Study of the Microstructural Characteristics of Low-Rank Coal under Different Degassing Pressures

Abstract

:1. Introduction

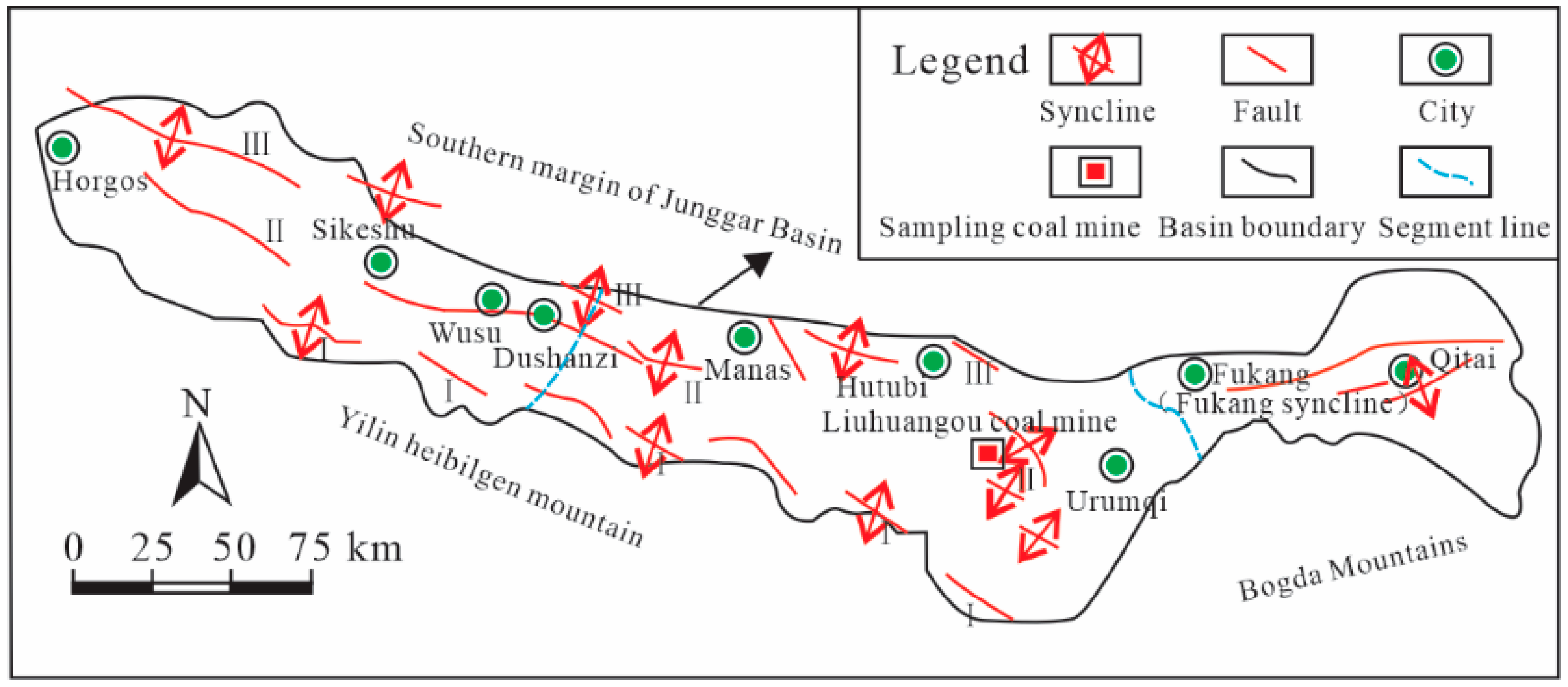

2. Geological Background

3. Sampling and Experimental Tests

3.1. Sample Collection and Processing

3.2. Experimental Tests

- (1)

