Energetic and Economic Analysis of Spineless Cactus Biomass Production in the Brazilian Semi-arid Region

Abstract

:1. Introduction

2. Materials and Methods

2.1. Definition of the Planting System

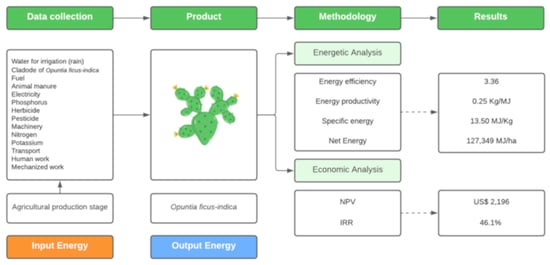

2.2. Analysis of the Energy Balance of the Cropping System

2.3. Energy Indicators

2.4. Economic Analysis of the Cropping System

3. Results and discussions

3.1. Energy Analysis

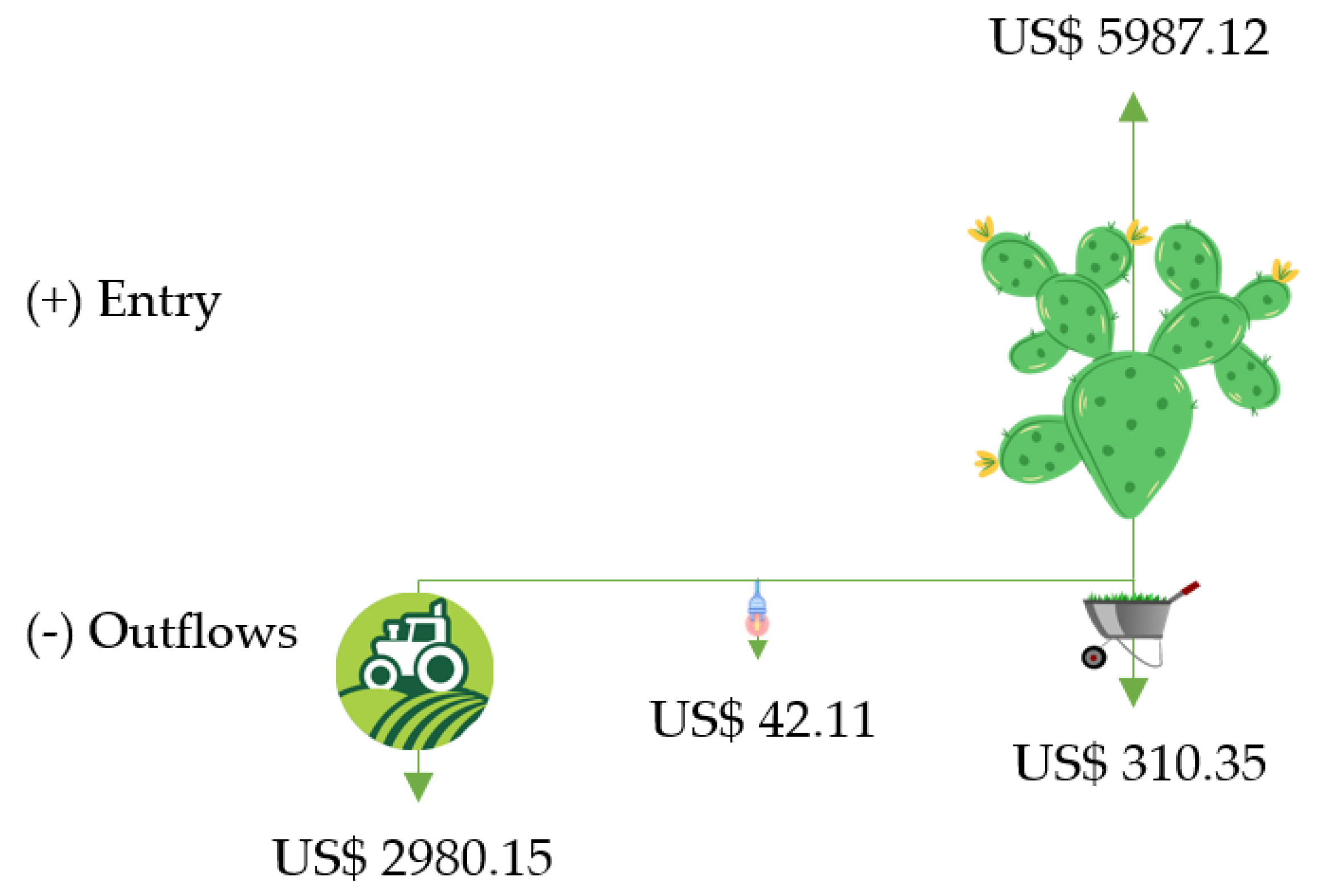

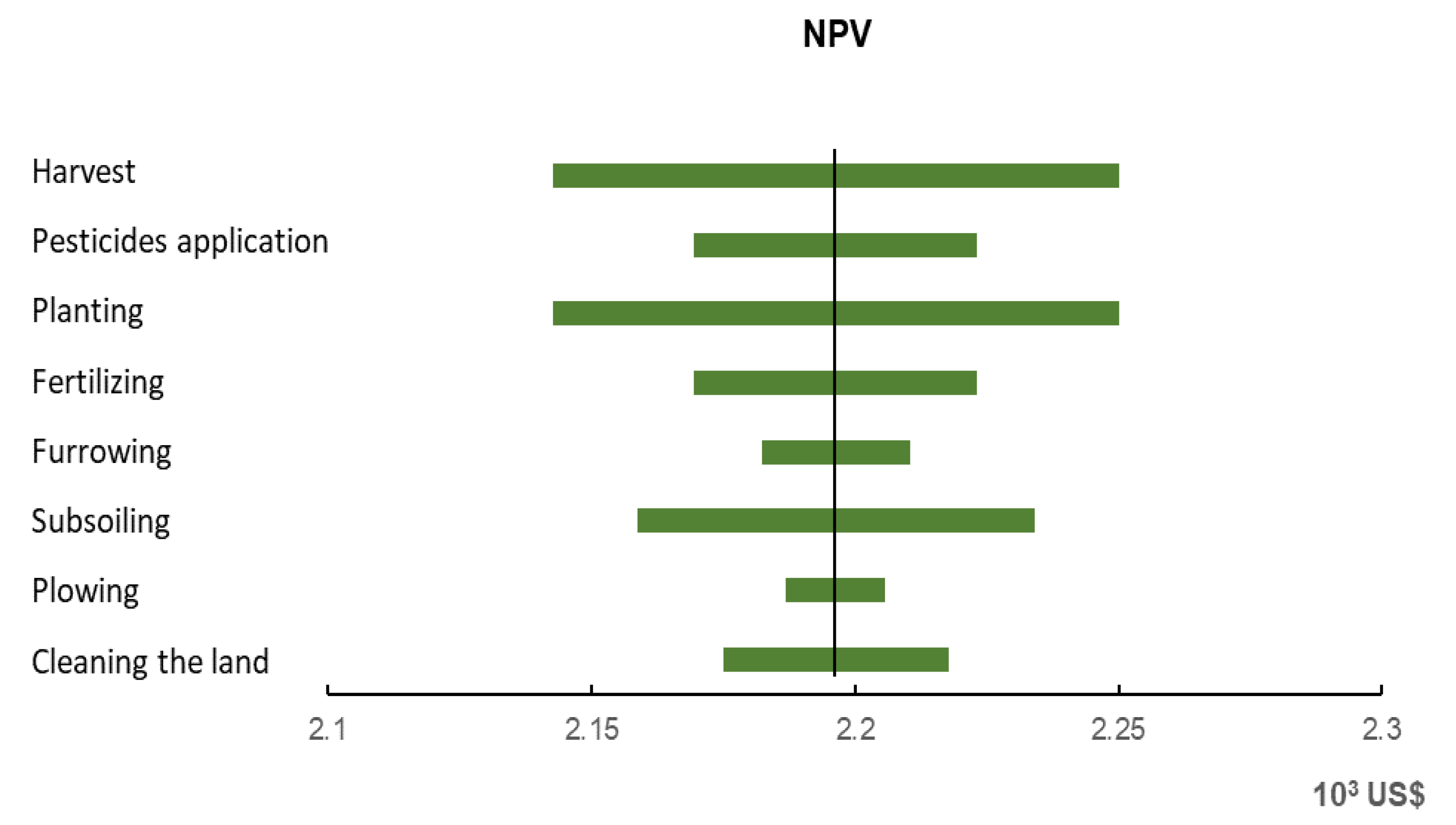

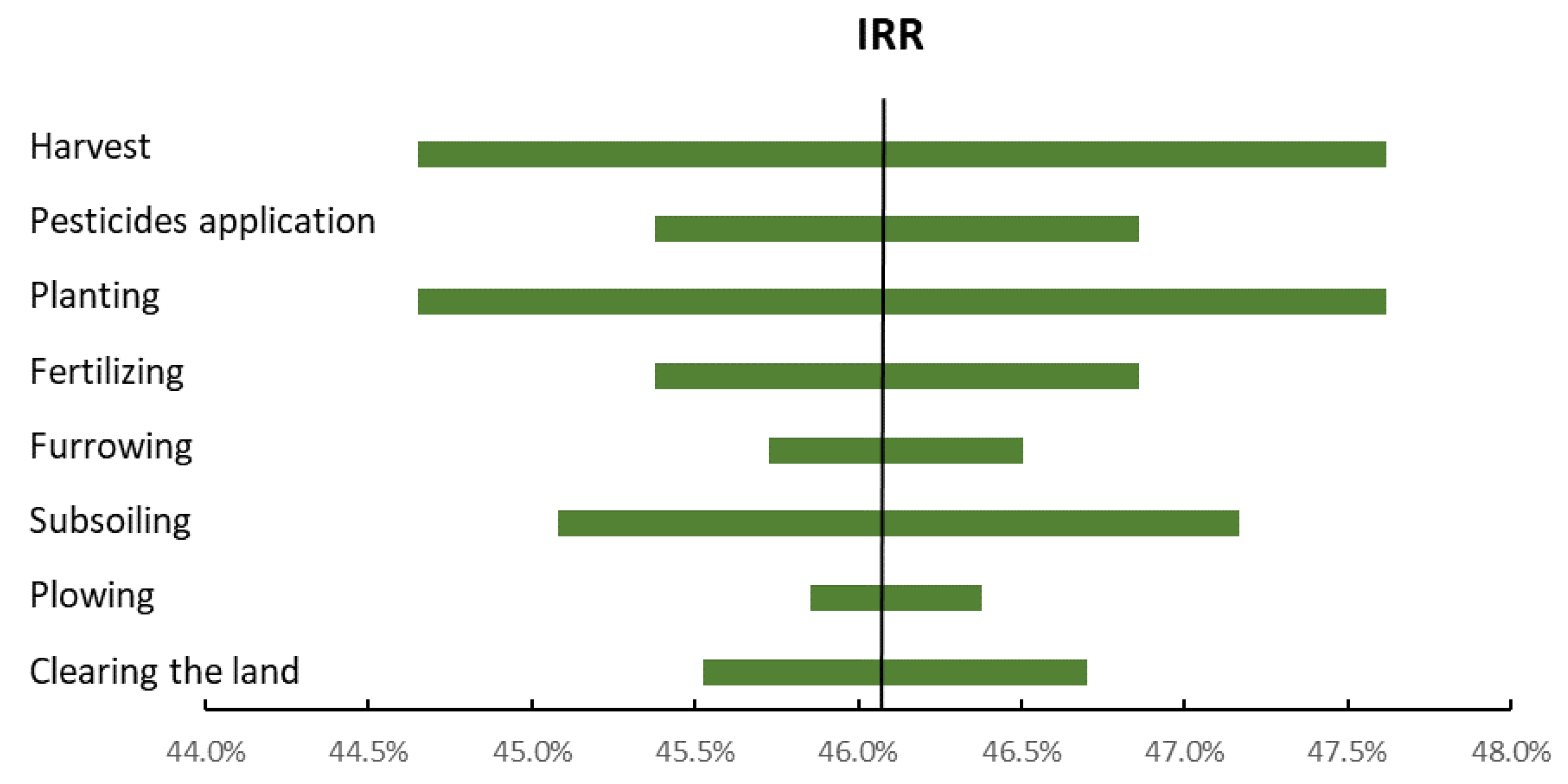

3.2. Economic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ET | Total energy |

| EM | Energy in materials, manufacturing, and transportation |

| EF | Energy in fuel |

| ELF | Energy in lubricants and filters |

| EMR | Energy in maintenance and repairs |

| ES | Energy in seeds |

| EFHP | Energy in fertilizers, herbicides, and pesticides |

| EL | Energy in labor |

| EE | Energy in electricity |

| MT | Mass of the tractor |

