Studies on the Impact of Hydrogen on the Results of THT Measurement Devices

Abstract

:1. Introduction

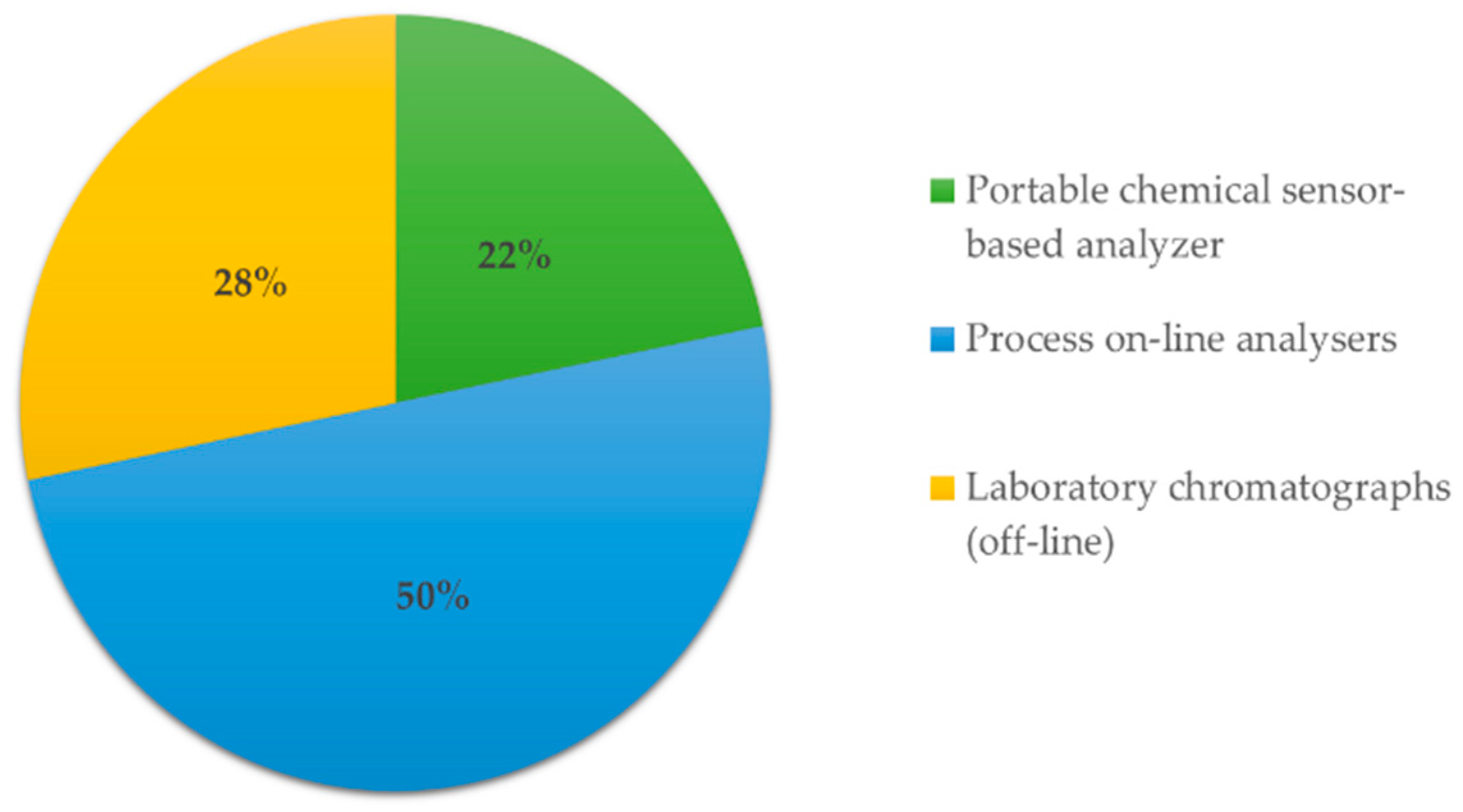

1.1. Detectors Used for Routine Checks of Natural Gas Odorization

1.2. Methods for THT Concentration Monitoring that Are Applied within the Gas Industry

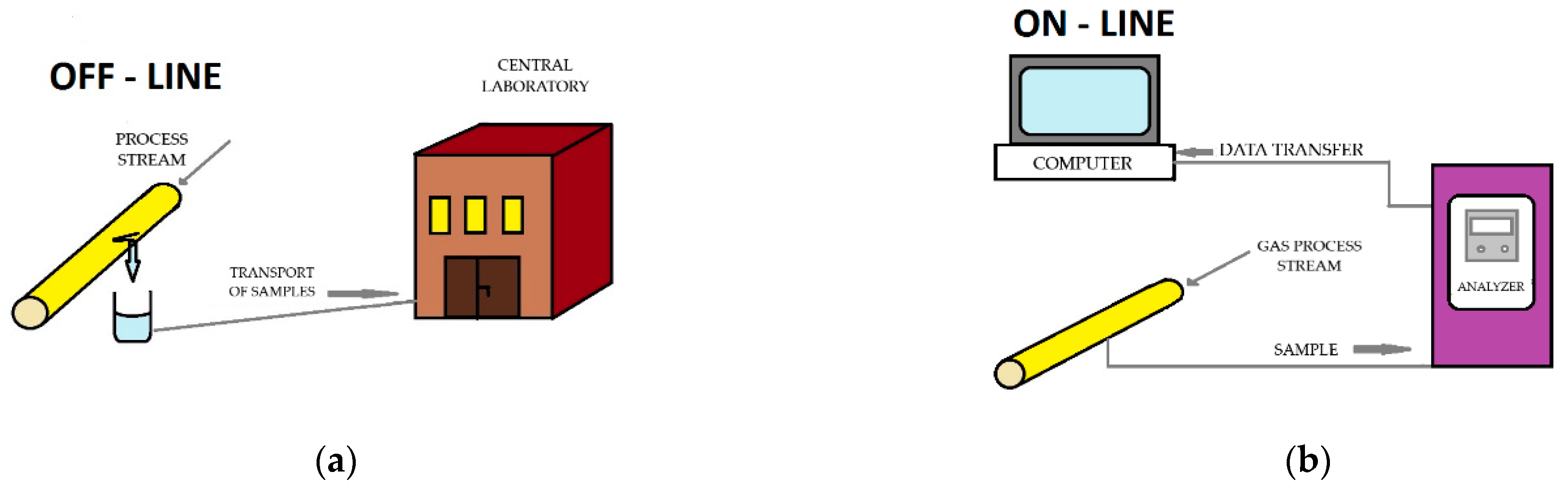

- Off-line using gas chromatography (executed in Poland and other countries by gas laboratories)—Figure 1,

- On-line with the direct detection method (usually used by operating services), and also with process chromatographic analyzers operating automatically (based on the gas chromatography method-similarly to laboratory equipment)—Figure 1.

- Type I.

- Stationary chromatographs adapted to measure sulfur compound content in gas (primarily THT) and equipped with PFPDs or PIDs, as a device operating off-line, in a laboratory (implemented THT measurement method constituted a reference method in studying the impact of hydrogen on the operation of chromatographic THT analyzers, including on-line devices, in particular);

- Type II.

- Chromatographic mobile analyzers equipped with EDs for periodic field control measurements of THT concentration, manifesting devices operating on-line (implemented only 1 selective THT measurement method);

- Type III.

- Chromatographic process analyzers with maintenance-free operating modes and EDs, for continuous monitoring measurement of THT concentrations within a gas network, as a device operating on-line (implemented only 1 selective THT measurement method)

- Type IV.

- Portable analyzers with EDs, for interim measurements of THT concentrations, as a device operating on-line (implemented only 1 selective THT measurement method-100% THT selective sensor).

- Measuring range: 0 to 200 mg/m3 for THT;

- Measurement accuracy, e.g., for THT: ±10% in the range of THT concentrations of 5–25 mg/m3 > ±20% beyond the a/m range;

- Resolution: 1 mg/m3;

