Mapping of Alternative Oilseeds from the Brazilian Caatinga and Assessment of Catalytic Pathways toward Biofuels Production

Abstract

1. Introduction

2. Materials and Methods

3. Results

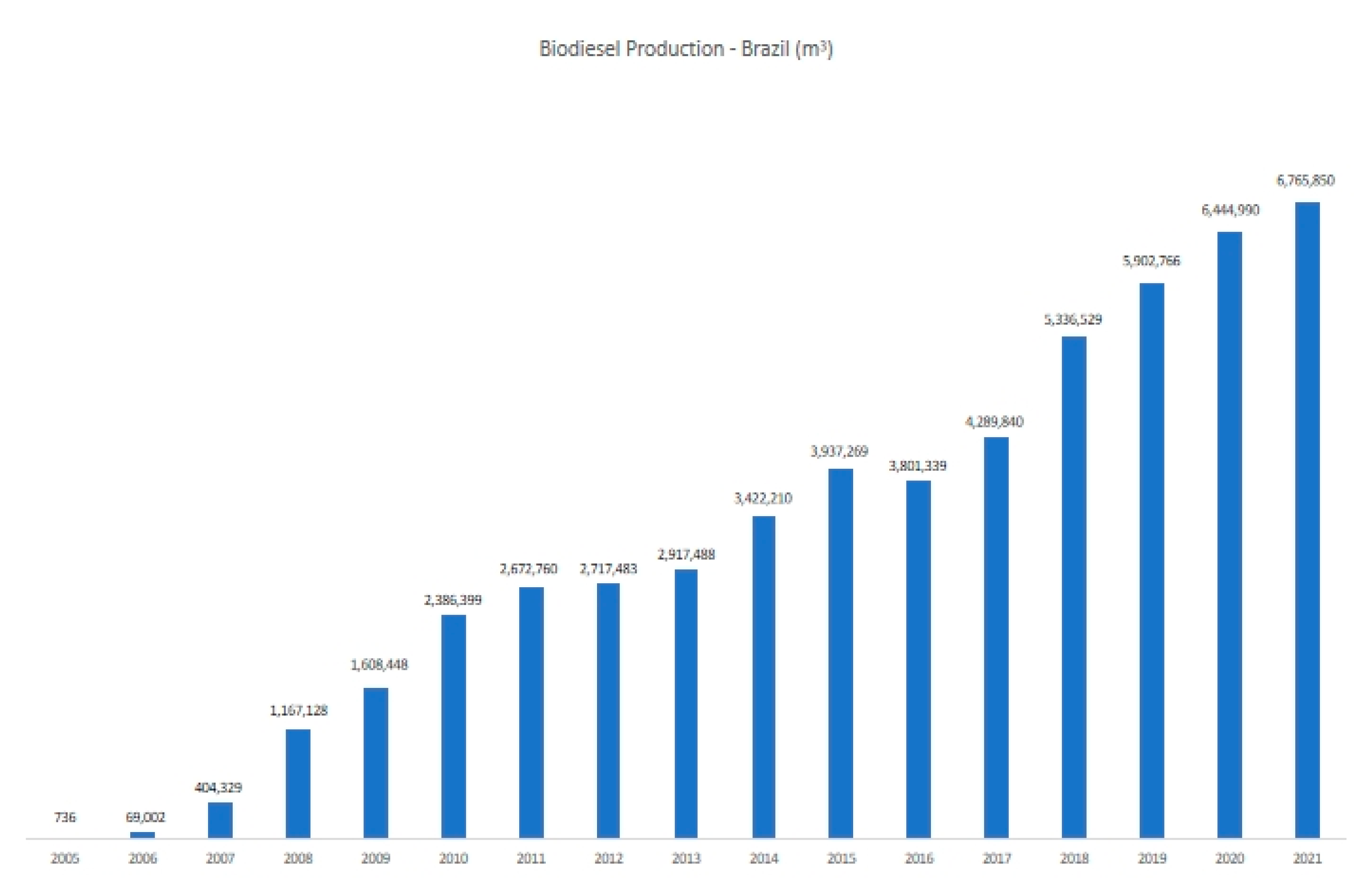

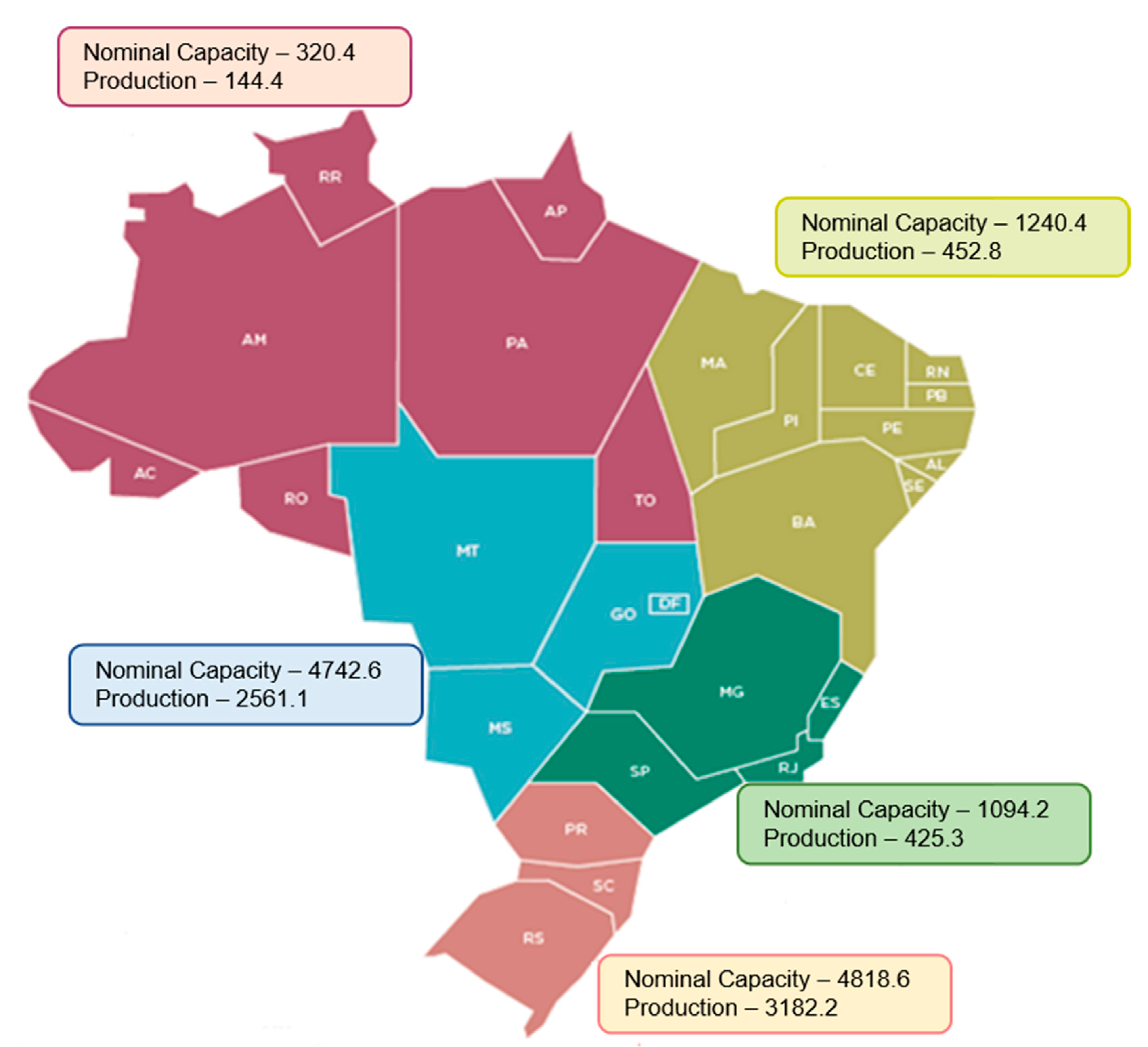

3.1. Biofuels as Renewable Energy Sources

3.2. Mapping of Alternative Vegetable Oil Crops Occurring in the Caatinga Biome as Candidate Feedstocks for Biofuels Production

| Family Species (Popular Name) | Studied Part | Occurrence | Vegetation Type | Oil Yield | Major Components a | Extraction Technique | Reference |

|---|---|---|---|---|---|---|---|

| Apocynaceae | |||||||

| Cascabela thevetia (L.) Lippold., synonym Thevetia peruviana (chapéu-de-napoleão) | Seed | NE, N, S, SE, CW | Shrub | 60–65% | 18:1 (43.4%) | Soxhlet, Hexane | [34] |

