A Comprehensive Performance Evaluation Method Targeting Efficiency and Noise for Muzzle Brakes Based on Numerical Simulation

Abstract

:1. Introduction

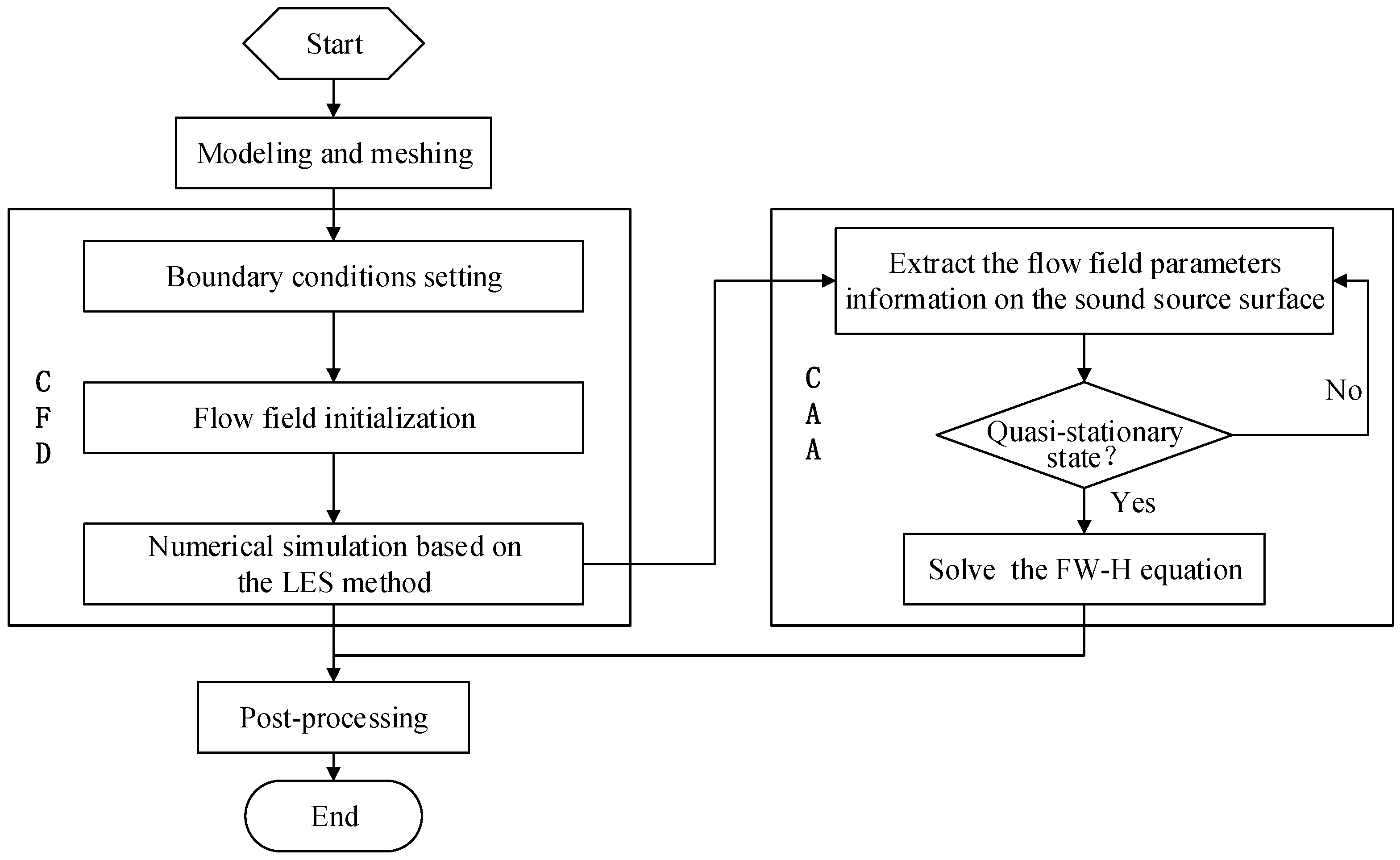

2. Mathematical Models

2.1. LES Method

2.2. FW-H Acoustic Analogy Method

3. Numerical Method and Uncertainty Analysis

3.1. Numerical Setup

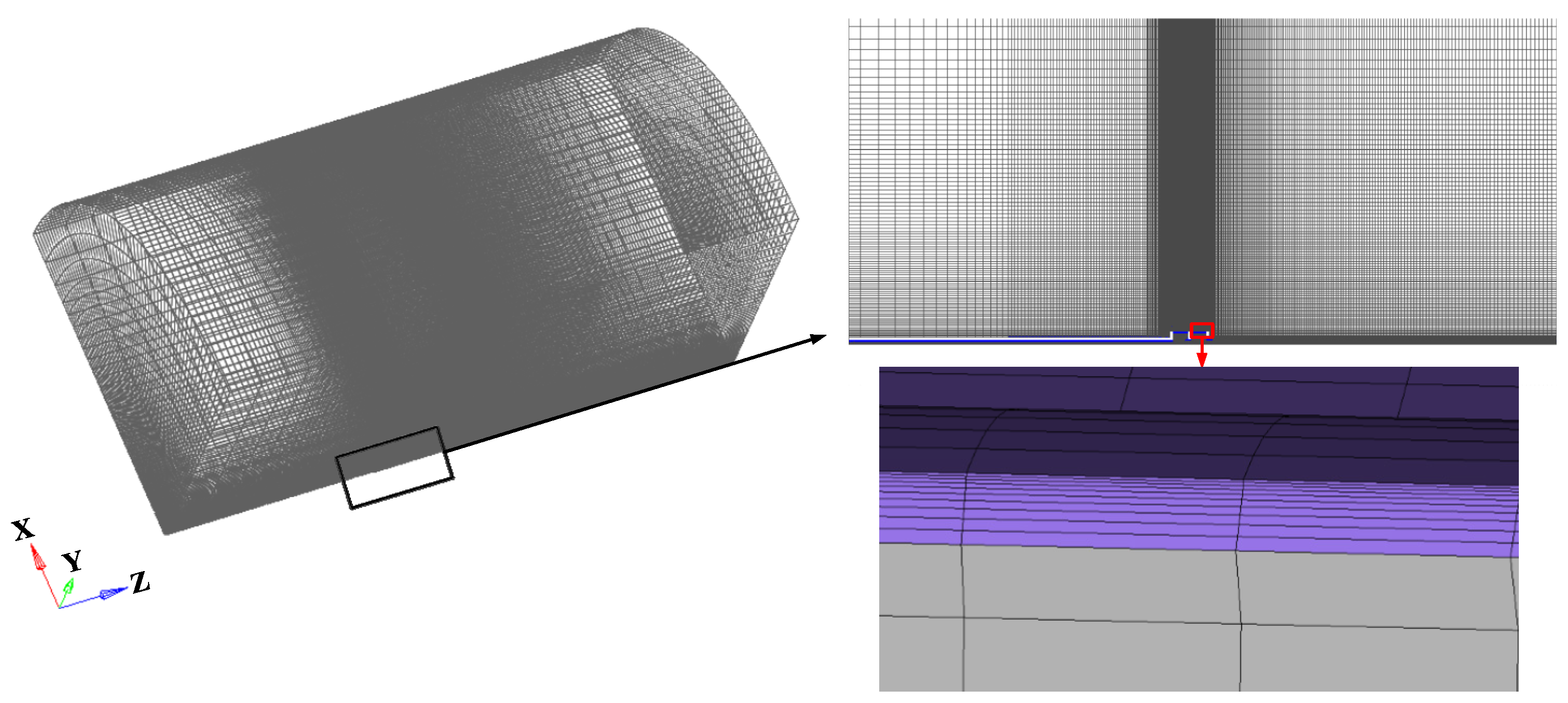

3.2. Numerical Method

