Control Strategy and Parameter Optimization Based on Grid Side Current Dynamic Change Rate for Doubly-Fed Wind Turbine High Voltage Ride Through

Abstract

1. Introduction

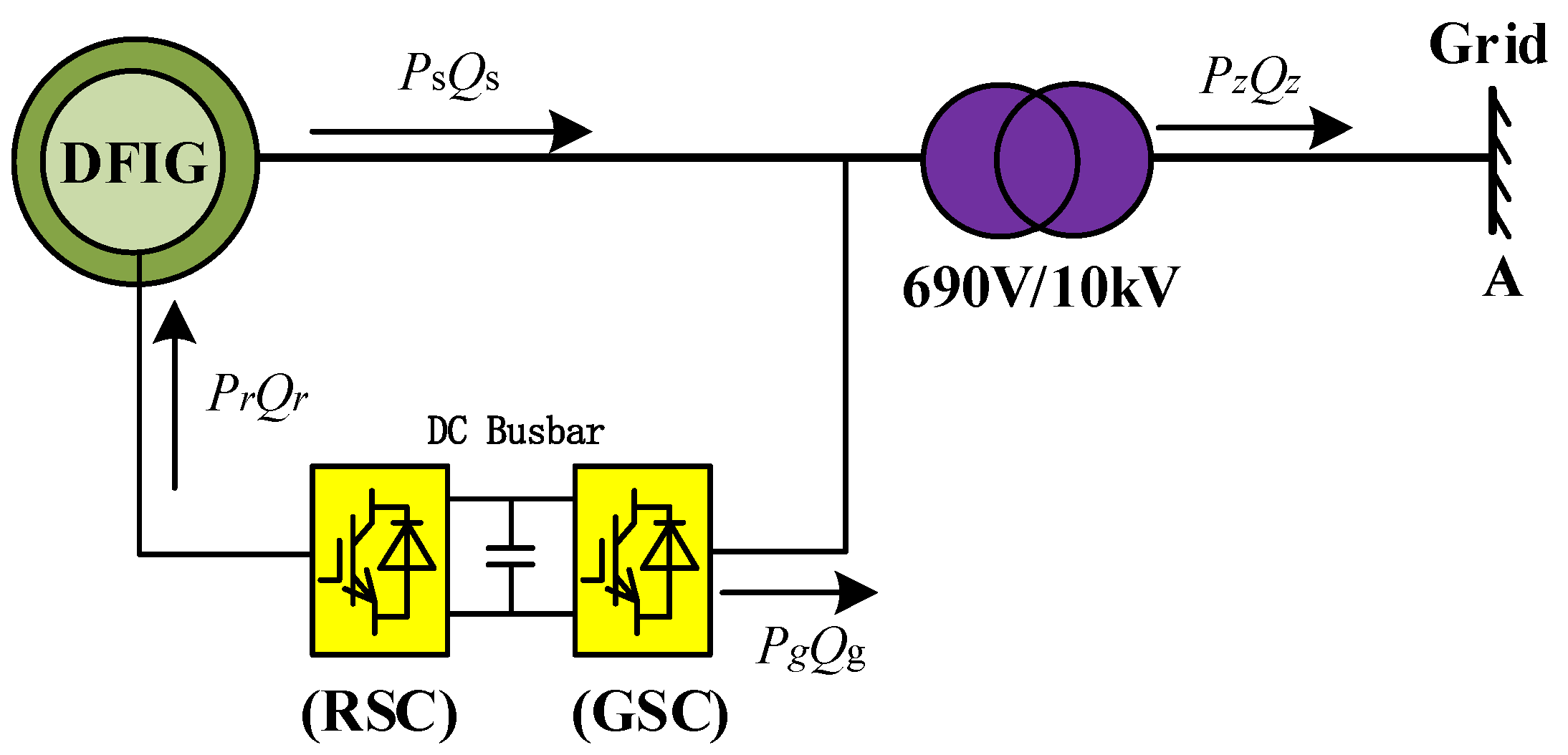

2. Analysis of the Reactive Current Limit of DFIG

2.1. Stator side Reactive Current Limit Analysis

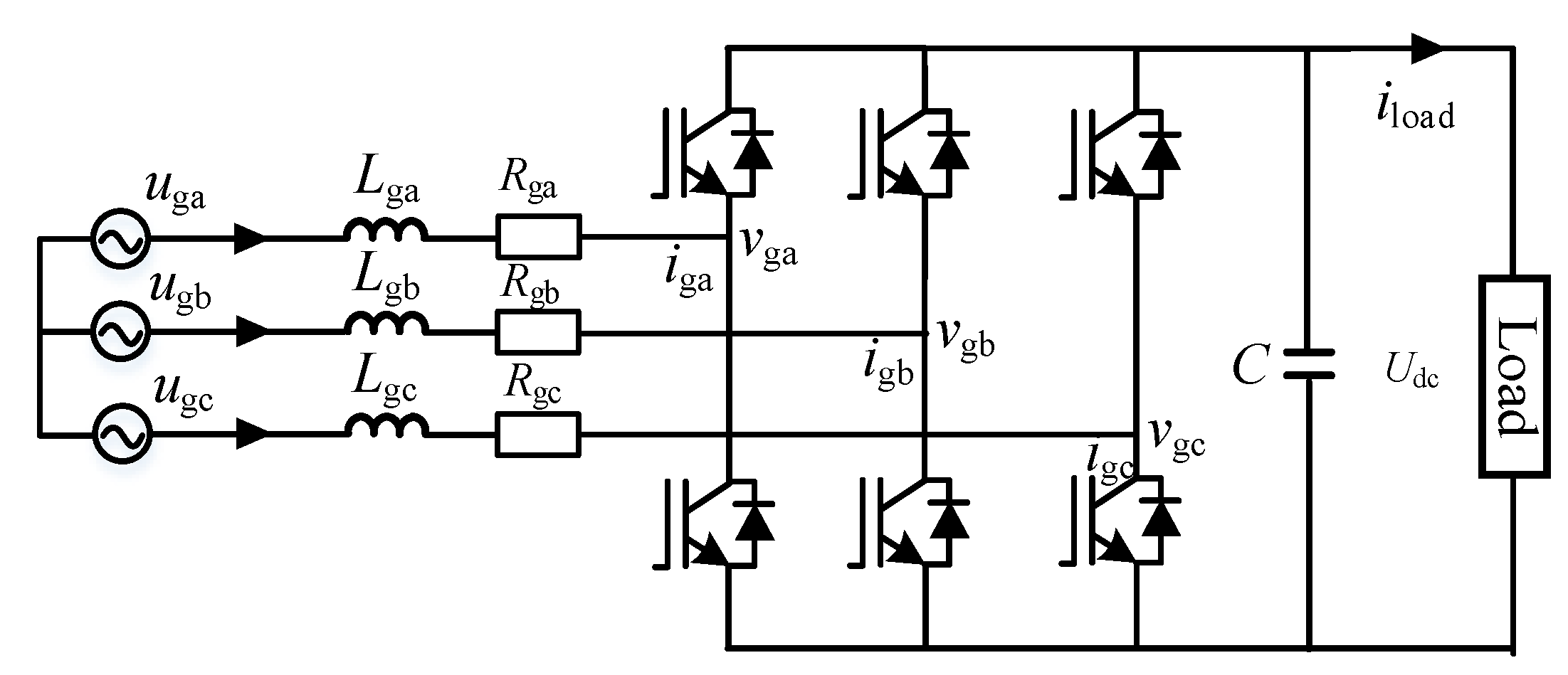

2.2. Grid Side Reactive Current Limit Analysis

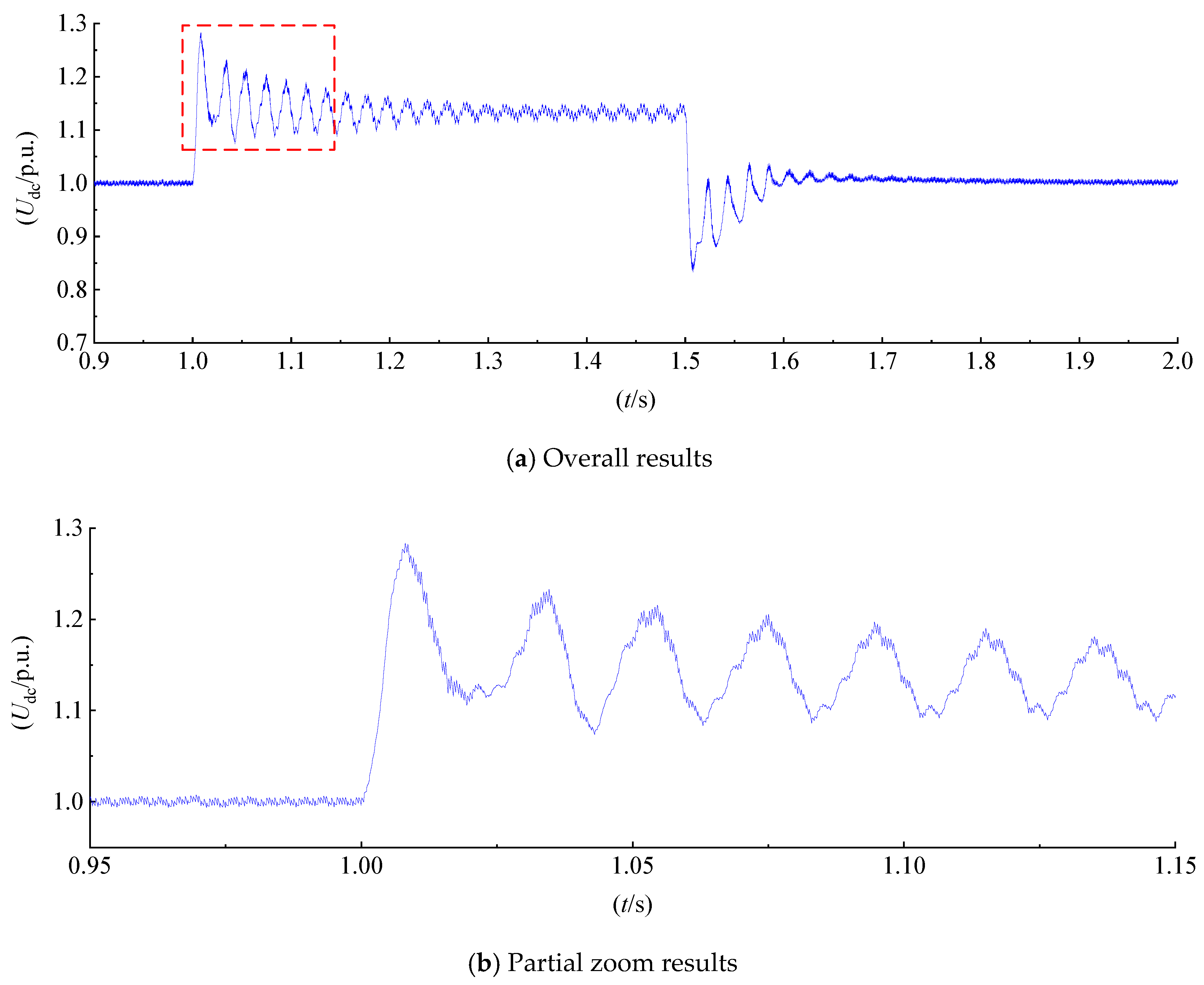

3. Analysis of the DC Bus Overvoltage Limiting Mechanism

