Oil Retention and Its Main Controlling Factors in Lacustrine Shales from the Dongying Sag, Bohai Bay Basin, Eastern China

Abstract

:1. Introduction

2. Samples and Experiments

2.1. Samples

2.2. Experiments

2.2.1. TOC Content and Rock-Eval Analysis

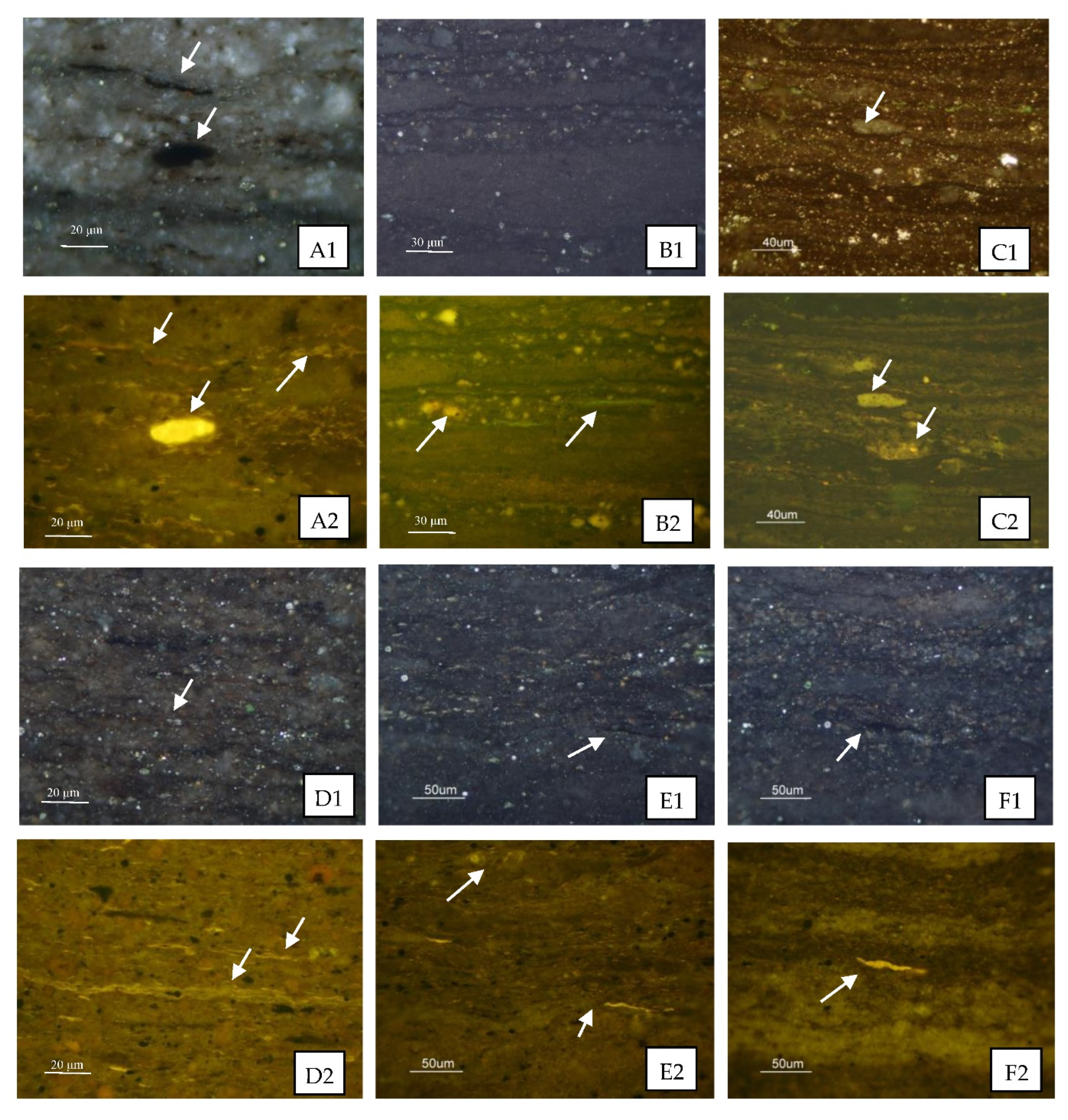

2.2.2. Organic Petrological Observation

2.2.3. Quantification of Soluble Organic Matter

2.2.4. Mineral Composition Analysis

2.2.5. Porosity and Pore Structure Analysis

3. Results and Discussion

3.1. Geochemical Characteristics of Samples

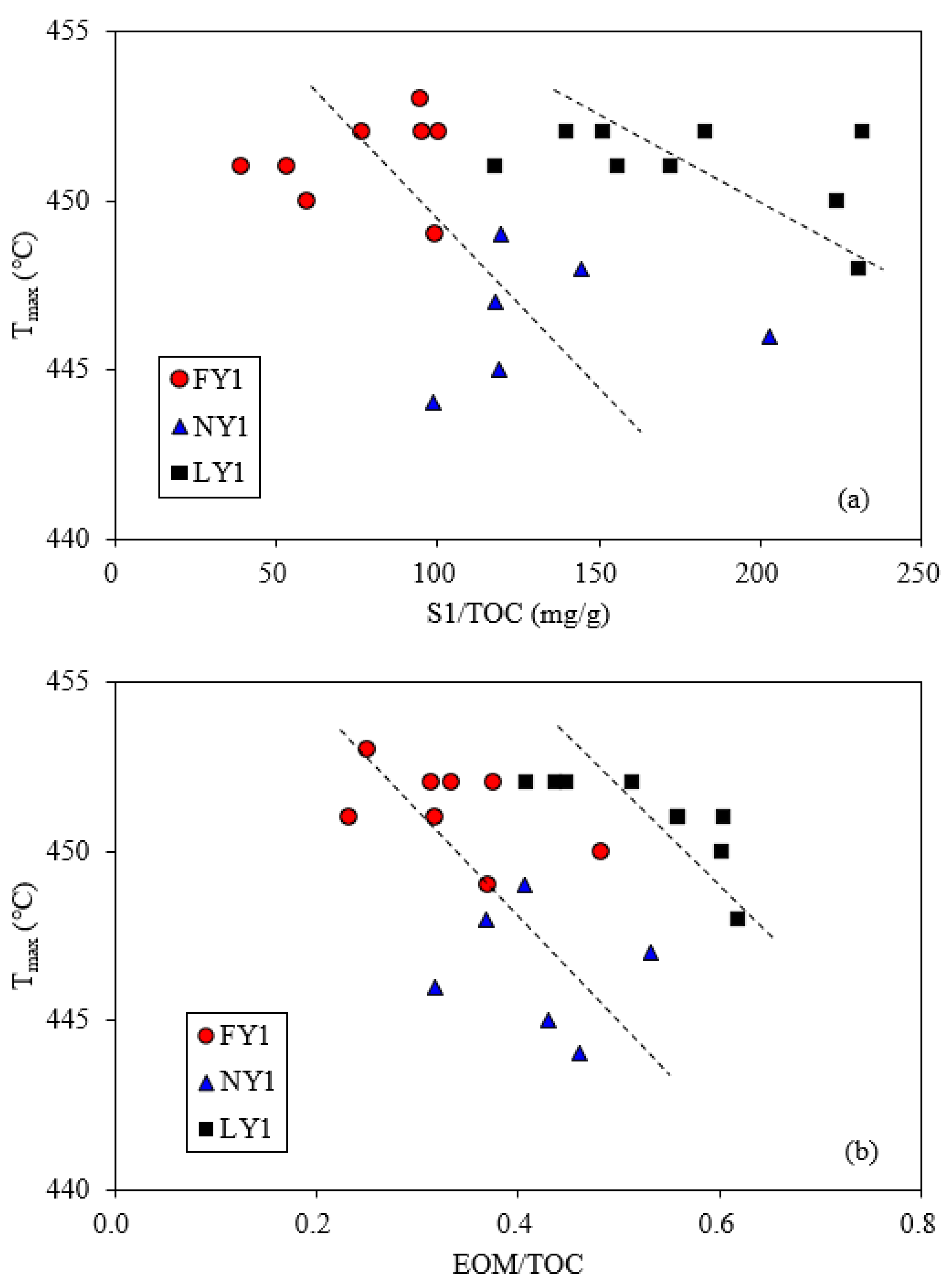

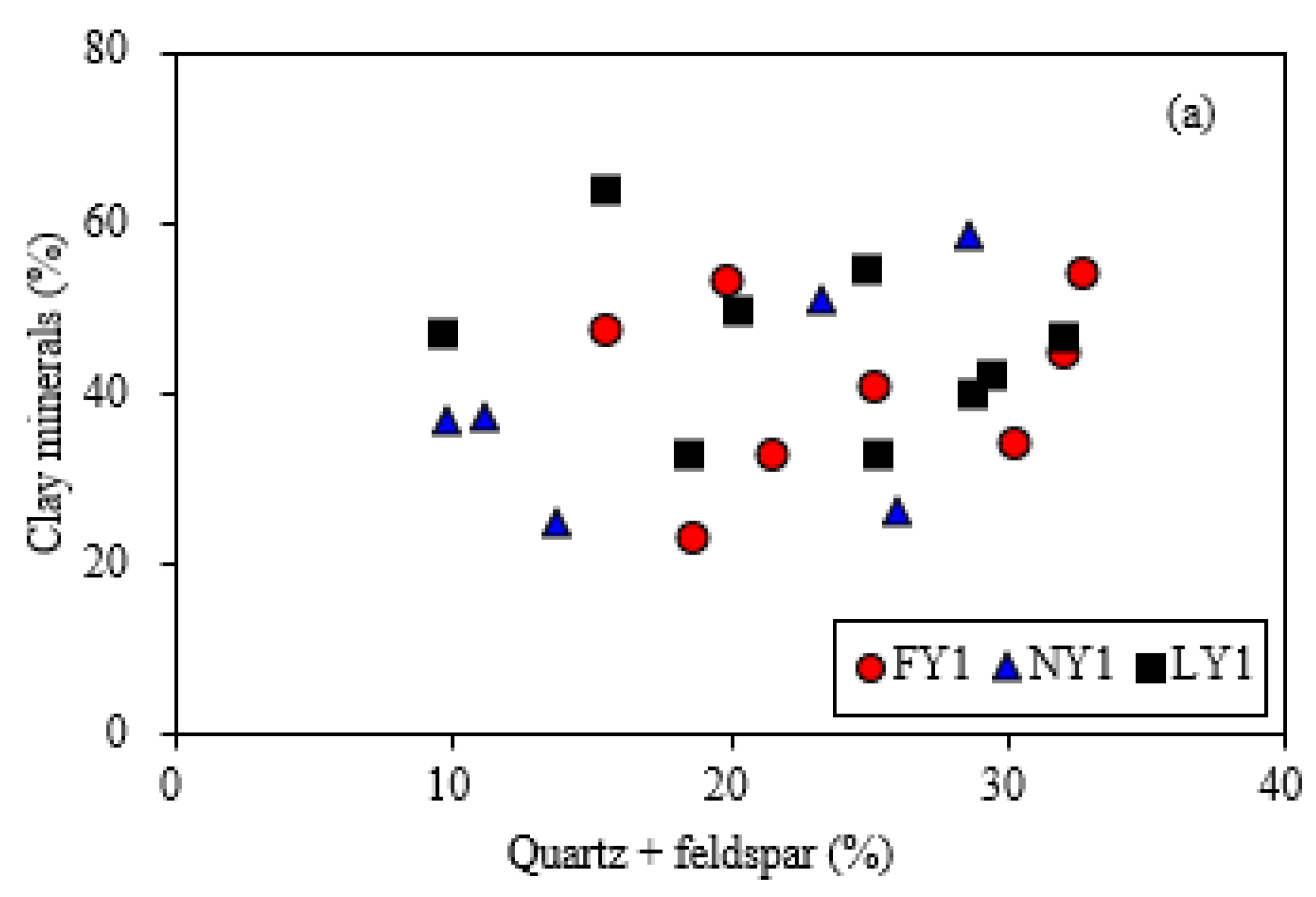

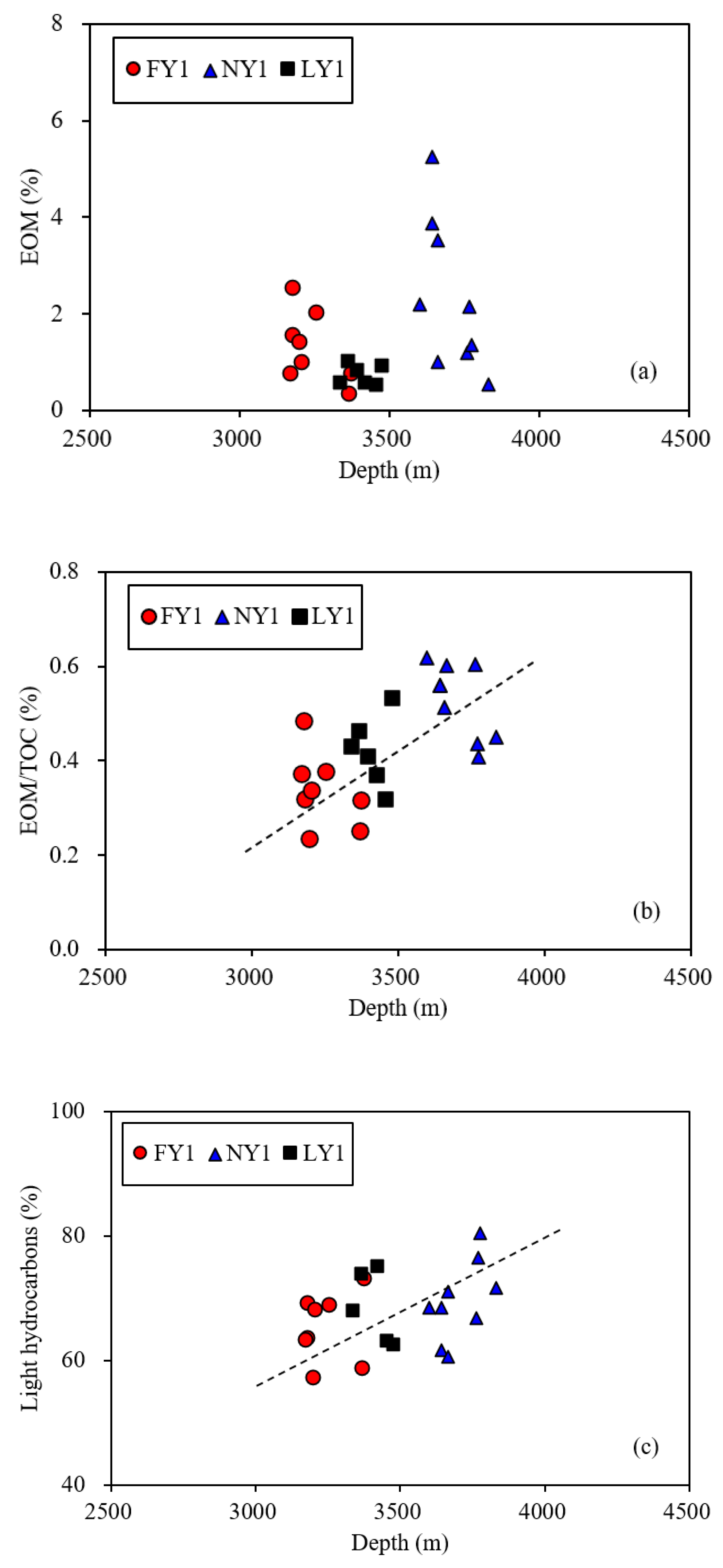

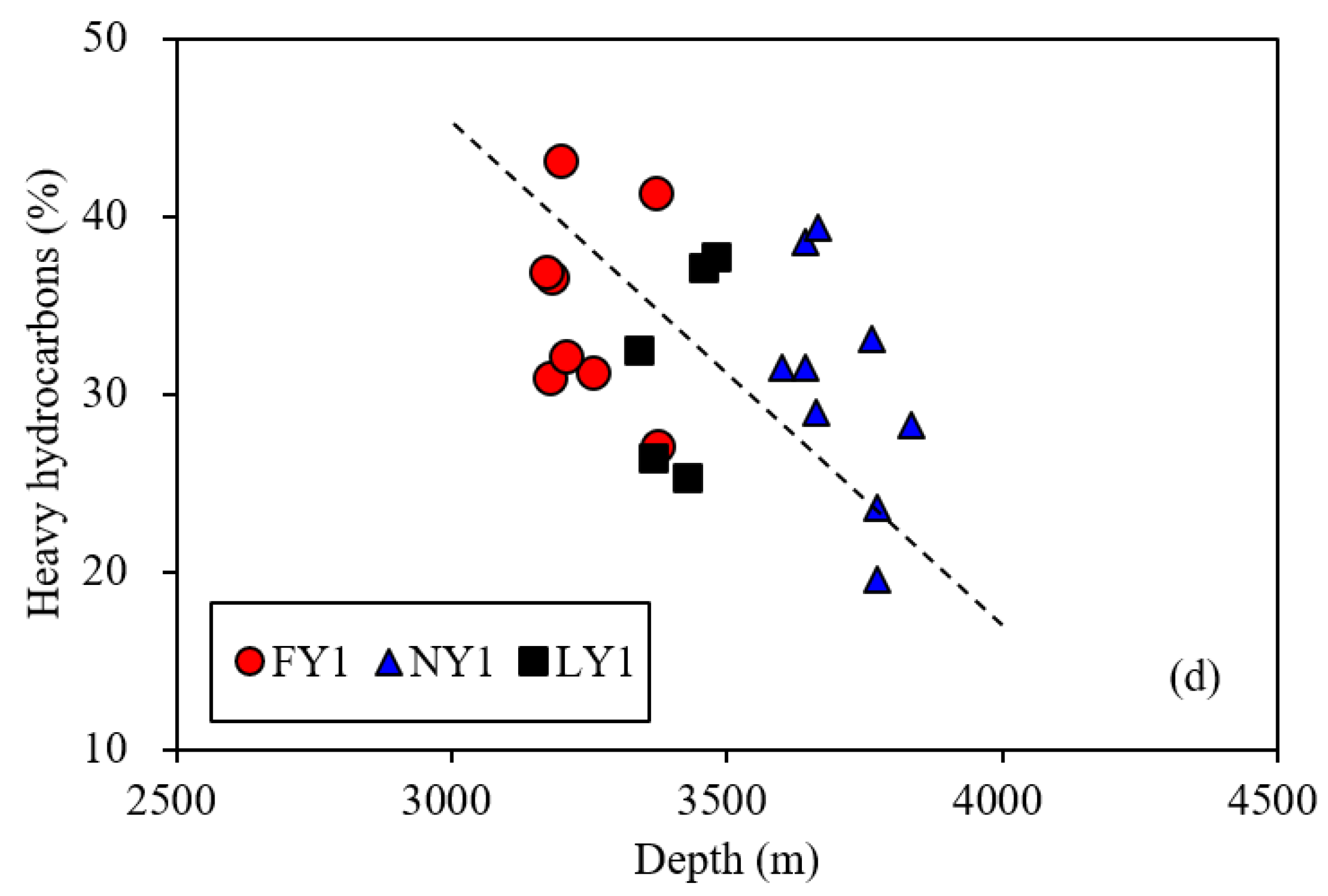

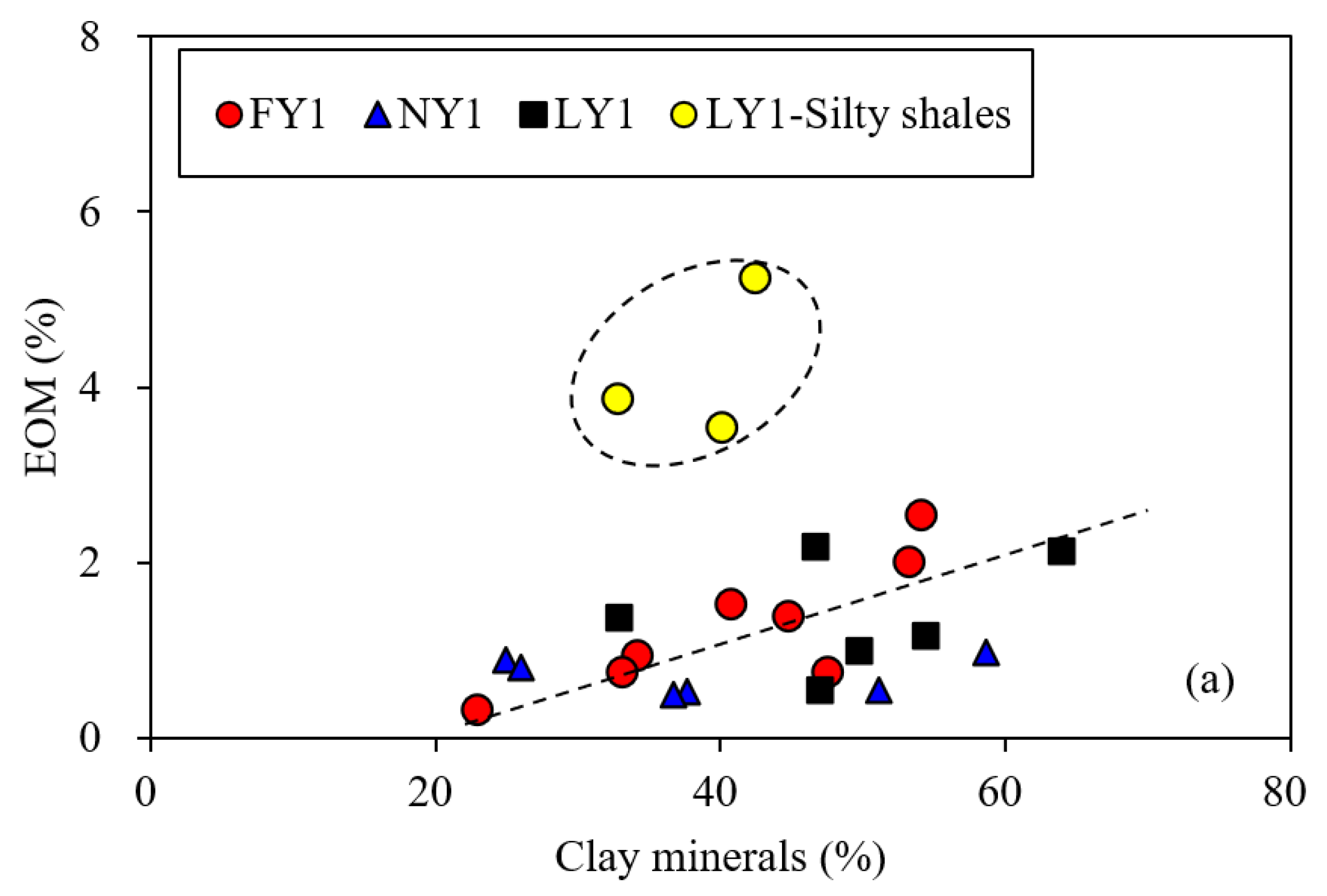

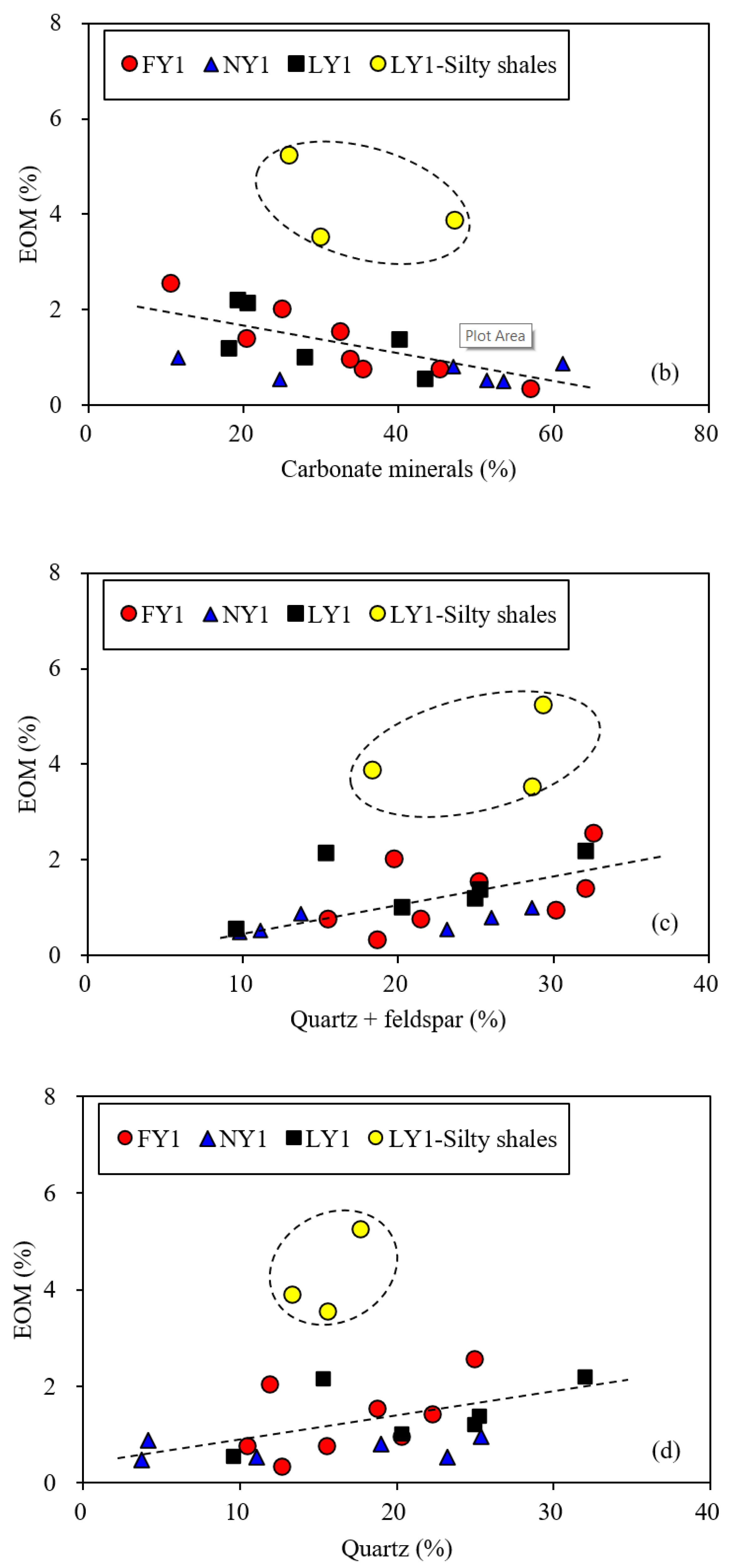

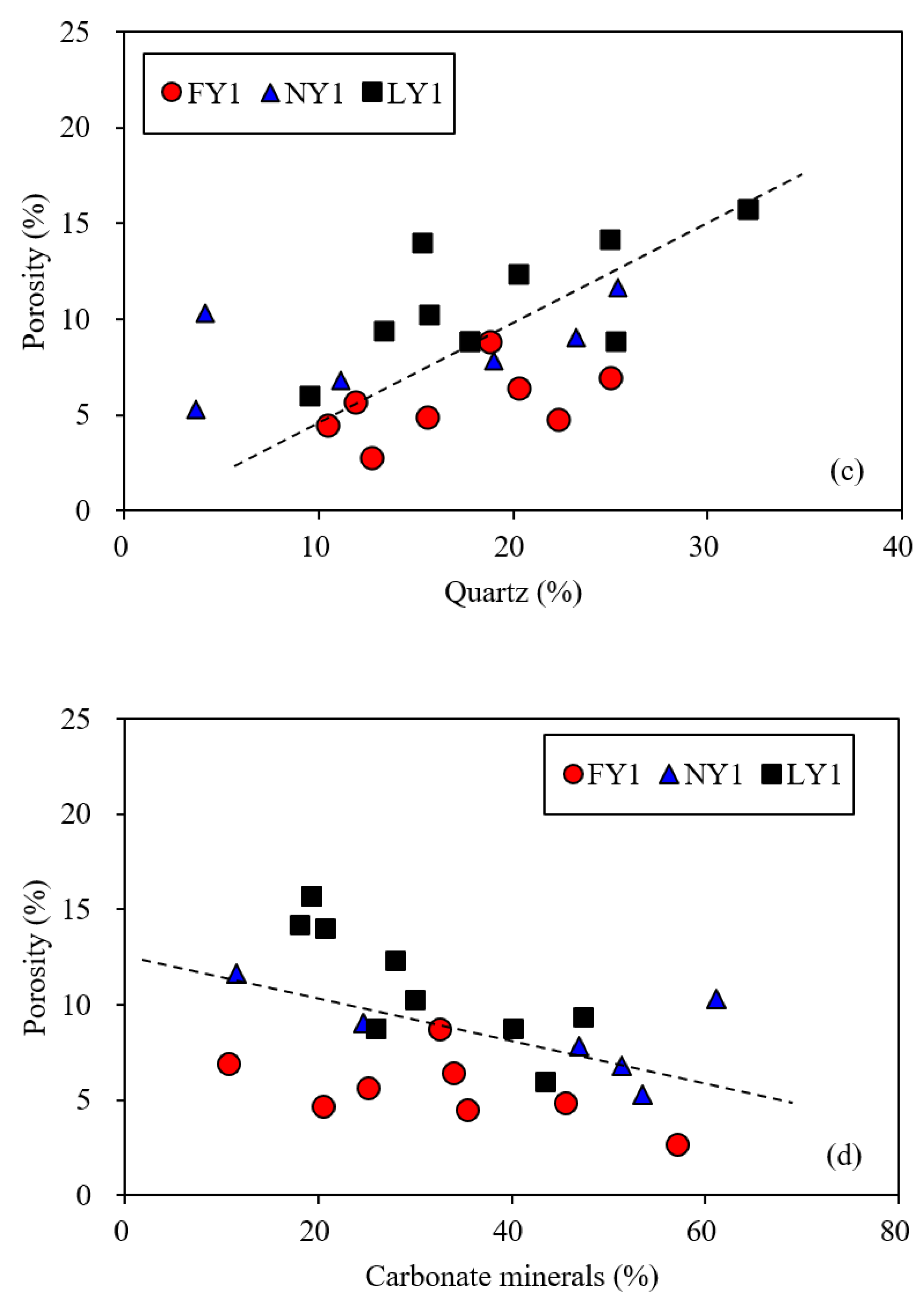

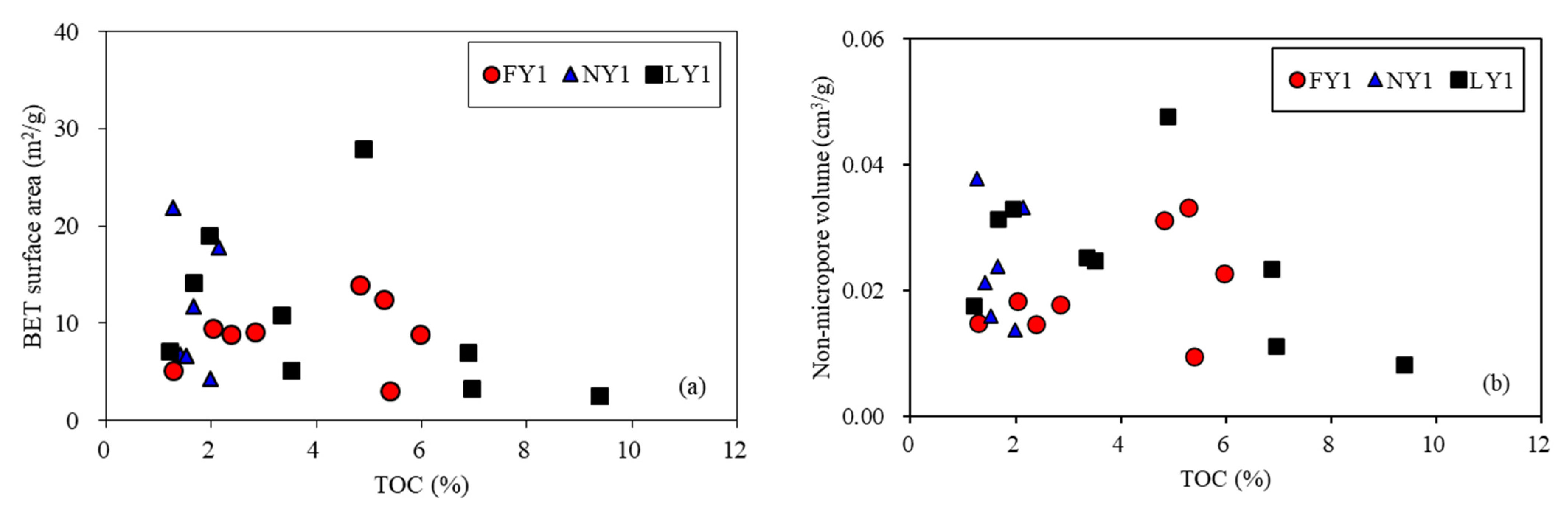

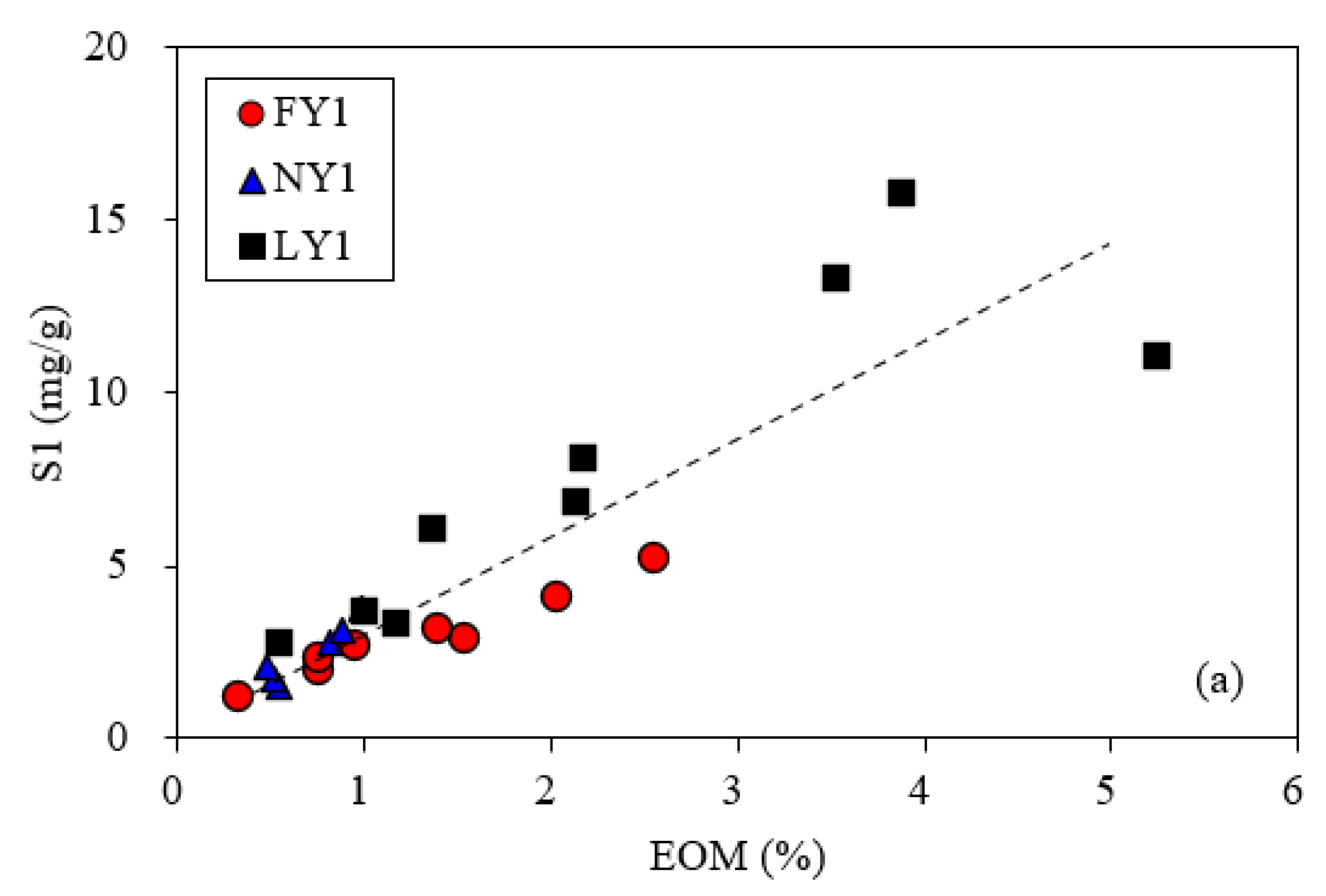

3.2. Controlling of Shale Compositions on Retained Oil

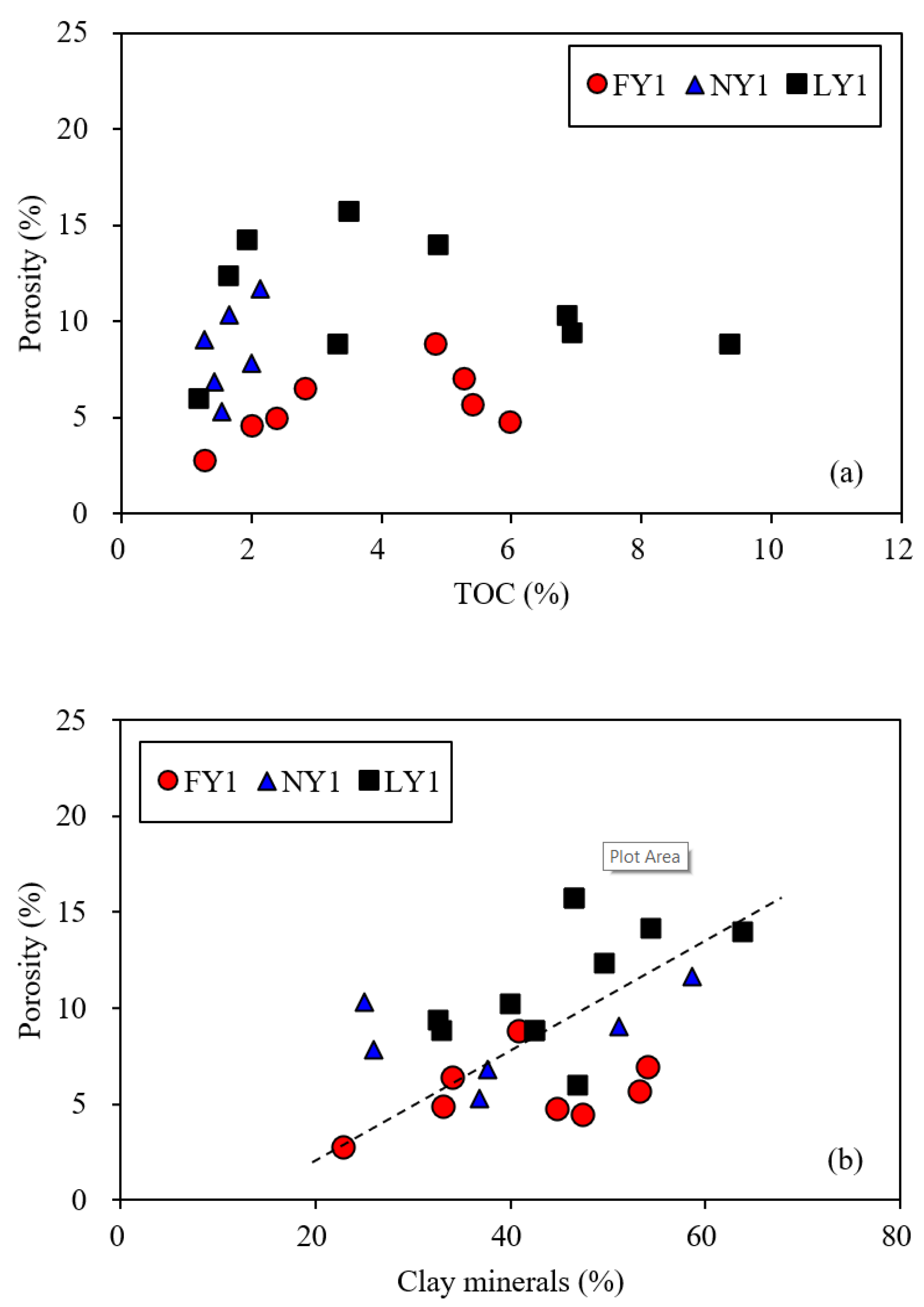

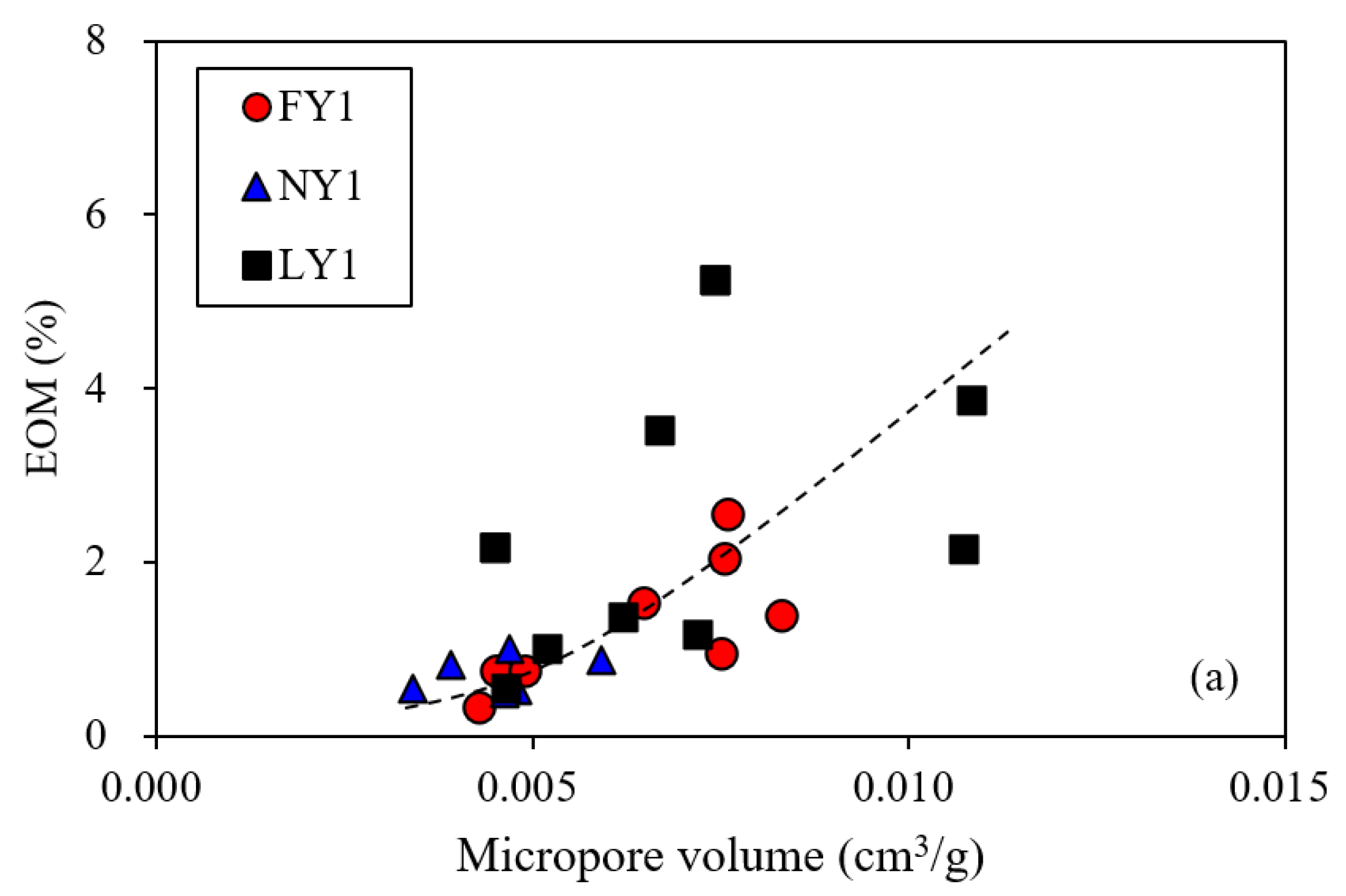

3.3. Pore Characteristics and Their Relationship with Retained Oil