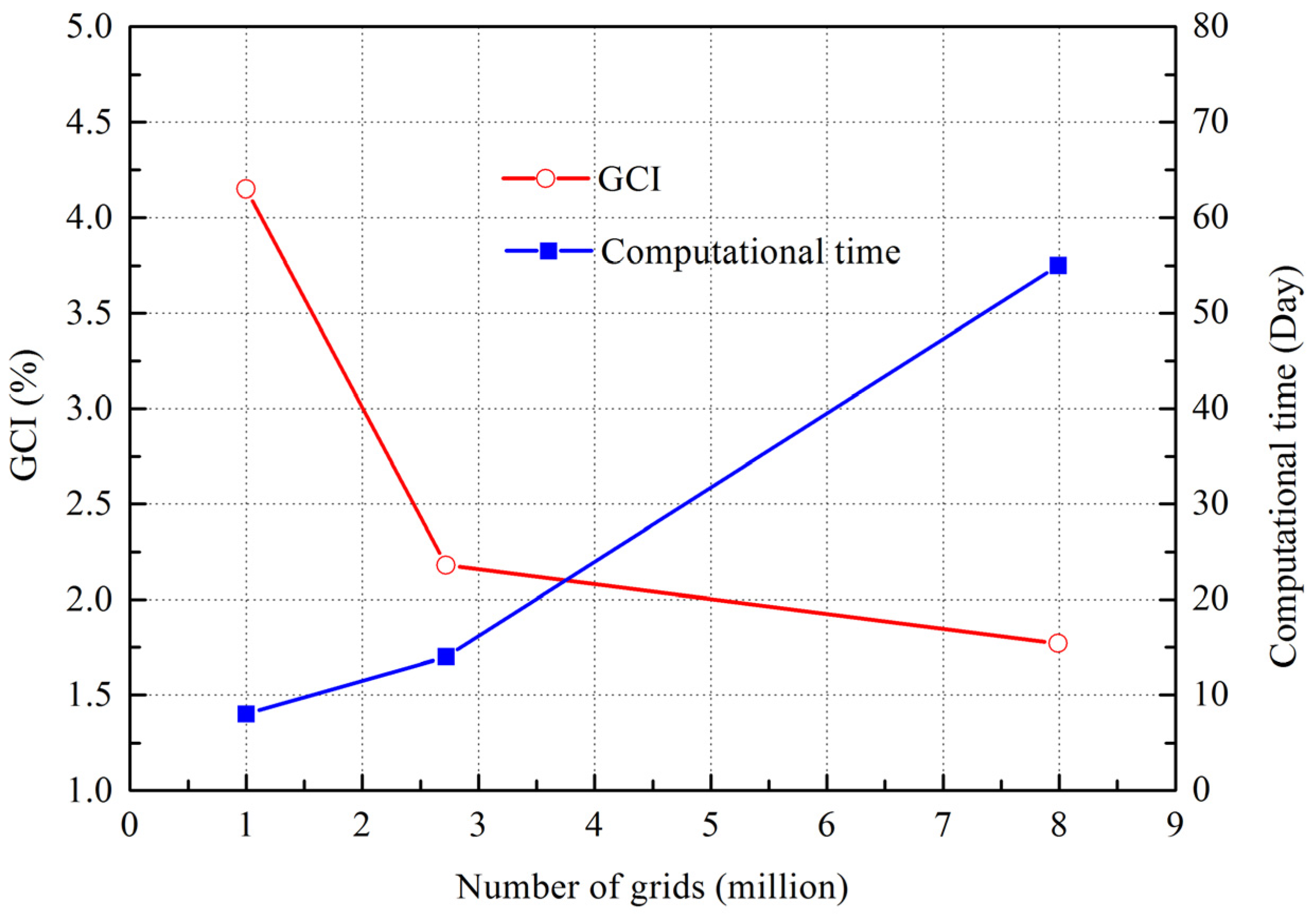

3.3. Grid Convergence Study

3.4. Computational Cost

4. Model Validation

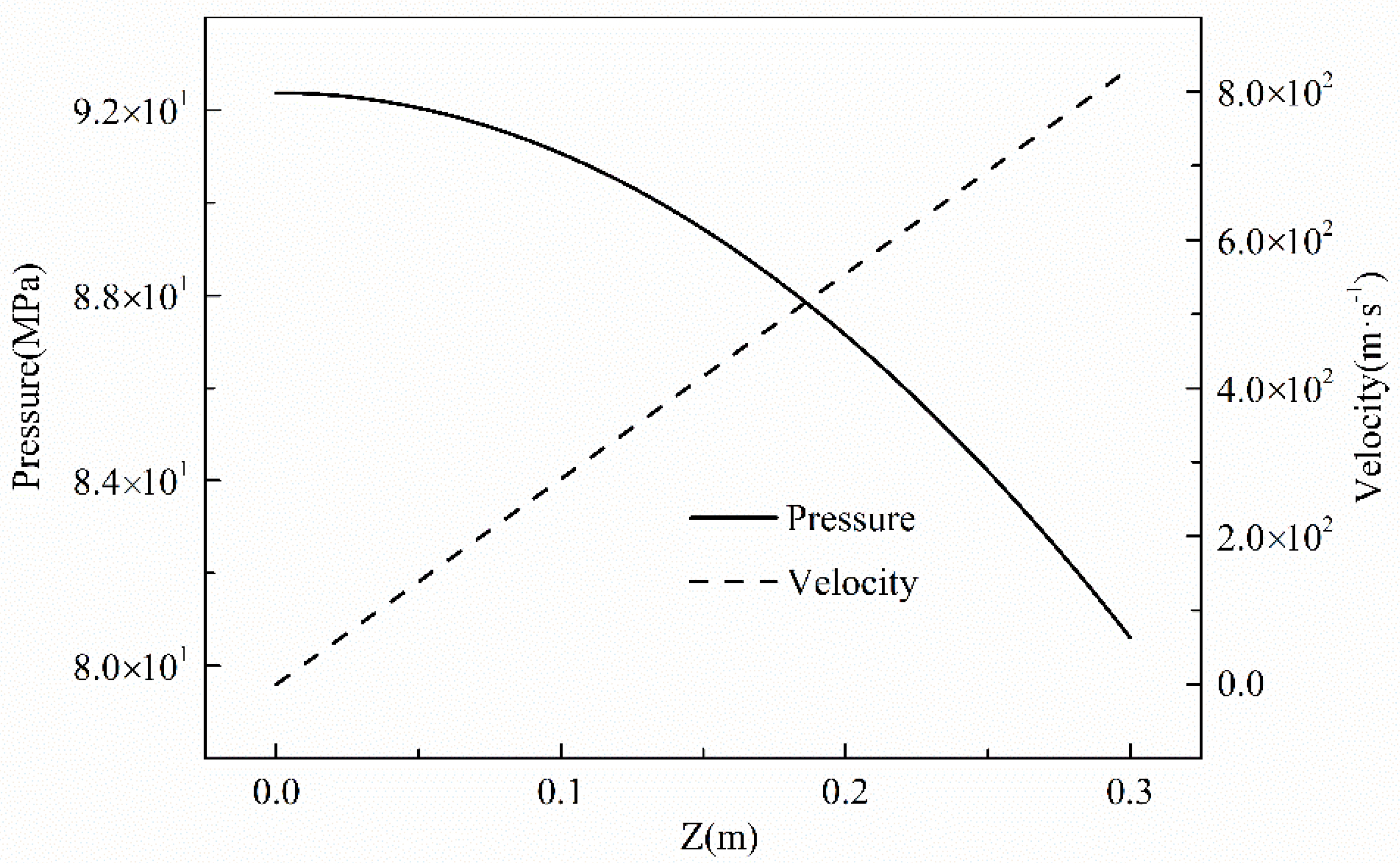

4.1. Numerical Results

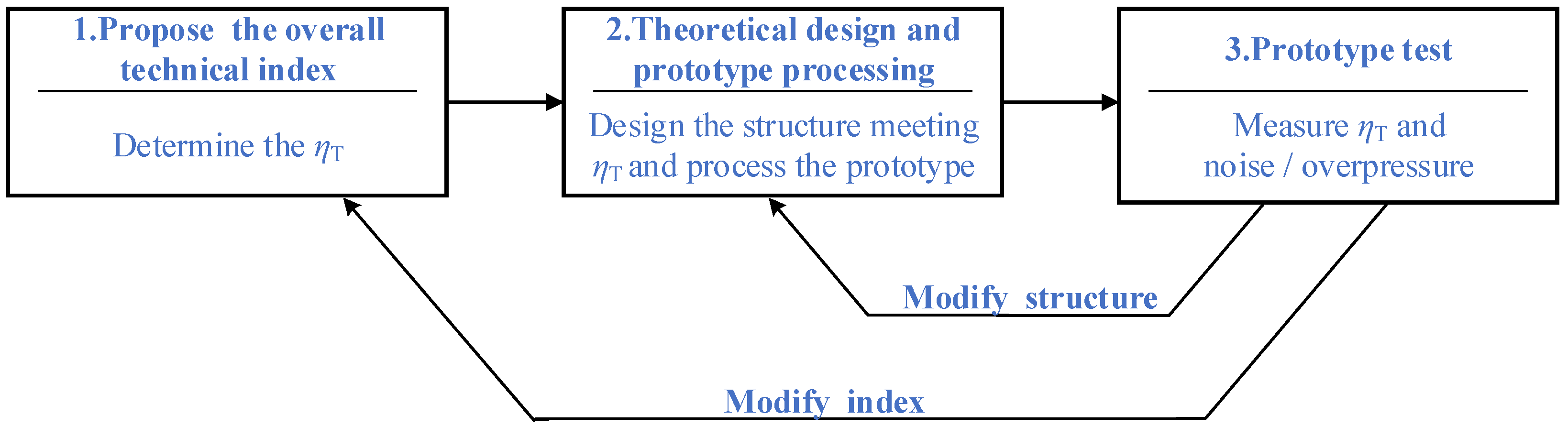

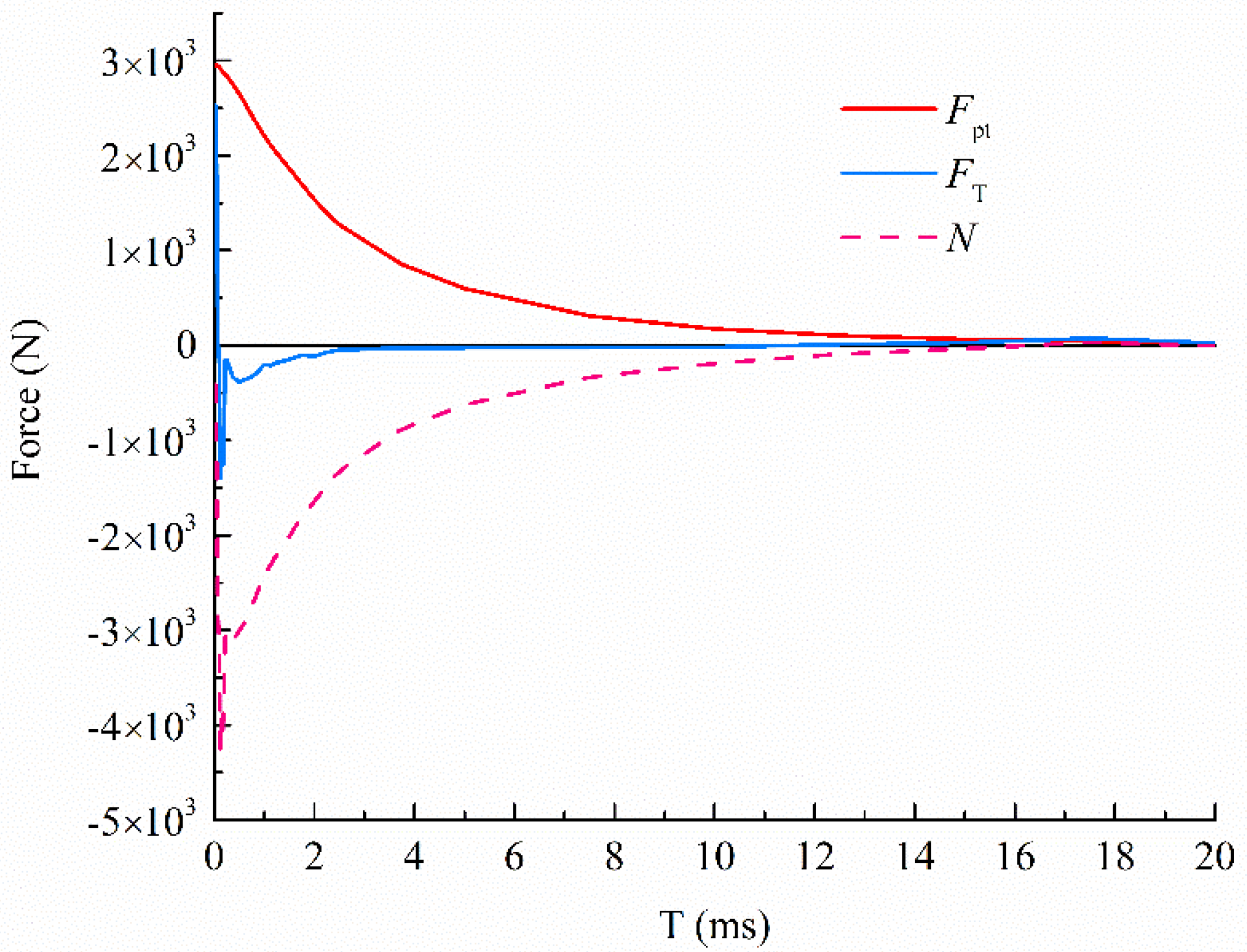

4.1.1. Muzzle Brake Efficiency

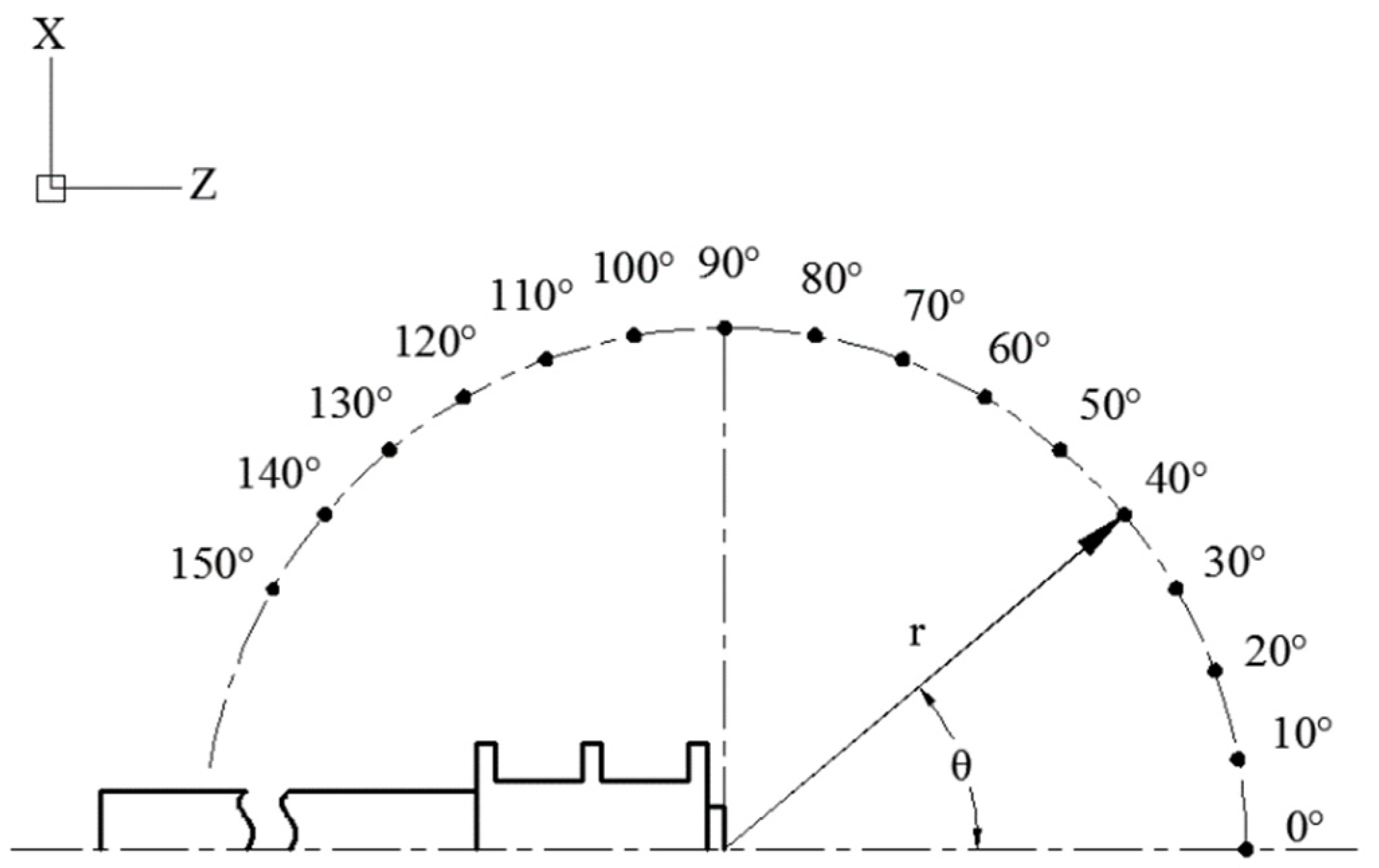

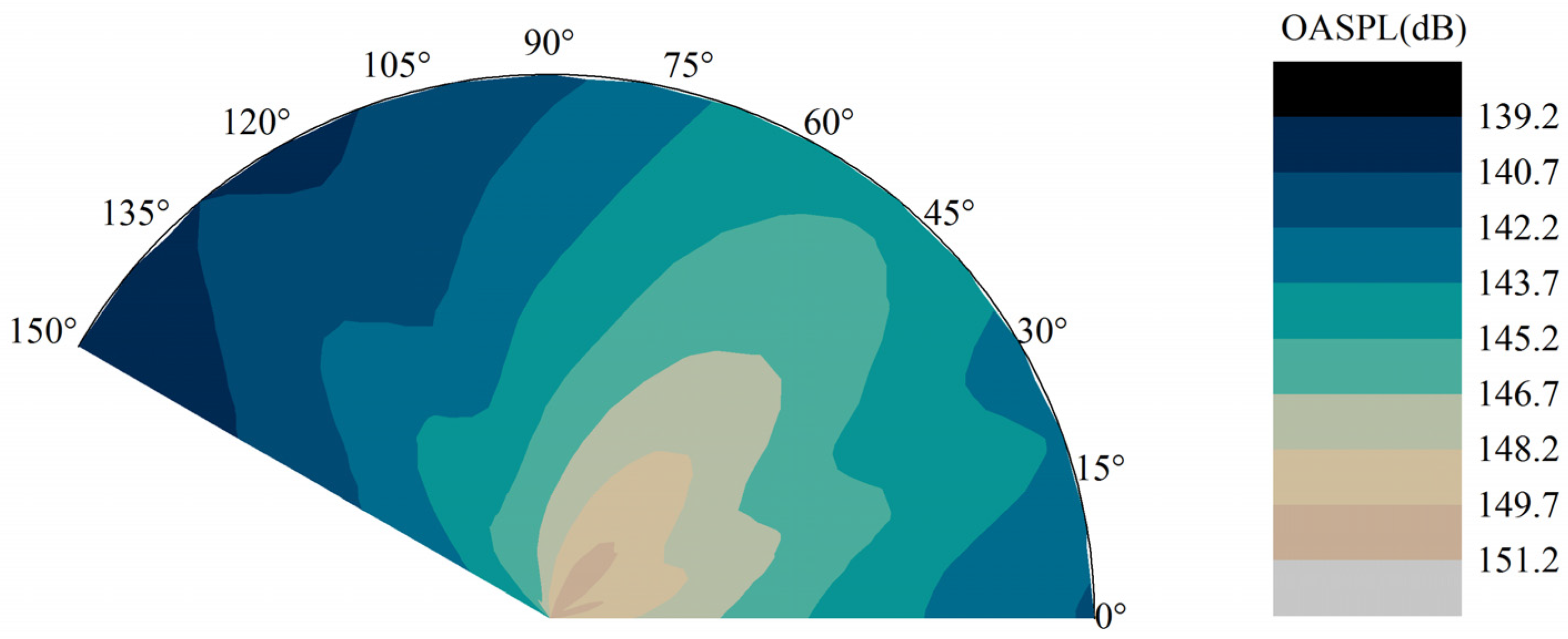

4.1.2. Muzzle Impulse Noise

