Experimentally Validated Coulomb Counting Method for Battery State-of-Charge Estimation under Variable Current Profiles

Abstract

:1. Introduction

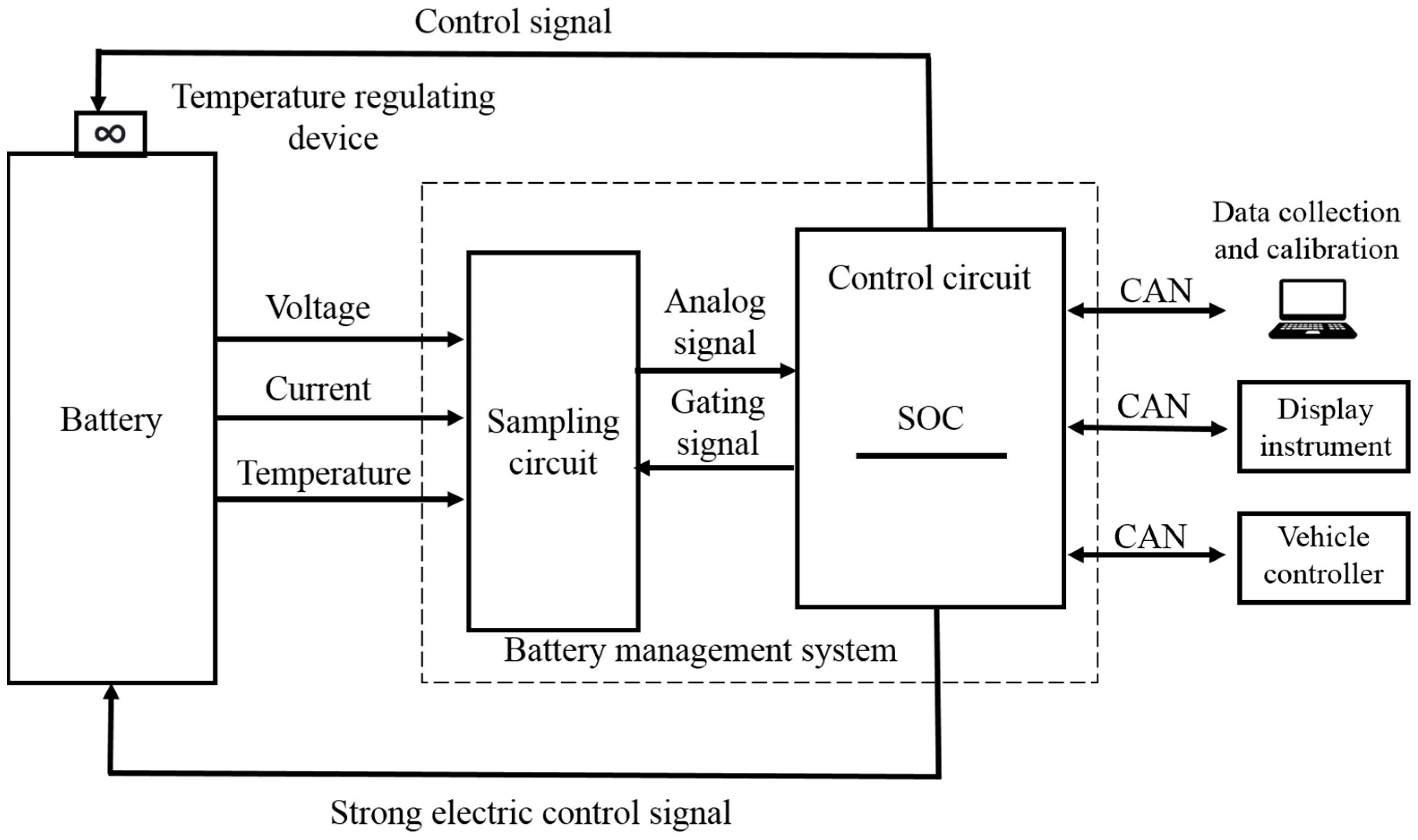

2. Battery Management System

3. Coulomb Counting Method

4. Generic Battery Model

- ✓

- The charge model (i* < 0)

- ✓

- The discharge model (i* > 0)

- ✓

- Limitations

- -

- The minimum no-load battery voltage is 0 V and the maximum battery voltage is equal to 2 × .

- -

- The minimum capacity of the battery is 0 Ah and the maximum capacity is .

- ✓

- Assumptions

- -

- The internal resistance is supposed as a constant value during the charge and the discharge cycles and does not vary with the amplitude of the current.

- -

- The parameters of the model are deduced from discharge characteristics and assumed to be the same for charging.

- -

- The capacity of the battery does not change with the amplitude of the current (no Peukert effect).

- -

- The model does not take the temperature into account.

- -

- The self-discharge of the battery is not represented. It can be represented by adding a large resistance in parallel with the battery terminals.

- -

- The battery has no memory effect.