3.1. Voltage Limitation of the DC Bus with the Grid side Converter

3.2. DC Bus Overvoltage Full Process Analysis

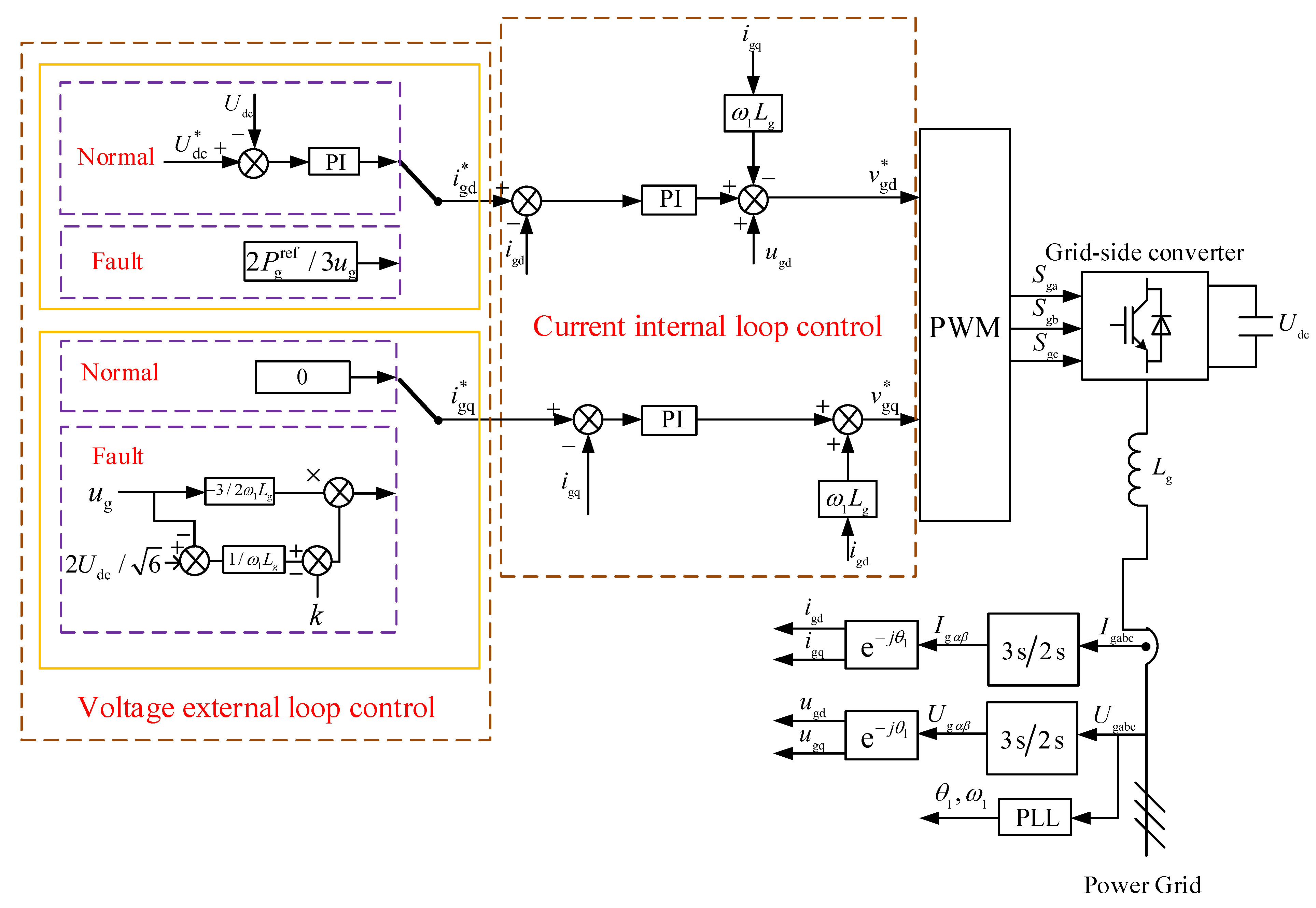

4. HVRT Control Strategy Based on Grid Side Current Variation

4.1. Grid Side d-Axis Control

4.2. Grid Side q-Axis Control

4.3. Rotor Side Control

5. Parameter Optimization for HVRT Control Strategy

5.1. Grey Wolf Advantage Search Algorithm

- (1)

- Encirclement: a mathematical model of the process of encirclement of prey by a wolf pack is established.

