Properties of Lightweight Controlled Low-Strength Materials Using Construction Waste and EPS for Oil and Gas Pipelines

Abstract

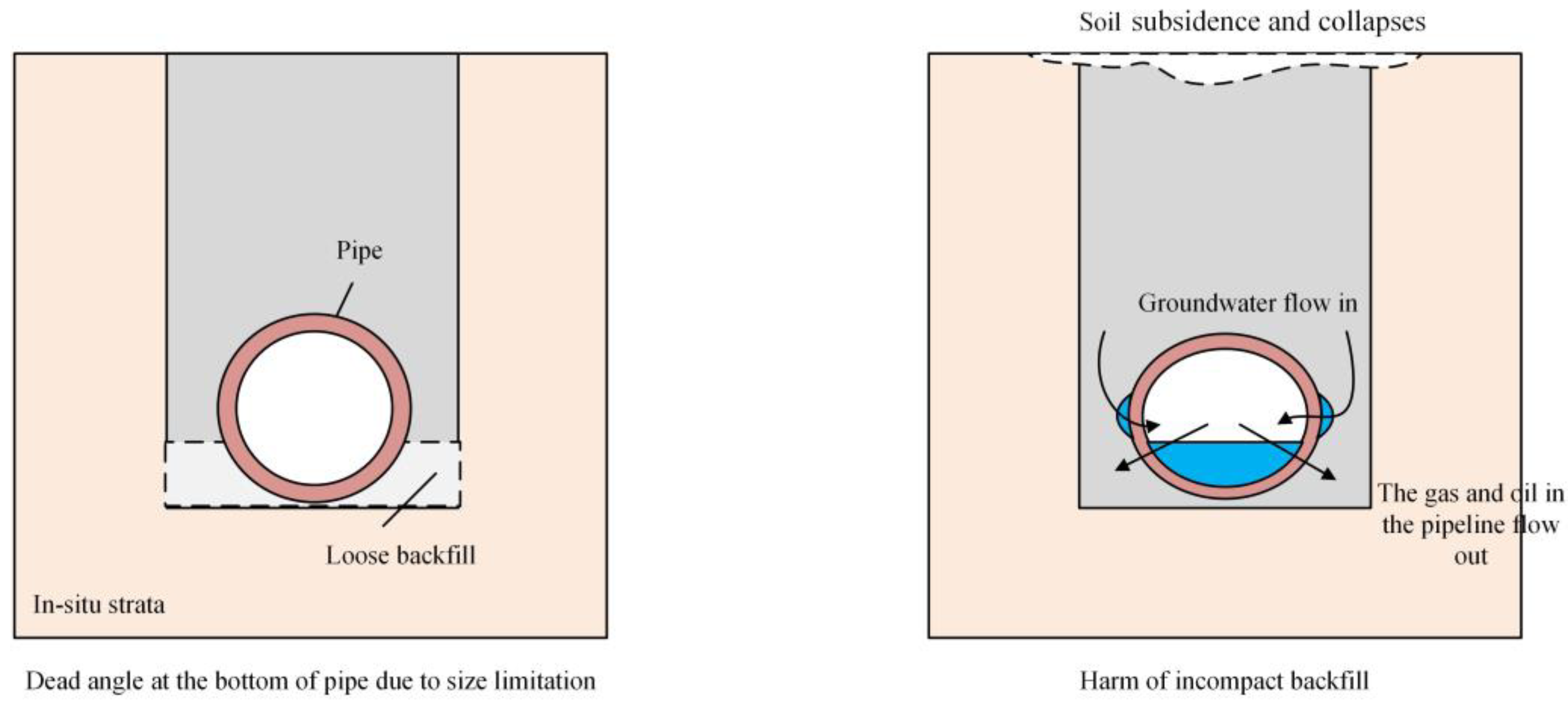

:1. Introduction

2. Experimental Investigation

2.1. Materials

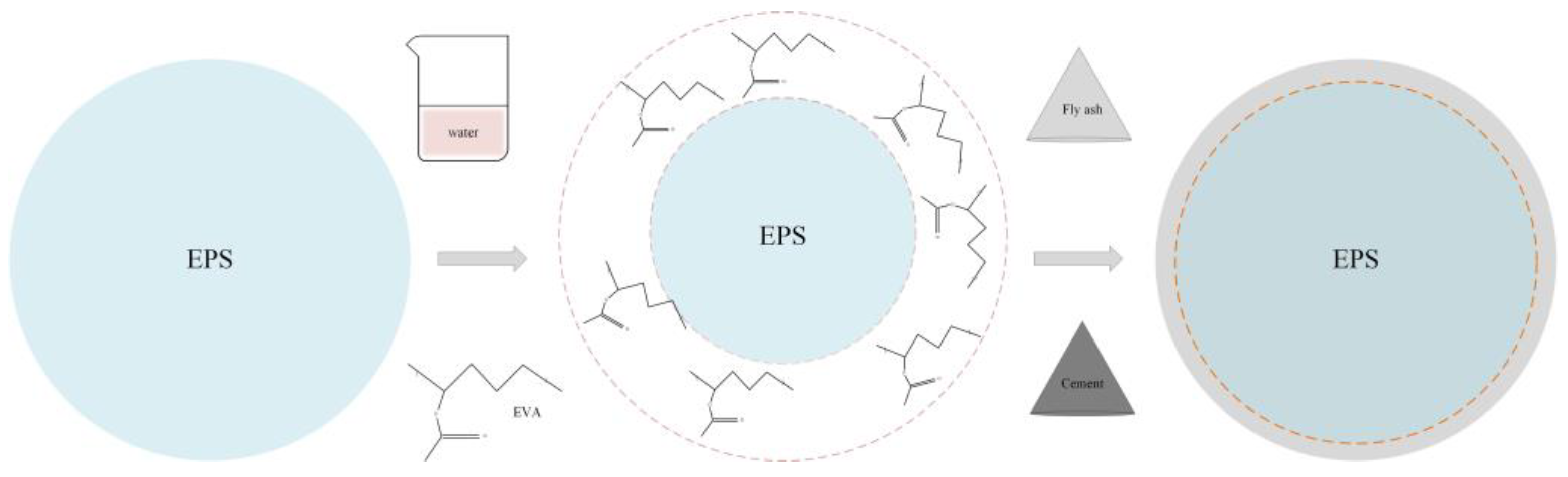

2.2. EPS Surface Modification Process

2.3. Test Method

2.4. Mix Proportion of CLSM

3. Results

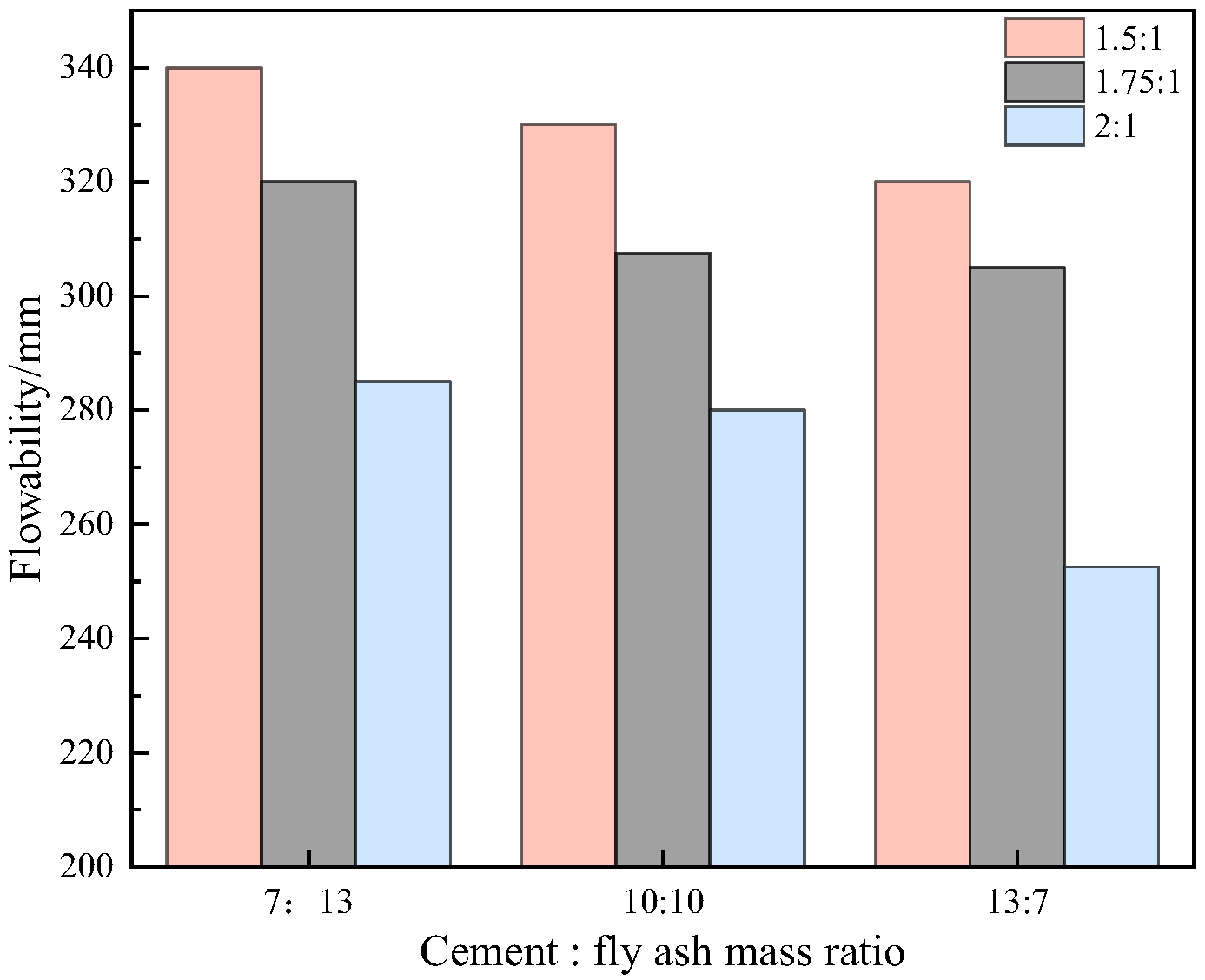

