Abstract

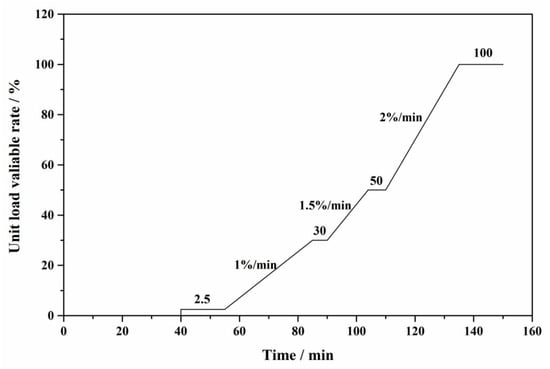

In order to meet the flexibility operation needs of coal-fired units under the goal of carbon peak and carbon neutralization, it is imperative for circulating fluidized bed (CFB) units to participate in deep peak regulation. By systematically summarizing deep peak regulation operation practice of existing SC and subcritical-parameter-levels CFB units, the feasibility of deep peak regulation technology of an ultra-supercritical (USC) CFB unit under development and being built is analyzed and demonstrated; meanwhile, the deep peak regulation capacity of the boiler is also predicted. The results show that by analyzing the structural characteristics and design performance of the USC-CFB boiler, for technical problems such as stable combustion under low load, hydrodynamic safety, denitration performance under wide load, and rapid boiler load change rate existing in deep peak regulation, technical measures were implemented by selecting advanced boiler furnace type, adopting good design technology of the secondary rising water wall and uniformity design of bed temperature and bed pressure, strengthening the reducing atmosphere inside the furnace, improving the performance of wear-resistant refractory materials, quickly controlling the furnace bed material stock under variable load, optimizing the control strategy of CFB unit, and so on. The boiler achieved good operation characteristics and good deep peak regulation performance, and the pollutant emissions can steadily achieve ultra-low emission standards. When the USC-CFB unit participates in deep peak regulation, the minimum stable combustion load of the boiler can reach 20~30% BMCR, and a boiler load change rate under 30% BMCR or above could reach 1.5~2% BMCR/min, while that below 30% BMCR could reach 1% BMCR/min. The research results can provide references for the deep peak regulation of in-service supercritical (SC) CFB units and design optimization of similar USC-CFB units.

1. Introduction

With the introduction of the policy of “carbon peak and carbon neutralization” in China, it is imperative to build a new power system with new energy as the main body. New energy power generation systems such as wind power and solar thermal power have the characteristics of intermittence, randomness and volatility, which have an important impact on the safety and stable operation of China’s power system. It is urgent for thermal power units to play the role of a regulating power source to ensure the smooth transition of energy structure adjustment, which puts forward higher requirements for the rapid and deep regulation performance of thermal power units [1]. Circulating fluidized bed (CFB) boilers, with their outstanding features of wide fuel adaptability and deep peak capability, have been developing rapidly in China and have now reached the supercritical (SC) steam parameter [2,3,4]. The deep peak regulation operation practice of SC-CFB boilers shows that there are still many technical problems in the aspects of low-load stable combustion, hydrodynamic safety, wide load denitration and rapid load change, which restrict the deep peak regulation ability of CFB boilers and affect the safety, economic and environmental operation of the unit [5,6,7].

