Abstract

In the context of increased energy demands and finding solutions for energetic autonomy, the use of waste base materials has increased in recent years in all areas of research. In this context, waste waters, sludge or slurry, biodegradable materials, second generation effluents, and their byproducts are some of the key substrates of interest to obtain biogas through AD (anaerobe digestion). The goal is to utilize these materials as a base for the generation of renewable energy and thereby make it the main source of energy for households or industries. This paper aims to characterize, from a physical and chemical point of view, wastewater from Timis county as a base substrate material in the co-fermentation process with cereal residual biomass. We aimed to determine the energetic potential of the wastewater and perform preliminary testing at a small and pilot-sized experimental installation for biogas production with Timis wastewater as the main energy carrier. The novelty of the paper stems from the use of a patented pilot installation as our experimental approach, as well as the use of a different comparative scale co-fermentation process for biogas production. The conclusions will be traced relative to the obtained results, and preliminary solutions will be proposed for further avenues on this topic.

1. Introduction

At present, biofuels are a potential solution in terms of possible capitalization for partially untapped sources of energy in order to partially solve the increasing energy demand related to demographical necessities and restrictive energy access in different locations due to various factors. This aspect is related to local and regional resource availabilities and offers at least a partial solution with regard to energetic autonomy.

In direct regard to the presented topic, biogas represents one of the used energy carriers that are obtained through anaerobic digestion or anaerobic fermentation, with different residence times for the tested organic substrates at different temperatures. This process has four stages: first, hydrolysis; then, acidogenesis, where pH can vary in large domains depending on the buffer capacity of the chosen substrate; then acetogenesis, where short chained products transform into acetic acid; and finally, methanogenesis, which has as its main result the production of methane, carbon dioxide, and parts of hydrogen sulfide [1,2,3,4].

Wastewaters represent a possible source of materials suitable for anaerobic digestion. Due to more frequent energy crises and an increase in global energy costs [5,6], the wastewater treatment sector’s need for sustainability becomes more relevant for all industries [7]. Given that in the last few decades there has been large energy consumption in the sludge activation process (~1 kWh/m3 which can reach up to 60% of the system energy budget) of conventional wastewater treatment technologies, there has been an increasing focus on sustainable wastewater treatment concepts designed for instances of low resource availability (mainly energy) [8,9].

They usually contain high concentrations of organic compounds and imply extensive costs in terms of biological treatment and energy consumption [10,11,12,13,14]. Based on typical biological (BOD) and chemical (COD) oxygen demand concentrations of industrially processed wastewaters, between 3 and 6 MJ of heat energy can be recovered from one cubic meter of wastewater [15].

However, activated sludge can be hazardous in different scenarios because of the contaminated waters that enter the treatment plant. Thus, efficient pretreatment (evaporation and condensation) processes are needed in this context [16].

At the European Union level, through its long-term strategy [17], it is expected that by 2030, biogas will be about 3.7% of the total EU energy budget, or the equivalent of 1.7 EJ. To achieve this goal, it is expected that two-thirds of total biogas production will be produced from manure and other organic waste and one-third from energy crops [18].

At present, sustainable and effective waste management in agriculture is possible through the production of biogas from crop residues and livestock wastes, with biogas yields depending on the season and storage. The main characteristics of biomass waste relevant for anaerobic digestion are cellulose, hemicellulose, and C/N content [19]. Despite these advantages, energy crops have the main disadvantage that they use agricultural land to the detriment of food and feed crops, thereby leading to significant environmental impacts [20,21,22]. Energy crops are rarely used for biogas production, mainly because of the large availability of agricultural waste byproducts, leading to sustainable biogas production [23].

The study analyzes the potential to use various agricultural lignocellulosic wastes in wastewater from beer factories as a substrate for biogas production through anaerobic digestion. The goal is to support the development of national strategies on the potential of biogas conversion into the energy market, especially as Romania [18], despite its large availability of agricultural waste resources, has installed only 13 biogas plants that together produce only 12 MW.

2. Materials and Methods

After material documentation, all agricultural wastes of barley, wheat, corn, and rye were oven-dried and passed through a hammer mill for size reduction to <1 mm. After mechanical processing, representative samples were taken to the laboratory for further analysis.

In addition, before making the laboratory determinations the biofuels standards and the user manuals for the equipment were consulted for laboratory analysis. The most relevant parameters of agricultural waste samples were determined following specific analytical standards for solid biofuels: moisture content (ISO 1834), ash content (ISO 18122), calorific value (ISO 14918), total content of carbon, hydrogen, nitrogen, sulfur, and chlorine (ISO 16948 & 16994), and volatile matter (ISO 18123). The ash melting behavior was analyzed following CEN/TS 15370 guidance.

Analytical equipment used:

- -

- Solid biomass comminution—FRITSCH P16 mill, Idar-Oberstein, Germany;

- -

- Solid biomass moisture content—Heating Oven, BINDER FD 115, Tuttlinger, Germany;

- -

- Solid biomass volatile matter and ash content—Heating Furnace, Nabertherm LE14/11/P300, Lilienthal, Germany;

- -

- Solid biomass calorific value—isoperibol oxygen bomb calorimeter, IKA C6000, Staufen, Germany;

- -

- C, H, N—combustion and thermal conductivity detection, ELEMENTAR Vario MACRO Cube, Ronkonkoma, NY, USA;

- -

- CO2, CH4—DELTA 1600 S-IV, NDIR analyzer, Neckarsulm, Germany.