- Detector service lifetime ca. 1 year or 3000 measurements.

1.3. Projected Hydrogen Content in Natural Gas

- 36% for gas from LNG regasification and 26% for 2E group gas-in terms of gas quality (maintaining legally required energy parameters of gas),

- 23%—in terms of combustion safety in end devices,

- 15%—in terms of combustion efficiency in end devices,

- 10%—in terms of the method for converting the compressibility coefficient,

- 8%—in terms of explosion safety of devices operation in Ex-zones.

2. Materials and Methods

2.1. Assumption for the Study

- Methane with added hydrogen in the amount from 0.1 to 15% (V/V),

- Methane-rich natural gas of the 2E group, with a hydrogen content of 1 and 15% (V/V).

- A.

- Preliminary studies of the impact of hydrogen on the response of electrochemical and other detectors used in the gas industry for monitoring odorization of gas within the distribution network—comparisons of hydrogen sensitivity of measuring devices used to test THT; the studies were conducted using methane/hydrogen mixtures diluted to H2 content of 5% and 8%, without added THT (Table 4) and for selected M/H + THT mixtures;

- B.

- Main studies of the impact of hydrogen on the quality of THT concentration measurement in various devices used in the gas industry, employing methane and hydrogen mixtures odorized with THT, with hydrogen content of: 1, 2, 8, 10, and 15%, and odorized methane-rich natural gas mixtures with hydrogen concentration of 2% (baseline mixture composition listed in Table 4)—selection of reference methods;

- C.

- Long-term studies on the impact of hydrogen on the quality of the THT concentration in gas measurement result, for two chosen devices with electrochemical detectors used in the gas industry for odorization monitoring; the research employed 2E methane-rich natural gas mixtures with hydrogen, odorized with THT in concentrations of: 1 and 15% (Table 4).