- (2)

- Capture: further capture of prey by the wolf pack, led jointly by three wolves, with constant updates of individual grey wolf positions, is mathematically modeled as follows:

- (3)

- Attack: Eventually the wolves attack the prey. If , the wolves focus on the attack and the algorithm performs local optimization. If , the wolves disperse, and global optimization is performed.

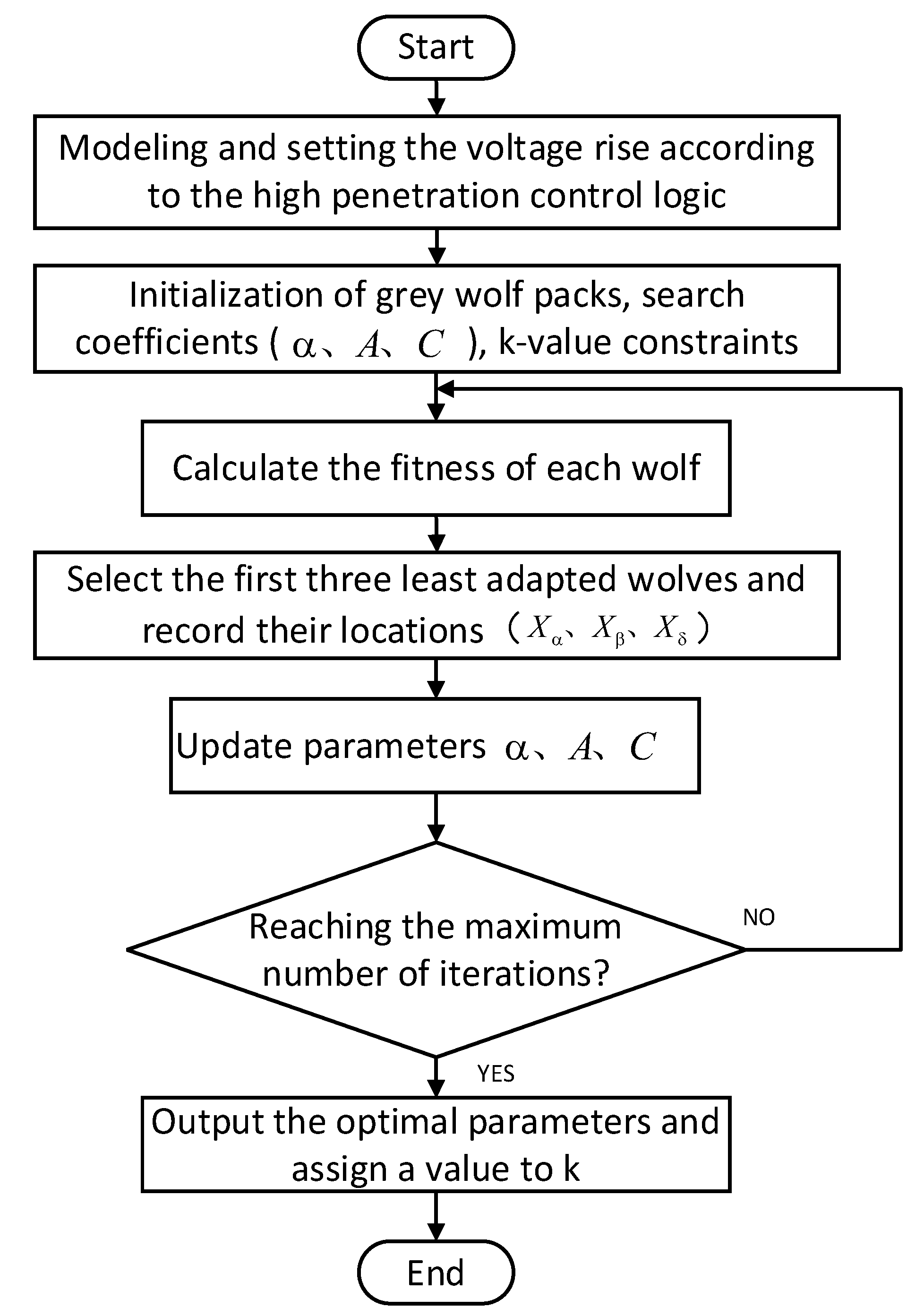

5.2. Application of the Grey Wolf Algorithm

- (1)

- Set up the DFIG HVRT model, establish the control logic in accordance with the previous section, and set the degree of voltage lift at the machine end.

- (2)

- Set up the assignment module in the grid side control logic, take values within the k constraint range as constant input and store the DC bus voltage maximum value as during the fault, and optimally solve the objective function.

- (3)

- Initialize the parameters of the grey wolf algorithm: pack size N, solution dimension d, maximum number of iterations Jmax, individual position, etc.

- (4)

- Use Equation (33) to calculate the fitness of individual grey wolves and rank them in order, defining the top three as and save their locations as

- (5)

- Update individual wolf pack locations and parameters .

- (6)

- The first three wolves are updated according to the fitness ranking, and an iterative search is continuously performed until the maximum number of iterations is reached, the iteration is cut off, and the optimal fitness function value is output.