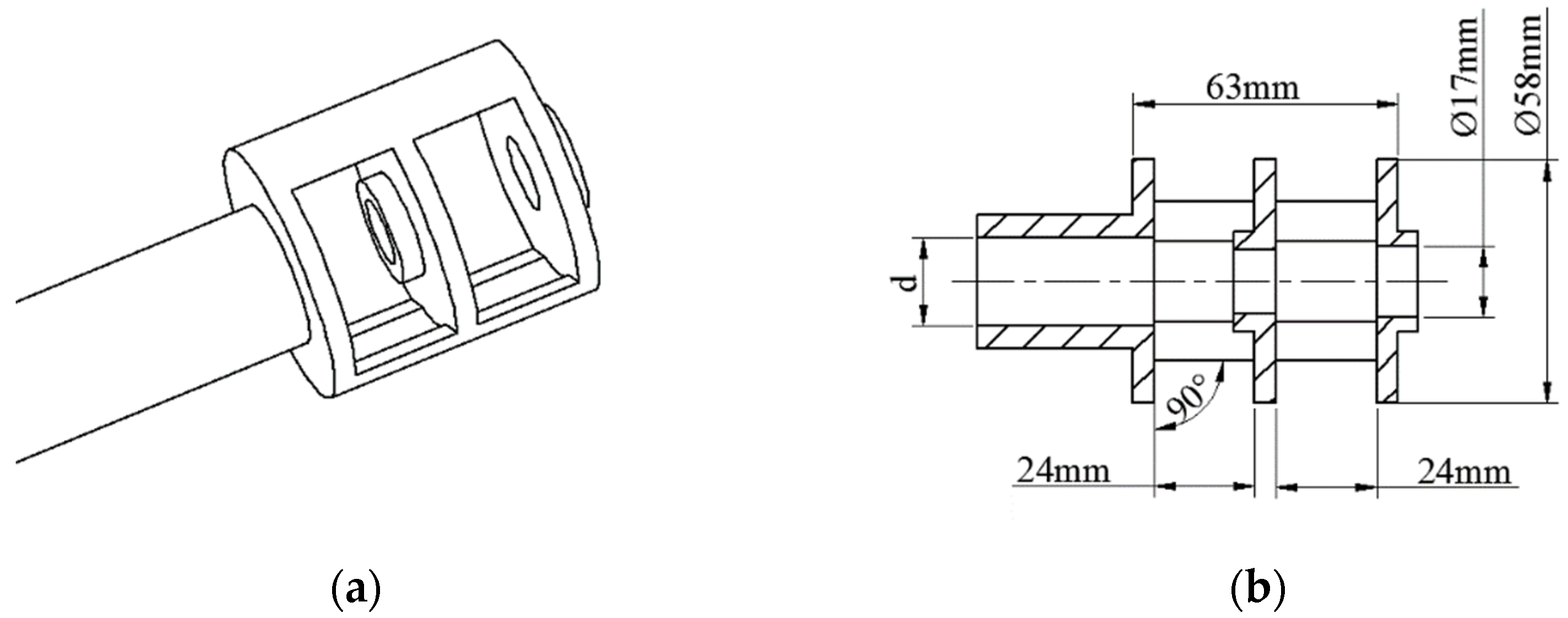

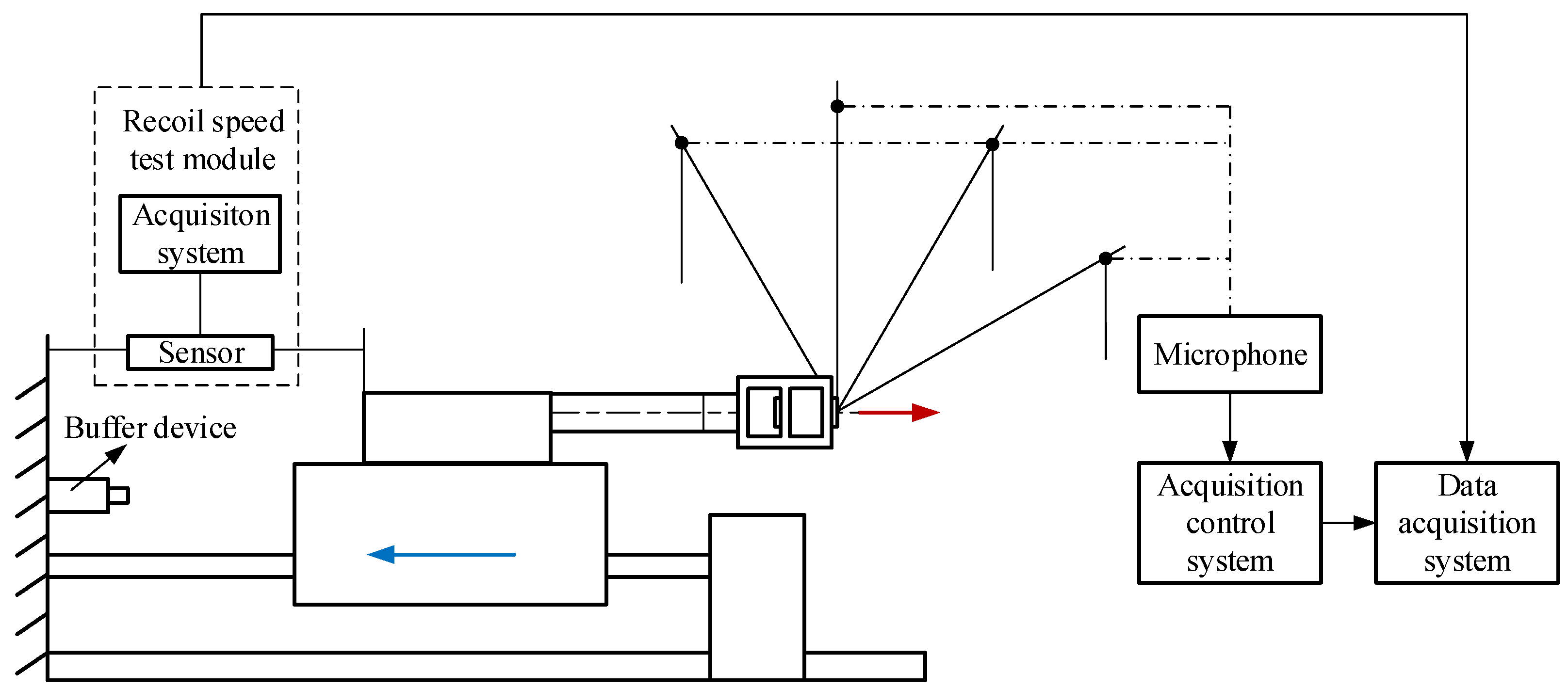

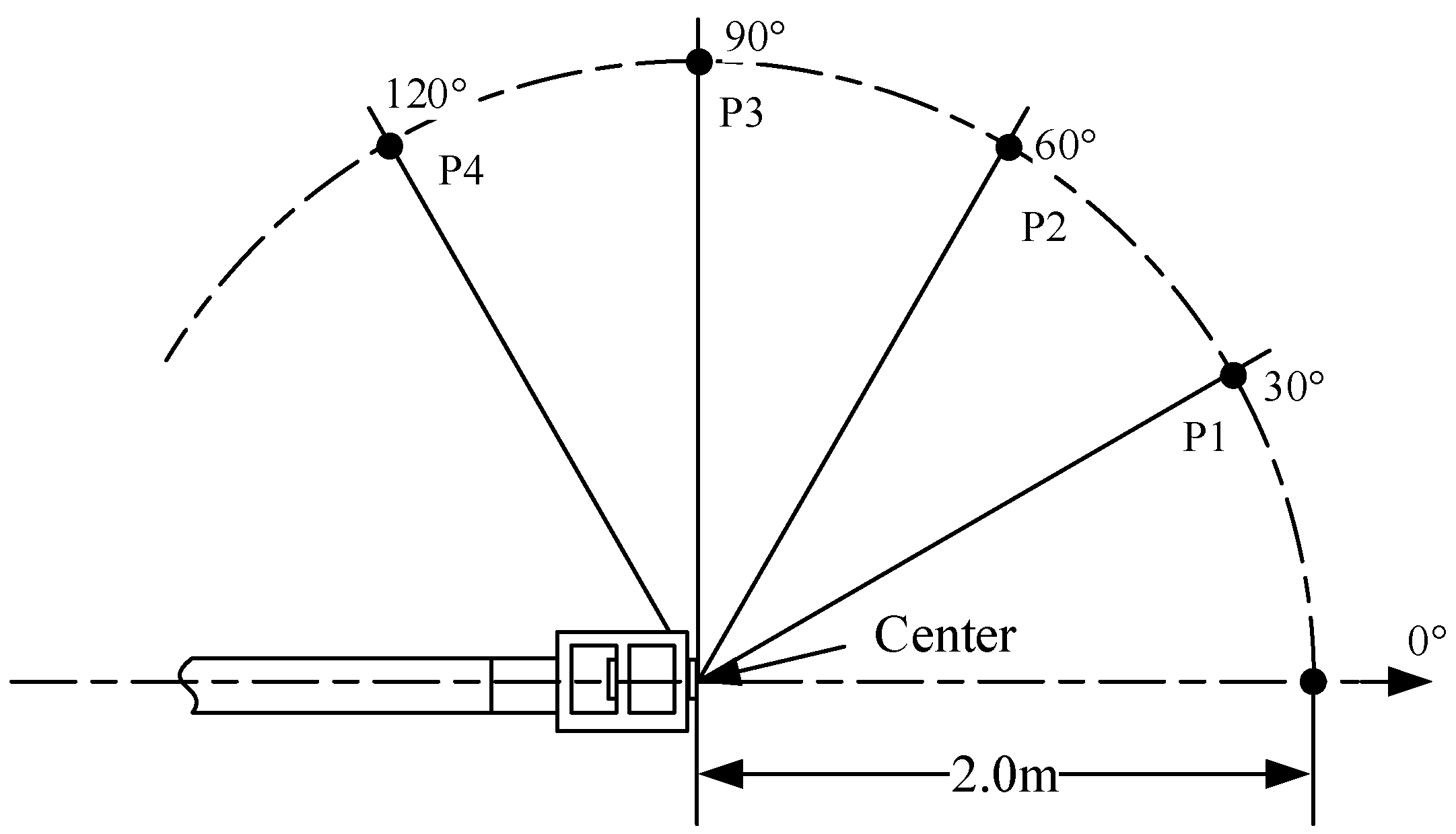

4.2. Experimental Setup

4.3. Comparison of Simulated and Experimental Results

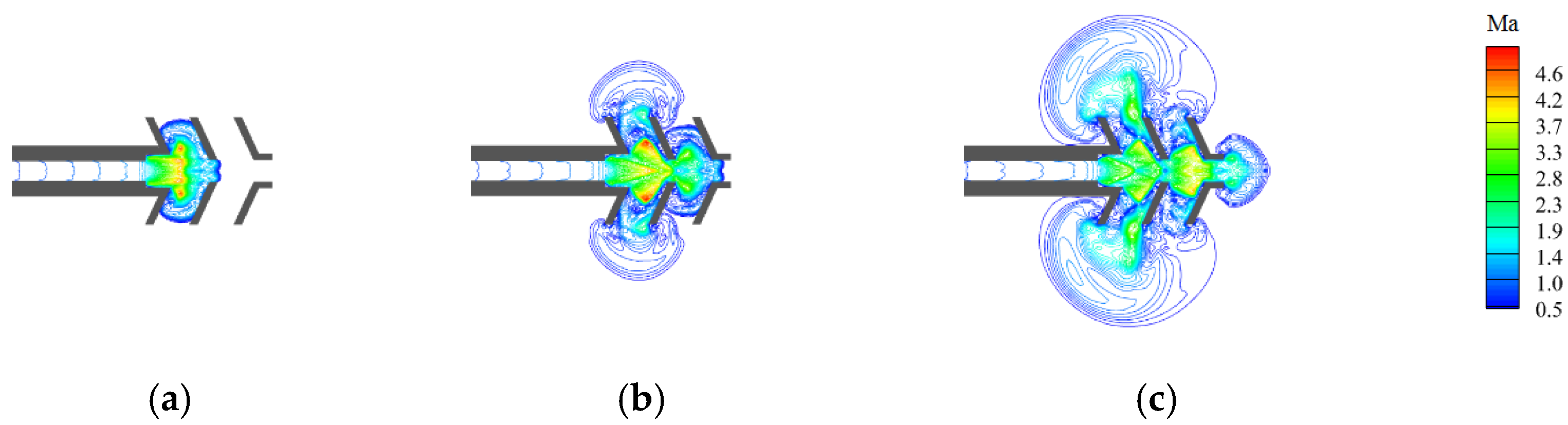

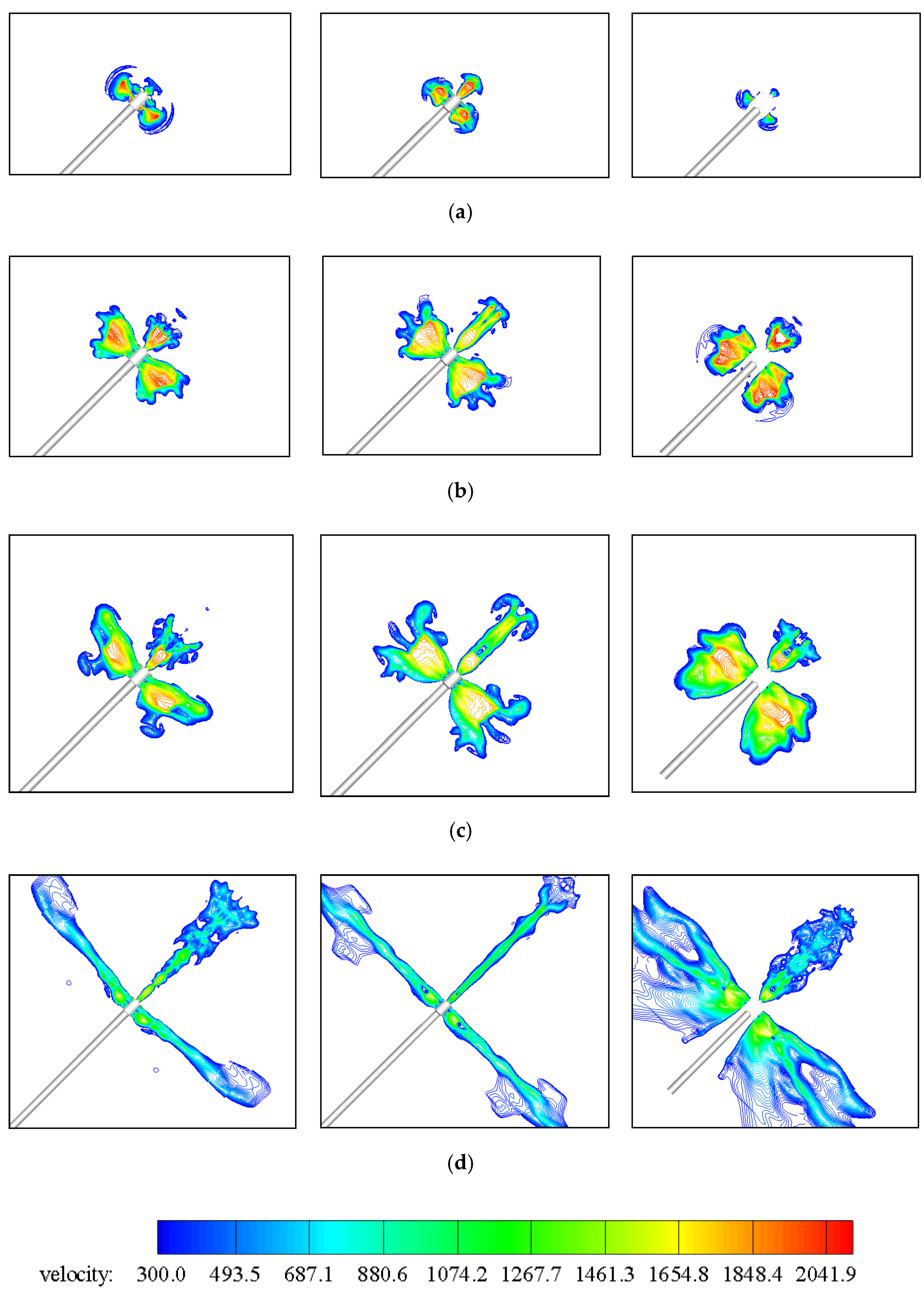

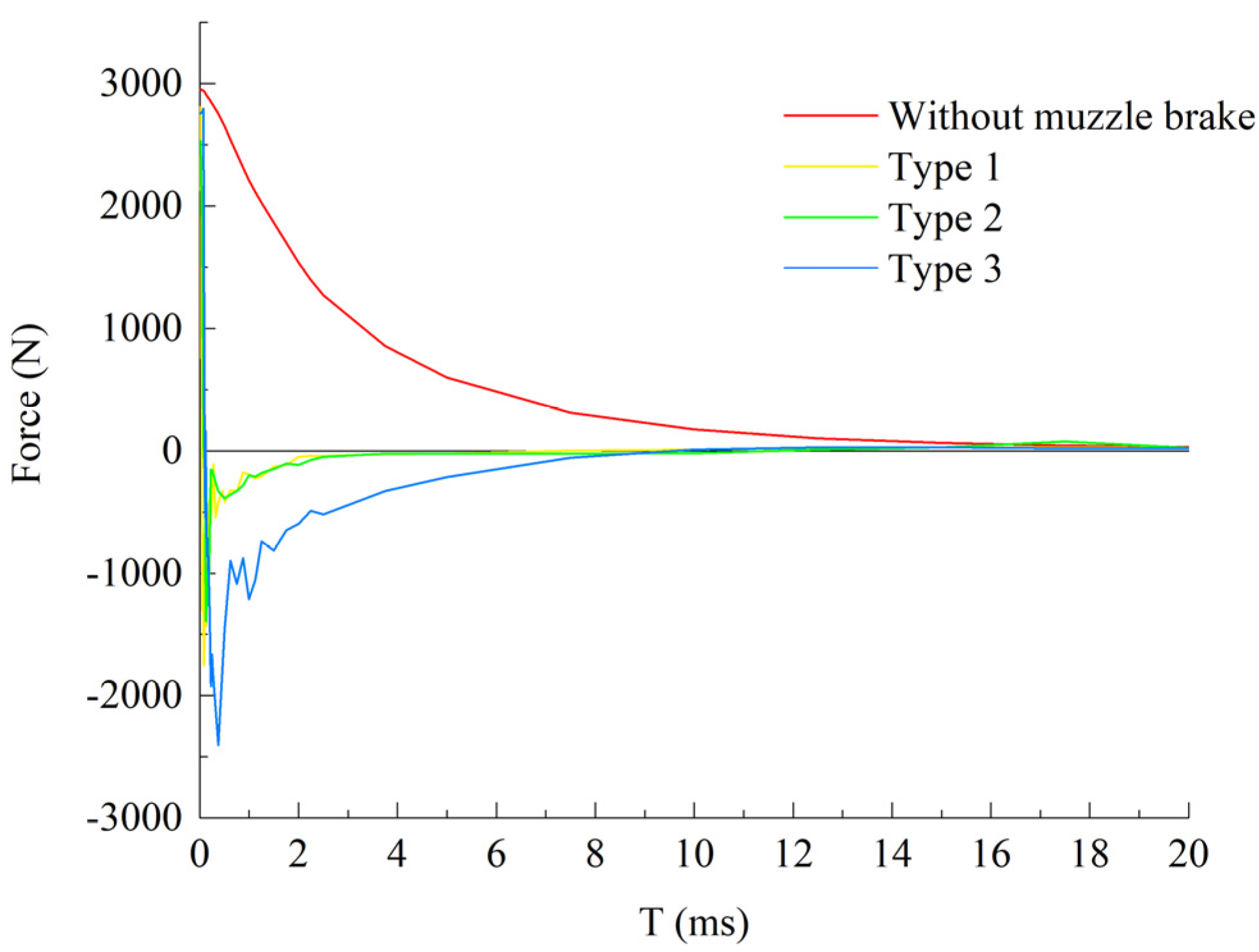

5. Comprehensive Performance Evaluation of Muzzle Brakes with Various Structures

