Abstract

One of the key areas of the UN’s sustainable development goals is growing affordable and clean energy. Utilizing solar energy that is now accessible will significantly lessen the demand for fossil fuels. Around the world, cooking is a crucial activity for homes and uses a lot of non-renewable energy. Uncontrolled firewood usage results in deforestation, whereas using biomass-related fuels in inefficient stoves can result in smoke emanating from the kitchen and associated health issues. The benefits of solar cooking include reducing smoke-related problems and saving on fossil fuels and firewood. Applying thermal storage systems in cooking helps households have all-day cooking. This review article presents the research and development of a solar cooking system that transfers solar energy into the kitchen and integrates with the thermal energy storage system, finding the factors affecting indoor solar cooking performance. Adding portable cooking utensils helps in improved solar indoor cooking. Multiple phase change materials arranged in cascaded to store thermal energy helps in quick heat transfer rate, thus enabling better and faster cooking. A novel indoor solar cooker with an innovative arrangement of evacuated tube-based compound concentrating parabolic (CPC) collectors with a cascaded latent heat thermal energy storage system is proposed and needs to be tested under actual meteorological conditions.

1. Introduction

It is paramount to develop cooking systems using clean and green energies as fuel prices are soaring and going beyond the reach of developing and underdeveloped nations’ citizens. Fuelwood, charcoal, agricultural leftovers, kerosene, and Liquefied petroleum gas (LPG) fuels are used in underdeveloped countries. Electricity has the highest global warming potential due to emissions from diesel generators. Charcoal has the second most significant effect (225 g CO2 eq./MJ), with the carbonization process accounting for 80% of the total, and the remaining is accounted for by Kerosene and LPG [1]. Many researchers have pointed out that solar energy saves 359 kg of the average mass of wood per household [2], and also the mass of wood saved in each site was estimated at 12 MJ/kg [3]. Solar cooking eliminates smoke-containing carcinogens, and microwaves, exposing food to possible harmful radio waves [4]. Developing a highly efficient and cost-effective system can occur in every kitchen, saving a lot of conventional fuels and a considerable amount of revenue for the country [5]. Solar energy research and development has generally focused on highly technical, capital-intensive uses, leaving small-scale applications untouched [6]. With the increased usage of non-renewable energy sources over the previous half-decade, there is a pressing need to employ energy-saving methods in every family’s cooking. It is pointed out by researchers that a policy for household cooking emphasizing the significance of consumer education, better appliance efficiency programs, and stand-by energy mode regulations, is to be introduced, and biogas and solar energy are to be given equal weight as alternative renewable energy sources [7].

As per the report published by the Ministry of New and Renewable Energy of the Govt. of India, the annual equal energy potential is 6000 million GWh. A massive population of India uses solar energy-based appliances for lighting needs, cooking, and heating. Cooking with solar energy helps to reduce carbon emissions and mitigate the effects of global warming. Researchers are looking for the most efficient materials to collect more solar energy in conventional PV cells or advanced PV cells [8] and solar thermal energy systems [9] to overcome these concomitant restrictions. For the sustainable energy solution, rare earth elements (REEs) can be successfully incorporated into host materials in controlled concentrations to provide competitive advantages for the manufacturing of portable energy devices and to enhance the performance of the solar system, which is of great interest to both industries and research organizations [10]. Solar energy is cheap, plentiful, and valuable for residential and commercial purposes. Cooking consumes a significant amount of energy every day in every household. Due to variables such as cost, efficiency, usability, and the possibility of replacing conventional solar cooking methods, the improvements do not benefit the end user [11]. A single household preparing 350 meals a year using a solar oven for 7–8 months; can save 1000 kWh per year of power [12]. Several solar cooking demonstrations, formations, and practical solar cooking coaching and follow-up are necessary to integrate the solar cooker into everyday user’s life and ensure that everyone understands how to use it. Because solar radiation is intermittent, the researchers delve into heat storage devices in conjunction with solar cookers to broaden their usefulness and reduce world poverty. The storage unit coupled with a solar oven can overcome this disadvantage [13]. It is highlighted in research that cooking habits, daily routine, and performance are essential considerations in the conception and design of an excellent solar cooker for a public health facility. Storage units in solar cookers might help enhance the existing cooking or a hybrid system that provides reliability even during the absence of sunlight [14].

Farooqui et al., developed a vacuum tube-based solar cooking system (SCS) consisting of a Fresnel reflector at a concentration ratio of 15 to 20, which can attain a maximum cooking temperature of 250 °C. The cooking chamber fitted at the end of the vacuum tube was filled with thermal fluid, and natural thermal siphoning allowed the thermal fluid to go back in between the cooking chamber and the vacuum tube. The exergy efficiency as a function of load, with a trend toward gradual growth as load increases. The cooker’s energy efficiency is substantially greater than its energy efficiency. Maximum exergy efficiency was maintained between 2.3 and 3.8%, and maximum exergy efficiency was between 20 and 25% [15]. Compound parabolic concentrating (CPC) collectors are used in evacuated tube solar collectors to collect solar radiation; due to their distinctive ability to capture diffused solar rays without tracking mechanism at low to moderate concentration, minimal heat loss, and higher collector efficiency. For solar radiation transfer into the storage medium and to the indoor cooking unit, CPC collectors are attractive to downstream temperature requirements from 60 to 240 °C that can be utilized for cooking applications [16]. Khatri et al., have presented the sustainable development of the solar cooker, applications of nanofluid, geometrical modifications, technological modification, and integration of the solar cooker. A major challenge faced was to modify the cooker to become more practical and less weather dependent. Energy economics is the most significant issue frequently ignored in research. If the SCS is not more cost-effective than the current one, it will never become the primary source of energy for cooking. TES media stands out for improving the effectiveness of solar cookers since it solves the primary issue, cooking during times when there is not sunlight.

A concentrator solar cooker using a cardboard box for humanitarian supplies by manually bonding an aluminum film with a reflectivity of 98% was developed using concentrating collectors in high-temperature applications [17]. Thermal storage integrated cooking units help keep the food warm for an extended period and help in having a higher working fluid temperature [18]. Using twelve cylindrical copper tubes filled with different thermal storage materials placed in the SBC, these researchers reached a higher temperature during natural convection because they directly contacted solar radiation. Conduction occurred from the sidewalls and the absorber plate [19]. Several PCM’s problems were reviewed and analyzed, and the solution is provided by increasing the solar energy utilization process using PCM to minimize heat losses, improve the heat transfer rate, and enhance storage of the solar thermal system in research work. Incorporating PCM in energy storage TES has increased heat storage capacity. The PCMs melt and solidify at a relatively constant temperature and minimize the system’s heat losses during the charging and discharging of heat [20].

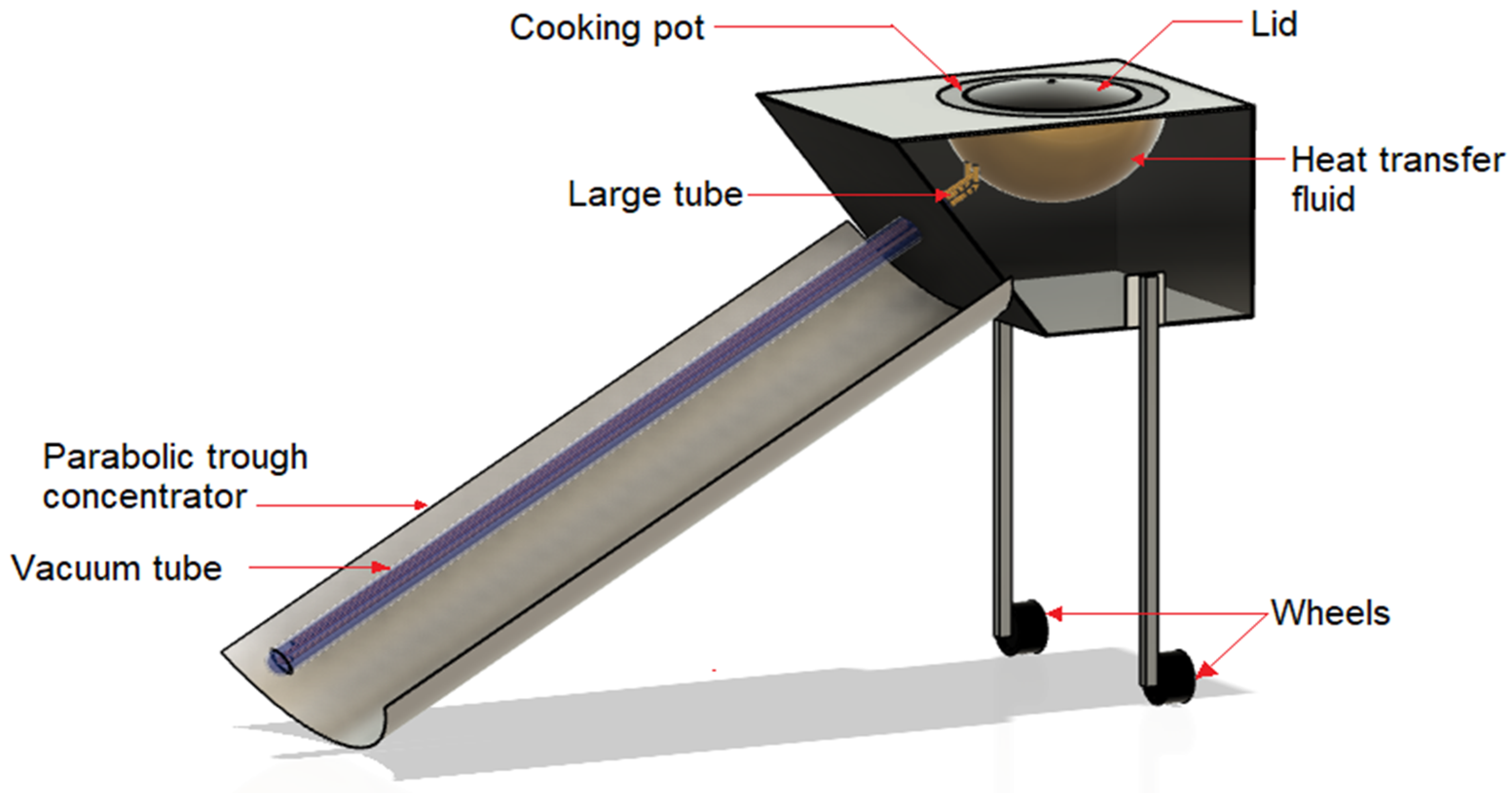

Omara et al., discussed solar cookers’ performance with PCMs, which could improve by 85% of the overall utilization efficiency of SC and reduce the heating time by up to 15% [21]. A novel design with the zero-emission cooking device using an evacuated tube-based SCS is developed and tested in research work. The evacuated glass tube minimizes heat loss to the environment by reducing cooking time. Using heat transfer fluid (HTF), heat transfer from the evacuated tube solar collector by thermosyphon cyclic effect heat transfer to the PCM-based cooking unit and then utilized for cooking [22]. Chaudhary and Yadav presented a twin-vessel cooking stove using HTF heat transfer from the evacuated tube solar collector to the cooking stove. The simultaneous cooking of two different culinary materials in two different vessels. A household of 5–6 people may have two meals prepared twice daily using this twin-vessel cooking setup. The maximum value of HTF’s instantaneous energy and the average temperature is 386.93 kJ and 130.35 °C, respectively [23].

Solar cookers have improved in performance in recent years. Several attempts to permit cooking indoors and away from the sun included adding thermal energy storage (TES) to solar cookers. No-cook relishes cooking while standing in the bright sun. As a result, to cook indoors, solar energy must be brought in. Compared to direct solar cookers, indirect solar cookers are more expensive. Nevertheless, they have several benefits, including the capacity to cook indoors or in conventional kitchens inside a building, high thermal output, and temperature with fewer monitoring devices [24]. Stumpf et al., modeled a single and double-stage heat pipe-based solar flat plate collector for the higher temperature requirement in the SCS. The advantages of the conceptual design are increasing the very high thermal conductance while using a double-stage heat pipe flat plate collector that increases the flexibility of the system and the distance of placing the cooking oven; so that cooking can be performed inside the kitchen without tracking and attains the maximum thermal power output while preheating the cooking oven [25]. Storage of solar energy is required to supply varying demands at different times. The most suitable approach for TES is Latent heat storage (LHS) in PCMs due to their high latent heat. The high storage density minimizes the system’s volume, higher latent fusion, and high specific heat improves energy storage density [26]. Raj et al., designed and developed a household solarized cooking system using a receiver heat exchanger for the Scheffler dish with a 2.7 m2 aperture area. The Receiver Heat Exchanger’s (RHX) receiving face was painted black and intentionally roughened to absorb as much concentrated solar energy as possible. The heat exchanger housing contains thermic fluid used as a heat transfer medium to the cooking stove. The receiver attains the maximum temperature of 100 °C within 100 min. A straight vertical fin attached at the back of the RHX enhances heat transfer from the receiver to the HTF [27]. PCMs increase the latent thermal energy system’s capability for storing energy and keep the PCM’s heat flow steady. Multiple PCM models perform better in terms of latent energy storage as compared to single PCM ones. A practically constant HTF exit temperature may be attained using numerous PCMs. It was discovered that cascading a sufficient number of PCMs with a good melting point might significantly improve LTES’s energy efficiency. When three or five different PCMs are utilized in place of a single PCM, the exergy efficiency of an LTES system can be increased by two or even three times [28].

