Advances in Proton Exchange Membrane Fuel Cell

A special issue of Energies (ISSN 1996-1073). This special issue belongs to the section "D2: Electrochem: Batteries, Fuel Cells, Capacitors".

Deadline for manuscript submissions: closed (5 April 2024) | Viewed by 15759

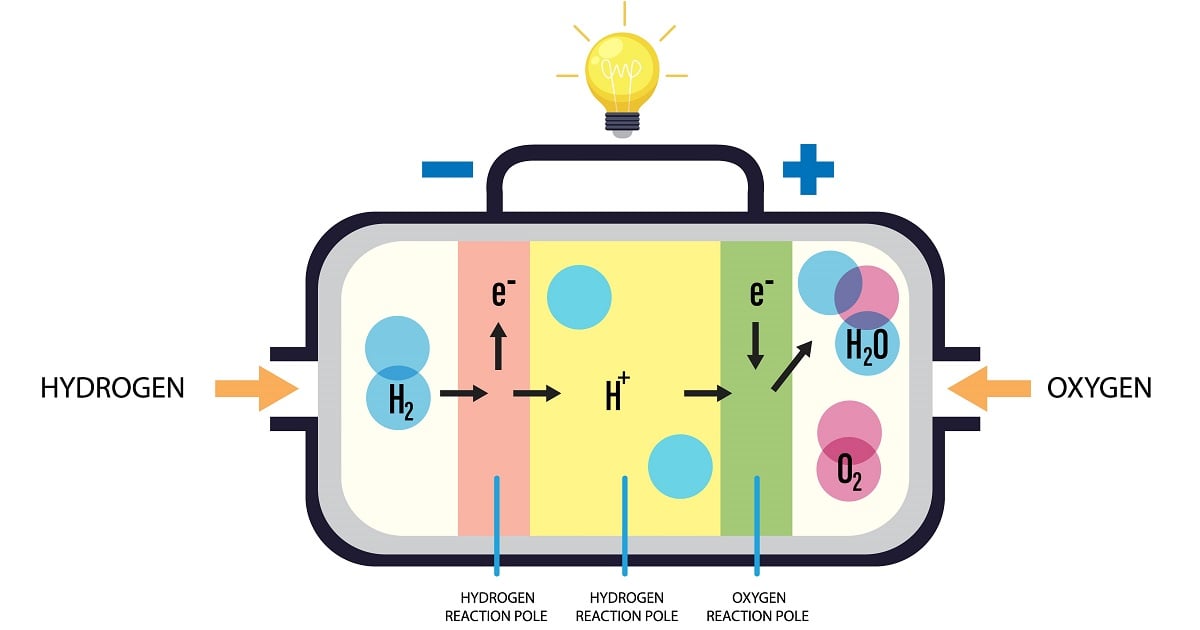

Image courtesy of brgfx on Freepik

Special Issue Editors

Interests: fuel cells; computational fluid dynamics; mathematical modeling; flow field design; dynamic models of fuel cells; continuum models; water and heat management; temporally and spatially resolved fuel cell performance monitoring; development of novel sensors and monitoring equipment for fuel cells; graded design of fuel cells; engineering thermodynamics; hydrogen energy

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

Due to increased political and economic interest towards green energy sources, hydrogen obtained from renewable energy sources presents itself as the most probable clean energy carrier of the near future. Proton exchange membrane fuel cells are electrochemical converters used to generate electricity from hydrogen and oxygen with only by-products of heat and water. Due to favorable characteristics, proton exchange membrane fuel cells are considered the most probable automotive power source due to significant advantages and simplified system design when compared to internal combustion engines and batteries. Nevertheless, fuel cells still require significant amounts of research and development to ensure higher durability, decrease system complexity, improve dynamic performance, and reduce production costs. Reductions in the system complexity and costs can be achieved by carefully designing the fuel cell system in such a manner that the generated water and heat are distributed evenly and in a controllable manner, resulting in increased durability, higher specific power, and dynamic performance, and consequently minimized overall size, complexity and cost of the system. Due to complex mass and heat transfer reactions transpiring during the operation of the fuel cell, computer simulations are indispensable for the analysis and interpretation of highly intertwined processes within this electrochemical device. By tackling the aforementioned problems, this Special Issue focuses on Advances in Proton Exchange Membrane Fuel Cells. The topics of interest for publication include but are not limited to:

- Development of validated steady-state, dynamic, and multi-scale models of fuel cells

- Development of flow fields for improved performance of fuel cells

- Development of techniques for utilization of the generated water and heat

- Development of models and experimental setups of fuel cell stacks

- Development of membrane-electrode assemblies for improved performance of fuel cells

- Development of micro and biological fuel cells

- Development of fuel cell monitoring systems and sensors

Dr. Željko Penga

Dr. Lei Xing

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Energies is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- PEM fuel cells

- single cell and stack development

- flow fields

- water and heat management

- improved performance of fuel cells

- multiscale modeling and validation

- steady-state and dynamic performance

- micro and biological fuel cells

- fuel cell sensors

- fuel cell monitoring system