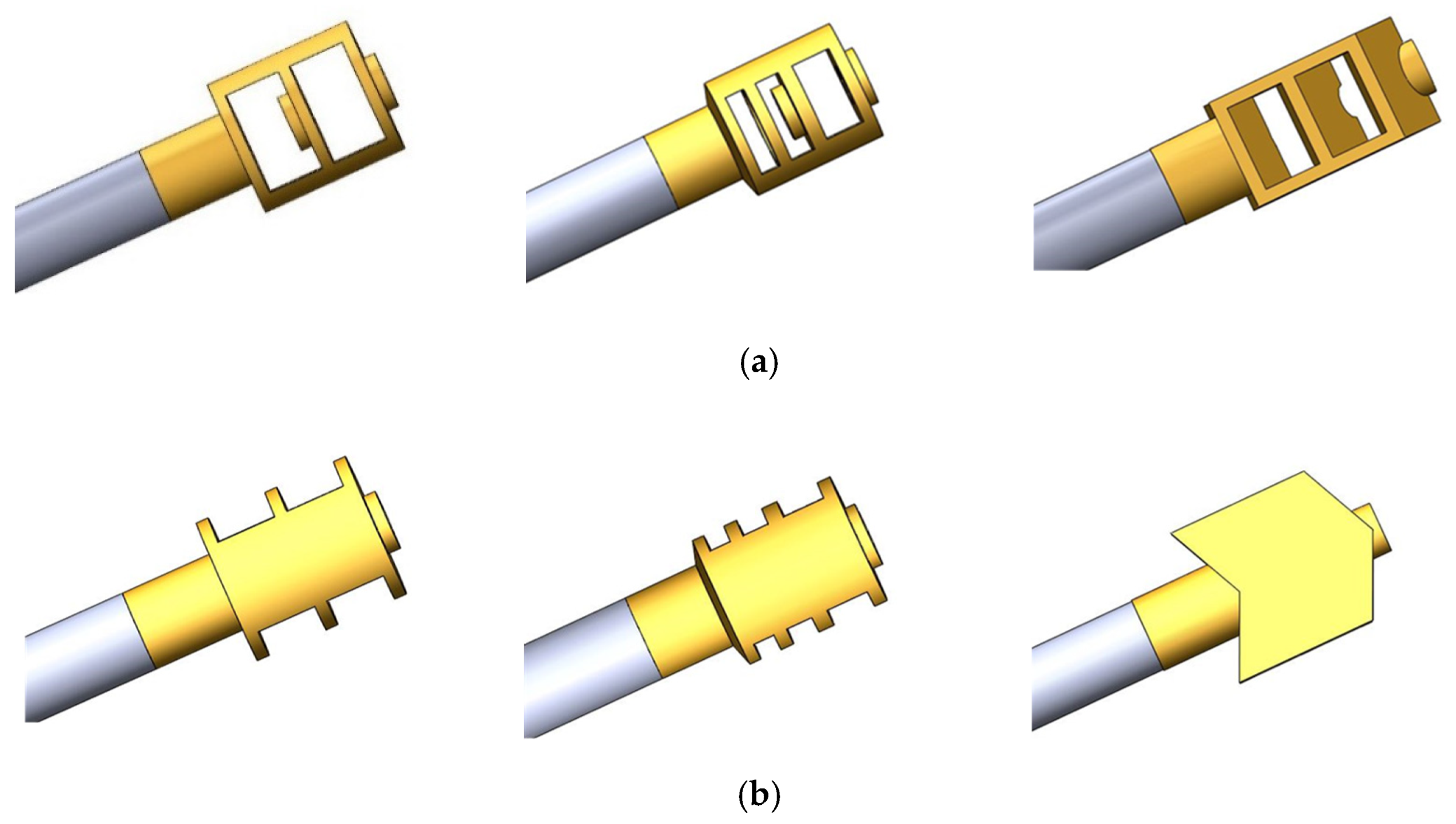

5.1. Design Details and Numerical Setup

5.2. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramezanizadeh, M.; Puia, A.; Ahmadi, M.; Chau, K.-w. Experimental and numerical analysis of a nanofluidic thermosyphon heat exchanger. Eng. Appl. Comput. Fluid Mech. 2019, 13, 40–47. [Google Scholar] [CrossRef]