This review article presents the indoor solar cooking development through which the thermal performance of the indoor solar cooking system (ISCS) was evaluated. At the same time, evaluating the temperature required for the cooking process, the collector area required for the ISCS, and the optical performance of the solar cooker to determine the necessity to improve the design of the ISCS. While incorporating a TES system into the indirect or ISCS, the effect of sensible and latent heat storage material was evaluated through several research articles. The main finding was incorporating multiple PCM cascaded arrangements of PCM in LHTES for the indoor solar cooking system application. A modular solar indoor cooking system is proposed using an evacuated tube-based compound parabolic concentrating collector with a cascaded PCM-based LHTES system.

2. History of Indoor Solar Cooking System and Development

The worldwide acceptance of solar cookers must meet specific requirements for the social conditions: cost and performance. The following goals must be met for an SCS to be accepted and used by most homes. The cooking takes place within the kitchen, minimizing the utilization of traditional energy sources, the cooking process must be carried out at any time, and cooking time should be equivalent to that of traditional cooking. Many researchers designed and developed various indoor or indirect solar cooking systems. The outline of the performance of indoor solar cooking is the transfer of solar energy into the kitchen. Over the past few years, research on indirect-type cooker prototypes has produced a range of technologies. In the indirect versions, the cooking chamber is retained inside the kitchen while the collector is kept outside. The conventional solar cooker (CSC), such as a box-type solar cooker (BTSC), takes a short time during the morning to prepare lunch. The drawback of using the cooker is that it does not attain the maximum temperature for cooking and can be used only during the day. One of the critical factors leading to the CSC is the indoor solar cooker or indirect solar cooker, which consists of a heat transfer medium to transfer heat to the cooking utensil. The ISCS can provide high thermal power at high temperatures without tracking the solar collector. With the intermittent nature of solar energy, there is no sunlight at night, with the potential for using TES for cooking during non-sunshine hours. Another crucial necessity for the optimal operation of the SCS is an appropriate rapid and efficient cooking unit. The indoor solar cooker is incorporated with a TES system that may be used to cook lunch and dinner and can retain the heat of a meal during the night and the following day. This history of indoor cooking demonstrates that stage by stage, from solar box-type cooking to concentrating type and with and without a TES system, the objective of the indoor solar cooker is that solar heat energy is transported into the kitchen unit [29]. Two indirect SCS options are available: single-stage and double-stage modes based on heat transfer. In the single-stage mode, heat is transferred directly from the solar collector to the cooking pot. In double-stage mode, heat transfer operates by charging and discharging. During the charging phase, heat is transferred from HTF to the storage tank, and then during the discharging phase, the stored energy is transferred to the cooking process.

Khalifa et al., developed an indoor solar cooker that physically separates the cooking pot from the collector and incorporates a heat pipe-based solar collector. The acetone-filled heat pipe evaporator section was placed in the flat plate collector to become heated up and transfer to the condenser inside the cooking chamber. This cooking system can boil water for 135 min. These researchers have recorded that the efficiency of the heat pipe is twice that of the steam cooker. Using a heat pipe in the indoor solar cooker doesn’t require a tracking system and is simple to operate and maintain [2]. Ramadan et al., presented a model by incorporating locally available sensible heat storage (SHS) material to store the heat at a higher temperature for cooking later in the evening. The portable cooking pot cover is welded with an absorber plate to achieve maximum heat through conduction, and the SHS material is stored inside the cooking utensil. The absorber plate with the cooking utensil placed inside the BTSC attains the maximum temperature of 100 °C at 6 h using a different mass of water [30]. Olwi et al., have presented a model with multiple glazing over the heat pipe-based solar collector that reduces the thermal loss used for the ISCS. It enhances thermal performance while using water to be heated up. They observed high contact resistance between the condenser pipe and the cooking pot in the stove-type oven. It was minimized by adding water to the condenser plate to form a pool-type heater, reducing the thermal resistance between the contact point of the cooking utensil over the condenser plate [31]. An indoor solar cooking unit was developed using a concentrating solar collector with a short-term TES system. The solar radiation was concentrated through a wall hole using a secondary reflector inside the kitchen, redirecting the radiation to the bottom of the storage-based cooking oven. Concentrated solar radiation charges the solid storage at a steady pace using granite and cast-iron solid storage blocks through the open focal cavity. The solid blocks’ maximum temperatures are 570 and 430 °C, respectively. Due to the increased conductivity of cast iron, the heat flow rate of the pot in the cast iron storage system is faster than the granite storage system. The storage height-to-diameter ratio shouldn’t be less than 0.2, according to the shape factor that affects the storage system’s performance [32].

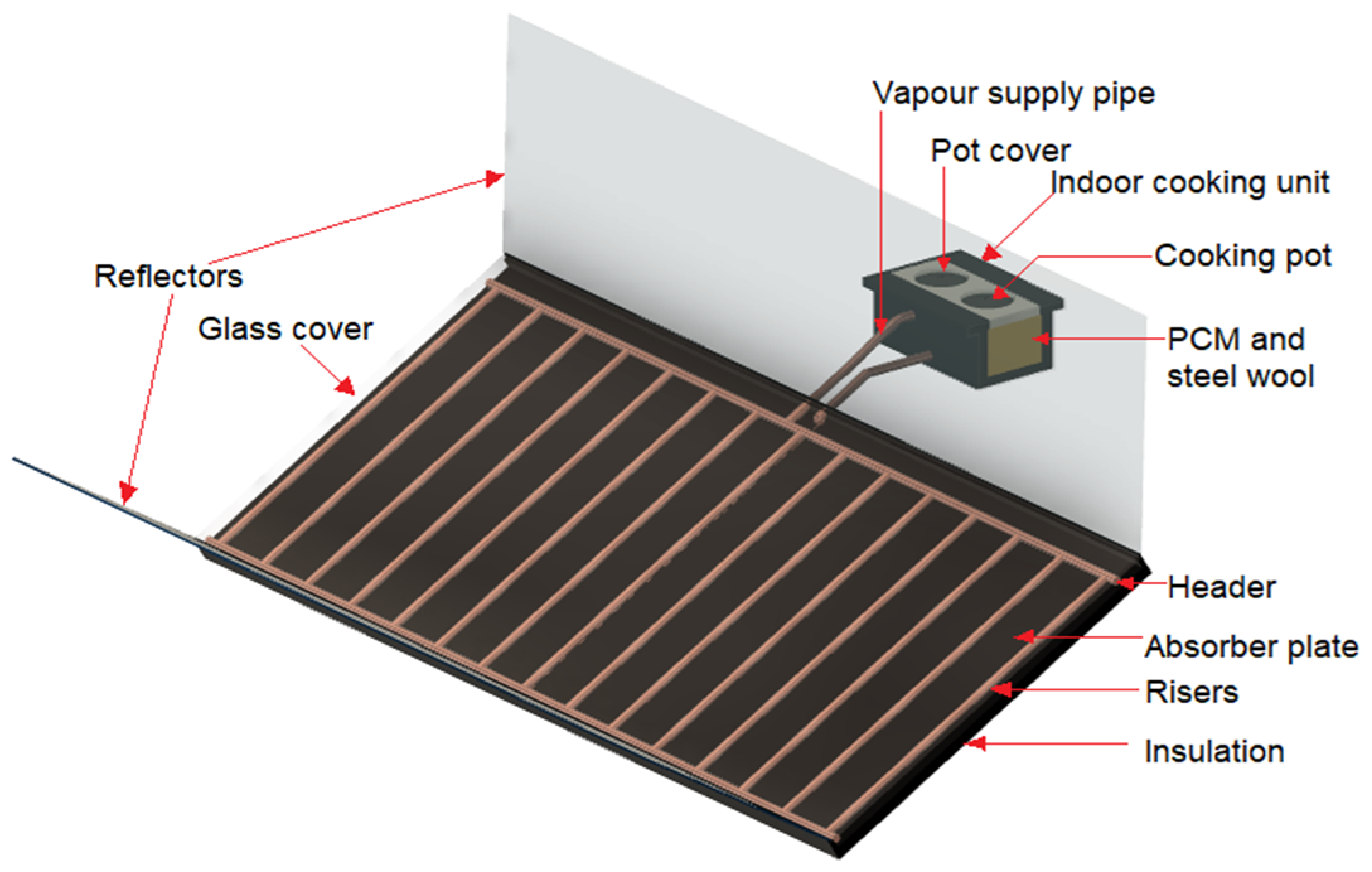

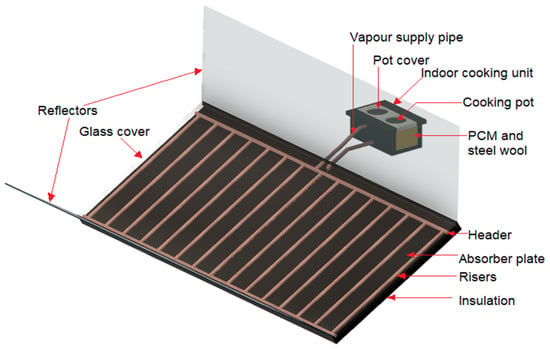

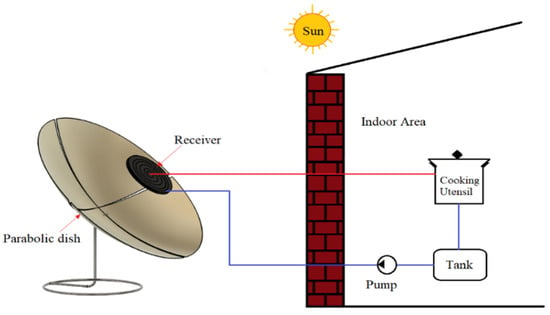

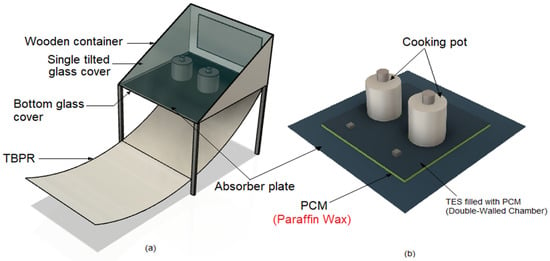

During cloudy days heat transfer from the evacuated collector tube to the cooking system should be effective using refrigerants or phase change fluids and the experimental setup integrated with a heat pipe. The water was loaded and tested to reach maximum temperature during the sunshine hours during the testing process. During this test period, it attained a maximum temperature of 97 °C. During the cooking experiments, the oven plate had to be preheated to 172 °C, and the oil temperature reached a maximum of 175 °C. Three different refrigerants, R22, R134a, and R1407c, were used to evaluate the cooking system, and cooking experiments were performed. Among the refrigerants, R 407c gives a shorter cooking time because of its lower boiling point and higher latent heat [33]. Sharma et al., have also developed an evacuated tube-based solar cooker (ETSC) using erythritol as PCM in the double-wall cooking unit. Here water is used as HTF, heated up from the ETSC, and heat is transferred to the PCM. Cooking experiments were conducted at a different flow rate of HTF without and with loading conditions to evaluate the performance of the solar cooker. Without tracking the ETSC, the PCM attains maximum temperature and allows cooking inside the building [34]. Hussein et al., developed a solar flat plate cooking system with a wickless heat pipe and added an indoor cooking unit composed of two cooking pots incorporated with the TES system shown in Figure 1 MNH used as PCM with steel wool. The wickless heat pipe network’s evaporator is included outside the flat plate solar collector. The heat pipe condenser section inserted inside the PCM-based cooking unit is made as a helical coil network of a closed-loop area. The distilled water filled with this degassed loop section has been evacuated with a 15% liquid filling ratio. By incorporating a wickless heat pipe thermal conductivity of the absorber plate was enhanced [35].

Figure 1.

Wickless heat pipes flat solar plate collector with an indoor cooking unit. Reprinted/adapted with permission from (2008), Hussein et al. [35].