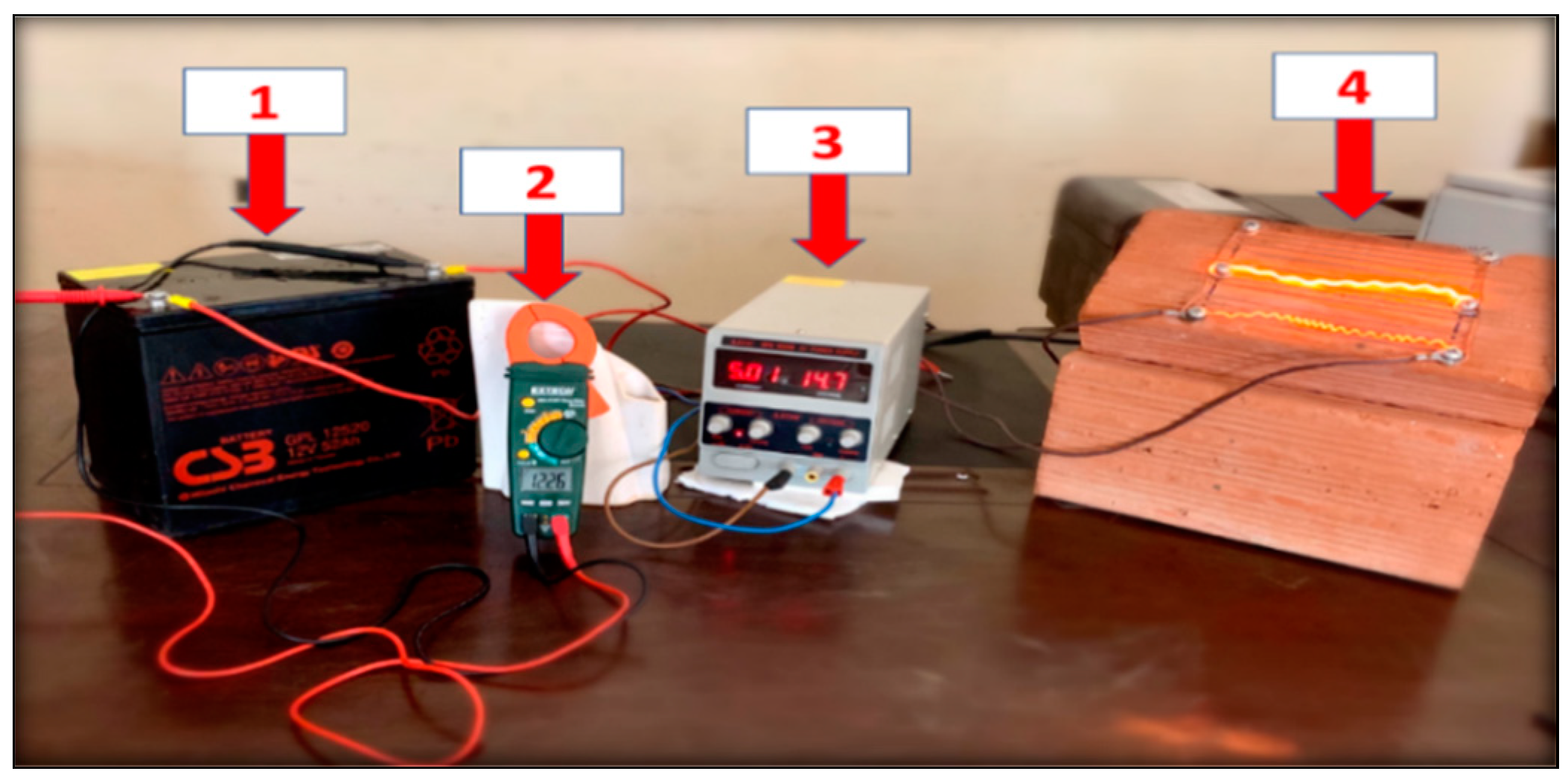

5. Experimental Method and Description

- Lead–acid battery

- Clamp meter

- DC power supply

- Variable resistor (handmade)