| MM | Mass of the machinery |

| TI | Tractor useful life |

| AI | Agricultural implements useful life |

| CM | Capacity of the machines |

| DM | Dry matter |

| EECLA | Energy equivalents of the planted cladodes |

| EEFER | Energy equivalents of the fertilizers used |

| EEHER | Energy equivalents of herbicides |

| EEPES | Energy equivalents of pesticides |

| Eman | Energy equivalents of manual work |

| Emec | Energy equivalents of mechanical work |

| LCP | Lower calorific power |

| NPV | Net Present Value |

| IRR | Internal Rate of Return |

References

- Neupane, D.; Mayer, J.A.; Niechayev, N.A.; Bishop, C.D.; Cushman, J.C. Five-year field trial of the biomass productivity and water input response of cactus pear (Opuntia spp.) as a bioenergy feedstock for arid lands. GCB Bioenergy 2021, 13, 719–741. [Google Scholar] [CrossRef]

- Menezes, R.S.C.; Sampaio, E.V.S.B. Simulação dos Fluxos e Balanços de Fósforo em Uma Unidade de Produção Agrícola Familiar no Semi-Árido Paraibano. Agricultura Familiar e Agroecologia no Semi-Árido; Avanços a partir do Agreste da Paraíba: Rio de Janeiro, Brazil, 2002; pp. 249–260. [Google Scholar]

- Bravo-Avilez, D.; Zavala-Hurtado, J.A.; Rendón-Aguilar, B. Evolution under domestication of correlated traits in two edible columnar cacti in Mexico. Evol. Ecol. 2022, 36, 33–54. [Google Scholar] [CrossRef]

- Dubeux, J.C.B.; Santos, M.V.F.D.; Cunha, M.V.D.; Santos, D.C.D.; Souza, R.T.D.A.; Mello, A.C.L.D.; Souza, T.C.D. Cactus (Opuntia and Nopalea) nutritive value: A review. Anim. Feed Sci. Technol. 2021, 275, 114890. [Google Scholar] [CrossRef]

- Grace, O.M. Succulent plant diversity as natural capital. Plants People Planet 2019, 1, 336–345. [Google Scholar] [CrossRef]

- Cortázar, V.G.; Varnero, M.T. Produção de energia. In Agroecologia, Cultivos e Usos da Palma Forrageira; (Paraíba: SEBRAE/PB); Barbera, G., Inglese, P., Eds.; SEBRAE/PB: João Pessoa, Brazil, 2001; pp. 187–210. [Google Scholar]