| Arecaceae | |||||||

| Acrocomia aculeata (Jacq.) Lodd. ex Mart. (macaúba/macaíba/mucajá) | Seed | N, NE, CW, SE | Arboral /palm | 56.1% | 12:0 (42.9%) | Soxhlet, Hexane | [29] |

| Attalea speciosa Mart. ex Spreng., formerly known as Attalea vitrivir Zona, synonym Orbignya phalerata (babassu/babaçu) | Almonds | N, NE, CW, SE | Arboreal /palm | 65.0% | 12:0 (50.8%) | Mechanical pressing | [8,30] |

| Syagrus cearensis (catolé/coco-babão) | Almonds | NE | Arboreal /palm | 57.0% | 12:0 (45.66%) | Hydraulic press, Ultrasonic-assisted in situ transesterification | [2] |

| Syagrus coronata (Mart.) Becc. (licuri/ouricuri) | Nuts/Almonds | NE, SE | Arboreal /palm | 50.0% | 12:0 (48.0%) | Pressing by hydraulic press | [28] |

| Bombacaceae | |||||||

| Pachira retusa (Mart.) Fern.Alonso, formerly known as Bombacopsis retusa (Mart. & Zucc.) A. Robyns, (ND) | Seeds | NE, SE | Arboreal/Tree | 55.60% | 16:0 (59.98%) | Soxhlet, Hexane | [27,35] |

| Calophyllaceae | |||||||

| Calophyllum brasiliense Cambess. (guanandi) | Almonds | N, NE, CW, SE, S | Arboreal | 58.20% | 18:2 (41.32%) | Maceration, Hexane | [36] |

| Caryocaraceae | |||||||

| Caryocar brasiliense Cambess. (pequi) | Pulp | N, NE, CW, SE, S | Shrub, Tree, Sub-shrub | 78.5% | 18:1 (64.66–67.59%) | Soxhlet, Petroleum ether | [31] |

| Clusiaceae | |||||||

| Platonia insignis Mart. (bacuri) | Seeds | N, NE | Arboreal | 63.0% | 18:1 (27.59%) | Soxhlet, Hexane | [37] |

| Cucurbitaceae | |||||||

| Fevillea trilobata L. (gindiroba) | Almonds | NE, CW, SE, S | Liana | 65–66% | 18:3 (39.0%) | Soxhlet | [38] |

| Euphorbiaceae | |||||||

| Jatropha curcas L. (pinhão-manso/pinhão-branco/pião-branco) | Seeds | N, NE, CW, SE, S | Arboreal | 53.4% | 18:1 (55.7%) | Soxhlet, Hexane | [39] |

| Myristicaceae | |||||||

| Virola sebifera Aubl. (mucuíba/bicuíba/ucuúba) | Almonds | N, NE, CW, SE | Arboreal | 69.0% | 14:0 (71.0%) | Soxhlet, Hexane | [40] |

| Virola surinamensis (Rol. ex Rottb.) Warb. (ucuúba) | Seeds | N, NE, CW | Arboreal | 64.39% | 14:0 (71.66%) | Supercritical CO2 | [41] |

| Olacaceae | |||||||

| Ximenia americana L. (ameixa-do-mato) | Seeds | N, NE, CW, SE, S | Shrub, Tree | 49.9% | 18:1 (72.09%) | Soxhlet, Petroleum ether | [42] |

| Sapindaceae | |||||||

| Serjania caracasana (Jacq.) Willd. (cipó-leiteiro/timbó) | Seeds | N, NE, CW, SE, S | Liana | 66.6% | 20:1 (69.4%) | Soxhlet, Hexane | [39] |

| Serjania salzmanniana Schltdl. (cipó-timbó) | Seeds | N, NE, CW, SE | Liana | 67.4% | 20:1 (64.7%) | Soxhlet, Hexane | [39] |

3.3. Biofuel Catalytic Routes for Selected Oil Seeds Occurring in the Caatinga Biome

3.3.1. Biodiesel Synthesis Processes

- i.

- Esterification

- ii.

- Transesterification

- iii.

- Pyrolysis

- iv.

- Ultrasound Process

- v.

- Reactive Distillation

3.3.2. Biodiesel Production from the Selected Oil Seeds Occurring in the Caatinga Biome

- i.

- Macaúba (Acrocomia aculeata)

- ii.

- Babassu (Attalea speciosa)

- iii.

- Pequi (Caryocar brasiliense)

- iv.

- Chapéu-de-napoleão (Cascabela thevetia)

- v.

- Pinhão-manso (Jatropha curcas L.)

- vi.

- Catolé (Syagrus cearensis)

- vii.

- Licuri (Syagrus coronata)

- viii.

- Cipó-leiteiro (Serjania caracasana Willd.) and Cipó-timbó (Serjania salzmanniana Schltdl.)

- ix.

- Ucuúba (Virola surinamensis (Rol. ex Rottb.) Warb.)

- x.

- Ameixa-do-mato (Ximenia americana L.)

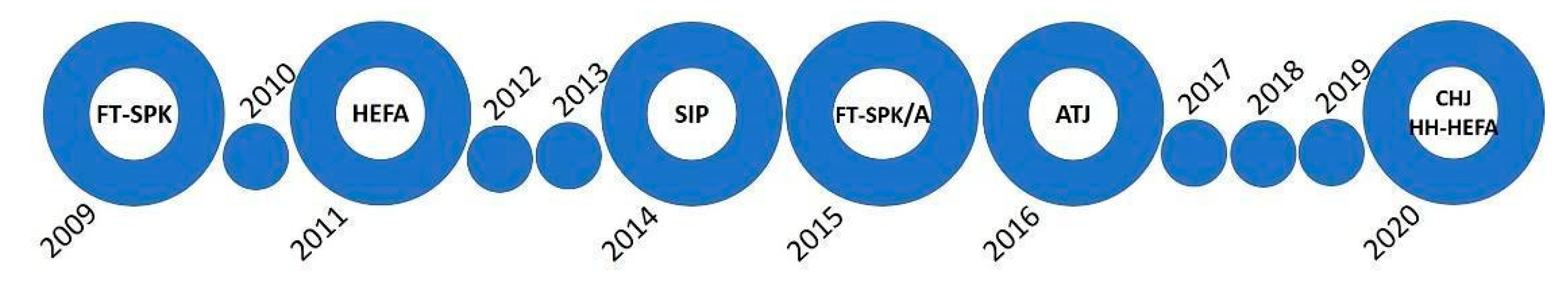

3.3.3. Biojet Synthesis Processes

- SPK-FT (Synthetic Paraffinic Kerosene—Fischer-Tropsch). The raw materials used in this process are urban solid waste, agricultural and forest waste, as well as natural gas and coal. First, biomass is gasified in an oxidizing atmosphere to generate syngas (mainly CO and H2), which is then converted to hydrocarbons mainly employing cobalt- or iron-based catalysts supported or not on zeolites or mesoporous materials. The former, more efficient at high temperatures, lead to the formation of n-paraffins, while the latter, used at low temperatures, produce α-olefins and oxygenated compounds. Steps of deoxygenation and fractionation are required to produce liquid paraffins similar to those of petroleum-based kerosene (C9–C15) and that can be mixed with it in various proportions up to a maximum percentage of 50% [105].

- SPK-HEFA (Synthetic Paraffinic Kerosene—Hydroprocess of Esters Fatty Acids). The hydrogenation of free fatty acids and fatty acid esters or vegetable and animal fats is basically the deoxygenation of triglycerides under conditions of temperature between 250 and 450 °C and hydrogen pressure between 10 and 300 bar in the presence of specific catalysts. After this step, isomerization is performed to adjust carbon chains in the desired hydrocarbon fractions, thus leading to an alternative biokerosene that can be mixed up to 50% with aviation kerosene. Since most of the oilseeds that serve as raw materials, such as licuri, catolé, macaúba, babassu, etc., are found in the Caatinga biome, this process has great potential to be applied in the northeast region of Brazil. In addition, the oil of these raw materials, which is the fraction of interest to produce aviation biokerosene, often has lauric acid (C12:0) as one of its main components, which can reduce the need for the above-mentioned isomerization step [106].

- SPK/A (Synthetic Paraffinic Kerosene—Aromatic). The SPK-FT process described above usually does not produce cyclic and aromatic hydrocarbons, which are typically found in oil-based aviation fuel; therefore, the process can be complemented by the addition of light aromatics, while the raw materials used for gasification are the same, i.e., urban or agroforestry solid waste. The addition of aromatic structures, mainly obtained by benzene alkylation, prevents fuel leaks, as it ensures the quality of seals in the aircraft components. Since the biokerosene produced by this process is made up of the same components found in the fossil kerosene, its full replacement would be technically possible if a 50% maximum blend were not imposed [105].