3.4. Implications for Shale Oil Exploration and Development

4. Conclusions

- This set of shales has type I–IIa kerogen with plenty of lamalginite and its debris, and the maturity of these shales spans the main oil generation window with Ro values ranging from 0.70% to 1.0%. In addition, the non-micropores that are mainly developed by inorganic minerals are greater than the micropores that are largely contributed by organic matter.

- The retained oils are mostly stored in the organic matter micropores resulting from the volume swelling of kerogen. Moreover, the content and mobility of the retained oils in shales are mainly controlled by their burial depth.

- In the Dongying Sag, shales with burial depths of greater than 3500 m (Ro > 0.90%) are predicted to have shale oil development potential, especially for shales with a siltstone or carbonate rock interlayer and carbonate-rich shales with laminated or layered textures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Q.F.; Jin, Z.J.; Yang, G.F.; Dong, N.; Shang, Z.C. Current situation and prospect of shale oil exploration and development in the United States. Oil Gas Geol. 2019, 40, 469–477. (In Chinese) [Google Scholar]

- EIA. Natural Gas Weekly Update [EB/OL]. Available online: https://www.eia.gov/naturalgas/weekly (accessed on 21 February 2019).

- EIA. Weekly Petroleum Status Report [EB/OL]. Available online: https://www.eia.gov/petroleum/supply/weekly (accessed on 21 February 2019).

- Jin, Z.J.; Bai, Z.R.; Gao, B. Has China ushered in the shale oil and gas revolution? Oil Gas Geol. 2019, 40, 451–458, (In Chinese with English Abstract). [Google Scholar]

- Zou, C.N.; Zhao, Q.; Cong, C.C.; Wang, H.Y.; Shi, Z.S.; Wu, J.; Pan, S.Q. Progress, potential and prospect of shale gas development in China. Nat. Gas Ind. 2021, 41, 1–14. (In Chinese) [Google Scholar]

- Zhao, W.Z.; Hu, S.Y.; Hou, L.H.; Yang, T.; Li, X.; Guo, B.C.; Yang, Z. Types of continental shale oil and its resource potential and boundary with tight oil in China. Pet. Explor. Dev. 2020, 47, 1–10. (In Chinese) [Google Scholar] [CrossRef]

- Zou, C.N.; Yang, Z.; Cui, J.W. Formation mechanism, geological characteristics, and development strategy of non–marine shale oil in China. Pet. Explor. Dev. 2013, 40, 14–26. (In Chinese) [Google Scholar] [CrossRef]

