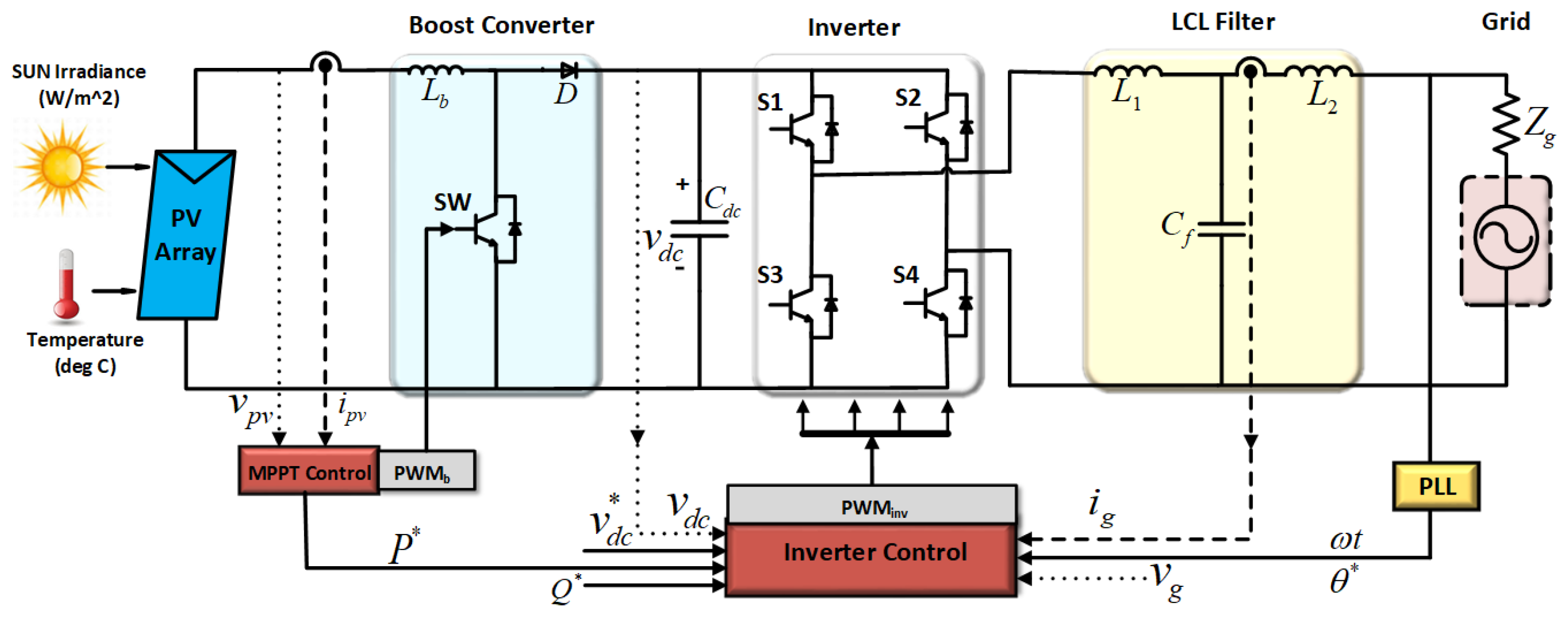

2. Proposed System and Control-Loop Design

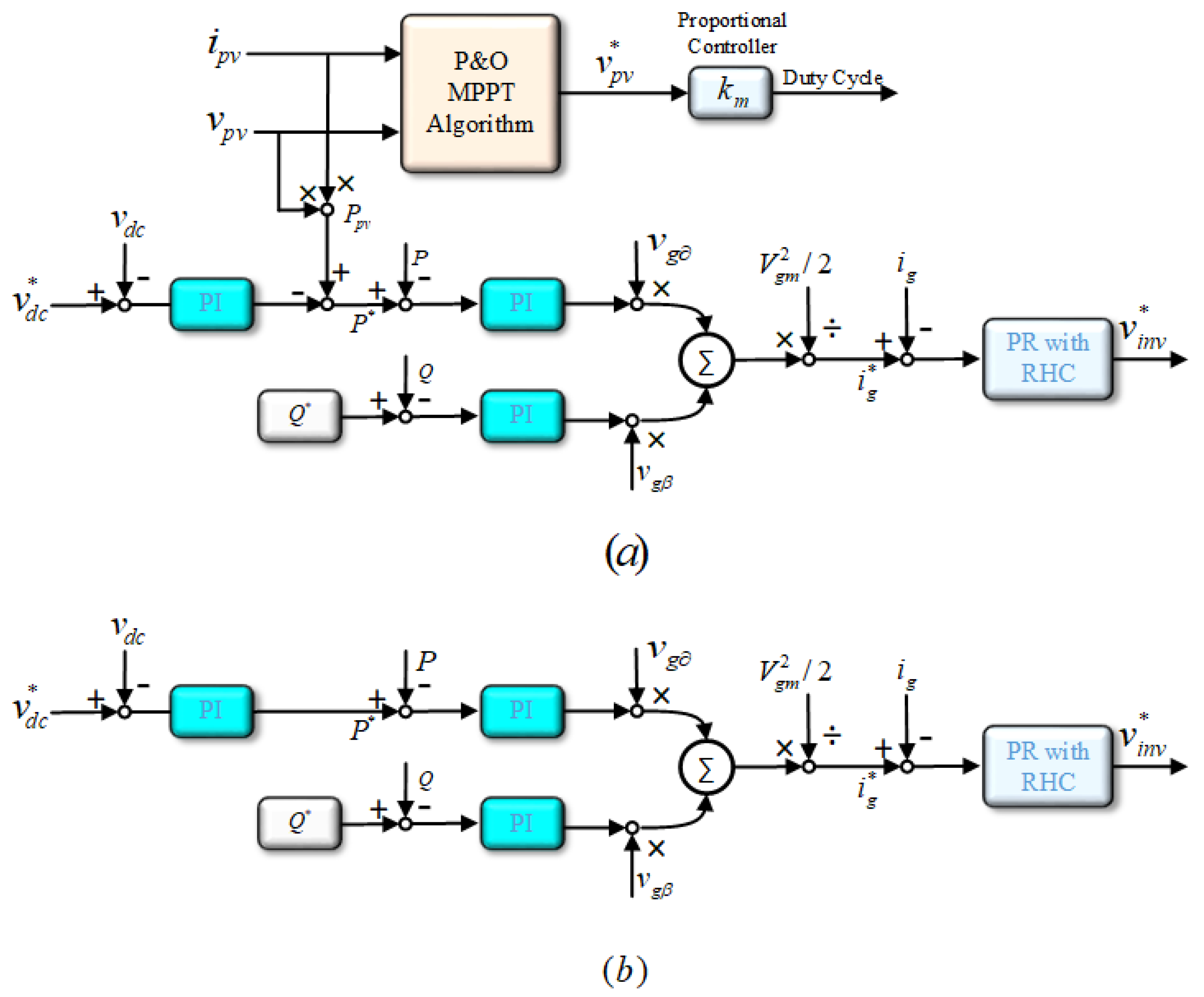

Control of Transformerless PV Inverter

Design of Control Loop

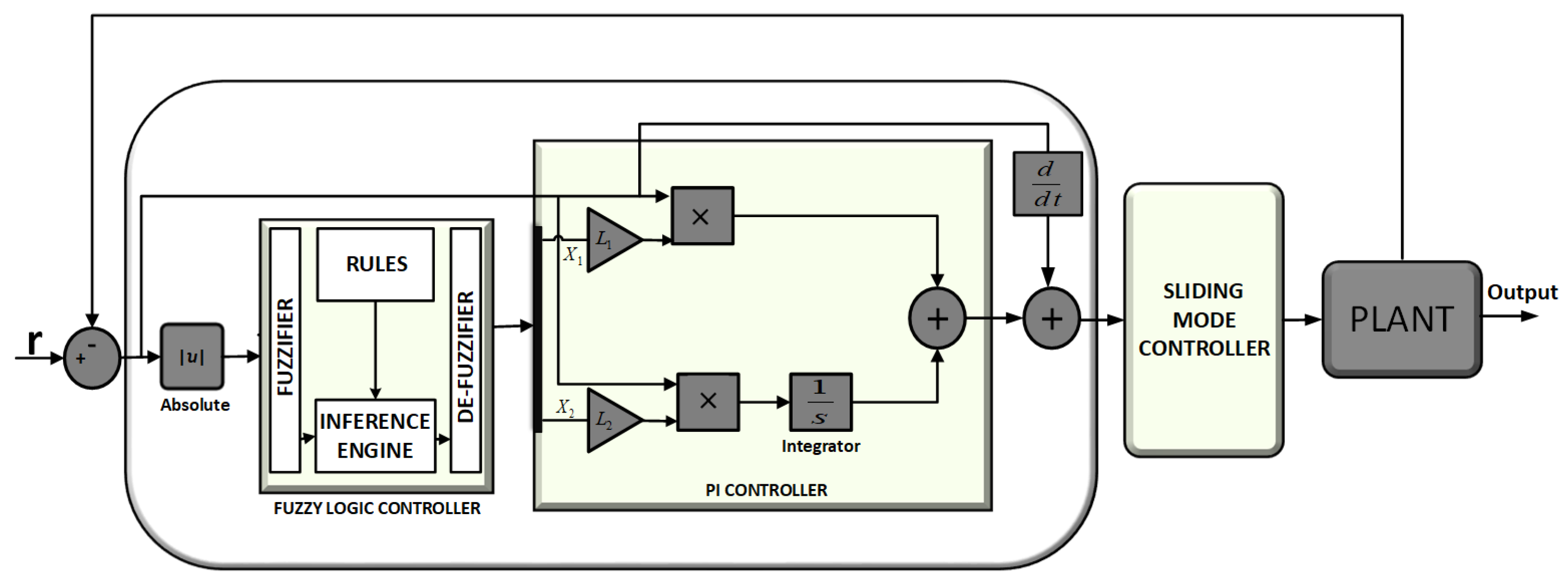

3. Proposed Controller Design

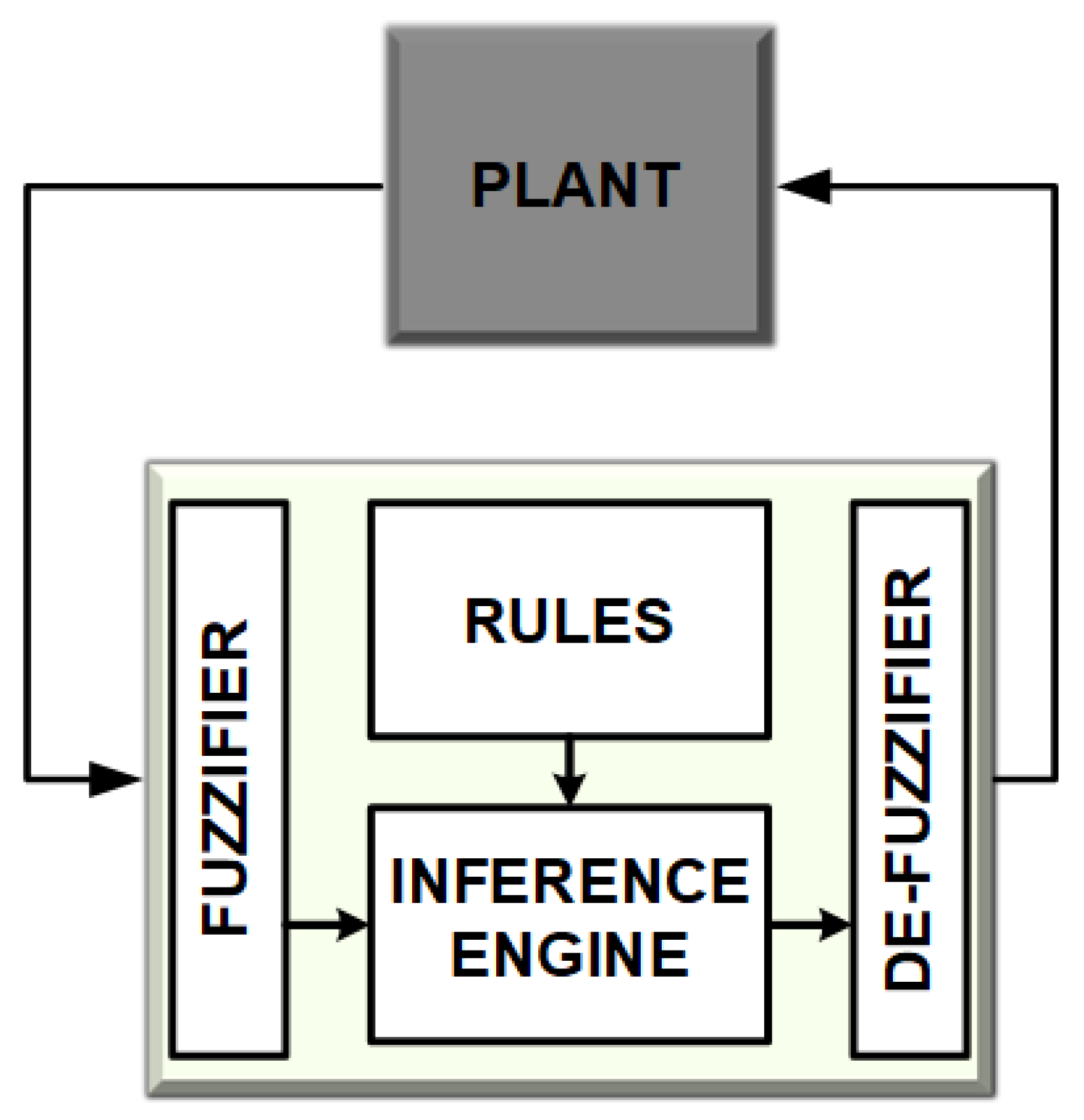