6. Simulation Testing and Analysis

6.1. System for Simulation Testing

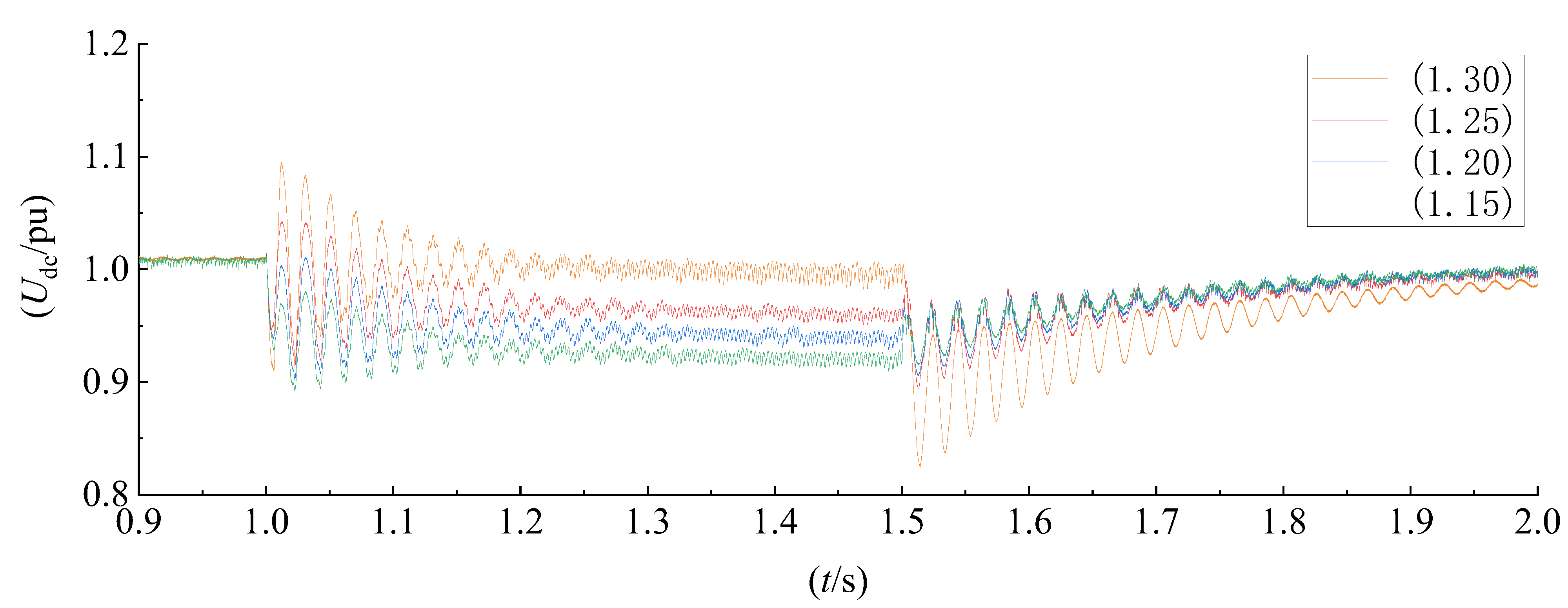

6.2. Simulation Test of HVRT Control Method under Different Voltage Rise Conditions

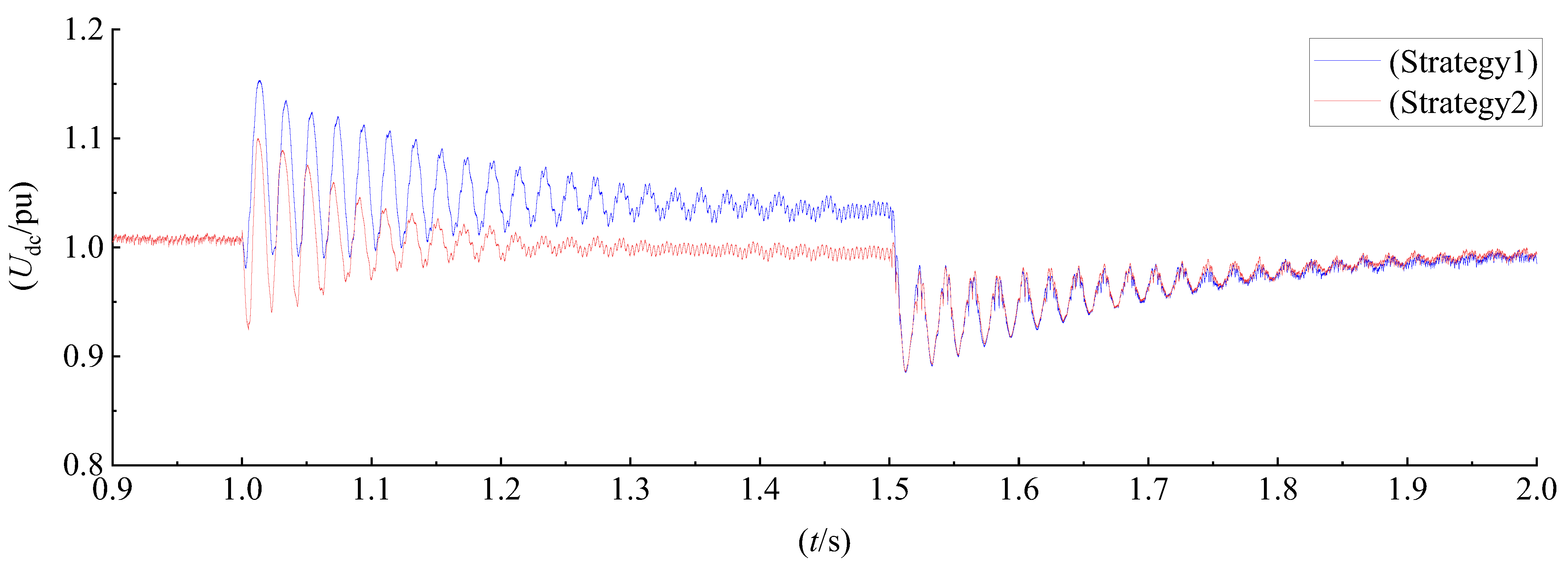

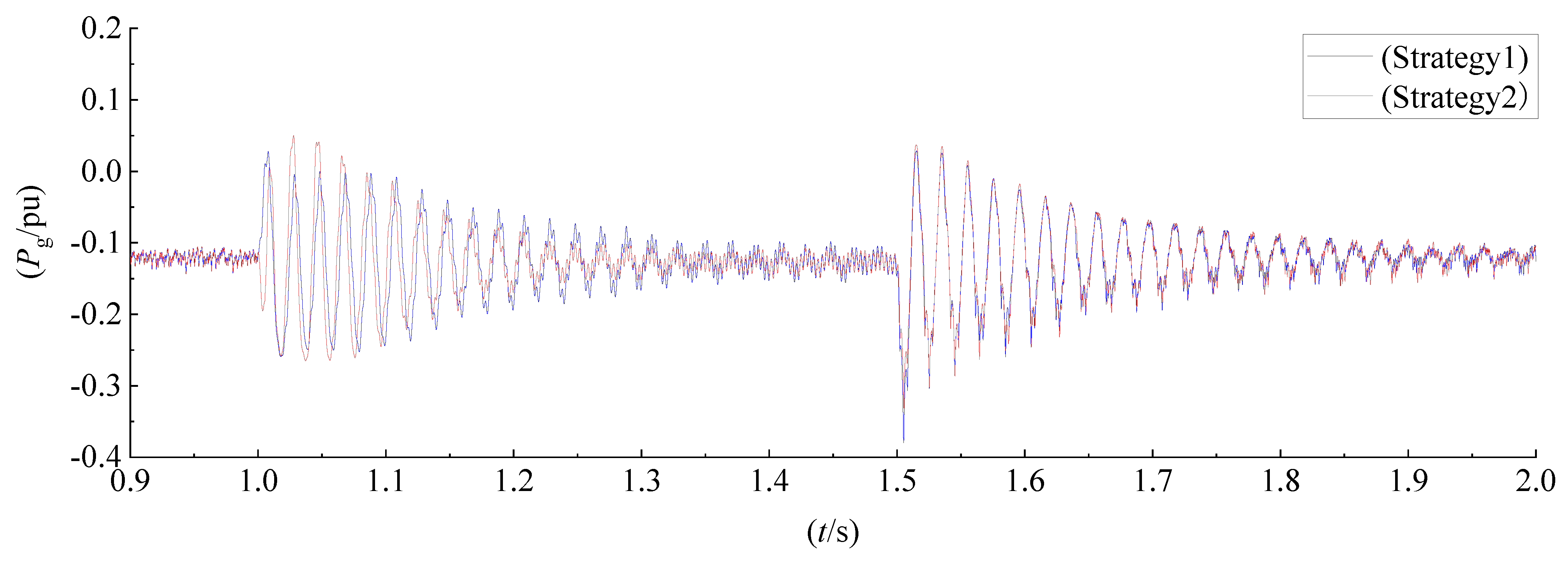

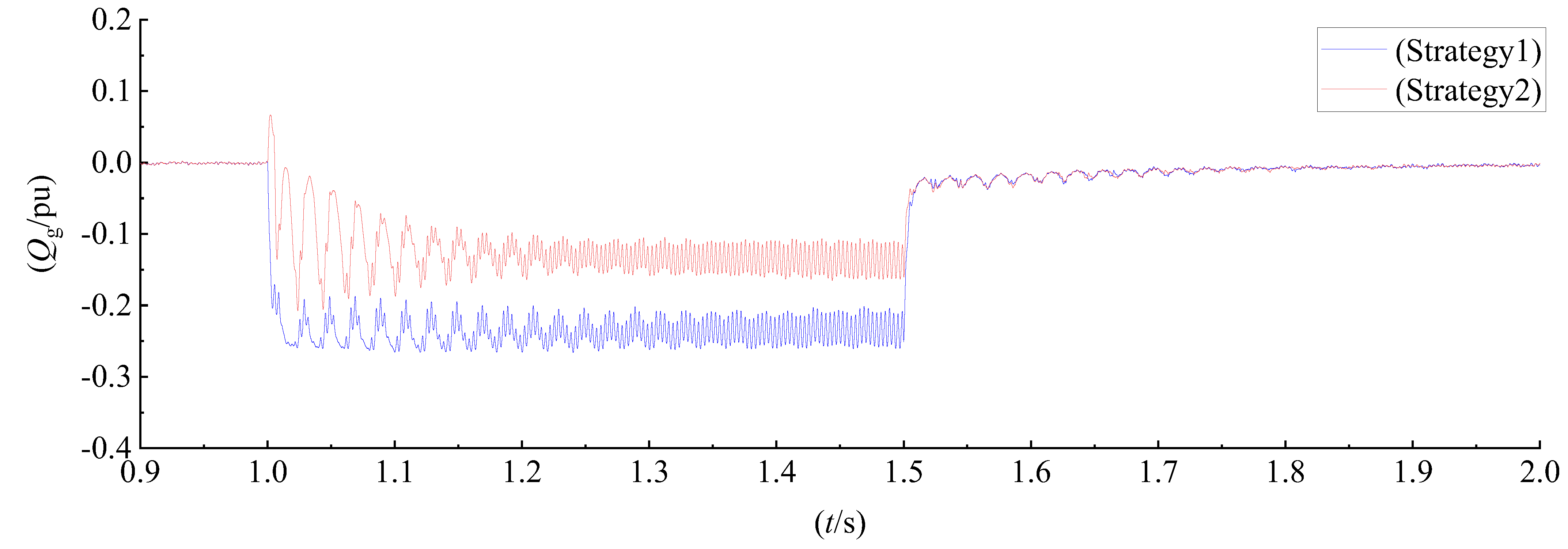

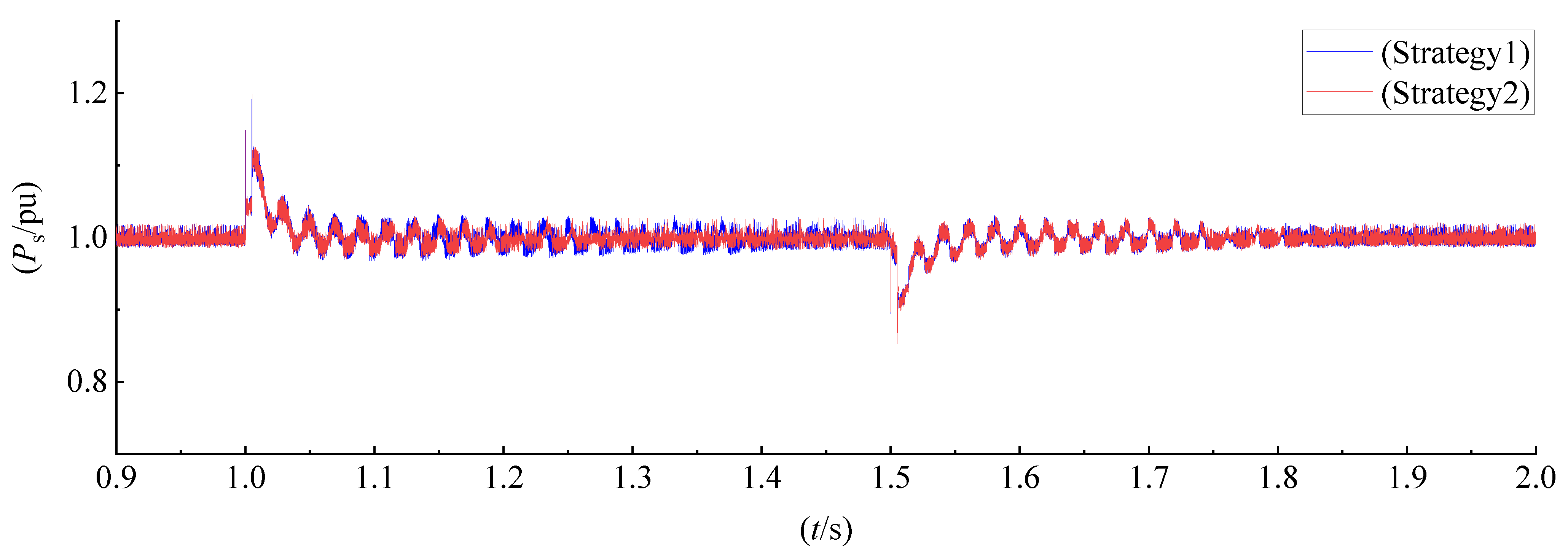

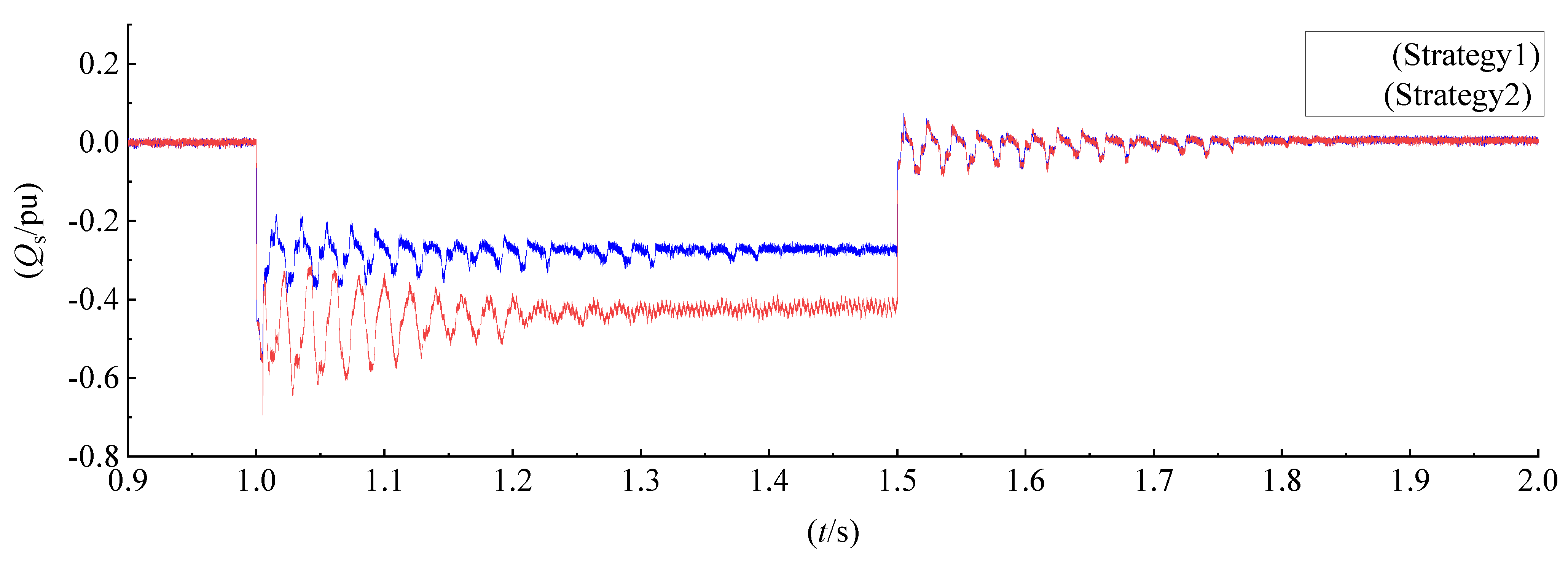

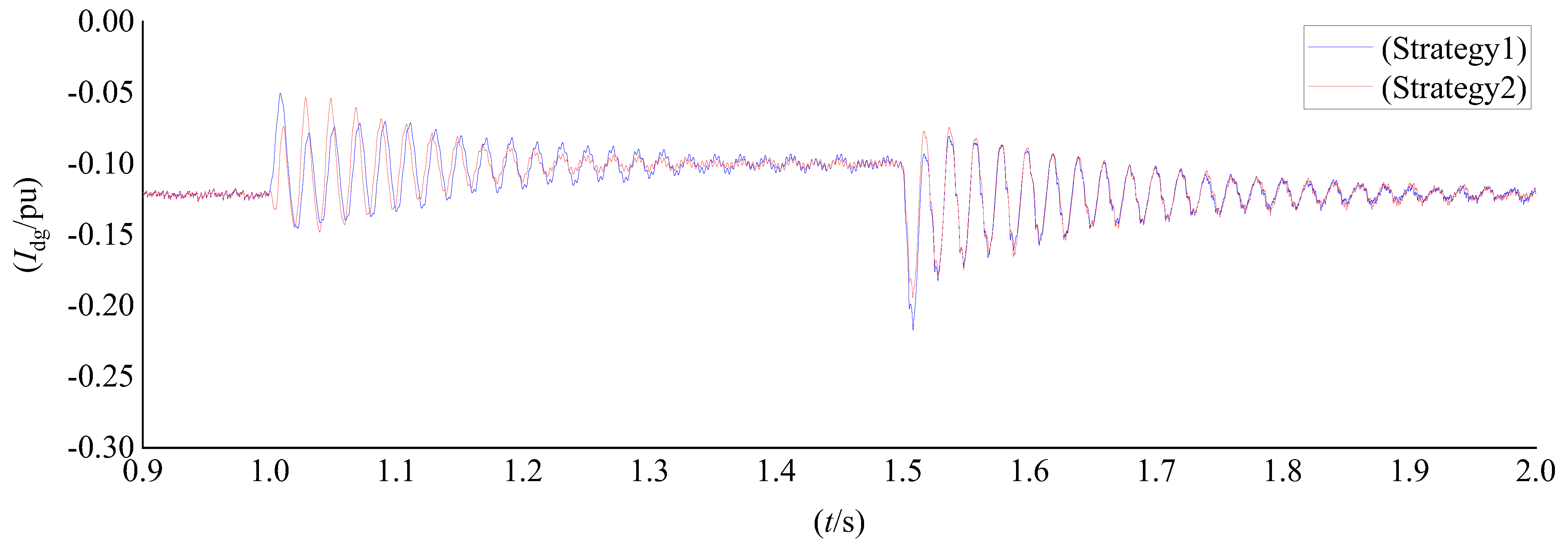

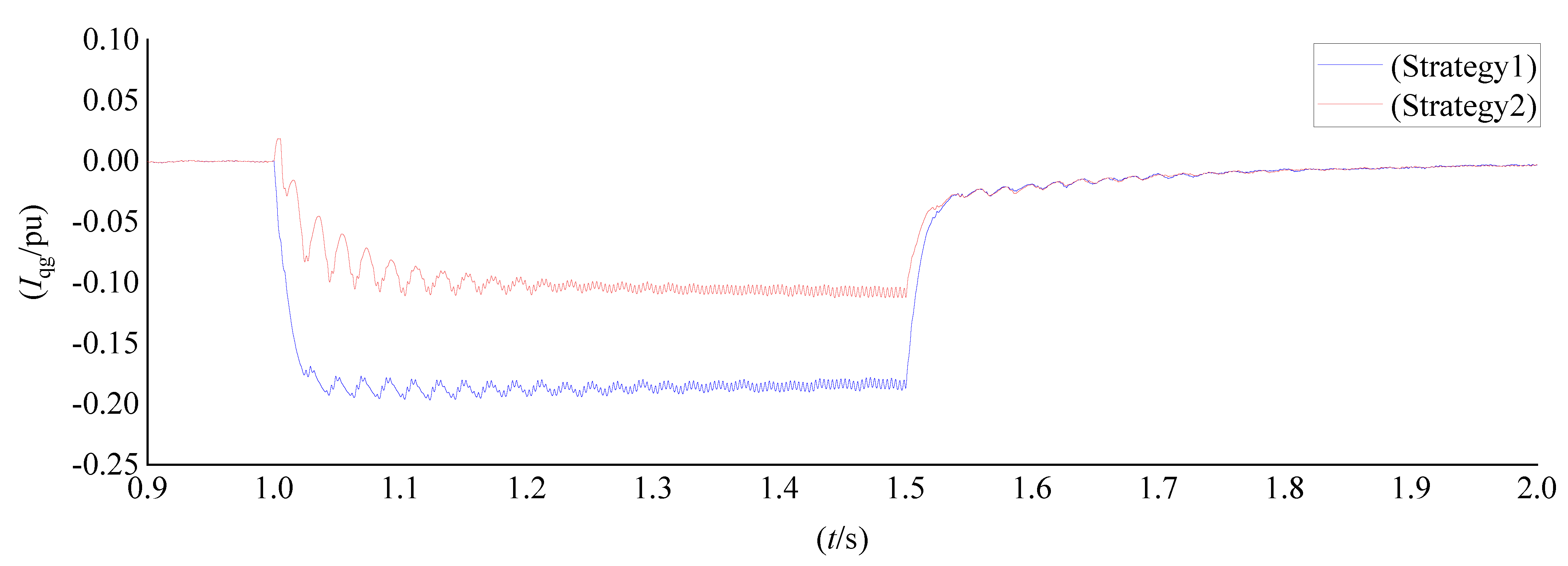

6.3. HVRT Control Methods Comparative Simulation

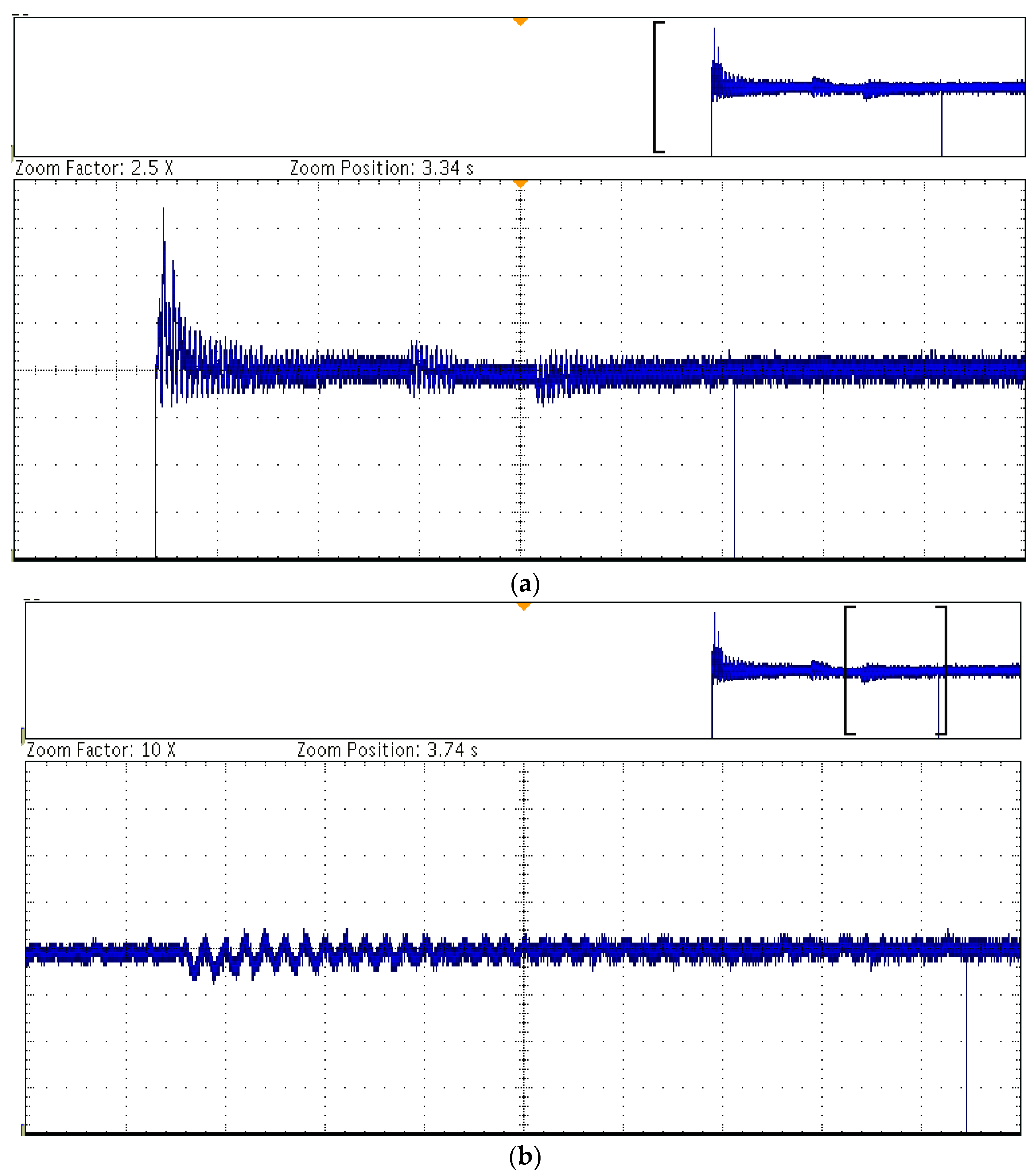

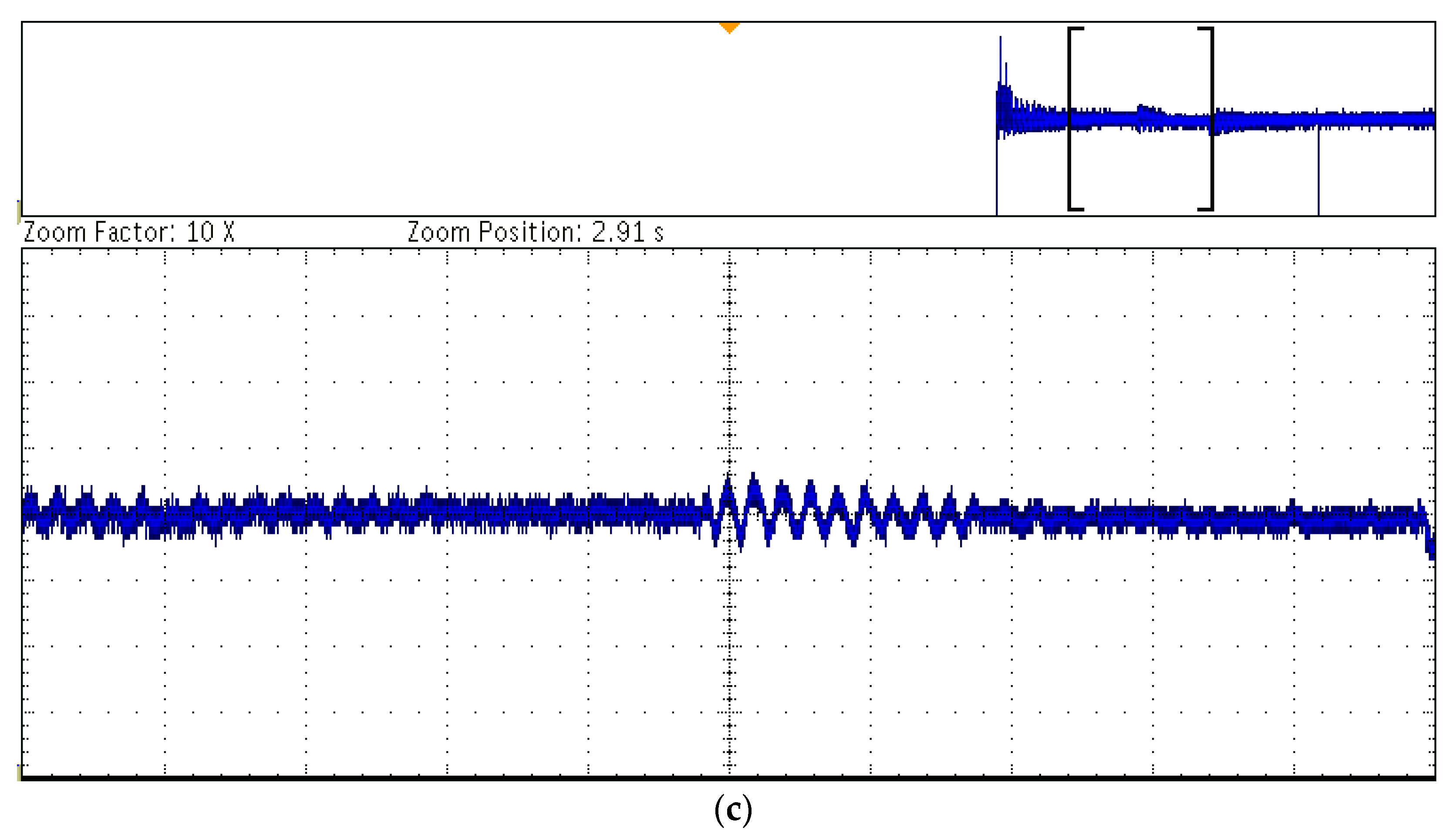

6.4. Performance Analysis of the Control Method Based on the RT−Lab Simulation Platform

7. Conclusions

- (1)

- In the DFIG HVRT process, the grid side and stator output reactive current limit is influenced by the initial value of active power and the degree of voltage lift, so a current limiting section is required