- -

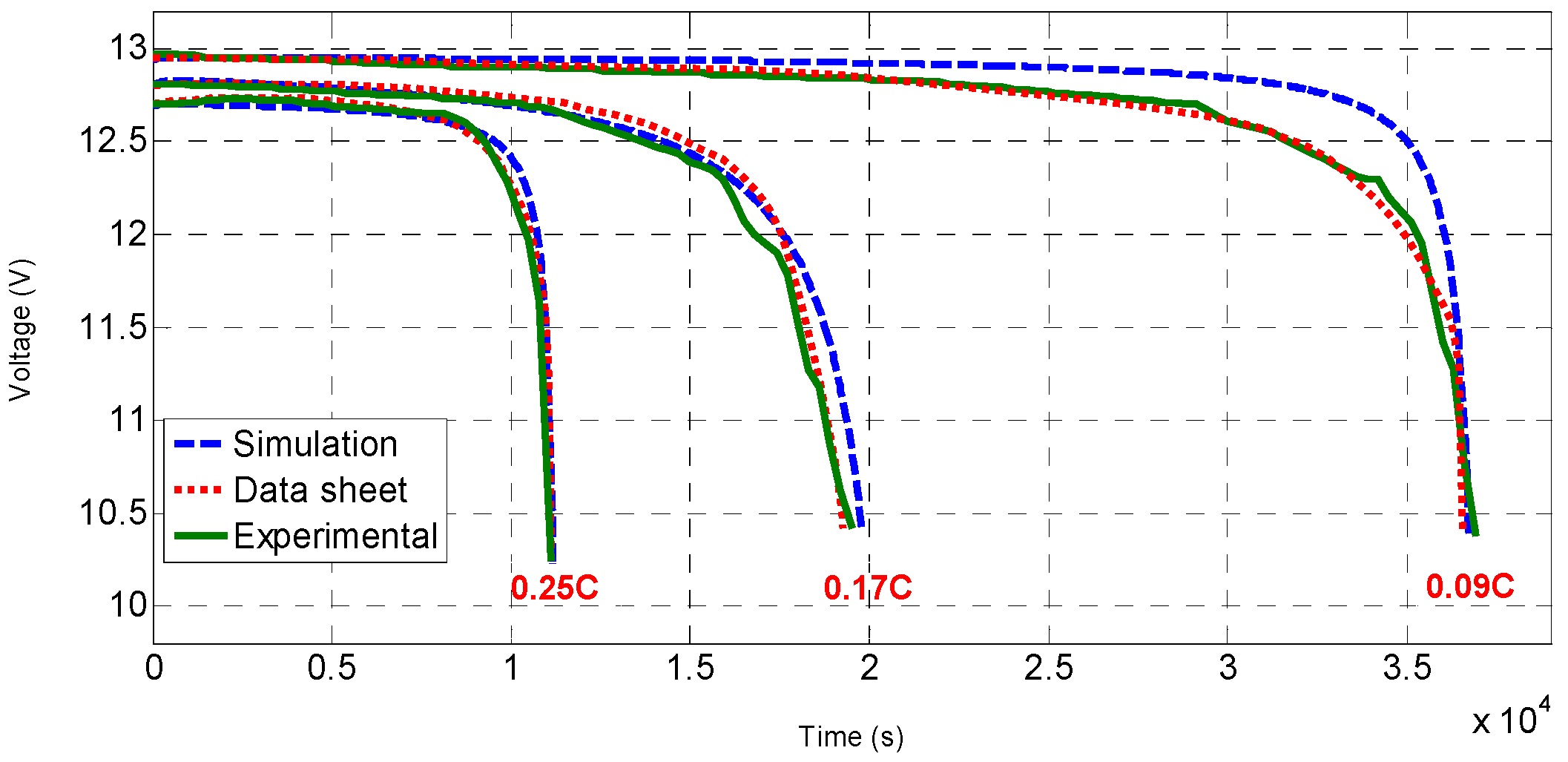

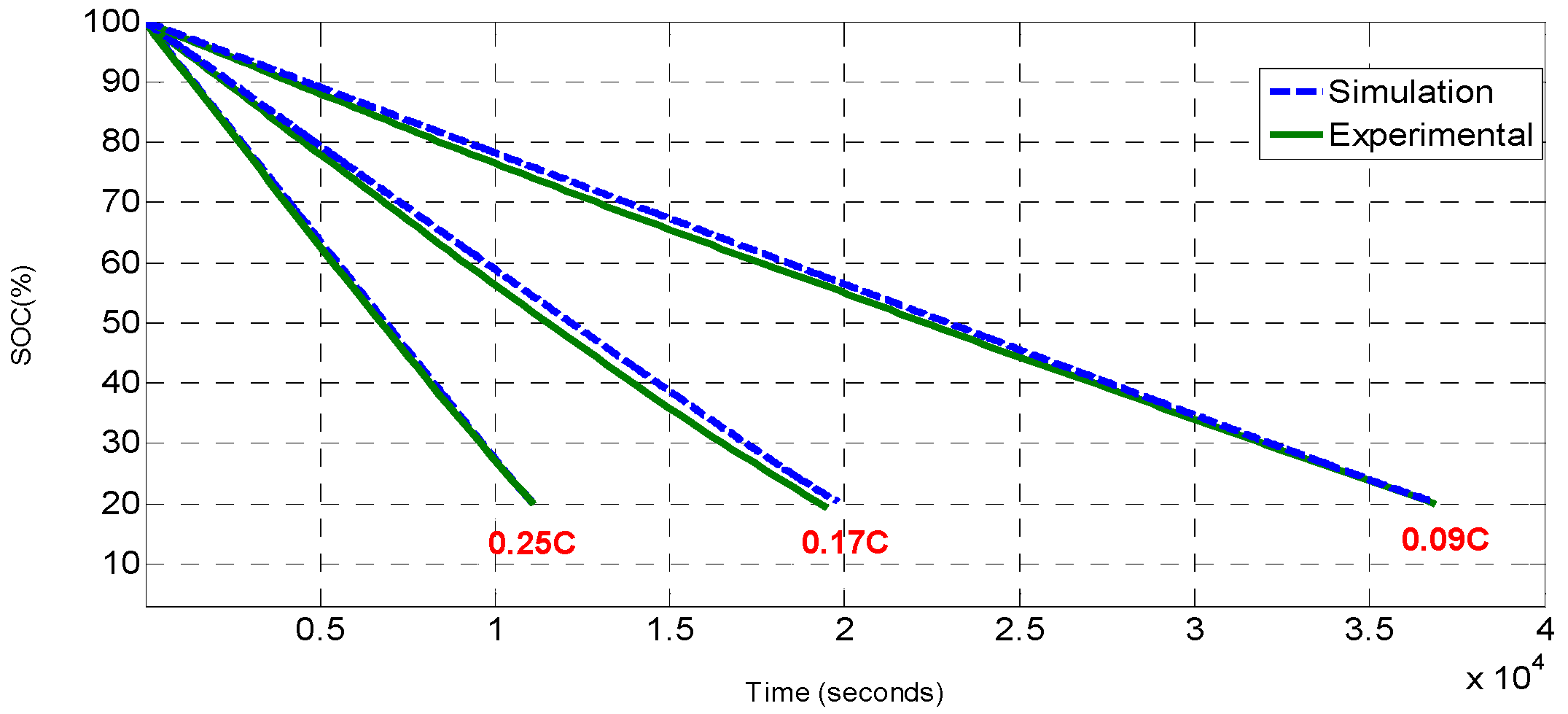

- Discharging with constant C-rates: a variable resistor is connected (for adjustment to variable C-rates, that is to reach discharge current at 0.25 C, 0.17 C, and 0.09 C respectively) with the battery. Consequently, the voltage and the discharge current are measured after every 5 min by using a clamp meter. After 3.05, 5.41, and 10.25 h, respectively (corresponding to the associated C-rate), it reaches the lower permissible limit of discharge voltage (cut-off voltage) 10.10, 10.37, and 10.39 V each. Afterwards, the discharge resistance is disconnected. The discharge resistance equaled Rdisch = [0.96–1] Ω, [1.42–1.50] Ω, and [2.69–3] Ω, with the ambient temperature T = 26.7°, 28.6°, and 26.1 °C.