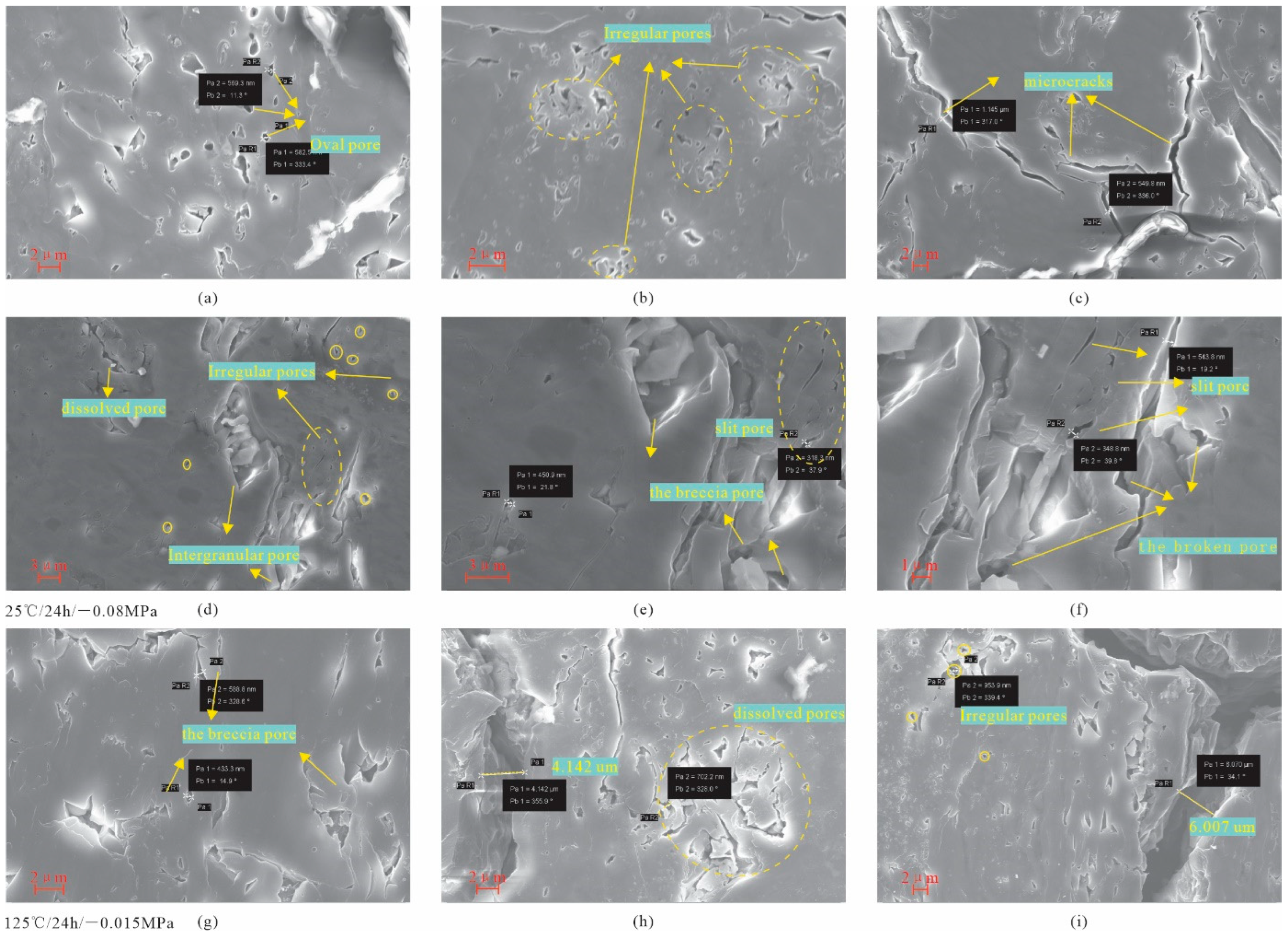

- Image analysis method: SEM was primarily used to study the formation of pores and fractures in low-rank coal reserves as well as to obtain coal sample pictures and analyze the size, shape, connectivity, and surface morphology of pores and fractures;

- (2)

- Physical adsorption method: The micropores and pores of low-rank coal reservoirs were characterized using am LT-N2A adsorption approach. The experiment used a fully automated physical adsorption apparatus (GEMSV-Sorb 2800TP). The particle size of the N2 adsorption test coal sample was 0.2~0.25 mm, and the weight of the coal sample was approximately 20 g;

- (3)

- Low-field nuclear magnetic resonance: The pore size distribution characteristics of low-rank coal reservoirs as well as the conversion relationship between porosity and T2 relaxation time were established using NMR relaxation time analysis, and the distribution characteristics of the T2 relaxation time at different spectral peaks corresponded to the distribution characteristics of the micropores, medium pores, large pores, and fractures in the low-rank coal samples. The instrument used was a medium-sized NMR analysis and imaging system, and the instrument model was MesoMR23-060H-I.