when designing the reactive current reference. Additionally, the rate of change in the grid side current will have a large impact on the DC bus voltage.

- (2)

- This paper proposes a method for reducing the rate of change in active and reactive currents to limit overvoltage at the DC bus point and investigates a HVRT control strategy that takes into account the dynamic changes in grid side currents.

- (3)

- Analysis of busbar overvoltage lift limiting conditions, on the basis of which active and reactive current reference values are set, can effectively reduce DC busbar overvoltage. At the same time, the DFIG can be controlled to absorb inductive reactive power from the grid according to different degrees of voltage rise.

- (4)

- The key parameter k in the grid side current reference value has a certain influence on the DC bus voltage. By introducing the gray wolf search algorithm, a convenient and accurate global optimum search for the key parameters can be carried out.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A. Constants | |

| Pi,t,max, Pi,t,min | Max/Min output power of unit i at time t. |

| Lm | Stator-rotor mutual inductance |

| Ls | Stator inductors |

| Rga, Rgb, Rgc | Line resistance |

| Rg, Lg | GSC incoming impedance |

| B. Variables | |

| ui,t, up2g,p,t, vmt | Commitment Statuses of unit i, P2G facility p, demand response user m at time t. |

| Ps, Qs | Stator active and reactive power |

| Pg, Qg | GSC active and reactive power |

| Us | Stator voltage |

| ird, irq | dq-axis component of the RSC current |

| Sga, Sgb, Sgc | Switching functions of the bridge arms of each phase respectively, and are 1 when the upper bridge arm is on and 0 when the lower bridge arm is on. |

| uga, ugb, ugc | Three-phase grid voltage |

| vga, vgb, vgc | Three-phase voltage on the AC side of the converter |

| iga, igb, igc | Three-phase input current |

| iload | Load current |

| Lga, Lgb, Lgc | Inlet reactor inductance |

| vgd, vgq | dq-axis component of the GSC AC-side voltage |

| ugd | d-axis component of the grid voltage |

| igd, igq | dq-axis component of the GSC input current |

| iTC | Total reactive current to be output |

| IN | DFIG rated current |

| UT | Grid voltage. |

References

- Li, B.Y.; Chao, P.P. Review on transient overvoltage issues of wind power transmission system via UHVDC Enhanced Publishing. Electr. Power Autom. Equip. 2022, 42, 26–35. [Google Scholar]

- Wessels, C.; Fuchs, F.W. High voltage ride through with FACTS for DFIG based wind turbines. In Proceedings of the 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; Volume 6, pp. 1–10. [Google Scholar]

- Jadhav, H.T.; Roy, R. A comprehensive review on the grid integration of doubly fed induction generator. Int. J. Electr. Power Energy Syst. 2013, 49, 8–18. [Google Scholar] [CrossRef]