- off-line (laboratory gas chromatograph with PFPD and PID, Type I as per the list in Section 1.2);

- on-line (mobile and portable analyzers with ED, Type II and IV, respectively, as per the list in Section 1.2);

- on-line/process (chromatographic analyzers with ED, Type III as per the list in Section 1.2).

2.2. Gas Mixtures for Testing

- Liquid tetrahydrothiophene (THT) (by Chevron Phillips Chemical, The Woodlands, TX, USA),

- Certified hydrogen/methane mixtures (M/H15, M/H10 and M/H8 with a purity of 15.009 ± 0.450% (mol/mol), 10.002 ± 0.300% (mol/mol) and 8.013 ± 0.240% (mol/mol), respectively) (by AirProducts, Allentown, PA, USA),

- Aforementioned hydrogen/methane mixtures and pure methane as make-up gas with a purity of 5.5 (99.9995%) (AirProducts), M/H01, M/H02, M/H05, M/H1 and M/H2,

- Natural gas (methane content > 96% (mol/mol)) and hydrogen (purity 5.0 (99.999%) mixtures) (by Air Products), 2E/H1 and 2E/H15.

2.3. Reference Standards, Reference Method and Applied Measuring Devices

- Stationary chromatographic analyzer with a photoionization detector (PD), lamp with ionization energy of 10.6 eV–Type I, with implemented THT concentration determination method, operating off-line; factory-set THT measurement method parameters—not subject to change;

- Mobile chromatographic analyzer with an electrochemical sensor (ED)—Type II, with implemented only 1 selective THT determination method for periodic on-line measurements; factory-set THT measurement method parameters—not subject to change (Table 3);

- Process chromatographic analyzer with an electrochemical sensor (ED)—Type III, with implemented only 1 selective THT determination method, for on-line measurements directly on the gas network; factory-set THT measurement method parameters—subject to slight modification only by an authorized service (Table 3);

- Portable indicator analyzer with an electrochemical sensor (ED)—Type IV, with implemented only 1 selective THT determination method for ad hoc on-line measurements (direct detection); factory-set THT measurement method parameters—not subject to change (Table 3).

- For the Type II.1 analyzer-M/H15 + THT, M/H10 + THT and M/H8 + THT,

- For the Type II.2 analyzer-M/H2 + THT and M/H8 + THT,

- For the Type III analyzer-M/H1 + THT.

- 27.75 ± 1.25 mg/m3 (7.56 ± 0.34 ppm) for the 2E/H15 + THT mixture,

- 45.26 ± 2.39 mg/m3 (12.33 ± 0.65 ppm) for the 2E/H1 + THT mixture.