3.1. Fluidity

3.2. Bleeding Rate

3.3. Wet Density

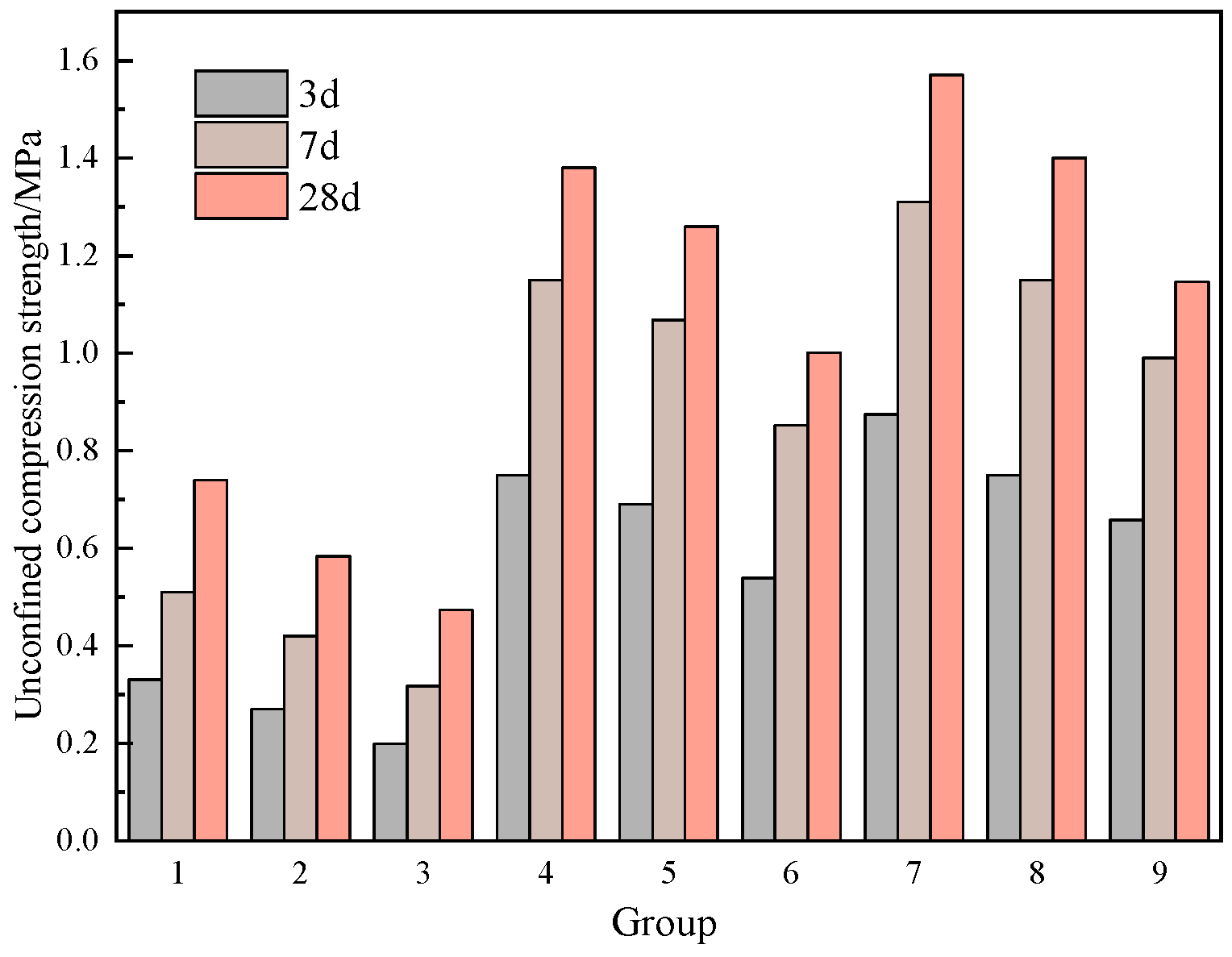

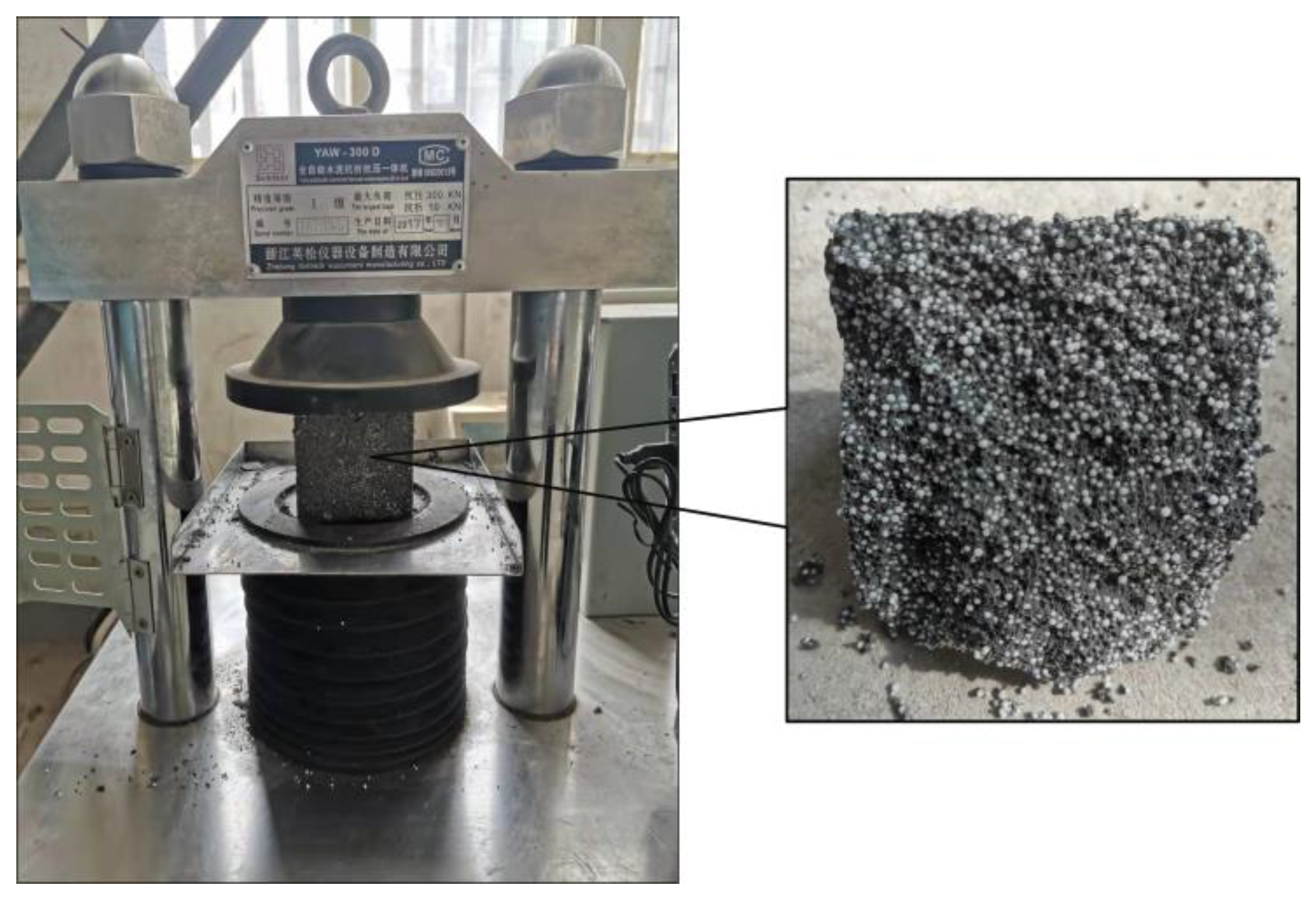

3.4. Unconfined Compressive Strength

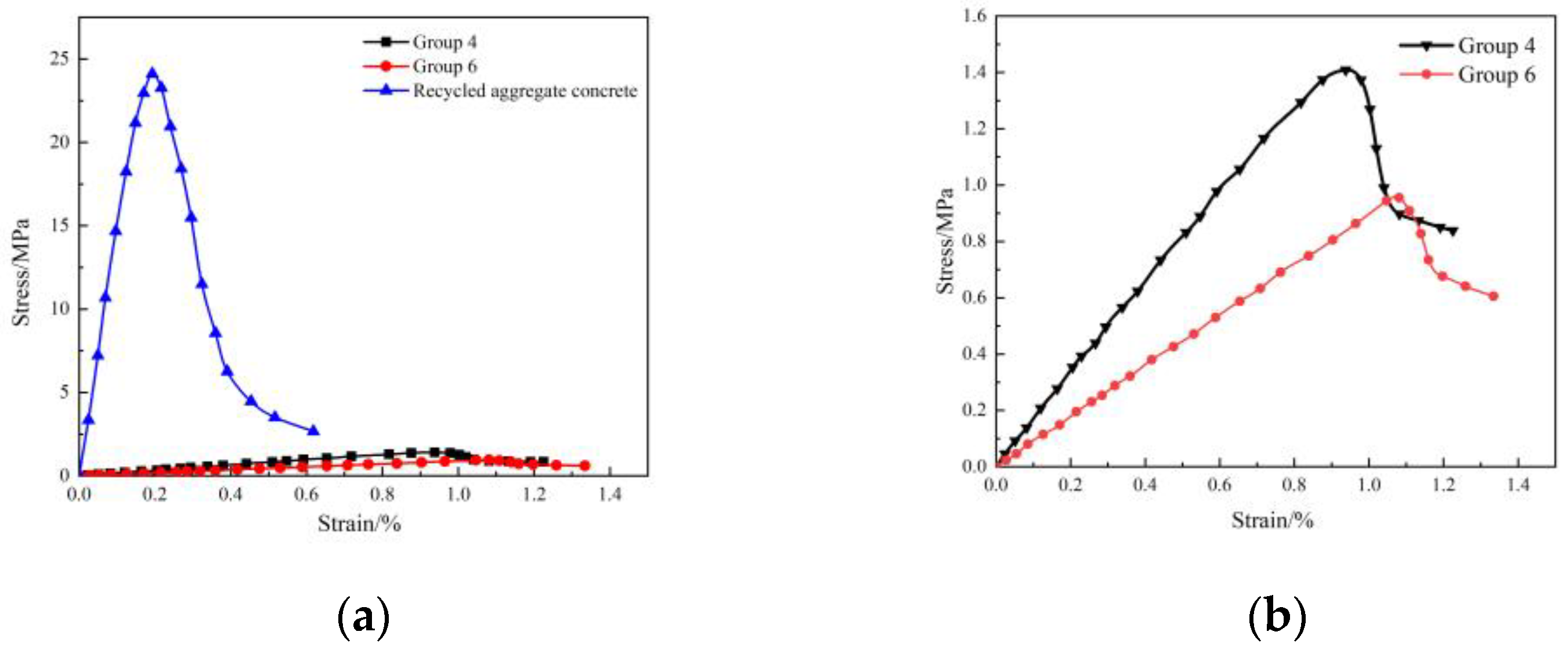

3.5. Stress–Strain Curve

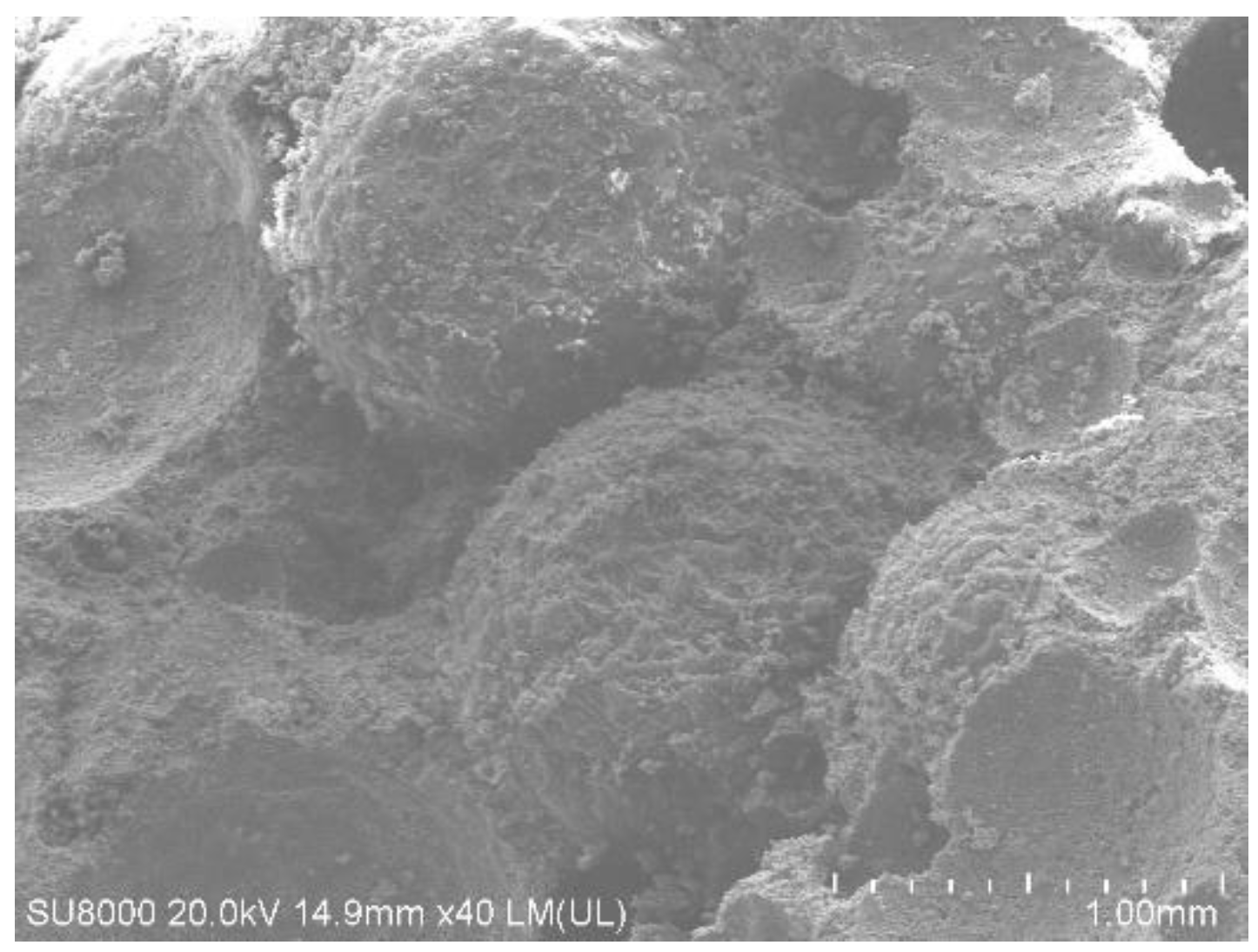

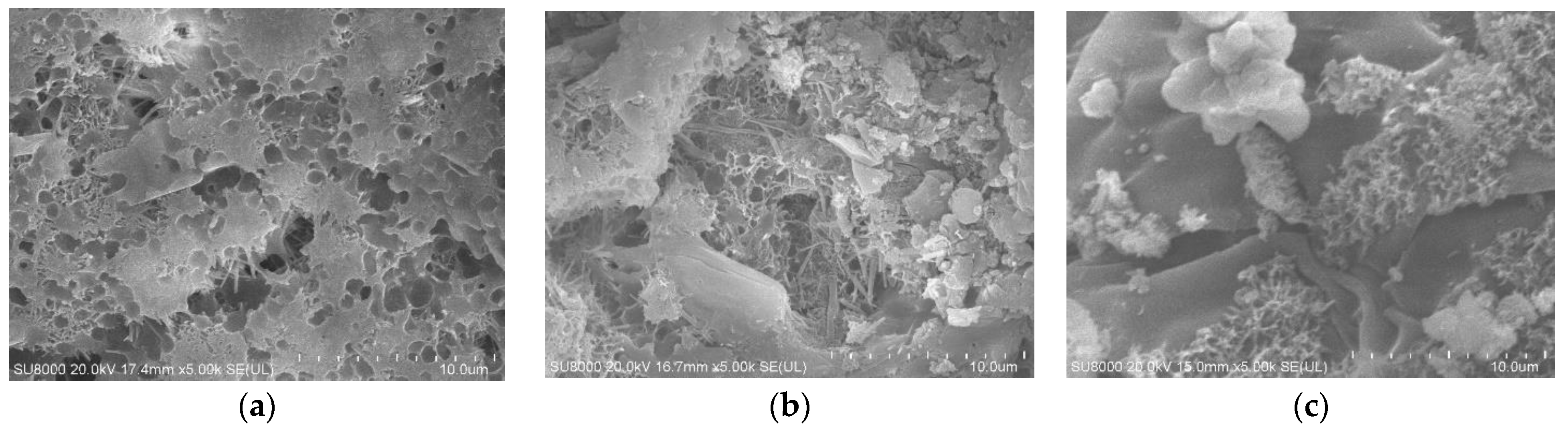

3.6. Microstructure

4. Conclusions