- Abadi, A.M.; Sadi, M.; Farzaneh-Gord, M.; Ahmadi, M.H.; Chau, K.-w. A numerical and experimental study on the energy efficiency of a regenerative Heat and Mass Exchanger utilizing the counter-flow Maisotsenko cycle. Eng. Appl. Comput. Fluid Mech. 2020, 14, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.H.; Lee, M.; Hwang, I.J.; Kim, Y.J. Noise Reduction of an Extinguishing Nozzle Using the Response Surface Method. Energies 2019, 12, 4346. [Google Scholar] [CrossRef] [Green Version]

- Nishad, K.; Ries, F.; Li, Y.; Sadiki, A. Numerical Investigation of Flow through a Valve during Charge Intake in a DISI—Engine Using Large Eddy Simulation. Energies 2019, 12, 2620. [Google Scholar] [CrossRef] [Green Version]

- Sakamoto, K.; Matsunaga, K.; Fukushima, J.; Tanaka, A. Numerical analysis of the propagating blast wave in a firing range. In Proceedings of the 19th International Symposium in Ballistic, Interlaken, Switzerland, 7–11 May 2001; pp. 289–296. [Google Scholar]

- Cler, D.L.; Chevaugeon, N.; Shephard, M.S.; Flaherty, J.E.; Remacle, J. Computational fluid dynamics application to gun muzzle blast—A validation case study. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, Nevada, 6–9 January 2003. [Google Scholar] [CrossRef]