- -

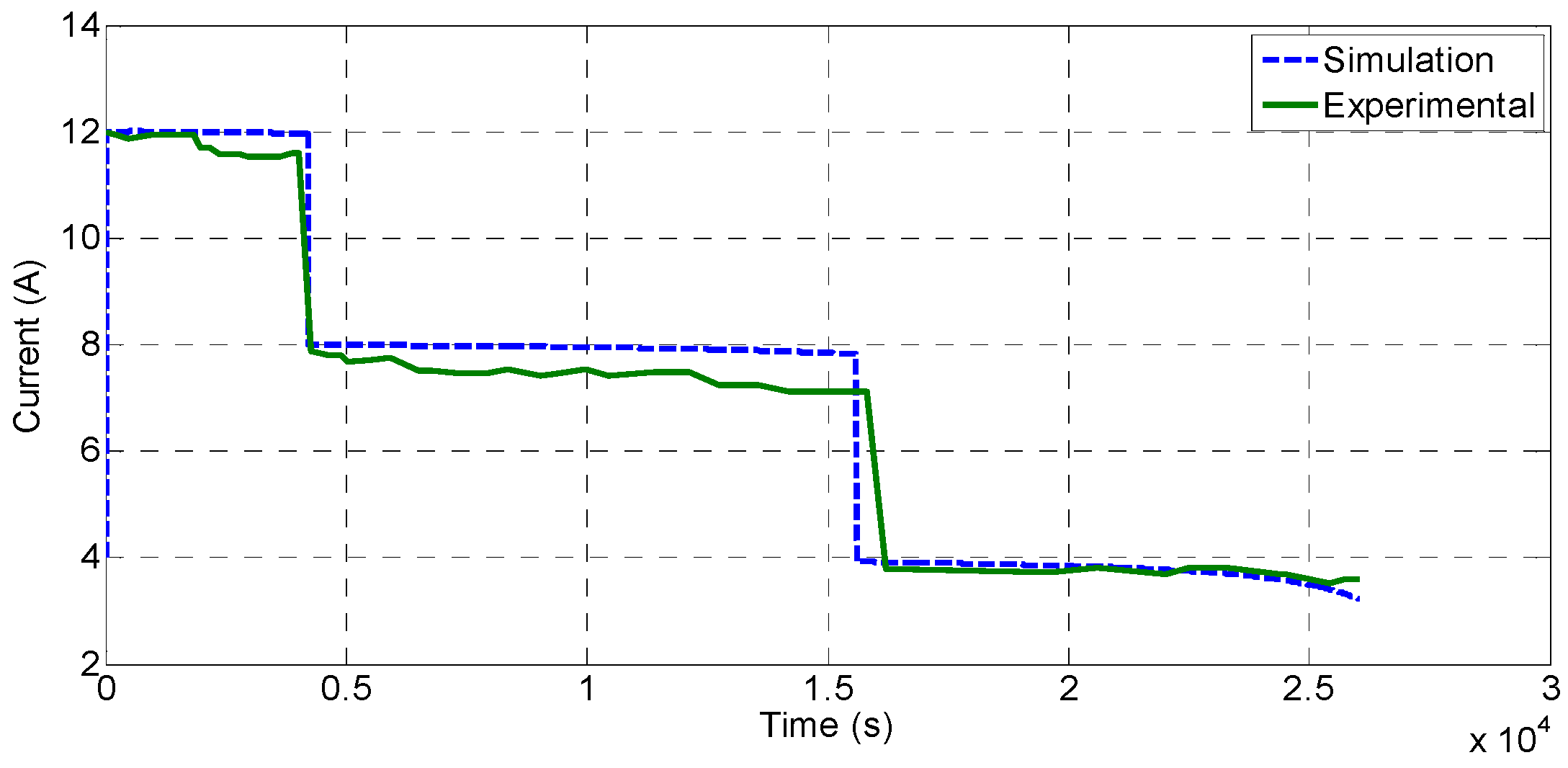

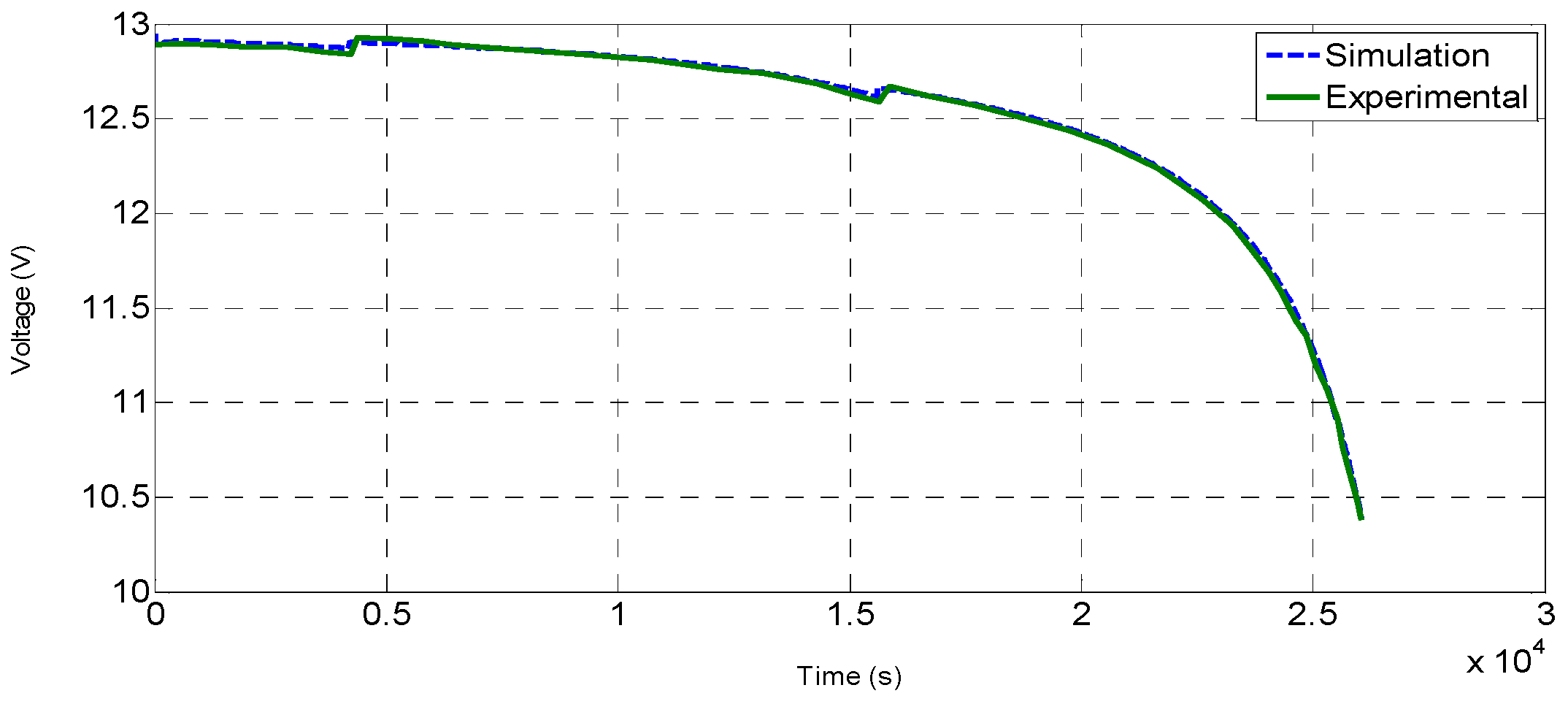

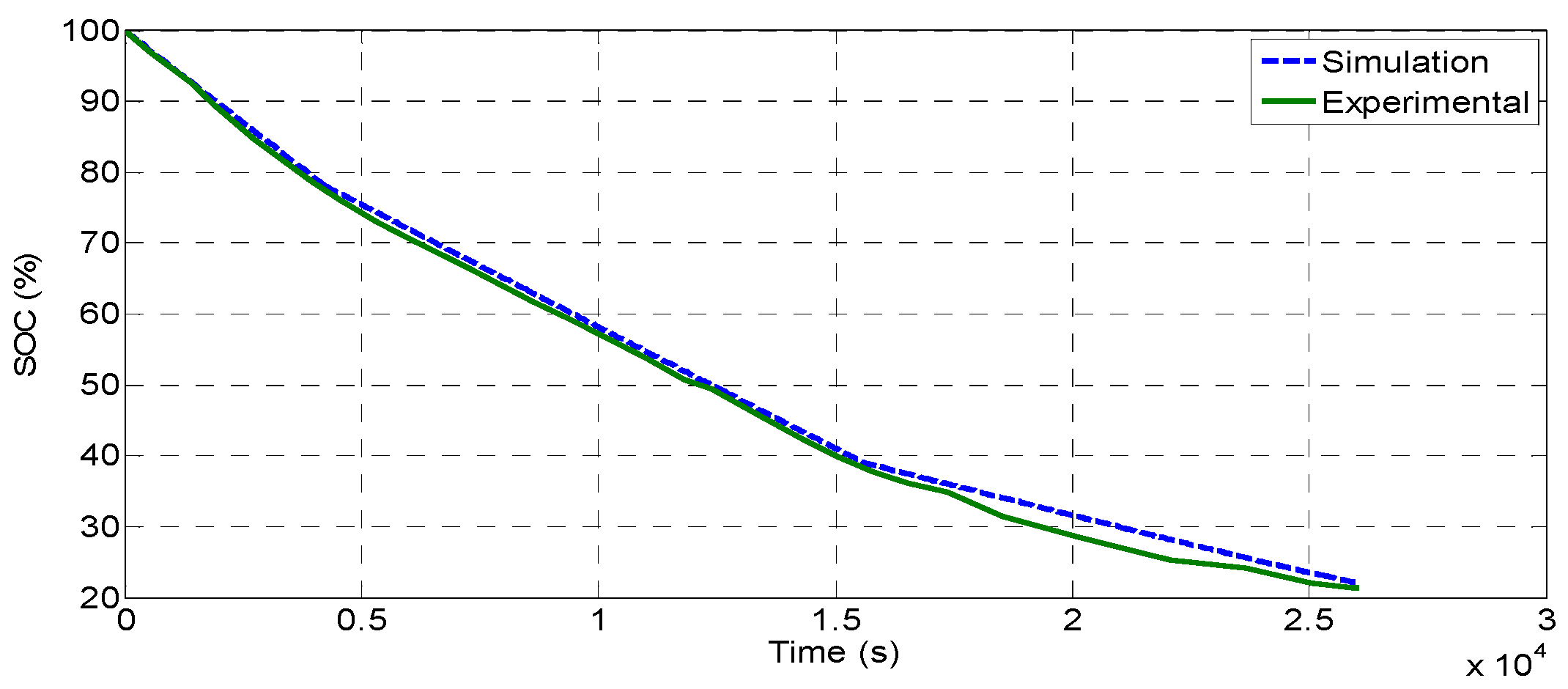

- Discharging with variable C-rates: the variable resistor is connected (for adjustment to variable C-rates discharge current 0.23 C, 0.115 C, and 0.057 C, respectively. These values of C-rates correspond to having three resistances connected in parallel. The value of each resistance is 3.225 Ω. During the first period, the discharge is performed at 0.23 C until 1.11 h. After that, the first resistance is disconnected, then the discharge continues at 0.115 C until 4.44 h. At this point, the second resistance is also disconnected. The discharge is pursued then with 0.057 C until 7.23 h, and at this moment, even the last resistance is disconnected, and the experiment is stopped. The battery voltage and discharging current are measured every 5 min with a clamp meter during the whole experimental session. After 7.23 h, the end of discharge is reached (cut-off voltage) which is equal to 10.39 V. At this point, the discharge resistance is completely disconnected. It is also worth mentioning that the ambient temperature equaled T = 27.1 °C (approx.) during the experimental session.