4. Results and Discussion

4.1. Pore Morphological Characteristics of Low-Rank Coal

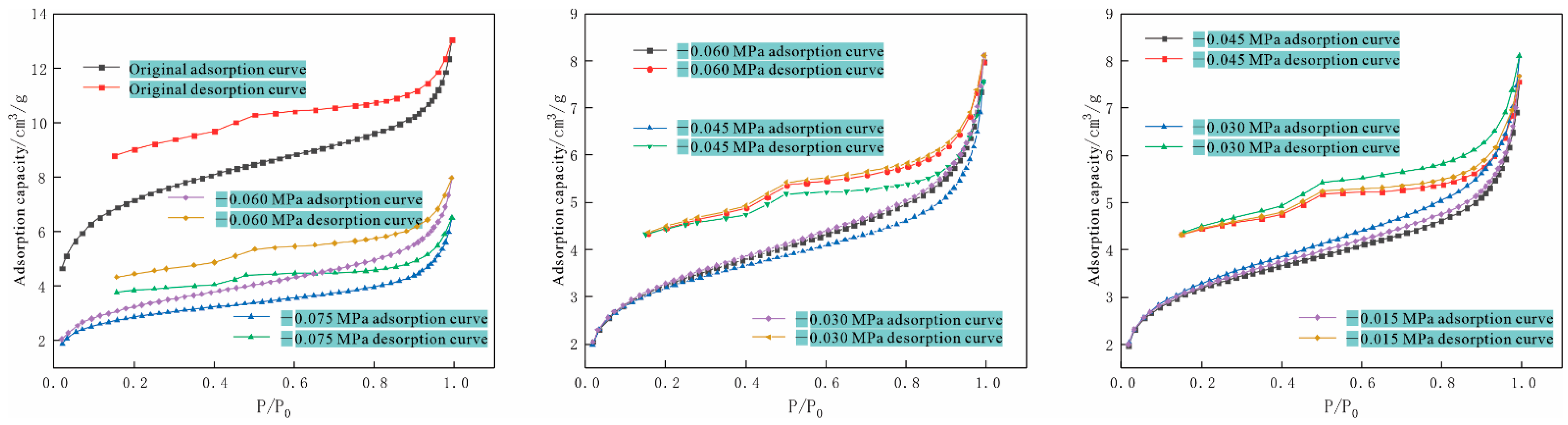

4.2. Characteristics of the LT-N2A Curves under Different Negative Pressure Conditions

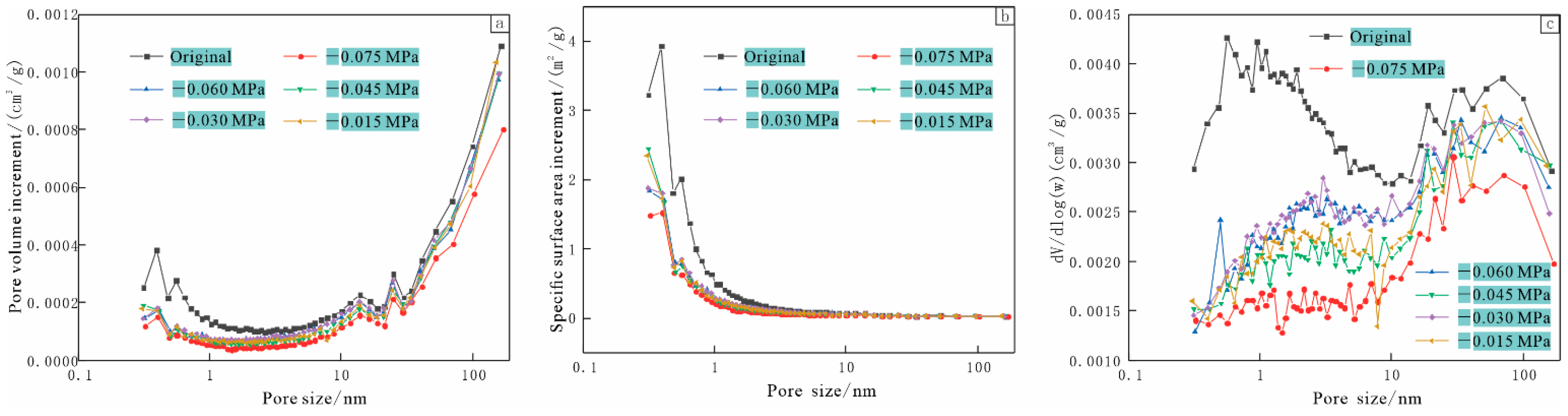

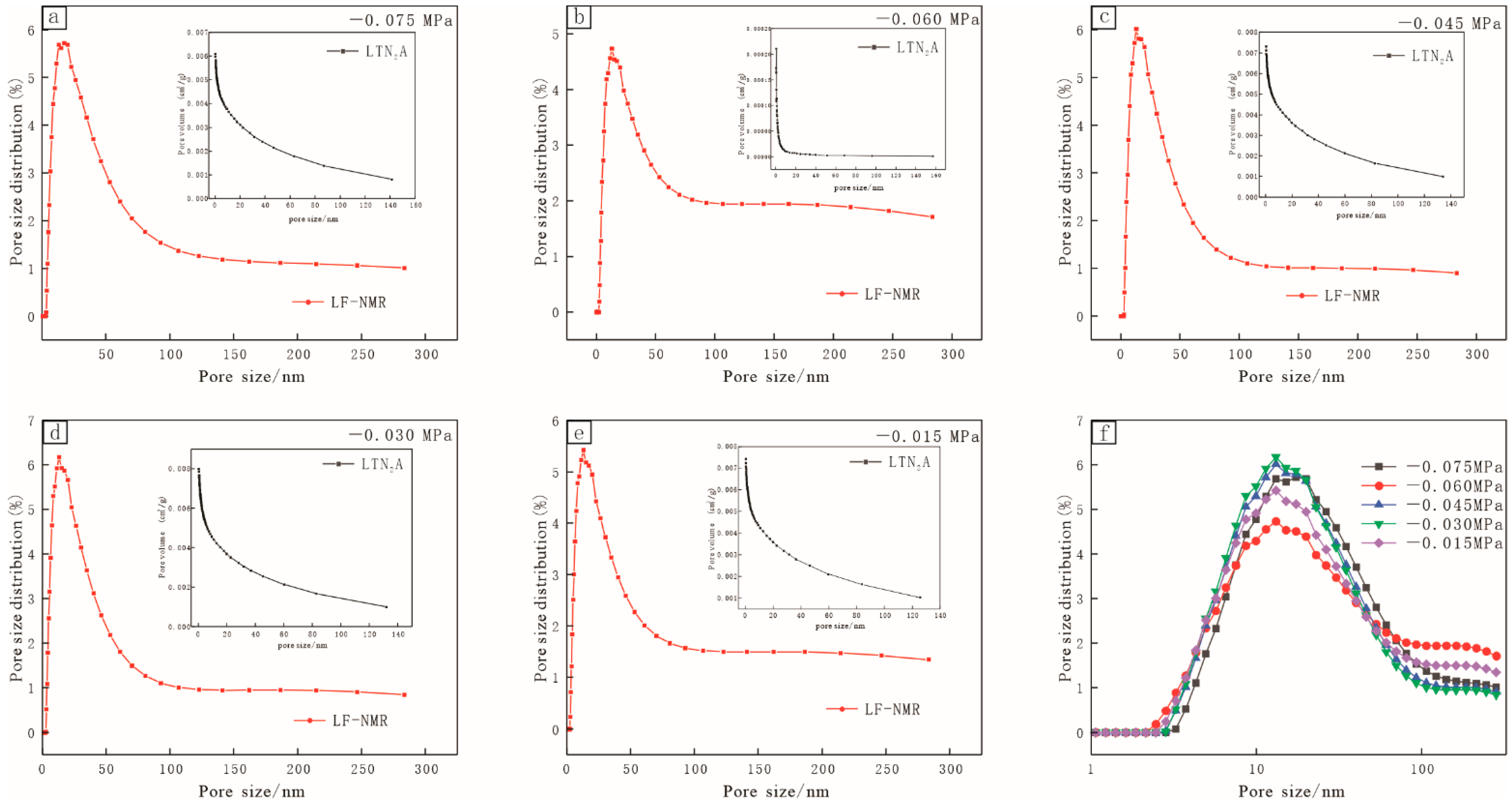

4.3. Characteristics of Pore Structure Parameters of the Low-Rank Coal under Different Negative Pressure Conditions

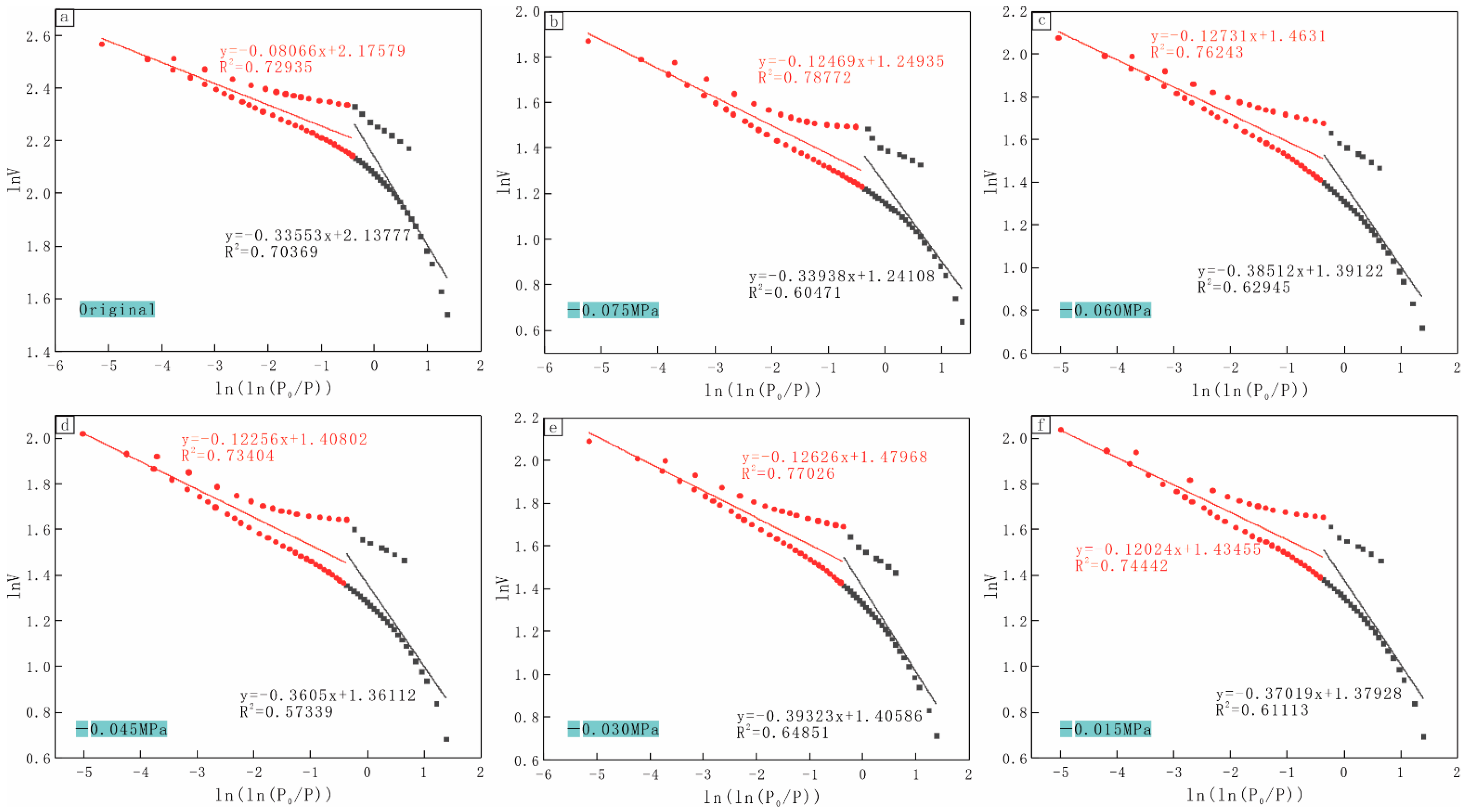

4.4. Heterogeneity of the Adsorption Pores

4.4.1. Fractal Theory and the Model of Adsorption Pores of Low-Rank Coal

4.4.2. Fractal Characteristics of Adsorption Pores of Low-Rank Coal

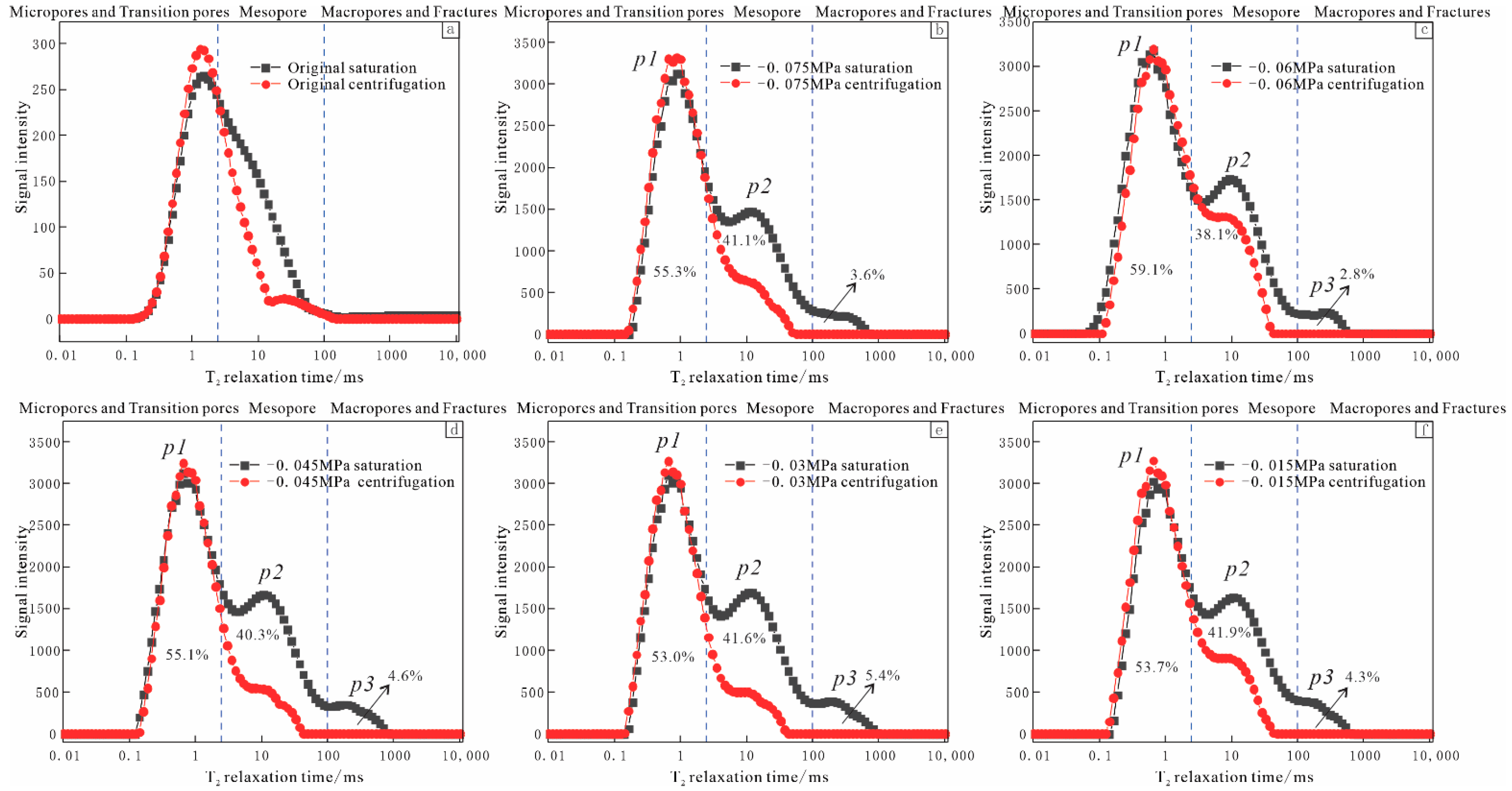

4.5. NMR Pore Characteristics

4.5.1. Fracture Characteristics of NMR Pores under Different Negative Pressure Treatment Conditions

4.5.2. Pore Size Distribution Characteristics of Micropores and Small Pores

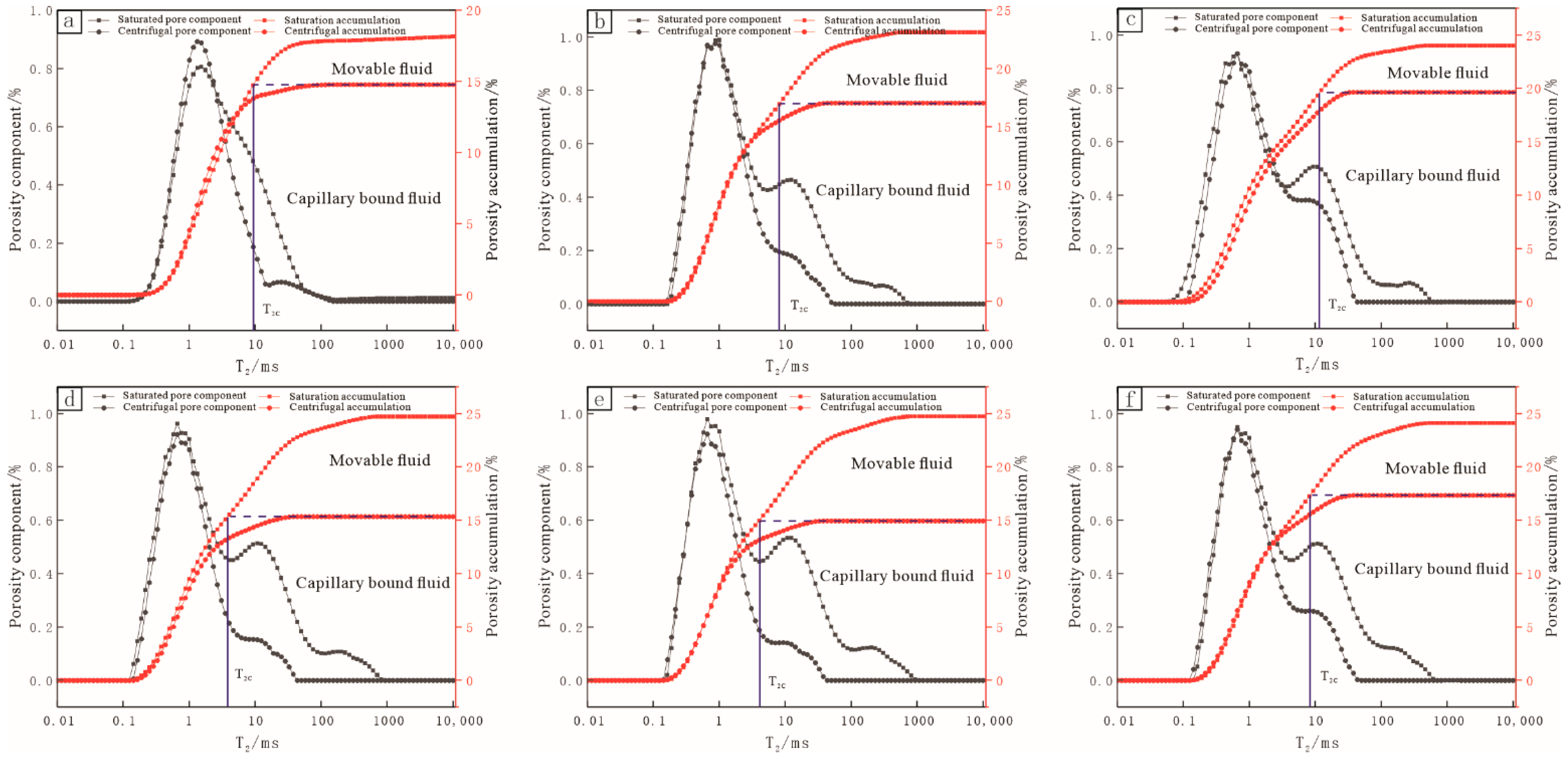

4.5.3. Effective Porosity

5. Conclusions

- (1)

- The vitrinite content of the low-rank coal from the study area was higher than that of inertinite; the minerals in the coal samples were mostly clay and carbonate minerals with a high organic matter content;

- (2)