As a result of the proximate analysis of substrates (solid and liquid), we determined the moisture content, volatile content, and ash content. ISO methodology was used for all analyses, on a dry basis, defined as the mass of the sample remaining after heating the sample at 105–110 °C for 1 h for solid substrates and until only the solid part of the sample remained. Through ultimate analysis, we analyzed the carbon, hydrogen, chlorine, nitrogen, and sulphur in dry substrates randomly sampled. The proximate/ultimate analysis of substrate characterization was chosen for accuracy, and all analytical methods used were in accordance with EU/ISO analytical standards [24,25].

Waste calorific values were also determined by direct combustion in a calorimeter with an oxygen bomb for all substrates (on a dry basis). [26] Low heating values, LHV, that exclude the latent heat of water vaporization from the sample and high heating values (that include water vaporization) were determined. Mechanical milling (comminution) was the only pretreatment method applied for solid agricultural wastes used as substrate (size under 1 mm for small size reactors and under 5 mm for large scale pilot installation).

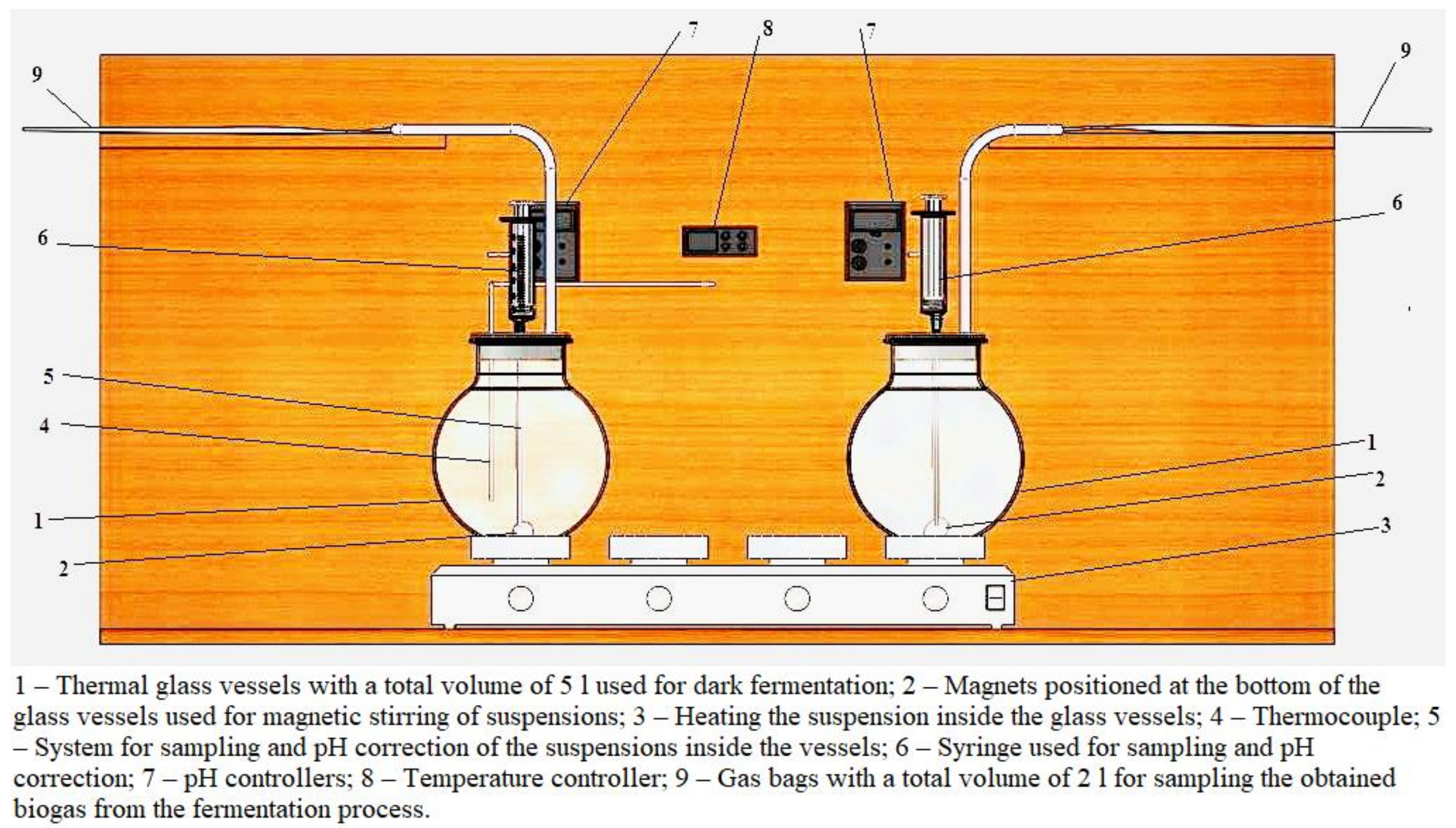

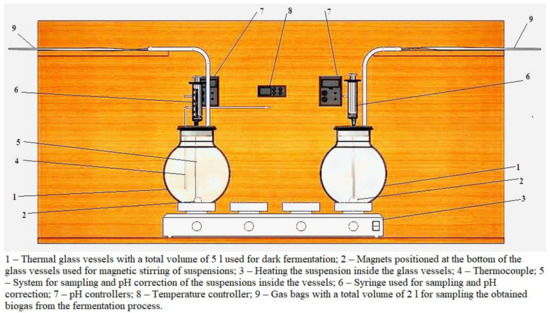