3.1. Fuzzy Controller Design

- Fuzzification: in this step, a fuzzifier uses linguistic variables, terms, and fuzzy membership functions to map real/crisp input data, obtained from the system, to the fuzzy set;

- Rule-base: this step contains a fuzzy set of rules, a condition, and a conclusion. These IF-THEN rules are used to define the controller action to control the output variables in terms of input variables;

- Fuzzy inference mechanism: this mechanism controls the plant in the best possible manner by taking expert decisions to interpret and apply the rules;

- Defuzzification: in this step, de-fuzzifier converts the fuzzy input from the inference mechanism to a real-time/crisp output, which goes to the plant as the controller effort/input.

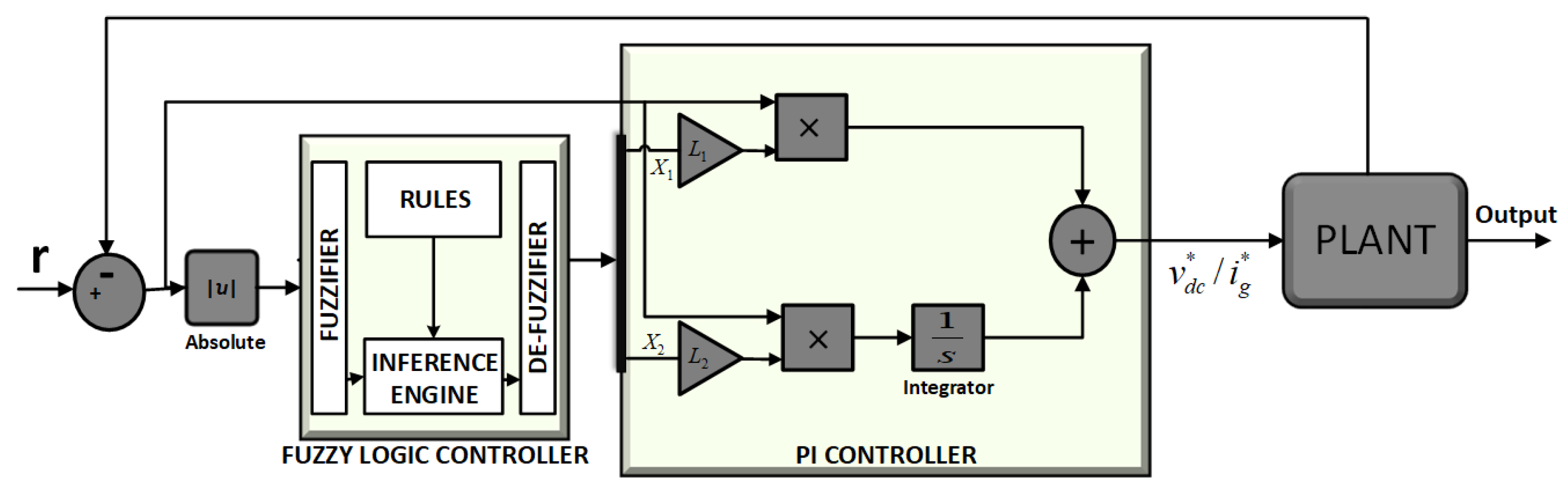

3.2. Adaptive-PI Controller Design

- If absolute error is small, then is zero and is large;

- If is large, then both and are large;

- If , then is smaller while is large.

