Numerical Analysis on Impact of Thickness of PEM and GDL with and without MPL on Coupling Phenomena in PEFC Operated at Higher Temperature Such as 363 K and 373 K

Abstract

:1. Introduction

2. Numerical Simulation Procedure

Governing Equations in 3D Numerical Simulation Model

3. Results and Discussion

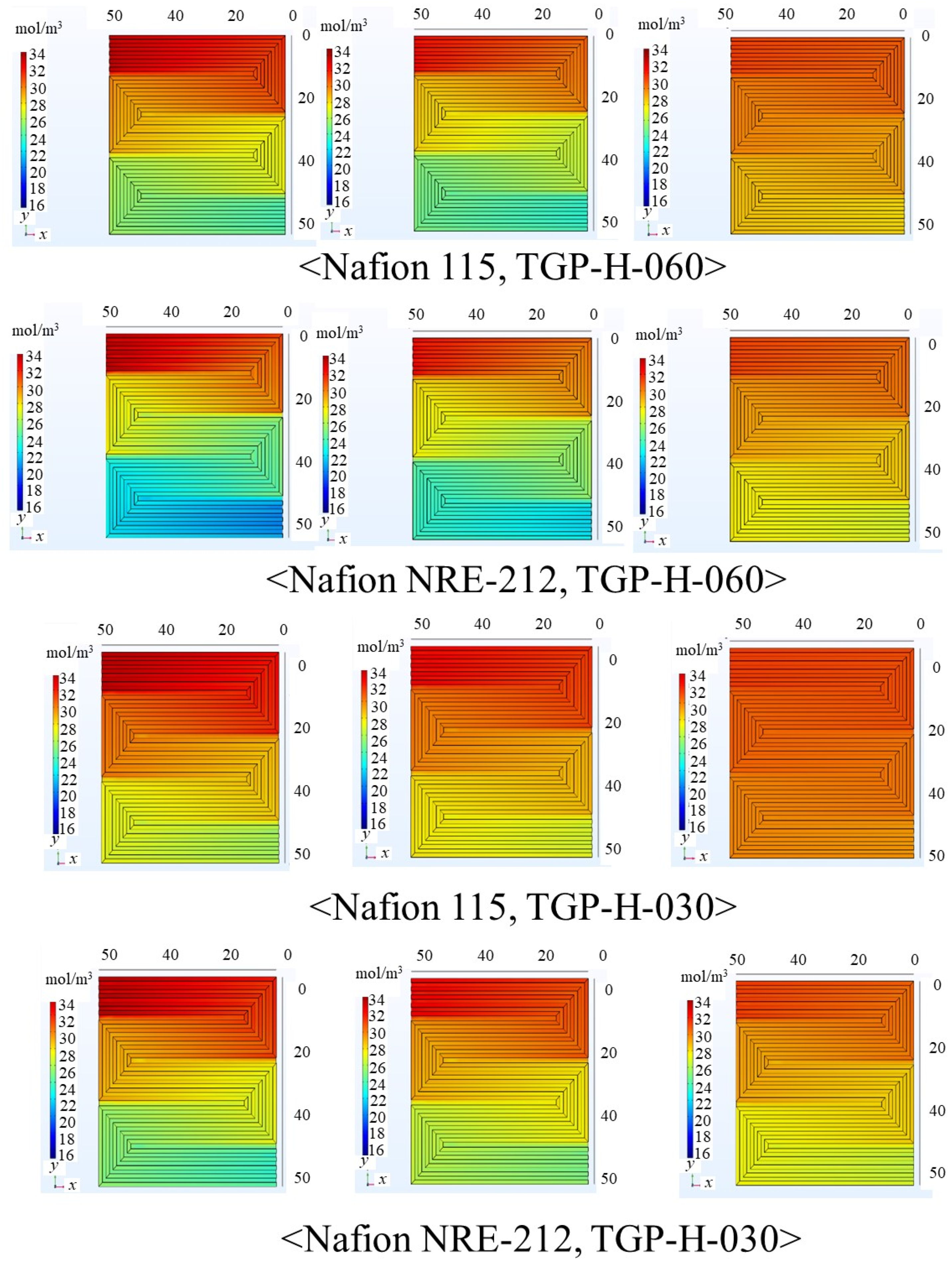

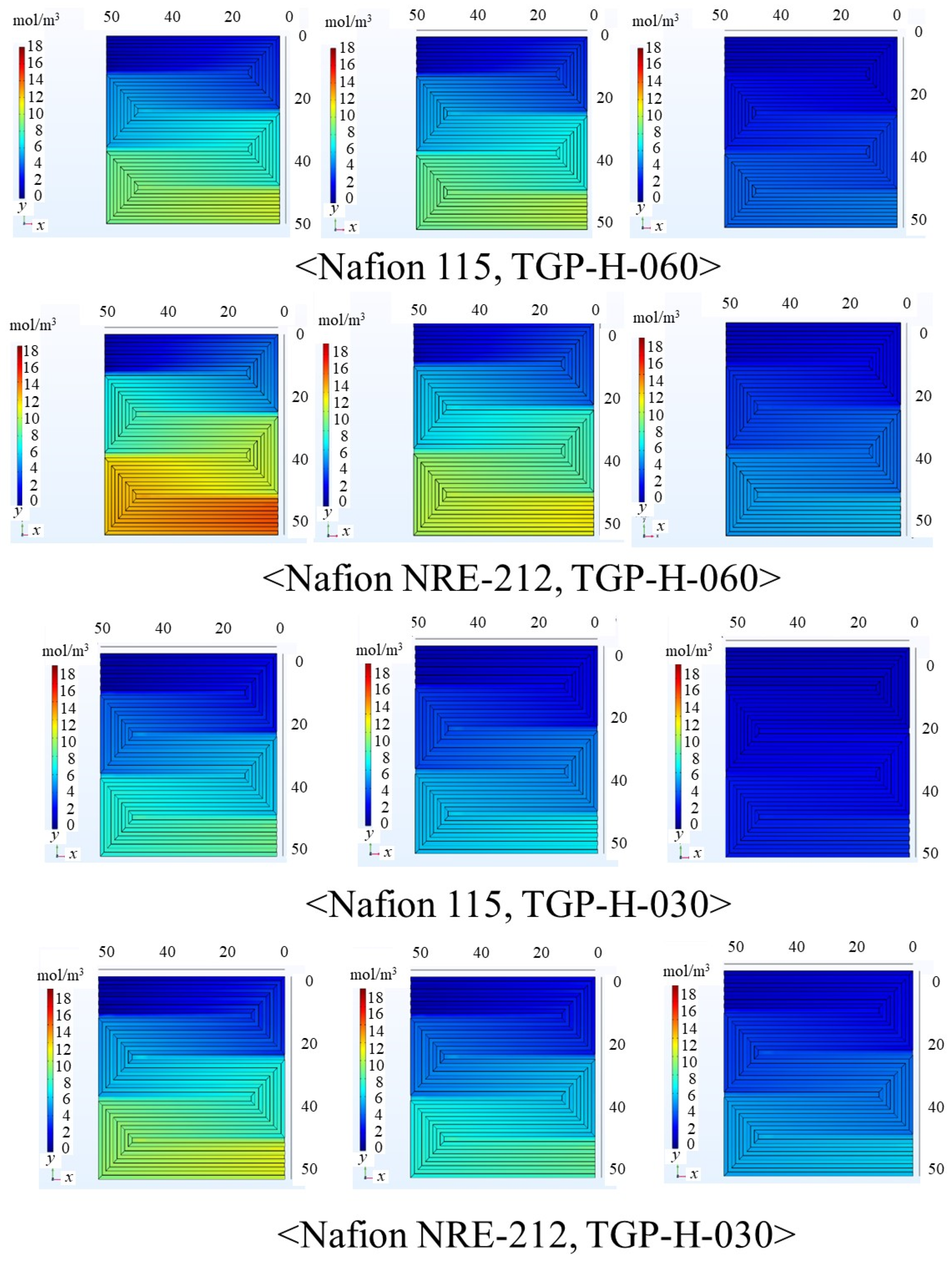

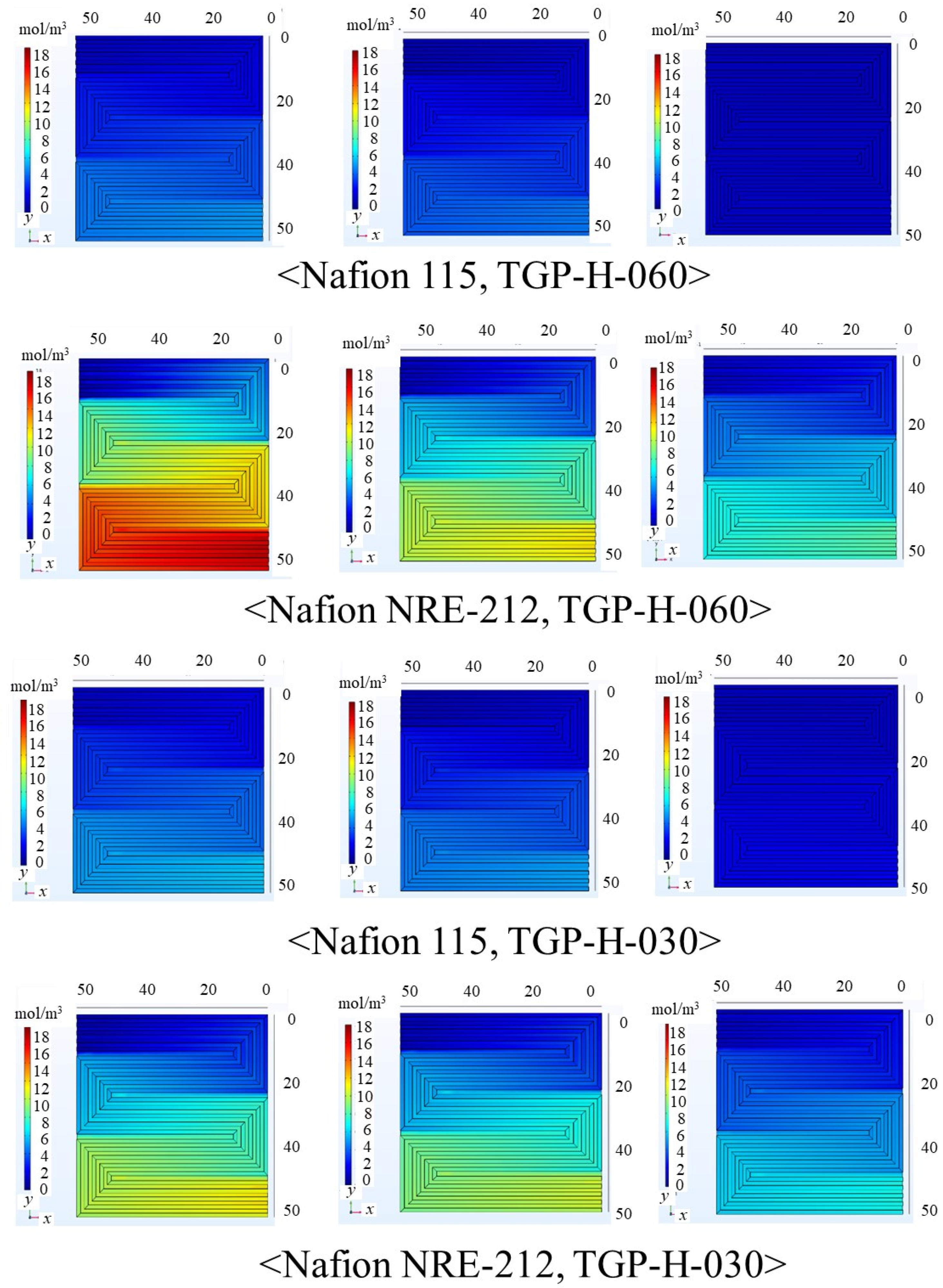

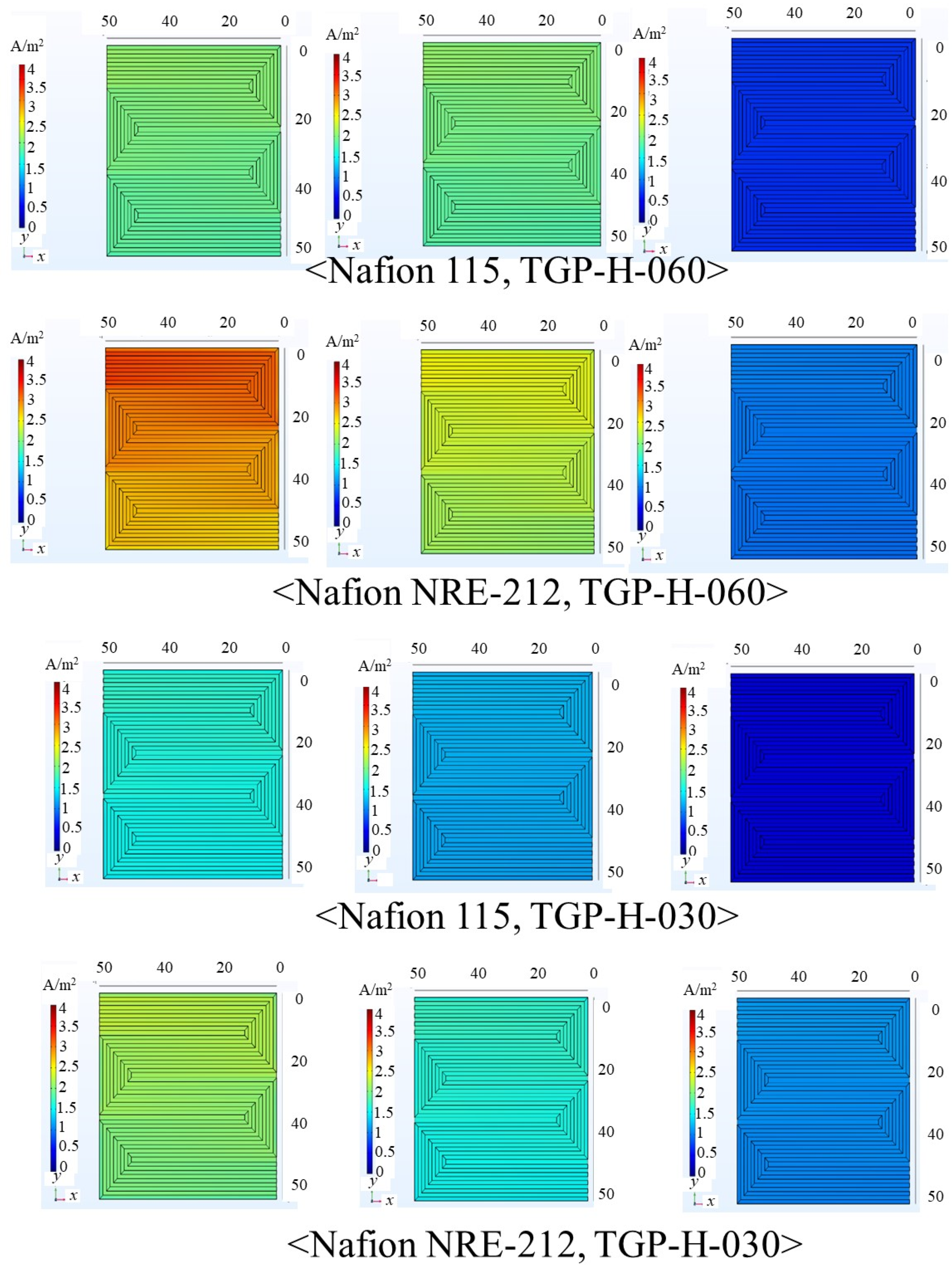

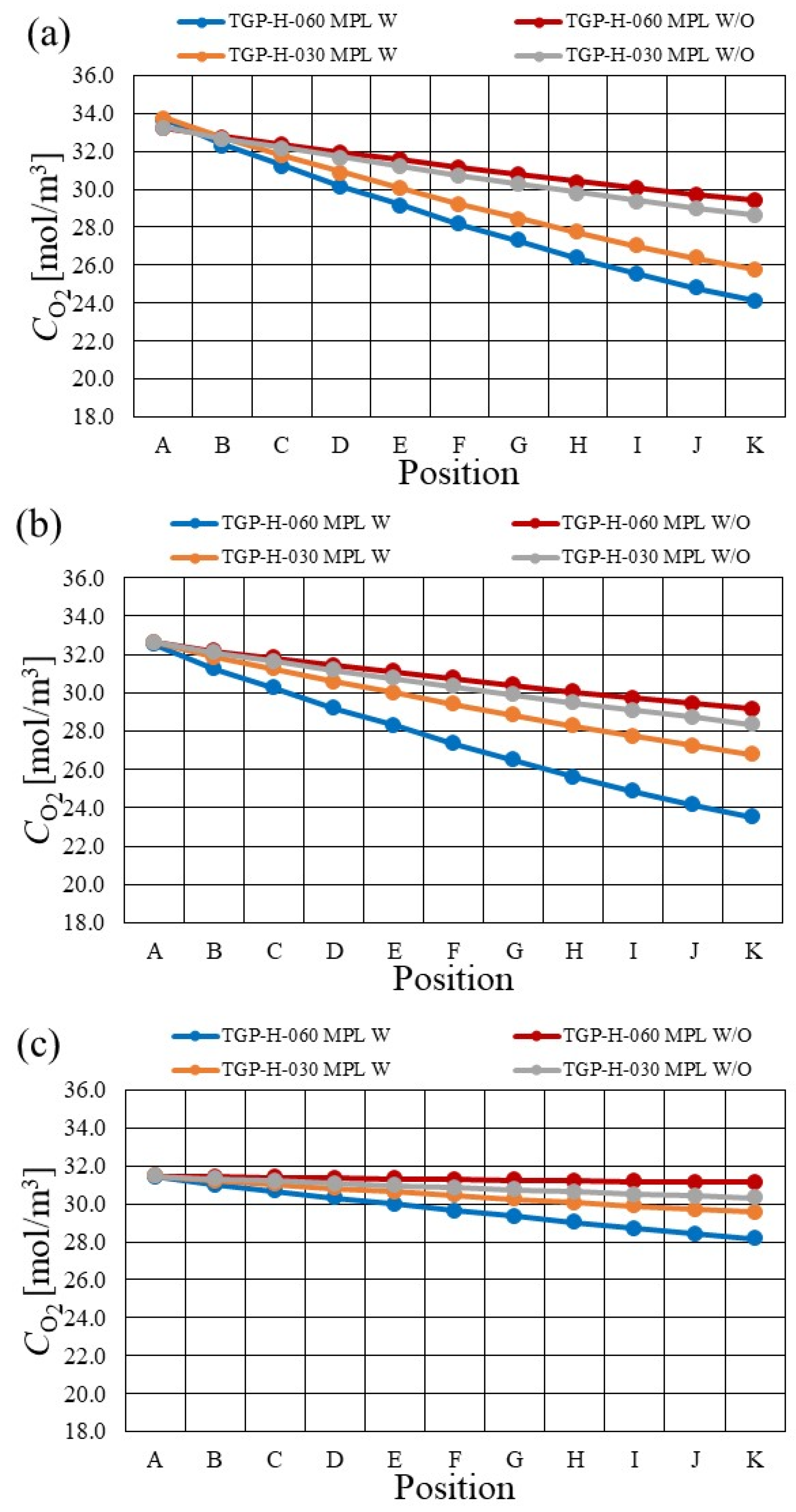

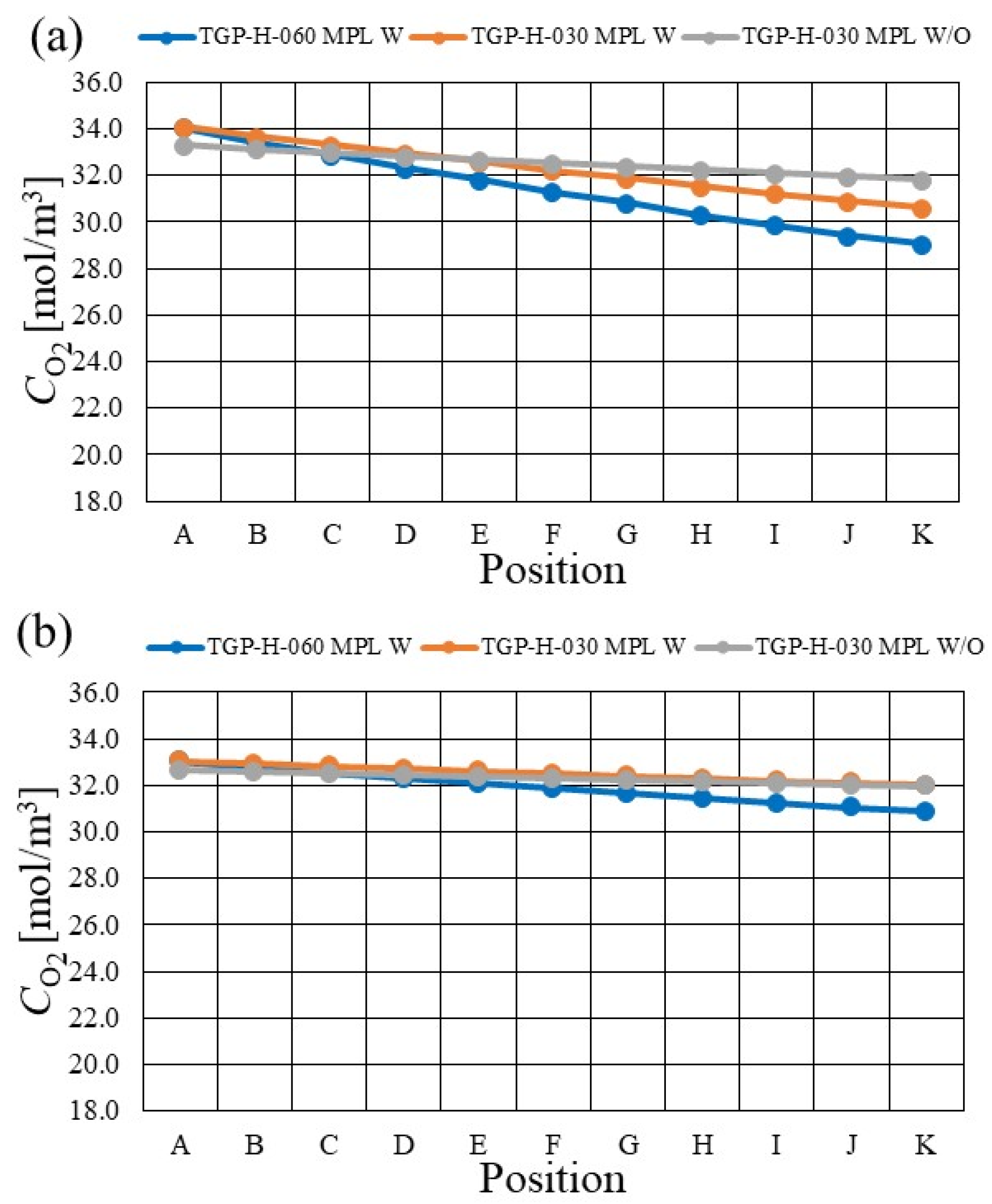

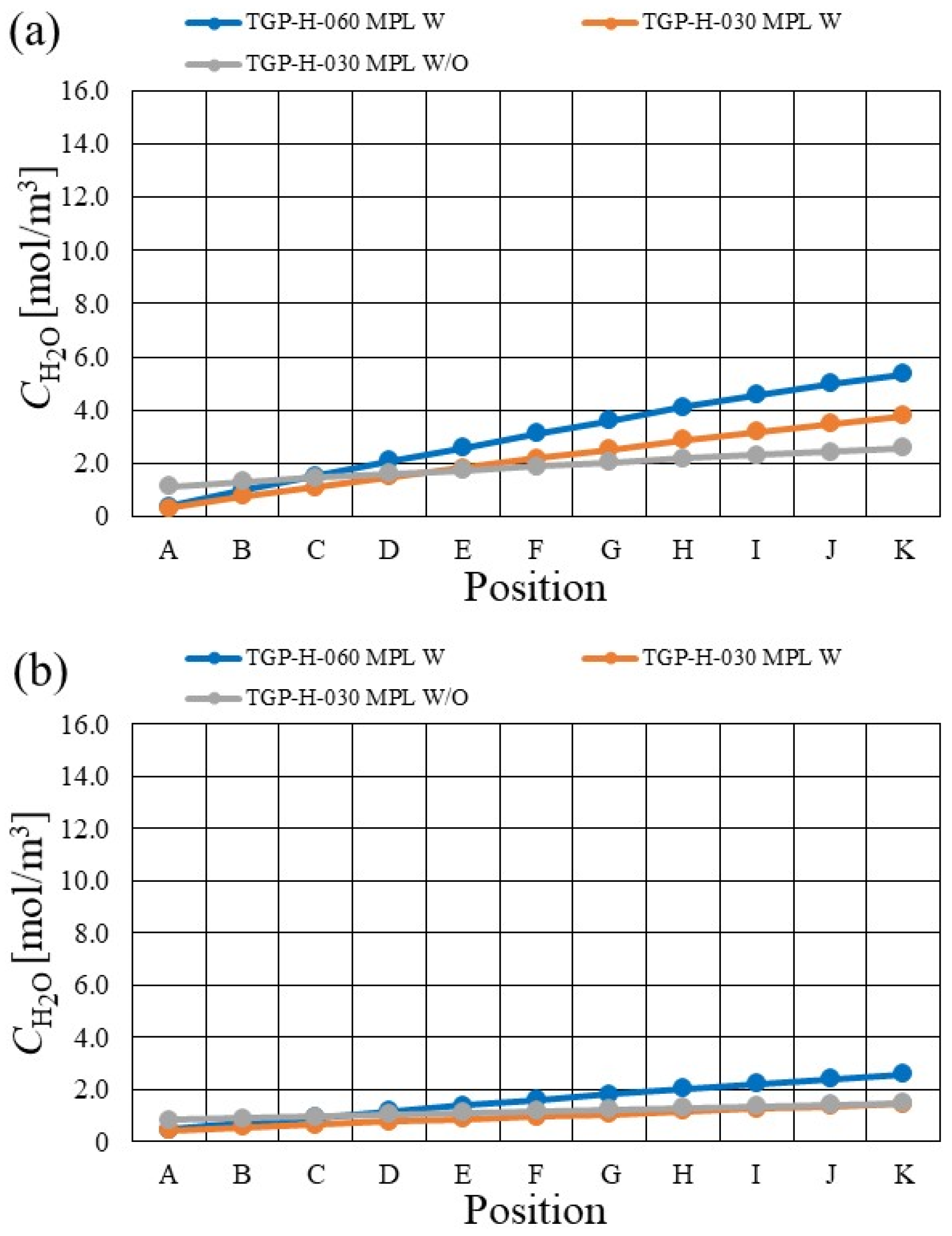

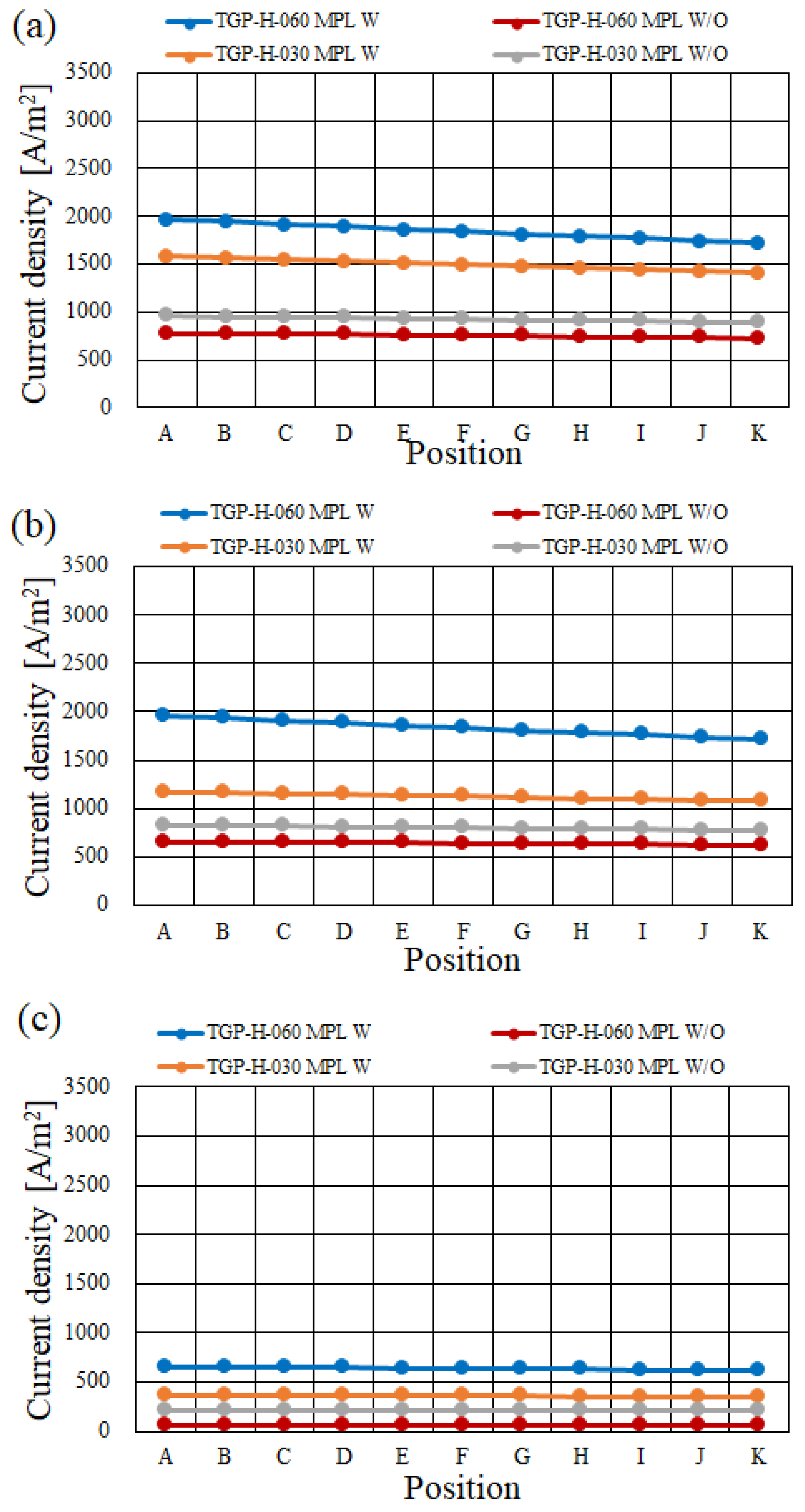

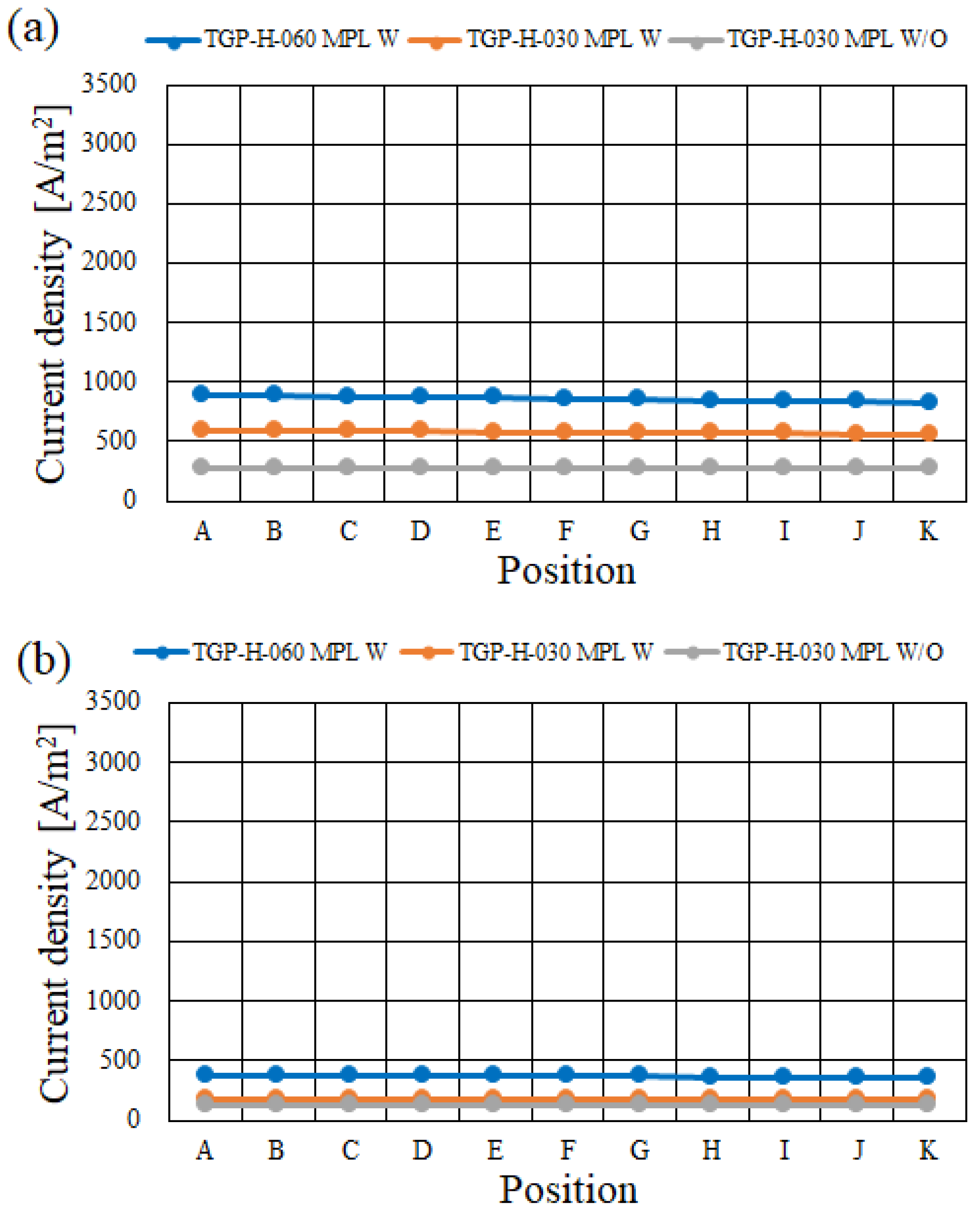

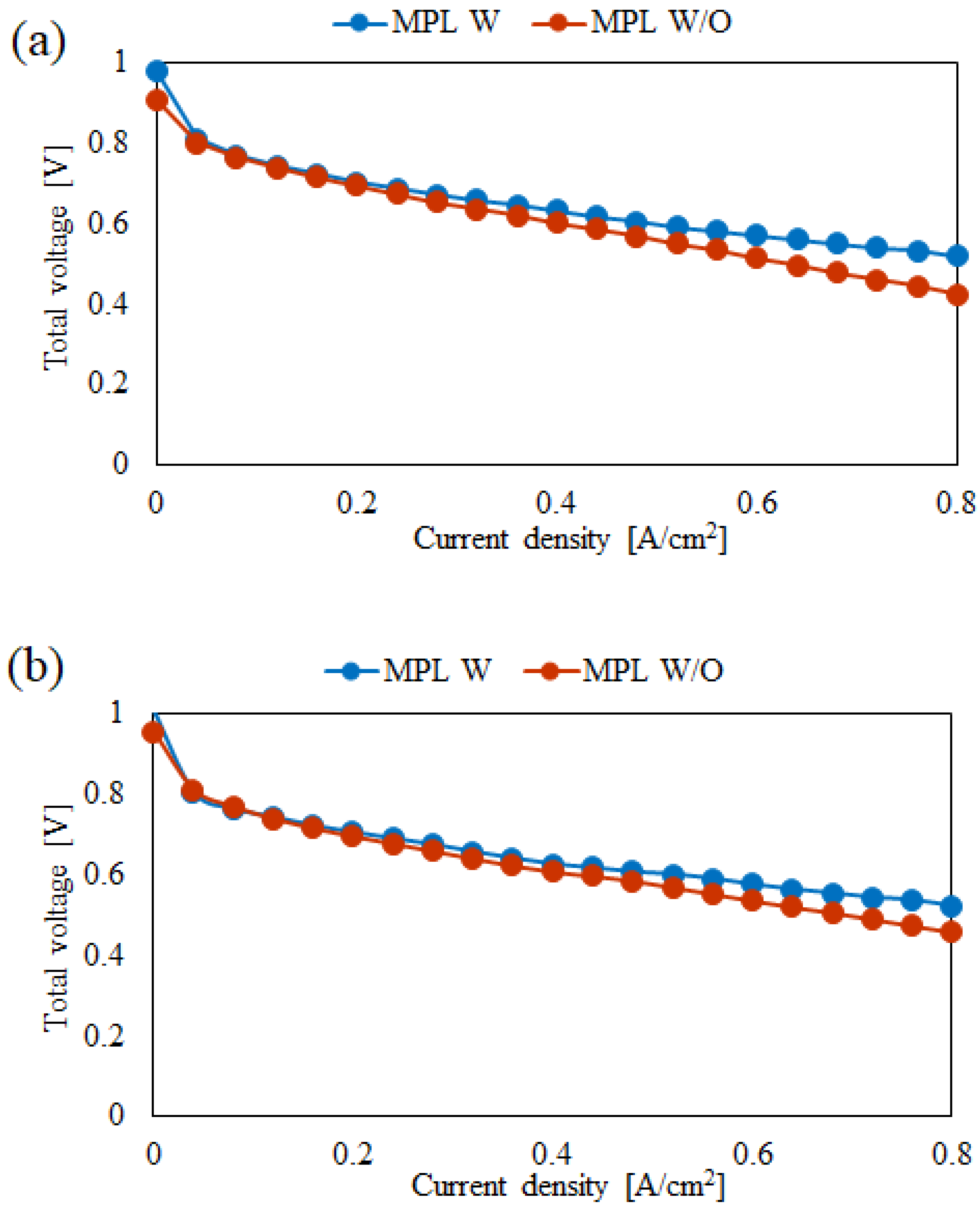

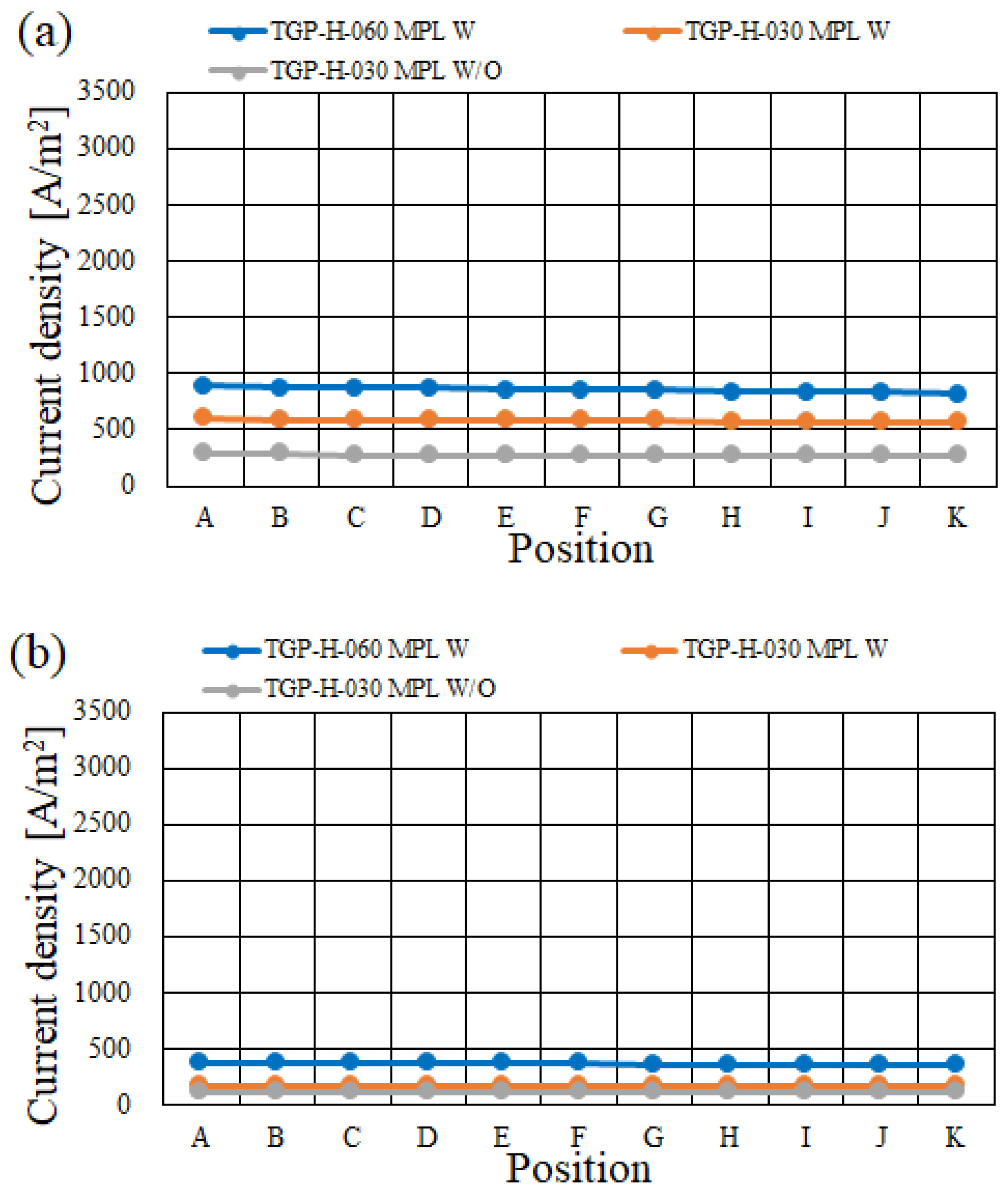

3.1. In-Plane Distribution of O2, H2O and Current Density on the Interface between PEM and Cathode Catalyst Layer

3.2. Analysis on Distribution of O2, H2O and Current Density along with the Gas Flow through the Gas Channel

4. Conclusions

- (i)

- The molar concentration of O2 decreases along the gas channel with and without MPL irrespective of the thickness of PEM and GDL as well as Tini. The change in the molar concentration of O2 from the inlet to the outlet is larger with MPL than that without MPL. In addition, the change in the concentration of O2 from the inlet to the outlet for A40%RH, C40%RH is smaller compared with that for A80%RH, C80%RH irrespective of the thickness of PEM and GDL and Tini.