The biogas potential production tests were conducted for 35 days in small-scale reactors (5 L total volume of one reactor) to evaluate the substrate mixture most suitable for the next step, and the 45 day biogas production tests were conducted in large-scale reactors. In the small-scale reactors, the content formed by adding 150 g of solid lignocellulosic to 4 L of waste water was stirred by hand (shaking the reactors) every day. To avoid degradation of the developed biota, the small reactors were fully tinted black. The biogas produced was collected for analysis in sampling bags, and the correction of pH (when necessary) was done through a syringe by the addition of NaOH [27]. One-year-old agricultural solid wastes (corn, wheat, barley, and rye) were collected in plastic bags from a large-scale farm in Timis County, Romania.

For the experimental setup, the test rigs presented in Figure 1 (schematics) and Figure 2 (real view) were used.

Figure 1.

Schematic of the components of the 5 L volume test rig.

Figure 2.

Front image of the test rig for 5 L volume.

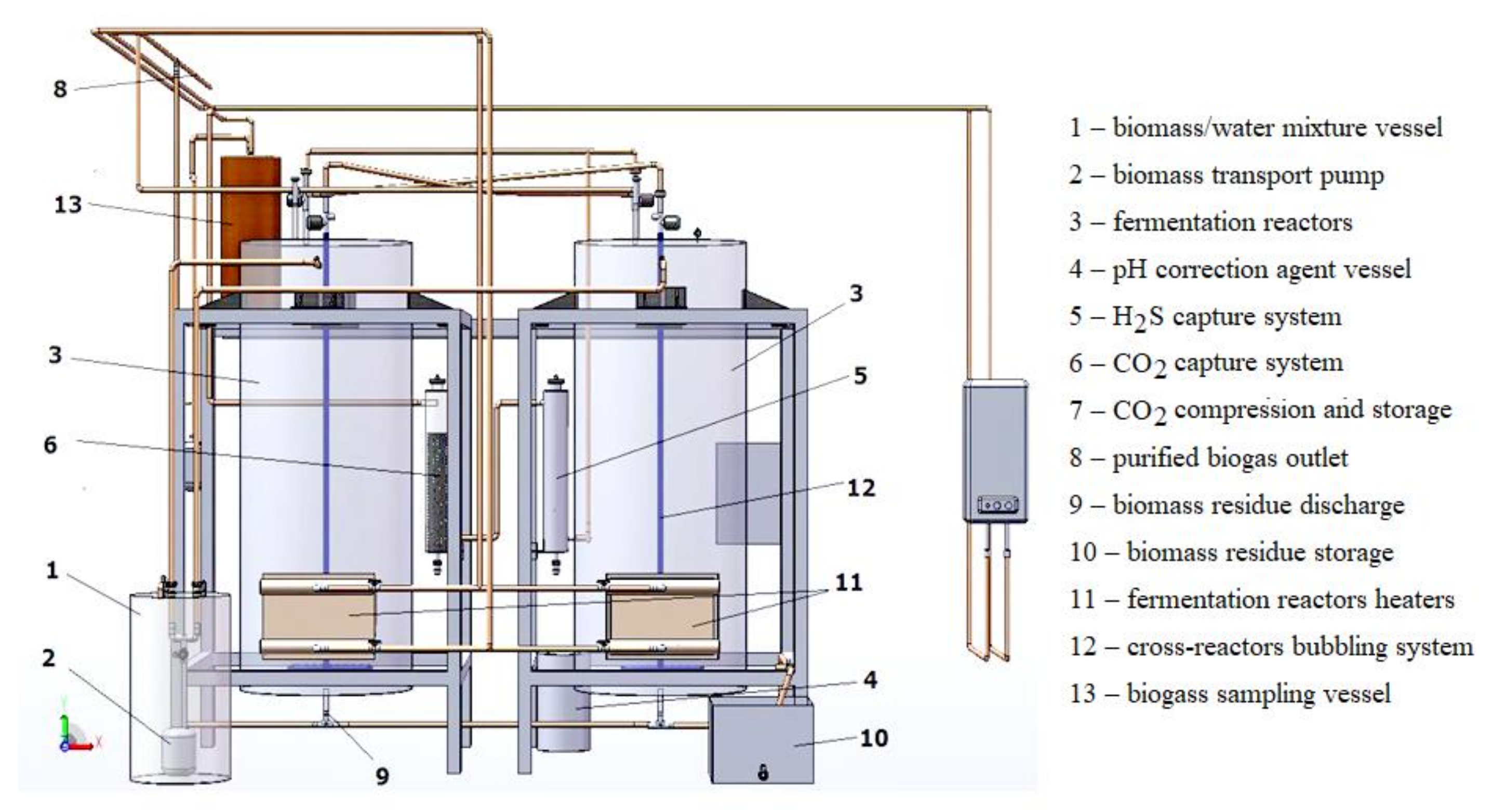

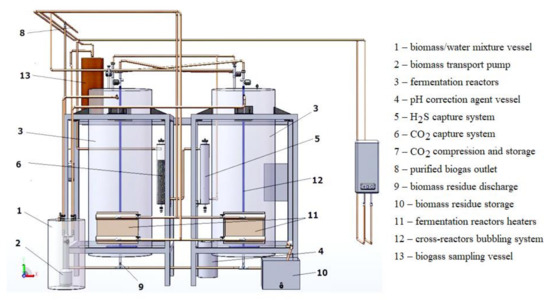

After initial determinations, the materials (75 kg of solid waste added to 2 m3 of waste water) were tested inside the pilot installation (Figure 3) in order to determine the potential of producing and the quality and quantity biogas by using this type of material mixture.