- Neves, F.P.; Spínola, A.M.; das Chagas, M.C.M.; de Carvalho Neves, J.D.; Küster, I.S.; de Figueiredo, M.R.P.; de Oliveira, F.S.; de Oliveira, E.F.; Pereira, S.L. Palma Forrageira: Opção e Potencialidades para Alimentação Animal e Humana em Propriedades Rurais do Estado do Espírito Santo; Incaper: Vitória, Brazil, 2020; Volume 276. [Google Scholar]

- Pereira, L.G.; Cavalett, O.; Bonomi, A.; Zhang, Y.; Warner, E.; Chum, H.L. Comparison of biofuel life-cycle GHG emissions assessment tools: The case studies of ethanol produced from sugarcane, corn, and wheat. Renew. Sustain. Energy Rev. 2019, 110, 1–12. [Google Scholar] [CrossRef]

- Cushman, J.C.; Davis, S.C.; Yang, X.; Borland, A.M. Development and use of bioenergy feedstocks for semi-arid and arid lands. J. Exp. Bot. 2015, 66, 4177–4193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Santos, T.D.N.; Dutra, E.D.; Gomes do Prado, A.; Leite, F.C.B.; de Souza, R.D.F.R.; dos Santos, D.C.; Moraes de Abreu, C.A.; Simões, D.A.; de Morais, M.A., Jr.; Menezes, R.S.C. Potential for biofuels from the biomass of prickly pear cladodes: Challenges for bioethanol and biogas production in dry areas. Biomass Bioenergy 2016, 85, 215–222. [Google Scholar] [CrossRef]

- Alencar, B.R.A.; Dutra, E.D.; Sampaio, E.V.D.S.B.; Menezes, R.S.C.; Morais, M.A. Enzymatic hydrolysis of cactus pear varieties with high solids loading for bioethanol production. Bioresour. Technol. 2018, 250, 273–280. [Google Scholar] [CrossRef]

- Quintero-Angel, M.; González-Acevedo, A. Tendencies and challenges for the assessment of agricultural sustainability. Agric. Ecosyst. Environ. 2018, 254, 273–281. [Google Scholar] [CrossRef]

- Patel, B.; Patel, A.; Syed, B.A.; Gami, B.; Patel, P. Assessing economic feasibility of bio-energy feedstock cultivation on marginal lands. Biomass Bioenergy 2021, 154, 106273. [Google Scholar] [CrossRef]

- Mazzeo, D.; Baglivo, C.; Matera, N.; Congedo, P.M.; Oliveti, G. A novel energy-economic-environmental multi-criteria decision-making in the optimization of a hybrid renewable system. Sustain. Cities Soc. 2020, 52, 101780. [Google Scholar] [CrossRef]

- Pimentel, D.; Hurd, L.E.; Bellotti, A.C.; Forster, M.J.; Oka, I.N.; Sholes, O.D.; Whitman, R.J. Food Production and the Energy Crisis. Science 1973, 182, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Pervanchon, F.; Bockstaller, C.; Girardin, P. Assessment of energy use in arable farming systems by means of an agro-ecological indicator: The energy indicator. Agric. Syst. 2002, 72, 149–172. [Google Scholar] [CrossRef]

- Karimi, M.; Pour, A.R.; Tabatabaeefar, A.; Borghei, A. Energy analysis of sugarcane production in plant farms—A case study in Debel Khazai agro-industry in Iran. Am. Eurasian J. Agric. Environ. Sci. 2008, 4, 165–171. [Google Scholar]

- Rafiee, S.; Mousavi Avval, S.H.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- López-Sandin, I.; Gutiérrez-Soto, G.; Gutiérrez-Díez, A.; Medina-Herrera, N.; Gutiérrez-Castorena, E.; Zavala-García, F. Evaluation of the Use of Energy in the Production of Sweet Sorghum (Sorghum Bicolor (L.) Moench) under Different Production Systems. Energies 2019, 12, 1713. [Google Scholar] [CrossRef] [Green Version]

- Hiloidhari, M.; Haran, S.; Banerjee, R.; Rao, A.B. Life cycle energy–carbon–water footprints of sugar, ethanol and electricity from sugarcane. Bioresour. Technol. 2021, 330, 125012. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Budzyński, W.S.; Kijewski, Ł. An analysis of energy efficiency in the production of oilseed crops of the family Brassicaceae in Poland. Energy 2015, 81, 674–681. [Google Scholar] [CrossRef]

- Macedo, I.; Terra, J.A.; Siri-Prieto, G.; Velazco, J.I.; Carrasco-Letelier, L. Rice-pasture agroecosystem intensification affects energy use efficiency. J. Clean. Prod. 2021, 278, 123771. [Google Scholar] [CrossRef]

- Rahman, S.; Hasan, M.K. Energy productivity and efficiency of wheat farming in Bangladesh. Energy 2014, 66, 107–114. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, A.; Rafiee, S.; Jafari, A.; Keyhani, A.; Mousavi-Avval, S.H.; Nonhebel, S. Energy use efficiency and greenhouse gas emissions of farming systems in north Iran. Renew. Sustain. Energy Rev. 2014, 30, 724–733. [Google Scholar] [CrossRef]

- Moreno, M.M.; Lacasta, C.; Meco, R.; Moreno, C. Rainfed crop energy balance of different farming systems and crop rotations in a semi-arid environment: Results of a long-term trial. Soil Tillage Res. 2011, 114, 18–27. [Google Scholar] [CrossRef] [Green Version]

