1. Introduction

The generation of electricity with photovoltaic (PV) systems has undergone a significant cost reduction in recent years. The global expansion of the technology has already resulted in PV electricity becoming the cheapest form of power generation in many markets. However, it is also known that a strong expansion of PV in the grid means that at times of very high irradiance, a considerable proportion of the possible production has to be curtailed because the generation would otherwise exceed the demand. The storage of larger amounts of PV electricity in batteries is not yet economically viable (2022). As a result, PV electricity utilization is not optimal when the installed production capacity is expanded, since the capacity of the grid is not sufficient at certain times, especially at midday. On the other hand, concentrated solar power (CSP) technology offers a proven and cost-effective storage option in the form of thermal storage, usually using molten salt stored in large tanks. So, it is possible to generate solar power even after sunset and at times of low irradiance. Thermal energy storage (TES) is economical and, due to its easy scale-up, has low marginal cost. The power block (PB) can work efficiently in a wide range of part-load conditions and is relatively flexible in terms of dispatchability (generation on-demand). At the same time, CSP solar fields can generate heat very efficiently. Compared to PV, CSP technology presents higher electricity generation costs, which can be attributed, among other things, to the fact that the installed capacity does not yet enable mass production. Nevertheless, there has been a significant cost reduction in CSP technology in recent years, which may lead to electricity production costs being below the level of conventional electricity generation if capacities are expanded further. Globally, by the end of 2021, approximately 6.4 GW of the CSP capacity was installed while there was about 843 GW of the PV installed capacity [

1].

Due to the specific advantages of each technology, it makes sense to combine them. There are currently approaches to integrate both types of power plants and thus use the respective advantages. Some publications show the research carried out on hybrid PV-CSP plants in recent years. DLR participated in the THERMVOLT project [

2], where the combination of CSP, PV, TES, battery energy storage system (BESS), and backup combined cycle power plants was examined. The focus was on fulfilling the representative load curves while at the same time limiting the specific CO

2 emissions in kg/kWh of produced electricity. Grid coupling of the systems was also investigated but without as deep an integration as in the current paper. Starke et al. [

3] conducted a techno-economic analysis to evaluate the performance of hybrid PV-CSP plants in northern Chile. The parametric analysis and optimization showed high potential in this region for the installation of hybrid PV-CSP plants due to the high levels of irradiation. Zhai et al. [

4] proposed a thermal storage PV-CSP plant and calculated the annual hourly performance of the system. Two different dispatch strategies were studied: a conventional strategy in which the PV and CSP system operated independently and a constant-output strategy that integrated both systems, producing some synergies. Lower values of the levelized cost of electricity (LCOE) were presented by the constant-output strategy, which resulted in a more fluid and stable power output. Zurita et al. [

5] performed a techno-economic evaluation of a hybrid PV-CSP plant integrated with thermal energy storage and large-scale battery energy storage for base load generation in northern Chile. LCOE and the capacity factor were used to evaluate the performance of the plant, identifying the configurations with a minimum LCOE. The results showed that the battery costs should be reduced by approximately 60–90% to attain competitive LCOEs in comparison to hybrid plants. Hamilton et al. [

6] published a paper about dispatch optimization of hybrid PV-CSP-BESS systems using mixed-integer linear programming. They did not consider an electric resistance heater (ERH) and the focus was on the optimization algorithm. They examined two sites (northern Chile and Sierra Nevada) with different solar resources and two price curves for the electricity. The authors concluded that the hybrid systems outperform the CSP-only plants dramatically in terms of the capacity factor and economics (21–33% lower LCOE). Schöniger et al. [

7] compared CSP with thermal storage, a photovoltaic system with a battery energy storage system (PV-BESS), and PV with thermal storage for a Spanish site with up to 24 h of storage capacity. They used simplified performance models for the subsystems and assumed a constant load of 100 MW. PV-BESS showed the lowest electricity costs for storage capacities lower than 4 h. Hassani et al. [