The existing deep peak regulation of CFB units is mainly aimed at the research of single technical links such as rapid load change and pollutant control of subcritical and SC-CFB units [8,9,10,11,12,13,14,15]. Sun et al. [12] analyzed the adjustment method of bed temperature, bed pressure, air volume and limestone volume of a 330 MW CFB boiler. The bed temperature and reheating-steam temperature are controlled by the compact splitting-type returning ash heat exchanger, and the boiler has good combustion characteristics and variable load performance. Liu et al. [13] proposed the utilization mode of energy storage for subcritical and SC-CFB boilers. By designing an advanced energy balance (AEB) system, the load response time of CFB units was shortened and the load change rate was significantly improved. Cai et al. [14] studied the operating parameters and variation trend of a 350 MW SC-CFB unit under variable load conditions, and found that the load can be quickly adjusted by reasonably controlling the operating conditions such as coal feed and air volume, and the original NOX emission concentration can be controlled in a low range by selecting appropriate bed temperature and air–coal ratio. Wang et al. [15] conducted a deep peak regulation test on a 350 MW SC-CFB boiler. Through a series of measures such as boiler combustion and air distribution adjustment, hydrodynamic maintenance, steam source pressure of steam-driven feed–water–pump and environmental protection parameter optimization, the CFB boiler had good performance in deep peak regulation. At present, the 660 MW ultra-supercritical (USC) CFB units must meet the latest “double carbon” target, and it is urgent to carry out a feasibility study of deep peak regulation at very low load and technology integration innovation.

Therefore, taking a 660 MW USC-CFB boiler as the research object, this paper analyzes the problems that may arise in the process of deep peak regulation, such as stable combustion at low load, hydrodynamic safety, wide load denitrification, rapid load change, etc. We implemented a series of technical measures such as optimizing the boiler structure and adopting an advanced control strategy, in order to ensure that the USC-CFB units have good performance in deep peak regulation, which would provide a technical reference for the long-term safe and reliable operation of the same type of units.

2. Boiler Configuration

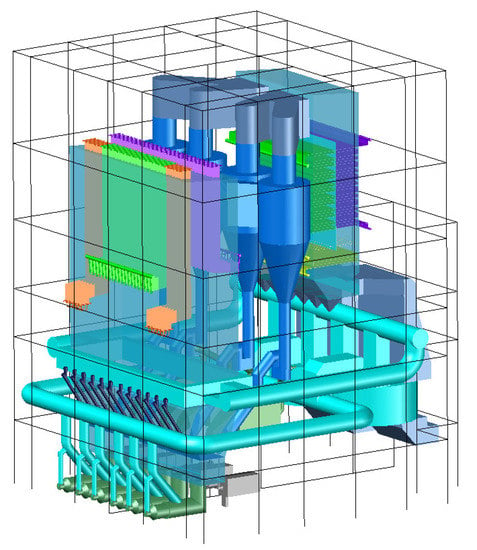

The 660 MW CFB boiler adopts a USC once-through boiler, single-furnace structure with single air distribution plate, M-shaped arrangement, single reheating, balanced ventilation, solid-slag removal, all-steel structure and circulating fluidized bed boiler. The boiler consists of a furnace, four large-diameter steam-cooled cyclone separators, four external heat exchangers (EHES) and a tail flue. Figure 1 presents the general layout of the boiler. See Table 1 for boiler coal quality characteristics.

Figure 1.

Schematic diagram of the 660 MW USC-CFB boiler.

Table 1.

Coal characteristics of the boiler.

The boiler furnace adopts the series connection mode of the membrane water wall and water-cooled panel, and a high-temperature superheater and high-temperature reheater are arranged in the furnace; a medium-temperature superheater is arranged in the EHE to control the bed temperature. The tail flue adopts the double-flue structure, and a low-temperature reheater, low-temperature superheater, economizer and rotary air preheater are arranged, respectively. The temperature of superheated steam is adjusted by the water–coal ratio, supplemented by two-stage spray desuperheating for fine adjustment. The temperature of reheated steam is adjusted by a tail flue damper, and an emergency spray desuperheater is set. The boiler adopts the mode of combined coal feeding in front of and behind the boiler, a multi-point air inlet at the bottom and slag discharge at the rear wall. The start-up system with water-circulating pump (BCP) is set. When the boiler load is lower than 25% BMCR, the BCP is started to maintain the stable working medium flow of the water wall. The boiler adopts combined desulfurization inside and outside the furnace, low-temperature staged combustion inside the furnace and selective non-catalytic reduction (SNCR) denitration. The design values of the main operating parameters of the boiler can be seen in Table 2.

