An Experimental and Numerical Study of the Burning of Calliandra Wood Pellets in a 200 kW Furnace

Abstract

:1. Introduction

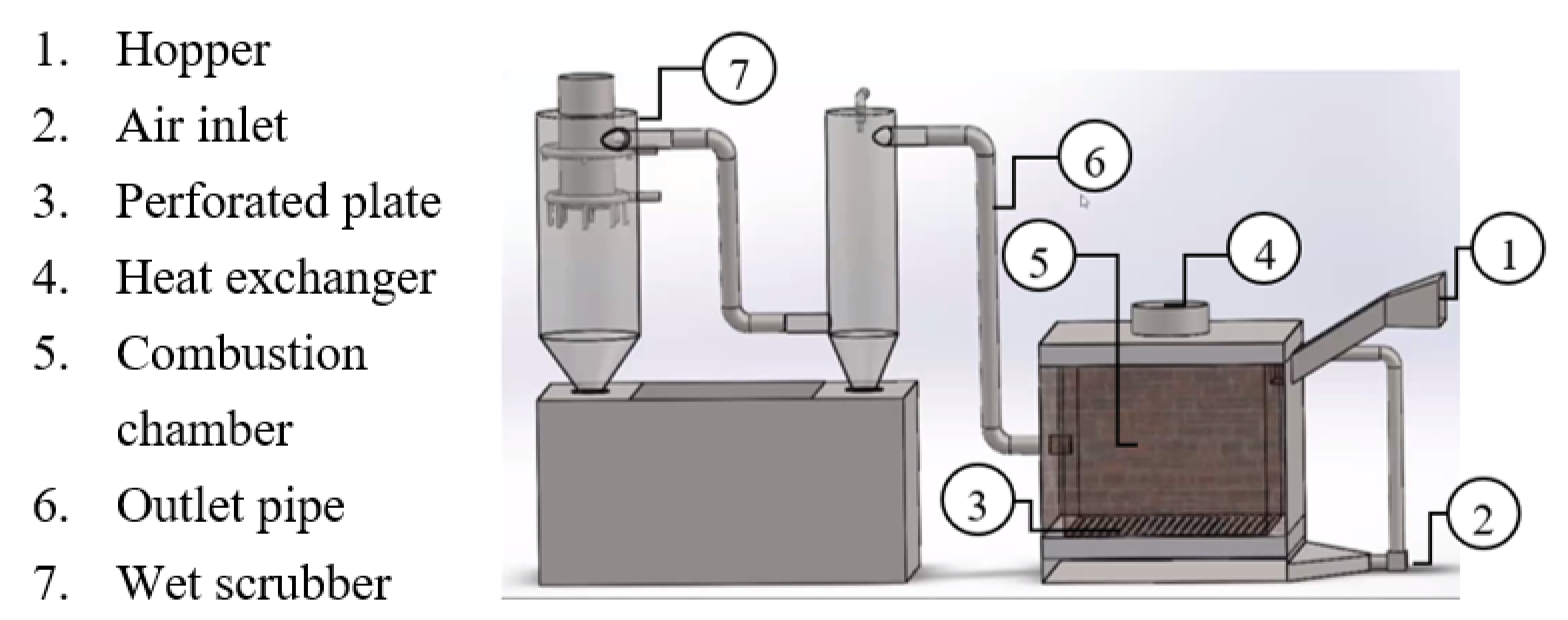

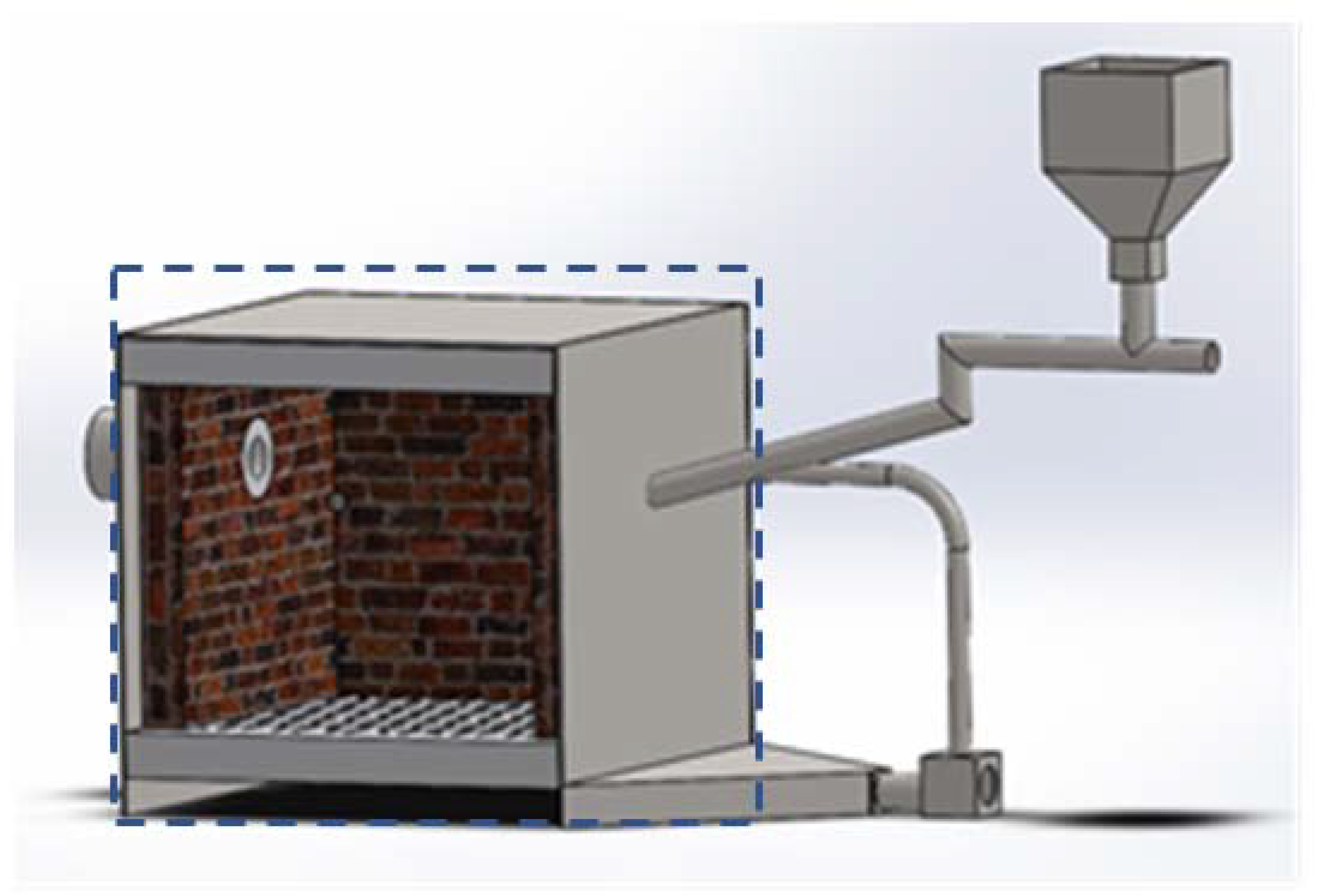

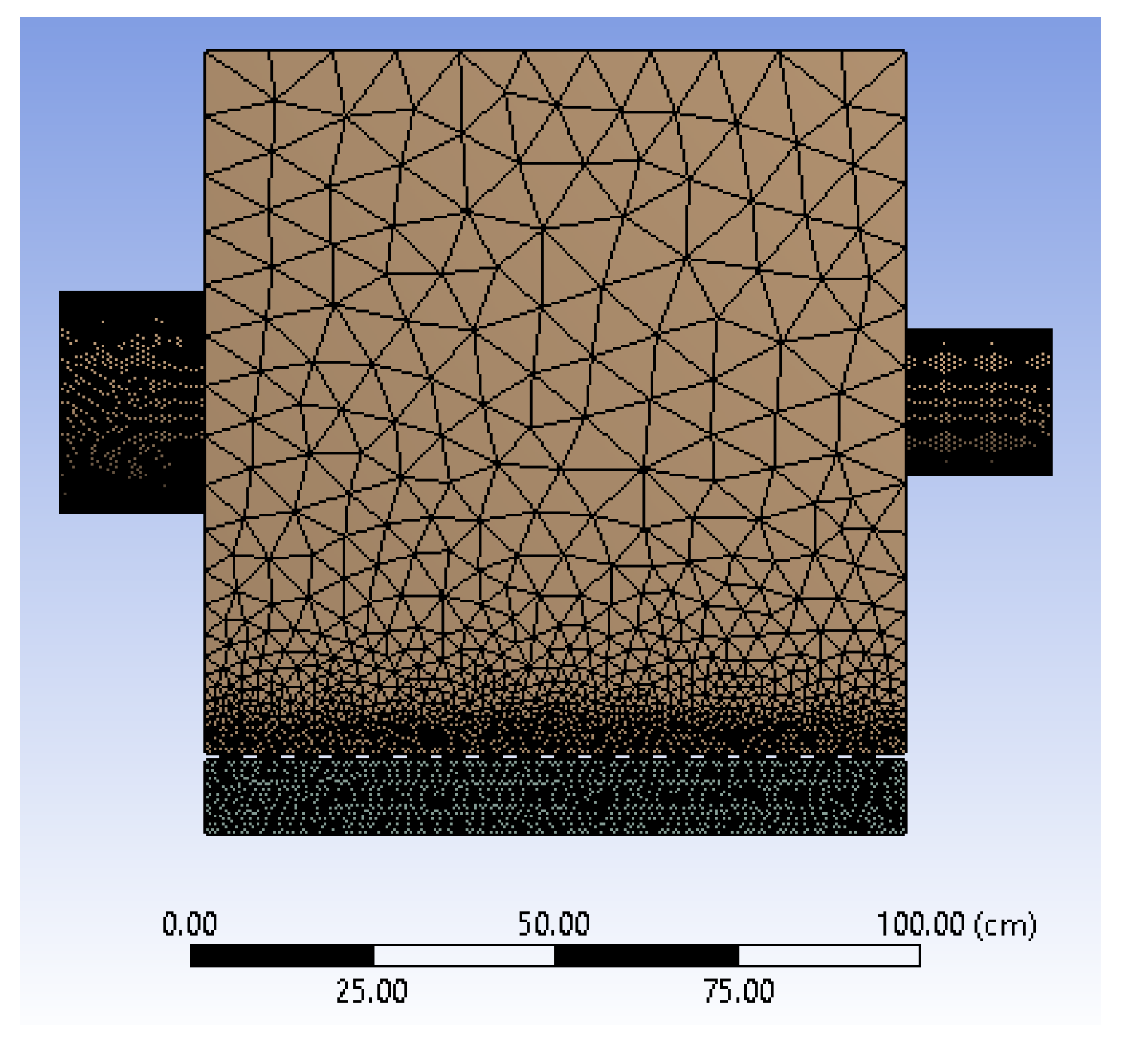

2. Materials and Methods

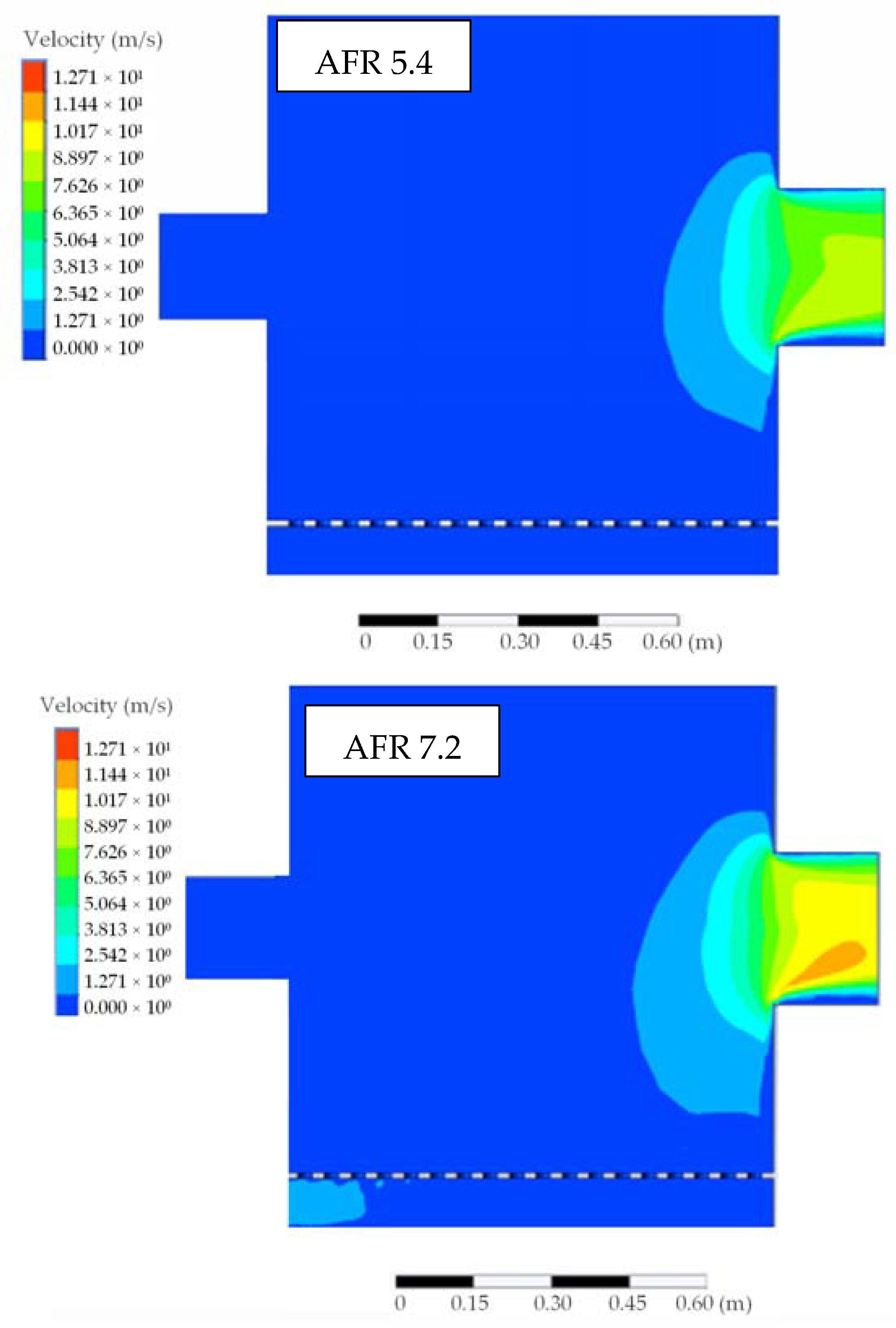

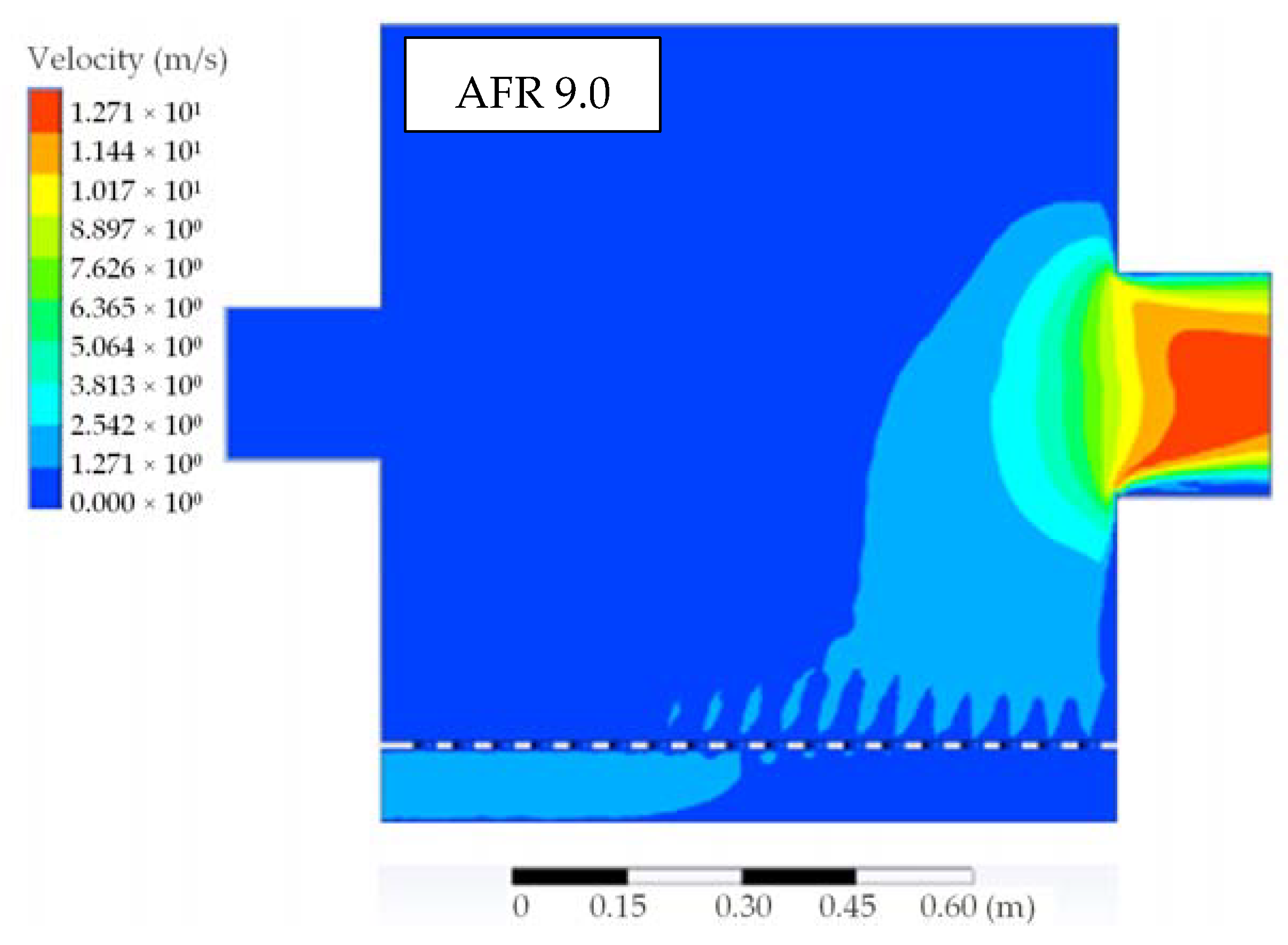