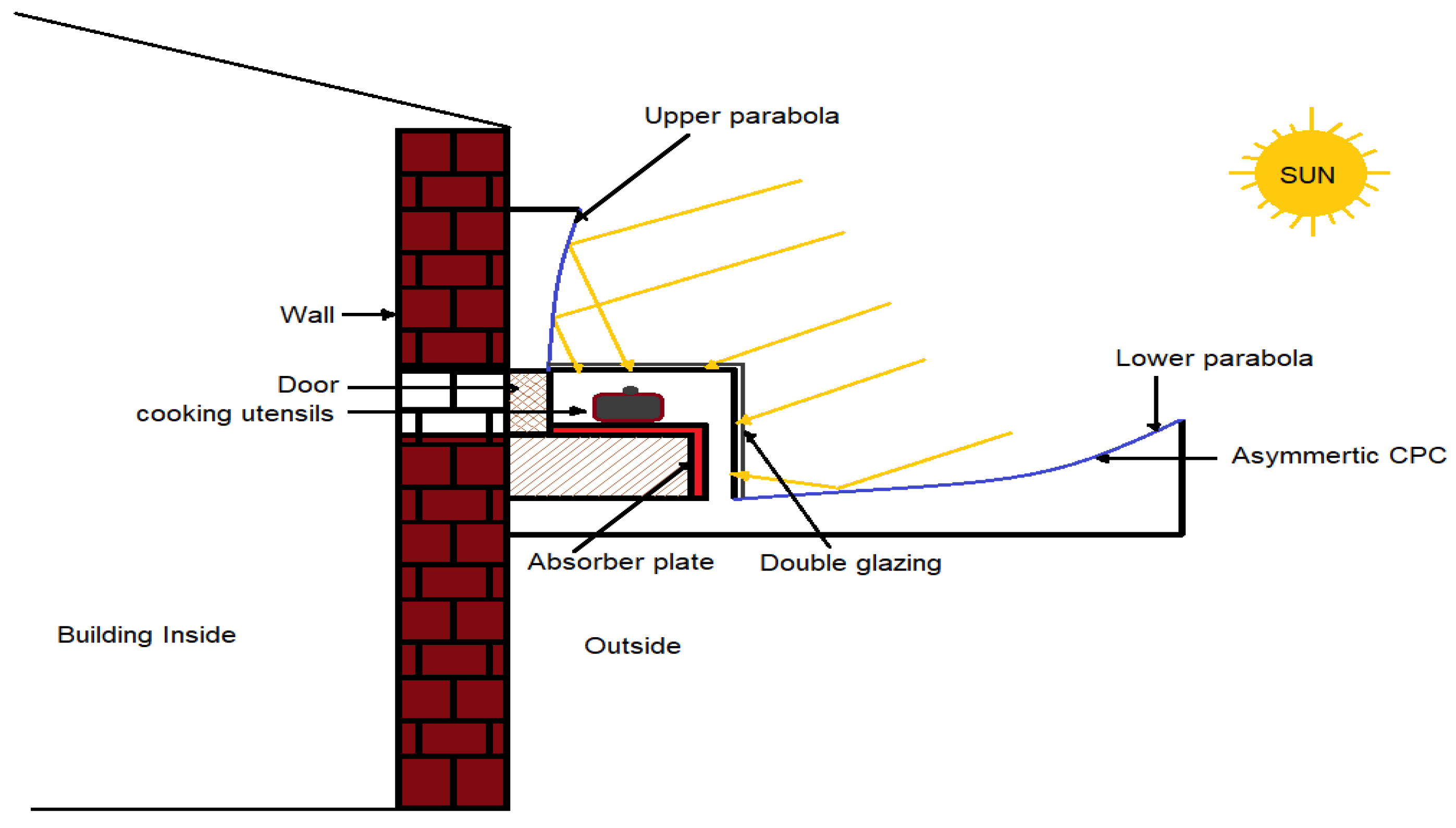

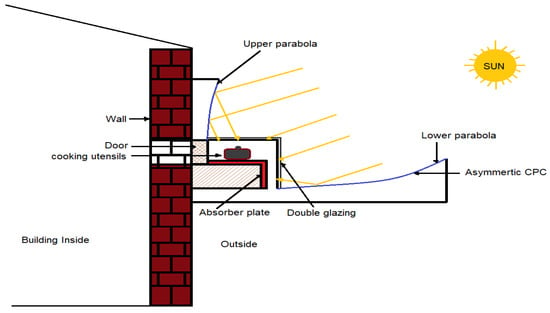

Sharma et al., reviewed a few solar cookers with the LHS system and developed a parabolic solar cooker (PSC) with the LHTES system to attain a maximum temperature of 250 °C. The variation of angle incident from the HTF column to the SK 14 parabolic solar collector, the cooking time was measured, and the optimized angle of the incident. While using sodium acetate as a PCM in the LHTES during discharge, cooking experiments were conducted. At a 45° angle of incident, the cooking time is minimum [36]. An indirect parabolic dish cooker with an oil/pebble-bed TES system was developed by Mawire et al. The simulation model developed using numerical integration of the Runge Kutta method was solved for the TES system. From discharging at a constant flow rate from the storage system, water and oil temperatures dropped quickly due to a high rate of energy extraction [37]. Prasanna and Umanand proposed a hybrid model, using the conventional LPG or electrical heater as an auxiliary source based on the cooking load requirement. The hybrid system’s efficiency is based on the solar collector and the pump. Two contradicting effects that optimize the pipe diameter to give the system are heat loss to ambient and pumping power required to circulate the fluid. The method of transferring solar heat involves two steps: first, energy from the collector is transferred to a storage buffer for intermediate energy, then transmitted from the buffer to the cooking load. Cooking may be performed at any time and takes about the same time as traditional methods [38]. Harmim et al., built a modified BTSC that integrated the building, as shown in Figure 2, with an asymmetric CPC, producing a maximum temperature of 165 °C [39]. Tesfay, Kahsay, and Nydal developed an indirect solar stove to cook traditional food injera for Ethiopians using a parabolic dish collector with an area of 2.54 m2. Baking injera requires a temperature range from 135 to 220 °C to obtain good quality bread. The heat transmission mechanism between the receiver and the stove has been controlled using natural circulation boiling-condensation. During the stagnation test, the maximum stagnation temperature achieved was 255 °C, and the stove temperature was 175 °C [40].

Figure 2.

Building integrated solar cooker. Reprinted/adapted with permission from (2013) Harmim et al. [39].

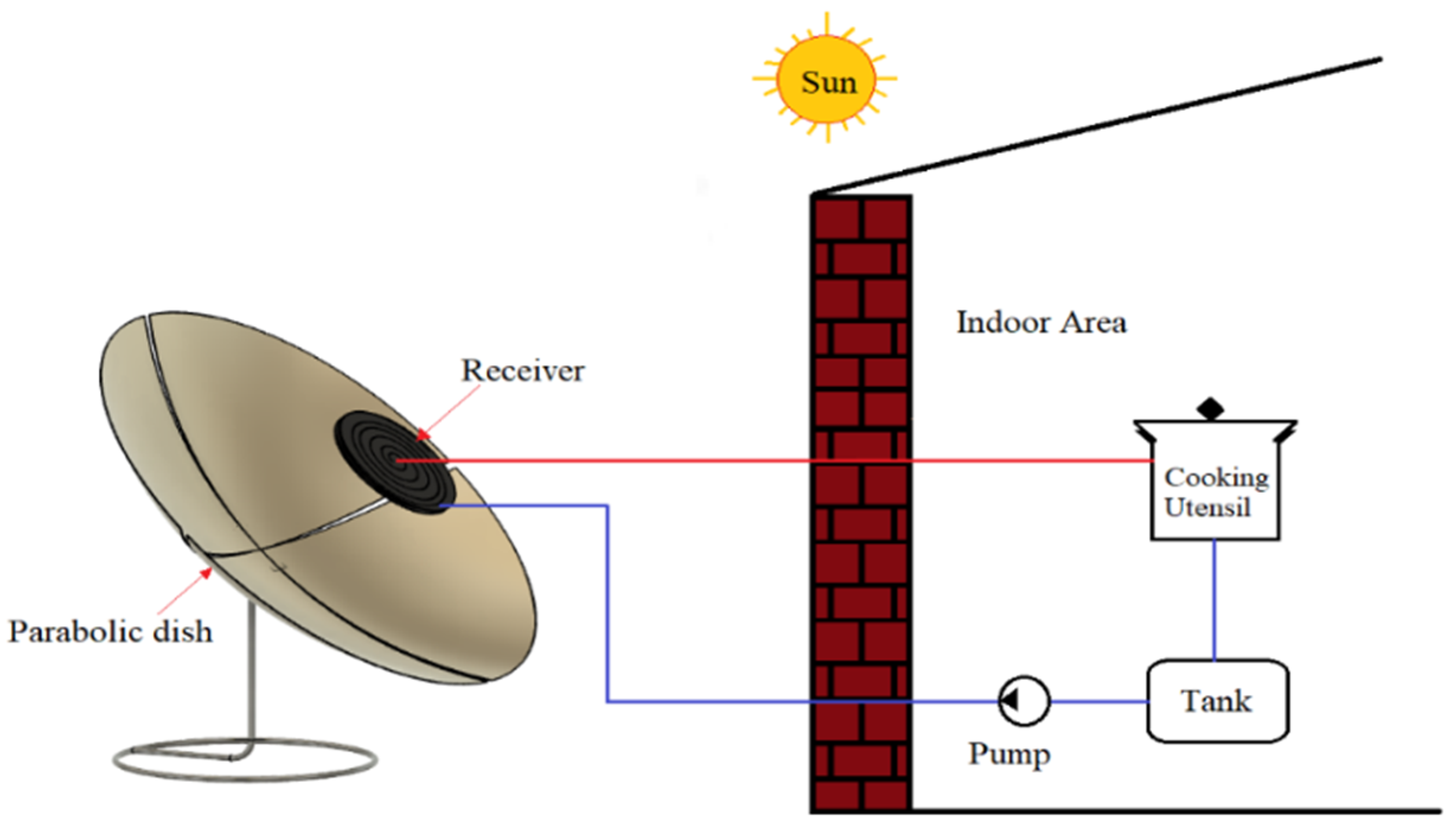

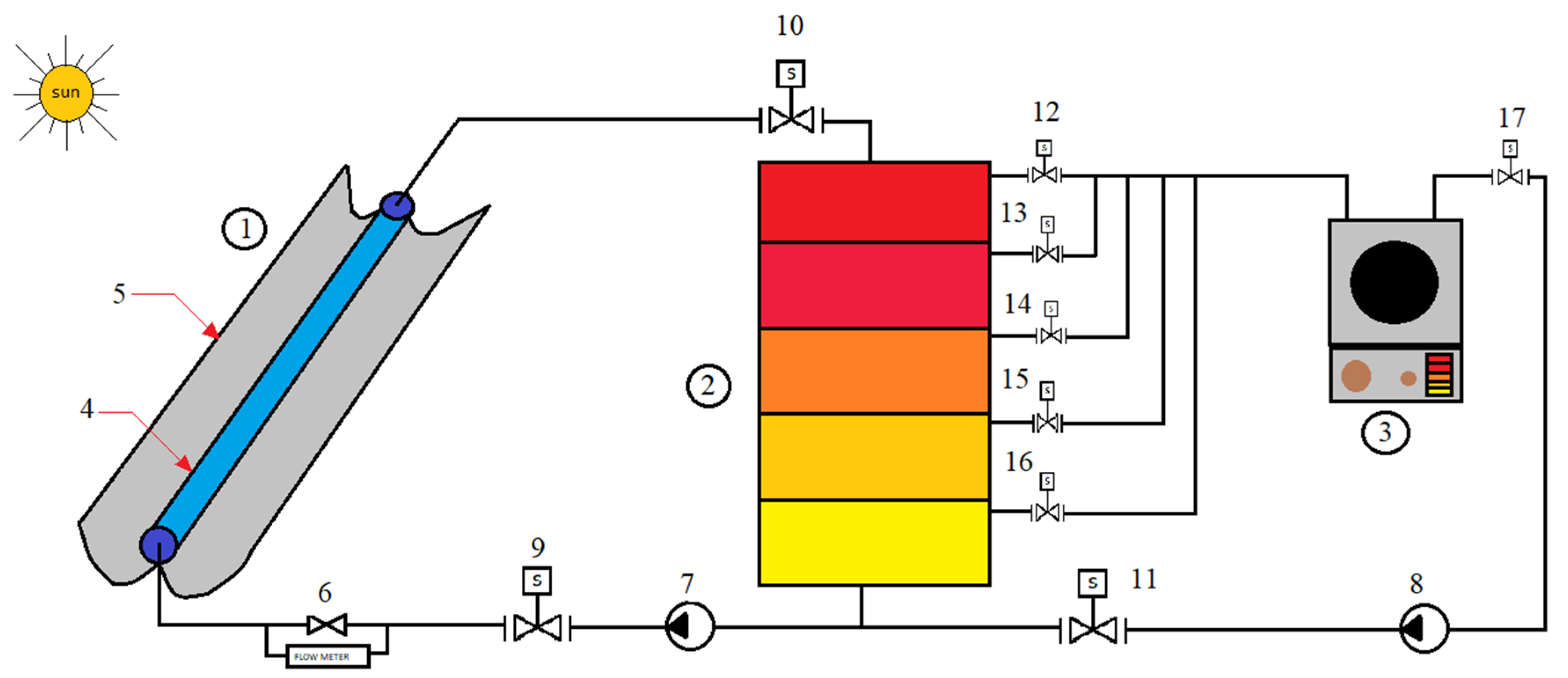

The charging performance of the solar cooker with an oil-based TES system was evaluated using energy and exergy analysis. The maximum average storage tank temperature was reached during low-power charging at a flow rate of 4.2 mL/s. Exergy factors characterize the TES system’s behavior better than energy storage efficiency [41]. Craig and Dobson developed a PSC with an SHS system that incorporated the spiral-type hot plate heat pipe and heat pipe plate to transfer heat from the storage tank to the cooking unit. The spiral-type heat pipe base system initially requires a pump to attain the maximum temperature; after that, it can control the flow rate of the heat transfer oil and the heat flow to the cooking unit [42]. Mbodji and Hajji developed a thermodynamic model using several thermal resistances for accounting for the heat transfer between various sections of a parabolic solar cooking system (PSCS). From the obtained convergence numerical solution, the theoretical fluid temperature at the upper part of the receiver reaches 153 °C in five hours. The bottom part of the receiver reached 150 °C after one hour of heating [43]. Kumaresan et al., developed an indoor solar cooking system using a flat plate cooking stove. Thermal energy is extracted from a solar parabolic collector or an LHTES system (see Figure 3).

Figure 3.

An indoor cooking system with a parabolic dish collector. Reprinted/adapted with permission from (2021) Hosseinzadeh et al. [29].

The heat transfer characteristics of the double-wall cooking unit and the overall system performance and efficiency of cooking units are evaluated using CFD and experimental analysis. In the FPCU, the average heat transmission rate is around 0.6 kW. They used D-Mannitol as the PCM, which gives a higher heat supply to the FPCU for a more extended period [44]. Kajumba et al., developed a cooking unit integrated with a TES system using hot sunflower oil as a storage and HTF transfer from the storage tank to the cooking unit; the flow was controlled by manual value, and HTF flow from the tank to the cooking unit was by gravity. They varied the flow rate of HTF to 4 mL/s, 6 mL/s, and 12 mL/s, increasing the water temperature and thereby decreasing cooking time. The two liters of water took 32 min to reach the boiling temperature of 95 °C at a constant flow rate. By increasing the mass flow rate, the average heat transfer coefficient of 120 W/m2 K, with efficient heat transfer, is made between the direct contact of the cooking pot and the flowing hot oil. The manual valve allows the users to modify the flow rate and manage the heating pace to meet the demands of a specific cuisine [45]. An indoor cooking system with a solar parabolic dish collector shown in Figure 3, with a CR of 32.55, was designed and studied by Hosseinzadeh et al., Increasing the mass fraction of the nanoparticle in the HTF enhances the cooking unit’s output thermal exergy rate of 10.71 W, 14.71 W, and 17.71 W and total energy efficiency of 12.85%, 15.93%, and 20.08%, using thermal oil, 0.2% and 0.5% of MWCNT nanofluids respectively [29]. Singh has pointed out that controlled cooking is possible inside the kitchen using the SCS by placing a heater plate to transfer heat from the solar collector. The HTF temperature rises from 34.2 to 100 °C within 55 min. The maximum energy and exergy efficiencies are 21.0119% and 1.955% at 9.45 h after 45 min of heating and 9.50 h after 50 min of heating, respectively [46].