3. Results

3.1. Preliminary Studies

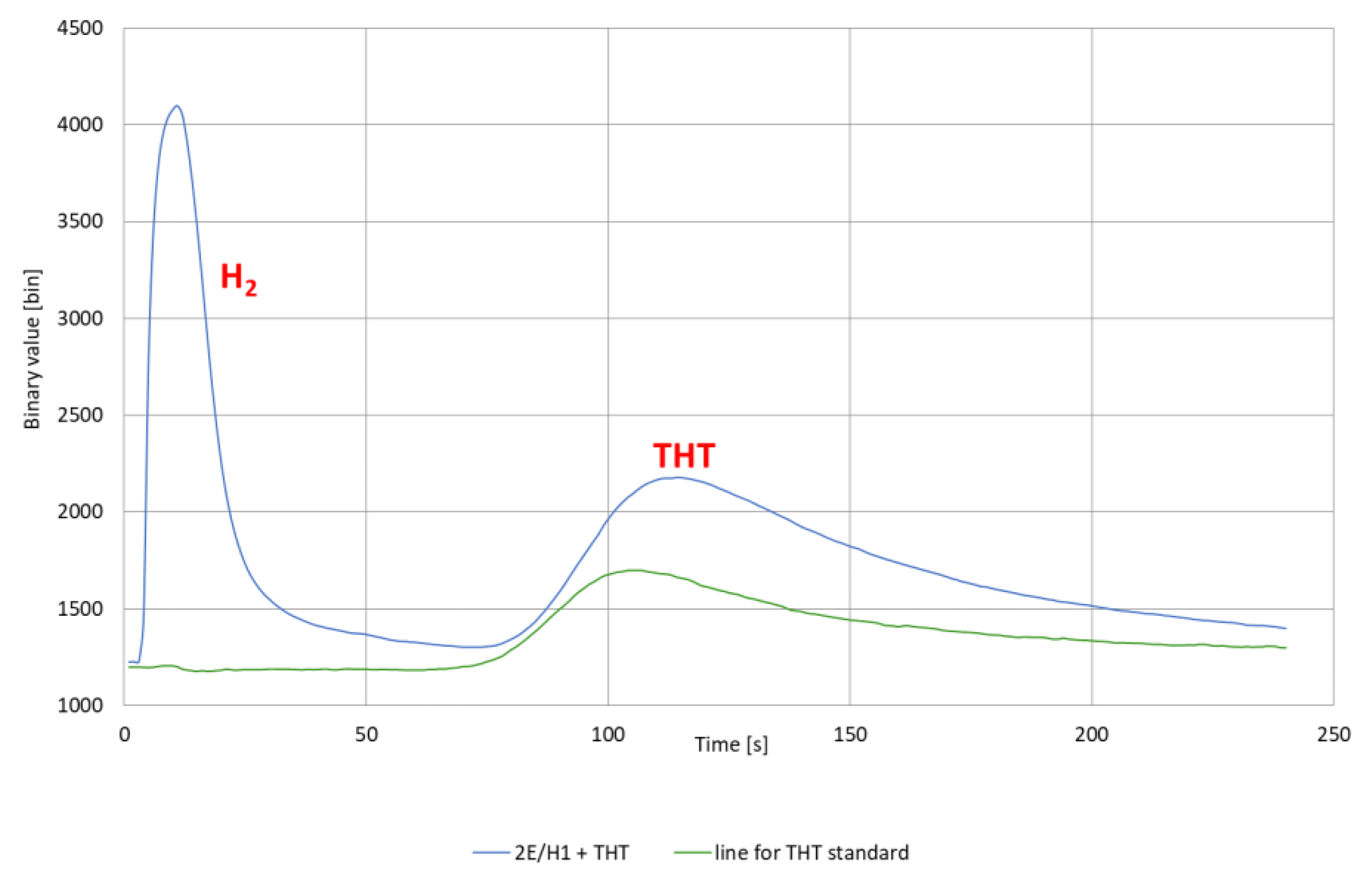

- A stationary Type I chromatographic analyzer (reference device; PID)–Figure 3, red color marks the THT-originating signal;

- A process Type III chromatographic analyzer (ED)—Figure 4. In order to trace the impact of baseline interference on the graph recorded by the analyzer, the red color in the graph marks the chromatogram waveform recorded for a THT standard (THT in nitrogen).

3.2. Main Studies

3.3. Long-Term Studies

4. Discussion

4.1. Preliminary Studies

4.2. Main Studies

- For verifications of the sensitivity of analyzers with electrochemical detection that are intended for measuring odorant content in gas, to gaseous pollutants, the maximum permissible measurement result difference relative to the reference value was ±20% of the minimum odorant warning concentration in gas (i.e., ± 2 mg/m3 for THT).

- Measurement results for Type I and Type II analyzers indicate high consistency of their indications (THT concentration) in methane/hydrogen mixtures, regardless of the hydrogen content. The percentage difference between the results ranged from –3.25 to –4.59% for a hydrogen content of ≥8% and amounted to –5.96% for a content of 2%;

- THT concentration results obtained with the Type II.2 analyzer for a hydrogen content in the mix at a level of 8% deviated by as much as 28% from the reference value. This confirms the previous conclusions that this analyzer is sensitive to higher hydrogen concentrations that induce distortions in the recorded chromatograph (baseline drift caused by the appearance of a significant hydrogen peak just prior to a THT peak), leading to obtaining an unreliable THT measurement;

- For very low hydrogen content values of approx. 1%, all verified Type II.1, Type II.2, and Type III analyzers provided results consistent with the reference value, thus satisfying the adopted criterion.

4.3. Long-Term Studies

- (1)

- Long-term stability: a device is stable provided its indications do not differ by more than ± 10% from the lowest odorant concentration in gas (MS-determined based on an odor curve of a give gas type) relative to the reference value; permissible difference for THT measurements is ±1 mg/m3;

- (2)

- Sensitivity to such gas components as biogas, hydrogen, LPG: other gas components that the standard ones in a methane-rich gas shall not induce a measurement error beyond ±20% of the MS value (i.e., ±2 mg/m3 for THT).

5. Conclusions

- Hydrogen, regardless of its concentration, does not impact the waveform and quality of THT analyses conducted with laboratory chromatographs with sulfur compound selective detectors (PFPDs in this case) and chromatographic analyzers with photoionization detectors (PIDs);

- The impact of hydrogen on the quality of analyses with mobile and process on-line analyzers equipped with electrochemical sensors (EDs) is strictly related to the individual sensitivity of the sensor and the measurement line technical solution applied within such a device; such sensitivity cannot be predicted only based on manufacturer’s data, e.g., a hydrogen concentration of 2% does not influence result quality and the waveform of THT concentration analyses conducted with mobile Type II.2 chromatographic analyzers, while in the case of Type III process analyzers, the adequate hydrogen limit in gas is 1%;

- Total lack of resistance to hydrogen may be indicated by mobile indicator-type THT analyzers used for ad hoc on-line measurements of gas samples collected directly from gas pipelines and following a direct electrochemical detection (ED) method; under the conditions of the described experiment, hydrogen content at a level of 0.1% was identified by such devices as THT, despite the lack of this odorant in the tested gas.