Table 2.

Design operation parameters of the CFB boiler.

3. Technology for Deep Peak Regulation of USC-CFB

3.1. Low-Load Stable Combustion Technology

It was determined by calculation and experimental studies that the designed coal and checked coal of the boiler are easy to ignite and have good stable-combustion characteristics, which is beneficial to the safe operation of the boiler at low load.

In order to further improve the deep-peak-regulation performance of the boiler and meet the requirements of stable combustion at low load, a series of integrated technologies were adopted in the performance design of the boiler. Firstly, the heat absorption distribution characteristics of the heating surface of the boiler were optimized, the heat absorption share of the furnace and the tail flue was reasonably distributed, and the EHE was used for bed temperature regulation to ensure that the bed temperature of the boiler reached 860 °C under full-load working conditions and was higher than 800 °C under 30~100% BMCR conditions. Secondly, the particle size range of coal entering the furnace was strictly controlled, the maximum particle size was no more than 6 mm, and meanwhile, the proportion of coal slime was reduced (or there was no coal slime) under low-load conditions, supplemented by a part of high-calorific-value raw coal, which can reduce the decline degree of the bed temperature under low load. Thirdly, primary air proportion and wind cap resistance were selected properly, so that the phenomenon of uneven fluidization of material on the air distribution plate under the low load was reduced, and the stability of the bed temperature and bed pressure was maintained under low load.

3.2. Hydrodynamic Safety Technology

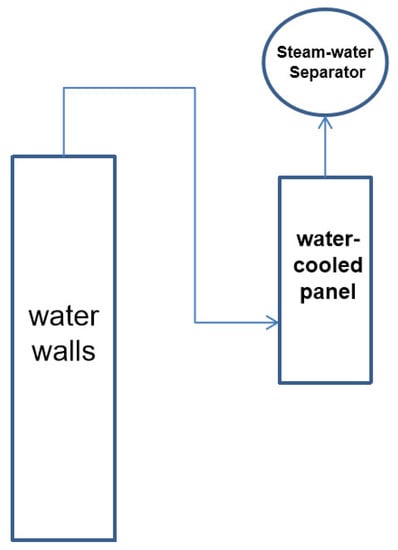

Under low-load conditions, the flow of feed water will decrease, and the cooling ability of the cooling medium to the water wall will also be weakened, so the hydrodynamic safety needs to be demonstrated urgently. Through the optimal design of the boiler, the Bunsen vertical tube and the low-mass-flow-rate water-cooled panel series technology were adopted (Figure 2). The mass flow rate of the water wall and water-cooled panel was about 1000 kg/(m2·s), which reduced the resistance of the water wall system under low-load conditions and enhanced the self-compensation characteristic between pipe groups, so as to ensure the uniform temperature distribution of the water wall outlet working medium and meet the requirements of boiler hydrodynamic safety.

Figure 2.

Secondary rise water cooling wall system.

At the same time, the unit is also equipped with a BCP. When the boiler load is lower than 25% BMCR (the pressure is 10.5 MPa (a)), the BCP starts to ensure that the flow of working medium in the water wall is basically stable, so that the water wall still has enough working medium for full cooling under low-load conditions, further improving the hydrodynamic safety.

3.3. Wide Load Denitration Technology

The boiler adopts low-nitrogen-combustion technologies such as bed temperature and bed pressure uniformity design, secondary air depth classification and operation oxygen optimization, which can significantly reduce the original NOX emission of the boiler and realize wide-load denitrification.