3.3. Adaptive Sliding Mode Controller Design

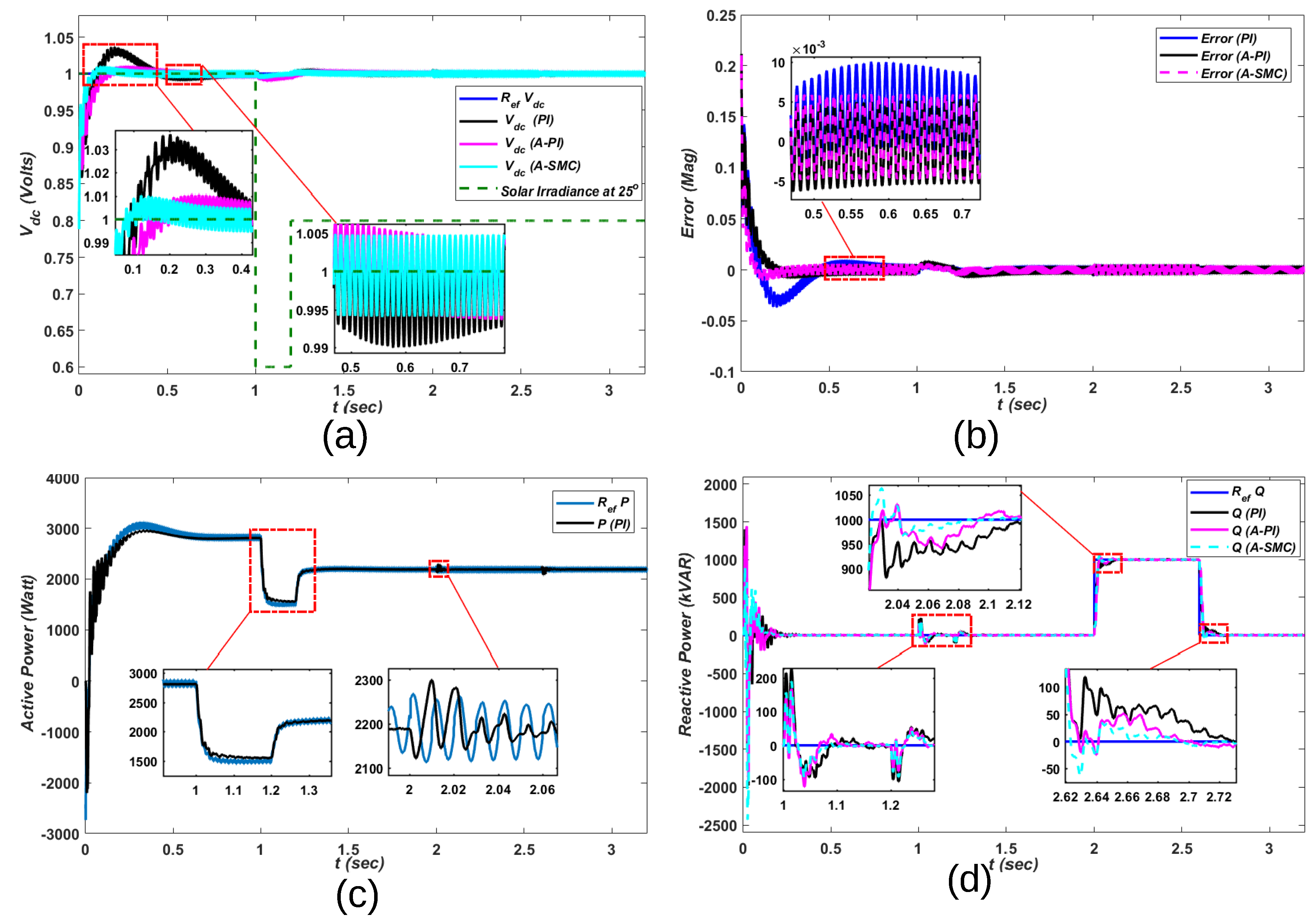

4. Results and Discussion

4.1. Case 1

4.2. Case 2

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Parameters | Symbols | Values |

|---|---|---|

| Grid voltage (RMS) | 65 W | |

| Open circuit voltage | 21.7 V | |

| Short circuit current | 3.99 A | |

| MPPT voltage | 17.6 V | |

| MPPT current | 3.69 A |

| Control Strategies | DC-Link Loop (V) | Active Power (P) | Reactive Power (Q) |

|---|---|---|---|

| PI | = 32 × 400, = 280 × 400 | = 11.2, = 35.5 | = 1.2, = 60.5 |

| A-PI | = 110, = 1080 | = 11.2, = 135.5 | = 1.2, = 155.5 |

| A-SMC | = 280, = 2980, = 150 | = 60.2, = 280.5 | = 3.2, = 315.5 |

| Control Strategies | DC-Link Loop (V) | Active Power (P) | Reactive Power (Q) |

|---|---|---|---|

| PI | = 32 × 400, = 280 × 400 | = 11.2, = 35.5 | = 1.2, = 60.5 |

| A-PI | = 110, = 1080 | = 11.2, = 135.5 | = 1.2, = 155.5 |

| A-SMC | = 280, = 2980, = 150 | = 60.2, = 280.5 | = 3.2, = 315.5 |

| PR + RHC | = 18, = 2200 | ||

| third harmonic’s compensation = 1200 | |||

| fifth harmonic’s compensation = 800 | |||

| seventh harmonic’s compensation = 200 |

References

- Khan, M.A.; Kurukuru, V.B.; Haque, A.; Mekhilef, S. Islanding Classification Mechanism for Grid-Connected Photovoltaic Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2020. [Google Scholar] [CrossRef]