- SPK/ATJ (Synthetic Paraffinic Kerosene—Alcohol to Jet). Biomass employed in the alcoholic fermentation of starch and sugars includes beets, sugarcane, corn, saccharine, sweet sorghum and tubers or derivatives of cellulosic biomass obtained by lignocellulose hydrolysis. Alcohol can also originate from biochemical conversion of other forms of hydrogen and carbon through the action of organisms able to convert CO, H2 and CO2. Processing of ethyl or isobutyl alcohol occurs through successive dehydration and oligomerization reactions followed by hydrogenation and fractionation. The step of alcohol dehydration employs acidic catalysts such as alumina, silica-alumina, zeolites (e.g., ZSM-5 and Y), silicoaluminophosphates and ion exchange resins such as Amberlyst and Nafion, while Ziegler-Natta-type catalysts, i.e., organometallic complexes and organoaluminum catalysts, are traditionally used for oligomerization. Even the biokerosene produced by this process can be mixed with aviation kerosene in a maximum proportion of 50% [107].

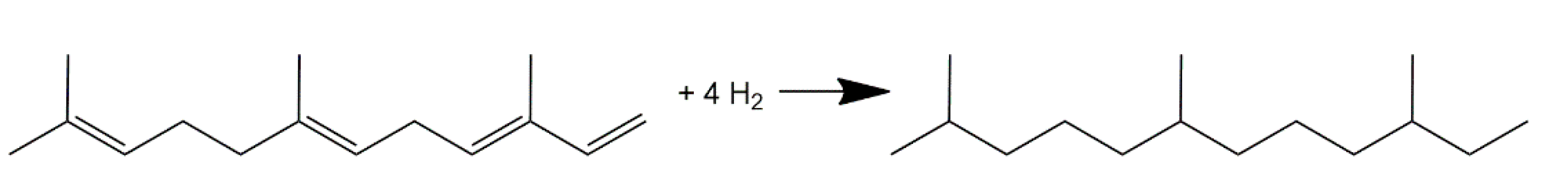

- SIP (Synthetic Isoparaffins). The biochemical route known as “Direct Sugar to Hydrocarbon” consists of sugar fermentation followed by hydrogenation performed by genetically modified strains of the yeast Saccharomyces cerevisiae, which allow directly obtaining hydrocarbons. The process leads to farnesene hydrogenation to farnesane (Figure 9), which is later mixed with aviation kerosene in a 10% maximum blend, as it is made up only of iso-paraffins [108].

- CHJ (Catalytic Hydrothermolysis to Jet). Similar to SPK-HEFA, catalytic hydrothermolysis uses vegetable or animal fatty acids and fatty acid esters as raw materials to produce a bio-oil, which is then submitted to hydrotreatment, hydrocracking or hydroisomerization and other conventional refinery steps, including fractionation, thus resulting in a biokerosene composed of n-paraffins, iso-paraffins, cyclo-paraffins and aromatic compounds. Even so, a maximum proportion of 50% is established for its blend with aviation kerosene [109].

- SPK-HC-HEFA ou SPK-HH (Hydroprocess of Hydrocarbons and Esters Fatty Acids). In this process, also similar to SPK-HEFA, only hydrocarbons (tri-terpenes) and fatty acid esters of the microalga Botryococcus braunii are hydroprocessed. The process consists of the extraction of hydrocarbons, deoxygenation (or hydrogenation) to remove oxygen and other undesirable compounds, cracking and isomerization. This alternative kerosene can be added to oil-based aviation kerosene up to a maximum proportion of 10% [110].

3.3.4. Oilseeds with Potential for Use in Biojet Synthesis in Brazil

- i.

- Macaúba (A. aculeata)

- ii.

- Babassu (A. speciosa)

- iii.

- Pinhão-manso (J. curcas L.)

- iv.

- Licuri (S. coronata)

4. Conclusions and Future Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergmann, J.C.; Tupinambá, D.D.; Costa, O.Y.A.; Almeida, J.R.M.; Barreto, C.C.; Quirino, B.F. Biodiesel production in Brazil and alternative biomass feedstocks. Renew. Sustain. Energy Rev. 2013, 21, 411–420. [Google Scholar] [CrossRef]

- Pascoal, C.V.P.; Oliveira, A.L.L.; Figueiredo, D.D.; Assunção, J.C.C. Optimization and kinetic study of ultrasonic-mediated in situ transesterification for biodiesel production from the almonds of Syagrus cearensis. Renew. Energy 2020, 147, 1815–1824. [Google Scholar] [CrossRef]

- Ramos, M.D.N.; Milessi, T.S.; Candido, R.G.; Mendes, A.A.; Aguiar, A. Enzymatic catalysis as a tool in biofuels production in Brazil: Current status and perspectives. Energy Sustain. Dev. 2022, 68, 103–119. [Google Scholar] [CrossRef]

- Lisboa, M.C.; Wiltshire, F.M.S.; Fricks, A.T.; Dariva, C.; Carrière, F.; Lima, A.S.; Soares, C.M.F. Oleochemistry potential from Brazil northeastern exotic plants. Biochimie 2020, 178, 96–104. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, A.S.; Almeida, M.B.; Torres, E.A.; Kalid, R.A.; Cohim, E.; Gasparatos, A. Alternative biodiesel feedstock systems in the Semi-arid region of Brazil: Implications for ecosystem services. Renew. Sustain. Energy Rev. 2018, 81, 2744–2758. [Google Scholar] [CrossRef]

- Gbif. Sistema Global de Informação Sobre Biodiversidade (Global Biodiversity Information Facility). Catolé (Syagrus cearensis). 2022. Available online: https://www.gbif.org/species/5293881 (accessed on 27 July 2022).

- Reflora. Syagrus in Flora e Funga do Brasil. Jardim Botânico do Rio de Janeiro. Licuri (Syagrus coronata (Mart.) Becc.). 2022. Available online: https://floradobrasil.jbrj.gov.br/FB15736 (accessed on 27 July 2022).

- Reflora. Attalea in Flora e Funga do Brasil. Jardim Botânico do Rio de Janeiro. Babassu (Attalea speciosa Mart. ex Spreng., Formerly Known as Attalea vitrivir Zona). 2022. Available online: https://floradobrasil.jbrj.gov.br/FB15686 (accessed on 27 July 2022).

- Publisher iNaturalist. Babassu/Babaçu (Attalea speciosa). Available online: https://www.inaturalist.org/taxa/364354-Attalea-speciosa/browse_photos (accessed on 27 July 2022).

- Publisher iNaturalist. Pequi (Caryocar brasiliense). Available online: https://www.inaturalist.org/taxa/464113-Caryocar-brasiliense/browse_photos (accessed on 27 July 2022).

- Publisher iNaturalist. Macúba (Acrocomia aculeata). Available online: https://www.inaturalist.org/taxa/244459-Acrocomia-aculeata/browse_photos (accessed on 27 July 2022).

- Reflora. Platonia in Flora e Funga do Brasil. Jardim Botânico do Rio de Janeiro. Bacuri (Platonia insignis Mart.). 2022. Available online: https://floradobrasil.jbrj.gov.br/FB16880 (accessed on 27 July 2022).

- Reflora. Calophyllum in Flora e Funga do Brasil. Jardim Botânico do Rio de Janeiro. Guanandi (Calophyllum brasiliense Cambess.). 2022. Available online: https://floradobrasil.jbrj.gov.br/FB6827 (accessed on 27 July 2022).

- Reflora. Serjania in Flora e Funga do Brasil. Jardim Botânico do Rio de Janeiro. Cipó-timbo (Serjania salzmanniana Schltdl.). 2022. Available online: https://floradobrasil.jbrj.gov.br/FB20977 (accessed on 27 July 2022).