- Naderi, S.B.; Negnevitsky, M.; Muttaqi, K.M. A modified DC chopper for limiting the fault current and controlling the DC-link voltage to enhance fault ride-through capability of doubly-fed induction-generator-based wind turbine. IEEE Trans. Ind. Appl. 2019, 55, 2021–2032. [Google Scholar] [CrossRef]

- Li, G.Q.; Zheng, R.F. Improvement of High-Voltage-Ride-Through Capability of DFIG Based Wind Turbines with D-STATCOM. Appl. Mech. Mater. 2014, 448–453, 1773–1778. [Google Scholar]

- Zou, Z.C.; Yao, J. Efficient HVRT Scheme of DFIG Using a SSFCL-Chopper Considering Grid Voltage Recovery. IEEE Trans. Appl. Supercond. 2021, 31, 1–3. [Google Scholar] [CrossRef]

- Chen, W.; Xu, D.; Zhu, N.; Chen, M.; Blaabjerg, F. Control of doubly-fed Induction generator to ride-through recurring grid faults. IEEE Trans. Power Electron. 2016, 31, 4831–4846. [Google Scholar] [CrossRef]

- Li, S.M.; Jia, D.; Xiao, Y. Low-high voltage chain fault ride-through technology of DFIG with active crowbar. Power Syst. Prot. Control. 2018, 46, 79–86. [Google Scholar]

- Mohseni, M.; Islam, S.M. Transient control of DFIG based wind power plants in compliance with the Australian grid code. IEEE Trans. Power Electron. 2012, 27, 2813. [Google Scholar] [CrossRef]

- Abo-Khalil, A.G.; Alharbi, W.; Al-Qawasmi, A.R.; Alobaid, M.; Alarifi, I. Modeling and control of unbalanced and distorted grid voltage of grid-connected DFIG wind turbine. Int. Trans. Electr. Energy Syst. 2021, 31, e12857. [Google Scholar] [CrossRef]

- Hu, S.; Lin, X.; Kang, Y.; Zou, X. An improved low-voltage ride-through control strategy of doubly fed induction generator during grid faults. IEEE Trans. Power Electron. 2011, 26, 3653–3665. [Google Scholar] [CrossRef]

- Zhou, D.; Song, Y.; Blaabjerg, F. Modeling and stress analysis of doubly-fed induction generator during grid voltage swell. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 4175–4180. [Google Scholar]

- Sun, L.L.; Wang, Y.J.; Xu, B.Q. Transient analysis and control strategy improvement of high voltage ride through of DFIG. Electr. Mach. Control. 2019, 23, 27–34. [Google Scholar]

- Sun, L.; Wang, Y. Analysis and Performance Evaluation for Transient Whole Process of Improved Control Strategy for Doubly-fed Induction Generator Crossed by High Voltage Ride Through. High Volt. Eng. 2019, 45, 593–599. [Google Scholar]

- Li, S.L.; Wang, W.S. Control Strategy and Experiment of High Voltage Ride Through for DFIG-based Wind Turbines. Autom. Electr. Power Syst. 2016, 40, 76–82. [Google Scholar]

- Ling, Y. Transient Characteristics Analysis of DFIG-based Wind Turbine Under Symmetrical Voltage Fault. Proc. CSEE 2022, 42, 6871–6880. [Google Scholar]

- Wang, H.; Wang, Y.F. High and Low Voltage Ride Through Control Strategy for DFIG Wind Power System Based on Variable Dynamic Voltage Command Value. High Volt. Eng. 2022, 48, 3680–3688. [Google Scholar]

- Xu, H.; Zhang, W.; Chen, J.; Sun, D.; He, Y. A High-voltage Ride-through Control Strategy for DFIG Based Wind Turbines Considering Dynamic Reactive Power Support. Proc. CSEE 2013, 33, 112–119. [Google Scholar]

- Jiang, H.L.; Wang, S.H.; Li, X.; Xiao, R. Cascading Fault Ride-through Control Strategy for Doubly-fed Wind Turbines Considering Reactive Power Support in Dynamic Voltage Range. High Volt. Eng. 2022, 48, 147–155. [Google Scholar]

- Wang, Y.; Wu, Q.; Xu, H.; Guo, Q.; Sun, H. Fast coordinated control of DFIG wind turbine generators for low and high voltage ride-through. Energies 2014, 7, 4140–4156. [Google Scholar] [CrossRef]

- GB/T 19963.1-2021; Wind Farm Access to the Power System Technical Regulations. National Standardization Committee: Beijing, China, 2021.

- Zhang, Z.; Deng, Y.; Li, C.; Liu, M. Photovoltaic MPPT method based on improved grey wolf optimization algorithm. Electr. Meas. Instrum. 2022, 59, 100–105. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Liu, J.; Wei, X.; Huang, H. An improved grey wolf optimization algorithm and its application in path planning. IEEE Access 2021, 9, 121944–121956. [Google Scholar] [CrossRef]

| Us | 1.15 | 1.2 |

| k range | −0.3861, −0.1861 | −0.4678, −0.2678 |

| Us | 1.25 | 1.3 |

| k range | −0.5431, −0.3431 | −0.6185, −0.4185 |

| Parameter Name | Numerical Value |

|---|---|

| Power Rating | 3 MW |

| Rated voltage at machine end | 690 V |

| Nominal DC bus voltage | 1200 V |

| Rated frequency | 50 Hz |

| polar logarithm | 3 |

| Stator resistance | 0.013 pu |

| Stator leakage resistance | 0.239 pu |

| Rotor leakage resistance | 0.213 pu |

| Rotor resistance | 0.024 pu |

| Stator-rotor mutual inductance | 3.99 pu |

| k | −0.6185 | −0.6169 | −0.6035 | −0.5885 | −0.5735 |

| Udc_max | 1.0922 | 1.090 | 1.0949 | 1.0992 | 1.106 |

| k | −0.5585 | −0.5435 | −0.5285 | −0.5135 | −0.4985 |

| Udc_max | 1.1095 | 1.1136 | 1.1182 | 1.1233 | 1.1256 |

| k | −0.4835 | −0.4685 | −0.4535 | −0.4385 | −0.4185 |

| Udc_max | 1.1323 | 1.1364 | 1.141 | 1.1407 | 1.1428 |

| Us | 1.15 | 1.20 | 1.25 | 1.30 |

| k | −0.3861 | −0.4652 | −0.5407 | −0.6169 |

| Udc_max | 1.026 | 1.034 | 1.068 | 1.090 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.; Qi, Z.; Xia, N.; Gao, T.; Zhang, Y.; Duan, J. Control Strategy and Parameter Optimization Based on Grid Side Current Dynamic Change Rate for Doubly-Fed Wind Turbine High Voltage Ride Through. Energies 2022, 15, 7977. https://doi.org/10.3390/en15217977

Deng J, Qi Z, Xia N, Gao T, Zhang Y, Duan J. Control Strategy and Parameter Optimization Based on Grid Side Current Dynamic Change Rate for Doubly-Fed Wind Turbine High Voltage Ride Through. Energies. 2022; 15(21):7977. https://doi.org/10.3390/en15217977

Chicago/Turabian StyleDeng, Jun, Zhenghao Qi, Nan Xia, Tong Gao, Yang Zhang, and Jiandong Duan. 2022. "Control Strategy and Parameter Optimization Based on Grid Side Current Dynamic Change Rate for Doubly-Fed Wind Turbine High Voltage Ride Through" Energies 15, no. 21: 7977. https://doi.org/10.3390/en15217977

APA StyleDeng, J., Qi, Z., Xia, N., Gao, T., Zhang, Y., & Duan, J. (2022). Control Strategy and Parameter Optimization Based on Grid Side Current Dynamic Change Rate for Doubly-Fed Wind Turbine High Voltage Ride Through. Energies, 15(21), 7977. https://doi.org/10.3390/en15217977