- Zeb, K.; Uddin, W.; Khan, M.A.; Ali, Z.; Ali, M.U.; Christofides, N.; Kim, H. A comprehensive review on inverter topologies and control strategies for grid connected photovoltaic system. Renew. Sustain. Energy Rev. 2018, 94, 1120–1141. [Google Scholar] [CrossRef]

- Zeb, K.; Islam, S.U.; Din, W.U.; Khan, I.; Ishfaq, M.; Busarello, T.D.C.; Ahmad, I.; Kim, H.J. Design of fuzzy-PI and fuzzy-sliding mode controllers for single-phase two-stages grid-connected transformerless photovoltaic inverter. Electronics 2019, 8, 520. [Google Scholar] [CrossRef]

- Kabalcı, E. Review on novel single-phase grid-connected solar inverters: Circuits and control methods. Sol. Energy 2020, 198, 247–274. [Google Scholar] [CrossRef]

- Yang, Y.; Blaabjerg, F. Low-voltage ride-through capability of a single-stage single-phase photovoltaic system connected to the low-voltage grid. Int. J. Photoenergy 2013, 2013, 257487. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Blaabjerg, F. Reactive power injection strategies for single-phase photovoltaic systems considering grid requirements. IEEE Trans. Ind. Appl. 2014, 50, 4065–4076. [Google Scholar] [CrossRef]

- Islam, S.U.; Zeb, K.; Din, W.U.; Khan, I.; Ishfaq, M.; Hussain, A.; Busarello, T.D.C.; Kim, H.J. Design of robust fuzzy logic controller based on the levenberg marquardt algorithm and fault ride trough strategies for a grid-connected PV system. Electronics 2019, 8, 429. [Google Scholar] [CrossRef]

- Bak, Y.; Lee, J.S.; Lee, K.B. Low-voltage ride-through control strategy for a grid-connected energy storage system. Appl. Sci. 2018, 8, 57. [Google Scholar] [CrossRef]

- Bighash, E.Z.; Sadeghzadeh, S.M.; Ebrahimzadeh, E.; Blaabjerg, F. Improving performance of LVRT capability in single-phase grid-tied PV inverters by a model-predictive controller. Int. J. Electr. Power Energy Syst. 2018, 98, 176–188. [Google Scholar] [CrossRef]

- Al-Shetwi, A.Q.; Sujod, M.Z.; Blaabjerg, F. Low voltage ride-through capability control for single-stage inverter-based grid-connected photovoltaic power plant. Sol. Energy 2018, 159, 665–681. [Google Scholar] [CrossRef]

- Chen, H.C.; Lee, C.T.; Cheng, P.T.; Teodorescu, R.; Blaabjerg, F. A low-voltage ride-through technique for grid-connected converters with reduced power transistors stress. IEEE Trans. Power Electron. 2016, 31, 8562–8571. [Google Scholar] [CrossRef]

- Arulkumar, K.; Palanisamy, K.; Vijayakumar, D. Recent advances and control techniques in grid connected PV system—A review. Int. J. Renew. Energy Res. 2016, 6, 1037–1049. [Google Scholar]

- Haidar, A.M.; Julai, N. An improved scheme for enhancing the ride-through capability of grid-connected photovoltaic systems towards meeting the recent grid codes requirements. Energy Sustain. Dev. 2019, 50, 38–49. [Google Scholar] [CrossRef]

- Patsalides, M.; Stavrou, A.; Efthymiou, V.; Georghiou, G.E. Towards the establishment of maximum PV generation limits due to power quality constraints. Int. J. Electr. Power Energy Syst. 2012, 42, 285–298. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Kumar, P.N.; Arya, A.; Anand, S. Noninvasive technique for DC-link capacitance estimation in single-phase inverters. IEEE Trans. Power Electron. 2017, 33, 3693–3696. [Google Scholar] [CrossRef]

- Zakzouk, N.E.; Abdelsalam, A.K.; Helal, A.A.; Williams, B.W. PV single-phase grid-connected converter: Dc-link voltage sensorless prospective. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 5, 526–546. [Google Scholar] [CrossRef]