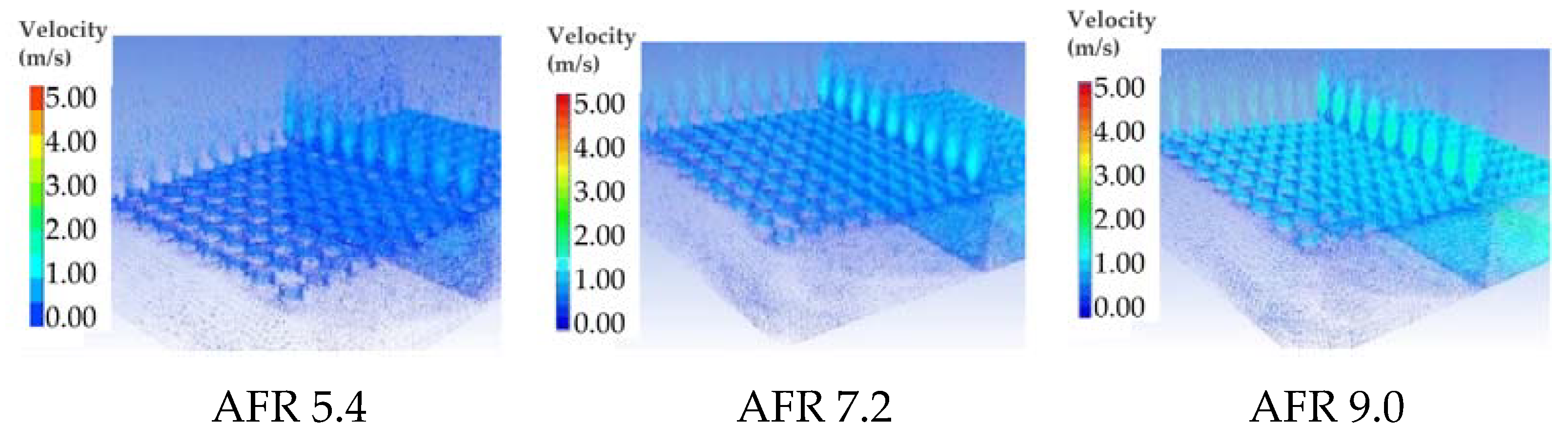

3. Results and Discussion

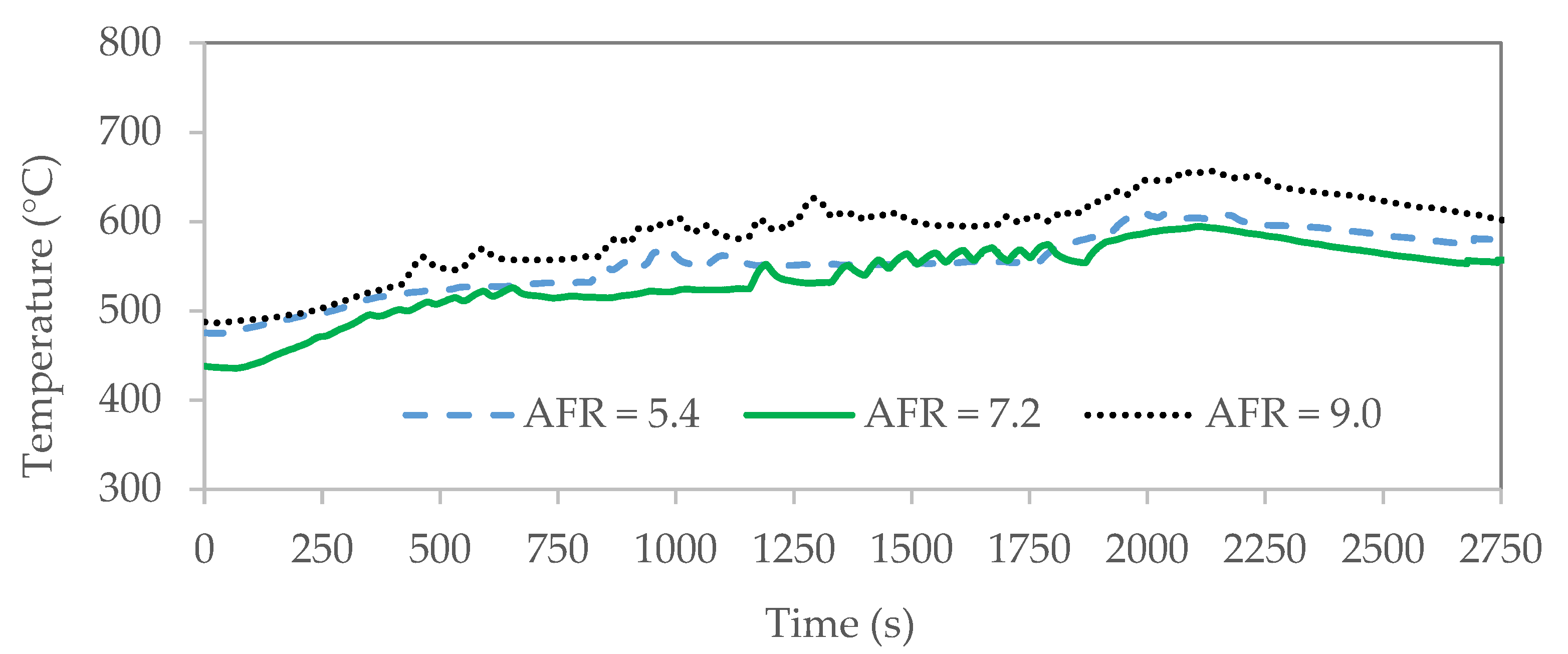

3.1. Combustion Temperature Profile

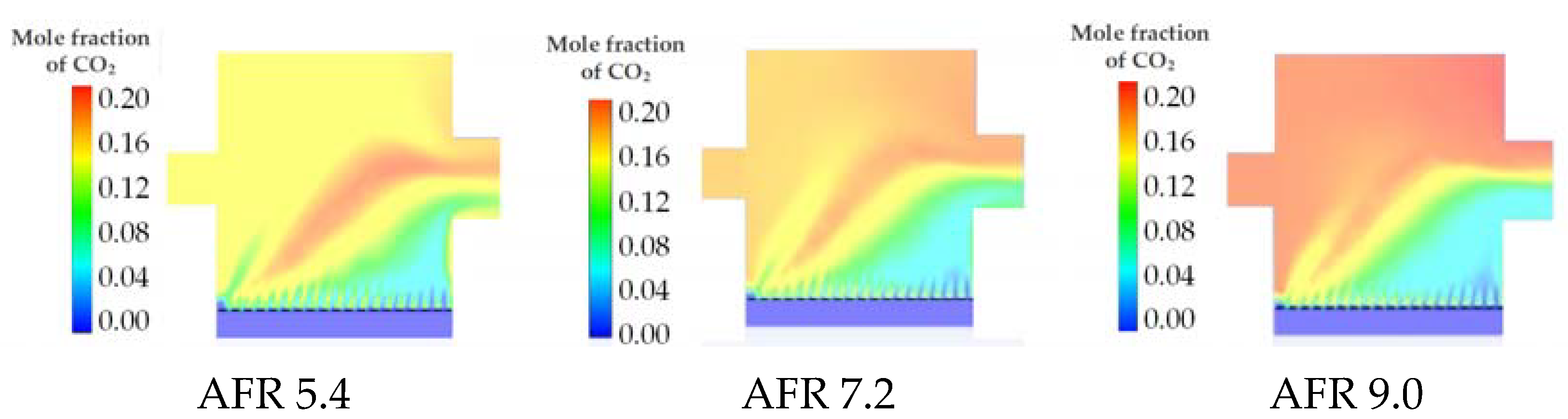

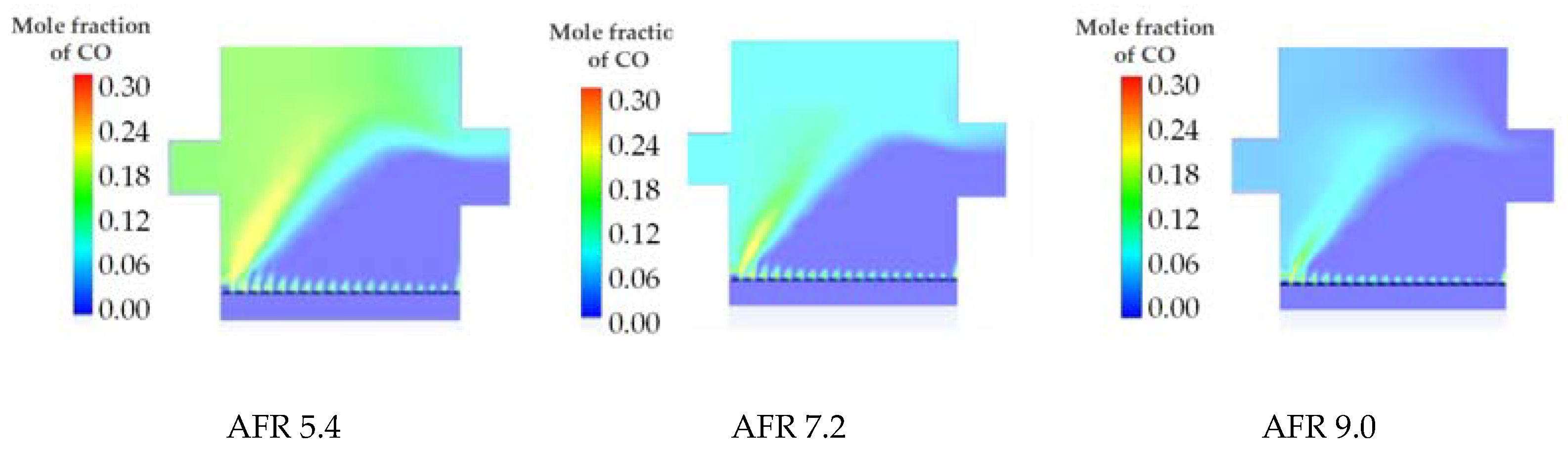

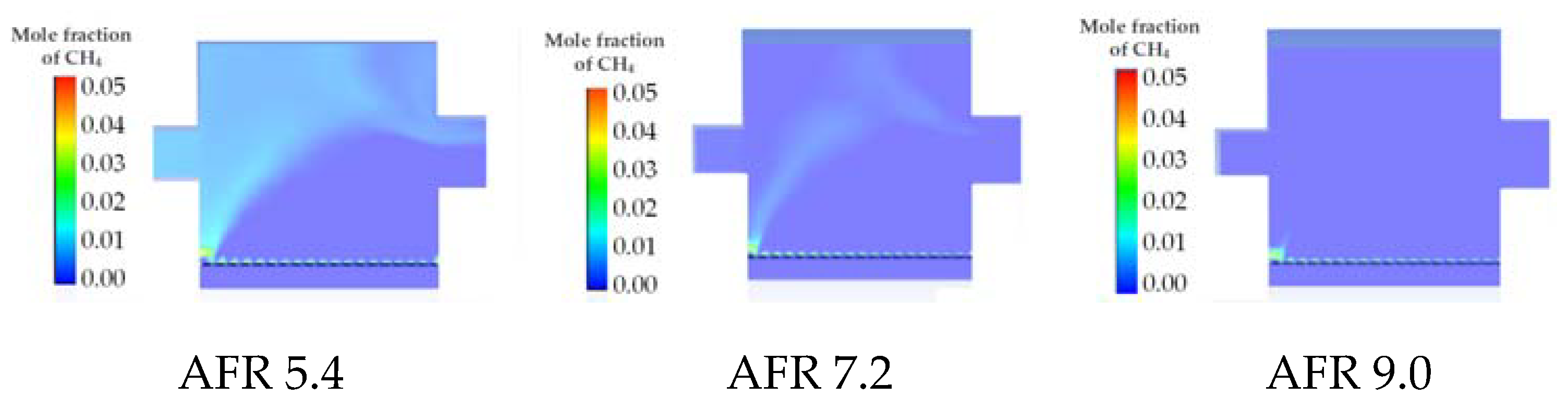

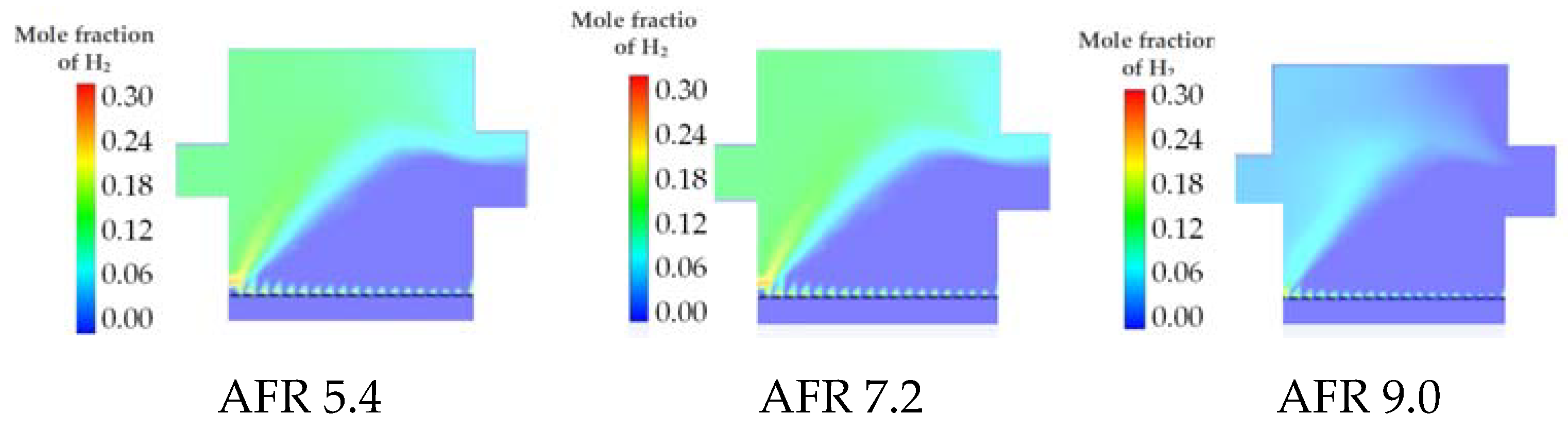

3.2. Gas Composition and Distribution

3.3. Energy Distribution