- In this study, EVA was used to modify the surface of EPS. The shell structure wrapped by hydration products was formed on the surface of EPS. The compatibility between EPS and hydration products was improved and the mechanical properties of lightweight CLSM were enhanced.

- Construction waste mainly refers to the solid waste generated during the renovation of the project and the demolition of old buildings. The lightweight CLSM prepared from EPS and construction waste has high fluidity, which was greater than 200 mm.

- Adding EPS and fly ash content can reduce the wet density of CLSM, and EPS played a major role in reducing the density of CLSM.

- EPS content and cement content in cementitious materials are important factors affecting the strength development of CLSM. When the volume ratio of EPS to construction waste was 200% and the cement content in the cementitious material was 35%, the 28-days unconfined compressive strength of CLSM was only 0.48 MPa. It can be concluded that the volume ratio of EPS to construction waste is 1.50, which is unfavorable for the compressive strength of CLSM.

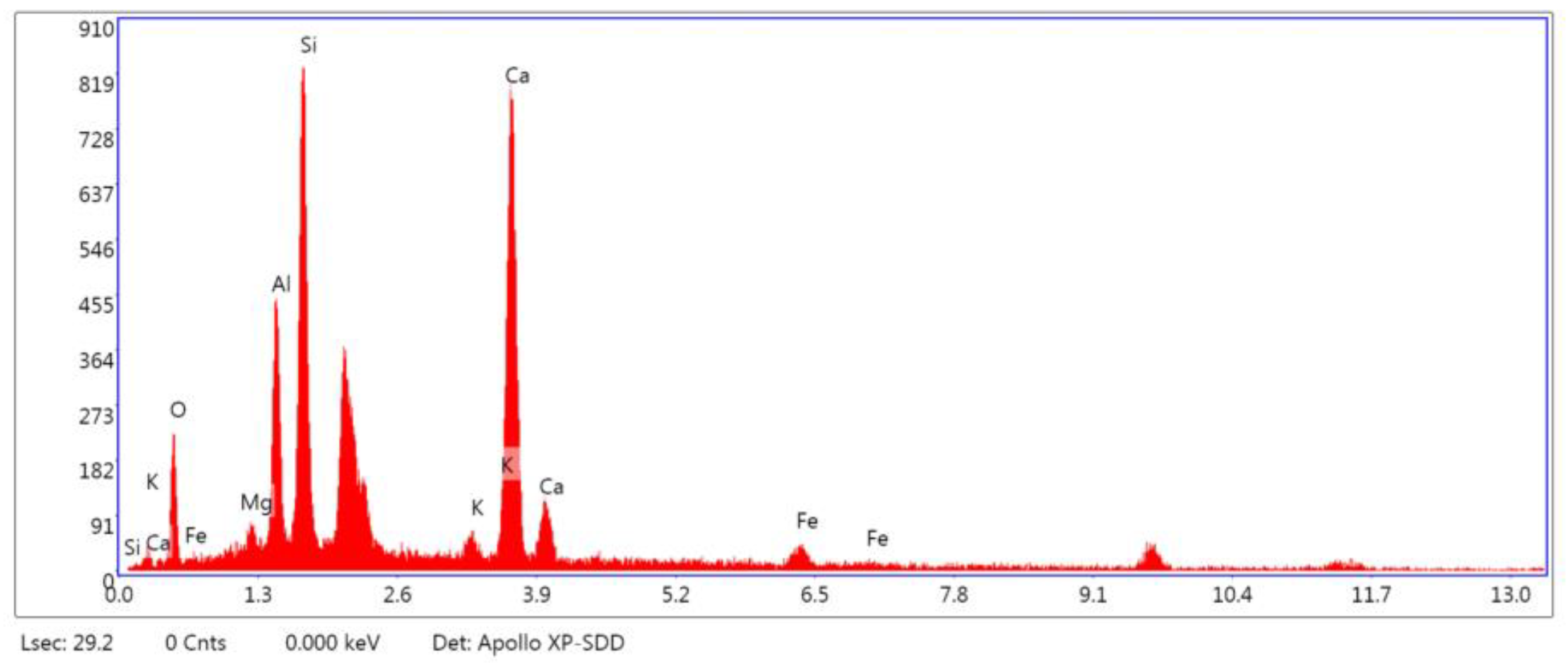

- From SEM morphology photographs, it can be concluded that the increase of EPS content will lead to the deterioration of pore uniformity in CLSM, forming a loose network structure with defects, which is unfavorable to the strength development. EDS spectrum analysis verified that the substances in SEM images were cement hydration products C-H, AFt, and C-S-H. And with the increase of EPS content, the content of hydration products in lightweight CLSM decrease, which leads to a decrease in strength.