- Eskander, S.; Fankhauser, S. Reduction in greenhouse gas emissions from national climate legislation. Nat. Clim. Chang. 2020, 10, 750–756. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O. Bioenergy and Biofuels. Sustainability 2021, 13, 9972. [Google Scholar] [CrossRef]

- Rodrigues, A.C.C. Policy, regulation, development and future of biodiesel industry in Brazil. J. Clean. Prod. 2021, 4, 100197–100209. [Google Scholar] [CrossRef]

- de Souza, T.A.Z.; Pinto, G.M.; Julio, A.A.V.; Coronado, C.J.R.; Perez-Herrera, R.; Siqueira, B.S.; da Costa, R.B.R.; Roberts, J.J.; Palacio, J.C.E. Biodiesel in South American countries: A review on policies, stages of development and imminent competition with hydrotreated vegetable oil. Renew. Sustain. Energy Rev. 2022, 153, 111755–111769. [Google Scholar] [CrossRef]

- Madsen, R.; Henkes, J.A. A aviação civil e a inserção do bioquerosene no Brasil. Rev. Bras. Aviação Civ. Ciências Aeronáuticas 2021, 1, 6–34. [Google Scholar]

- Anuário Estatístico Brasileiro do Petróleo, Gás Natural e Biocombustíveis: 2021/Agência Nacional do Petróleo, Gás Natural e Biocombustíveis.—Rio de Janeiro: ANP. 2008. Available online: https://www.gov.br/anp/pt-br/centrais-de-conteudo/publicacoes (accessed on 12 August 2022).

- Cremonez, P.A.; Feroldi, M.; Nadaleti, W.C.; de Rossi, E.; Feiden, A.; de Camargo, M.P.; Cremonez, F.E.; Klajn, F.F. Biodiesel production in Brazil: Current scenario and perspectives. Renew. Sustain. Energy Rev. 2015, 42, 415–428. [Google Scholar] [CrossRef]

- Milanez, A.Y.; Maia, G.B.; Guimarães, D.D.; Ferreira, C.L.A. Aviation biofuels in Brazil: An agenda of sustainability. R. BNDES 2021, 28, 361–398. [Google Scholar]

- BRASIL. Resolução nº 856, de 22 de Outubro de 2021. Estabelece as Especificações do Querosene de Aviação; Diário Oficial da União: Brasília, Brazil, 2021; Volume 1, p. 89. [Google Scholar]

- De Souza, L.M.; Mendes, P.A.S.; Aranda, D.A.G. Assessing the current scenario of the Brazilian biojet market. Renew. Sustain. Energy Rev. 2018, 98, 426–438. [Google Scholar] [CrossRef]

- Walter, A.; Seabra, J.; Rocha, J.; Guarenghi, M.; Vieira, N.; Damame, D.; Santos, J.L. Spatially Explicit Assessment of the Feasibility of Sustainable Aviation Fuels Production in Brazil: Results of Three Case Studies. Energies 2021, 14, 4972. [Google Scholar] [CrossRef]

- Harand, W.; Pinho, R.S.; Felix, L.P. Alternative oilseeds for Northeastern Brazil: Unrevealed potential of Brazilian biodiversity. Braz. J. Bot. 2016, 39, 169–183. [Google Scholar] [CrossRef]

- Reflora. Pachira in Flora e Funga do Brasil. Jardim Botânico do Rio de Janeiro. Castanha (Pachira retusa (Mart.) Fern.Alonso, Formerly Known as Bombacopsis retusa (Mart. & Zucc.) A. Robyns). 2022. Available online: https://floradobrasil.jbrj.gov.br/FB25757 (accessed on 27 July 2022).

- Iha, O.K.; Alves, S.C.F.C.; Suarez, P.A.Z.; de Oliveira, M.B.F.; Meneghetti, S.M.P.; Santos, B.P.T.; Soletti, J.I. Physicochemical properties of Syagrus coronata and Acrocomia aculeata oils for biofuel production. Ind. Crops Prod. 2014, 62, 318–322. [Google Scholar] [CrossRef]

- Lieb, V.M.; Schex, R.; Esquivel, P.; Jiménez, V.M.; Schmarr, H.-G.; Carle, R.; Steingass, C.B. Fatty acids and triacylglycerols in the mesocarp and kernel oils of maturing Costa Rican Acrocomia aculeata fruits. NFS J. 2019, 14, 6–13. [Google Scholar] [CrossRef]

- Oliveira, R.A.D.; Conceição, N.S.; Ribeiro, L.M.; Nascimento, L.P.S.; Silvério, F.O. Storage, oil quality and cryopreservation of babassu palm seeds. Ind. Crops Prod. 2016, 91, 332–339. [Google Scholar] [CrossRef]

- Faria-Machado, A.F.; Tres, A.; van Ruth, S.M.; Antoniassi, R.; Junqueira, N.T.V.; Lopes, P.S.N.; Bizzo, H.R. Discrimination of pulp oil and rernel oil from pequi (Caryocar Brasiliense) by fatty acid methyl esters fingerprinting, using GC-FID and multivariate analysis. J. Agric. Food Chem. 2015, 63, 10064–10069. [Google Scholar] [CrossRef]

- Pinho, R.S.; Oliveira, A.F.M.; Silva, S.I. Potential oilseed crops from the semiarid region of Northeastern Brazil. Bioresour. Technol. 2009, 100, 6114–6117. [Google Scholar] [CrossRef]

- Girardi, J.C.; Bariccatti, R.A.; Souza, S.N.M.; Amaral, C.Z.; Guedes, C.L.B.; Bauni, J.; Bertosse, C.M. Potential of babassu biofuels use as aviation fuel. Res. Soc. Dev. 2022, 11, e51911125226. [Google Scholar] [CrossRef]

- Sut, D.; Chutia, R.S.; Bordoloi, N.; Narzari, R.; Kataki, R. Complete utilization of non-edible oil seeds of Cascabela thevetia through a cascade of approaches for biofuel and by-products. Bioresour. Technol. 2016, 213, 111–120. [Google Scholar] [CrossRef]

- Pereira, N.P. Extraction, determination of the fatty profile and potential application of oil from the seeds of Bombacopsis retusa (Mart. & Zucc.) A. Robyns. Acta Sci. Technol. 2013, 35, 573–579. [Google Scholar] [CrossRef][Green Version]

- Bernabé-Antonio, A.; Álvarez, L.; Salcedo-Pérez, E.; López-Dellamary Toral, F.A.; Anzaldo-Hernández, J.; Cruz-Sosa, F. Fatty acid profile of intact plants of two different sites and callus cultures derived from seed and leaf explants of Calophyllum brasiliense cambess: A new resource of non-edible oil. Ind. Crops. Prod. 2015, 77, 1014–1019. [Google Scholar] [CrossRef]

- Oliveira, M.D.A.; Alves, P.S.; Sousa, H.G.; da Costa Silva, C.; Rai, M.K.; Lima, N.M.; Andrade, T.J.A.S.; Feitosa, C.M.; Costa Júnior, J.S. Genotoxic and cytotoxic activities of hexane extract in seeds from Platonia insignis Mart. Res. Soc. Dev. 2022, 11, e13911225504. [Google Scholar] [CrossRef]

- Gentry, A.H.; Wettach, R.H. Fevillea-a new oil seed from Amazonian Peru. Econ. Bot. 1986, 40, 177–185. [Google Scholar] [CrossRef]

- Coutinho, D.J.G.; Barbosa, M.O.; de Souza, R.J.C.; da Silva, A.S.; da Silva, S.I.; de Oliveira, A.F.M. Comparative study of the physicochemical properties of FAME from seed oils of some native species of Brazilian Atlantic Forest. J. Am. Oil Chem. Soc. 2016, 93, 1519–1528. [Google Scholar] [CrossRef]

- Rocha Filho, G.N.; Bentes, M.H.S.; Brodzki, D.; Djéga-Mariadassou, G. Catalytic conversion of Hevea brasiliensis and Virola sebifera oils to hydrocarbon fuels. J. Am. Oil Chem. Soc. 1992, 69, 266–271. [Google Scholar] [CrossRef]

- Cordeiro, R.M.; Silva, A.P.d.S.; Pinto, R.H.H.; da Costa, W.A.; da Silva, S.H.M.; de Souza Pinheiro, W.B.; Arruda, M.S.P.; Carvalho Junior, R.N. Supercritical CO2 extraction of ucuúba (virola surinamensis) seed oil: Global yield, kinetic data, fatty acid profile, and antimicrobial activities. Chem. Eng. Commun. 2019, 206, 86–97. [Google Scholar] [CrossRef]

- Eromosele, C.O.; Eromosele, I.C. Fatty acid compositions of seed oils of Haematostaphis barteri and Ximenia americana. Bioresour. Technol. 2002, 82, 303–304. [Google Scholar] [CrossRef]

- Changi, S.; Pinnarat, T.; Savage, P.E. Mechanistic Modeling of Hydrolysis and Esterification for Biofuel Processes. Ind. Eng. Chem. Res. 2011, 50, 12471–12478. [Google Scholar] [CrossRef]