- 1% for Type III chromatographic process THT analyzers, and

- 15% for Type II.1 mobile analyzers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| cTHT | Tetrahydrothiophene concentration in gas, [mg/m3] or [ppm] |

| d | deviation from standard value, [mg/m3] |

| e | relative error, [%] |

| s | standard deviation value |

| U | concentration uncertainty, [mg/m3] or [ppm] |

| x0 | reference value for THT concentration, [mg/m3] or [ppm] |

| xn,THT | measured THT concentration, [mg/m3] or [ppm] |

Abbreviations

| INiG—PIB | Oil and Gas Institute—National Research Institute |

| CEN | European Committee for Standardization |

| 2E | natural gas of group E of the second gas (high-methane) described in EN 437 |

| 2E/H1 | 2E natural gas mixture with a 1% hydrogen content (V/V) |

| 2E/H15 | 2E natural gas mixture with a 15% hydrogen content (V/V) |

| GC | gas chromatography |

| ED | electrochemical detector |

| M | pure methane |

| M/H | methane gas mixture with hydrogen |

| M/H01 | methane gas mixture with a 0.1% hydrogen content (V/V) |

| M/H02 | methane gas mixture with a 0.2% hydrogen content (V/V) |

| M/H05 | methane gas mixture with a 0.5% hydrogen content (V/V) |

| M/H1 | methane gas mixture with a 1% hydrogen content (V/V) |

| M/H2 | methane gas mixture with a 2% hydrogen content (V/V) |

| M/H5 | methane gas mixture with a 5% hydrogen content (V/V) |

| M/H8 | methane gas mixture with a 8% hydrogen content (V/V) |

| M/H10 | methane gas mixture with a 10% hydrogen content (V/V) |

| M/H15 | methane gas mixture with a 15% hydrogen content (V/V) |

| MS | minimum concentration of odorant in gas necessary to obtain the odor of required intensity |

| NPL | National Physical Laboratory |

| PFPD | pulsed flame photometric detector |

| PID | photoionization detector |

| PSG | Polska Spółka Gazownictwa Sp. z o.o. |

| THT | Tetrahydrothiophene |

References

- Szczepaniak, W. Metody Instrumentalne w Analizie Chemicznej; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2011; pp. 255–384. ISBN 978-83-01-14210-0. [Google Scholar]

- Pham Tuan, H.; Janssen, H.-G.; Cramers, C.A.; Smit, A.L.C.; van Loo, E.M. Determination of sulfur components in natural gas: A review. J. High Resolut. Chrom. 1994, 17, 373–389. [Google Scholar] [CrossRef]

- Pham Tuan, H.; Janssen, J.G.M.; Cramers, C.A.M.G.; Kuiper-Van Loo, E.M.; Vlap, H. Evaluation of the performance of various universal and selective detectors for sulfur determination in natural gas. J. High Resolut. Chrom. 1995, 18, 333–342. [Google Scholar] [CrossRef] [Green Version]

- Stradiotto, N.R.; Yamanaka, H.; Zanoni, M.V.B. Electrochemical Sensors: A Powerful Tool in Analytical Chemistry. J. Braz. Chem. Soc. 2003, 14, 159–173. [Google Scholar] [CrossRef] [Green Version]

- Hayward, T.C.; Thurbide, K.B. Characteristics of Sulfur Response in a Micro-flame Photometric Detector. J. Chrom. A 2006, 1106, 66–70. [Google Scholar] [CrossRef]

- Boczkaj, G.; Kamiński, M.; Przyjazny, A. Process Control and Investigation of Oxidation Kinetics of Postoxidative Effluents Using Gas Chromatography with Pulsed Flame Photometric Detection (GC-PFPD). Ind. Eng. Chem. Res. 2010, 49, 12654–12662. [Google Scholar] [CrossRef]

- Report Emerson Automation Solutions Electrochemical vs. Semiconductor Gas Detection—A Critical Choice, 00870-0200-4928, Rev AA, 2019. Available online: https:// emersonexchange365.com/products/measurement-instrumentation/f/analytical-discussions-questions/7791/electrochemical-vs-semiconductor-gas-detection-a-critical-choice (accessed on 15 October 2021).

- Poole, C.F.; Riffenburgh, R.H. The Essence of Chromatography; Elsevier: Amsterdam, The Netherlands, 2003; ISBN 9780444501981. [Google Scholar] [CrossRef]

- Nollet, L.M.L. Chromatographic Analysis of the Environment, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9781420027983. [Google Scholar]

- Sielemann, S.; Teepe, M.; Vautz, W.; Baumbach, J.I. Bestimmung des Odorierungsgehaltes in Erdgas mittels Ionenbeweglichkeitsspektrometrie. Gas Erdgas 2004, 145, 642–646. [Google Scholar]

- Pritsching, K. Odorierung, 3rd ed.; Vulkan Verlag: Essen, Germany, 2010; pp. 68–86. [Google Scholar]

- Tenkrat, D.; Hlincik, T.; Prokes, O. Natural Gas Odorization; IntechOpen: London, UK, 2010; Available online: https://www.intechopen.com/books/natural-gas/natural-gas-odorization (accessed on 15 October 2020).