- Fu, X. Current status, challenges and prospects of shale oil exploration and development in China. Oil Drill. Prod. Technol. 2015, 37, 58–62. (In Chinese) [Google Scholar]

- Wang, M.; Guo, Z.Q.; Jiao, C.X.; Lu, S.F.; Li, J.B.; Xue, H.T.; Li, J.J.; Li, J.Q.; Chen, G.H. Exploration progress and geochemical features of lacustrine shale oils in China. J. Pet. Sci. Eng. 2019, 178, 975–986. [Google Scholar] [CrossRef]

- Zhao, W.Z.; Zhu, R.K.; Hu, S.Y.; Hou, L.H.; Wu, S.T. Reservoir formation differences between continental organic rich shale and mudstone and its significance in shale oil evaluation. Pet. Explor. Dev. 2020, 47, 1–11. (In Chinese) [Google Scholar] [CrossRef]

- Sheng, X.; Chen, X.; Zhang, X.W.; Jia, Y.Y.; Luo, X. Prospects and challenges of continental shale oil development in China. Pet. Geol. Exp. 2015, 37, 267–271. (In Chinese) [Google Scholar]

- Zhang, L.Y.; Li, Z.; Li, J.Y. Exploitable oil and gas resources in Paleogene shale in Dongying Sag. Nat. Gas Geosci. 2012, 23, 1–13. (In Chinese) [Google Scholar]