Figure 3.

Schematic of the 6 m3 (2 × 3 m3) biogas pilot installation.

The mid-size two reactor pilot installation (2 × 3 m3 in volume) was designed and built to extend the results obtained from testing different mixtures of substrates in a 5 L test rig onto a larger installation with much higher working volumes, as shown in Figure 3. The bottles of the small test rig were flushed before and after each test with nitrogen gas, while the large-scale reactors were flushed with tap water and dried under atmospheric conditions.

The pilot installation is designed for low energy consumption, with two reactors (3) mounted in parallel, with the biogas output of one reactor connected to the lower bottom of the other and vice versa. This was done so that homogenization of suspension is done through a biogas bubbling system (12) controlled by the reactor’s pressure. The fermentation reactors are fed with substrate by a pump (2). The anaerobic process is controlled through the injection of high ammonia (90%) concentrated water from a small reservoir (4). Before leaving the pilot installation (8) the biogas CO2 and H2S content is reduced in capture and desorption systems (5, 6). If necessary, the CO2 can be compressed and stored in bottles (7) through a compressor unit. The substrate temperature is assured by hot water produced in solar panels and distributed in pipe heaters (11) immersed in the substrate. The delivery of hot water is controlled by a thermostat. The substrate residue is discharged (9) from the reactor;s bottom into a storage vessel (10) and prepared for drying, neutralization, or discharge. Small quantities of biogas can be extracted from reactors and stored in a vessel (13) where they can be sampled and analyzed.

3. Results and Discussion

Before the AD process there were initial laboratory investigations for the substrates used. The results are summarized in Table 1.

Table 1.

Elemental composition of analyzed substrates for biogas tests.

From a calorific value point of view, it can be determined that the tested materials present a high energetic potential, while the wastewater has a relatively high calorific value by correspondence with the usual material tested in the same conditions. Of course, the ash content is very high for wastewater because of the high mineral and amorphous components that are found in it.

From a biomass point of view, the obtained data is characteristic for this type of material, while the high ash content can be translated in the case of wastewater into a very high carbon content.

The sulphur and chlorine contents indicate that wastewater solid residue is not suitable for co-combustion processes because of the high values in those two parameters.

Based on other research conducted [25,28,29], the heating values of different types of food industry (beverage) wastewaters can be found between 11–25 MJ/kg of volatile matter on a dry basis, and the amount of carbon content is in direct relation with the calorific values of substrates. Similar findings were obtained during the present research, both for brewery factory waste waters and agricultural residues.