- GDS Corp Sensors for Gas Odorants Sensor Selection for GDS-68SXP Natural Gas Odorant Monitors. Available online: http://www.gdscorp.com/Products/download/others_1532539416Sensors%20for%20Odorant%20Monitors_updated.pdf (accessed on 15 October 2020).

- Juszczak, M.; Szyłak-Szydłowski, M. Chromatographic Examinations in the Gas Network Odourised by Tetrahydrothiophene. Ecol. Chem. Eng. S 2019, 26, 265–277. [Google Scholar] [CrossRef] [Green Version]

- Advertising materials (application note) PAC L.P.: Analysis of Ultra low Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatography and Chemiluminescence according to ASTM D5504. Available online: http://www.paclp.com/lab-instruments/application/gases/product/83/sense-sulfur-selective-detector (accessed on 15 October 2020).

- De Santoli, L.; Paiolo, R.; Lo Basso, G. An overview on safety issues related to hydrogen and methane blend applications in domestic and industrial use. Energy Procedia 2017, 126, 297–304. [Google Scholar] [CrossRef]

- Parra, D.; Gillott, M.; Walker, G.S. The role of hydrogen in achieving the decarbonization targets for the UK domestic sector. Int. J. Hydrog. Energy 2014, 39, 4158–4169. [Google Scholar] [CrossRef]

- Huszał, A. Nawanianie paliw gazowych gwarancją ich bezpiecznego użytkowania [Odorization of gaseous fuels as a guarantee of their safe use]. Naft. Gaz 2017, 11, 878–886. [Google Scholar] [CrossRef]

- Yunusa, Z.; Hamidon, M.N.; Kaiser, A.; Awang, Z. Gas Sensors: A Review. Sens. Transducers 2014, 168, 61–75. [Google Scholar]

- Karthikeyan, S.; Pandya, H.M.; Sharma, M.U.; Gopal, K. Gas Sensors—A Review. J. Environ. Nanotechnol. 2015, 4, 1–14. [Google Scholar] [CrossRef]

- Levitsky, I.A. Porous Silicon Structures as Optical Gas Sensors. Sensors 2015, 15, 19968–19991. [Google Scholar] [CrossRef] [PubMed]

- Hök, B.; Blückert, A.; Löfving, J. Acoustic gas sensor with ppm resolution. Sens. Rev. 2000, 20, 139–142. [Google Scholar] [CrossRef] [Green Version]

- Szlęk, M.; Holewa, J. Optymalizacja metody oznaczania zawartości związków siarki występujących w paliwach gazowych. Naft. Gaz 2015, 5, 308–313. [Google Scholar]

- Manufacturer’s Data Sheet. Available online: https://www.citytech.com/en-gb (accessed on 15 October 2020).

- Huszał, A. Nadzór nad poziomem nawonienia paliw gazowych świetle obowiązujących uregulowań prawnych i normatywnych. Naft. Gaz 2016, 11, 953–960. [Google Scholar] [CrossRef]

- Natural Gas Odorisation practices in Europe. Marcogaz Report 2020, GI-OD-09-04. Available online: https://www.marcogaz.org/wp-content/uploads/2021/04/GI-OD-09-04.pdf (accessed on 15 June 2020).

- ISO 19739; Natural Gas. Determination of Sulfur Compounds Using Gas Chromatography. Technical Committee ISO/TC 193/SC 1. International Organization for Standardization: Geneva, Switzerland, 2004.

- Jaworski, J.; Kukulska-Zając, E.; Kułaga, P. Wybrane zagadnienia dotyczące wpływu dodatku wodoru do gazu ziemnego na elementy systemu gazowniczego. Naft. Gaz 2019, 10, 625–632. [Google Scholar] [CrossRef]

- Jaworski, J.; Dudek, A. Study of the Effects of Changes in Gas Composition as Well as Ambient and Gas Temperature on Errors of Indications of Thermal Gas Meters. Energies 2020, 13, 5428. [Google Scholar] [CrossRef]

- Jaworski, J.; Kułaga, P.; Blacharski, T. Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters. Energies 2020, 13, 3006. [Google Scholar] [CrossRef]

- Schuster, T.; Holewa-Rataj, J.; Kukulska-Zając, E. Ocena jakości paliw gazowych w kontekście wprowadzania wodoru do sieci gazu ziemnego. Gaz Woda I Tech. Sanit. 2019, 2, 42–46. [Google Scholar] [CrossRef]

- Wojtowicz, R. Analiza wpływu dodatku wodoru do gazu ziemnego na pracę urządzeń gazowych [Analysis of the impact of adding hydrogen to natural gas on the operation of gas equipment]. Naft. Gaz 2019, 8, 465–473. [Google Scholar] [CrossRef]