8] performed a techno-economic analysis of hybrid PV-CSP plants in eastern Morocco and found that hybrid PV-CSP plants provide dispatching energy at a lower LCOE than standalone CSP plants and that the capacity factor could reach a value of more than 90%. Zurita et al. [

9] investigated two sites in Chile with different solar resources (high and moderate). The TRNSYS and MATLAB models were used to create a surrogate model, which was then used for multi-objective optimization. Four load scenarios, including the baseload, were considered. The authors showed LCOE over the sufficiency factor (fulfilment of the load curve). They did not investigate the close integration with ERH. Only solar tower systems were simulated but no parabolic trough systems. Riffelmann et al. [

10] studied different options to combine the benefits of PV and CSP technologies. A small PV plant that supplied its own consumption of the CSP plant, hybrid CSP-PV plants with an optional electric heater, and a PV system with an additional electric heater were simulated in different scenarios. For the Spanish location, the most economic configuration combined the CSP plant, which charged the thermal storage during daytime and produced electricity during nighttime, and a PV system, which delivered electricity during day hours, additionally charging the thermal storage with an electric heater. In contrast, the calculation of the best configuration in a high direct normal irradiance (DNI) site such as South Africa resulted in a system without an electric heater. For both locations, the electricity produced with the CSP plant and thermal storage was more economic than the one that originated from the PV system with an electric heater. Mata-Torres et al. [

11] assessed the impact of solar irradiation and plant location for a hybrid PV-CSP plant integrated with a multi-effect distillation plant for simultaneous power generation and seawater desalination. A techno-economic analysis was performed at different locations to determine the most suitable sites for this kind of plant, showing that inland locations with a considerable increase in DNI with respect to the coast (over 300 kWh/m

2-year), distances from the sea of no more than 60 km, and altitudes up to 750–1000 m presented the most appropriate conditions. Richter et al. [

12] defined a predictive storage strategy for the optimal design of hybrid PV-CSP plants with an immersion heater. It was proven that the strategy had a significant impact on the output of the plant and the subsystem sizing. Lui at al. [

13] published a study about the optimization of hybrid PV-CSP-systems with ERH and BESS for a Chinese site. A 100 MW constant load was assumed for all systems. They showed LCOE over the loss of power supply probability (LPSP), which is the remaining fraction of the electricity demand that cannot be satisfied by the system. The lowest LCOE was found for the systems with TES capacities of about 16–18 h. The combination of PV, ERH, and CSP can reduce costs and lead to high fulfilment of the load curve.

Moreover, some hybrid plants are already under construction or operational. Phase 4 of MBR Solar Park in Dubai is under construction and will combine a 600 MW (three units of 200 MW each) parabolic trough, 100 MW molten salt solar power tower, and 250 MW photovoltaic plant [

14]. Noor Midelt 1 in Morocco will have a total installed capacity of 800 MW and hybridize concentrated solar power and photovoltaic technologies with a 5 h thermal storage, using electrical heaters to increase the storage temperature and convert excess PV energy to heat [

15]. Cerro Dominador was inaugurated in Chile in 2021 and has a 110 MW central tower and a 100 MW photovoltaic field [

16]. Additionally, four projects that combine CSP and PV have been started in China. Each project will include 100 MW of CSP and 900 MW of PV [

17].