- Taner, A.; Arısoy, R.Z.; Kaya, Y.; Gültekin, İ.; Partigöç, F. Comparison of energy of planting methods in wheat production in a semi-arid region. Arch. Agron. Soil Sci. 2021, 67, 1961–1973. [Google Scholar] [CrossRef]

- Sahabi, H.; Feizi, H.; Amirmoradi, S. Which crop production system is more efficient in energy use: Wheat or barley? Environ. Dev. Sustain. 2013, 15, 711–721. [Google Scholar] [CrossRef]

- Testa, R.; Foderà, M.; Di Trapani, A.M.; Tudisca, S.; Sgroi, F. Giant reed as energy crop for Southern Italy: An economic feasibility study. Renew. Sustain. Energy Rev. 2016, 58, 558–564. [Google Scholar] [CrossRef]

- Sgroi, F.; Di Trapani, A.M.; Foderà, M.; Testa, R.; Tudisca, S. Economic assessment of Eucalyptus (spp.) for biomass production as alternative crop in Southern Italy. Renew. Sustain. Energy Rev. 2015, 44, 614–619. [Google Scholar] [CrossRef]

- Hauk, S.; Knoke, T.; Wittkopf, S. Economic evaluation of short rotation coppice systems for energy from biomass—A review. Renew. Sustain. Energy Rev. 2014, 29, 435–448. [Google Scholar] [CrossRef]

- Testa, R.; Di Trapani, A.M.; Foderà, M.; Sgroi, F.; Tudisca, S. Economic evaluation of introduction of poplar as biomass crop in Italy. Renew. Sustain. Energy Rev. 2014, 38, 775–780. [Google Scholar] [CrossRef]

- Styles, D.; Thorne, F.; Jones, M.B. Energy crops in Ireland: An economic comparison of willow and Miscanthus production with conventional farming systems. Biomass Bioenergy 2008, 32, 407–421. [Google Scholar] [CrossRef]

- Ramos, J.; Ramos, J.P.F.; Santos, E.M.; Freitas, F.F.D.; Candido, E.P.; Lima Junior, A.C.D.; Leite, M.L.V.; Oliveira Junior, S.D. Caracterização técnica dos sistemas de produção de palma forrageira em Soledade, PB. Agropecuária Técnica 2014, 35, 23–30. [Google Scholar] [CrossRef]

- Lima, G.F.C.; Wanderley, A.M.; Guedes, F.X.; Rego, M.M.T.; Dantas, F.D.G.; Silva, J.G.M.; Novaes, L.P.; Aguiar, E.M. Palma Forrageira Irrigada e Adensada: Uma Reserva Forrageira Estratégica para o Semiárido Potiguar; EMPARN, Parnamirim: Rio Grande do Norte, Brazil, 2015. [Google Scholar]

- Dantas, S.F.D.A.; Lima, G.F.D.C.; Mota, E.P.D. Viabilidade econômica da produção de palma forrageira irrigada e adensada no semiárido Potiguar. Rev. IPecege 2017, 3, 59–74. [Google Scholar] [CrossRef] [Green Version]

- Rondón, P.P.; Rodríguez, Y.S. Costo energético de la cosecha mecanizada del arroz en Cuba. Rev. Cienc. Técnicas Agropecu. 2006, 15, 19–23. [Google Scholar]

- De las Cuevas Milán, H.R.; Rodríguez Hernández, T.; Paneque Rondón, P.; Díaz Álvarez, M. Costo energético del rodillo de cuchillas CEMA 1400 para cobertura vegetal. Rev. Cienc. Técnicas Agropecu. 2011, 20, 53–56. [Google Scholar]

- Acaroglu, M.; Aksoy, S.A. The cultivation and energy balance of Miscanthus  giganteus production in Turkey. Biomass Energy 2005, 29, 42–48. [Google Scholar] [CrossRef]

- Kitani, O.; Jungbluth, T.; Peart, R.M.; Ramdani, A. Energy and biomass engineering. In CIGR Handbook of Agricultural Engineering; American Society of Agricultural Engineers: St Joseph, MI, USA, 1999; p. 17. [Google Scholar]

- Mittal, S.P.; Singh, P. Studies on Intercropping of Field Crops with Foddercrops of Subabul under Rainfed Conditions; Annual Report; Central Soil & Water Conservation Research and Training Institute: Dehra Dun, India, 1983. [Google Scholar]

- Hatirli, S.A.; Ozkan, B.; Fert, C. An econometric analysis of energy input-output in Turkish agriculture. Renew. Sustain. Energy Rev. 2005, 9, 608–623. [Google Scholar] [CrossRef]

- Yilmaz, I.; Akcaoz, H.; Ozkan, B. An analysis of energy use and input costs for cotton production in Turkey. Renew. Energy 2005, 30, 145–155. [Google Scholar] [CrossRef]

- Meul, M.; Nevens, F.; Reheul, D.; Hofman, G. Energy use efficiency of specialised dairy, arable and pig farms in Flanders. Agric. Ecosyst. Environ. 2007, 119, 135–144. [Google Scholar] [CrossRef]