- According to the observation of the SEM, the pores and fissures of the low-rank coal samples from the study area developed mainly as nanoscale pores and dissolution pores. At the same time, there were also micron cracks. After negative pressure treatment, the dissolution of the pores and fissures was strong;

- (3)

- According to the low-temperature nitrogen adsorption experiment, the adsorption–desorption curves of the low-rank coal samples from the study area was the H2 type, and the lag ring and inflection point were obvious, the pores were mainly “ink bottle pores”, and micropores and pores were developed. The adsorption mechanisms of the low-rank coal samples at different pressure sections were different. The fractal dimension D1 of the low-pressure section (P/P0 < 0.5) was the surface fractal dimension, and the fractal dimension D2 of the high-pressure section (P/P0 > 0.5) was the structural fractal dimension. The structural fractal dimension D2 of the low-rank coal samples from the study area was relatively large, and the pore structure of the coal samples was complex;

- (4)

- The T2 spectral peak of the NMR transverse relaxation time of the low-rank coal from the research area was of three peak types. The T2 value spectral peaks corresponding to the three peaks were distributed at 0.1~2.5 ms, approximately 10 ms, and a T2 greater than 100 ms, respectively, and the area of the T2 spectral peak corresponding to the signal section accounted for the largest proportion. Therefore, the development of the pore diameter was mainly micropores, accompanied by the development of medium and large pores and fractures;

- (5)

- The surface relaxation rate of the low-rank coal was approximately 2.6128 × 10−8 m/ms. The conversion coefficient, C, of a coal sample was obtained from the surface coal relaxation rate of low-rank coal, which was 7.8384 × 10−8 m/ms, and then the pore size structure of the micropores in the low-rank coal was finely characterized. According to the cumulative porosity curve, the T2C cut-off value was 6.136~14.175 ms, and the effective porosity was 3.385%~9.797%. It was found that the effective porosity was low.

- (6)

- With the increase in degassing pressure, the changes in the pore volume, pore specific surface area, and pore diameter of the low-rank coal were closely related to the collapse of micropores and small pores in the coal rock under different degassing pressures.