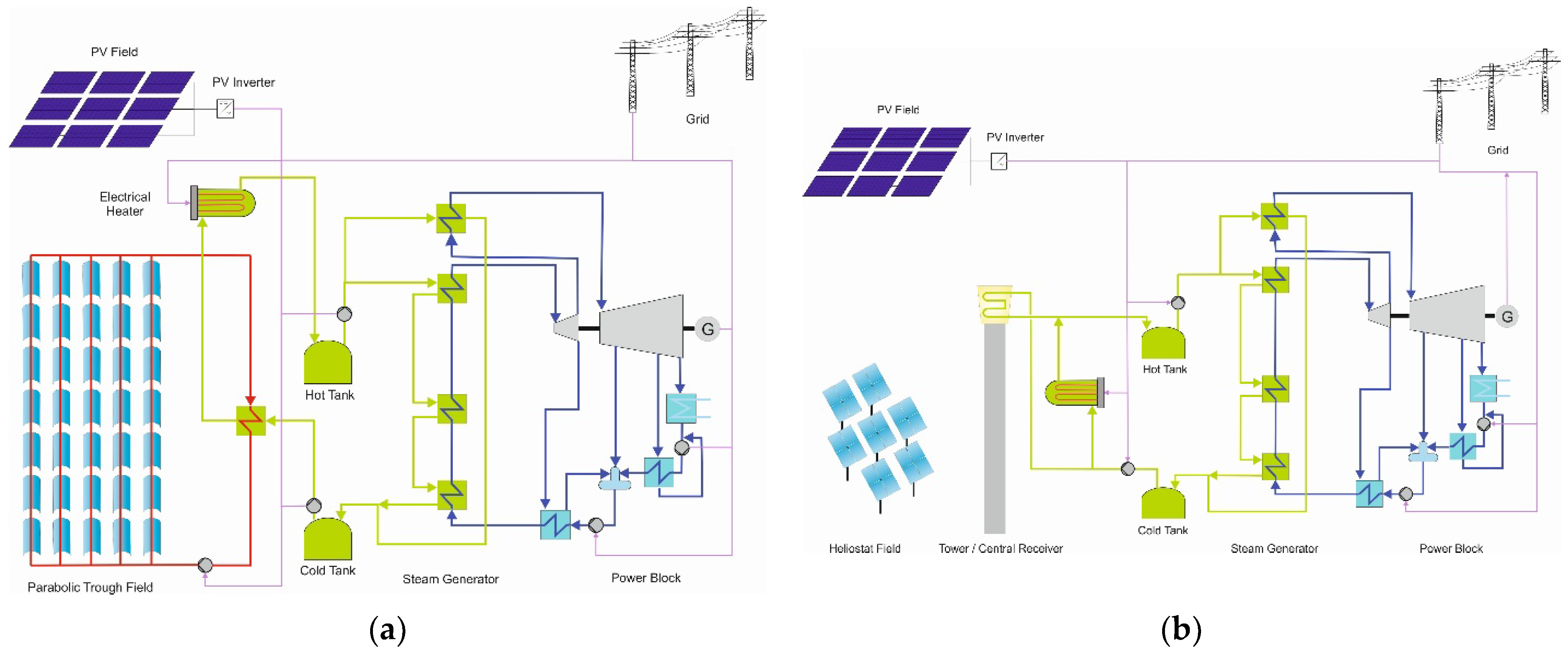

The literature review shows that hybrid CSP-PV power plants can offer cost-effective solar power generation with high security of the supply and high solar coverage. A full integration of both technologies, which hybridizes them on the system level or, in other words, “inside the fence”, was studied in this paper. These plants have only one common grid-access point and the plant operator is responsible for controlling the separate subsystem outputs, their interactions, and their contribution to the grid power (and ancillary services) supply. Electrical and thermal energy is enabled to flow between subsystems in order to provide charging power to energy storage systems or for unidirectional supply of auxiliary power. A fully integrated solar hybrid power plant benefits from multiple synergies but also comes with more challenges due to the higher number of degrees of freedom in the system design and operating strategy.