- Long, F.; Liu, W.; Jiang, X.; Zhai, Q.; Cao, X.; Jiang, J.; Xu, J. State-of-the-art technologies for biofuel production from triglycerides: A review. Renew. Sustain. Energy Rev. 2021, 148, 111269. [Google Scholar] [CrossRef]

- Chandrasekaran, S.R.; Murali, D.; Marley, K.A.; Larson, R.A.; Doll, K.M.; Moser, B.R.; Scott, J.; Sharma, B.K. Antioxidants from slow pyrolysis bio-oil of birch wood: Application for biodiesel and biobased lubricants. ACS Sustain. Chem. Eng. 2016, 4, 1414–1421. [Google Scholar] [CrossRef]

- Mahamuni, N.N.; Adewuyi, Y.G. Optimization of the synthesis of biodiesel via ultrasound-enhanced base-catalyzed transesterification of soybean oil using a multifrequency ultrasonic reactor. Energy Fuels 2009, 23, 2757–2766. [Google Scholar] [CrossRef]

- Kiss, A.A.; Dimian, A.C.; Rothenberg, G. Biodiesel by catalytic reactive distillation powered by metal oxides. Energy Fuels 2008, 22, 598–604. [Google Scholar] [CrossRef]

- Souza, G.K.; Scheufele, F.B.; Pasa, T.L.B.; Arroyo, P.A.; Pereira, N.C. Synthesis of ethyl esters from crude macauba oil (Acrocomia aculeata) for biodiesel production. Fuel 2016, 165, 360–366. [Google Scholar] [CrossRef]

- Santos, R.C.M.; Gurgel, P.C.; Pereira, N.S.; Breves, R.A.; de Matos, P.R.R.; Silva, L.P.; Sales, M.J.A.; Lopes, R.V.V. Ethyl esters obtained from pequi and macaúba oils by transesterification with homogeneous acid catalysis. Fuel 2020, 259, 116206. [Google Scholar] [CrossRef]

- Prado, R.G.; Almeida, G.D.; de Oliveira, A.R.; de Souza, P.M.T.G.; Cardoso, C.C.; Constantino, V.R.L.; Pinto, F.G.; Tronto, J.; Pasa, V.M.D. Ethanolysis and methanolysis of soybean and macauba oils catalyzed by mixed oxide Ca−Al from hydrocalumite for biodiesel production. Energy Fuels 2016, 30, 6662–6670. [Google Scholar] [CrossRef]

- Ramos, L.; Martin, L.S.; Santos, J.C.; de Castro, H.F. Combined use of a two-stage Packed bed reactor with a glycerol extraction column for enzymatic biodiesel synthesis from macaw palm oil. Ind. Eng. Chem. Res. 2017, 56, 1–7. [Google Scholar] [CrossRef]

- Paiva, E.J.M.; da Silva, M.L.C.P.; Barboza, J.C.S.; de Oliveira, P.C.; de Castro, H.F.; Giordani, D.S. Non-edible babassu oil as a new source for energy production–a feasibility transesterification survey assisted by ultrasound. Ultrason. Sonochem. 2013, 20, 833–838. [Google Scholar] [CrossRef]

- Ferrari, R.A.; Soler, M.P. Obtention and characterization of coconut babassu derivatives. Sci. Agric. 2015, 72, 291–296. [Google Scholar] [CrossRef]

- Girardi, J.C.; Barricatti, R.A.; de Sousa, R.N.M.; do Amaral, C.Z.; Guedes, C.L.B. Natural compounds as antifreeze additives to improve babassu biodiesel. Fuel 2021, 289, 119746. [Google Scholar] [CrossRef]

- Oliveira, V.F.; Parente, E.J.S., Jr.; Manrique-Rueda, E.D.; Cavalcante, C.L., Jr.; Luna, F.M.T. Fatty acid alkyl esters obtained from babassu oil using C1–C8 alcohols and process integration into atypical biodiesel plant. Chem. Eng. Res. Des. 2015, 160, 224–232. [Google Scholar] [CrossRef]

- Carvalho, L.M.G.; Abreu, W.C.; Silva, M.G.O.; Lima, J.R.O.; Oliveira, J.E.; Matos, J.M.E.; Moura, C.V.R.; Moura, E.M. Heterogeneous Catalysis Afford Biodiesel of Babassu, Castor oil and Blends. J. Braz. Chem. Soc. 2013, 24, 550–557. [Google Scholar] [CrossRef]

- Andrade, G.S.S.; Freitas, L.; Oliveira, P.C.; de Castro, H.F. Screening, immobilization and utilization of whole cell biocatalysts to mediate the ethanolysis of babassu oil. J. Mol. Catal. B Enzym. 2012, 84, 183–188. [Google Scholar] [CrossRef]

- Da Rós, P.C.M.; Silva, W.C.; Grabaukas, D.; Perez, V.H.; de Castro, H.F. Biodiesel from babassu oil: Characterization of the product obtained by enzymatic route accelerated by microwave irradiation. Ind. Crops Prod. 2014, 52, 313–320. [Google Scholar] [CrossRef]

- Moreira, K.S.; Moura Junior, L.S.; Monteiro, R.R.C.; de Oliveira, A.L.B.; Valle, C.P.; Freire, T.M.; Fechine, P.B.A.; de Souza, M.C.M.; Fernandez-Lorente, G.; Guisan, J.M.; et al. Optimization of the Production of Enzymatic Biodiesel from Residual Babassu Oil (Orbignya sp.) via RSM. Catalysts 2020, 10, 414. [Google Scholar] [CrossRef]

- Borges, K.A.; Batista, A.C.F.; Rodrigues, H.S.; Terrones, M.H.; Vieira, A.T.; de Oliveira, M.F. Production of methyl and ethyl biodiesel fuel from Pequi oil. Chem. Technol. Fuels Oils 2012, 48, 83–89. [Google Scholar] [CrossRef]

- Oster, V.V. Influência do Tempo de Extração e da Razão Amostra: Solvente no Processo de Extração do Óleo do Caroço do Pequi Visando a Produção de Biodiesel. Master’s Thesis, Universidade Federal de Tocantins, Palmas, Brazil, 2013. Available online: http://hdl.handle.net/11612/547 (accessed on 12 August 2022).

- Silva, T.A.; de Assunção, R.M.N.; Vieira, A.T.; de Oliveira, M.F.; Batista, A.C.F. Methylic and ethylic biodiesels from pequi oil (Caryocar brasiliense Camb.): Production and thermogravimetric studies. Fuel 2014, 136, 10–18. [Google Scholar] [CrossRef]

- Ferreira, E.N. Utilização de Pequi (Caryocar brasilienses Camb.) Para Produção Sustentável de Combustíveis e Lubrificantes. Master’s Thesis, Universidade Federal do Ceará, Fortaleza, Brazil, 2019. Available online: http://www.repositorio.ufc.br/handle/riufc/53435 (accessed on 12 August 2022).

- Guimarães, M.G. Produção de Biocombustível Líquido a Partir de Resíduo Agroindustrial: Caroço de Pequi; Universidade de Brasília: Brasilia, Brazil, 2015; Available online: https://bdm.unb.br/handle/10483/11245 (accessed on 12 August 2022).

- Souza, M.G.S.; Guimarães, M.G.; Macedo, J.L.; Rodrigues, J.P.; Ghesti, G.F. Characterization and Use of Pequi Residual Oil (Caryocar brasiliense) in the Production of Liquid Biofuels. RIPE 2019, 5, 41–49. [Google Scholar] [CrossRef]

- Guimarães, M.G.; Evaristo, R.B.W.; de Macedo, J.L.; Ghesti, G.F. Extraction and characterization of pequi seed oil for biodiesel production: A green management of waste to biofuel using ethanol and heterogeneous catalysis. J. Braz. Chem. Soc. 2022, 33, 327–339. [Google Scholar] [CrossRef]

- Dhoot, S.B.; Jaju, D.R.; Deshmukh, S.A.; Panchal, B.M.; Sharma, M.R. Extraction of Thevetia peruviana seed oil and optimization of biodiesel production using alkali-catalyzed methanolysis. JoAEST 2011, 2, 8–16. [Google Scholar]

- Olatunji, O.M.; Akor, A.J.; Abowei, M.F.N. Modeling the chemical kinetics of milk bush (Thevetia peruviana) oil transesterification process for biodiesel production. Cont. J. Eng. Sci. 2012, 7, 40–48. [Google Scholar]

- Oseni, M.I.; Obetta, S.E.; Orukotan, F.V. Evaluation of fatty acids profile of ethyl esters of yellow oleander and groundnut oils as biodiesel feedstock. Am. J. Sci. Ind. Res. 2012, 3, 62–68. [Google Scholar] [CrossRef]

- Yarkasuwa, C.I.; Wilson, D.; Michael, E. Production of Biodiesel from Yellow Oleander (Thevetia peruvian) Oil and its Biodegradability. J. Korean Chem. Soc. 2013, 57, 377–381. [Google Scholar] [CrossRef]

- Yadav, A.K.; Khan, M.E.; Pal, A.; Dubey, A.M. Biodiesel production from Nerium oleander (Thevetia peruviana) oil through conventional and ultrasonic irradiation methods. Energy Sources A Recovery Util. Environ. Eff. 2016, 38, 3447–3452. [Google Scholar] [CrossRef]

- Sanjay, B. Heterogeneous Catalyst Derived from Natural Resources for Biodiesel Production: A Review. Res. J. Chem. Sci. 2013, 3, 95–101. Available online: https://www.cabdirect.org/cabdirect/abstract/20133301549 (accessed on 6 August 2022).