- The use of EPS and construction waste to prepare lightweight CLSM provides a green idea for the production of lightweight controlled low strength materials, which provides a reference for the backfill protection of the material in oil and gas pipelines in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lilly, M.T.; Ihekwoaba, S.C.; Ogaji, S.O.T.; Probert, S.D. Prolonging the lives of buried crude-oil and natural-gas pipelines by cathodic protection. Appl. Energy 2007, 84, 958–970. [Google Scholar] [CrossRef] [Green Version]

- Ijaola, A.O.; Farayibi, P.K.; Asmatulu, E. Superhydrophobic coatings for steel pipeline protection in oil and gas industries: A comprehensive review. J. Nat. Gas Sci. Eng. 2020, 83, 103544. [Google Scholar] [CrossRef]

- ACI 229R–13; ACI, Controlled Low Strength Materials. American Concrete Institute: Farmington Hill, MI, USA, 2013.

- Riviera, P.P.; Bertagnoli, G.; Choorackal, E.; Santagata, E. Controlled low-strength materials for pavement foundations in road tunnels: Feasibility study and recommendations. Mater. Struct. 2019, 52, 72. [Google Scholar] [CrossRef]

- Do, T.M.; Do, A.N.; Kang, G.O.; Kim, Y.S. Utilization of marine dredged soil in controlled low-strength material used as a thermal grout in geothermal systems. Constr. Build. Mater. 2019, 215, 613–622. [Google Scholar] [CrossRef]

- Kaliyavaradhan, S.K.; Ling, T.C.; Guo, M.Z.; Mo, K.H. Waste resources recycling in controlled low-strength material (CLSM): A critical review on plastic properties. J. Environ. Manag. 2019, 241, 383–396. [Google Scholar] [CrossRef]

- Kim, Y.S.; Do, T.M.; Kim, H.K.; Kang, G. Utilization of excavated soil in coal ash-based controlled low strength material (CLSM). Constr. Build. Mater. 2016, 124, 598–605. [Google Scholar] [CrossRef]

- Etxeberria, M.; Ainchil, J.; Pérez, M.E.; González, A. Use of recycled fine aggregates for Control Low Strength Materials (CLSMs) production. Constr. Build. Mater. 2013, 44, 142–148. [Google Scholar] [CrossRef]

- Chittoori, B.; Puppala, A.J.; Raavi, A. Strength and Stiffness Characterization of Controlled Low-Strength Material Using Native High-Plasticity Clay. J. Mater. Civ. Eng. 2014, 26, 04014007. [Google Scholar] [CrossRef] [Green Version]

- Xiao, R.; Polaczyk, P.; Jiang, X.; Zhang, M.; Wang, Y.; Huang, B. Cementless controlled low-strength material (CLSM) based on waste glass powder and hydrated lime: Synthesis, characterization and thermodynamic simulation. Constr. Build. Mater. 2021, 275, 122157. [Google Scholar] [CrossRef]

- Wang, H.; Chen, B.; Wu, Y. A study of the fresh properties of controlled low-strength rubber lightweight aggregate concrete (CLSRLC). Constr. Build. Mater. 2013, 41, 526–531. [Google Scholar] [CrossRef]

- Dueramae, S.; Sanboonsiri, S.; Suntadyon, T.; Aoudta, B.; Tangchirapat, W.; Jongpradist, P.; Pulngern, T.; Jitsangiam, P.; Jaturapitakkul, C. Properties of lightweight alkali activated controlled Low-Strength material using calcium carbide residue—Fly ash mixture and containing EPS beads. Constr. Build. Mater. 2021, 297, 123769. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. J. A Sustain. Circ. Econ. 2013, 31, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.Y.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Fernando, P.L.N.; Jayasinghe, M.T.R.; Jayasinghe, C. Structural feasibility of Expanded Polystyrene (EPS) based lightweight concrete sandwich wall panels. Constr. Build. Mater. 2017, 139, 45–51. [Google Scholar] [CrossRef]

- Li, H.; Du, T.; Wu, X. Research on recycled aggregate concrete for construction waste recycling. J. Huazhong Univ. Sci. Technol. 2001, 6, 83–84. [Google Scholar]

- Tittarelli, F.; Giosuè, C.; Mobili, A.; di Perna, C.; Monosi, S. Effect of Using Recycled Instead of Virgin EPS in Lightweight Mortars. Procedia Eng. 2016, 161, 660–665. [Google Scholar] [CrossRef] [Green Version]

- Petrella, A.; Di Mundo, R.; Notarnicola, M. Recycled expanded polystyrene as lightweight aggregate for environmentally sustainable cement conglomerates. Materials 2020, 13, 988. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Qin, D.; Li, L.; Li, Y.; Wang, C.; Wang, P. EVA enhances the interfacial strength of EPS concrete: A molecular dynamics study. J. Exp. Nanosci. 2021, 16, 382–396. [Google Scholar] [CrossRef]

- Yong, F.; Caihua, Y.; Kui, H.; Yujing, C.; Yu, L.; Taoli, Z. A study of the microscopic interaction mechanism of styrene–butadiene-styrene modified asphalt based on density functional theory. Mol. Simul. 2021, 35, 1–12. [Google Scholar] [CrossRef]