- Zhu, R.F.; Zhang, L.Y.; Li, Z.; Wang, R.; Zhang, S.C.; Zhang, L. Evaluation of shale oil resource potential in continental faulted basins—A case study of the lower sub–member of Es3 formation in Dongying Sag. Pet. Geol. Recovery Effic. 2019, 26, 129–136. (In Chinese) [Google Scholar]

- Chen, S.Y.; Liu, Y.; Zhang, S. Microstructural Characteristics of Dongying Depression. Sci. Technol. Eng. 2015, 15, 35–47. (In Chinese) [Google Scholar]

- Xie, X.M.; Li, M.W.; Littke, R.; Huang, Z.K.; Ma, X.X.; Jiang, Q.; Snowdon, L.R. Petrographic and geochemical characterization of microfacies in a lacustrine shale oil system in the Dongying Sag, Jiyang Depression, Bohai Bay Basin, eastern China. Int. J. Coal Geol. 2016, 165, 49–63. [Google Scholar] [CrossRef]

- Ning, F.X.; Wang, X.J.; Hao, X.F.; Yang, W.Q.; Ding, J.H. Lithofacies association characteristics of fine–grained sedimentary rocks in Dongying Sag. J. Southwest Pet. Univ. (Nat. Sci. Ed.) 2020, 42, 55–65. (In Chinese) [Google Scholar]

- Liu, H.M.; Zhang, S.; Bao, Y.S.; Fang, Z.W.; Yao, S.P.; Wang, Y. Geological characteristics and effectiveness of shale oil reservoir in Dongying Sag. Oil Gas Geol. 2019, 40, 512–524. (In Chinese) [Google Scholar]