3.1. Small Scale Reactors Biogas Production Tests

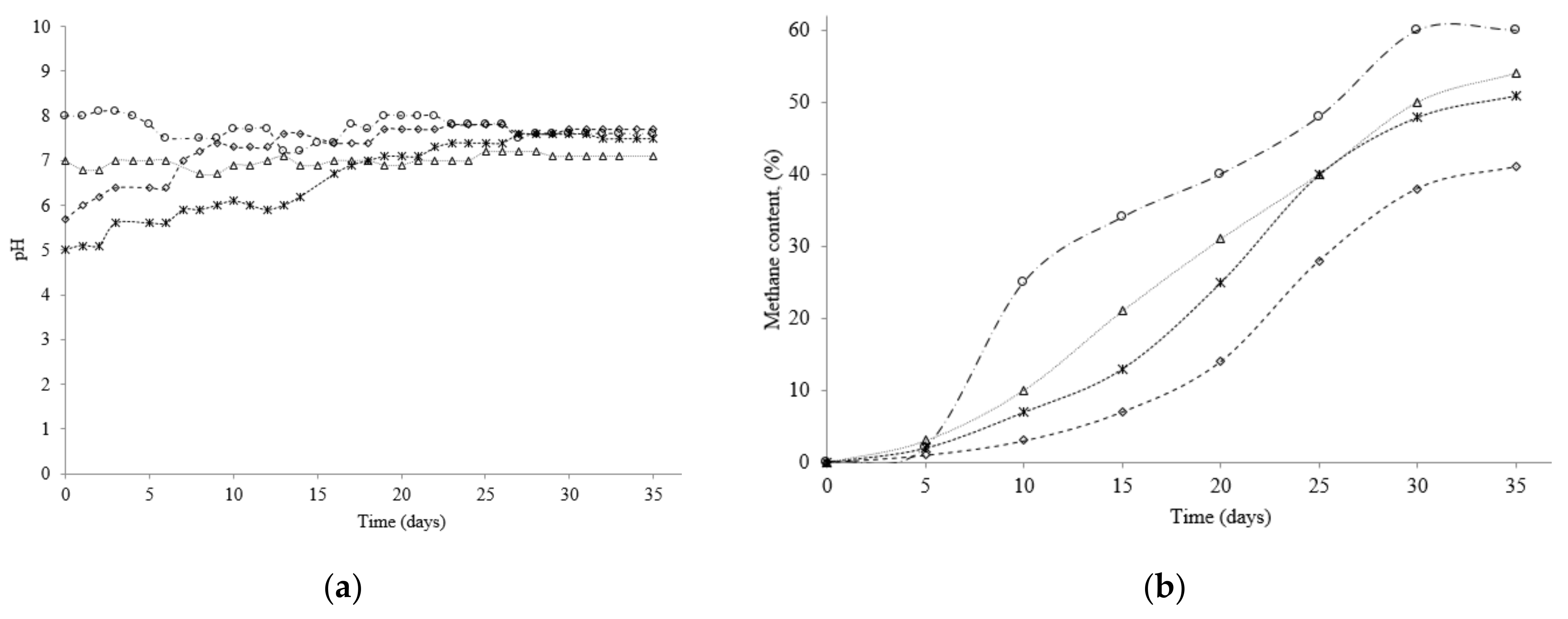

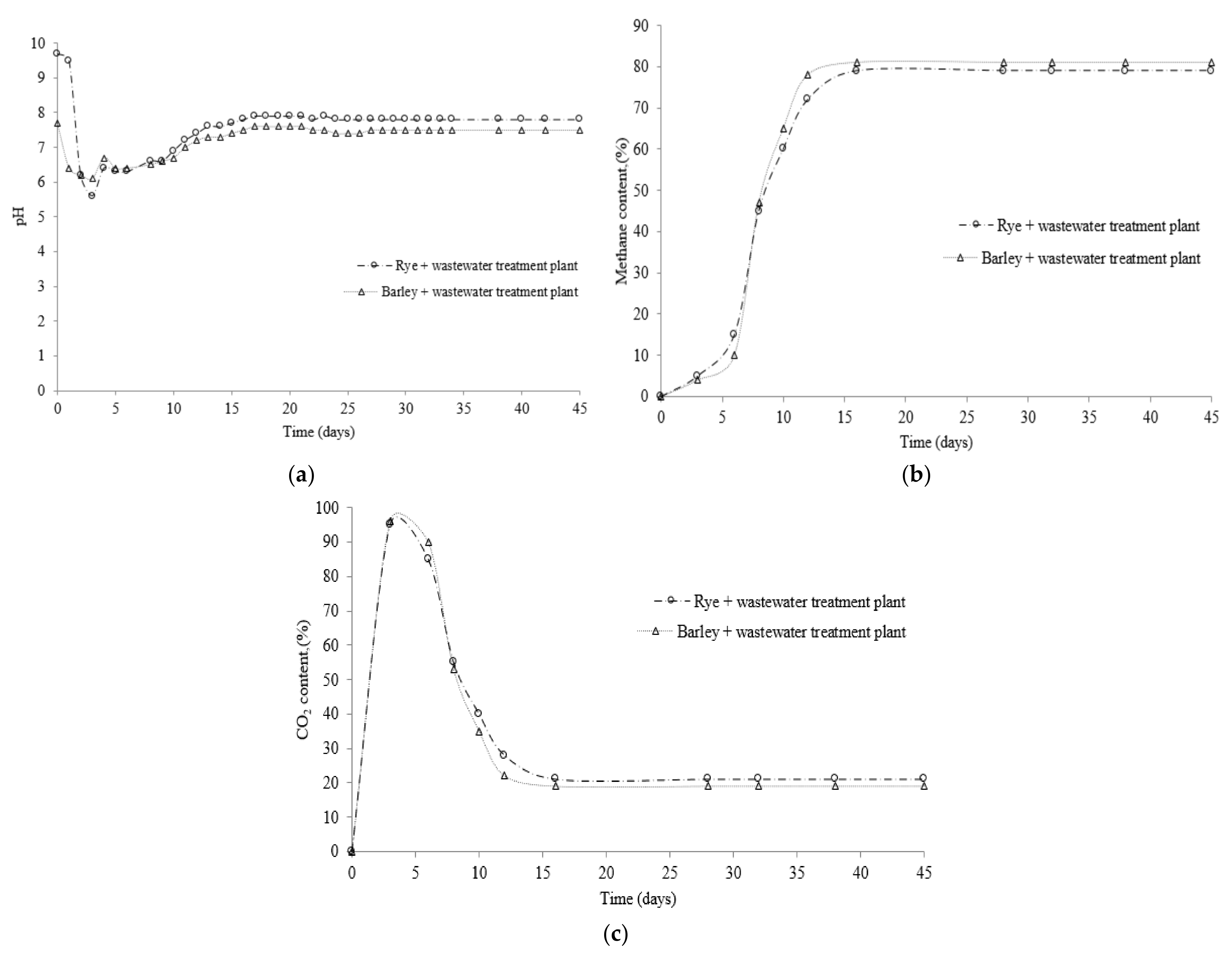

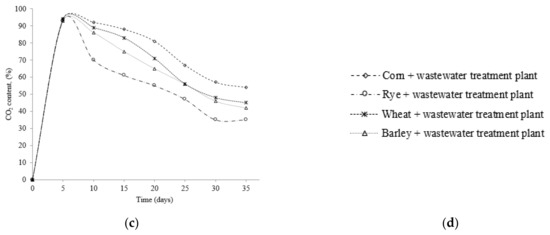

The small-scale reactors were described in Figure 1 and Figure 2. The substrates analyzed were formed from a mixture of beer factory sludge treatment plant wastes and solid agricultural wastes (corn, wheat, barley, and rye). The substrate mixture ratio was 22:1, for 1.5 kg of wastewater 0.07 kg of solid agricultural waste was added. The results obtained for four substrates for the anaerobic digestion (no additional inoculum) for receipt tests are presented in Figure 4.