- Tabatabaeefar, A.; Emamzadeh, H.; Varnamkhasti, M.; Rahimizadeh, R.; Karimi, M. Comparison of energy of tillage systems in wheat production. Energy 2009, 34, 41–45. [Google Scholar] [CrossRef]

- Vilche, M.S. El uso de la energía en los sistemas agropecuarios del distrito de Zavalla (Santa Fé). Rev. Científica Agropecuaria. 2006, 10, 7–19. [Google Scholar]

- Fluck, R.C. Energy Sequestered in Repairs and Maintenance of Agricultural Machinery. Trans. ASAE 1985, 28, 738–744. [Google Scholar] [CrossRef]

- Balastreire, L.A. Máquinas Agrícolas; Manole: São Paulo, Brazil, 1987; p. 307. [Google Scholar]

- Pacheco, E.P. Seleção e Custo Operacional de Máquinas Agrícolas; Embrapa Acre: Rio Branco, Brazil, 2000; p. 21. [Google Scholar]

- Rondón, P.P.; Fernandes, H.C.; Oliveira, A.D. Comparación de cuatro sistemas de labranza/siembra en relación con su costo energético. Rev. Ciências Técnicas Agropecu. 2002, 11, 1–6. [Google Scholar]

- Rondón, P.P.P. Gastos energéticos de la poda mecanizada en las plantaciones citrícolas de Cuba. Rev. Cienc. Técnicas Agropecu. 2000, 9, 23–28. [Google Scholar]

- Ibañez, M.; Rojas, E. Costos de Operación y Producción por Concepto de Maquinaria Agrícola; Boletin de Ext. No 26; Universidad de Concepción, Facultad de Ingeniería Agrícola: Concepción, Chile, 1994; p. 58. [Google Scholar]

- Ren, L.T.; Liu, Z.X.; Wei, T.Y.; Xie, G.H. Evaluation of energy input and output of sweet sorghum grown as a bioenergy crop on coastal saline-alkali land. Energy 2012, 47, 166–173. [Google Scholar] [CrossRef]

- Valadares Filho, S.C.; Cabral, L.S. Aplicação dos princípios de nutrição de ruminantes em regiões tropicais. Reun. Anu. Soc. Bras. Zootec. 2002, 39, 514–543. [Google Scholar]

- Oliveira, A.S.C. A palma forrageira: Alternativa para o Semi-árido. Rev. Verde Agroecol. Desenvolv. Sustentável 2011, 6, 49–58. [Google Scholar]

- Silva, L.M.D.; Fagundes, J.L.; Viegas, P.A.A.; Muniz, E.N.; de Albuquerque Rangel, J.H.; Moreira, A.L.; Backes, A.A. Produtividade da palma forrageira cultivada em diferentes densidades de plantio. Ciência Rural 2014, 44, 2064–2071. [Google Scholar] [CrossRef] [Green Version]

- Tabatabaie, S.M.H.; Rafiee, S.; Keyhani, A.; Ebrahimi, A. Energy and economic assessment of prune production in Tehran province of Iran. J. Clean. Prod. 2013, 39, 280–284. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Rafiee, S.; Hosseinzadeh-Bandbafha, H.; Shamshirband, S. Modeling energy consumption and greenhouse gas emissions for kiwifruit production using artificial neural networks. J. Clean. Prod. 2016, 133, 924–931. [Google Scholar] [CrossRef]

- Tao, J.Y.; Finenko, A. Moving beyond LCOE: Impact of various financing methods on PV profitability for SIDS. Energy Policy 2016, 98, 749–758. [Google Scholar] [CrossRef]

- Chen, S.; Feng, H.; Zheng, J.; Ye, J.; Song, Y.; Yang, H.; Zhou, M. Life Cycle Assessment and Economic Analysis of Biomass Energy Technology in China: A Brief Review. Processes 2020, 8, 1112. [Google Scholar] [CrossRef]

- Lima, D.O.; Araújo, C.D.A.; Melo, L.M.D. Análise descritiva do custo de implantação de palma forrageira em plantio de sequeiro no Semiárido alagoano: Um estudo de caso. Divers. J. 2020, 5, 1271–1280. [Google Scholar] [CrossRef]

- Superintendência do Desenvolvimento do Nordeste—SUDENE; Instituto Nacional do Semiárido—INSA. Documento de referência sobre palma forrageira. [S.l.]: Superintendência do Desenvolvimento do Nordeste—SUDENE. 2020. Available online: https://www.gov.br/sudene/pt-br/centrais-de-conteudo/documento-de-referncia-palma-sudene-verso-05-03-20-final-pdf (accessed on 10 May 2022).