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of Binders on the Properties of Bio-Char Pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Simões Amaral, S.; Andrade de Carvalho, J., Jr.; Martins Costa, M.A.; Pinheiro, C. Particulate Matter Emission Factors for Biomass Combustion. Atmosphere 2016, 7, 141. [Google Scholar] [CrossRef] [Green Version]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Mixed Biomass Pellets for Thermal Energy Production: A Review of Combustion Models. Appl. Energy 2014, 127, 135–140. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of Sustainable Biomass Pellets Production–A Study for Agricultural Residues Pellets’ Market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Sjoding, D.; Kanoa, E.; Jensen, P. Developing a Wood Pellet/Densified Biomass Industry in Washington State: Opportunities and Challenges; Technical Assessment: Washington, DC, USA, 2013. [Google Scholar]

- Rosyadi, I.; Suyitno, S.; Ilyas, A.X.; Faishal, A.; Budiono, A.; Yusuf, M. Producing Hydrogen-Rich Syngas via Microwave Heating and Co-Gasification: A Systematic Review. Biofuel Res. J. 2022, 9, 1573–1591. [Google Scholar] [CrossRef]

- Gravitiani, E.; Arifin, Z.; Muqoffa, M.; Hadi, S. Feasibility of Electric Generation from Municipal Solid Wastes by Incineration and Gasification. In Proceedings of the 6th International Conference and Exhibition on Sustainable Energy and Advanced Materials, Surakarta, Indonesia, 16–17 October 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 485–491. [Google Scholar]