Figure 4.

Substrate evolution during biogas production tests in small-scale reactors: (a) pH evolution; (b) Methane production; (c) Carbon dioxide production; and (d) graphics legend.

From Figure 4a, one may observe the fact that the initial values for pH were higher for rye and barley substrates, which were advantageous because this implied lower pH correction agent quantities. After about 10–12 days, all of the materials reached the correct domain for anaerobic fermentation.

From Figure 4b, it can be observed that the methane concentration values are slightly higher, with a maximum value for rye—about 60%; also, the CO2 production, Figure 4c shows a similar behavior.

For all substrates, it was found that optimal pH values for biogas production from selected substrate mixtures are approximately 7–7.5 and that pH values below 6.5 will inhibit the digestion process. Similar optimal pH ranges for biogas digestion can be found in the literature [30] with optimal pH values between 6.7–7.5. In this study and for these specific substrate mixtures, we found that the optimal pH value for the highest biogas production is between 7–7.5.

Table 2 presents the total biogas volumes produced during the small-scale tests.

Table 2.

Biogas production in small-scale testing rig.

Results obtained at small scale testing rigs shows a relatively high potential for biogas production for rye and barley wastes with wastewater addition, so these two substrates were chosen for large-scale testing rig experiments.

3.2. Large-Scale Reactors Biogas Production Tests Validation

After testing at a small-scale, substrate mixtures of wastewater and rye and waste water and barley were selected for experimental production of biogas in large-scale reactors (3 m3 each).