- Wang, H.J.; Wu, W.; Chen, T.; Yu, J.; Pan, J.N. Pore structure and fractal analysis of shale oil reservoirs: A case study of the Paleogene Shahejie Formation in the Dongying Depression, Bohai Bay, China. J. Pet. Sci. Eng. 2019, 177, 711–718. [Google Scholar] [CrossRef]

- Zhang, P.F.; Lu, S.F.; Li, J.Q. Characterization of pore size distributions of shale oil reservoirs: A case study from Dongying Sag, Bohai Bay basin, China. Mar. Pet. Geol. 2019, 100, 297–308. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, F.M.; Wang, M.; Liu, X.J.; Liu, H.L.; Bao, Y.S.; Wang, W.Q.; Li, R.Z.; Luo, X.; Fang, Z.W. Shale pore characteristics of Shahejie Formation: Implication for pore evolution of shale oil reservoirs in Dongying Sag, north China. Pet. Res. 2019, 4, 113–124. [Google Scholar] [CrossRef]

- Zhang, S.L.; Yan, J.P.; Hu, Q.H.; Wang, J.; Tian, T.H.; Chao, J.; Wang, M. Integrated NMR and FE–SEM methods for pore structure characterization of Shahejie shale from the Dongying Depression, Bohai Bay Basin. Mar. Pet. Geol. 2019, 100, 85–94. [Google Scholar] [CrossRef]