3.3.1. Bed Temperature and Bed Pressure Uniformity Design

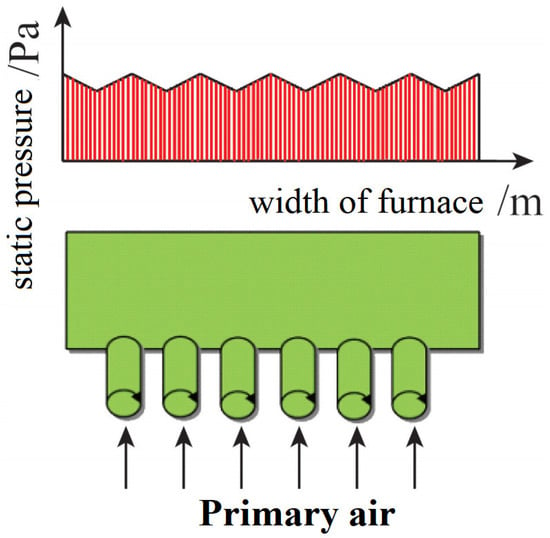

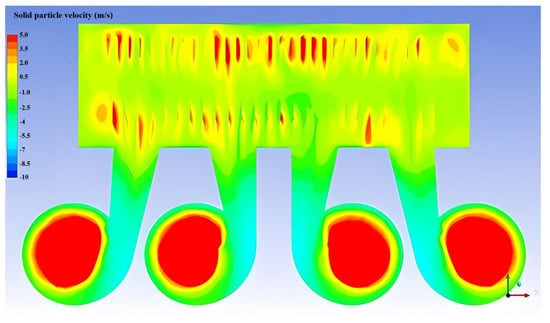

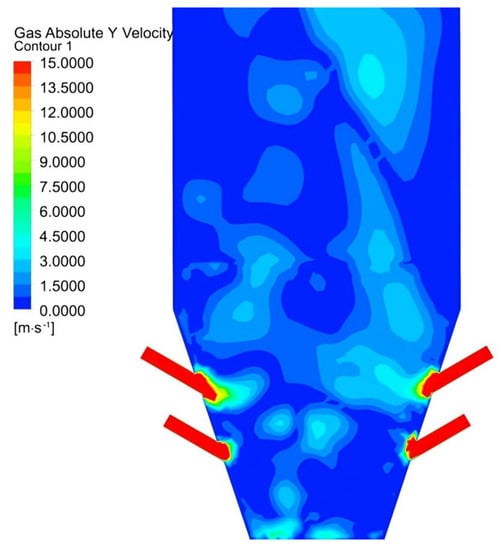

The boiler air chamber adopts a 6-point air inlet mode at the bottom (see Figure 3), and the bed pressure distribution is more uniform than the traditional rear wall air inlet and bilateral air inlet. The boiler adopts front- and rear-wall combined coal feeding and rear-wall slag discharge mode to ensure the uniform mixing of fuel and air in the furnace and improve the uniformity of combustion in the furnace. The boiler is provided with four EHEs, in which medium-temperature superheaters are arranged to adjust the bed temperature and reduce the bed temperature deviation along the width direction of the large-section furnace. The boiler uses four steam-cooled cyclone separators symmetrically arranged along the center line of the furnace to ensure the geometric symmetry of the external circulation loop. The gas–solid fluid dynamics simulation results show that the maximum deviation of the circulating ash flow rate among the four separators of the furnace type with the M-shaped arrangement of four separators is 7.9%, which can ensure the uniformity of the boiler material circulation system (see Figure 4). Additionally, the influence of the ash flow deviation of each circulation loop on the combustion uniformity in the furnace is reduced.

Figure 3.

Static pressure distribution of the wind chamber with feeding multiple wind.

Figure 4.

Axial velocity distribution of solid phase at 50 m distance from air distribution plate.

3.3.2. Secondary Air Depth Classification

The furnace height of the USC-CFB boiler is higher than that of the SC-CFB boiler. According to the numerical calculation results of the secondary air arrangement of the boiler (see Figure 5), the distance between the upper and lower layers of secondary air ports should be increased by 1.5 m or more on the basis of 350 MW SC-CFB boilers. By optimizing the layout and structure size of the secondary air, increasing the proportion of the upper secondary air, and controlling the proportion of the primary air to about 40%, not only the effective jet stiffness and penetration ability of the secondary air are ensured, but also the reducing atmosphere at the bottom of the furnace is enhanced, which can further reduce the original emission concentration of NOX.