- Hu, Y.; Du, Y.; Xiao, W.; Finney, S.; Cao, W. DC-link voltage control strategy for reducing capacitance and total harmonic distortion in single-phase grid-connected photovoltaic inverters. IET Power Electron. 2015, 8, 1386–1393. [Google Scholar] [CrossRef]

- He, F.; Zhao, Z.; Yuan, L.; Lu, S. A DC-link voltage control scheme for single-phase grid-connected PV inverters. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 3941–3945. [Google Scholar]

- Zakzouk, N.; Abdelsalam, A.; Helal, A.; Williams, B. DC-link voltage sensorless control technique for single-phase two-stage photovoltaic grid-connected system. In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), Cavtat, Croatia, 13–16 May 2014; pp. 58–64. [Google Scholar]

- Zeb, K.; Din, W.U.; Khan, M.A.; Khan, A.; Younas, U.; Busarello, T.D.C.; Kim, H.J. Dynamic Simulations of Adaptive Design Approaches to Control the Speed of an Induction Machine Considering Parameter Uncertainties and External Perturbations. Energies 2018, 11, 2339. [Google Scholar] [CrossRef]

- Zeb, K.; Islam, S.U.; Uddin, W.; Khan, I.; Ishfaq, M.; Busarello, T.D.C.; Kim, H. High-Performance and Multi-Functional Control for Transformerless S ingle-Phase Smart Inverter for Grid-connected PV System. J. Mod. Power Syst. Clean Energy 2020. [Google Scholar] [CrossRef]

- Zeb, K.; Busarello, T.D.C.; Ul Islam, S.; Uddin, W.; Raghavendra, K.V.G.; Khan, M.A.; Kim, H.J. Design of Super Twisting Sliding Mode Controller for a Three-Phase Grid-connected Photovoltaic System under Normal and Abnormal Conditions. Energies 2020, 13, 3773. [Google Scholar] [CrossRef]

- Islam, S.U.; Zeb, K.; Din, W.U.; Khan, I.; Ishfaq, M.; Busarello, T.D.C.; Kim, H.J. Design of a proportional resonant controller with resonant harmonic compensator and fault ride trough strategies for a grid-connected photovoltaic system. Electronics 2018, 7, 451. [Google Scholar] [CrossRef]

- Seyedalipour, S.S. A Novel Deadbeat Control for Three-Phase Grid-Connected VSI with an Output LCL Filter in Natural Frame. In Proceedings of the 2019 International Power System Conference (PSC), Tehran, Iran, 9–11 December 2019; pp. 447–452. [Google Scholar]

- Nguyen-Van, T.; Abe, R.; Tanaka, K. MPPT and SPPT control for PV-connected inverters using digital adaptive hysteresis current control. Energies 2018, 11, 2075. [Google Scholar] [CrossRef]

- Hassan, S.Z.; Li, H.; Kamal, T.; Arifoğlu, U.; Mumtaz, S.; Khan, L. Neuro-Fuzzy wavelet based adaptive MPPT algorithm for photovoltaic systems. Energies 2017, 10, 394. [Google Scholar] [CrossRef]

- Zeb, K.; Islam, S.U.; Uddin, W.; Ullah, K.; Asghar, R.; Busarello, T.; Kim, H.J. DC-link Voltage Regulation of Single-Phase Grid-Tied PV System using Fuzzy-PI Controller. In Proceedings of the 2019 15th International Conference on Emerging Technologies (ICET), Peshawar, Pakistan, 2–3 December 2019; pp. 1–6. [Google Scholar]

- Mukherjee, S.; Chowdhury, V.R.; Shamsi, P.; Ferdowsi, M. Model reference adaptive control based estimation of equivalent resistance and reactance in grid-connected inverters. IEEE Trans. Energy Convers. 2017, 32, 1407–1417. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, P.; Yu, C.; Li, F.; Do, H.T.; Cao, R. Study of a current control strategy based on multisampling for high-power grid-connected inverters with an LCL filter. IEEE Trans. Power Electron. 2016, 32, 5023–5034. [Google Scholar] [CrossRef]

- Ishfaq, M.; Uddin, W.; Zeb, K.; Khan, I.; Ul Islam, S.; Adil Khan, M.; Kim, H.J. A new adaptive approach to control circulating and output current of modular multilevel converter. Energies 2019, 12, 1118. [Google Scholar] [CrossRef]