In the preceding history analyses from 1985, the performance of ISCSs represents a promising start for functional, cutting-edge solar energy technology. Every household can access solar cooking by connecting pipes to rooftops, which can be utilized to mount the cooking unit. The indirect solar cooking system satisfies the necessary thermal and technological requirements, including efficiency, simplicity of use, modularity, relatively low maintenance costs, and extended lifespan. Due to the separation of the collecting section and stove unit, they offer excellent thermal power and higher temperatures without tracking and permit cooking in the shade or even in typical kitchens. Incorporating TES in the ISCS is that cooking can also occur during non-sunshine hours. Cooking power can be effectively controlled by the flow rate of HTF flow from the TES system to the cooking pot. The small flow rate can sufficiently maintain heat and keep the food warm during the simmering process. The ideas put forward in this review might be used in various contexts, such as residences solar thermal collection and usage for solar cooking and water heating for households in suburban and rural settings. Several modules might produce large amounts of heat for food processing and industrial cooking.

3. The Parameter Which Affects the Development of ISC

The weather conditions, such as solar radiation and wind, affect the development of ISC depending on the testing locations. The optical properties of materials are reflectivity, absorptivity, and emissivity. The design parameters of the solar cooker aperture area, absorber plate area, insulation thickness, glazing thickness, etc. the operating parameters can all have a significant impact on the performance of the indoor solar cooker. This section reviews the temperature requirement for the cooking medium and their supportable SCS, the effect of the solar collector area for indoor cooking, and the optical performance of the solar cooker.

3.1. Temperature Requirement

The four main cooking techniques may be categorized into four groups based on the cooking temperature and cooking media. These include baking, roasting, frying, and boiling. About 4.2 kJ/kg °C of energy is needed to obtain the food to cooking temperature due to the high-water content in most meals. High temperatures (over 200 °C) are needed for successful grilling, frying, and baking. The boiling point of oil, between 200 and 300 °C, determines how much one can cook. Since frying uses a lot of power, cooking is often finished quickly. After the cooking temperature is reached, the cooking speed may be almost entirely independent of the heat input rate as long as the thermal energy supply meets the thermal losses from the utensils.

A BTSC’s usable energy production would be influenced by several factors, including the aperture area, the amount of solar insolation, and the kind and quantity of meals cooked. The first group of procedures (boiling) is the only one for which a BTSC is appropriate [47]. The evaluation of BTSCs is summarized in Table 1, along with significant findings and observations on different aspects of the same report. Significant improvements in many important factors such as cooker geometry, glazing system, utensils design, storage system, and booster mirrors of the SBC have occurred till now. The modified box cookers are simple to construct, portable to use, require very little maintenance, and easy to clean and cook at low temperatures. The performance of the SBC in low ambient temperatures and the maximum plate temperature attained was from 101 to 155 °C. Most solar box-type cookers parameters were found to meet international standards. The modified solar cooker produces cooking power ranging from 53 W to 222 W. The modified oven could deliver satisfactory thermal and cooking performance at all levels. The thermal performance parameter increases by adding interior and exterior reflectors, changing the shape to a truncated pyramid and trapezoidal shape, and adding a booster mirror and magnifying glass in the BTSC. Various heat transfer mechanisms are introduced in the modified solar box-type cooker.

Enhancing the heat transfer in the absorber plate using the forced convection method, adding fins and black paint coating over the absorber plate by adding sensible and LHS material. The modified cooking vessel also improves heat transfer by adding fins outside the cooking utensil, finned aluminum vessels, black paint coating, hollow cylindrical vessels, and PCM-containing vessels. Increasing vessel area decreases the day and night cooking time.

ASAE developed a standardized measure of the thermal performance of household solar cookers. The parabolic solar cooker heated water the fastest and carried more water among the three types: box-type cooker, solar panel cooker, and solar concentrating cooker [48]. Parabolic Trough Concentric (PTC) solar collector produced a maximum water temperature in the receiver pipe with an ambient temperature of 31 °C and solar radiation of 927 W/m2. India’s typical family dinner cooking requirement is 1.4 MJ of final energy. The sensible heat added to the food to raise the internal temperature, a small amount of heat necessary for the culinary transformation, and heat losses throughout the time needed for both processes make up the heat needed for cooking [49]. Table 2 summarizes solar concentrating cookers that reach maximum temperatures of over 450 °C. It has a wide variety of applications. A concentrated collector is beneficial because it has better thermal efficiency since the receiver has a comparatively small area per unit of solar energy gathered. It considerably lowers heat loss and other expenses related to vacuum insulation and selective surface treatment. The major disadvantages of solar concentrating collectors are the need for a tracking system and collecting the diffused insolation at a higher CR. Pranesh et al., have presented several benefits of employing a stationary CPC solar collector. CPC collectors can achieve a view area for a given geometric concentration; a considerable amount of diffused radiation is gathered by the CPC without a tracking mechanism. Evacuated tube-based CPC solar collectors increase the quantity of solar energy collected due to the absence of a tracking device. The CPC may be less expensive than the PTC for reaching maximum temperatures and gathering diffused radiation [16].

Table 1.

A summary of the studies for Solar box-type Cooker.

Table 1.

A summary of the studies for Solar box-type Cooker.

| Reference | Type of Study | Solar Cooker Design | F1 (m2 °C/W) | F2 (m2 °C/W) | Max Tp and Tw (°C) | Highlights |

|---|---|---|---|---|---|---|

| Mahavar et al. [50] | Theoretical expression and experimental evaluation | Single family solar cooker | 0.116 | 0.401 to 0.512 | - | (1) Optimum load range specifies the load levels a cooker should ideally provide for acceptable thermal and cooking performance. (2) The optimum load range of a single-family solar cooker has been evaluated to be between 1.2 and 1.6 kg. |

| Saxena and Agarwal [51] | Experimental | Hybrid SBC | 0.12 | 0.46 | 117 & 92.7 | (1) A 200 W halogen lamp enhances heat transfer by forced convection inside the SBC. (2) 450 tiny copper hollow balls were employed to increase the thermal performance, particularly in forced convection mode. The maximum efficiency is 45.11%. |

| Farooqui 2013 [52] | Experimental | SBC | 0.1258 | 0.369 | - | It has developed a solar tracking system that needs tracking energy extracted from a spring linked to a water container, which stores potential energy. |

| Farooqui 2015a [53] | Experimental | SBC | - | - | - | (1) Box-type cookers with an aspect ratio of at least 2.66 can run without solar tracking for at least six hours a day. (2) As the aspect ratio of the solar cooker increases, the specific heat loss coefficient drops. At the same time, both peak exergy gains and exergy loss at peak exergy gain rise. |

| Zamani, Moghiman, and Kianifar [54] | Experimental | SBC | - | - | 111.8 | (1) Adjustable flat mirrors are positioned on a parabolic curved substrate in double-exposure BTSC, and the solar radiation is concentrated at the bottom of the absorber plate. (2) The overall efficiency increases up to 35.5%. |

| Sethi, Pal, and Sumathy [55] | Experimental | SBC | 0.16 | 0.54 | 125 & 95 | The inclined cooker’s parallelepiped-shaped cooking vessel took 37% less time to boil water and had 40% higher cooking power. |

| Nayak et al. [56] | Computational approach | Trapezoidal solar cooker | - | - | - | (1) The trapezoidal-shaped solar cooker was analysed using a computational platform it mainly focused on heat loss analysis. (2) According to the setup, the solar cooker gets both direct and diffuse solar radiation. The absorber plate is selectively coated to maximize heat absorption and minimize heat loss. (3) For various parametric changes, natural convection contributes 20–30% of total heat losses. |

| Khallaf et al. [57] | Mathematical modelling | Quonset solar cooker | 0.0657 to 0.079 | 0.76/4 kg of water and 2.03/4 kg of glycerine | 134.2 | (1) The dome-shaped polymeric glazing of the cooker is transparent, lightweight, and long-lasting. With internal reflectors, the cooker shell is separated into two cooking sections. (2) The fluid’s efficiency rises as the fluid’s mass grows due to the fluid’s greater heat capacity. Water and glycerine can be used as cooking fluids in the suggested solar cooker, ranging from 6 to 35% to 9 to 92%, respectively. (3) The cooker Opto-thermal Ratio value, while heating water, is 0.093 ± 0.005, and heating glycerine is 0.087 ± 0.003. |

| Harmim et al. [58] | Experimental | SBC with asymmetric CPC | 0.1681 | 0.35 | 140.5 & 100 | (1) Asymmetric CPC reflector allows the cooker to be used in a stationary position. (2) The cooking pots in the current cooker are not immediately exposed to intense solar radiation, limiting the oven’s effectiveness. |

| Harmim et al. [39] | Experimental | SBC with asymmetric CPC | 0.152 | 0.470 | 166 | (1) As a booster-reflector, a fixed asymmetric CPC is used, and its absorber plate is in the shape of stairs. (2) The standard cooking power is 78 W. |

| Soria-Verdugo [3] | Experimental and simulation | SBC | - | - | - | (1) Based on solar radiation and exterior temperature, a heat transfer model for the performance of an SBC was developed. (2) The average energy delivered to food was 1.22 kWh. |

| Guidara et al. [59] | Numerical study and experimental investigation | SBC | 0.14 | 0.39 | 133.6 & 96 | (1) The solar cooker’s optical efficiency was increased using four exterior reflectors. (2) It permits a gain of 64.3% of the maximum absorber plate’s temperature. (3) The difference between experimental and computed values is less than 4% for all component temperatures, indicating that the mathematical model is accurate. |

| Ghosh, Biswas, and Neogi [60] | Experimental | SBC | 0.004 (km2/W) | - | - | Radiative heat loss is reduced when a cooker box with a low-efficient indium oxide glass cover is used instead of an uncoated Soda Lime Silicate glass cover. |

| Chatelain et al. [61] | Nodal modelling | SBC | 0.15 | 0.315 | - | (1) The ULOG is a typical solar oven with double glass. Its walls are made of a timber framework stuffed with around 5 cm of bulk sheep wool. A thin black aluminium foil is used to cover the inside walls. (2) The model predicts the cooking vessel’s temperature with an average relative error of roughly 5%. (3) This supports the primary hypothesis that solar cooking is appropriate for distant locations, such as high-altitude locales. |

| Siddique et al. [62] | Experimental | SBC-dryer unit | 0.11 | 0.303 | 120 | The drying efficiency appears relatively low while cooking simultaneously. |

| Engoor et al. [63] | Experimental | SBC | 0.12 | 0.45 | 113.6 & 95 | (1) Fresnel lens magnifiers have significantly increased heat transmission to the vessel’s contents. (2) Using Fresnel lens magnifier glass, the SBC’s efficiency rose by 8.24%. |

| Vengadesan and Senthil [64] | Experimental | SBC | 0.1202 | 0.4654 | 138 & 102 | Aluminium finned cooking vessels directly transferred heat from the fin to water with a higher heat transfer coefficient. |

| Saxena et al. [19] | Experimental | SBC-LHTES | 0.13 | 0.37 | 101 & 83 | (1) Granular carbon powder was used as an SHS material, paraffin wax was used as an LHS material, and both heat storage materials were evaluated as high-capacity heat storage media. (2) The maximum thermal efficiency is 53.41% using composite heat storage material in SBC. (3) The heat transfer coefficient of SBC is 56.78 W/m2 °C, and overall heat loss coefficient is 5.11 W/m2 °C, and the cooking power is 68.81 W. |

3.2. Effects of Solar Collector Area for Indoor Solar Cooking

The solar intercept area, total heat loss coefficient, and thermal conductivity of the absorber plate are three controllable factors that may be used to determine the cooking capacity of a solar cooker. The insolation, temperature differential, and load distribution are three uncontrolled variables [65]. As per the ISI standard, the thermal performance of the solar box-type cooker is evaluated based on the two figures of merits F1 and F2; they provide a benchmark of each merit for F1 values that should not be less than 0.12, F2 values should be greater than 0.40. Based on the benchmark values, the solar cookers are classified as Grade A only if the F1 value is higher than 0.12 or otherwise, and it is classified as Grade B. The importance of the first and second figures of merits are compared with other box-type solar cookers in Table 1. The Majority of the BTSC absorber plate area of 0.49 × 0.54 m2 is made up of copper plate at a thickness of 0.002 m used for absorbing incoming solar insolation [66]. The determination of the first figure of merit (F1) and second figure of merit (F2) entails measurements of the related meteorological and operational factors, such as the temperatures of the cooking utensil, water, and ambient air, sun irradiation, mass of the water as load, and cooker dimensions. Evaluating the design parameters of SBC, such as optical efficiency and heat capacity, which can be determined through the experimental evaluation of the second figure of merit data by varying the water load [67]. Evaluating the cooker Opto-thermal ratio and overall thermal performance of the solar cooker evaluated in the two different solar funnel cookers. While incorporating a glass-type encloser in the cooking utensil will enhance the cooking Opto-thermal performance relatively higher value of stagnation temperature, reduces the cooking time, and minimizes heat loss (see Figure 4) [68].