- Ogunkule, O.; Oniya, O.O.; Adebayo, A.O. Yield response of biodiesel production from heterogeneous and homogeneous catalysis of milk bush seed (Thevetia peruviana) oil. Energy Policy Res. 2017, 4, 21–28. [Google Scholar] [CrossRef]

- Osakwe, E.U.; Ani, I.J.; Akpan, U.G.; Olutoye, M.A. Kolanut Pod Husk as a Biobase Catalyst for Fatty Acid Methyl Ester Production Using Thevetia peruviana (Yellow oleander) Seed Oil. IOP Conf. Ser. Earth Environ. Sci. 2018, 173, 012008. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/173/1/012008/meta (accessed on 6 August 2022). [CrossRef]

- Deka, D.C.; Basumatary, S. High quality biodiesel from yellow oleander (Thevetia peruviana) seed oil. Biomass Bioenergy 2011, 35, 1797–1803. [Google Scholar] [CrossRef]

- Betiku, E.; Ajala, S.O. Modeling and optimization of Thevetia peruviana (yellow oleander) oil biodiesel synthesis via Musa paradisiacal (plantain) peels as heterogeneous base catalyst: A case of artificial neural network vs. response surface methodology. Ind. Crops. Prod. 2014, 53, 314–322. [Google Scholar] [CrossRef]

- Borah, M.J.; Devi, A.; Das, V.; Deka, D. Catalytic Conversion of Thevetia peruviana Oil into Biodiesel by TiO2-ZnO Nanocatalyst. Int. J. Res. Eng. Technol. 2017, 6, 56–60. Available online: https://ijret.org/volumes/2017v06/i13/IJRET20170613012.pdf (accessed on 6 August 2022).

- Arun, S.B.; Suresh, R.; Avinash, E. Optimization of biodiesel production from yellow oleander (Thevetia peruviana) using response surface methodology. Mater. Today 2017, 4, 7293–7301. [Google Scholar] [CrossRef]

- Oyekunle, D.T.; Oyekunle, D.O. Biodiesel Production from Yellow Oleander Seed Oil via Heterogeneous Catalyst: Performance Evaluation of Minitab Response Surface Methodology and Artificial Neural Network. J. Mater. Environ. Sci. 2018, 9, 2468–2477. Available online: https://www.jmaterenvironsci.com/Document/vol9/vol9_N8/271-JMES-3784-Oyekunle.pdf (accessed on 6 August 2022).

- Prueksakorn, K.; Gheewala, S.H. Full chain energy analysis of biodiesel from Jatropha curcas L. in Thailand. Environ. Sci. Technol. 2008, 42, 3388–3393. [Google Scholar] [CrossRef]

- Diwani, G.E.; Attia, N.K.; Hawash, S.I. Int. Development and evaluation of biodiesel fuel and by-products from jatropha oil. J. Environ. Sci. Tech. 2009, 6, 219–224. [Google Scholar] [CrossRef]

- Patil, P.D.; Gude, V.G.; Deng, S. Biodiesel production from Jatropha Curcas, waste cooking, and Camelina sativa oils. Ind. Eng. Chem. Res. 2009, 48, 10850–10856. [Google Scholar] [CrossRef]

- Mascal, M.; Nikitin, E.B. Co-processing of carbohydrates and lipids in oil crops to produce a hybrid biodiesel. Energy Fuels 2010, 24, 2170–2171. [Google Scholar] [CrossRef]

- Shuit, S.H.; Lee, K.T.; Kamaruddin, A.H.; Yusup, S. Reactive extraction of Jatropha curcas L. seed for production of biodiesel: Process optimization study. Environ. Sci. Technol. 2010, 44, 4361–4367. [Google Scholar] [CrossRef]

- Kumar, G.R.; Ravi, R.; Chadha, A. Kinetic studies of base-catalyzed transesterification reactions of non-edible oils to prepare biodiesel: The effect of co-solvent and temperature. Energy Fuels 2011, 25, 2826–2832. [Google Scholar] [CrossRef]

- Joshi, G.; Lamba, B.Y.; Rawat, D.S.; Mallick, S.; Murthy, K.R.S. Evaluation of additive effects on oxidation stability of Jatropha curcas biodiesel blends with conventional diesel sold at retail outlets. Ind. Eng. Chem. Res. 2013, 52, 7586–7592. [Google Scholar] [CrossRef]

- Fernandes, A.M.A.P.; El-Khatib, S.; Cunha, I.B.S.; Porcari, A.M.; Eberlin, M.N.; Silva, M.J.; Cunha, V.S.; Daroda, R.J.; Alberici, R.M. Chemical characterization of Jatropha curcas L. seed oil and its biodiesel by ambient desorption/ionization mass spectrometry. Energy Fuels 2015, 29, 3096–3103. [Google Scholar] [CrossRef]

- Sitoé, B.V.; Mitsutake, H.; Guimarães, E.; Gontijo, L.C.; Santos, D.Q.; Neto, W.B. Quality control of biodiesel content of B7 blends of methyl jatropha and methyl crambe biodiesel using mid-infrared spectroscopy and multivariate control charts based on net analyte signal. Energy Fuels 2016, 30, 1062–1070. [Google Scholar] [CrossRef]

- Chang, C.C.; Teng, S.; Yuan, M.H.; Ji, D.R.; Chang, C.Y.; Chen, Y.H.; Shie, J.L.; Ho, C.; Tian, S.Y.; Tacca, C.A.A.; et al. Esterification of Jatropha oil with isopropanol via ultrasonic irradiation. Energies 2018, 11, 1456. [Google Scholar] [CrossRef]

- Hossain, A.K.; Hussain, A. Impact of Nanoadditives on the performance and combustion characteristics of neat Jatropha biodiesel. Energies 2019, 12, 921. [Google Scholar] [CrossRef]

- ANR, R.; Saleh, A.A.; Islam, M.S.; Hamdan, S.; Maleque, M.A. Biodiesel production from crude Jatropha oil using a highly active heterogeneous nanocatalyst by optimizing transesterification reaction parameters. Energy Fuels 2016, 30, 334–343. [Google Scholar] [CrossRef]

- Shah, S.; Sharma, S.; Gupta, M.N. Biodiesel preparation by lipase-catalyzed transesterification of jatropha oil. Energy Fuels 2004, 18, 154–159. [Google Scholar] [CrossRef]

- Akoh, C.C.; Chang, S.W.; Lee, G.C.; Shaw, J.F. Enzymatic approach to biodiesel production. J. Agric. Food Chem. 2007, 55, 8995–9005. [Google Scholar] [CrossRef] [PubMed]

- Jothiramalingam, R.; Wang, M.K. Review of recent developments in solid acid, base, and enzyme catalysts (heterogeneous) for biodiesel production via transesterification. Ind. Eng. Chem. Res. 2009, 48, 6162–6172. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.J.; Ngadi, M. Enzyme-catalyzed synthesis and kinetics of ultrasonic-assisted methanolysis of waste choice white grease for fatty acid methyl ester production. Energy Fuels 2015, 29, 6412–6421. [Google Scholar] [CrossRef]

- Gao, J.; Yin, L.; Feng, K.; Zhou, L.; Ma, L.; He, Y.; Wang, L.; Jiang, Y. Lipase immobilization through the combination of bioimprinting and cross-linked protein-coated microcrystal technology for biodiesel production. Ind. Eng. Chem. Res. 2016, 55, 11037–11043. [Google Scholar] [CrossRef]