- Jankowski, K.J.; Dubis, B.; Sokólski, M.M.; Załuski, D.; Bórawski, P.; Szempliński, W. Productivity and energy balance of maize and sorghum grown for biogas in a large-area farm in Poland: An 11-year field experiment. Ind. Crops Prod. 2020, 148, 112326. [Google Scholar] [CrossRef]

- Salla, D.A.; Cabello, C. Análise Energética de Sistemas de Produção de Etanol de Mandioca, Cana-de-Açúcar e Milho. Energ. NA Agric. 2010, 25, 32. [Google Scholar] [CrossRef] [Green Version]

- Melo, D.D.; Pereira, J.O.; Souza, E.G.D.; Filho, A.G.; Nóbrega, L.H.P.; Neto, R.P. Balanço energético do sistema de produção de soja e milho em uma. Acta Sci. Agron. 2007, 29, 173–178. [Google Scholar] [CrossRef]

- Schroll, H. Energy-flow and ecological sustainability in Danish agriculture. Agric. Ecosyst. Environ. 1994, 51, 301–310. [Google Scholar] [CrossRef]

- Santos, D.F.L.; Souza, C.A.F.; Farinelli, J.B.D.M.; Silva, B.L.D.; Horita, K. Análise Econômica da Produção de Cana-de-Açúcar em Diferentes Pacotes Tecnológicos. Rev. Estud. Debate 2018, 25, 262–283. [Google Scholar] [CrossRef]

- Patel, B.; Patel, M.; Gami, B.; Patel, A. Cultivation of bioenergy crops in Gujarat state: A consultative survey process to understand the current practices of landowners. Environ. Dev. Sustain. 2021, 23, 8991–9013. [Google Scholar] [CrossRef]

- Kaneko, F.H.; Tarsitano, M.A.A.; Rapassi, R.M.A.; Chioderolli, C.A.; Nakayama, F.T. Análise Econômica da Produção de Cana-De-Açúcar Considerando-se a Terceirização das Operações Agrícolas: O Caso de um Produtor. Pesq. Agropec. Trop. 2009, 3, 266–270. [Google Scholar]

| Variables | Units | Description |

|---|---|---|

| Cultivated species | - | Opuntia ficus-indica |

| Purpose of the cactus | - | Biofuel production |

| Cultivated area | Ha | 1 |

| Crop density | Plants ha−1 | 25,000 |

| Planting time | - | Beginning of the rainy season |

| Type of planting | - | Manual |

| Cladode position | - | |

| Clearing the area | d h−1 ** | 10 |

| Subsoiling | h tractor−1 * | 8 |

| Plowing | h tractor−1 * | 2 |

| Organic fertilization | t ha−1 | 25 |

| Fertilization labor | d h−1 ** | 12.5 |

| Furrow opening | h tractor−1 * | 3 |

| Herbicide | L | 7 |

| Planting labor | d h−1 ** | 25 |

| Application of pesticides | d h−1 ** | 12.5 |

| Harvest labor | d h−1 ** | 35 |

| Variables | Units | Energy Equivalent (MJ × Unit−1) | Source |

|---|---|---|---|

| Water for irrigation (rain) | L | 1.02 | [38] |

| Cladode of Opuntia ficus-indica | Kg | 13.5 | [10] |

| Fuel | L | 47.8 | [39] |

| Animal manure | Kg | 0.3 | [40] |

| Electricity | Kwh | 11.93 | [41] |

| Phosphorus | Kg | 12.44 | [42] |

| Herbicide | L | 214 | [43] |

| Pesticide | L | 278 | [43] |

| Machinery | Kg | 138 | [44] |

| Nitrogen | Kg | 77.5 | [45] |

| Potassium | Kg | 11.15 | [42] |

| Transport | MJ Km−1 h−1 | 4.5 | [44] |

| Human work | h | 1.95 | [44] |

| Mechanized work | h | 1.05 | [44] |

| Equipment | Description | Mass (kg) | Lifespan (h) |

|---|---|---|---|

| Small tractor | 60 HP | 3065 | 10,000 |

| Subsoiler | Hydraulic, 5 stems. | 400 | 2000 |

| Plow | Fixed, 3 disks. | 400 | 2000 |

| Furrower | Single line | 105 | 2000 |

| Machinery | Width (m) | Operating Speed (km h−1) |

|---|---|---|

| Subsoiler | 1.24 | Between 4 and 7 |

| Plow | 0.9 | Between 4 and 8 |

| Furrower | 0.6 | Between 4 and 7 |

| Activity | Energy Deposited (MJ h−1) | Converted Energy (MJ ha−1) |

|---|---|---|

| EM | 104,105.74 | 3032.73 |

| EF | 621.40 | 17,965.85 |

| ELF | 31.07 | 890.79 |

| EMR | 135.11 | 390.47 |

| Variables | Units | Values |

|---|---|---|

| Mass of planted cladodes | Kg ha−1 | 25,000 |

| Mass of fertilizers | Kg ha−1 | 25,000 |

| Volume of herbicides | L ha−1 | 7 |

| Dry matter content in cladodes | % | 9.63 |

| Activity | Units | Amount |

|---|---|---|

| Clearing the land | d h−1 | 10 |

| Subsoiling | h tractor−1 | 8 |

| Plowing | h tractor−1 | 2 |

| Furrow opening | h tractor−1 | 3 |

| Fertilizing | d h−1 | 12.5 |

| Planting | d h−1 | 25 |

| Pesticide application | d h−1 | 12.5 |

| Harvest | d h−1 | 25 |

| Services | Unit | Quantities | Unit Value (USD) | Total Amount (USD) | Participation |