Figure 5.

Calculated results of secondary air arrangement.

3.3.3. Optimization of Oxygen Content in Operation

The oxygen content in operation directly affects the combustion efficiency and NOX emission of the boiler. The furnace height of the USC-CFB boiler is higher, and the burnout time of coal particles is significantly increased, which effectively improves the combustion efficiency of the boiler. Based on the design of the bed temperature and bed pressure uniformity, the fluidization uniformity in the furnace can be ensured by using lower-fluidization air velocity, so the boiler can be properly controlled to operate under the condition of lower oxygen content, and the excess air coefficient of the boiler can be reduced from the traditional 1.2 to 1.15; the original emission concentration of NOX is further reduced, and the combustion efficiency of the boiler does not change significantly at this time.

3.4. Rapid-Load-Change Technology

3.4.1. Performance Improvement of Wear-Resistant Refractory Material

A USC-CFB boiler has no steam drum, which is beneficial to the improvement in variable load capacity of the boiler. However, the boiler is laid with a large number of wear-resistant refractory materials, which have strict requirements on temperature change, limiting the further improvement in load change rate. Through the continuous operation practice and technology research and development of SC-CFB boilers in service, the new high-strength, non-metallic, wear-resistant refractory material has been widely used. The thickness of the material is about 50 mm, and the temperature rise rate can reach 3 °C/min, which can adapt to faster furnace temperature changes.

3.4.2. Fast Control of Bed Inventory in Furnace during Load Changing

There are a large number of circulating materials and wear-resistant refractory materials in the CFB boiler, and the thermal inertia of the boiler is large, which affects the rapid load change of the unit. Therefore, in the process of boiler load reduction, the concentration of fine particles participating in the heat transfer in the furnace can be effectively reduced by means of a large amount of slag discharge or storage of circulating ash, so as to achieve the purpose of reducing the evaporation heat absorption in the furnace and reducing the load quickly. In the process of slag discharge, it is necessary to strictly control the fluctuation of bed temperature and pressure to avoid affecting the safe and stable operation of the boiler. In the process of increasing the load of the boiler, a separate circulating-ash-adding system is set to actively add circulating ash or bed materials into the circulating system, and the material circulation required for increasing the load is quickly established, so as to achieve the purpose of quickly increasing the load.

3.4.3. Unit Control Strategy Optimization

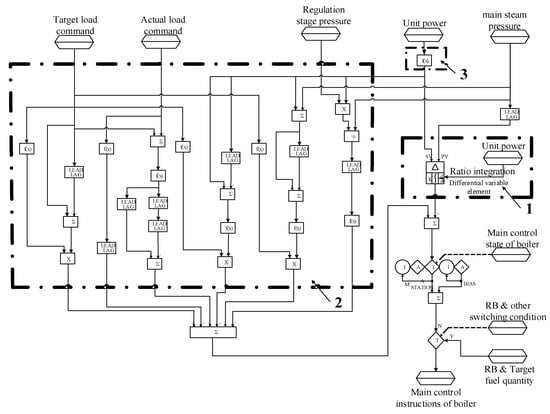

Figure 6 shows the main control loop of the boiler in the coordinated control system of the USC-CFB unit. The main control loop of the boiler in the coordinated control system usually sets the power or the pressure before the machine corresponding to the feed forward or the pressure before the machine corresponding to the feed forward. As the once-through boiler has a small heat storage capacity and is difficult to control, the main control loop of the boiler adopts the energy signal (P1/PT) P0 required by the steam turbine, in which P1 is the first-stage pressure, PT is the upstream pressure and P0 is the upstream pressure’s set value of the turbine.

Figure 6.

Adjustment block diagram of the boiler main control loop of USC-CFB unit.