- Moussavou, R.W.M.; Brunschwig, C.; Baréa, B.; Villenevue, P.; Blin, J. Assessing the enzyme activity of different plant extracts of biomasses from sub-saharan africa for ethyl biodiesel production. Energy Fuels 2016, 30, 2356–2364. [Google Scholar] [CrossRef]

- Gusniah, A.; Veny, H.; Hamzah, F. Ultrasonic assisted enzymatic transesterification for biodiesel production. Ind. Eng. Chem. Res. 2019, 58, 581–589. [Google Scholar] [CrossRef]

- Melo, K.R.B.; Lopes, G.C.; Coelho, D.G.; Soletti, J.I. Liquid-liquid equilibrium for systems composed by biodiesel from catolé oil (Syagrus cearensis), methanol and glycerol. Chem. Ind. Chem. Eng. Q. 2020, 26, 21–29. [Google Scholar] [CrossRef]

- La Salles, K.T.S.; Meneghetti, S.M.P.; de La Salles, W.F.; Meneghetti, M.R.; dos Santos, I.C.F.; da Silva, J.P.V.; de Carvalho, S.H.V.; Soletti, J.I. Characterization of Syagrus coronata (Mart.) Becc. oil and properties of methyl esters for use as biodiesel. Ind. Crops Prod. 2010, 32, 518–521. [Google Scholar] [CrossRef]

- Araújo, P.H.M.; Maia, A.S.; Cordeiro, A.M.T.M.; Gondim, A.D.; Santos, N.A. Catalytic deoxygenation of the oil and biodiesel of licuri (Syagrus coronata) to obtain n-alkanes with chains in the range of biojet fuels. ACS Omega 2019, 4, 15849–15855. [Google Scholar] [CrossRef]

- Lacerda, O.S., Jr. Gordura de Ucuúba: Caracterização Química e Síntese de Biodiesel. Master’s Thesis, Universidade Federal do Amazonas, Manaus, Brazil, 2009. Available online: https://tede.ufam.edu.br/handle/tede/3351 (accessed on 6 August 2022).

- Senthil, R.; Sivakumar, E.; Silanbarasam, R.; Pranesh, G. Performance and emission characteristics of using sea lemon biodiesel with thermal barrier coating in a direct-injection diesel engine. Biofuels 2016, 8, 235–241. [Google Scholar] [CrossRef]

- Hariharan, V.S.; Reddy, K.V.; Rajagopal, K. Study of the Performance, Emission and Combustion Characteristics of a Diesel Engine Using Sea Lemon Oil Based Fuels. Indian J. Sci. Technol. 2019, 2, 43–47. Available online: https://ijabe.org/index.php/ijabe/article/view/116 (accessed on 6 August 2022). [CrossRef]

- Meurer, A.; Kern, J. Fischer-Tropsch synthesis as the key for decentralized sustainable kerosene production. Energies 2021, 14, 1836. [Google Scholar] [CrossRef]

- Monteiro, R.R.C.; dos Santos, I.A.; Arcanjo, M.R.A.; Cavalcante., C.L., Jr.; de Luna, F.M.T.; Fernandez-Lafuente, R.; Vieira, R.S. Production of jet biofuels by catalytic hydroprocessing of esters and fatty acids: A review. Catalysts 2022, 12, 237. [Google Scholar] [CrossRef]

- Wang, W.C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef]

- Vogelsang, D.; Faßbach, T.A.; Kossmann, P.P.; Vorholt, A. Terpene-derived highly branched C30-amines via palladium-catalysed telomerisation of β-farnesene. Adv. Synth. Catal. 2018, 360, 1984–1991. [Google Scholar] [CrossRef]

- Eswaran, S.; Subramaniam, S.; Geleynse, S.; Brandt, K.; Wolcott, M.; Zhang, X. Techno-economic analysis of catalytic hydrothermolysis pathway for jet fuel production. Renew. Sustain. Energy Rev. 2021, 151, 111516–111527. [Google Scholar] [CrossRef]

- O’Neil, G.W.; Knothe, G.; Reddy, C.M. Jet biofuels from algae. In The Biomass, Biofuels and Biochemicals, 2nd ed.; Pandey, A., Chang, J., Soccol, C.R., Lee, D., Chisti, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 359–395. [Google Scholar] [CrossRef]

- Carvalho, F.M. Evaluation of the Brazilian Potential for Producing Aviation Biofuels through Consolidated Routes. Master’s Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2017. [Google Scholar]

- Goh, B.H.H.; Chong, C.T.; Ong, H.C.; Seljak, T.; Katrasnik, T.; Jozsa, V.; Ng, J.; Tian, B.; Karmarkar, S.; Ashokkumar, V. Recent advancements in catalytic conversion pathways for synthetic jet fuel produced from bioresources. Energy Convers. Manag. 2022, 251, 114974–114998. [Google Scholar] [CrossRef]

- Escalante, E.S.R.; Ramos, L.S.; Coronado, C.J.R.; Carvalho, J.A., Jr. Evaluation of the potential feedstock for biojet fuel production: Focus in the Brazilian context. Renew. Sustain. Energy Rev. 2022, 153, 111716–111738. [Google Scholar] [CrossRef]

- Moreira, J.B.D.; Rezende, D.B.; Pasa, V.M.D. Deoxygenation of macauba acid oil over Co-based catalyst supported on activated biochar from macauba endocarp: A potential and sustainable route for green diesel and biokerosene production. Fuel 2020, 269, 117253–117265. [Google Scholar] [CrossRef]

- Freitas, L.N.S.; Souza, F.P.; Carvalho, A.R.; Pasa, V.M.D. Study of direct synthesis of bio-hydrocarbons from macauba oils using zeolites as catalysts. Fuel 2021, 287, 119472–119483. [Google Scholar] [CrossRef]

- Vilalva, J.B. Produção de Ésteres Leves Derivados de Óleo de Amêndoa da Macaúba Para Potencial Aplicação Como Biocombustível de Aviação; Final Project; Universidade Estadual Paulista: Rosana, Brazil, 2021. [Google Scholar]

- Azevedo, W.J. Inventário do Ciclo de Vida da Produção de Bioquerosene Para Aviação Utilizando a Macaúba Como Fonte de Matéria-Prima. Master’s Thesis, Universidade Federal dos Vales do Jequitinhonha e Mucuri, Diamantina, Brazil, 2021. [Google Scholar]

- Llamas, A.; Al-Lal, A.; Hernandez, M.; Lapuerta, M.; Canoira, L. Biokerosene from babassu and camelina oils: Production and properties of their blends with fossil kerosene. Energy Fuels 2012, 26, 5968–5976. [Google Scholar] [CrossRef]

- Oliveira, V.F. Estudo da Obtenção de Bioquerosene a Partir da Destilação Molecular de Biodiesel de Babaçu; Final Project; Universidade Federal do Ceará: Fortaleza, Brazil, 2016. [Google Scholar]

- Ranucci, C.R.; Alves, H.J.; Monteiro, M.R.; Kugelmeier, C.L.; Bariccatti, R.A.; Rodrigues, C.O.; da Silva, E.A. Potential alternative aviation fuel from jatropha (Jatropha curcas L.), babassu (Orbignya phalerata) and palm kernel (Elaeis guineensis) as blends with Jet-A1 kerosene. J. Clean. Prod. 2018, 185, 860–869. [Google Scholar] [CrossRef]

- Alherbawi, M.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Jatropha curcas for jet biofuel production: Current status and future prospects. Renew. Sustain. Energy Rev. 2021, 135, 110396–110415. [Google Scholar] [CrossRef]

- Alherbawi, M.; McKay, G.; Mackey, H.R.; Al-Ansari, T. A novel integrated pathway for Jet Biofuel production from whole energy crops: A Jatropha curcas case study. Energy Convers. Manag. 2021, 229, 113662–113683. [Google Scholar] [CrossRef]

- Altalhi, A.A.; Mohamed, E.A.; Morsy, S.M.; Abou Kana, M.T.H.; Negm, N.A. Catalytic manufacture and characteristic valuation of biodiesel-biojet achieved from Jatropha curcas and waste cooking oils over chemically modified montmorillonite clay. J. Mol. Liq. 2021, 340, 117175–117183. [Google Scholar] [CrossRef]

- Muharam, Y.; Dianursanti; Wirya, A.S. Modeling of jatropha oil hydrocracking in a trickle-bed reactor to produce green fuel. Int. J. Chem. Eng. 2021, 1, 7079459. [Google Scholar] [CrossRef]