- (ii)

- The molar concentration of H2O increases along the gas channel irrespective of the thickness of PEM, GDL and Tini with and without MPL, which follows the progress of the O2 reduction reaction.

- (iii)

- In the case of Nafion 115 which is the thick PEM, the change in the molar concentration of H2O along the gas channel is larger with MPL than that without MPL irrespective of the thickness of GDL, Tini and RH condition.

- (iv)

- In the case of Nafion NRE-212 which is the thin PEM, the change in the molar concentration of H2O along the gas channel is larger with MPL than that without MPL in the case of TGP-H-060, while that is smaller with MPL than that without MPL at 363 K and 363 K in the case of TGP-H-030. Although it is believed that the actual RH in cell increases with the decrease in Tini due to the exponential increase in the saturation pressure of H2O vapor with the temperature, the function of MPL which exhausts H2O works well when using thin PEM and GDL. As a result, the change in the molar concentration of H2O from the inlet to the outlet is smaller with MPL than that without MPL at 353 K and 363 K in the case of TGP-H-030.

- (v)

- The change in the concentration of H2O along the gas channel decreases with the increase in Tini with and without MPL, irrespective of the thickness of PEM and GDL as well as the RH condition.

- (vi)

- The change in the concentration of H2O along the gas channel for A40%RH, C40%RH is smaller compared with that for A80%RH, C80%RH with and without MPL, irrespective of the thickness of PEM and GDL.

- (vii)

- In the case of Nafion 115 which is the thick PEM, the current density with MPL is larger than that without MPL irrespective of the thickness of GDL, Tini and RH condition. Since the proton conductivity of PEM is smaller due to the thick PEM, the function of MPL works well.

- (viii)

- In the case of Nafion NRE-212 which is the thin PEM, the current density with MPL is larger than that without MPL in the case of TGP-H-060, while that with MPL is smaller than that without MPL at 353 K and 363 K in the case of TGP-H-030. Although it is believed that the actual RH in cell increases with the decrease in Tini due to the exponential increase in the saturation pressure of H2O vapor with temperature, the function of MPL which exhausts H2O works well when using the thin PEM and GDL. Since the actual RH is lower with MPL due to the small amount of H2O, the ohmic loss is larger. Therefore, the current density with MPL is smaller compared with that without MPL.