The combination of both systems would not lead to lower electricity generation costs compared to standalone PV plants. However, the generation of solar power at times of the day when the sun does not shine cannot be achieved by a PV plant without storage. In this respect, the storage of energy in the heat storage tank should be viewed in comparison to an alternative storage concept. Joint optimization of PV and CSP to a specific power generation profile will therefore lead to electricity generation costs that will lie between those of pure PV (without battery) and a pure CSP power plant. A shift in power generation from the CSP power plant to the evening hours can result, for example, in this CSP power plant having a smaller solar field than the pure CSP plant that also supplies electricity during the day. In this case, the storage size and the power plant unit remain basically unchanged. Consequently, savings are primarily made in the solar field, which may account for about 50% of the investment costs of the CSP power plant (this is given here only as an indicative value, since the cost fraction of the solar field depends on the storage size).

The impact of boundary conditions on the optimum configurations was another fundamental aspect of this investigation. Different locations with different radiation and latitude conditions were simulated. The most suitable plant types and configurations for the given boundary conditions were considered. The hybrid systems analyzed were the parabolic trough collectors in combination with a PV plant and the central receiver system also in combination with a PV plant. These systems were optimized and compared with other technologies such as pure CSP plants, PV with battery storage and photovoltaic system plus an electric resistance heater, thermal energy storage, and power block (PV+ERH+PB). This optimization was performed not only to achieve the lowest solar electricity costs for the systems but also to increase the proportion of electricity delivered to the grid during night hours.

The deeper integration of technologies to increase synergies, the representation of results considering the nighttime electricity fraction instead of the capacity factor, and the greater number of locations used for the calculation differentiate this work from previous publications.

A final report of the project [

18] was also written and includes additional analyses such as the influence of the demand curve profile and systematic sensitivity analyses. More detailed information and explanations of the results are also included.

3. Materials and Methods

The software greenius was used for the simulations with an hourly time step resolution for typical years. DLR developed greenius several years ago as a software tool for the annual yield calculation and economic evaluation of renewable energy systems, with an emphasis on CSP plants. An official version is available for free from the DLR website [

19] in addition to a manual with further details about the models used. For the evaluation of the results, the LCOE and the nighttime fraction of electricity were used. The LCOE is not sufficient for evaluating and comparing hybrid power plants. With LCOE as the only criteria, a standalone PV plant would be the least-cost solution, but it would just provide electricity during sunshine hours, providing no dispatchability. Hybrid solar power plants are instead capable of providing solar electricity even after sunset, often at elevated costs, and the aim of this project was to find cost-optimized combinations. Therefore, at least a second parameter had to be fixed to make the systems comparable on the same basis. This parameter was the nighttime electricity fraction.

Blended LCOE was used for the evaluation of the results. This is made of the tariff for direct feed-in and the tariff for electricity generated from the storage. Equation (1) shows how it was calculated. Equation (2) shows, on the other hand, the formula for the nighttime electricity:

where

r is the interest rate,

t is the year within the period of use (1, 2, …

tges),

tges is the period of use (system lifetime in years) [a], and

d is the yearly degradation rate:

A parameter variation in greenius was used to identify the system configurations with the least LCOE. The steps and limits of this variation are shown in

Table 2. The configurations with the lowest LCOE for each storage size were selected as the representation of the results.

The costs of each component used for the simulations were assumed by DLR and Dornier Suntrace GmbH, based on project experience, market analysis, and published information, and are shown in

Table 3 for 2021 and 2030. The CSP costs were taken from [

20] and BESS costs from [

21] and [

22]. According to an analysis conducted by DLR, the costs of the parabolic trough (PT) and central receiver tower (CRT) are expected to decrease by 12% between 2021 and 2030. The BESS cost is expected to decrease by only 20% for power and 23% for the capacity due to strong competition with the automotive sector, limited raw material availability, and high demand. The ERH cost values were assumed from DLR projects, with a 10 percent cost reduction expected from 2021 to 2030. The cost of the PV system was determined by Dornier Suntrace GmbH project experience and current market scenarios, and it is expected to fall by only 23% between 2021 and 2030. The storage costs for both TES and BESS refer to the net capacity. The costs for electricity supplied by the grid were adjusted for each site using the prices from [

23]. The land costs were set to zero because of their negligible influence on the LCOE (assuming low-cost desert sites). Engineering, procurement, and construction (EPC) surcharges were assumed to be different for each subsystem because of the different maturity levels of the technologies and were related to the capital expenditure (CAPEX). Increased operation and maintenance costs for BESS were used to account for the replacement or addition of batteries in order to enable the lifetime of 25 years assumed for all systems. For all systems, a 5% debt interest rate was assumed.