- Romero-Izquierdo, A.G.; Gutiérrez-Antonio, C.; Gómez-Castro, F.I.; Hernández, S. Synthesis and intensification of a biorefinery to produce renewable aviation fuel, biofuels, bioenergy and chemical products from Jatropha curcas fruit. IET Renew. Power Gener. 2022, 1, 1–21. [Google Scholar] [CrossRef]

- Oliveira, J.L.F.; Batista, L.M.B.; dos Santos, N.A.; Araújo, A.M.M.; Fernandes Junior, V.F.; Araújo, A.S.; Alves, A.P.M.; Gondim, A.D. Clay-supported zinc oxide as catalyst in pyrolysis and deoxygenation of licuri (Syagrus coronata) oil. Renew. Energy 2021, 168, 1377–1387. [Google Scholar] [CrossRef]

| Feedstock | Homogeneous Catalyst | Heterogeneous Catalyst | Enzyme Catalyst (Lipase) | Catalyst Dosage (%) | Temperature (°C) | Time (h) | Yield (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Macaúba | KOH, H2SO4 | CaO, Al2O3 | Burkholderia cepacia | 1–10 | 25–115 | 1.5–16 | 94–98 | [48,49,50,51] |

| Babassu | KOH, H2SO4, NaOCH3 | SrO, SrCO3, Sr(OH)2 | Burkholderia cepacia Candida antartica | 0.05–20 | 30–100 | 0.2–120 | 16–99 | [52,53,54,55,56,57,58,59] |

| Pequi | KOH, NaOCH3, H2SO4 | CeO2, CoO, Zeolite HUSY, PRZr | --- | 1–50 | 30–100 | 0.5–24 | 67–96 | [60,61,62,63,64,65,66] |

| Chapéu-de-napoleão | NaOH, KOH, H2SO4 | Musa balbisiana Musa paradisiacal CaCO3, CaO, TiO2-ZnO, Cola acuminata | --- | 0.1–20 | 30–70 | 0.2–5 | 66–97 | [67,68,69,70,71,72,73,74,75,76,77] |

| Pinhão-manso | NaOH, KOH, H2SO4, HCl, | CaO, Co-Mo/Al2O3, Ni-Mo/Al2O3 | Candida rugosa Chromobacterium viscosum Porcine pancreas Candida antartica | 0.01–30 | 30–200 | 0.3–48 | 80–98 | [80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98] |

| Catolé | KOH, NaOH, HCl | --- | --- | 1–5 | 60–65 | 0.5–2 | 97–99 | [2,99] |

| Licuri | KOH, NaOH, NaOCH3, H2SO4 | ZnO | --- | 5–20 | 30 | 0.6–4 | 91–98 | [28,100,101] |

| Cipó-leiteiro | KOH, H2SO4 | --- | --- | 0.5–1 | 60 | 1 | 97 | [39] |

| Cipó-timbó | KOH, H2SO4 | --- | --- | 0.5–1 | 60 | 1 | 97 | [39] |

| Ucuúba | HCl, KOH | Fe2(SO4)3 | --- | 0.5–2 | 80–90 | 2–4 | 20–88 | [102] |

| Ameixa-do-mato | KOH | --- | --- | 1 | 70 | 1 | 92 | [103,104] |

| Process | Feedstock (Biomass) | Pre-Treatment | Intermediate Product | Conversion Process | Catalysts | Blend (%) | Ref. |

|---|---|---|---|---|---|---|---|

| SPK-FT SPK-FT/A | Solid waste (agricultural or urban) | Gasification | Syngas (CO + H2) | Hydrocracking/ distillation | Fe, Co sup. zeolites; mesoporous materials | 50 | [105] |

| SPK-HEFA | Vegetable and animal fats | Neutralization | Hydrocarbons | Hydrocracking/ distillation | Pd, Ni, Pt sup. activated carbon; zeolites | 50 | [106] |

| SPK-ATJ | Sugar, starch and cellulose | Fermentation | Ethanol and isobutanol | Dehydration/ oligomerization/ hydrogenation/ distillation | Ziegler-Natta catalysts, zeolites; ionic resins | 50 | [107] |

| SIP | Sugar cane | Extraction | Sugar | Fermentation/ hydrogenation | Ni, Pt, Rh, Pd complexes | 10 | [108] |

| CHJ | Vegetable and animal fats | Catalytic hydrothermolysis | Bio-oil | Hydrogenation/ distillation | Ni and Pt supported on activated carbon | 50 | [109] |

| SPK-HH | Microalga Botryococcus braunii | Extraction | Bio-derived hydrocarbons | Hydrogenation/ cracking/ Isomerization | Ni, Mo, Co, Pd, Pt, Ru supported on zeolites | 10 | [110] |

| Feedstock | Process | Catalyst | Reaction Conditions | Hydrocarbons Yield (%) | Reference |

|---|---|---|---|---|---|

| Macaúba | SPK-HEFA | Co/activated carbon | 350 °C, 30 bar H2, 2 h | 94 | [114] |

| SPK-HEFA | Beta/ZSM-5 zeolite | 350 °C, 10 bar H2, 3 h | 100/80 | [115] | |

| Transesterification Distillation | NaOH * | 60 °C, 2 h, 1:6 methanol/oil Distillation: 214–266 °C | 82 | [116] | |

| Transesterification Distillation | H2SO4 * | 74 °C, 4 h, 1:8 methanol/oil Distillation: 110–224 °C | 60 | [117] | |

| Babassu | Transesterification Distillation | NaOCH3 * | Distillation: 124–359 °C; 2,66 × 10−3 bar | 69 | [118] |

| Transesterification Distillation | NaOH * | 60 °C, 1 h, 1:6 methanol/oil Distillation: 140 °C; 3 × 10−5 bar | 80 | [119] | |

| Transesterification Distillation | NaOH * | 65 °C, 5 h, 1:2 methanol/oil Distillation: 115–157 °C; 0.19 bar | 74 | [120] | |

| Pinhão-manso | SPK-FT | Ni/Al2O3 Ni/ZSM-5 Pt/γAl2O3 Co/Al2O3 Ni/Al2O3 | Hydrogenation (300 °C, 45 bar H2) Hydrocracking (350 °C, 80 bar H2) Isomerization Fischer-Tropsch (240 °C, 25 bar H2) Reforming (900 °C, 15 bar H2) | 77.5 | [121] |

| SPK-HEFA | Sulfonated montmorillonite | Cracking (350 °C, 4 h) Distillation 250 °C | 79 | [123] | |

| SPK-HEFA | Ni-W/SiO2Al2O3 | 500 °C, 80 bar H2 | 79.5 | [124] | |

| ATJ SPK-HEFA | Ni Pd/activated carbon | Oligomerization (120 °C, 35 bar H2) Hydrogenation (100 °C, 30 bar H2) Hydroprocessing (320 °C, 80 bar H2) | 40 (ATJ) 47 (SPK-HEFA) | [125] | |

| Licuri | Transesterification SPK-HEFA | KOH * Pd/activated carbon | 30 °C, 40 min, 1:6 methanol/oil Hydrodeoxygenation (300 °C, 14.3 bar He/H2, 4 h) | 39 | [101] |

| CHJ | ZnO/vermiculite | Pyrolysis/deoxygenation (500 °C) | 53.5 | [126] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aquino, A.S.; Silva, M.F.d.; Almeida, T.S.d.; Bilheri, F.N.; Converti, A.; Melo, J.C.d. Mapping of Alternative Oilseeds from the Brazilian Caatinga and Assessment of Catalytic Pathways toward Biofuels Production. Energies 2022, 15, 6531. https://doi.org/10.3390/en15186531

Aquino AS, Silva MFd, Almeida TSd, Bilheri FN, Converti A, Melo JCd. Mapping of Alternative Oilseeds from the Brazilian Caatinga and Assessment of Catalytic Pathways toward Biofuels Production. Energies. 2022; 15(18):6531. https://doi.org/10.3390/en15186531

Chicago/Turabian StyleAquino, Aline Scaramuzza, Milena Fernandes da Silva, Thiago Silva de Almeida, Filipe Neimaier Bilheri, Attilio Converti, and James Correia de Melo. 2022. "Mapping of Alternative Oilseeds from the Brazilian Caatinga and Assessment of Catalytic Pathways toward Biofuels Production" Energies 15, no. 18: 6531. https://doi.org/10.3390/en15186531

APA StyleAquino, A. S., Silva, M. F. d., Almeida, T. S. d., Bilheri, F. N., Converti, A., & Melo, J. C. d. (2022). Mapping of Alternative Oilseeds from the Brazilian Caatinga and Assessment of Catalytic Pathways toward Biofuels Production. Energies, 15(18), 6531. https://doi.org/10.3390/en15186531