- (ix)

- As it is important to prevent the dehydration of PEM and catalyst layer in order to attain the higher power generation performance at higher temperature such as 363 K and 373 K, it is suggested that the equipment to humidify the gas is added to the cell of PEFC as well as the humidifier pre-installed for the gas supplied to the cell, e.g., installing it into the gas channel of the separator. Additionally, the smoothly removal of the heat generated from power generation by means of carefully designing and controlling the thermal properties of MPL, catalyst layer, GDL, and separator is also important.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- NEDO (New Energy and Industry Technology Development Organization). Road Map 2017 of NEDO Fuel Cell and Hydrogen Technology Development. Available online: http://www.nedo.go.jp/cotent/100871973 (accessed on 28 July 2022). (In Japanese)

- Zhang, G.; Kandlikar, S.G.A. Critical review of cooling technique in proton exchange membrane fuel cell stacks. Int. J. Hydrogen Energy 2012, 37, 2412–2429. [Google Scholar] [CrossRef]

- Agbossou, K.; Kolhe, M.; Hamelin, J.; Bose, T.K. Performance of a stand-alone renewable energy system based on energy storage as hydrogen. IEEE Trans. Energy Convers. 2004, 19, 633–640. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, C.; Hao, D.; Ni, M.; Huang, S.; Liu, D.; Zheng, Y. 3D non-isothermal dynamic simulation of high temperature proton exchange membrane fuel cell in start-up process. Int. J. Hydrogen Energy 2021, 46, 2577–2593. [Google Scholar] [CrossRef]

- Li, Q.; He, R.; Jensen, J.O.; Bjerrum, N.J. Approaches and recent development polymer electrolyte membrane for fuel cells operating above 100 °C. Chem. Mater. 2003, 15, 4896–4915. [Google Scholar] [CrossRef]

- Lee, C.Y.; Wng, F.; Kuo, Y.W.; Tsai, C.H.; Cheng, Y.T.; Cheng, C.K.; Lin, J.T. In-situ measurement of high-temperature proton exchange membrane fuel cell stack using flexible five-in-one micro sensor. Sensors 2016, 16, 1731. [Google Scholar] [CrossRef]

- Lee, C.Y.; Weng, F.B.; Kuo, Y.W.; Cheng, Y.T.; Cheng, C.K.; Tsai, C.H.; Lee, T.J. Persistent effect test for high temperature resistant integrated microsensor embedded in high temperature proton exchange membrane fuel cell stack. Sens. Actuators A Phys. 2016, A250, 202–209. [Google Scholar] [CrossRef]

- Ryu, S.K.; Vinothkannan, M.; Kim, A.R.; Yoo, D.J. Effect of type and stoichiometry of fuels on performance of polybenzimidazole-based proton exchange membrane fuel cells operating at the temperature range of 120–160 °C. Energy 2022, 238, 121791. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, T.; Che, X.; Dong, J.; Liu, R.; Yang, J. New high-performance bulky N-heterocyclic group functionalized poly(terphenyl piperidinium) membranes for HT-PEMFC applications. J. Membr. Sci. 2022, 641, 119884. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Li, W.; Zhang, J.; Lu, D.; Yan, W.; Xiang, Y.; Lu, S. Effect of catalyst layer microstructure on performance and stability for high temperature polymer electrolyte membrane fuel cells. J. Power Sources 2021, 505, 230059. [Google Scholar] [CrossRef]

- Nanadegani, F.S.; Lay, E.N.; Sunden, B. Computational analysis of the impact of a micro porous layer (MPL) on the characteristics of a high temperature PEMFC. Electrochim. Acta 2020, 333, 135552. [Google Scholar] [CrossRef]

- Fu, X.; Li, T.; Tang, L.; Deng, X.; Zhang, R.; Hu, S.; Zhao, F.; Li, X.; Liu, Q. Reticulated polyaniline nanowires as a cathode microporous layer for high-temperature PEMFCs. Int. J. Hydrogen Energy 2021, 46, 8802–8809. [Google Scholar] [CrossRef]

- Kanchan, B.K.; Randive, P.; Pati, S. Implications of non-uniform porosity distribution in gas diffusion layer on the performance of a high temperature PEM fuel cell. Int. J. Hydrogen Energy 2021, 46, 18571–18588. [Google Scholar] [CrossRef]