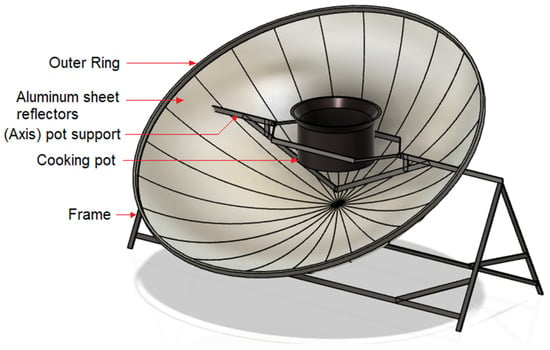

Figure 4.

SK14 type parabolic dish-type solar cooker (2020) Mekonnen, Liyew, and Tigabu [69].

Evaluating the solar parabolic concentrating cooker’s exergy efficiency is less than energy efficiency. Increasing the reflector area of the solar collector and the convective heat transfer coefficient of the cooking system causes the reduction in efficiencies because of convection loss. While increasing the overall heat transfer coefficient, the system’s efficiency increased. While the 1st law efficiency does not predict the presence of an optimum temperature, the 2nd law efficiency demonstrates a specific operating temperature at which efficiency is at its highest point. By altering the length of the cooker or the water flow rate, the desired temperature may be attained [70]. Due to the heat generated by the storage media at the base of the night cooking vessel and its increased area fraction, the night cooking process is faster. The cooking vessel should be as large as feasible to cover the bigger absorber surface and facilitate more heat transmission and faster cooking [71]. A combined outdoor and indoor cooking stove with a larger Fresnel lens concentrator area was developed by Valmiki et al.; for cooking and heating purposes using manual solar tracking. The 0.95 m × 1.25 m, 2 mm thick flat PMMA Fresnel lens was chosen for its lightweight, flexible, and valuable qualities. The lens has a factor of 1229 times the capacity for magnifying incident sunlight. This cooking stove consists of an aluminum chamber’s TES device with a heat-receiving surface that receives the concentrated sunlight from the Fresnel lens concentrator [72].

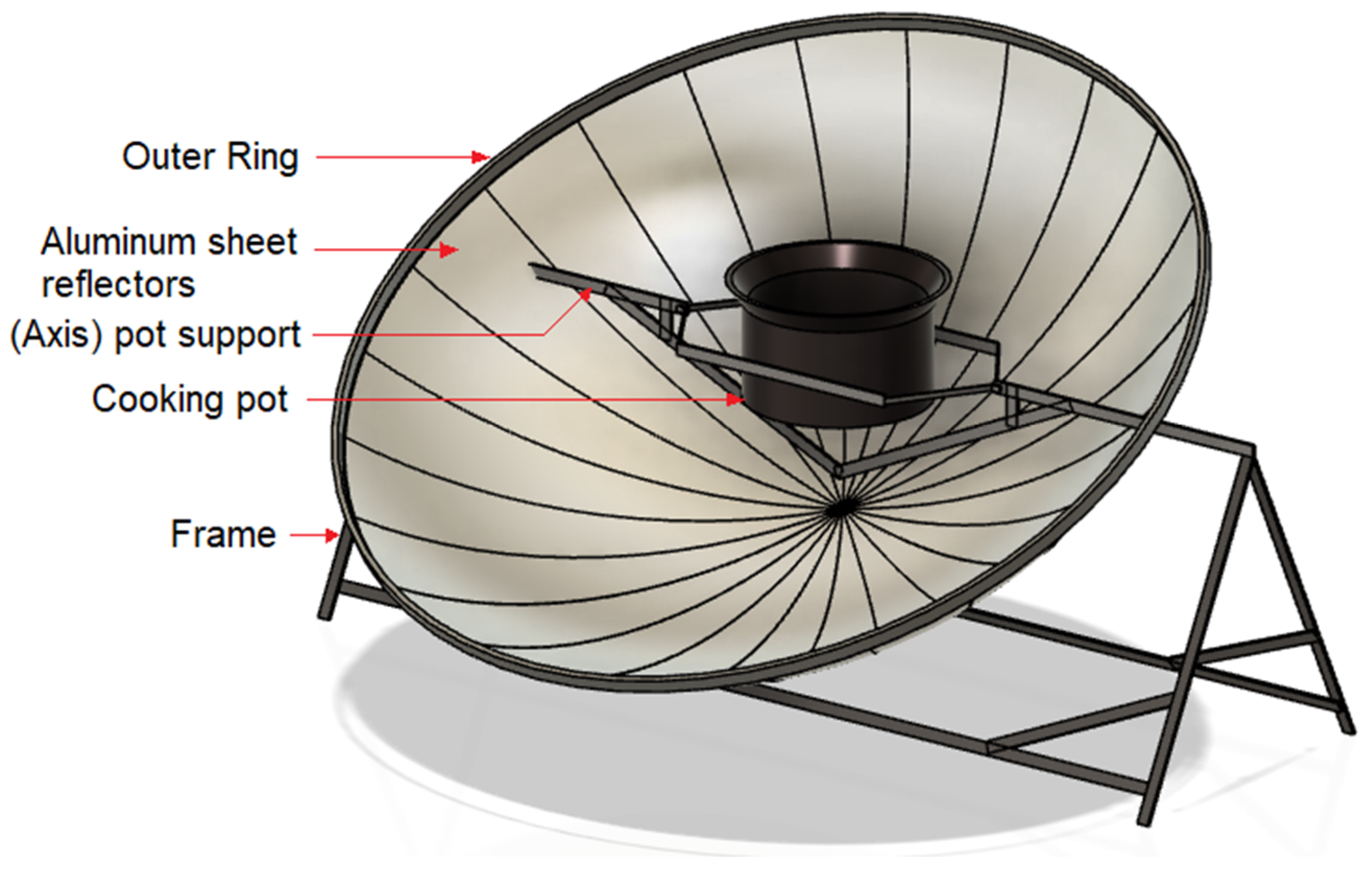

Mekonnen et al., analyzed the SK14-type parabolic dish-type solar cooker shown in Figure 4 made using 24 aluminum sheet reflectors with 0.9 reflective indexes and a CR of 25.25, which was tested in Ethiopian climatic conditions. Experiments were conducted at the stagnation point, and the maximum temperature reached was 370 °C. They used a granite-coated cooking pot with a specific heat capacity of 0.79 kJ/kg K. The cooking power varies from 113 to 339 W. The standard cooking power from the manufacturer is 375.8 W, with a 10% error less than standard. The thermal efficiency of the cooker and the second figure of merit are 46.4% and 0.625, respectively [69]. Haraksingh et al., developed a flat plate solar collector with a double-glazed area of 1.82 × 0.91 m. Compared to black paint in domestic collector systems, it performs 20 to 30% better overall, with solar absorptance of 0.95 to 99 and infrared emittance at 100 °C of 0.08 to 0.11. Reflectors connected along the collector’s two longer sides can increase the collector’s surface area. This adjustment makes longer cooking times possible due to the greater storage capacity [73]. Schwarzer and Vieira da Silva tested a solar cooker with a TES system for single-family or institutional cooking. They reviewed the possibilities of indoor cooking using solar thermal energy. The system’s main benefits are the high working fluid temperatures reached in a short period, which allows fast cooking, frying, and roasting. Large family homes have small systems with collector sizes between 1 and 2 m2. Schools with 250 students included pots with a capacity of up to 100 L and 12 m2 of collecting area [18]. An SCS with heat pipes and vacuum-tube collectors that use a refrigerant as the working fluid has been developed, and the system’s performance has been experimentally evaluated. A flat-plate collector container with an aperture size of 0.96 m2 held all the evacuated glass tubes with heat pipes and reflectors. The heat flow direction was not changed since the heat pipes function as thermal diodes. Between 8:30 to 20:00, 2.95 kWh of thermal irradiated on the aperture area and was passed into the pot during the day [33].

PCM-based storage unit and an evacuated tube solar collector were used to develop a prototype solar cooker. When there is enough sunlight, the 1.82 m2 absorber area of the evacuated tube solar collector allows warm water and heat transfer to the PCM, which is then stored as latent heat. The meal is cooked using this stored heat at night or when the sun’s intensity is insufficient. In the summer, PCM temperatures during night-time cooking exceeded 110 °C. It enables cooking in the shade and offers high PCM temperatures without tracking up to 130 °C [34]. The device included the ability to cook inside or at night and pot heat flow control. Using the heat pipe-based solar collector with an additional plane reflector enhances the absorbing solar radiation by about 36% at noon. At the same time, it is discovered that there is an improvement in the collection of average daily solar energy incidence on the collector of around 24% [35]. A solar indoor cooking system was developed using a parabolic trough collector with an LHTES system. Due to their relatively small receiver area per unit of solar energy collected, concentrating collectors are used in high-temperature applications because they have a higher thermal efficiency than flat plate collectors. They experience significantly less heat loss and incur fewer expenses for vacuum insulation and selective surface treatment. The parabolic trough collector works in the operating temperature range of 100 °C to 450 °C for the indoor solar cooking system. The PTC reached its maximum instantaneous efficiency at 12:00 h, which is 62.5%. The incoming beam radiation and the beneficial heat gain affect the PTC’s instantaneous efficiency. These two elements are more favorable between 8:00 and 9:30, which significantly boosts the collector efficiency during this period [26].

Since indirect or ISCSs have no fundamental size restrictions, they can efficiently collect solar energy from large surfaces. It needs to optimize the collector area based on the temperature required for cooking; the solar collector is first subjected to a stagnation test to determine when it is in this stagnation test condition the highest temperature that may be achieved.

3.3. The Optical Performance of Solar Cooker

Asrori et al., presented a Fresnel lens-concentrating solar cooking stove, increasing the optical performance of the receiver. They used three cavity-based receivers (spherical, cylindrical, and conical). The Fresnel solar cooker has a thermal efficiency of less than 30% [74]. A portable unit has a CR of 40.6 using a curved Fresnel lens concentrator and an evacuated tube. It evaluated the light-receiving rate with different deflection angles and 90% of the light rate received while placing the deflection angle α less than 3° and β less than 2.2°. The time required to cook meat was the shortest (34 min), and the system’s maximum efficiency was 22.6% while cooking meat (all lean) [75]. A non-imaging solar concentric cooker was developed using a commercially available mylar film coated with four reflective panels from the upper half-section. The concentrated sunlight was guided via the upper and lower half sections via two concentric cylindrical reflectors onto the bottom of a rectangular cooking pan. This type of solar cooker can minimize the radiative and convective losses from the cooking unit [76]. A solar parabolic concentrating collector was designed with three reflective materials. Using a Mylar tape reflector in the solar parabolic dish cooker is more efficient than the other two types of reflective material. The maximum temperature received from the receiver is 132.2 °C, and the maximum temperature of the food item is 118.7 °C to fry the egg [77].

Table 2.

Summer of the Concentrating type of solar cooker.

Table 2.

Summer of the Concentrating type of solar cooker.

| Reference No | Types of Study | SC Design | Highlights |

|---|---|---|---|

| Edmonds et al. [76] | Experimental | Non-imaging concentrator | (1) A concentrator comprises eight planar reflectors with a geometrical concentration of 12%. (2) A solar selective absorption base and a polished aluminium lid is required for high-temperature cooking (baking, frying, grilling, roasting). (3) With just 322 W of cooking power available on a clear day, the cooking pan needed to be designed to minimize radiative, conductive, and convective losses. (4) Cooking time is roughly 30 min, and one shouldn’t have to modify the concentrator’s orientation more than once. |

| Goswami, Basu, and Sadhu [78] | Experimental | DSPC | When a solar cooker with an activated carbon-coated pot was utilized, the energy production increased by 32 W compared to when a regular pot was used. |

| Edmonds [79] | Experimental | DSPC | Highly reflective coatings have been applied to paraboloids. The solar cooker’s average cooking power was 485 W. |

| González-Avilés et al. [80] | Experimental | DSPC | (1) This technique makes it easier to record temperature trends indicating how well the solar cooker works. (2) Stove use monitors can inform about new technology uptake and its impact on usage patterns. |

| Nazari et al. [81] | Optimization and Experimental study | AI-based DSPC | Choosing the right design determines the texture of baked food. The networks are trained for this purpose using experimentally observed data. |

| Kumar, Shukla, and Kumar [82] | Numerical | DSPC | (1) With average solar insolation of 500 W/m2, the temperature at the focus may reach a maximum of 181.5 °C, while the cooker’s utensil temperature reached 82.1 °C. (2) Hours after midday, when the cooking pot temperature was high, the cooker had its highest losses. (3) The system is 100% efficient when the Performance Index value reaches 18. However, it is not feasible because of the many losses. |

| Li, Kane, and Mokler [83] | Modelling | Fresnel lens stove | (1) The motors for angular positioning are controlled using a proportional-integral control technique. (2) Automated tracking helped manufacture the cooker’s unattended efficient operation. |

| Farooqui [84] | Experimental | Single vacuum tube-based solar cooker | (1) Every 10 min, two-dimensional manual tracking was done. (2) The vacuum tube type may reach a maximum temperature of 250 °C and can generate 55.6 W of peak exergy power. (3) The cooker’s energy efficiency ranges from 25 to 30%, while its energy efficiency ranges from 4 to 6%. |

| Ebersviller and Jetter [48] | Experimental | Solar panel, SBC, and DSPC | (1) The three household solar cookers’ standardized cooking power is low compared to customarily fuelled cookstoves. (2) Typical cookstoves have a maximum cooking power of between 800 and 1500 W, compared to the maximum standardized cooking power of between 100 and 300 W. |