The grid injection limit was fixed at 150 MWel for all the systems (power block and battery net power) to allow the comparability of all concepts. In this way, it was also possible to avoid difficulties in the design of the PV plant. This limit might be caused by an upper limit of the grid connection of the solar power plant as well. It was necessary to set the nominal gross output of the CSP power block to 160 MWel because this plant should be able to deliver the required net power of 150 MWel to the grid and cover the auxiliary demand of the plant even under hot ambient conditions. A constant load curve for the whole day (“baseload”) was assumed. This means that the required load at night was also 150 MW for each system. The power block and CSP solar field auxiliary requirements were modeled as being dependent on the ambient temperature. Stand-by auxiliaries (solar fields, PV, BESS) were considered with fixed values. Grid connection, substations, and transmission lines were not included in the project scope to allow the comparison of plants independently of their location.

The techno-economic evaluation was performed for different locations to consider different boundary conditions (e.g., DNI and global horizontal irradiance (GHI) values) and latitudes. The widest possible variety of locations was sought. Depending on the characteristic values of the sites, some locations are more suitable for CSP plants or for PV plants. Seven sites were used, for which high-quality meteorological datasets were available. Unfortunately, it was not possible to find sites with almost identical parameters but differing in only one parameter.

Table 4 shows the main parameters of the selected sites.

The definition of the night hours was carried out for each month and location separately. An hour was considered to be nighttime if the PV output of a sunny day in the middle of the month (days with clear sky conditions and an almost ideal DNI curve) did not reach 25% of its nominal value for that hour. A time resolution of one hour was adopted for the meteorological datasets.

4. Results and Discussion

The results of the simulations were compared for each technology and site. This paper only shows the technology comparison diagram for Riyadh (

Figure 4).

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9 compare the results of each site for every technology (standalone tower, hybrid tower, hybrid parabolic trough, PV with battery, and PV plus ERH, TES, and PB).

Figure 4 shows the LCOE values versus the nighttime electricity fraction of the optimal configurations for different storage sizes of different topologies in Riyadh. Each point stands for an LCOE-optimized configuration for a certain storage capacity (3, 6, 9, and 12 h duration of discharge at the full power block output). Cases without storage are not displayed with one exception, which is the standalone PV system as a reference.

The top lines show the results for pure CSP systems. These plants have the highest LCOE since they do not benefit from the low electricity cost of PV. They are shown as a reference and their LCOE is higher than that of the hybrid systems. The LCOE decreases with increasing nighttime electricity fraction, which is caused by the cheap TES and better utilization of the PB (which is kept at a constant nominal power but reaches more operating hours with the increasing TES size).

The higher storage cost of BESS compared to TES results in a different dependency of LCOE with the increasing nighttime electricity fraction. PV with a battery is the technology that provides the lowest LCOE for nighttime fractions below 20–25% (approximately 4–5 h of storage capacity). However, from the 20–25% nighttime fraction upwards, the costs start to increase and this difference grows linearly as the storage size increases. For a storage size of 12 h, the LCOE is similar to standalone CSP plants. Hybrid PV-CSP systems, in contrast, show less dependency of LCOE on the nighttime electricity fraction and they are almost constant as shown in

Figure 4.