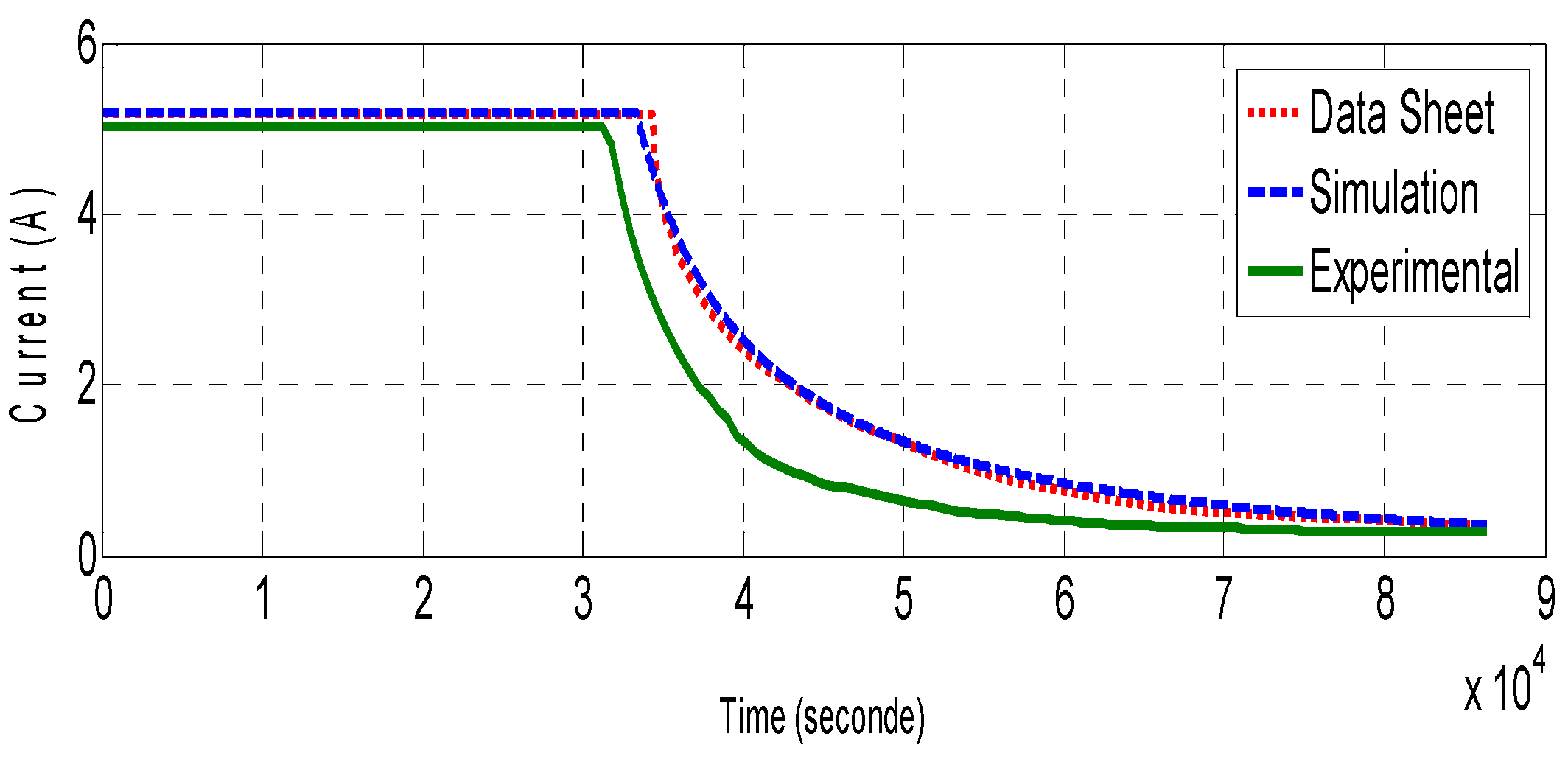

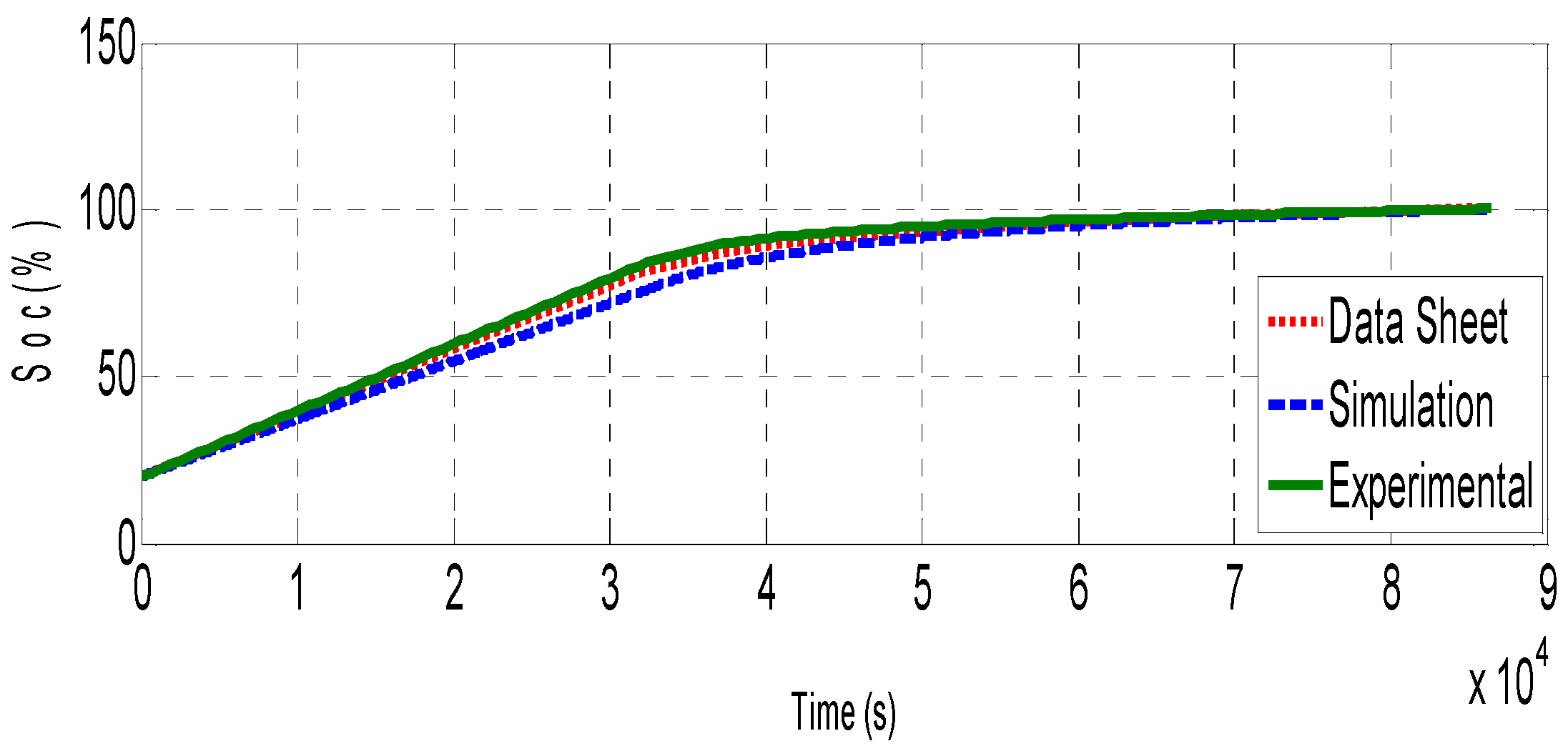

6. Results and Discussion

7. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SOC | State of charge |

| Ah | Ampere hour |

| OCV | Open circuit voltage |

| AC | Alternative current |

| SOH | State of health |

| CC | Constant current |

| CV | Constant voltage |

| CN | Nominal capacity of the battery |

| Coulomb efficiency | |

| I(τ) | The current versus time (negative during charge and positive during discharge) |

| Vbatt | The battery voltage (V) |

| E0 | The constant battery voltage (V) |

| K | The polarization constant (V/(Ah)) or polarization resistance (Ω) |

| Q | The battery capacity (Ah) |

| =∫Idt: actual battery charge (Ah) | |

| A | The exponential voltage (V) |

| B | The exponential capacity (Ah) − 1 |

| R | The internal resistance (Ω) |

| I | The battery current (A) |

| i* | The filtered current (A) |

| Idis | The value of the current of discharge |

| SOC0 | Initial state of charge |

| SOCmin | Minimum state of charge |

| SOCexp | Experimental state of charge |

| SOCth | Theoretical state of charge |

| Vchint | Initial charge voltage |

| Vchend | End charge voltage |

| Tchsum | Simulation charge time |

| Vdisint | Initial discharge voltage |

| Vdisend | End discharge voltage |

| Tdissum | Simulation discharge time |

| VRLA | Valve regulated lead–acid battery |

| BMS | Battery management system |

| VCU | Vehicle control unit |

| SOP | State of power |

| RUL | Remaining useful life |

| DOD | Depth of discharge |

References

- Yang, R.; Xiong, R.; He, H.; Chen, Z. A fractional-order model-based battery external short circuit fault diagnosis approach for all-climate electric vehicles application. J. Clean. Prod. 2018, 187, 950–959. [Google Scholar] [CrossRef]

- Rodrigues, S.; Munichandraiah, N.; Shukla, A. A review of state-of-charge indication of batteries by means of a.c. impedance measurements. J. Power Sources 2000, 87, 12–20. [Google Scholar] [CrossRef]

- Huet, F. A review of impedance measurements for determination of the state-of-charge or state-of-health of secondary batteries. J. Power Sources 1998, 70, 59–69. [Google Scholar] [CrossRef]

- Weng, C.; Sun, J.; Peng, H. A unified open-circuit-voltage model of lithium-ion batteries for state-of-charge estimation and state-of-health monitoring. J. Power Sources 2014, 258, 228–237. [Google Scholar] [CrossRef]

- Dubarry, M.; Svoboda, V.; Hwu, R.; Liaw, B.Y. Capacity loss in rechargeable lithium cells during cycle life testing: The importance of determining state-of-charge. J. Power Sources 2007, 174, 1121–1125. [Google Scholar] [CrossRef]

- Schmidt, J.P.; Chrobak, T.; Ender, M.; Illig, J.; Klotz, D.; Ivers-Tiffée, E. Studies on LiFePO4 as cathode material using impedance spectroscopy. J. Power Sources 2011, 196, 5349–5355. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Guo, H. Online estimation of model parameters and state-of-charge of LiFePO4 batteries in electric vehicles. Appl. Energy 2012, 89, 413–420. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, W.; Lin, S.; Feng, Z. A novel model of the initial state of charge estimation for LiFePO4 batteries. J. Power Sources 2014, 248, 1028–1033. [Google Scholar] [CrossRef]

- Wang, J.; Cao, B.; Chen, Q.; Wang, F. Combined state of charge estimator for electric vehicle battery pack. Control Eng. Pract. 2007, 15, 1569–1576. [Google Scholar] [CrossRef]