| Zhao et al. [75] | MATLAB Simulation with Experimental analysis | Fresnel Lens with Evacuated tube portable solar cooker | (1) When the system is steady, the maximum average temperature without load changes almost linearly with irradiance. (2) The system’s maximum energy utilization efficiency during a load test is 18.9%, and the inner tube’s top and lower surfaces reach their peak temperatures of 255 °C and 170 °C, respectively. |

| Ahmed et al. [77] | Experimental | DSPC | (1) The parabolic cooking vessel was created specifically for rural homes, refugee camps, and disaster relief efforts. Stainless steel, aluminium foil, and mylar tape were three distinct forms of reflective material. (2) From 35.6 °C to 93.1 °C, the temperature of the reception vessel was changed. The temperature range for water was 39.9 °C to 75.4 °C, with aluminium foil as the reflecting material. (3) For the cooker to operate more effectively, the CR must be higher than 20. |

| Mussard, Gueno, and Nydal [85] | Experimental | SK 14 DSPC, PTSC with LHTES | (1) The SK14 system took 27 min, and the heat storage unit took 38 min to reach the boiling point for water. (2) Instead of placing the cooking pot over the absorber plate, heat storage is placed over it and continuously heated up to 215 °C. (3) A significant problem that can significantly enhance heat transmission to the cooking vessel is the contact between the utensil and the plate. This time will be cut down and fall within permissible periods for food preparation with better surface contact. (4) Work on simulations was done to comprehend the experiments better. The heat flow can be seen, and the COMSOL simulation demonstrates that the temperature within the storage is still high and relatively consistent. |

| Keith, Brown, and Zhou [86] | Experimental | Portable parabolic solar cooker and cooking pot with PCM | (1) The composite cooking pot’s surface area to volume ratio should be reduced to minimize conduction-related heat loss. (2) The solar cooker can produce temperatures of about 60 °C, while these temperatures might be raised with specific enhancements to heat retention. (3) Stearic acid would need to be supplied with a total of around 137 kJ for the system to reach a temperature of 100 °C. Up until 19:00 h, the PCM kept the food pleasantly heated. |

| Rekha et al. [87] | Experimental | DSPC with LHTES | (1) The solar cooking module benefits from using heat batteries by controlling the heat supply and protecting cooking ingredients. (2) The heat batteries work to control the active layer temperature during any abnormal variations in solar irradiation, keeping the system’s efficiency constant and ensuring that the cooking conditions are acceptable throughout the day. (3) The focal receiver point of the parabolic solar concentrator may attain a maximum temperature of 84 °C. |

| Mawire, Lentswe, and Owusu [88] | Experimental | DSPC with portable LHTES | (1) The sunflower pot exhibits somewhat higher storage efficiency because it can reach greater temperatures because of its reduced thermal mass. (2) This setup exhibits a greater storage efficiency of 3.2–4.4% than the erythritol pot of 2.5–3.9%. (3) The pots are placed in a wonder bag during the storage cooking time. |

Coccia et al., developed a solar cooker using a wooden frame supporting the Fresnel lens and reflective mirror. The solar radiation concentrated from the Fresnel lens reflection mirror has a small focal area. The radiation reflected towards the cooking surface made up of an aluminum sheet where the cooking pot has been placed. The performance of the SC was analyzed using water and silicon oil as testing fluids [89]. Experiments were carried out in a cooker under a vacuum to determine the energy and exergy analysis compared with other major types of solar cookers. Using 17 plain mirror strips, a mini linear Fresnel collector reflects the incoming light into the single vacuum-based absorber tube. The cooker’s energy efficiency is from 20 to 30%, and its exergy efficiency is from 4 to 6%. The maximum attainable temperature in the SBC is around 120 °C [84]. A solar cooking stove using a large Fresnel lens to concentrate sunlight was designed, and the device showcases the use of a working fluid to transmit heat for interior heating and cooking. With a bottom reflecting cone angle of 90°, the cavity receiver can store more incoming energy from the concentrator. Cavity receivers with cylindrical and conical bottom reflecting cones are employed. The optical efficiency and flux uniformity are affected mainly by the absorptivity of the receiver and sunlight incidence angle, respectively. For spherical, cylindrical, and conical geometries receivers with bottom reflective cone angles of 90°, the maximum optical efficiency was 75.21%, 74.15%, and 76.52%, respectively. The advantages of the solar cooker offer better thermal efficiency with simple tracking [90].

4. Requirement of Thermal Energy Storage for ISC

Energy storage is crucial for any system that relies heavily on solar energy. Adjusting the temporal inconsistencies between the load demand and supply increases the system’s utility and operability. The past and contemporary research in this area of energy storage for solar cookers are presented in this review section. Sensible, latent, and thermochemical heat or cold storage are the three main types of TES. Therefore, late-night cooking is possible with the storage unit when previously impossible with a CSC. However, an SCS with a storage unit is great for energy conservation while being suitable for people.

4.1. Effects of Sensible Heat Storage Materials

Steel balls, pebbles, sand, and iron grits were used in the SHS, along with coconut oil, olive oil, and sunflower oil. The SHS materials improve the cooking pot’s thermal performance and are helpful for cooking without solar insolation. For lower temperature requirements, water is used as a storage material up to 100 °C. Oil is used as SHS material for medium temperature (100 to 300 °C) requirements. For higher temperature needs, molten salts and inorganic salts were used as SHS materials. SHS materials provide several benefits, including high thermal stability, low material cost, and high heat capacity. Materials for SHS in solar cookers included liquids, solids, and solid-liquid combinations.

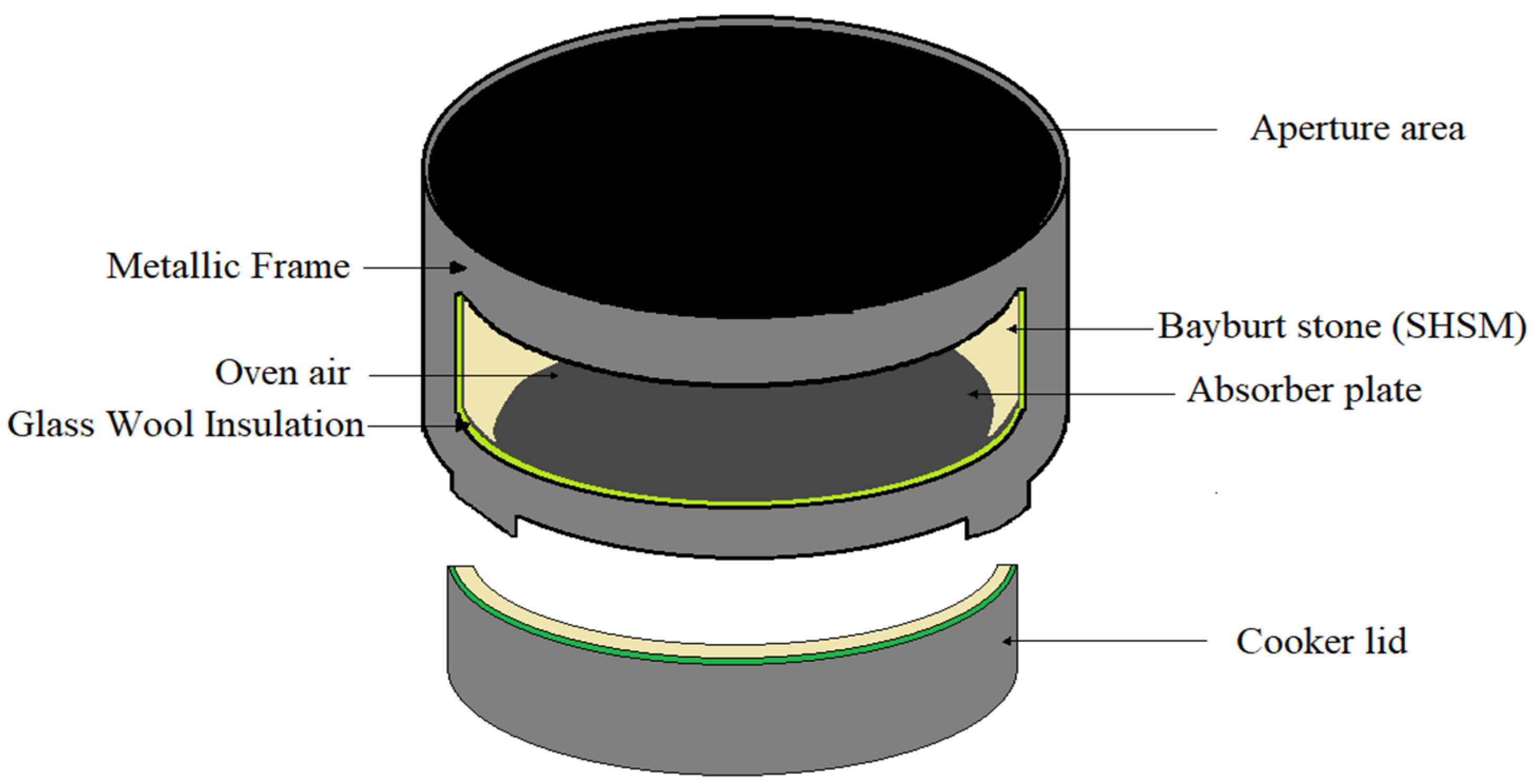

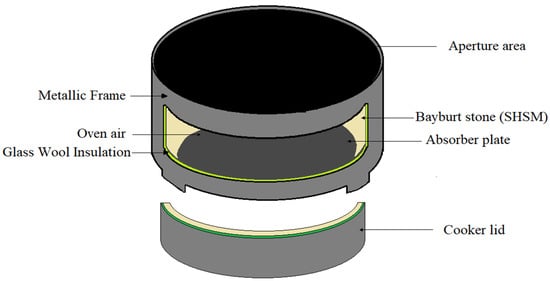

Compared to a standard SBC, the SHS-based SBC has enough heat retention to maintain higher temperatures into the late evening. Saxena used sand and granular carbon as cheap storage materials in SBC and optimized the quality of the sand and granular carbon mixture to maintain the highest temperature range with long-term heat storage. A primary temperature rise source was discovered when the carbon ratio in test sections increased. The thermal efficiency was 37.1%, and the cooking power was 44.81% [91]. The evaluation was made on three primary parameters: storage and vessel area fraction during the day and night. Increasing the area fraction decreases cooking time. Increasing the day fraction leads to increases in night-time cooking [71]. A twin-vessel solar cooker using an ETSC was designed to simultaneously cook two different food items under two different cooking processes. The maximum efficiency of this solar cooker was 78.57%. Another type of solar cooker that gained attention was a storage-based solar cooker [23]. Cuce et al., have pointed out that a cylindrical SBC integrated with sensible TES using Bayburt stone, shown in Figure 5 has a low density and high specific heat capacity. Materials used in TES were sand, stone, and oil, a maximum plate temperature of 120.58 °C was reached using Bayburt stone storage material. The energy efficiency was between 35.3 and 21.7%, and the typical solar oven was between 27.6 and 16.9%. For SBCs to provide efficient and continuous cooking, Bayburt stone is an excellent sensible TES medium [92].

Figure 5.

Cylindrical SBC with sensible heat storage material (SHSM). Reprinted/adapted with permission from (2018) Cuce et al. [92].

An improved SBC (IBSC) with TES material specifically was built for Ethiopia’s isolated areas. The inner and outer reflectors direct radiation and diffuse energy to absorb TES. Compared with CBSC, the IBSC has 20% less inner surface area. The improved solar oven has an extra 5 cm height to accommodate TES materials such as black stones and concrete. IBSC, with TES, has absorbed more solar radiation and reached a maximum temperature of 155 °C on its absorber plate. A high F1 value implies that the absorber plate has high optical efficiency. The F1 values of the IBSC with the SHSM-based cooker for black stone is 0.1349, and concrete is 0.1238 [93]. Equations from an iterative approach were employed to optimize the composition of the low-cost mixed SHSM for the solar cooker. The SHSM transfers maximum heat to the cooking load, and the plate temperature attains a maximum of 106 °C. The modified solar cooker’s energy and exergy efficiency were 0.61% and 16.1%. A typical SBC can only be used for cooking during the day when the sun’s intensity is at its highest. Heat loss from the cooker cavity through convection, conduction, and radiation significantly affects the cooker’s performance, and the cooker’s efficiency is decreased. Cooking in the late evening hours is possible with a practical heat storage system installed in a solar cooker. Adding an SHSM behind the absorber plate may rectify this inherent disadvantage [94]. A solar parabolic trough concentrating cooker can be seen in Figure 6.

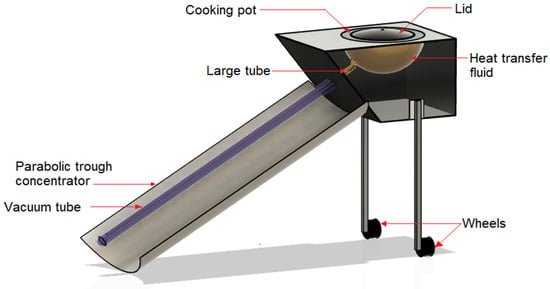

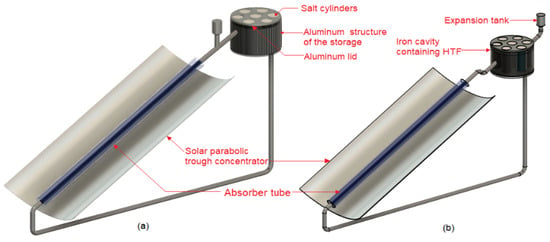

Figure 6.

Solar Parabolic trough concentrating cooker. Reprinted/adapted with permission from (2020) El Moussaoui et al. [95].