- Zhang, P.F.; Lu, S.F.; Li, J.Q.; Chang, X.C.; Li, J.J.; Li, W.B.; Chen, G.; Wang, S.; Feng, W.J. Broad ion beam–scanning electron microscopy pore microstructure and multifractal characterization of shale oil reservoir: A case sample from Dongying Sag, Bohai Bay Basin, China. Energy Explor. Exploit. 2020, 38, 613–628. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.Y.; Bao, Y.S.; Li, J.Y.; Li, Z.; Zhu, R.F.; Zhang, J.G. Mobility of lacustrine shale oil—A case study of Dongying Sag of Jiyang Depression in Bohai Bay Basin. Oil Explor. Dev. 2014, 41, 641–649. (In Chinese) [Google Scholar]

- Hu, Q.H.; Zhang, Y.X.; Meng, X.H.; Li, Z.; Xie, Z.H.; Li, M.W. Characterization of micro–nano pore networks in shale oil reservoirs of Paleogene Shahejie Formation in Dongying Sag of Bohai Bay Basin, East China. Pet. Explor. Dev. 2017, 44, 720–730. [Google Scholar] [CrossRef]

- Sun, H.Q. Exploration practice and cognitions of shale oil in Jiyang Depression. China Pet. Explor. 2017, 22, 1. (In Chinese) [Google Scholar]

- Wang, M.; Ma, R.; LIJ, B.; Lu, S.F.; Li, C.M.; Guo, Z.Q.; Li, Z. Occurrence mechanism of lacustrine shale oil in the Paleogene Shahejie Formation of Jiyang Depression, Bohai Bay Basin, China. Pet. Explor. Dev. 2019, 46, 833–846. [Google Scholar] [CrossRef]

- Zhang, S. Shale oil enrichment elements and geological dessert types in Jiyang Depression. Sci. Technol. Eng. 2021, 21, 504–511. (In Chinese) [Google Scholar]

- He, J.Y.; CaiIJ, G.; Lei, T.Z.; Zhang, S.P.; Zhang, C.X. The characteristics of soluble organic matter and shale oil dessert prediction. Pet. Geol. Recovery Effic. 2019, 26, 174–183. [Google Scholar]

- Li, M.W.; Chen, Z.H.; Ma, X.X.; Cao, T.T.; Qian, M.H.; Jiang, Q.G.; Tao, G.L.; Li, Z.N.; Song, G.Q. Shale oil resource potential and oil mobility characteristics of the Eocene-Oligocene Shahejie Formation, Jiyang Super-Depression, Bohai Bay Basin of China. Int. J. Coal Geol. 2019, 204, 130–143. [Google Scholar] [CrossRef]

- Song, M.S.; Liu, H.M.; Wang, Y.; Liu, Y.L. Enrichment rules and exploration practices of Paleogene shale oil in Jiyang Depression, Bohai Bay Basin, China. Pet. Explor. Dev. 2020, 47, 242–253. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.M.; Liu, Y.L.; Wang, Y.S.; Wang, M.; Bao, Y.S.; Hu, Q.H.; Li, Z.; Zhang, S.P.; Yao, S.P.; et al. Main controls and geological sweet spot types in Paleogene shale oil rich areas of the Jiyang Depression, Bohai Bay basin, China. Mar. Pet. Geol. 2020, 111, 576–587. [Google Scholar] [CrossRef]

- Liu, H.M.; Zhang, S.; Song, G.Q.; Wang, X.J.; Teng, J.B.; Wang, M.; Bao, Y.S.; Yao, S.P.; Wang, W.Q.; Zhang, S.P.; et al. Effect of shale diagenesis on pores and storage capacity in the Paleogene Shahejie Formation, Dongying Depression, Bohai Bay Basin, east China. Mar. Pet. Geol. 2019, 103, 738–752. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, X.M.; Cheng, P.; Tian, H. Formation and evolution of nanopores in shales and its impact on retained oil during oil generation and expulsion based on pyrolysis experiments. J. Pet. Sci. Eng. 2019, 176, 509–520. [Google Scholar] [CrossRef]

- Ning, F.X. Difference analysis on different types of shale oils in Jiyang depression. Pet. Geol. Recov. Effic. 2014, 21, 6–9. (In Chinese) [Google Scholar]

- Song, M.S. Shale oil exploration practice and current situation in Jiyang Depression. Pet. Geol. Recovery Effic. 2019, 26, 1–12. (In Chinese) [Google Scholar]

- Sun, H.Q.; Cai, X.Y.; Zhou, D.H.; Gao, B.; Zhao, P.R. Sinopec shale oil exploration practice and prospect. China Pet. Explor. 2019, 24, 569–575. (In Chinese) [Google Scholar]

- Liu, Y.L.; Zhang, S.; Liu, H.M.; Wang, W.Q.; Bao, Y.S.; Tang, D.; Liu, P.; Wang, Y.; Li, Z.; Wang, M.; et al. Basic characteristics and exploration prospect of organic–rich shales in steep slope zone of faulted basin—A case study of Jiyang Depression. J. China Univ. Min. Technol. 2021, 50, 1146–1156. (In Chinese) [Google Scholar]

- Behar, F.; Beaumont, V.; De Penteado, B. Rock-Eval 6 technology: Performances and developments. Oil Gas Sci. Technol. 2001, 56, 111–134. [Google Scholar] [CrossRef]

- Taylor, G.H.; Teichmüller, M.; Davis, A.; Diessel, C.F.K.; Littke, R.; Robert, P. Organic Petrology; Gebrüder Borntraeger: Berlin, Germany, 1998. [Google Scholar]

- Tang, X.; Zhang, J.C.; Jiang, Z.X.; Zhao, X.Z.; Liu, K.Y.; Zhang, R.F.; Xiong, J.Y.; Du, K.F.; Huang, Z.L.; Yu, J.D. Characteristics of solid residue, expelled and retained hydrocarbons of lacustrine marlstone based on semi-closed system hydrous pyrolysis: Implications for tight oil exploration. Fuel 2015, 162, 186–193. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Zavalij, P.Y. Fundamentals of Powerder Diffraction and Structural Characterization of Minerals; Kluwer Academic Publishers: New York, NY, USA, 2003; p. 713. [Google Scholar]

- Chalmers, G.R.L.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doigunits. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar] [CrossRef]

- Pan, L.; Xiao, X.; Tian, H.; Zhou, Q.; Cheng, P. Geological models of gas in place of the Longmaxi shale in Southeast Chongqing, South China. Mar. Pet. Geol. 2016, 73, 433–444. [Google Scholar] [CrossRef]

- Cheng, P.; Tian, H.; Xiao, X.M.; Gai, H.F.; Li, T.F.; Wang, X. Water distribution in overmature organic–rich shales: Implications from water adsorption experiments. Energy Fuels 2017, 31, 13120–13132. [Google Scholar] [CrossRef]

- Wu, L.Y.; Gu, X.Z.; Sheng, Z.W.; Fan, C.L.; Cheng, K.M. Rapid Quantitative Evaluation of Pyrolysis of Oil Source Rocks; Science Press: Beijing, China, 1986; pp. 1–198. [Google Scholar]

- Snowdon, L.R. Rock-Eval Tmax suppression: Documentation and amelioration. AAPG Bull. 1995, 79, 1337–1348. [Google Scholar]

- Cao, Z.; Liu, G.; Kong, Y.; Wang, C.; Niu, Z.; Zhang, J.; Geng, C.; Shan, X.; Wei, Z. Lacustrine tight oil accumulation characteristics: Permian Lucaogou formation in Jimusaer Sag, Junggar Basin. Int. J. Coal Geol. 2016, 153, 37–51. [Google Scholar] [CrossRef]

- Lo, H.B. Correction criteria for the suppression of vitrinite reflectance in hydrocarbon-rich kerogen: Preliminary guidelines. Org. Geochem. 1993, 20, 653–670. [Google Scholar] [CrossRef]

- Guo, R.T.; Wang, J.B.; Gao, X.L.; Lu, H.Y.; Xiao, X.M. Application of laser probe technology to evaluate the maturity of source rocks—A case study of source rocks in Dongying sag. Prog. Nat. Sci. 2003, 13, 626–630. (In Chinese) [Google Scholar]

- Yan, Y.H.; Zou, Y.R.; Qu, Z.Y.; Cai, Y.L.; Wei, Z.F.; Peng, P.A. Experimental study on hydrocarbon retention and expulsion of source rocks in the fourth member of Shahejie Formation in the Dongying Sag. Geochemistry 2015, 44, 79–86. (In Chinese) [Google Scholar]

- Li, Z. Comparison of oil bearing and mobility of shale with different lithology in continental basin—A case study of the upper member of Forth section of Paleogene Shahejie Formation in Dongying Sag of Bohai Bay Basin. Pet. Exp. Geol. 2020, 42, 545–552. (In Chinese) [Google Scholar]

- Hua, B.; Zeng, J.Q. Carbonate genesis and geological significance of shale in Dongying Sag. Fault–Block Oil Gas Field 2019, 26, 453–458. (In Chinese) [Google Scholar]