- Boman, C.; Pettersson, E.; Westerholm, R.; Boström, D.; Nordin, A. Stove Performance and Emission Characteristics in Residential Wood Log and Pellet Combustion, Part 1: Pellet Stoves. Energy Fuels 2011, 25, 307–314. [Google Scholar] [CrossRef]

- Sippula, O.; Hytönen, K.; Tissari, J.; Raunemaa, T.; Jokiniemi, J. Effect of Wood Fuel on the Emissions from a Top-Feed Pellet Stove. Energy Fuels 2007, 21, 1151–1160. [Google Scholar] [CrossRef]

- Ryu, C.; Yang, Y.B.; Khor, A.; Yates, N.E.; Sharifi, V.N.; Swithenbank, J. Effect of Fuel Properties on Biomass Combustion: Part I. Experiments—Fuel Type, Equivalence Ratio and Particle Size. Fuel 2006, 85, 1039–1046. [Google Scholar] [CrossRef]

- Rhén, C.; Öhman, M.; Gref, R.; Wästerlund, I. Effect of Raw Material Composition in Woody Biomass Pellets on Combustion Characteristics. Biomass Bioenergy 2007, 31, 66–72. [Google Scholar] [CrossRef]

- Biswas, A.K.; Rudolfsson, M.; Broström, M.; Umeki, K. Effect of Pelletizing Conditions on Combustion Behaviour of Single Wood Pellet. Appl. Energy 2014, 119, 79–84. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, J.J. Combustion and Heat Transfer Characteristics inside the Combustion Chamber of a Wood Pellet Boiler. J. Mech. Sci. Technol. 2014, 28, 789–795. [Google Scholar] [CrossRef]

- Marigo, M.; Zulli, F.; Bordignon, S.; Carnieletto, L.; Emmi, G.; De Carli, M. Energy Analysis of a Wood or Pellet Stove in a Single-Family House Equipped with Gas Boiler and Radiators. Build. Simul. 2022, 15, 1577–1593. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef] [Green Version]

- Orjala, M. Burner for Pellets. U.S. Patent 4515088, 7 May 1985. [Google Scholar]

- Zempel, A.M. System for Burning Biomass Pellets. U.S. Patent 4454828, 19 June 1984. [Google Scholar]

- Klason, T.; Bai, X.S. Computational Study of the Combustion Process and NO Formation in a Small-Scale Wood Pellet Furnace. Fuel 2007, 86, 1465–1474. [Google Scholar] [CrossRef]

- Lee, Y.-W.; Ryu, C.; Lee, W.-J.; Park, Y.-K. Assessment of Wood Pellet Combustion in a Domestic Stove. J. Mater. Cycles Waste Manag. 2011, 13, 165–172. [Google Scholar] [CrossRef]

- Kshirsagar, M.P.; Kalamkar, V.R. Application of Multi-Response Robust Parameter Design for Performance Optimization of a Hybrid Draft Biomass Cook Stove. Renew. Energy 2020, 153, 1127–1139. [Google Scholar] [CrossRef]

- Shimizu, T.; Han, J.; Choi, S.; Kim, L.; Kim, H. Fluidized-Bed Combustion Characteristics of Cedar Pellets by Using an Alternative Bed Material. Energy Fuels 2006, 20, 2737–2742. [Google Scholar] [CrossRef]

- Roy, M.M.; Dutta, A.; Corscadden, K. An Experimental Study of Combustion and Emissions of Biomass Pellets in a Prototype Pellet Furnace. Appl. Energy 2013, 108, 298–307. [Google Scholar] [CrossRef]

- Ahn, J.; Jang, J.H. Combustion Characteristics of a 16 Step Grate-Firing Wood Pellet Boiler. Renew. Energy 2018, 129, 678–685. [Google Scholar] [CrossRef]

- Jetter, J.J.; Kariher, P. Solid-Fuel Household Cook Stoves: Characterization of Performance and Emissions. Biomass Bioenergy 2009, 33, 294–305. [Google Scholar] [CrossRef]

- Zadravec, T.; Rajh, B.; Kokalj, F.; Samec, N. The Impact of Secondary Air Boundary Conditions on CFD Results in Small-Scale Wood Pellet Combustion. Fuel 2022, 324, 124451. [Google Scholar] [CrossRef]

- Hafiz, M.; Nelwan, L.O.; Yulianto, M. CFD-Based Analysis of Non-Premixed Combustion Model in Biomass Grate Furnaces. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bogor, Indonesia, 23–25 October 2017; IOP Publishing: Bristol, UK, 2018; Volume 147, p. 12029. [Google Scholar]

- Zhang, J.; Li, T.; Ström, H.; Løvås, T. Computationally Efficient Coarse-Graining XDEM/CFD Modeling of Fixed-Bed Combustion of Biomass. Combust. Flame 2022, 238, 111876. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, J.; Zhong, S.; Li, T.; Løvås, T.; Fatehi, H.; Bai, X.-S. CFD Modeling of Biomass Combustion and Gasification in Fluidized Bed Reactors Using a Distribution Kernel Method. Combust. Flame 2022, 236, 111744. [Google Scholar] [CrossRef]

- Kallis, K.X.; Susini, G.A.P.; Oakey, J.E. A Comparison between Miscanthus and Bioethanol Waste Pellets and Their Performance in a Downdraft Gasifier. Appl. Energy 2013, 101, 333–340. [Google Scholar] [CrossRef]

- Glassman, I.; Yetter, R.A.; Glumac, N.G. Combustion of Nonvolatile Fuels. Combustion 2015, 4, 495–550. [Google Scholar]