- Becherif, M.; Pera, M.; Hissel, D.; Jemei, S. Estimation of the lead-acid battery initial state of charge with experimental validation. In Proceedings of the 2012 IEEE Vehicle Power and Propulsion Conference, Seoul, Korea, 9–12 October 2012; pp. 469–473. [Google Scholar]

- Ng, K.S.; Moo, C.-S.; Chen, Y.-P.; Hsieh, Y.-C. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Appl. Energy 2009, 86, 1506–1511. [Google Scholar] [CrossRef]

- Chan, C.; Lo, E.; Weixiang, S. The available capacity computation model based on artificial neural network for lead–acid batteries in electric vehicles. J. Power Sources 2000, 87, 201–204. [Google Scholar] [CrossRef]

- Gu, W.B.; Wang, C.Y. Thermal-Electrochemical Modeling of Battery Systems. J. Electrochem. Soc. 2000, 147, 2910–2922. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Shen, W. Lithium-Ion Battery Pack State of Charge and State of Energy Estimation Algorithms Using a Hardware-in-the-Loop Validation. IEEE Trans. Power Electron. 2016, 32, 4421–4431. [Google Scholar] [CrossRef]

- Xiong, R.; He, H.; Sun, F.; Zhao, K. Evaluation on State of Charge Estimation of Batteries With Adaptive Extended Kalman Filter by Experiment Approach. IEEE Trans. Veh. Technol. 2012, 62, 108–117. [Google Scholar] [CrossRef]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs Part 2. Modeling and identification. J. Power Sources 2004, 134, 262–276. [Google Scholar] [CrossRef]

- Cuadras, A.; Kanoun, O. Soc li-ion battery monitoring with impedance spectroscopy. In Proceedings of the 2009 6th International Multi-Conference on Systems, Signals and Devices, SSD, Djerba, Taiwan, 23–26 March 2009. [Google Scholar]

- Chau, K.; Wu, K.; Chan, C. A new battery capacity indicator for lithium-ion battery powered electric vehicles using adaptive neuro-fuzzy inference system. Energy Convers. Manag. 2004, 45, 1681–1692. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Wang, T. The online monitoring system software design and the SOC estimation algorithm research for power battery. In Proceedings of the 2013 IEEE International Conference on Vehicular Electronics and Safety, ICVES 2013, Dongguan, China, 28–30 July 2013; pp. 89–92. [Google Scholar]

- Lv, J.; Yuan, H.; Lv, Y. Battery state-of-charge estimation based on fuzzy neural network and improved particle swarm optimization algorithm. In Proceedings of the 2012 2nd International Conference on Instrumentation and Measurement, Computer, Communication and Control, Washington, DC, USA, 8–10 December 2012; pp. 22–27. [Google Scholar]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Ahmed, R.; Emadi, A.; Kollmeyer, P. Long Short-Term Memory Networks for Accurate State-of-Charge Estimation of Li-ion Batteries. IEEE Trans. Ind. Electron. 2018, 65, 6730–6739. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Chen, C.; Pecht, M. State of charge estimation for Li-ion batteries using neural network modeling and unscented Kalman filter-based error cancellation. Int. J. Electr. Power Energy Syst. 2014, 62, 783–791. [Google Scholar] [CrossRef]

- Kang, L.; Zhao, X.; Ma, J. A new neural network model for the state-of-charge estimation in the battery degradation process. Appl. Energy 2014, 121, 20–27. [Google Scholar] [CrossRef]

- Junping, W.; Quanshi, C.; Binggang, C. Support vector machine based battery model for electric vehicles. Energy Convers. Manag. 2006, 47, 858–864. [Google Scholar] [CrossRef]

- Li, I.-H.; Wang, W.-Y.; Su, S.-F.; Lee, Y.-S. A Merged Fuzzy Neural Network and Its Applications in Battery State-of-Charge Estimation. IEEE Trans. Energy Convers. 2007, 22, 697–708. [Google Scholar] [CrossRef]

- Xiong, R.; Shen, W. Advanced Battery Management Technologies for Electric Vehicles; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 1–297. [Google Scholar]

- Yang, K.; Chen, Z.; He, Z.; Wang, Y.; Zhou, Z. Online estimation of state of health for the airborne Li-ion battery using adaptive DEKF-based fuzzy inference system. Soft Comput. 2020, 24, 18661–18670. [Google Scholar] [CrossRef]

- Lami, M.; Shamayleh, A.; Mukhopadhyay, S. Minimizing the state of health degradation of Li-ion batteries onboard low earth orbit satellites. Soft Comput. 2019, 24, 4131–4147. [Google Scholar] [CrossRef]

- Modi, S.; Bhattacharya, J.; Basak, P. Convolutional neural network–bagged decision tree: A hybrid approach to reduce electric vehicle’s driver’s range anxiety by estimating energy consumption in real-time. Soft Comput. 2020, 25, 2399–2416. [Google Scholar] [CrossRef]

- Iqbal, M.; Becherif, M.; Ramadan, H.S.; Badji, A. Dual-layer approach for systematic sizing and online energy management of fuel cell hybrid vehicles. Appl. Energy 2021, 300, 117345. [Google Scholar] [CrossRef]

- Kularatna, N. Dynamics, Models, and Management of Rechargeable Batteries; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Iqbal, M.; Laurent, J.; Benmouna, A.; Becherif, M.; Ramadan, H.S.; Claude, F. Ageing-aware load following control for composite-cost optimal energy management of fuel cell hybrid electric vehicle. Energy 2022, 254, 124233. [Google Scholar] [CrossRef]

- Salazar, D.; Garcia, M. Estimation and Comparison of SOC in Batteries Used in Electromobility Using the Thevenin Model and Coulomb Ampere Counting. Energies 2022, 15, 7204. [Google Scholar] [CrossRef]

- González, I.; Ramiro, A.; Calderón, M.; Calderón, A.; González, J. Estimation of the state-of-charge of gel lead-acid batteries and application to the control of a stand-alone wind-solar test-bed with hydrogen support. Int. J. Hydrogen Energy 2012, 37, 11090–11103. [Google Scholar] [CrossRef]

- Lin, C.; Mu, H.; Xiong, R.; Shen, W. A novel multi-model probability battery state of charge estimation approach for electric vehicles using H-infinity algorithm. Appl. Energy 2016, 166, 76–83. [Google Scholar] [CrossRef]

- Wu, G.; Lu, R.; Zhu, C.; Chan, C. An improved Ampere-hour method for battery state of charge estimation based on temperature, coulomb efficiency model and capacity loss model. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–4. [Google Scholar]

- Xiong, R.; Sun, F.; Chen, Z.; He, H. A data-driven multi-scale extended Kalman filtering based parameter and state estimation approach of lithium-ion polymer battery in electric vehicles. Appl. Energy 2014, 113, 463–476. [Google Scholar] [CrossRef]