Hybrid plants show a significant decrease in costs compared to standalone CSP plants. LCOE remains relatively constant regardless of the nighttime fraction (storage capacity). There is better utilization of the TES as it increases in size, but there is also an increase in the dumping and component costs. Both hybrid plants show almost the same LCOE, with a small advantage of the parabolic trough hybrid system for a low storage capacity and a small advantage of hybrid tower systems for a higher storage capacity.

Another interesting question is whether a system using PV, ERH, TES, and PB could be cheaper than a hybrid PV-CSP plant and how much nighttime electricity it can offer.

Figure 4 shows that the LCOE values and night fractions of the PV+ERH+PB system are higher than those in hybrid plants. Note that the operating strategy of this kind of system prioritizes TES charging over direct grid injection. This operating strategy was used for direct comparison since, as in the case of hybrid systems, storage charging is prioritized. It can be seen that for a three-hour storage, the night share tends towards zero because the small storage capacity does not justify the cost of the ERH. The model considers fixed PB and TES costs even without any ERH. The optimized three-hour storage system would have storage and PB that would not be used at all. It would basically be a standalone PV plant but with a shared LCOE as a fixed PB and TES cost item is included. This changes for higher storage capacities, where the electric heater and storage tank would be used. Although the LCOE is higher than that for hybrid systems, the nighttime electricity fractions are much higher for large storage capacities. This is also of great importance since not only is reducing costs one of the objectives of the plant but also being able to provide a greater amount of electricity during the night.

Table 5 shows the main parameters of the optimized systems with 6 h of storage. The parabolic hybrid plant has the smallest CSP field. This is due to the greater flexibility in the design of this plant. The hybrid tower plant has a minimum CSP field design size of 200 MW, which represents the lower field size limit considered in the parametric study. Due to the significantly lower daytime electricity costs with PV, the slightly lower night costs with PV and ERH, and the relatively small storage size, a larger PV field is advantageous. For this reason, in the parabolic trough hybrid power plant, there is a significant difference in the size between the module area of the PV and the aperture area of the CSP fields. The PV field of the hybrid parabolic trough is also larger than the field of the PV battery system. The hybrid trough additionally uses PV electricity to charge the TES and due to the lower efficiency of the PB (compared to the battery system), a larger PV field is required. This optimized design is very sensitive to the cost assumptions. Slightly lower CSP costs would change this figure. The thermal capacity of the storage tank for the standalone parabolic trough powerplant is higher than that for the hybrid plants since the PB has a lower efficiency due to the lower temperature level and therefore requires more energy to deliver 150 MW

el for 6 h.

Table 6 shows the parameters of the optimized systems with 12 h of storage. The sizes of the components are considerably increased to cover greater nighttime demand, allowing, at the same time, a higher load coverage during the daytime. The optimization of the hybrid tower prioritizes an increase in the PV field because of the lower heat production costs with PV and ERH. The ERH works in parallel, and does not require the CSP field to increase. In the case of parabolic trough hybrid plants, there is a greater increase in the CSP field aperture for higher storage capacities because the booster system requires an increase in both fields (PV and CSP) due to the fixed ratio of heat provided by each system. For the non-hybrid plants, the size of their main components is increased to make use of the additional storage capacity. The nominal power of the tower reaches 1150 MW, which is the upper limit available in greenius for the simulation.

There is a large difference in the land area of the standalone tower and the parabolic trough plant. Tower plants have a greater land use factor, and it increases with the increase in the system size. Heliostats far away from the central tower require a larger separation from their neighbors to limit shading of each other. This shows how the total land area of the tower plant increases significantly for plants with larger storage sizes. This considerable land use difference does not occur for hybrid plants because the CSP field of the hybrid tower is not as large as that of standalone tower plants. PV with ERH and PB also shows a significantly larger land use because of the greater PV capacity required. Land area costs were not included in the calculation.