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Cao, D.Y.; Wei, Y.C. Middle to low-rank coalbed methane accumulation and reservoiring in the southern margin of Junggar Basin. Acta Pharm. Sin. 2016, 37, 1472–1482. [Google Scholar]

- Fu, H.J.; Tang, D.Z.; Pan, Z.J. A study of hydrogeology and its effect on coalbed methane enrichment in the southern Junggar Basin, China. AAPG Bull. 2018, 103, 189–213. [Google Scholar] [CrossRef]

- Kang, J.Q.; Fu, X.H.; Gao, L. Production profile characteristics of large dip angle coal reservoir and its impact on coalbed methane production: A case study on the Fukang west block, southern Junggar Basin, China. J. Pet. Sci. Eng. 2018, 171, 99–114. [Google Scholar] [CrossRef]

- Fu, H.J.; Tang, D.Z.; Xu, T. Preliminary research on CBM enrichment models of low-rank coal and its geological controls: A case study in the middle of the southern Junggar Basin, NW China. Mar. Pet. Geol. 2017, 83, 97–110. [Google Scholar] [CrossRef]

- Fu, H.J.; Tang, D.Z.; Xu, T. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Zhou, S.D.; Liu, D.M.; Yao, Y.B. Fractal characterization of pore–fracture in low-rank coals using a low-field NMR relaxation method. Fuel 2016, 181, 218–226. [Google Scholar] [CrossRef]