- Llamas, Á.D.G.; Guo, N.; Li, T.; Gebart, R.; Umeki, K. Rapid Change of Particle Velocity Due to Volatile Gas Release during Biomass Devolatilization. Combust. Flame 2022, 238, 111898. [Google Scholar] [CrossRef]

- Yang, Y.B.; Sharifi, V.N.; Swithenbank, J. Effect of Air Flow Rate and Fuel Moisture on the Burning Behaviours of Biomass and Simulated Municipal Solid Wastes in Packed Beds. Fuel 2004, 83, 1553–1562. [Google Scholar] [CrossRef]

- Contreras-Trejo, J.C.; Vega-Nieva, D.J.; Heya, M.N.; Prieto-Ruíz, J.A.; Nava-Berúmen, C.A.; Carrillo-Parra, A. Sintering and Fusibility Risks of Pellet Ash from Different Sources at Different Combustion Temperatures. Energies 2022, 15, 5026. [Google Scholar] [CrossRef]

- Kuptz, D.; Kuchler, C.; Rist, E.; Eickenscheidt, T.; Mack, R.; Schön, C.; Drösler, M.; Hartmann, H. Combustion Behaviour and Slagging Tendencies of Pure, Blended and Kaolin Additivated Biomass Pellets from Fen Paludicultures in Two Small-Scale Boilers < 30 KW. Biomass Bioenergy 2022, 164, 106532. [Google Scholar] [CrossRef]

- Youssef, M.A.; Wahid, S.S.; Mohamed, M.A.; Askalany, A.A. Experimental Study on Egyptian Biomass Combustion in Circulating Fluidized Bed. Appl. Energy 2009, 86, 2644–2650. [Google Scholar] [CrossRef]

| Parameters | Unit | Basis | Results |

|---|---|---|---|

| Proximate Analysis | |||

| Total moisture | % | ar | 6.41 |

| Volatile matter | % | adb | 77.82 |

| Total Sulphur | % | adb | 0.06 |

| Ash content | % | adb | 1.12 |

| Gross calorific value | MJ/kg | adb | 18.17 |

| Net calorific value | MJ/kg | adb | 16.79 |

| Chlorine (Cl) | ppm | adb | 498.75 |

| Ultimate Analysis | |||

| Carbon | % | adb | 46.80 |

| Hydrogen | % | adb | 5.61 |

| Nitrogen | % | adb | 0.26 |

| Oxygen by difference | % | adb | 47.33 |

| Aspect Ratio | Skewness | Orthogonal Quality | ||||||

|---|---|---|---|---|---|---|---|---|

| Max | Min | Average | Max | Min | Average | Max | Min | Average |

| 9.31 | 1.16 | 1.86 | 0.80 | 1.72 × 10−4 | 0.24 | 0.99 | 0.20 | 0.76 |

| Location | Temperature (K) | Deviation (%) | Average | |

|---|---|---|---|---|

| Simulation | Experiment | (%) | ||

| AFR 5.4 | ||||

| Top | 864 | 881 | 1.93 | 5.2 |

| Middle | 864 | 927 | 6.80 | |

| Bottom | 864 | 928 | 6.90 | |

| AFR 7.2 | ||||

| Top | 875 | 860 | 1.74 | 3.22 |

| Middle | 875 | 907 | 3.52 | |

| Bottom | 947 | 907 | 4.41 | |

| AFR 9.0 | ||||

| Top | 879 | 919 | 4.35 | 3.99 |

| Middle | 879 | 945 | 6.98 | |

| Bottom | 951 | 945 | 0.63 | |

| No. | Gas Type | AFR 5.4 | AFR 7.2 | AFR 9.0 |

|---|---|---|---|---|

| 1 | N2 | 67.19 | 70.35 | 72.37 |

| 2 | O2 | 3.45 | 6.13 | 8.29 |

| 3 | CO | 2.50 | 1.07 | 0.23 |

| 4 | H2 | 2.31 | 0.85 | 0.14 |

| 5 | H2O | 9.91 | 8.95 | 7.92 |

| 6 | CO2 | 14.56 | 12.64 | 11.05 |

| 7 | CH4 | 0.07 | 0.01 | 0.00 |

| TOTAL | 100 | 100 | 100 | |

| Domain | Total Heat Transfer (kW) | |||||

|---|---|---|---|---|---|---|

| Simulation | Experiment | |||||

| AFR = 5.4 | AFR = 7.2 | AFR = 9.0 | AFR = 5.4 | AFR = 7.2 | AFR = 9.0 | |

| Outlet | 272.23 | 273.51 | 275.56 | 270.97 | 270.58 | 275.24 |

| Wall | −29.83 | −31.02 | −29.90 | −36.40 | −34.01 | −37.70 |

| Total | 242.40 | 242.49 | 245.66 | 234.57 | 236.57 | 237.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suyitno; Sutanto, H.; Muqoffa, M.; Nurrohim, T.G. An Experimental and Numerical Study of the Burning of Calliandra Wood Pellets in a 200 kW Furnace. Energies 2022, 15, 8251. https://doi.org/10.3390/en15218251

Suyitno, Sutanto H, Muqoffa M, Nurrohim TG. An Experimental and Numerical Study of the Burning of Calliandra Wood Pellets in a 200 kW Furnace. Energies. 2022; 15(21):8251. https://doi.org/10.3390/en15218251

Chicago/Turabian StyleSuyitno, Heru Sutanto, Mohammad Muqoffa, and Tito Gusti Nurrohim. 2022. "An Experimental and Numerical Study of the Burning of Calliandra Wood Pellets in a 200 kW Furnace" Energies 15, no. 21: 8251. https://doi.org/10.3390/en15218251

APA StyleSuyitno, Sutanto, H., Muqoffa, M., & Nurrohim, T. G. (2022). An Experimental and Numerical Study of the Burning of Calliandra Wood Pellets in a 200 kW Furnace. Energies, 15(21), 8251. https://doi.org/10.3390/en15218251