Figure 5 shows LCOEs for the standalone solar tower plants at each site. The order in which the curves are placed corresponds to the magnitude of the annual DNI sums. The site with the lowest DNI is represented by the upper line and the site with the highest radiation by the lowest line. PSA has a higher LCOE than expected considering its DNI sum. This is due to the higher latitude of this site, which reduces the solar field performance in winter to a greater extent. Having a similar DNI to Riyadh, the worse distribution of radiation during the year for PSA implies a higher LCOE due to the lower efficiency of the CSP field. There is also a slightly higher than expected LCOE for De Aar for the CSP technologies. This is mainly due to the intercept heat, which must be dumped to protect the receiver. DNI exceeds 1000 W/m

2 in De Aar for several hours during the year, which causes greater dumping, increasing the LCOE. This explains why, despite having an annual DNI similar to Daggett, the LCOE is higher. The results at Diego de Almagro are outstanding, despite the dumping, for exceeding the maximum absorbable radiation for many hours. On the other hand, the LCOEs at Dunhuang and PSA exceed the LCOEs of the other sites by almost two cents. Most sites have values between 8 and 10 cents per kWh. There are no significant differences in the nighttime fraction, except for Diego de Almagro.

The positions in which the hybrid tower curves are arranged is shown in

Figure 6 and can also be explained by the annual DNI and GHI sums, with the first still being very important even though the PV fields provide the majority of energy. The LCOE advantage for Diego de Almagro is not as big as for the standalone tower, but it is still significant. The hybridization causes a significant overall decrease in the costs compared to the standalone CSP systems.

The same dependence on solar resources can be observed for trough hybrid plants in

Figure 7. There is a slight cost increase as the storage capacity increases because of the higher component costs and dumping. It should also be noted that the nighttime fraction is higher for Riyadh and Diego de Almagro due to the greater proximity to the equator. Parabolic troughs suffer from low sun angles and sites close to the equator show smaller differences in the sun angles between summer and winter. Furthermore, the day length is also rather constant compared to sites with higher latitudes. This is an advantage as storage charging and discharging is more equally balanced over the year. More pronounced seasons with variable day lengths are not ideal, leading to storage and ERH over dimensioning for winter days. Moreover, there is an additional clear correlation of the nighttime electricity fraction and the solar resource. The plant with 12 h of thermal storage at Dunhuang only shows a nighttime fraction of 0.33 while the plant with the same storage size at Diego the Almagro shows a nighttime fraction of 0.43. For all sites, LCOE is below 8 cents per kWh. Due to the larger PV field, GHI increases its influence compared to the DNI. PSA clearly shows lower LCOE values than Dunhuang because of the higher GHI. Riyadh, the site with the second highest GHI, also displays a clear improvement, with this technology showing lower LCOE than Ouarzazate and De Aar for large storage capacities.

Figure 8 shows a similar trend for PV-BESS. This trend is dependent on the solar irradiation too. Similar values are observed for the De Aar, Riyadh, Ouarzazate, and Daggett sites.

The PV+ERH+PB systems (

Figure 9) show some similar effects to the PV-BESS systems. The higher impact of GHI causes a proportionally lower LCOE and higher nighttime electricity fraction in Riyadh in relation to the other technologies because PV is less susceptible to low DNI as long as GHI stays high. Daggett shows lower LCOEs compared to Riyadh and Ouarzazate, although GHI is lower.

From the results, it can be concluded that Riyadh is particularly suited for PV technology and De Aar and Daggett are better suited for the introduction of CSP technologies. The design of the plant is thus highly dependent on the site, resulting in different optimums for each case. The results show that DNI and GHI are the determinant factors but not the only ones.

A financial sensitivity analysis of the electric heater cost was performed to reliably determine its impact on the LCOE.

Figure 10 shows the results of varying the price of the heater from 278 (solid line) to 140 (dashed line) and 70

$/kW (dotted line). This cost reduction implies a decrease in LCOE in the order of 1 cent per kWh for the PV+EH+PB system. A similar order of magnitude is observed for the hybrid parabolic power plant. This cost reduction would also mean a significant shift to the left of the cut-off point with the battery PV system. All this proves the significant influence of this cost on the final techno-economic analysis and the final design of the hybrid power plants.