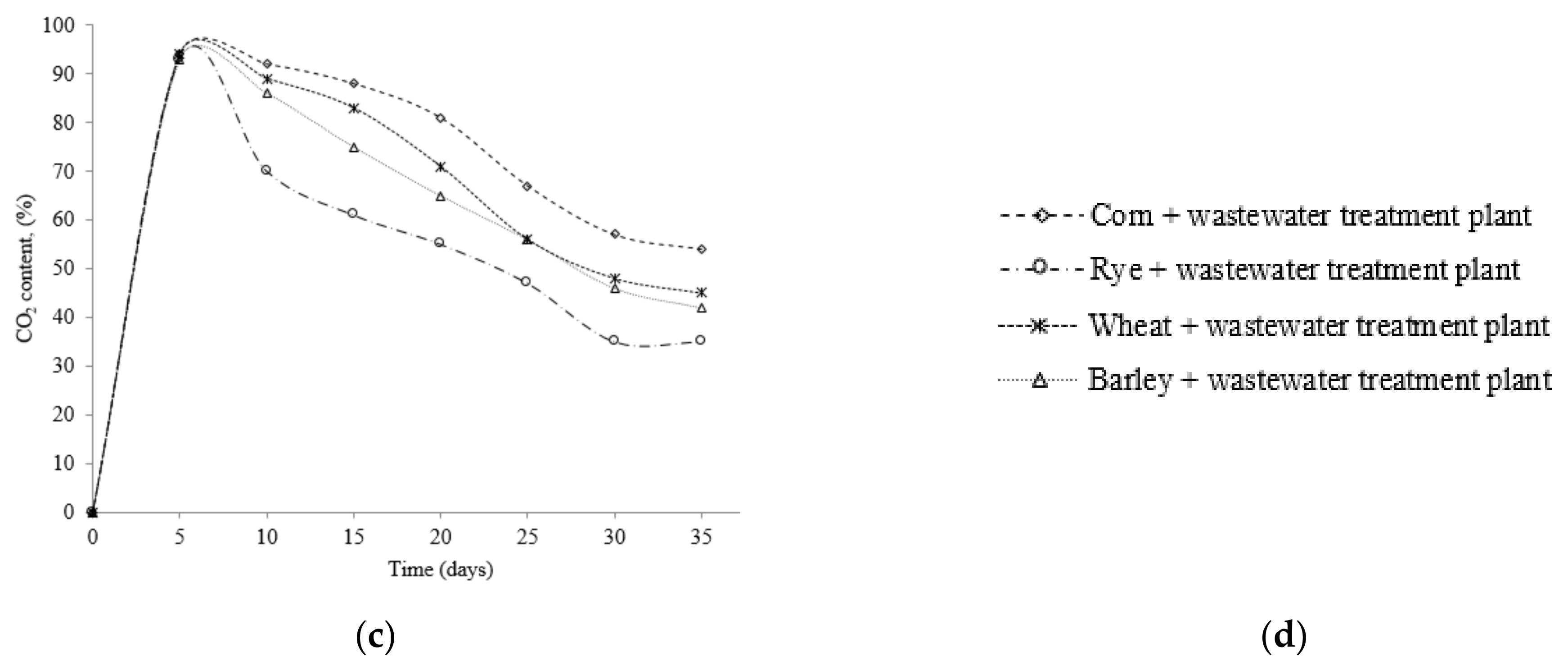

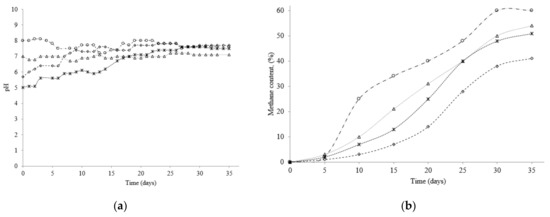

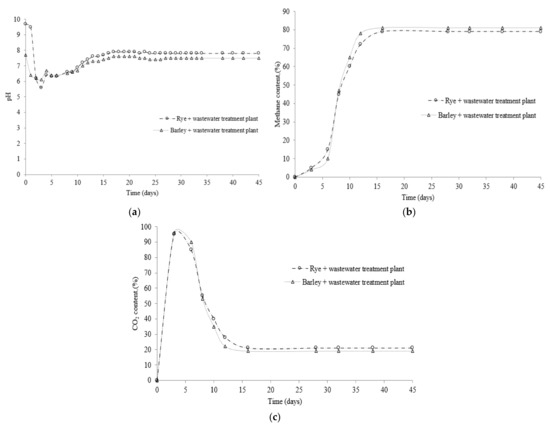

The large-scale reactors are described in Figure 3. The substrates analyzed were formed from a mixture of beer factory sludge treatment plant wastes and solid agricultural wastes (rye and barley). The substrate mixture ratio was 22:1, for 1650 kg of wastewater 75 kg of a solid substrate was added. The anaerobic digestion (no additional inoculum) results obtained for the two substrate mixtures are presented in Figure 5.

Figure 5.

Substrate evolution during biogas production tests in large-scale reactors: (a) pH evolution; (b) Methane production; and (c) Carbon dioxide production.

The pH for the two batches (Figure 5a) started atypically, with values over seven from the first day, because of the initial pH correction, but decreased to appropriate values by days four to five and remained stable until the end of the process. The initial pH correction served as a buffer in order for the material to decrease the initial pH with acid fermentation/CO2 production, which is suitable for cereal materials, and thus, shorten the time to reach correct pH values and decrease the initial period in order to maximize the biogas production time.

Methane production (Figure 5b) started from the first days of the process, reaching a maximum of 78–81% for barley and 74–76% for rye. The materials used in the large-sclae tests showed even greater potential than the first batch.

The CO2 values (Figure 5c) decreased accordingly, showing minimum values of under 20%—this aspect is relevant in order to further reduce the concentration of CO2 with other means and to improve the methane concentration inside the obtained biogas composition

From Table 3, one can observe that the mixture composed of degraded rye and beer factory wastewater from the treatment plant had the highest biogas production potential.

Table 3.

Biogas production in the large-scale installation.

4. Conclusions

A study of the anaerobic digestion of agricultural resources was performed at a mesophilic temperature in batch mode. The results demonstrated that agricultural waste barley mixed with beer factory wastewater is a highly suited substrate for anaerobic digestion processes because of its high potential for generating biogas with high methane content.

The paper quantitatively presents the production of biogas from four mixtures of substrates, without additional inoculum: beer factory wastewater mixed with solid agricultural degraded wastes, rye, barley, corn, and wheat. All tests were conducted at optimal experimental conditions for anaerobic digestion, temperature in the range of 35–40 °C and a pH in the range of 7–7.5. While all four substrate mixtures showed good biogas production potential, the waste rye addition to beer factory wastewater produced a much higher CH4 content of biogas at optimal digestion conditions.

In general, the research conducted showed that beer factory wastewater with the addition of agricultural wastes is a very good feedstock for anaerobic digestion (e.g., for electricity generation) due to the high quality of biogas produced with approximately 76% CH4 content.

The research presented, in the form of anaerobic digestion receipts with no additional inoculums of biogas production from various substrates mixtures based on beer factory waste water and agricultural degraded wastes, could be of interest to the scientific community, not only as an energy saving technology (e.g., in the municipal sector) [31,32] but also as a source of mitigating greenhouse gas emissions [25]. Our findings can also help develop local/regional circular economies, which have both environmental and economic benefits.

Author Contributions

Conceptualization and methodology, A.E.C. and F.P.; experimental analysis, A.E.C., F.P. and T.B.B.; substrates digestion; A.E.C. and T.B.B.; writing—review, all authors; editing, F.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The complete data set can be obtained upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ofoefule, A.U.; Uzodinma, E.O.; Onukwuli, O.D. Comparative study of the effect of different pretreatment methods on biogas yield from water Hyacinth (Eichhornia crassipes). Int. J. Phy. Sci. 2009, 4, 535–539. [Google Scholar]

- Veeken, A.; Kalyuzhnyi, S.; Scharff, H.; Hamelers, B. Effect of pH and VFA on hydrolysis of organic solid waste. J. Environ. Eng. ASCE 2001, 4, 1076–1081. [Google Scholar] [CrossRef]

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Zinder, S.H. Physiological ecology of methanogenesis. In Methanogenesis: Ecology, Physiology, Biochemistry and Genetics; Ferry, J.G., Ed.; Chapman and Hall: New York, NY, USA, 1993; pp. 128–206. [Google Scholar]

- Ahmad, T.; Zhang, D. A critical review of comparative global historical energy consumption and future demand: The story told so far. Energy Rep. 2020, 6, 1973–1991. [Google Scholar] [CrossRef]

- Milewska, B.; Milewski, D. Implications of Increasing Fuel Costs for Supply Chain Strategy. Energies 2022, 15, 6934. [Google Scholar] [CrossRef]