- Telmoudi, A.J.; Soltani, M.; Ben Belgacem, Y.; Chaari, A. Modeling and state of health estimation of nickel–metal hydride battery using an EPSO-based fuzzy c-regression model. Soft Comput. 2019, 24, 7265–7279. [Google Scholar] [CrossRef]

- Sun, F.; Xiong, R.; He, H. Estimation of state-of-charge and state-of-power capability of lithium-ion battery considering varying health conditions. J. Power Sources 2014, 259, 166–176. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Xiong, R.; He, H.W.; Pecht, M. Validation and verification of a hybrid method for remaining useful life prediction of lithium-ion batteries. J. Clean. Prod. 2019, 212, 240–249. [Google Scholar] [CrossRef]

- Mohammed, N.; Saif, A.M. Programmable logic controller based lithium-ion battery management system for accurate state of charge estimation. Comput. Electr. Eng. 2021, 93, 107306. [Google Scholar] [CrossRef]

- Feng, F.; Lu, R.; Zhu, C. A Combined State of Charge Estimation Method for Lithium-Ion Batteries Used in a Wide Ambient Temperature Range. Energies 2014, 7, 3004–3032. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Guo, X.; Dou, X.; Zhang, X. A data-driven coulomb counting method for state of charge calibration and estimation of lithium-ion battery. Sustain. Energy Technol. Assessments 2020, 40, 100752. [Google Scholar] [CrossRef]

- Gismero, A.; Schaltz, E.; Stroe, D.-I. Recursive State of Charge and State of Health Estimation Method for Lithium-Ion Batteries Based on Coulomb Counting and Open Circuit Voltage. Energies 2020, 13, 1811. [Google Scholar] [CrossRef] [Green Version]

- Hinz, H. Comparison of Lithium-Ion Battery Models for Simulating Storage Systems in Distributed Power Generation. Inventions 2019, 4, 41. [Google Scholar] [CrossRef] [Green Version]

- Tremblay, O.; Dessaint, L.-A.; Dekkiche, A.-I. A Generic Battery Model for the Dynamic Simulation of Hybrid Electric Vehicles. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 284–289. [Google Scholar]

- Zine, B.; Marouani, K.; Becherif, M.; Yahmedi, S. Estimation of Battery Soc for Hybrid Electric Vehicle using Coulomb Counting Method. Int. J. Emerg. Electr. Power Syst. 2018, 19. [Google Scholar] [CrossRef]

- Baroody, R. UNLV Theses, Dissertations, Professional Papers, and Capstones; UNLV: Las Vegas, NV, USA, 2009. [Google Scholar]

- Ren, G.; Wang, H.; Chen, C.; Wang, J. An energy conservation and environmental improvement solution-ultra-capacitor/battery hybrid power source for vehicular applications. Sustain. Energy Technol. Assess. 2021, 44, 100998. [Google Scholar] [CrossRef]

- Coleman, M.; Lee, C.K.; Zhu, C.; Hurley, W.G. State-of-charge determination from EMF voltage estimation: Using impedance, terminal voltage, and current for lead-acid and lithium-ion batteries. IEEE Trans. Ind. Electron. 2007, 54, 2550–2557. [Google Scholar] [CrossRef]

| Methodology | Benefits | Drawbacks | Precision | Sturdiness |

|---|---|---|---|---|

| Method based on characteristic param |

|

| poor | good |

| Ampere-hour integral approach |

|

| average | poor |

| Model-driven estimation approach |

|

| excellent | excellent |

| Method of data-driven estimation |

|

| excellent | poor |

| C-Rates of Discharge | 0.25 C | 0.17 C | 0.09 C | Different C-Rates |

|---|---|---|---|---|

| Nominal voltage (V) | 12 | 12 | 12 | 12 |

| Rated capacity (Ah) | 52 | 52 | 52 | 52 |

| Initial state-of-charge (%) | 100 | 100 | 100 | 100 |

| Max. capacity (Ah) | 40.1999 | 53.8 | 47.5 | 47.5 |

| Fully charged voltage (V) | 12.7 | 12.8 | 12.9 | 12.9 |

| Nominal discharge current (A) | 13 | 8.84 | 4.68 | 12 |

| Internal resistance (Ω) | 0.0055 | 0.0055 | 0.0055 | 0.0055 |

| Capacity (Ah) @ nominal voltage | 38.2 | 44.80 | 46 | 46 |

| Exp. zone [Voltage(V), capacity(Ah)] | [12.7, 2.5] | [12.8, 1.9] | [12.9, 2.225] | [12.9, 2.225] |

| Cells per unit | 6 |

| Voltage per unit | 12 V |

| Capacity | 52 Ah @ 20 h-rate to 1.75 V per cell @25 °C (77 °F) |

| Weight | Approx. 18 Kg (39.68 lbs.) |

| Maximum discharge current | 500 A (5 s) |

| Internal resistance | Approx. 5.5 mΩ |

| Operating temperature range | Discharge: −15 °C~50 °C (5 °F~122 °F) Charge: −15 °C~40 °C (5 °F~104 °F) Storage: −15 °C~40 °C (5 °F~104 °F) |

| Float charging voltage | 13.5 to 13.8 VDC/unit Average at 25 °C (77 °F) |

| Maximum charging current limit | 15.6 A |

| Equalization and cycle service | 14.4 to 15.0 VDC/unit Average at 25 °C (77 °F) |

| Self discharge | Batteries can be stored for 6 months at 25 °C (77 °F). |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zine, B.; Bia, H.; Benmouna, A.; Becherif, M.; Iqbal, M. Experimentally Validated Coulomb Counting Method for Battery State-of-Charge Estimation under Variable Current Profiles. Energies 2022, 15, 8172. https://doi.org/10.3390/en15218172

Zine B, Bia H, Benmouna A, Becherif M, Iqbal M. Experimentally Validated Coulomb Counting Method for Battery State-of-Charge Estimation under Variable Current Profiles. Energies. 2022; 15(21):8172. https://doi.org/10.3390/en15218172

Chicago/Turabian StyleZine, Bachir, Haithem Bia, Amel Benmouna, Mohamed Becherif, and Mehroze Iqbal. 2022. "Experimentally Validated Coulomb Counting Method for Battery State-of-Charge Estimation under Variable Current Profiles" Energies 15, no. 21: 8172. https://doi.org/10.3390/en15218172

APA StyleZine, B., Bia, H., Benmouna, A., Becherif, M., & Iqbal, M. (2022). Experimentally Validated Coulomb Counting Method for Battery State-of-Charge Estimation under Variable Current Profiles. Energies, 15(21), 8172. https://doi.org/10.3390/en15218172