The period during which energy can be stored with acceptable losses is one of the essential aspects of the TES. A TES system was used with used engine oil and rock as TES in the double-wall hollow concentric cylindrical insulated absorber where a cooking pot was placed at its center. The maximum temperature of the water reaches 82 °C after 40 min. This cooker comprises two hollow concentric cylindrical ones made up of carbon steel. It has high energy effectiveness and good specular reflectance with a reflectivity of 85%. The maximum temperature of the absorber surface, used engine oil, and rock is 203, 138, and 72 °C, respectively. After being lifted from the CPC, the maximum temperature of the water reached after 40 min is 85 °C [96]. A dynamic system consists of a solar-concentrating cooking system with a rock bed for heat storage. A compressible flow considers the air as a heat-carrying fluid. The conservation equation is used to determine the behaviors of the components. The equations are solved and implemented using a staggered grid without iterations. Charging the rock bed thermal storage took up to 5 h, and the maximum temperature of 350 °C was reached. Convection is the primary heat transmission technique during the charging of the bed, especially at low temperatures. At high temperatures, however, the proportion of radiation heat transfer rises [97]. A 1D finite-difference computation model was developed and tested by Kedida et al. Using the simulation model to charge the pebble bed thermal storage for 11 h on a typical day in March and July, the highest temperature reached was 468.4 °C. When discharging from the storage cooking pot placed over the pebbles, the maximum water temperature reaches 93 °C at 53 min by the forced convection heat discharge at the flow rate of 0.0048 kg/s [98].

El Moussaoui et al., developed a cooker with a parabolic trough collector; the cooking temperature exceeded 200 °C with heat storage. The Parabolic Trough Solar Cookers, as shown in Figure 6 consist of a parabolic trough concentrator. An extra booster with a 1.30 m2 surface area is a PTC. The concentrator can generate heat at extremely high temperatures (100 to 300 °C). A quicker charge is anticipated by resuming the heating on the next day at a higher temperature, allowing for an oversizing of the store and superior thermal performance [95]. An oil-based storage system for solar cooking, due to the high specific heat capacity and density of the oil, tends to increase the charging power, energy, and exergy. During charging, the temperature at the top of the tank is higher than the initial temperature, which increases the thermal stratification during a low charging flow rate, resulting in a higher TES temperature [41].

Due to higher heat loss at a high temperature, the maximum energy storage efficiency becomes low at high-power charging. The increasing thermal gradient caused by the sensible heat transfer to the storage tanks from the inlet to the exit initially causes the stratification number to rise. The stratification eventually achieves a peak value, then sharply followed by a decrease to a residual level, denoting a significant degradation. Due to the poor TES density of SHS materials, the main drawback of SHTES is that it needs a lot of storage space and inadequate thermal conductivity; materials’ corrosivity causes substantial heat losses. While selecting the SHTES system for indoor cooking, it should be chemically stable with no decomposition. It should have good mechanical stability and thermos-physical properties of high energy density, high heat capacity, and higher thermal conductivity. An LHTES material, in contrast to a SHTES material, stores both sensible and latent heat when it transitions through phases within a specific temperature range. Research efforts focus on discovering substitute materials and technologies for SHS to overcome these drawbacks. The most advanced solution to commercialization is LHS using phase-change materials (PCMs).

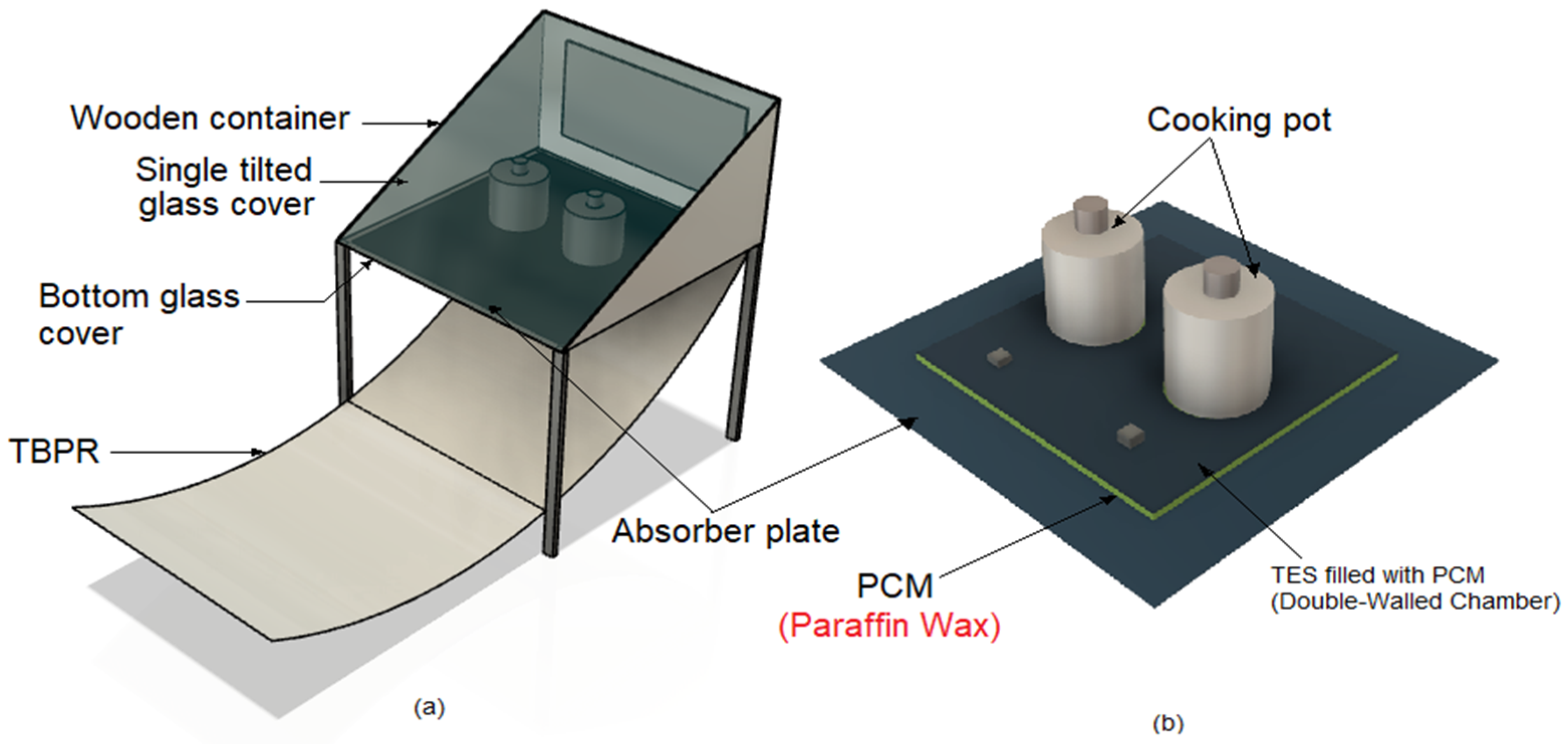

4.2. Effects of Latent Heat Storage Materials

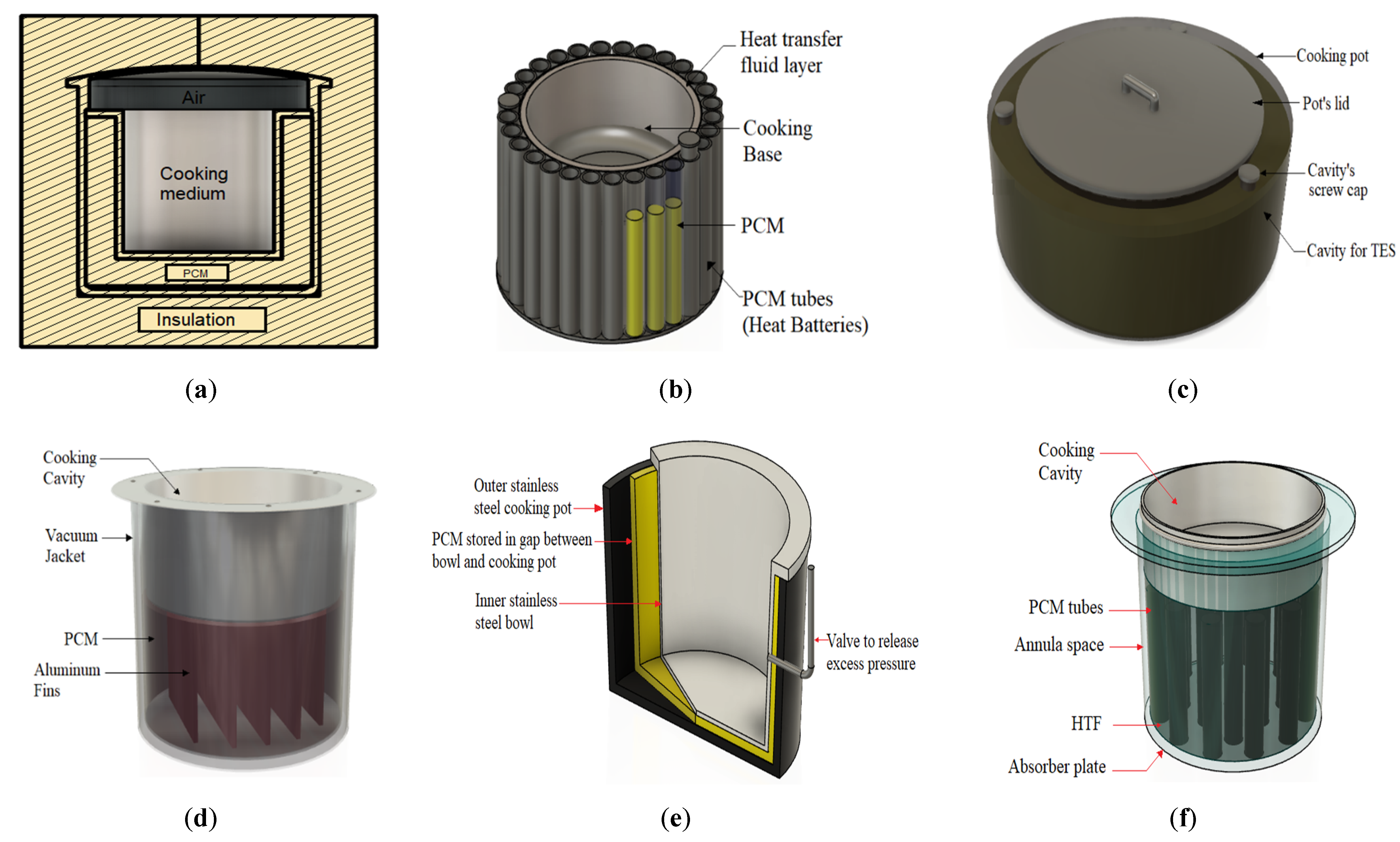

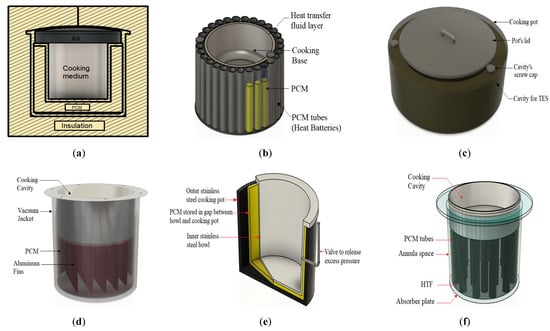

PCM is used to store latent heat and to transfer it into the food through a narrow temperature range. LHS systems that combine a high-temperature cooking method have some appeal since they make it possible to cook more items more quickly. In winter, the system’s solar fraction (SF) was greatly enhanced by adding PCM. PCMs are used in LHTES technology, which makes it possible to discharge thermal energy during cooling while also allowing the absorption of solar energy during heating. The benefit of using a PCM-based TES is clear, leading to a considerable increase in the cooker’s thermal stability (see Figure 7).

Figure 7.

(a) Solar cooker with bottom parabolic reflector Tawfik et al., (2021) [99]. (b) Absorber plate incorporated with PCM Tawfik et al., (2022) [100]. Reprinted/adapted with permission.

Using an LHTES system for high-temperature solar cookers is appealing because it makes it possible to prepare a greater variety quickly. The design parameters were tested experimentally by applying a finned cooking vessel, and PCM storage contained a cooking container in the SBC. PCM is filled in the vessel to increase heat transfer and LHS capacity in the cooking utensil [67]. The temperature components of the SBC were analyzed using a Laplacian approach based on the energy balance equation. Predicting the fuzzy rule to optimize the design parameter of the SBC significantly influenced the suggested cooker’s performance. The SBC was designed as a base cavity-based absorber plate made up of a copper bar plate that can hold the PCM of paraffin wax. Green synthesis was used to make NiO2 nanoparticles, then mixed with mat-black paint [101]. Chen et al., have numerically investigated the selected PCMs used in the SBC as a storage medium for a 2D simulation model based on the enthalpy technique to analyze the melt fraction with conduction. When the heat conductivity of container materials increases, the melt fraction also rises. The LHS systems were compatible with acetanilide and acetamide. Both PCMs had a high melt fraction compared to other PCMs during the same period [102].