- Uddin, W.; Zeb, K.; Adil Khan, M.; Ishfaq, M.; Khan, I.; Islam, S.u.; Kim, H.-J.; Park, G.S.; Lee, C. Control of output and circulating current of modular multilevel converter using a sliding mode approach. Energies 2019, 12, 4084. [Google Scholar] [CrossRef]

- Khan, I.; Zeb, K.; Din, W.U.; Islam, S.U.; Ishfaq, M.; Hussain, S.; Kim, H.-J. Dynamic modeling and robust controllers design for doubly fed induction generator-based wind turbines under unbalanced grid fault conditions. Energies 2019, 12, 454. [Google Scholar] [CrossRef]

- Hassan, Z.; Amir, A.; Selvaraj, J.; Rahim, N.A. A review on current injection techniques for low-voltage ride-through and grid fault conditions in grid-connected photovoltaic system. Sol. Energy 2020, 207, 851–873. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Ionel, D.M. Renewable Energy Devices and Systems with Simulations in Matlab® and Ansys®; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Yang, Y.; Blaabjerg, F.; Wang, H.; Simoes, M.G. Power control flexibilities for grid-connected multi-functional photovoltaic inverters. IET Renew. Power Gener. 2016, 10, 504–513. [Google Scholar] [CrossRef]

- Zeb, K.; Uddin, W.; Haider, A.; Belal, S.; Mehmood, C.; Khan, M.; Kim, H. Robust speed regulation of indirect vector control induction motor using fuzzy logic controllers based on optimization algorithms. Electr. Eng. 2018, 100, 787–802. [Google Scholar] [CrossRef]

- Zhu, Y.; Fei, J. Disturbance observer based fuzzy sliding mode control of PV grid connected inverter. IEEE Access 2018, 6, 21202–21211. [Google Scholar] [CrossRef]

- Fang, Y.; Zhu, Y.; Fei, J. Adaptive intelligent sliding mode control of a photovoltaic Grid-connected inverter. Appl. Sci. 2018, 8, 1756. [Google Scholar] [CrossRef]

| Specification | Symbols | Values |

|---|---|---|

| DC-link voltage reference | 400 V | |

| Boost inductance | 20 mH | |

| Switching frequency of boost-converter | 20 KHz | |

| LCL filter | 1.5 mH, 2.35 F, 1.8 mH | |

| DC-link voltage capacitance | 2200 F | |

| Switching frequency of inverter | 10 KHz | |

| RMS voltage of grid | 230 V | |

| Operating frequency of grid | 314 rad/s | |

| Impedance of grid | 0.5 mH, 0.2 |

| S. No. | Input Membership Function | Rules | Output Membership Function |

|---|---|---|---|

| 1. | Linguistic Term: zero, Range: [0,0.2] | IF Input: zero THEN Output: zero | Linguistic Term: zero, Range: [0,0.2] |

| 2. | Linguistic Term: small, Range: [0.3,0.7] | IF Input: small THEN Output: small | Linguistic Term: small, Range: [0.3,0.7] |

| 3. | Linguistic Term: large, Range: [0.8,1.0] | IF Input: large THEN Output: large | Linguistic Term: large, Range: [0.8,1.0] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeb, K.; Nazir, M.S.; Ahmad, I.; Uddin, W.; Kim, H.-J. Control of Transformerless Inverter-Based Two-Stage Grid-Connected Photovoltaic System Using Adaptive-PI and Adaptive Sliding Mode Controllers. Energies 2021, 14, 2546. https://doi.org/10.3390/en14092546

Zeb K, Nazir MS, Ahmad I, Uddin W, Kim H-J. Control of Transformerless Inverter-Based Two-Stage Grid-Connected Photovoltaic System Using Adaptive-PI and Adaptive Sliding Mode Controllers. Energies. 2021; 14(9):2546. https://doi.org/10.3390/en14092546

Chicago/Turabian StyleZeb, Kamran, Muhammad Saqib Nazir, Iftikhar Ahmad, Waqar Uddin, and Hee-Je Kim. 2021. "Control of Transformerless Inverter-Based Two-Stage Grid-Connected Photovoltaic System Using Adaptive-PI and Adaptive Sliding Mode Controllers" Energies 14, no. 9: 2546. https://doi.org/10.3390/en14092546

APA StyleZeb, K., Nazir, M. S., Ahmad, I., Uddin, W., & Kim, H.-J. (2021). Control of Transformerless Inverter-Based Two-Stage Grid-Connected Photovoltaic System Using Adaptive-PI and Adaptive Sliding Mode Controllers. Energies, 14(9), 2546. https://doi.org/10.3390/en14092546