In order to further improve the load response capability, it is necessary to make more detailed adjustments to the controller parameters and feed forward quantities in the coordinated control system of the unit under low-load conditions, and the relevant parameters of the boiler main control feed forward need to be corrected (the dotted box 2 in Figure 6). If necessary, the relevant parameters of several main feedforwards can be set as a function of the unit load to meet the specific requirements of the unit’s coordinated control system. For the characteristics of the control object of the unit change at low load (the dotted box 1 in 6), the relevant proportional, integral and differential parameters of the boiler master PID controller are modified to the variable parameter scheme, which can satisfy the control requirements under deep-peak-regulation conditions.

The feedwater control strategy for the USC-CFB boiler is based on intermediate point enthalpy correction and water with coal. In order to satisfy the requirements of deep peak regulation, other feed water quantity acceleration or correction instructions can be added in the design of the feed water control system. The instructions can be in the form of signals calculated from pressure deviation signals and consideration of desuperheating water quantity, so as to speed up the response speed and improve the control effect of the feedwater control system. When the unit is in low-load operation, the feed water control system uses PID variable parameters and a correction function to correct the unit load or other parameters to ensure the safe and reliable operation of the feed water system.

In the steam temperature control system of the USC-CFB boiler, the variable parameter logic of the main and auxiliary controllers’ changes with the load of the boiler are selected. At the same time, combined with the large time delay and nonlinear characteristics of the main steam temperature control system of the unit, the correction and feed forward loops are added to the set values and output instructions of the main and auxiliary regulation loops, respectively, to ensure the control performance and response speed of the main steam temperature under the low load of the unit.

4. Prediction of Unit’s Deep-Peak-Load-Regulation Performance

4.1. Low-Load Stable-Combustion Performance

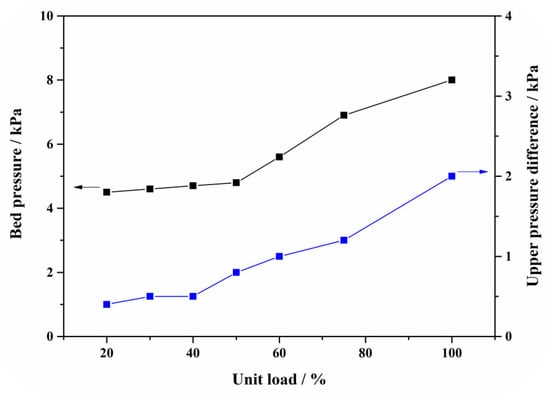

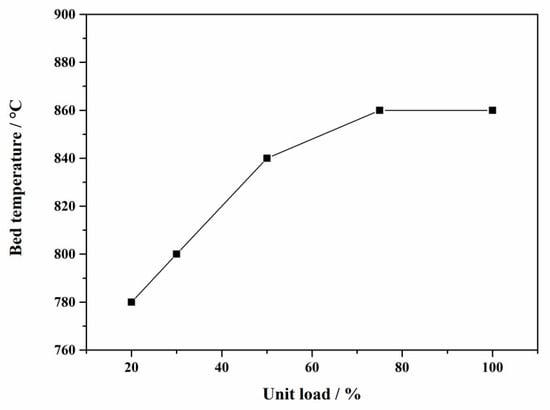

Figure 7 and Figure 8 show the change in bed pressure and bed temperature with load was obtained by calculating the material balance and heat balance model of the USC-CFB boiler. Because the outlet of the furnace is the zero-pressure point of the boiler, the bed pressure of the furnace reflects the upper pressure of the air distribution plate, and the bed pressure reflects the pressure of the dilute phase zone of the upper part of the furnace. As can be seen from the figure, as the coal particle size of the USC-CFB boiler is controlled below 6 mm, there are few large-particle materials in the furnace, and less invalid bed material in the bottom of the furnace. With the load dropping, the bed pressure and upper pressure difference gradually decline, and when the boiler load reaches 40% or below, the bed pressure drops gently. When the USC-CFB boiler burns the design coal, the design bed temperature reaches above 780 ℃ at 20~100% BMCR, which can maintain the stable combustion of the boiler. Therefore, the minimum stable-combustion load of the USC-CFB boiler without oil can reach 20~30% BMCR.