- Xia, L.; Ni, M.; He, Q.; Xu, Q.; Cheng, C. Optimization of gas diffusion layer in high temperature PEMFC with the focuses on thickness and porosity. Appl. Energy 2021, 300, 117357. [Google Scholar] [CrossRef]

- Xu, Y.; Fan, R.; Chang, G.; Xu, S.; Cai, T. Investigating temperature-driven water transport in cathode gas diffusion media of PEMFC with a non-isothermal, two-phase model. Energy Convers. Manag. 2021, 248, 114791. [Google Scholar] [CrossRef]

- Zhang, T.; Li, J.; Li, Q.; Yu, M.; Sun, H. Combination effects of flow field structure and assembly force on performance of high temperature proton exchange membrane fuel cells. Int. J. Energy Res. 2021, 45, 7903–7917. [Google Scholar] [CrossRef]

- Hoppe, E.; Janssen, H.; Muller, M.; Lehnert, W. The impact of flow field plate misalignment on the gas diffusion layer intrusion and performance of a high-temperature polymer electrolyte fuel. J. Power Sources 2021, 501, 230036. [Google Scholar] [CrossRef]

- Nishimura, A.; Kamiya, S.; Okado, T.; Sato, Y.; Hirota, M.; Kolhe, M.L. Heat and mass transfer analysis in single cell of PEFC using different PEM and GDL at higher temperature. Int. J. Hydrogen Energy 2019, 44, 29631–29640. [Google Scholar] [CrossRef]

- Nishimura, A.; Okado, T.; Kojima, Y.; Hirota, M.; Hu, E. Impact of MPL on temperature distribution in single polymer electrolyte fuel cell with various thickness of polymer electrolyte membrane. Energies 2020, 13, 2499. [Google Scholar] [CrossRef]

- Nishimura, A.; Okado, T.; Kojima, Y.; Hu, E. Impact of microporous layer on heat and mass transfer in a single cell of polymer electrolyte fuel cell using a thin polymer electrolyte membrane and a thin gas diffusion layer operated at a high-temperature range. ACS Omega 2021, 6, 14575–14584. [Google Scholar] [CrossRef]

- Nishimura, A.; Sato, Y.; Kamiya, S.; Okado, T.; Yamamoto, K.; Hirota, M.; Hu, E. Impact of thickness of polymer electrolyte membrane and gas diffusion layer on temperature distribution in polymer electrolyte fuel cell operated at temperature around 90 °C. J. Energy Power Eng. 2019, 13, 97–115. [Google Scholar] [CrossRef]

- Nishimura, A.; Yamamoto, K.; Okado, T.; Kojima, Y.; Hirota, M.; Kolhe, M.L. Impact analysis of MPL and PEM thickness on temperature distribution within PEFC operating at relatively higher temperature. Energy 2020, 205, 117875. [Google Scholar] [CrossRef]

- Nishimura, A.; Kono, N.; Toyoda, K.; Kojima, Y.; Kolhe, M.L. Impact analysis of MPL on a PEFC cell’s temperature distribution with thin PEM and GDL for operating at higher temperature than usual. J. Energy Power Eng. 2021, 15, 39–51. [Google Scholar] [CrossRef]

- Nishimura, A.; Toyoda, K.; Kojima, Y.; Ito, S.; Hu, E. Numerical simulation on impacts of thickness of nafion series membranes and relative humidity on PEMFC operated at 363 K and 373 K. Energies 2021, 14, 8256. [Google Scholar] [CrossRef]

- Das, S.K.; Gibson, H.A. These dimensional multi-physics modeling and simulation for assessment of mass transport impact on the performance of a high temperature polymer electrolyte membrane fuel cell. J. Power Sources 2021, 499, 161–188. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Qu, Z.G.; Xu, H.T.; Talkhoncheh, F.K.; Liu, S.; Gao, Q. A Numerical study on the performance of PEMFC with wedge-shaped fins in the cathode channel. Int. J. Hydrogen Energy 2021, 46, 27700–27708. [Google Scholar] [CrossRef]

- Chen, H.; Guo, H.; Ye, F.; Ma, C.F. Improving two-phase mass transportation under non-darcy flow effect in oriented-type flow channels of proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2021, 46, 21600–21618. [Google Scholar] [CrossRef]

- Chen, H.; Guo, H.; Ye, F.; Ma, C.F. A numerical study of oriented-type flow channels with porous-blocked baffles of proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2021, 46, 29443–29458. [Google Scholar] [CrossRef]

- Penga, Z.; Tolj, I.; Barbir, F. Computational fluid dynamics study of PEM fuel cell performance. Int. J. Hydrogen Energy 2016, 41, 17585–17594. [Google Scholar] [CrossRef]

- Freunberger, S.A.; Reum, M.; Evertz, J.; Wokuan, A.; Buchi, F.M. Measuring the current distribution in PEFCs with sub-millimeter resolution. J. Electrochem. Soc. 2006, 153, A2158–A2165. [Google Scholar] [CrossRef]

- Nishimura, A.; Sato, A.; Yoshimura, M.; Kamiya, S.; Hirota, M. Impact of thickness of polymer electrolyte membrane on temperature distribution in single cell of polymer electrolyte fuel cell operated at high temperature. J. Energy Power Eng. 2018, 12, 80–92. [Google Scholar] [CrossRef]

- Nishimura, A.; Shibuya, K.; Morimoto, A.; Tanaka, S.; Hirota, M.; Nakamura, M.; Kojima, Y.; Narita, M.; Hu, E. Dominant factor and mechanism of coupling phenomena in single cell of polymer electrolyte fuel cell. Appl. Energy 2012, 1, 73–79. [Google Scholar] [CrossRef]

- Copper, N.J.; Santamaria, A.D.; Becton, M.K.; Park, J.W. Neutron radiography measurements of in-situ PEMFC liquid water saturation in 2D & 3D morphology gas diffusion layers. Int. J. Hydrogen Energy 2017, 42, 6269–16278. [Google Scholar]

- The Japan Society of Mechanical Engineers. JSME Heat Transfer Handbook, 1st ed.; The Japan Society of Mechanical Engineers: Tokyo, Japan; Maruzen: Tokyo, Japan, 1993; p. 387. [Google Scholar]

- Reid, R.C.; Prausnitz, J.M.; Poling, B.E. The Properties of Gases and Liquids, 1st ed.; McGraw-Hill: Columbus, TX, USA, 1987; p. 591. [Google Scholar]

- Merck. Available online: http://www.sigmaaldrich.com/japan/materialscience/alternative/nafion.html (accessed on 5 November 2021).

- Senn, S.M.; Poulikakos, D. Polymer electrolyte fuel cells with porous materials as fluid distributors and comparisons with traditional channeled systems. Trans. ASME 2004, 126, 410–418. [Google Scholar] [CrossRef]

- Kang, K.; Ju, H. Numerical modeling and analysis of micro-porous layer effects in polymer electrolyte fuel cells. J. Power Sources 2006, 194, 763–773. [Google Scholar] [CrossRef]

- TORAY. Available online: http://www.torayca.com/en/lineup/composites/com_009_01.html (accessed on 5 November 2021).