- Cayzac, R.; Carette, E.; Patry, J.N. Computational Fluid Dynamics and Experimental Validations of the Direct Coupling Between Interior, Intermediate and Exterior Ballistics Using the Euler Equations. J. Appl. Mech. 2011, 78, 1774–1800. [Google Scholar] [CrossRef]

- Chen, M.; Li, Z.; Mi, B. A Study of Muzzle Brake Structure Characteristics Based on CFD. Ordnance Ind. Autom. 2013, 32, 4–7. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Jiang, X.; Li, H. Investigations on the exterior flow field and the efficiency of the muzzle brake. J. Mech. Sci. Technol. 2013, 27, 95–101. [Google Scholar] [CrossRef]

- Gao, J.; Liu, S.H. Computation Methods of Muzzle Brake Efficiency. Mech. Eng. Autom. 2013, 2013, 176–177. [Google Scholar] [CrossRef]

- Lee, I.C.; Lee, D.J.; Ko, S.H.; Dong, S.L.; Kang, G.J. Numerical analysis of a blast wave using CFD-CAA hybrid method. In Proceedings of the 12th Aiaa/Ceas Aeroacoustics Conference, Cambridge, MA, USA, 8–10 May 2006. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Jiang, X.H.; Yang, X.P.; Guo, Z.Q.J.E.; Waves, S. Numerical simulation on jet noise induced by complex flows discharging from small caliber muzzle. Explos. Shock Waves 2014, 34, 508–512. [Google Scholar] [CrossRef]

- Bogey, C.; Marsden, O.; Bailly, C. Effects of moderate Reynolds numbers on subsonic round jets with highly disturbed nozzle-exit boundary layers. Phys. Fluids 2012, 24, 53. [Google Scholar] [CrossRef] [Green Version]

- Wan, Z.H.; Zhou, L.; Yang, H.H.; Sun, D.J. Large eddy simulation of flow development and noise generation of free and swirling jets. Phys. Fluids 2013, 25, 564–587. [Google Scholar] [CrossRef]

- Bogey, C.; Marsden, O.; Bailly, C. Influence of initial turbulence level on the flow and sound fields of a subsonic jet at a diameter-based Reynolds number of 105. J. Fluid Mech. 2012, 701, 352–385. [Google Scholar] [CrossRef] [Green Version]

- Brès, G.A.; Jaunet, V.; Rallic, M.L.; Jordan, P.; Colonius, T.; Lele, S.K. Large eddy simulation for jet noise: The importance of getting the boundary layer right. In Proceedings of the Aiaa/Ceas Aeroacoustics Conference, Dallas, TX, USA, 22–26 June 2015. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.Y.; Zhou, K.D.; HE, L.; LU, Y.; Li, J.S. Wavelet Analysis and Numerical Simulation of Jet Noise induced by a Large Caliber Small Arms. Acta Armamentarii 2019, 40, 2195–2203. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Zhou, K.D.; He, L.; Lu, Y.; Zheng, Q. Numerical Simulation and Experiment on Impulse Noise in a Small Caliber Rifle with Muzzle Brake. Shock Vib. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Rodi, W. Turbulence Modeling and Simulation in Hydraulics: A Historical Review. J. Hydraul. Eng. 2017, 143, 03117001. [Google Scholar] [CrossRef]

- Lilly, D.K. A proposed modification of the Germano subgrid-scale closure method. Phys. Fluids A Fluid Dyn. 1998, 4, 633–635. [Google Scholar] [CrossRef]

- Ffowcs Williams, J.E.; Hawkings, D.L. Sound Generation by Turbulence and Surfaces in Arbitrary Motion. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1969, 264, 321–342. [Google Scholar] [CrossRef]

- Carlucci, D.E.; Jacobson, S.S. Interior Ballistics; Taylor and Francis: Oxford, UK, 2014; p. 2014. [Google Scholar]

- Roache, P. Error bars for CFD. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, Nevada, 6–9 January 2003. [Google Scholar] [CrossRef]

- Manna, P.; Dharavath, M.; Sinha, P.K.; Chakraborty, D. Optimization of a flight-worthy scramjet combustor through CFD. Aerosp. Sci. Technol. 2013, 27, 138–146. [Google Scholar] [CrossRef]

- Carter, P.H. Unknown transient detection using wavelets. Wavelet Appl. 1994, 2242, 137–149. [Google Scholar] [CrossRef]

- Zhou, F.; Jiang, Y.; Zhang, X.; Hao, J. Time-frequency Analysis of Test Data from Complex Noise of Rocket Engine Jet. J. Proj. Rocket. Missiles Guid. 2012, 32, 145–147. [Google Scholar] [CrossRef]

| Type | Number of Grid Cells | Average Skewness | |

|---|---|---|---|

| 1 | Coarse | 1,001,200 | 0.85 |

| 2 | Medium | 2,720,810 | 0.88 |

| 3 | Fine | 7,989,430 | 0.90 |

| Point | Grid | Pressure/Pa | GCI |

|---|---|---|---|

| P1 | 1 | 103,391.9 | 4.03% |

| 2 | 101,828.6 | 2.12% | |

| 3 | 101,507.5 | 1.72% | |

| P2 | 1 | 102,995.9 | 3.54% |

| 2 | 101,626.2 | 1.86% | |

| 3 | 101,344.8 | 1.51% | |

| P3 | 1 | 103,721.8 | 4.89% |

| 2 | 101,831.2 | 2.56% | |

| 3 | 101,443.2 | 2.08% |

| Measured | Calculated | Difference/% | |

|---|---|---|---|

| muzzle brake efficiency/% | 29.7 | 29.02 | 2.29 |

| Point (r = 2.0 m) | θ/° | OASPL/dB | Difference/% | |

|---|---|---|---|---|

| Measured | Calculated | |||

| P1 | 30 | 149.75 | 142.95 | −4.54 |

| P2 | 60 | 150.63 | 144.05 | −4.37 |

| P3 | 90 | 148.87 | 141.78 | −4.71 |

| P4 | 120 | 147.20 | 140.56 | −4.51 |

| Muzzle Brake Efficiency/% | Point A (r = 0.5 m) | Point B (r = 1.0 m) | Point C (r = 2.0 m) | ||||

|---|---|---|---|---|---|---|---|

| OASPL/dB | Difference | OASPL/dB | Difference | OASPL/dB | Difference | ||

| Without | - | 141.31 | - | 141.56 | - | 137.46 | - |

| Type1 | 29% | 143.54 | 2.23 | 143.24 | 1.68 | 142.24 | 4.78 |

| Type2 | 31% | 140.90 | −0.41 | 143.49 | 1.93 | 146.07 | 8.61 |

| Type3 | 37% | 142.64 | 1.33 | 145.53 | 3.97 | 144.75 | 7.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Lu, Y. A Comprehensive Performance Evaluation Method Targeting Efficiency and Noise for Muzzle Brakes Based on Numerical Simulation. Energies 2022, 15, 3576. https://doi.org/10.3390/en15103576

Zhao X, Lu Y. A Comprehensive Performance Evaluation Method Targeting Efficiency and Noise for Muzzle Brakes Based on Numerical Simulation. Energies. 2022; 15(10):3576. https://doi.org/10.3390/en15103576

Chicago/Turabian StyleZhao, Xinyi, and Ye Lu. 2022. "A Comprehensive Performance Evaluation Method Targeting Efficiency and Noise for Muzzle Brakes Based on Numerical Simulation" Energies 15, no. 10: 3576. https://doi.org/10.3390/en15103576

APA StyleZhao, X., & Lu, Y. (2022). A Comprehensive Performance Evaluation Method Targeting Efficiency and Noise for Muzzle Brakes Based on Numerical Simulation. Energies, 15(10), 3576. https://doi.org/10.3390/en15103576