Figure 7.

Boiler bed pressure varies with the load.

Figure 8.

Boiler bed temperature varies with the load.

4.2. Hydrodynamic Safety Performance

Based on the calculation of the USC-CFB boiler hydrodynamic model, the temperature deviation of the outlet working medium of the water wall and water-cooled panel under different load conditions was obtained (Table 3). It can be seen from the table that the working medium temperature distribution at the outlet of the water wall under different loads was relatively uniform, and the maximum deviation of the working medium temperature of adjacent circuits at the outlet of the water-cooled panel was only 7 °C/min. When the boiler load was lower than 25% BMCR, the BCP starts to operate to maintain the working medium flow in the water wall at a basically unchanged level, so the hydrodynamic safety of the boiler under deep-peak-regulation conditions can be effectively guaranteed.

Table 3.

Outlet tube temperature deviation of the water wall system under different boiler load.

4.3. Environmental Protection Performance

Table 4 shows the environmental performance of 20% BMCR and above-load boilers. It can be seen from the table that the design technology of low nitrogen combustion in the furnace, supplemented by SNCR denitration, can ensure the denitration capacity of the boiler under wide load.

Table 4.

Environmental performance of different boiler load above 20% BMCR.

4.4. Variable Load Performance of Unit

The prediction of the maximum variable load rate of the USC-CFB unit was obtained through the calculation of the material balance and heat balance model of the USC-CFB boiler (Figure 9). The current operation practice of the SC-CFB boiler in service shows that the boiler load change rate can reach 1% BMCR/min under 30% BMCR and 1.7% BMCR/min under 30% BMCR and above. USC-CFB boilers are expected to further improve the variable load rate of CFB units by further optimizing the structure of the boiler body and the performance of wear-resistant refractories, rapidly controlling the bed stock in the furnace during variable load, and improving the performance of the unit control system. The variable load rate of the unit can reach 2% BMCR/min under the working condition of 50–100% BMCR, the load change rate of 30~50% BMCR can reach 1.5% BMCR/min, and the load change rate below 30% BMCR can reach 1% BMCR/min.

Figure 9.

Predicted maximum load variable rate for a USC-CFB unit.

5. Conclusions

The USC-CFB boiler can maintain a high bed temperature under normal conditions, and the minimum stable-combustion load can reach 20~30% BMCR, while the bed temperature is still close to 800 °C. The hydrodynamic safety of the boiler at low load can be ensured by adopting the secondary rising water wall system with low mass flow rate, setting the BCP, optimizing the bed temperature and bed pressure uniformity, deeply grading the secondary air, and controlling the lower oxygen content in the operation of the boiler; at the same time, the original emission concentration of NOX can be further reduced to achieve the purpose of denitrification at wide load.

USC-CFB boilers can significantly improve the load change rate of units by improving the performance of wear-resistant refractories, rapidly controlling the bed stock in the furnace during load change, and optimizing the control logic of the unit coordinated control system and feed water steam temperature, which is expected to further improve the load change rate of CFB boilers. The variable load rate reaches 3% BMCR/min under 30% BMCR and above, and 1~2% BMCR/min below 30% BMCR.

USC-CFB boiler technology is the main development direction of large-scale CFB boilers in the future. The 660 MW USC-CFB boiler under construction integrates almost all the advanced design concepts and the latest research results of SC-CFB boilers in service. It has good deep peak regulation performance and can better meet the flexible operation needs of coal-fired units under the “double carbon” target, with strong feasibility and wide application and popularization prospects.