- Teng, J.B. Origin and evidence of calcite in shale oil reservoir of Dongying Sag. Pet. Geol. Recovery Effic. 2020, 27, 18–26. (In Chinese) [Google Scholar]

- Li, Z.; Zou, Y.R.; Xu, X.Y.; Sun, J.N.; Li, M.W.; Peng, P.A. Adsorption of mudstone source rock for shale oil-Experiments, model and a case study. Org. Geochem. 2016, 92, 55–62. [Google Scholar] [CrossRef]

- Han, Y.J.; Mahlstedt, N.; Horsfield, B. The Barnett Shale: Compositional fractionation associated with intraformational petroleum migration, retention, and expulsion. AAPG Bull. 2015, 99, 2173–2202. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Lu, Z.Y.; Feng, M.S.; Wang, J.; Tian, T.H.; Chao, J. Microscopic pore characteristics of shale oil reservoir in the Shahejie Formation, Dongying Sag, Bohai Bay Basin. Acta Geol. Sin. 2017, 91, 629–644. (In Chinese) [Google Scholar]

- Zhang, S.; Liu, H.M.; Song, G.Q.; Wang, Y.S.; Chen, S.Y.; Zhang, S.P. Causes and control factors of shale oil reservoir space in the Dongying Sag. Acta Pet. Sin. 2016, 37, 495–508. (In Chinese) [Google Scholar]

- Jarvie, D.M. Shale resource systems for oil and gas: Part 2 Shale oil resource systems. In Shale Reservoirs-Giant Resources for the 21st Century: AAPG Memoir; Breye, J.A., Ed.; Worldwide Geochemistry, LLC: Humble, TX, USA, 2012; Volume 97, pp. 89–119. [Google Scholar]

- Fathy, D.; Wagreich, M.; Ntaflos, T.; Sami, M. Paleoclimatic variability in the southern Tethys, Egypt: Insights from the mineralogy and geochemistry of Upper Cretaceous lacustrine organic-rich deposits. Cretac. Res. 2021, 126, 104880. [Google Scholar] [CrossRef]

- Curtis, J.B. Fractured shale gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett shale of north central Texas as one model for thermogenic shale-gas assessment. AAPG Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Gensterblum, Y.; Ghanizadeh, A.; Cuss, R.J.; Amann-Hildenbrand, A.; Krooss, B.M.; Clarkson, C.R.; Harrington, J.F.; Zoback, M.D. Gas transport and storage capacity in shale gas reservoirs–A review. Part A: Transport processes. J. Unconv. Oil Gas Resour. 2015, 12, 87–122. [Google Scholar] [CrossRef]

- Yassin, M.R.; Dehghanpour, H.; Wood, J.; Lan, Q. A theory for relative permeability of unconventional rocks with dual-wettability pore network. SPE J. 2016, 21, 1970–1980. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C.G. Permeability measurement of the fracture-matrix system with 3D embedded discrete fracture model. Pet. Sci. 2022; in press. [Google Scholar] [CrossRef]

- Gasparik, M.; Bertier, P.; Gensterblum, Y.; Ghanizadeh, A.; Krooss, B.M.; Littke, R. Geological controls on themethane storage capacity in organic-rich shales. Int. J. Coal Geol. 2014, 123, 34–51. [Google Scholar] [CrossRef]

- Cheng, P.; Xiao, X.M.; Wang, X.; Sun, J.; Wei, Q. Evolution of water content in organic-rich shales with increasing maturity and its controlling factors: Implications from a pyrolysis experiment on a water-saturated shale core sample. Mar. Petrol. Geol. 2019, 109, 291–303. [Google Scholar] [CrossRef]

- Cheng, P.; Xiao, X.M.; Tian, H.; Gai, H.F.; Zhou, Q.; Li, T.F.; Fan, Q.Z. Differences in the distribution and occurrence phases of pore water in various nanopores of marine-terrestrial transitional shales in the Yangquan area of the northeast Qinshui Basin, China. Mar. Pet. Geol. 2022, 137, 105510. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B. Formation damage issues impacting the productivity of low permeability, low initial water saturation gas producing formations. J. Energy Resour. Technol. 2005, 127, 240–247. [Google Scholar] [CrossRef]

- Ambrose, R.J.; Hartman, R.C.; Campos, M.D.; Akkutlu, I.Y.; Sondergeld, C.H. New Pore-Scale Considerations for Shale Gas in Place Calculations; Society of Petroleum Engineers: Richardson, TX, USA, 2010; pp. 1–17. [Google Scholar]

- Cheng, P.; Xiao, X.M.; Tian, H.; Wang, X. Water content and equilibrium saturation and their influencing factors of the Lower Paleozoic overmature organicrich shales in the Upper Yangtze Region of Southern China. Energy Fuels 2018, 32, 11452–11466. [Google Scholar] [CrossRef]

| Sample Information | TOC (%) | S1 (mg/g) | S2 (mg/g) | Tmax (°C) | HI (mg/gTOC) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Well | Name | Formation | Depth (m) | Lithology | |||||

| FY1 | FY1-1 | ES33 | 3172 | Shale | 2.02 | 2.01 | 6.22 | 449 | 307 |

| FY1-2 | ES33 | 3180 | Shale | 5.28 | 5.24 | 18.89 | 450 | 358 | |

| FY1-3 | ES33 | 3183 | Shale | 4.82 | 2.9 | 25.76 | 451 | 534 | |

| FY1-4 | ES33 | 3200 | Shale | 5.97 | 3.18 | 36.19 | 451 | 606 | |

| FY1-5 | ES33 | 3209 | Shale | 2.83 | 2.7 | 11.58 | 452 | 409 | |

| FY1-6 | ES41 | 3257 | Shale | 5.4 | 4.13 | 21.11 | 452 | 391 | |

| FY1-7 | ES41 | 3373 | Shale | 1.28 | 1.21 | 2.33 | 453 | 182 | |

| FY1-8 | ES41 | 3376 | Shale | 2.38 | 2.39 | 3.97 | 452 | 167 | |

| NY1 | NY1-1 | ES33 | 3342 | Shale | 1.27 | 1.51 | 6.12 | 445 | 482 |

| NY1-2 | ES33 | 3368 | Shale | 2.13 | 3.76 | 12.56 | 444 | 589 | |

| NY1-3 | ES33 | 3398 | Shale | 1.99 | 2.78 | 9.52 | 449 | 478 | |

| NY1-4 | ES41 | 3429 | Shale | 1.42 | 1.7 | 8.42 | 448 | 595 | |

| NY1-5 | ES41 | 3459 | Shale | 1.52 | 2.09 | 5.69 | 446 | 373 | |

| NY1-6 | ES41 | 3482 | Shale | 1.66 | 3.13 | 6.08 | 447 | 366 | |

| LY1 | LY1-1 | ES33 | 3600 | Shale | 3.51 | 8.11 | 14.06 | 448 | 400 |

| LY1-2 | ES33 | 3642 | Silty shale * | 9.38 | 11.08 | 33.58 | 451 | 358 | |

| LY1-3 | ES33 | 3643 | Silty shale * | 6.94 | 15.83 | 20.61 | 451 | 297 | |

| LY1-4 | ES33 | 3660 | Silty shale * | 6.87 | 13.37 | 18.67 | 452 | 272 | |

| LY1-5 | ES33 | 3665 | Shale | 1.66 | 3.71 | 4.64 | 450 | 279 | |

| LY1-6 | ES41 | 3764 | Shale | 1.94 | 3.35 | 3.96 | 451 | 204 | |

| LY1-7 | ES41 | 3772 | Shale | 4.89 | 6.86 | 7.88 | 452 | 161 | |

| LY1-8 | ES41 | 3774 | Shale | 3.34 | 6.12 | 3.31 | 452 | 99 | |

| LY1-9 | ES41 | 3835 | Shale | 1.2 | 2.78 | 2.23 | 452 | 186 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, P.; Xiao, X.; Fan, Q.; Gao, P. Oil Retention and Its Main Controlling Factors in Lacustrine Shales from the Dongying Sag, Bohai Bay Basin, Eastern China. Energies 2022, 15, 4270. https://doi.org/10.3390/en15124270

Cheng P, Xiao X, Fan Q, Gao P. Oil Retention and Its Main Controlling Factors in Lacustrine Shales from the Dongying Sag, Bohai Bay Basin, Eastern China. Energies. 2022; 15(12):4270. https://doi.org/10.3390/en15124270

Chicago/Turabian StyleCheng, Peng, Xianming Xiao, Qizhang Fan, and Ping Gao. 2022. "Oil Retention and Its Main Controlling Factors in Lacustrine Shales from the Dongying Sag, Bohai Bay Basin, Eastern China" Energies 15, no. 12: 4270. https://doi.org/10.3390/en15124270