- Zhou, S.D.; Liu, D.M.; Cai, Y.D. Multi-scale fractal characterizations of lignite, subbituminous and high-volatile bituminous coals pores by mercury intrusion porosimetry. J. Nat. Gas Sci. Eng. 2017, 44, 338–350. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Pan, J.N.; Hou, Q.L. Anisotropic characteristics of low-rank coal fractures in the Fukang mining area, China. Fuel 2018, 211, 182–193. [Google Scholar] [CrossRef]

- Li, X.; Fu, X.H.; Liu, A.H. Methane adsorption characteristics and adsorbed gas content of low-rank coal in China. Energy Fuels 2016, 30, 3840–3848. [Google Scholar] [CrossRef]

- Yang, M.; Bi, J.C. Influence of extreme temperature on the pore and fracture development of high-rank coal. Adv. Civ. Eng. 2018, 2018, 4529751. [Google Scholar] [CrossRef]

- Yang, M.; Bi, J.C. Low-field NMR ecological research on the effects of confining pressure changes on pore fissurecharacteristics of high-rank coal. Ekoloji 2018, 106, 817–825. [Google Scholar]

- Yao, Y.B.; Liu, J.; Liu, D.M. A new application of NMR in characterization of multiphase methane andadsorption capacity of shale. Int. J. Coal Geol. 2019, 201, 76–85. [Google Scholar] [CrossRef]

- Ridvan, A.; Nazareth, T.P.; Jay, V.H. Nmr Logging of Natural Gas Reservoirs; 6094048[P]. 2000-07-25; OnePetro: Richardson, TX, USA, 2000. [Google Scholar]

- Wang, C.X.; Zhang, X.B.; Lu, F.C. Study on coal cracking under liquid nitrogen soaking based onnuclear magnetic resonance and stress analysis. China Saf. Sci. J. 2019, 29, 156–163. [Google Scholar]

- Yao, Y.B.; Liu, D.M.; Yao, C. Petrophysical characterization of coals by low-field nuclear magneticresonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Xu, K.N. Study on the Accumulation of Multi-Energy Resources in Jurassic in the Southern Margin of Junggar Basin; Library of China University of Geosciences: Beijing, China, 2017. [Google Scholar]

- Li, B.L.; Guan, S.W.; Chen, Z.X. Theory and Application of Fault Related Folds; Petroleum Industry Press: Beijing, China, 2010; pp. 111–119. [Google Scholar]

- Ou, C.H.; Li, C.C.; Zhi, D.M. Coupling accumulation model with gas-bearing features to evaluate low-rank coalbed methane resource potential in the southern Junggar Basin, China. AAPG Bull. 2018, 102, 153–174. [Google Scholar] [CrossRef]

- Li, Z.W. Study on Microstructure Characteristics of Low-Rank Coal and Its Control Mechanism on Gas Adsorption/Desorption; China University of Mining and Technology: Xuzhou, China, 2015. [Google Scholar]

- Xoдoт, B.B. Coal and Gas Outburst (Chinese Translated Version); China Industry Press: Beijing, China, 1966; pp. 27–28. [Google Scholar]

- Zhang, H. Genetical type of proes in coal reservoir and its research significance. J. China Coal Soc. 2001, 26, 40–44. [Google Scholar]

- Li, T.; Wang, H.C. Pore structure characteristics of low-rank coal under various degassing temperatures: A case study of lignite from Xishanyao Formation, Turpan-Hami Basin, Xinjiang. J. China Coal Soc. 2021, 46, 414–422. [Google Scholar]

- Everett, D.H.; Koopal, L.K. International union of pure and applied chemistry. Polymer 2001, 31, 1598. [Google Scholar]

- Xie, W.D.; Wang, M.; Dai, X.G. Microscopic characteristics of shale gas reservoirs in middle and southern coal measures of Hedong Coalfield, Shanxi Province. Nat. Gas Geosci. 2019, 30, 512–525. [Google Scholar]

- Yao, Y.B.; Liu, D.M.; Tang, D.Z. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tang, S.H.; Tang, D.Z. Determining fractal dimensions of coal pores by FHH model: Problems and effects. J. Nat. Gas Sci. Eng. 2014, 21, 929–939. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M. Fine Quantitative Characterization and Comprehensive Evaluation Model of Coal Reservoir; Geological Publishing House: Beijing, China, 2013. [Google Scholar]

- Yao, Y.B.; Liu, D.M. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coal. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Li, Y.; Tang, D.Z.; Xu, H. Experimental research on coal permeability: The roles of effective stress and gas slippage. J. Nat. Gas Sci. Eng. 2014, 21, 481–488. [Google Scholar] [CrossRef]

- Ren, H.K.; Wang, A.M.; Li, C.F. Study on porosity characteristics of low-rank coal reservoirs based on nuclear magnetic resonance technology. Coal Sci. Technol. 2017, 45, 143–148. [Google Scholar]

- Xie, S.B.; Yao, Y.B.; Chen, J.Y. Research of micropore structure in coal reservoir using low–field NMR. J. China Coal Soc. 2015, 40, 170–176. [Google Scholar]

- Yang, M.; Liu, L.; Zhang, X.B. Nuclear magnetic resonance experimental study on pore structure and fluid characteristics of coal at different ranks. China Saf. Sci. J. 2021, 31, 81–88. [Google Scholar]