Author Contributions

Conceptualization, S.X. and H.W.; methodology, S.X.; software, H.W.; validation, P.C., P.Z. and X.L.; writing—original draft preparation, S.X.; writing—review and editing, H.W.; visualization, P.C. and P.Z.; supervision, J.L., G.W. and Q.W.; project administration, G.W.; funding acquisition, S.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research & Development Program of China [grant number 2016YFB0600201] and 2030 Pilot project of Major project [GJNY2030XDXM-19].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| BCP | boiler circulation pump |

| BMCR | boiler maximum continuous rating |

| CFB | circulating fluidized bed |

| EHE | external heat exchanger |

| MW | megawatt |

| SC | supercritical |

| SNCR | selective non-catalytic reduction |

| USC | ultra-supercritical |

References

- Mao, J.; Guo, H.; Wu, Y. Road to low-carbon transformation of coal power in China: A review of biomass co-firing policies and technologies for coal power abroad and its inspiration on biomass utilization. Clean Coal Technol. 2022, 28, 1–11. [Google Scholar]

- Lv, J.; Yang, H.; Yang, F.; Liu, D.; Zhang, M.; Huang, D. Analysis on current situation of low calorific value coal resources and application of circulating fluidized bed power generation. China Coal 2021, 47, 101–108. [Google Scholar]

- Lyu, J.; Zhang, M.; Yang, H.; Liu, Q.; Liu, Z.; Zhao, Y. Conceptual design of a simplified 660MW USC-circulating fluidized bed boiler. Proc. CSEE 2014, 34, 741–747. [Google Scholar]

- Yue, G.X.; Lu, J.; Xu, P.; Hu, X.K.; Ling, W.; Chen, Y. The up-to-date development and future of circulating fluidized bed combustion technology. Electr. Power 2016, 49, 1–13. [Google Scholar]

- Peng, Z.; Yang, G.; Wu, W. 600MW SC-CFB unit deep peak-regulating operation technology. Energy Technol. 2020, 18, 55–58. [Google Scholar]

- Zhang, C.; Ma, S.; Zhang, J.; Li, S.; Sun, W. Pollutant emission from 350MW CFB boiler under varying load condition. Therm. Power Gener. 2020, 49, 41–47. [Google Scholar]

- Li, J.J.; Yang, H.R.; Lv, J.F. Low NOX emission characteristic of low energy consumption CFB boilers. J. Combust. Sci. Technol. 2013, 19, 293–298. [Google Scholar]

- Jiang, C.; Niu, R. Research on operation method of deep peak-shaving of 330 MW CFB unit. J. Shenyang Inst. Eng. Nat. Sci. 2017, 13, 326–330. [Google Scholar]

- Yu, H.Y.; Gao, M.M.; Zhang, M. Performance analysis and evaluation of deep peak-regulating for circulating fluidized bed units. Therm. Power Gener. 2020, 49, 65–72. [Google Scholar]

- Yu, R.; Wang, T. Economic analysis of deep peak load Regulation of 350 MW SC-CFB Unit. Coal Sci. Technol. Mag. 2020, 41, 12–13+27. [Google Scholar]

- Yang, Q. Experiment study on deep peak regulation of CFB units. Shanxi Electr. Power 2018, 213, 51–53. [Google Scholar]

- Sun, X.; Shi, B.; Shi, Z. Regulation and load variation performance of the domestic 330 MW CFB boiler. Electr. Power 2013, 46, 16–20. [Google Scholar]

- Liu, J.; Hong, F.; Gao, M.; Li, C.; Chen, F. Research on the control strategy for quick load change of circulating fluidized bed boiler units. Proc. CSEE 2017, 37, 4130–4137+S20. [Google Scholar]

- Cai, J.; Shan, L.; Wang, Z.; Zhang, M.; Jin, Y.; Cai, X.; Wang, P.; Yang, H. Variable load characteristics of a 350MW SC-circulating fluidized bed boiler. Therm. Power Gener. 2020, 49, 98–103+108. [Google Scholar]

- Wang, P.; Deng, B.; Cai, J.; Wang, K.; Kong, H.; Li, L.; Zhang, M.; Yang, H. Technical difficulties and related control strategies on deep peak regulation for SC-circulating fluidized bed boiler. Electr. Power 2021, 54, 206–212. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).