An interesting aspect to consider (though hard to determine) are cost projections for the future. There was active discussion about the cost values to be taken in the simulations for 2030. The costs of the components are continuously evolving depending on numerous factors and there is uncertainty in estimating their future values. The PV and BESS markets are currently (2022) in a crisis that has multiple causes, with a general raw material shortage, high demands for renewable energy technologies, and shortages in logistic capacities being only a few examples. The projection of costs for 2030 therefore has to be balanced between conservative cost assumptions reflecting the current crisis and allowing some optimism for market growth and potential cost reduction that can be expected as a result. The presented results are based on cost assumptions that are balanced between both extremes considering cost development forecasts from before the crisis and current medium-term price increases specifically for PV and BESS components.

Table 3 shows the assumed costs. A general decrease in LCOE can be seen in

Figure 11 for all technologies by 2030. It is interesting to note how the cut-off point of PV-BESS plants with hybrid plants shifts from the 4.5–5 h of storage expected in 2021 to approximately 6 h or more observed for 2030. For PV+ERH+PB systems, the distance to hybrid plants is becoming smaller due to the overall greater cost decrease expected for PV compared to the CSP components.

With regards to other publications, the results are overall comparable. As in [

7], PV-BESS provides the lowest LCOE for storage capacities lower than 4 h and this break-even point will shift to larger storage capacities if battery costs decrease significantly. Hybrid plants’ electricity costs are lower than those of standalone CSP plants as described in [

6,

8]. The outstanding performance of hybrid PV-CSP plants was calculated for high DNI sites in Chile in this paper, as reported in previous articles [

3,

6,

9].

5. Conclusions

PV-CSP hybrid power plants were optimized by parameter variation and compared to standalone CSP plants, PV-battery plants, and PV plants with an electric heater, thermal storage, and power block. Hybrid plants show a significant cost decrease compared to pure CSP plants because of lower PV electricity costs. Hybrid PV-CSP plants show lower LCOE than PV-BESS for nighttime electricity fractions above 20–25% (corresponding to an approximately 4–5 h storage capacity) and different dependencies of LCOE for increasing nighttime electricity fraction (or storage capacity). Hybrid plants show a relatively constant LCOE for increasing storage capacities, but PV-BESS system costs grow significantly due to the higher storage costs. Heat production costs by CSP and by PV plus an electric heater are comparable and very sensitive to cost assumptions. The LCOE values for the PV system with an electric heater, thermal storage, and power block are higher than for hybrid systems but nighttime fractions are significantly higher as well, which is considered to be a really important factor in the design and optimization of the plant. Hybrid plants present the lowest LCOE values for nighttime electricity fractions above 20–25% and PV with a battery for lower fractions.

Close coupling and real integration offer additional benefits for hybrid plants. Parabolic trough systems using an ERH as a booster (in series to the solar field) show comparable LCOE and nighttime electricity fractions to molten salt solar tower systems using an ERH in parallel to the solar receiver.

To investigate the impact of latitude and irradiance, the systems were simulated and optimized for seven different sites. Considering nighttime fractions above 25%, sites with high direct normal irradiation are more suitable for higher CSP field shares in hybrid plants whereas sites with low direct normal irradiation are more suitable for higher PV field shares in hybrid plants. This trend was seen for all sites.

Costs projections for 2030 were made and the LCOE calculations were repeated for all technologies. A cost decrease in the next years may shift the break-even point of hybrid plants and PV-battery towards higher nighttime electricity fractions of around 25–30% (about 6 h storage capacity). This will depend on the actual decrease rates. PV with thermal storage and, particularly, with batteries may benefit to a greater extent than systems with CSP due to the higher cost reduction projected for their components.