- Yao, Y.B.; Liu, D.M.; Cai, Y.D. Advanced characterization of pores and fractures in coals by nuclear magnetic resonance and X-ray computed tomography. Sci. China Earth Sci. 2010, 53, 854–862. [Google Scholar] [CrossRef]

| Sample Name | Depth (m) | Position | Ro, max | Macerals % | Mineral Base % | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | Vitrinite | Inertinite | Exinite | Clay | Sulfide | Carbonate | Oxides | Organic | |||

| LHG | 735 | J2x | 0.68 | 60.35 | 35.90 | 3.74 | 4.54 | 0.20 | 1.97 | 1.38 | 91.91 |

| Treatment Conditions/Coal Sample (Block) | SEM | LT-N2A | LF-NMR |

|---|---|---|---|

| LHG original coal sample (without negative pressure treatment) | 1 | 1 | 1 |

| Pressure (−0.015/−0.03/−0.045/−0.06/−0.075 MPa) | 5 | 5 | 5 |

| Negative Pressure | BET Specific Surface Area | Total Pore Volume | Average Pore Diameter | Pore Volume of Each Pore Diameter Section (cm³/g) | ||

|---|---|---|---|---|---|---|

| (m2/g) | (cm3/g) | (nm) | <10 nm | 10–100 nm | >100 nm | |

| −0.075 MPa | 10.0975 | 0.006094 | 2.7378 | 0.002318 | 0.002396 | 0.001380 |

| −0.060 MPa | 11.5472 | 0.007820 | 2.6896 | 0.003353 | 0.003492 | 0.000974 |

| −0.045 MPa | 11.2849 | 0.007315 | 2.6096 | 0.002940 | 0.003380 | 0.000994 |

| −0.030 MPa | 11.7648 | 0.007984 | 2.6483 | 0.003424 | 0.003568 | 0.000993 |

| −0.015 MPa | 11.4370 | 0.007422 | 2.5550 | 0.003051 | 0.003339 | 0.001033 |

| Negative Pressure | Relative Pressure P/P0: 0~0.5 | Relative Pressure P/P0: 0.5~1.0 | ||||

|---|---|---|---|---|---|---|

| α1 | D1 = 3 + α1 | R2 | α2 | D2 = 3 + α2 | R2 | |

| Original | −0.33553 | 2.66447 | 0.70369 | −0.08066 | 2.91934 | 0.72935 |

| −0.075 MPa | −0.33938 | 2.66062 | 0.60471 | −0.12469 | 2.87531 | 0.78772 |

| −0.06 MPa | −0.38512 | 2.61488 | 0.62945 | −0.12731 | 2.87269 | 0.76243 |

| −0.045 MPa | −0.3605 | 2.6395 | 0.57339 | −0.12256 | 2.87744 | 0.73404 |

| −0.03 MPa | −0.39323 | 2.60677 | 0.64851 | −0.12626 | 2.87374 | 0.77026 |

| −0.015 MPa | −0.37019 | 2.62981 | 0.61113 | −0.12024 | 2.87976 | 0.74442 |

| Negative Pressures | Adsorption Peak Relaxation Time (ms) | S (m2/g) | V (cm3/g) | ρ2 (10−8 m/ms) |

|---|---|---|---|---|

| −0.075 MPa | 5.174 | 10.0975 | 0.010061 | 1.9258 |

| −0.06 MPa | 3.458 | 11.5472 | 0.012335 | 3.0891 |

| −0.045 MPa | 3.914 | 11.2849 | 0.011690 | 2.6466 |

| −0.03 MPa | 3.895 | 11.7648 | 0.012543 | 2.7372 |

| −0.015 MPa | 3.895 | 11.4370 | 0.011873 | 2.6653 |

| Negative Pressures | Total Porosity (%) | T2C (ms) | BVI (%) | FFI (%) | Effective Porosity (%) | Bound Porosity (%) | Effective Void Ratio (%) |

|---|---|---|---|---|---|---|---|

| (a) Original | 18.166 | 10.723 | 83.572 | 16.428 | 3.385 | 14.781 | 18.634 |

| (b) −0.075 MPa | 23.114 | 14.175 | 79.301 | 20.699 | 6.068 | 17.046 | 26.252 |

| (c) −0.060 MPa | 24.037 | 12.329 | 12.329 | 87.671 | 4.39 | 19.647 | 18.264 |

| (d) −0.045 MPa | 24.717 | 6.136 | 68.409 | 31.591 | 9.379 | 15.338 | 37.946 |

| (e) −0.030 MPa | 24.743 | 7.055 | 68.16 | 31.84 | 9.797 | 14.946 | 39.595 |

| (f) −0.015 MPa | 24.126 | 14.175 | 77.747 | 22.253 | 6.781 | 17.345 | 28.107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Wang, M.; Zhao, X.; Dai, X.; He, Y. Study of the Microstructural Characteristics of Low-Rank Coal under Different Degassing Pressures. Energies 2022, 15, 3691. https://doi.org/10.3390/en15103691

Ma Y, Wang M, Zhao X, Dai X, He Y. Study of the Microstructural Characteristics of Low-Rank Coal under Different Degassing Pressures. Energies. 2022; 15(10):3691. https://doi.org/10.3390/en15103691

Chicago/Turabian StyleMa, Yuanzhen, Meng Wang, Xinzhuo Zhao, Xuguang Dai, and Ye He. 2022. "Study of the Microstructural Characteristics of Low-Rank Coal under Different Degassing Pressures" Energies 15, no. 10: 3691. https://doi.org/10.3390/en15103691

APA StyleMa, Y., Wang, M., Zhao, X., Dai, X., & He, Y. (2022). Study of the Microstructural Characteristics of Low-Rank Coal under Different Degassing Pressures. Energies, 15(10), 3691. https://doi.org/10.3390/en15103691