- Huszal, A.; Jaworski, J. Studies of the Impact of Hydrogen on the Stability of Gaseous Mixtures of THT. Energies 2020, 13, 6441. [Google Scholar] [CrossRef]

- Szewczyk, P.; Jaworski, J. Analiza wpływu dodatku wodoru do gazu ziemnego na szczelność połączeń wybranych elementów sieci i instalacji. Pr. Nauk. Inst. Naft. I Gazu 2020, 231, 1–134. [Google Scholar] [CrossRef]

- Jaworski, J.; Kułaga, P.; Ficco, G.; Dell’Isola, M. Domestic Gas Meter Durability in Hydrogen and Natural Gas Mixtures. Energies 2021, 14, 7555. [Google Scholar] [CrossRef]

- Łach, M. The accuracy of determining the compressibility factor for gas with increased hydrogen content—comparison of the calculation methods. Naft. Gaz 2016, 5, 329–338. [Google Scholar] [CrossRef]

- ISO 6146; Gas Analysis. Preparation of Calibration Gas Mixtures. Manometric Method. Technical Committee ISO/TC 158. International Organization for Standardization: Geneva, Switzerland, 1979.

- ISO 6144; Gas Analysis. Preparation of Calibration Gas Mixtures. Static Volumetric Method. Technical Committee ISO/TC 158. International Organization for Standardization: Geneva, Switzerland, 2003.

- ISO 6143; Gas Analysis. Comparison Methods for Determining and Checking the Composition of Calibration Gas Mixtures. Technical Committee ISO/TC 158. International Organization for Standardization: Geneva, Switzerland, 2001.

- DVGW G 5902(P); Odoriermittel-Messgeräte Ohne Gaschromatographische Trennung Des Analyten in Seine Einzelkomponenten. DVGW Deutscher Verein des Gas- und Wasserfaches e. V.: Bonn, Germany, 2012.

| Detector | Sensitivity | Selectivity | Detection Limit | Linearity | Application |

|---|---|---|---|---|---|

| TCD | 5–20 ng | all compounds | 400 pg/mL (propane) | 105–106 | universal |

| PID | 25–50 pg (aromatic compounds) | depends on lamp energy | 0.2 pg/s | 105–106 | mainly environmental analyses, e.g., air |

| FPD | 10–100 pg (S) 1–10 pg (P) | >105 (S) >106 (P) | <20 pg (S/s) <0.9 pg (P/s) | non-linear (S) 103–105 (P) | sulphur compounds (393 nm) phosphorous compounds (526 nm) |

| PFPD | 10 pg S/s (signal/noise) S/N > 300 (peak/noise) | >106 S/s (S) >106 (P) | <1 pg S/s (S) <100 fg P/s (P) | sulfur–quadratic relationship | sulfur compounds phosphorous compounds |

| ED | usually not determined | 100% for selected compounds, e.g., THT | for THT <0.03 ppm | sulfur-linear dependence on concentration orders of magnitude | mainly toxic gases, in gas industry: odorants |

| Type of Gas Tested | Concentration in Sample | Detector Reading (Identified as THT) [mg/m3] |

|---|---|---|

| Carbon dioxide CO2 | 5000 ppm | 0 |

| Carbon oxide CO | 100 ppm | 2 |

| Carbon sulfide CS2 | 1% | 10 |

| Ethylene C2H4 | 1% | Yes numeric value not determined |

| Hydrocarbons | order of magnitude% | 0 |

| Hydrogen H2 | 1% | 0 |

| Hydrogen sulfide H2S | 20 ppm | 0 1 |

| Isopropanol C3H8O | 200 ppm | 400 |

| Methane CH4 | 100% | 0 |

| Nitrogen N2 | 100% | 0 |

| Tert-butyl mercaptan (CH3)3CSH | 10 mg/m3 | 10 |

| Measurement Method | Laboratory/ Off-Line | Periodic Measurements/ On-Line | Process Measurements/ On-Line |

|---|---|---|---|

| Device | Laboratory Chromatograph (Type I) | Mobile Analyzer (Type II) | Process Analyzer (Type III) |

| Detector | PFPD | ED | ED |

| Detector specificity | selective for sulfur comp. | selective for THT | selective for THT |

| Response linearity | 103 for sulfur comp. | throughout the entire range of measured concentrations | throughout the entire range of measured concentrations |

| Accuracy | declared: ±5% determined *: ±1% | declared and determined *: ±5% | declared and determined *: ±7% |

| Precision | determined *: 1.5 ÷ 2% | determined *: 2% | determined *: 2 ÷ 3% |

| Result repeatability | determined *: <5% | determined *: <5% | determined *: <5% |

| Expanded uncertainty | determined *: ±9.0% | determined *: ±8.2% | determined *: ±9.9% |

| Measurement range | method application range in THT analyses: 0 ÷ 200 mg/m3 | 0 ÷ 100 mg/m3 | 5 ÷ 100 mg/m3 |