|---|---|---|---|---|---|

| Services | |||||

| Clearing the land | D.M−1 | 10 | 10.73 | 107.30 | 3.60% |

| Plowing | H.M−1 | 2 | 23.61 | 47.21 | 1.58% |

| Subsoiling | H.M−1 | 8 | 23.61 | 188.84 | 6.34% |

| Furrowing | H.M−1 | 3 | 23.61 | 70.82 | 2.38% |

| Fertilizing | D.M−1 | 12.5 | 10.73 | 134.12 | 4.50% |

| Planting | D.M−1 | 25 | 10.73 | 268.24 | 9.00% |

| Pesticide application | D.M−1 | 12.5 | 10.73 | 134.12 | 4.50% |

| Harvest | D.M−1 | 25 | 10.73 | 268.24 | 9.00% |

| Lease of equipments | ha | 1 | 42.92 | 42.92 | 0.07% |

| Land taxes | ha | 1 | 2.15 | 2.15 | 0.07% |

| Inputs | |||||

| Cladodes | Unit | 25,000 | 0.04 | 1072.96 | 36.00% |

| Animal manure | t | 25 | 21.46 | 536.48 | 18.00% |

| Herbicide | L | 7 | 3.22 | 22.53 | 0.76% |

| Electricity | kWh | 720 | 0.12 | 84.23 | 2.83% |

| 2980.15 | 100% | ||||

| Revenue | |||||

| Sale of cladodes | Un | 139,500 | 0.04 | 5987.12 | - |

| Activity | Energy Consumed (MJ ha−1) |

|---|---|

| Machinery | 303 |

| Fuels | 1796 |

| Lubricants and filters | 90 |

| Maintenance and repair | 390 |

| Cactus cladodes | 32,501 |

| Fertilizers, herbicides, and pesticides | 8999 |

| Labor | 1340 |

| Electricity | 8590 |

| Total: 54,008 |

| Description | Units | Quantities |

|---|---|---|

| Number of plants | Plants ha−1 | 25,000 |

| Number of cladodes | Cladodes plants−1 | 5.58 |

| Cutting time | Years | 2 |

| Cladode weight | Kg | 1 |

| Lower calorific value | MJ kg−1 | 13.50 |

| Dry matter content | % | 9.63 |

| Energy obtained after harvest | MJ ha−1 | 181,357 |

| Indicator | Units | Value |

|---|---|---|

| Energy efficiency | - | 3.36 |

| Energy productivity | Kg MJ−1 | 0.25 |

| Net energy | MJ kg−1 | 13.50 |

| Energy balance | MJ ha−1 | 127,349 |

| Time Course (Year) | Cash Flow (USD) | Discount Rate (%) | Cash Flow Corrected to Present Value |

|---|---|---|---|

| 0 | −2628 | 8.00 | −2628 |

| 1 | −44 | −41 | |

| 2 | 6748 | 5254 | |

| NPV (USD) | 2196 | ||

| IRR (%) | 46.1 | ||

| Cost of Cladodes USD kg−1 | Total Cost of Cladodes USD ha−1 | NPV USD | IRR % |

|---|---|---|---|

| 0.02 | 536.5 | 2732.9 | 63.7 |

| 0.03 | 804.7 | 2464.6 | 54.1 |

| 0.04 | 1073.0 | 2196.4 | 46.1 |

| 0.05 | 1341.2 | 1928.2 | 39.2 |

| 0.06 | 1609.4 | 1659.9 | 33.2 |

| Total Sale Value USD ha−1 | NPV USD | IRR % | |

| 0.02 | 2993.6 | −370.1 | 0.2 |

| 0.03 | 4490.3 | 913.2 | 25.2 |

| 0.04 | 5987.1 | 2196.4 | 46.1 |

| 0.05 | 7483.9 | 3479.7 | 64.4 |

| 0.06 | 8980.7 | 4762.9 | 80.8 |

| Cladodes Per Plant | Cladode Productivity ha−1 | NPV USD | IRR % |

|---|---|---|---|

| 2.58 | 64,500 | −563 | −4.2 |

| 3.58 | 89,500 | 357 | 15.0 |

| 4.58 | 114,500 | 1276 | 31.5 |

| 5.58 | 139,500 | 2196 | 46.1 |

| 6.58 | 164,500 | 3116 | 59.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, J.B.; Santos Júnior, E.P.; Pedrosa, J.G.T.; Sales, A.T.; Sampaio, E.V.d.S.B.; Menezes, R.S.C.; Dutra, E.D.; Junior, P.R. Energetic and Economic Analysis of Spineless Cactus Biomass Production in the Brazilian Semi-arid Region. Energies 2022, 15, 5270. https://doi.org/10.3390/en15145270

da Silva JB, Santos Júnior EP, Pedrosa JGT, Sales AT, Sampaio EVdSB, Menezes RSC, Dutra ED, Junior PR. Energetic and Economic Analysis of Spineless Cactus Biomass Production in the Brazilian Semi-arid Region. Energies. 2022; 15(14):5270. https://doi.org/10.3390/en15145270

Chicago/Turabian Styleda Silva, Jéssica Bárbara, Edvaldo Pereira Santos Júnior, João Gabriel Távora Pedrosa, Aldo Torres Sales, Everardo Valadares de Sa Barretto Sampaio, Rômulo Simões Cezar Menezes, Emmanuel Damilano Dutra, and Paulo Rotella Junior. 2022. "Energetic and Economic Analysis of Spineless Cactus Biomass Production in the Brazilian Semi-arid Region" Energies 15, no. 14: 5270. https://doi.org/10.3390/en15145270