Tawfik et al., developed a solar cooker with double exposure, having an external tracking system, as depicted in Figure 7a, and three interior booster mirrors are features of a novel design for solar cookers. Reducing heat loss in the bottom surface improved the cooker’s capacity to retain heat. During experiments, the maximum achievable fluid temperature was 123.1 °C, and the reference time was 66 min. Tracking-type bottom parabolic reflector cookers have an overall efficiency of 12.5% [99]. Tawfik et al., tested their model by incorporating PCM in the absorber plate (as shown in Figure 7b) in a 10 mm indented dip around the absorber plate. The absorber plate acted as a fin, enhancing the heat transfer surface area, reducing heat loss, reducing overheating of the cooking interior, and optimizing the amount of PCM in the absorber container. The Thermal Performance Parameter was analyzed without tracking and with tracking. The maximum temperature of the PCM was 70 °C with paraffin as PCM. The lower reflector causes the absorber plate and TES to heat up more quickly. The solar cooker reaches the standard cooking temperature in 61–66 min and maintains heat from 70 to 72 °C until 18:00 h in the evening [100]. Kumar et al., have developed a PCM-based solar cooker for rural applications. Paraffin wax encapsulated with 144 cylindrical capsules kept over the absorber helped the systems to have an extended fin surface. The maximum temperature attained was 139.15 °C. The average thermal efficiency was 46.21%, and the maximum cooking power was attained at 49 W using a hollow cylindrical capsule. The average thermal efficiency of 50.01% and maximum cooking power attained 53.21 W while using an encapsulated PCM capsule [103].

Coccia et al. [104,105,106] used 12 booster mirrors with different tilt angles placed over the SBC tested with a high CR of 10.78. The maximum temperature reached was 200 °C while using peanut oil. During the no-load test condition, the first figure of merits was 0.39 °C/(W/m2). The higher value indicated excellent optical efficiency and low heat losses. While incorporating a thermal storage unit (TSU), the effectiveness of the thermal system was analyzed using 4 kg of three base salts, NaNO2, NaNO3, and KNO3. The maximum temperature reached was 170 °C. Another SBC was developed using eight booster mirrors with a CR of 4.08. During the test without load, the maximum temperature over the absorber plate was 189 °C. The average first figure of merits was evaluated using different test numbers F1 is 0.19. Water is used with additional mass in the solar cooking during the load test. The water temperature increases from 40 to 90 °C in 1.68 h. The average second figure of merits varied from 0.08 to 0.14 by ranging the mass of water from 2 kg to 3 kg, respectively. While using silicon oil loaded in the cooking with 1.5 kg, the temperature rises from 55 to 125 °C. When silicon oil temperature reaches the maximum, the average cooking efficiency and its second figure of merits become low. At the same time, they tested the TES system with silicone oil used as a cooking load, and the temperature increased from 55 to 125 °C in 2.52 h (see Figure 8).

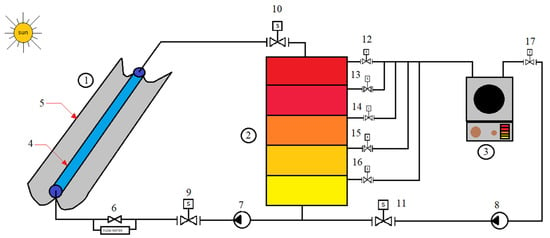

Figure 8.

Solar parabolic trough concentrating cooker with aluminum (a) and oil-based Mussard and Nydal (2013b) [107]. (b) storages coupled with a self-circulated loop Mussard and Nydal (2013a) [108]. Reprinted/adapted with permission.

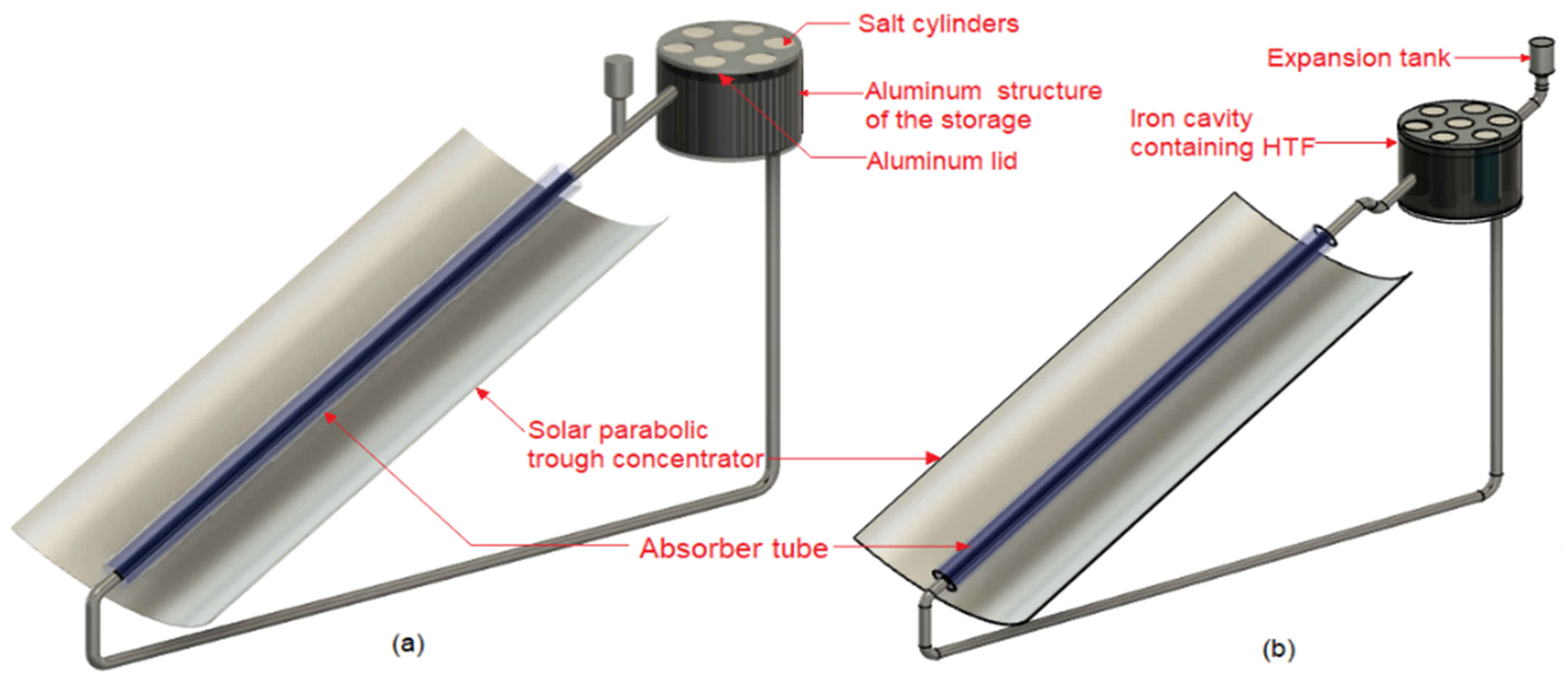

Mussard and Nydal used the oil-based TES system charging with solar parabolic trough collectors shown in Figure 8b. The oil gets self-circulated due to the cold and hot oil density difference. During the six hours of experimentation, the heat collection was close to 200 °C. In the second experiment, the solar collecting system melting temperature reached five hours and melted all the salts. From this stored energy, cooking in the evening may be possible to cook a small quantity for the next morning’s breakfast, but it is more complicated. While testing, water starts boiling after 38 min. The maximum temperature reached while frying meat in oil was 130 °C and 80 °C for meat [108]. Mussard and Nydal developed two different heat storage systems with the same heat capacity and storage containing PCM of a Nitrate mixture heat (NaNO3-KNO3) (salts) to store the latent heat at a melting temperature ranging from 210 to 220 °C. An aluminum cylindrical block is first storage had eight holes filled with PCM, shown in Figure 8a. The second heat storage contains an oil-based cylindrical container filled with PCM dipped into the tank to loop with both storage systems and a solar parabolic trough collector. The model indicates the difficulties in reaching 200 °C [107]. A comparative experimental study was conducted using a solar cooker with a parabolic trough and a storage unit. The HTF used in the loop was the Duratherm 630. SK-14 is more efficient than the heat storage unit. The oil is then stored long enough to discharge its energy. The system then becomes hotter than aluminum-based, allowing salts to melt at around 220 °C [85].

The additional mass of PCM is responsible for extended heating time. The solar oven’s average heating time was increased by 114.41%, coupled with PCM, compared to the silicon oil only used. The average percentage deviation between these two-cooling test sets is around 351.16%. Xie et al., evaluated the performance of the cooker numerically, by adding a PCM-based heat storage layer in the vacuum tubular glass structure of the solar oven. They used solar salt 60% NaNO3, 40% KNO3 as a PCM and achieved a temperature of 220 °C that can withstand the thermal properties under 600 °C [109]. A pressure cooker was positioned between two hollow concentric cylindrical pot cores. An annular cavity filled with acetamide PCM and four SHSMs were used. The cooker comprised 40 segments of the anodized aluminum sheet joint to gather from the concentrator with a CR of 33. In addition, thermally evaluated the four different combinations of the PCM with SHSMs. From the other combination of the PCM and SHSMs, PCM with sand and stone pebbles attained the maximum PCM, and SHSMs temperature and food were thoroughly cooked [110]. An evacuated tube-based parabolic trough collector has a CR of 12.14 integrated with a cooker unit containing a PCM-based TES system. The ultimate food temperature reached 81.8 °C in the morning and 72.3 °C in the evening [111]. A cooker was designed using pentaerythritol and with fins. The heat retention performance of the TES with pentaerythritol to fin volume ratio (P/F) 21 was poor. P/F > 12 significantly impacts heat retention efficacy and temperature dispersion during the discharge of finned pentaerythritol-based TES. An optimal pentaerythritol to fin volume ratio (P/F) is equal to12 in the balance charging and discharging performance [112].

4.2.1. Effect of Phase Change Materials on the Solar Indoor Cooking System

It was discovered that the sun intensity, cooking medium mass, and PCM’s thermophysical characteristics significantly impacted the indoor solar cooker’s performance. PCMs were employed as an energy storage medium for the SC, designed to prepare meals late at night and/or during non-sunny hours. The different PCM used in the solar cooker is summarized in Table 3. The suitable PCM for the ISCS was investigated using the melting and solidifying of up to 500 cycles of acetanilide and MgCl2.6H2O. It is possible to use acetanilide as a PCM for indoor cooking during minimum solar radiation, using aluminum containers in the compatible mode: nevertheless, it corrodes steel containers. Using MgCl2.6H2O is also said to be incompatible with aluminum and stainless steel [113]. John et al., investigated galactitol as a PCM in solar cookers once a day that thermally cycled. Galactitol has a lifespan of fewer than 100 days, which is less than the lifespan of the other components of the cooker system, which was unstable and had a limited lifetime, making it unsuitable for use as a PCM for medium-temperature TES [114]. Tarwidi, et al., evaluated various PCMs numerically for TES. PCMs are investigated based on the stored energy. Compared to other PCMs, MgCl2.6H2O has the highest heat capacity, and the temperature range from 121 to128 °C is used effectively for cooking for an hour. If a longer cooking time is needed, erythritol or magnesium chloride hexahydrate is recommended [115]. The major problem arises while using salt hydrates as a PCM due to phase segregation that melts incongruently to form a saturated aqueous phase and their poor nucleating properties; that is, liquid salt hydrates must be subcooled before freezing [116].

4.2.2. Enhancing Storage Thermal Performance Using PCM

The main constraints of SHSMs are limited specific heat capacity and a decrease in cooking efficacy when the temperature of the storage material drops during discharge. Aside from the heat transmission mechanism of the PCM, the choice of PCM is critical [117]. Nanomaterials and conductive materials are some of the most popular methods for enhancing PCM’s thermal conductivity. The energy efficiency of LTES may be considerably increased by cascading an adequate number of PCMs with correct melting points [28]. Using PCMs in the TES system allows for successful charging in various heating applications. The TES system’s thermal performance passively improves by storing more energy in a multiple PCM structure with narrow melting temperatures [118].

Table 3.

Phase change materials used in a different configuration of the solar cooker.

Table 3.

Phase change materials used in a different configuration of the solar cooker.

| Reference | Material | Melting Temperature Tm (°C) | Latent Heat Capacity (kJ/kg) | Specific Heat Capacity (kJ/kg K) | Density (ρ) (kg/m3) | Thermal Conductivity (W/mK) | Encapsulation | Solar Cooker | Findings |

|---|---|---|---|---|---|---|---|---|---|

| Saxena et al. [19] | Paraffin Wax | 41–44 | 250 | 2 | 0.7 (at 80 °C) | 0.2 | Cylindrical tube | SBC | The storage material in all cylindrical tubes reaches greater temperatures within the cooker. Inside SBC, hot air circulation was created by a small extended geometry of all the copper tubes. |

| Palanikumar et al. [119] | Stearic acid (C18H36O2) | 69.4 | 199 | - | - | - | Copper coil | SBC | The egg-boiling efficiency of the cooker inside has been improved by adding PCM & nanoparticles in the absorber plate, which are 52.17% and 75.47%, respectively. |

| Coccia et al. [106] | Erythritol | 117.7 | 339.8 | 2.76 | 1300 (at 140 °C) | - | Placing inside the cooking utensil | IBSC | (1) The benefit of using a PCM-based TES is clear, as it significantly increases the cooker’s thermal stability. (2) The cooling time is longer than it would have been without the TES solution. |

| Coccia et al. [105] | Nitrate salts | 145.14 | 101.50 | 1462 | - | - | Placing inside the cooking utensil | IBSC | (1) To raise its temperature from 40 to 170 °C, the PCM required was around 1.80 h. (2) In the absence of solar radiation, Nitrate salts as the PCM thermal storage considerably enhance thermal load stability. |

| Kumar et al. [103] | RT64HC | 64 | 250 | 2 | 780 (at 88 °C) | 0.2 | 144 Capsules | SBC | (1) The encapsulated PCM over the absorber plate, the maximum plate temperature attained was 130.9 °C during the stagnation test. (2) The average thermal efficiency of 50.01% and maximum cooking power attained 53.21 W while using an encapsulated PCM capsule. |

| Tawfik et al. [100] | Paraffin wax | 41–60 | - | 2.15 | 822 | 0.213 | Double wall absorber plate container | IBSC | The bottom reflector, absorber plate, and TES work together to keep the cooker’s interior heated and comfortable for an extended period. |