| Sample dispensing method | manual | manual or automatic | automatic |

| No. | Mixture Designation | Composition of Tested Gas Mixture |

|---|---|---|

| 1 | M/H01 | 99.9% Methane + 0.1% H2 (V/V) |

| 2 | M/H02 | 99.8% Methane + 0.2% H2 (V/V) |

| 3 | M/H05 | 99.5% Methane + 0.5% H2 (V/V) |

| 4 | M/H1 | 99% Methane + 1% H2 (V/V) |

| 5 | M/H2 | 98% Methane + 2% H2 (V/V) |

| 6 | M/H5 | 95% Methane + 5% H2 (V/V) |

| 7 | M/H8 | 92% Methane + 8% H2 (V/V) |

| 8 | M/H10 | 90% Methane + 10% H2 (V/V) |

| 9 | M/H15 | 85% Methane + 15% H2 (V/V) |

| 10 | 2E/H1 | 99% Group 2E natural gas + 1% H2 (V/V) |

| 11 | 2E/H15 | 85% Group 2E natural gas + 15% H2 (V/V) |

| Measuring Device | Mean THT Concentration in a M/H Mixture, d [mg/m3]/[ppm] | ||

|---|---|---|---|

| M/H8 + THT | M/H10 + THT | M/H15 + THT | |

| Varian 450 GC | 20.6 ± 0.4/ 5.61 ± 0.11 * | 23.5 ± 0.7/ 6,.0 ± 0.19 * | 25.2 ± 0.3/ 6.87 ± 0.08 * |

| * Reference values (x0) | |||

| Type I device | 19.6 ± 0.7/ 5.34 ± 0.19 | 24.6 ± 0.3/ 6.70 ± 0.08 | 25.1 ± 0.7/ 6.84 ± 0.19 |

| Difference in mean values | −4.85% | +4.68% | −0.40% |

| Device Reading in the Form of THT Concentration [mg/m3] | ||||||

| Hydrogen Concentra- tion | 0.1% (V/V) | 0.2% (V/V) | 0.5% (V/V) | 1% (V/V) | 2% (V/V) | |

| Series | ||||||

| I | 24.5 35.0 40.0 | 91.1 60.0 70.0 | 90.7 80.5 85.9 | 97.2 (no further reaction *) | 94.6 (no further reaction *) | |

| II | 35.0 40.0 42.2 | 65.0 72.0 95.0 | 74.2 83.0 92.2 | 96.8 (no further reaction *) | 101.0 (no further reaction *) | |

| III | 26.0 24.8 37.0 | 93.1 65.7 68.4 | 91.0 82.5 74.7 | 99.0 (no further reaction *) | 105.0 (no further reaction *) | |

| Measuring Device | Measured Mean THT Concentration in a M/H + THT Mixture, d [mg/m3] | ||||

|---|---|---|---|---|---|

| M/H15 + THT | M/H10 + THT | M/H8 + THT | M/H2 + THT | M/H1 + THT | |

| Type I | 25.1 ± 0.7 * | 24.6 ± 0.3 * | 19.6 ± 0.7 * | 21.8 ± 0.8 * | 12.3 ± 0.5 * |

| * Reference values (x0) | |||||

| Type II.1 | 24.2 ± 0.3 | 23.8 ± 0.2 | 18.7 ±0.4 | 20.5 ± 0.7 | not tested |

| Difference relative to reference value | −3.58% | −3.25% | −4.59% | −5.96% | - |

| Type II.2 | testing not possible | testing not possible | 14.1 ± 0.2 | 19.7 ± 0.5 | 11.1 ± 0.2 |

| Difference relative to reference value | - | - | −28.06% | −9.63% | −9.76% |

| Type III | testing not possible | testing not possible | testing not possible | testing not possible | 11.5 ± 0.7 |

| Difference relative to reference value | - | - | - | - | −6.50% |

| Measuring Device | Hydrogen Content | Mean THT Concentration xn | Standard Deviation s | Measurement Accuracy * | |

|---|---|---|---|---|---|

| Deviation from Actual Value d | Relative Error e | ||||

| [%] | [mg/m3] | [mg/m3] | [mg/m3] | [%] | |

| Type II.1 | 15 | 26.71 | 0.68 | −1.0 | −3.5 |

| Type III | 1 | 46.42 | 1.59 | 1.2 | 2.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huszal, A.; Jaworski, J. Studies on the Impact of Hydrogen on the Results of THT Measurement Devices. Energies 2022, 15, 221. https://doi.org/10.3390/en15010221

Huszal A, Jaworski J. Studies on the Impact of Hydrogen on the Results of THT Measurement Devices. Energies. 2022; 15(1):221. https://doi.org/10.3390/en15010221

Chicago/Turabian StyleHuszal, Anna, and Jacek Jaworski. 2022. "Studies on the Impact of Hydrogen on the Results of THT Measurement Devices" Energies 15, no. 1: 221. https://doi.org/10.3390/en15010221