- Takayama, T. Numerical simulation of transient internal states of PEFC cell and stack considering control of anode system. Res. Rep. Mizuho Res. Technol. 2018, 9, 1–14. [Google Scholar]

- Rostami, L.; Nejad, P.M.G.; Vatani, A. A numerical investigation of serpentine flow channel with different bend sizes in polymer electrolyte membrane fuel cells. Energy 2016, 97, 400–410. [Google Scholar] [CrossRef]

- Xing, L.; Das, P.K.; Song, X.; Mamlouk, M.; Scott, K. Numerical analysis of the optimum membrane/ionomer water content of PEMFCs: The interface of nafion ionomer content and cathode relative humidity. Appl. Energy 2015, 138, 242–257. [Google Scholar] [CrossRef]

- Akimoto, F.; Sasabe, T.; Yoshida, T.; Naito, H.; Kawamura, K.; Hirai, S. Investigation of effects of high temperature and pressure on a polymer electrolyte fuel cell with polarization analysis and X-ray imaging of liquid water. J. Power Sources 2019, 431, 205–209. [Google Scholar]

- Jia, T.; Shen, S.; Zhao, J.; Jin, J.; Pan, B.; Duan, X.; Meng, C.; Che, Q. Ultrathin membranes formation via the layer by layer self-assembly of carbon natotubes-based inorganics as high temperature proton exchange membranes. Int. J. Hydrogen Energy 2020, 45, 14517–14527. [Google Scholar] [CrossRef]

- Wong, C.Y.; Wong, W.Y.; Ramya, K.; Khalid, M.; Loh, K.S.; Daud, W.R.W.; Lim, K.L.; Walvekar, R.; Kadhum, A.A.H. Additives in proton exchange membranes for low- and high-temperature fuel cell applications: A review. Int. J. Hydrogen Energy 2019, 44, 6116–6135. [Google Scholar] [CrossRef]

- Ferreria, R.B.; Falcao, D.S.; Oliveira, V.B.; Pinto, A.M.F.R. Experimental study on the membrane electrode assembly of a proton exchange membrane fuel cell: Effects of microporous layer, membrane thickness and gas diffusion layer hydrophobic treatment. Electrochim. Acta 2017, 224, 337–345. [Google Scholar] [CrossRef]

- Zamel, N.; Becker, J.; Wiegmann, A. Estimating the thermal conductivity and diffusion coefficient for the microporous layer of polymer electrolyte membrane fuel cells. J. Power Sources 2012, 207, 70–80. [Google Scholar] [CrossRef]

- Blanco, M.; Wilkinson, D.P. Investigation of the effect of microporous layers on water management in a proton exchange membrane fuel cell using novel diagnostic methods. Int. J. Hydrogen Energy 2014, 39, 16390–16404. [Google Scholar] [CrossRef]

- Zhou, J.; Shukla, S.; Putz, A.; Secanell, M. Analysis of the role of the microporous layer in improving polymer electrolyte fuel cell performance. Electrochim. Acta 2018, 268, 366–382. [Google Scholar] [CrossRef]

- Springer, T.E.; Zowodzinski, T.A.; Gottesfeld, S. Polymer electrolyte fuel cell model. J. Electrochem. Soc. 1991, 138, 2334–2342. [Google Scholar] [CrossRef]

- Nishimura, A.; Kojima, Y.; Ito, S.; Hu, E. Impacts of separator thickness on temperature distributions and power generation characteristics of a single PEMFC operated at higher temperature of 363 and 373 K. Energies 2022, 15, 1558. [Google Scholar] [CrossRef]

- Liu, F.; Lu, G.; Wang, C.Y. Water transport coefficient distribution through the membrane in a polymer electrolyte fuel cell. J. Membr. Sci. 2007, 287, 126–131. [Google Scholar] [CrossRef]

- Kim, H.Y.; Kim, K. Numerical study on the effects of gas humidity on proton-exchange membrane fuel cell performance. Int. J. Hydrogen Energy 2016, 41, 11776–11783. [Google Scholar] [CrossRef]

- NEDO (New Energy and Industry Technology Development Organization). Road Map 2010 of NEDO Fuel Cell and Hydrogen Technology Development. Available online: http://www.nedo.go.jp/cotent/100642947 (accessed on 2 August 2022). (In Japanese)

| Components of Cell | Size | Characteristics |

|---|---|---|

| PEM | 50.0 mm × 50.0 mm × 0.127 mm (for Nafion 115) and 0.051 mm (for Nafion NRE-212) | Nafion 115 and Nafion NRE-212 (manufactured by Du Pont Corp.) |

| Catalyst layer | 50.0 mm × 50.0 mm × 0.01 mm | Pt/C (Pt: 20 wt%) |

| MPL | 50.0 mm × 50.0 mm × 0.003 mm | PTFE + carbon black |

| GDL | 50.0 mm × 50.0 mm × 0.19 mm (for TGP-H-060) and 0.11 mm (for TGP-H-030) | TGP-H-060 and TGP-H-030 (manufactured by Toray Corp.) |

| Gas separator | 50.0 mm × 50.0 mm × 2.00 mm (thickness of rib: 1.00 mm) (width of gas channel and rib: 1.0 mm, thickness of gas channel: 1.0 mm) | Carbon graphite, serpentine |

| Parameter | Value |

|---|---|

| Density of H2 [kg/m3] | 7.10 × 10−2 (353 K), 6.89 × 10−2 (363 K), 6.69 × 10−2 (373 K) [33] |

| Density of O2 [kg/m3] | 1.11 (353 K), 1.08 (363 K), 1.05 (373 K) [33] |

| Density of H2O [kg/m3] | 2.95 × 10−1 (353 K), 4.26 × 10−1 (363 K), 6.01 × 10−1 (373 K) [33] |

| Viscosity of H2 [Pa·s] | 9.96 × 10−6 (353 K), 1.02 × 10−5 (363 K), 1.03 × 10−5 (373 K) [33] |

| Viscosity of O2 [Pa·s] | 2.35 × 10−5 (353 K), 2.40 × 10−5 (363 K), 2.45 × 10−5 (373 K) [33] |

| Viscosity of H2O [Pa·s] | 1.16 × 10−5 (353 K), 1.19 × 10−5 (363 K), 1.23 × 10−5 (373 K) [33] |

| Binary diffusion coefficient between H2 and H2O [m2/s] | 9.27 × 10−5 [34] |

| Binary diffusion coefficient between O2 and H2O [m2/s] | 3.57 × 10−5 [34] |

| Porosity of catalyst layer [-] | 0.78 [14,22,30,31,32] |

| Permeability of catalyst layer [m2] | 8.69 × 10−12 [14,22,30,31,32] |

| Porosity of MPL [-] | 0.60 [14,22,30,31,32] |

| Permeability of MPL [m2] | 1.00 × 10−13 [14,22,30,31,32] |

| Porosity of GDL [-] | 0.78 [14,22,30,31,32] |

| Permeability of GDL [m2] | 8.69 × 10−12 [14,22,30,31,32] |

| Conductivity of PEM [S/m] | 10 [35] |

| Conductivity of catalyst layer [S/m] | 53 [36] |

| Conductivity of MPL [S/m] | 1000 [37] |

| Conductivity of GDL [S/m] | 1250 [38] |

| Anode reference equilibrium potential [V] | 0 |

| Cathode reference equilibrium potential [V] | 1.229 |

| Anode reference exchange current density [A/m2] | 1000 [39] |

| Cathode reference exchange current density [A/m2] | 1 [39] |

| Anode charge transfer coefficient [-] | 0.5 [40] |

| Cathode charge transfer coefficient [-] | 0.5 [41] |

| Condition | Value | |

|---|---|---|

| The initial temperature of cell (Tini) [K] | 353, 363, 373 | |

| Cell voltage [V] | Experimental data are applied [18,19] | |

| Supply gas condition | Anode | Cathode |

| Gas type | H2 | O2 |

| Temperature of supply gas at inlet [K] | 353, 363, 373 | 353, 363, 373 |

| RH of supply gas [%RH] | 40, 80 | 40, 80 |

| Pressure of supply gas at inlet (absolute) [MPa] | 0.4 | 0.4 |

| Flow rate of supply gas at inlet [NL/min] (Stoichiometric ratio [-]) | 0.210 (1.5) | 0.105 (1.5) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nishimura, A.; Toyoda, K.; Mishima, D.; Ito, S.; Hu, E. Numerical Analysis on Impact of Thickness of PEM and GDL with and without MPL on Coupling Phenomena in PEFC Operated at Higher Temperature Such as 363 K and 373 K. Energies 2022, 15, 5936. https://doi.org/10.3390/en15165936

Nishimura A, Toyoda K, Mishima D, Ito S, Hu E. Numerical Analysis on Impact of Thickness of PEM and GDL with and without MPL on Coupling Phenomena in PEFC Operated at Higher Temperature Such as 363 K and 373 K. Energies. 2022; 15(16):5936. https://doi.org/10.3390/en15165936

Chicago/Turabian StyleNishimura, Akira, Kyohei Toyoda, Daiki Mishima, Syogo Ito, and Eric Hu. 2022. "Numerical Analysis on Impact of Thickness of PEM and GDL with and without MPL on Coupling Phenomena in PEFC Operated at Higher Temperature Such as 363 K and 373 K" Energies 15, no. 16: 5936. https://doi.org/10.3390/en15165936