- Li, W.W.; Yu, H.Q.; He, Z. Towards sustainable wastewater treatment by using microbial fuel cells-centered technologies. Energy Environ. Sci. 2013, 7, 911–924. [Google Scholar] [CrossRef]

- Metcalf, E. Wastewater Engineering. Treatment and Reuse, 4th ed.; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Chachuat, B.; Roche, N.; Latifi, M.A. Long-term optimal aeration strategies for small-size alternating activated sludge treatment plants. Chem. Eng. Process. Process Intensif. 2005, 44, 591–604. [Google Scholar] [CrossRef]

- Scherbakov, V.; Gogina, E.; Schukina, T.; Kuznetsova, N.; Makisha, N.; Poupyrev, E. Calculation of biogas facilities for recycling of organic sewage sludge of breeding factories. Int. J. App. Eng. Res. 2015, 10, 44353–44356. [Google Scholar]

- Gogina, E.; Gulshin, I. Simultaneous denitrification and nitrification in the lab-scale oxidation ditch with low C/N ratio. Proc. Eng. 2015, 117, 107–113. [Google Scholar]

- Gogina, E.S.; Ruzhitskaya, O.A.; Yantsen, O.V. Investigation of the processes of nitrification and denitrification in wastewater treatment. Adv. Mat. Res. 2014, 919, 2145–2148. [Google Scholar] [CrossRef]

- Gogina, E.; Makisha, N. Information technologies in view of complex solution of waste water problems. Appl. Mech. Mater. 2014, 587, 636–639. [Google Scholar] [CrossRef]

- Kulakov, A.A.; Lebedeva, E.A. Development of Engineering Solutions concerning Modernization of Wastewater Treatment Facilities Based on Technology Simulation. Wat. Treat. 2011, 12, 10–19. [Google Scholar]

- Makisha, N. Waste water and biogas—Ecology and economy. Proc. Eng. 2016, 165, 1092–1097. [Google Scholar] [CrossRef]

- Den, W.; Sharma, V.K.; Lee, M.; Nadadur, G.; Varma, R.S. Lignocellulosic Biomass Transformations via Greener Oxidative Pretreatment Processes: Access to Energy and Value-Added Chemicals. Front. Chem. 2018, 6, 141. [Google Scholar] [CrossRef]

- European Commission. Eur-Lex COM/2018/773, In-depth analysis in support on the COM(2018) 773. In A Clean Planet for All—European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Kampman, B.; Leguijt, C.; Scholten, T.; Tallat-Kelpsaite, J.; Brückman, R.; Maroulis, G.; Lesschen, J.P.; Meesters, K.; Sikirica, N.; Elbersen, B. Optimal Use of Biogas from Waste Streams. An Assessment of the Potential of Biogas from Digestion in the EU Beyond 2020; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Kamperidou, V.; Terzopoulou, P. Anaerobic Digestion of Lignocellulosic Waste Materials. Sustainability 2021, 13, 12810. [Google Scholar] [CrossRef]

- Erisman, J.W.; van Grinsven, H.; Leip, A.; Mosier, A.; Bleeker, A. Nitrogen and biofuels; an overview of the current state of knowledge. Nutr. Cycl. Agroecosyst. 2010, 86, 211–223. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, F.; Liu, S.; Wang, L.; Qiu, L.; Alexandrov, G.; Jothiprakash, V. Bioenergy production and environmental impacts. Geosci. Lett. 2018, 5, 14. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fári, M. The effect of bioenergy expansion: Food, energy and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health Part. A Toxic Hazard. Subst. Environ. Eng. 2018, 53, 899–906. [Google Scholar] [CrossRef]

- Pierie, F.; van Someren, C.E.J.; Benders, R.M.J.; Bekkering, J.; van Gemert, W.J.T.; Moll, H.C. Environmental and energy system analysis of bio-methane production pathways: A comparison between feedstocks and process optimizations. Appl. Energy 2015, 160, 456–466. [Google Scholar] [CrossRef]

- Admasu, A.; Bogale, W.; Mekonnen, Y.S. Experimental and simulation analysis of biogas production from beverage wastewater sludge for electricity generation. Sci. Rep. 2022, 12, 9107. [Google Scholar] [CrossRef]

- Murphy, J.D.; Thamsiriroj, T. Fundamental science and engineering of the anaerobic digestion process for biogas production. In The Biogas Handbook. Science, Production and Applications; Wellinger, A., Murphy, J., Baxter, D., Eds.; Series in Energy; Woodhead Publishing: Sawston, UK, 2013; pp. 104–130. [Google Scholar] [CrossRef]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The anaerobic digestion of solid organic waste. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A review of sludge-to-energy recovery methods. Energies 2019, 12, 60. [Google Scholar] [CrossRef]

- Sreekrishnan, T.R.; Kohli, S.; Rana, V. Enhancement of biogas production from solid substrates using different techniques—A review. Bioresour. Technol. 2004, 95, 1–10. [Google Scholar] [CrossRef]

- Rosenberg, L.; Kornelius, G. Experimental investigation of biogas production from feedlot cattle manure. J. Energy S. Afr. 2017, 28, 1–8. [Google Scholar] [CrossRef]

- Debowski, M.; Zielinki, M. Wastewater Treatment and Biogas Production: Innovative Technologies, Research and Development Directions. Energies 2022, 15, 2122. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).