- Ghahari, S.; Assi, L.N.; Alsalman, A.; Alyamaç, K. Fracture Properties Evaluation of Cellulose Nanocrystals Cement Paste. Materials 2020, 13, 2507. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Tian, W.; Jiang, X. Study on microstructure and properties of EVA modified EPS concrete. J. Build. Mater. 2010, 13, 243–246. [Google Scholar]

- Jin, Z.; Ma, B.; Su, Y.; Qi, H.; Lu, W. Preparation of eco-friendly lightweight gypsum: Use of beta-hemihydrate phosphogypsum and expanded polystyrene particles. Constr. Build. Mater. 2021, 297, 123837. [Google Scholar] [CrossRef]

- ASTM D6103-04; American Society for Testing and Materials. Standard Test Method for Flow Consistency of Controlled Low Strength Material (CLSM). American Society for Testing and Materials Press: Conshohocken, AL, USA, 2004.

- JGJ/T 70—2009; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Testing Basic Performance of Building Mortar. China Architecture & Building Press: Beijing, China, 2009.

- Fernández-Jiménez, A.; Palomo, A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem. Concr. Res. 2005, 35, 1984–1992. [Google Scholar] [CrossRef]

| Property | Aggregate Type | |

|---|---|---|

| Natural Fine Sand | Recycled Aggregate | |

| Apparent density/kg/m3 | 2.60 | 2.44 |

| Moisture content/% | 8.05 | 7.03 |

| Water absorption/% | 4.6 | 15.66 |

| Fineness modulus | 2.2 | 2.69 |

| Material | Chemical Compositions/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | TiO2 | MgO | Na2O | SO3 | Other | |

| Cement (PA) | 18.16 | 3.57 | 4.03 | 63.35 | 1.11 | 0.29 | 2.66 | - | 2.20 | 4.63 |

| Fly ash (FA) | 53.97 | 31.15 | 4.16 | 4.01 | 2.04 | 1.13 | 1.01 | 0.89 | 0.73 | 0.91 |

| Solid Content | pH | Free Monomer (wt%) | Viscosity (mPa·s) | Appearance | |

|---|---|---|---|---|---|

| Result | 55.49% | 4.9 | 0.0539 | 3250 | Milky white |

| ExperimentGroups | Content (kg/m3) | EPS: Construction Waste (Volume Ratio) | Fluidity of CLSM (mm) | ||||

|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Water | EPS | Construction Waste | |||

| 1(W7V1.5) * | 140 | 260 | 317.13 | 8.75 | 400 | 1.50 | 340.0 |

| 2(W7V1.75) | 140 | 260 | 316.00 | 10.00 | 400 | 1.75 | 320.0 |

| 3(W7V2) | 140 | 260 | 314.88 | 11.25 | 400 | 2.00 | 285.0 |

| 4(W10V1.5) | 200 | 200 | 317.13 | 8.75 | 400 | 1.50 | 330.0 |

| 5(W10V1.75) | 200 | 200 | 316.00 | 10.00 | 400 | 1.75 | 307.5 |

| 6(W10V2) | 200 | 200 | 314.88 | 11.25 | 400 | 2.00 | 280.0 |

| 7(W13V1.5) | 260 | 140 | 317.13 | 8.75 | 400 | 1.50 | 320.0 |

| 8(W13V1.75) | 260 | 140 | 316.00 | 10.00 | 400 | 1.75 | 305.0 |

| 9(W13V1.75) | 260 | 140 | 314.88 | 11.25 | 400 | 2.00 | 252.5 |

| Group | Atomic Percent (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | O | Mg | Al | Si | Ca | K | P | |

| 4 | 19.82 | 42.90 | 1.24 | 5.14 | 11.72 | 15.46 | 0.73 | 2.99 |

| 7 | - | 29.83 | 0.98 | 9.42 | 19.92 | 35.09 | 1.12 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Liu, K.; Xiao, Y.; Zhang, P.; Zhang, M.; Zhu, Y.; Liu, K.; Xu, T.; Huang, R. Properties of Lightweight Controlled Low-Strength Materials Using Construction Waste and EPS for Oil and Gas Pipelines. Energies 2022, 15, 4301. https://doi.org/10.3390/en15124301

Liu H, Liu K, Xiao Y, Zhang P, Zhang M, Zhu Y, Liu K, Xu T, Huang R. Properties of Lightweight Controlled Low-Strength Materials Using Construction Waste and EPS for Oil and Gas Pipelines. Energies. 2022; 15(12):4301. https://doi.org/10.3390/en15124301

Chicago/Turabian StyleLiu, Hao, Kaizhi Liu, Yiqi Xiao, Peng Zhang, Meixia Zhang, Youzeng Zhu, Kaixin Liu, Tianshuo Xu, and Rui Huang. 2022. "Properties of Lightweight Controlled Low-Strength Materials Using Construction Waste and EPS for Oil and Gas Pipelines" Energies 15, no. 12: 4301. https://doi.org/10.3390/en15124301

APA StyleLiu, H., Liu, K., Xiao, Y., Zhang, P., Zhang, M., Zhu, Y., Liu, K., Xu, T., & Huang, R. (2022). Properties of Lightweight Controlled Low-Strength Materials Using Construction Waste and EPS for Oil and Gas Pipelines. Energies, 15(12), 4301. https://doi.org/10.3390/en15124301