Agricultural and Forestry Biomass for Meeting the Renewable Fuel Standard: Implications for Land Use and GHG Emissions

Abstract

1. Introduction

- (1)

- Optimal mix of agricultural and forest biofuel feedstocks;

- (2)

- Land use change between and within the agricultural and forestry sectors over time;

- (3)

- GHG emission implications of cellulosic ethanol production.

2. Literature Review

3. Methods

3.1. Model Description

3.2. Algebraic Illustration of the Model

3.3. Data and Parametric Assumptions

3.4. Scenarios Description

- (a)

- No-cell EtOH: corn ethanol production is assumed to maintain at the maximum level of 56.78 BL under the RFS, and biodiesel production is maintained at the 2015 level of 4.8 BL.

- (b)

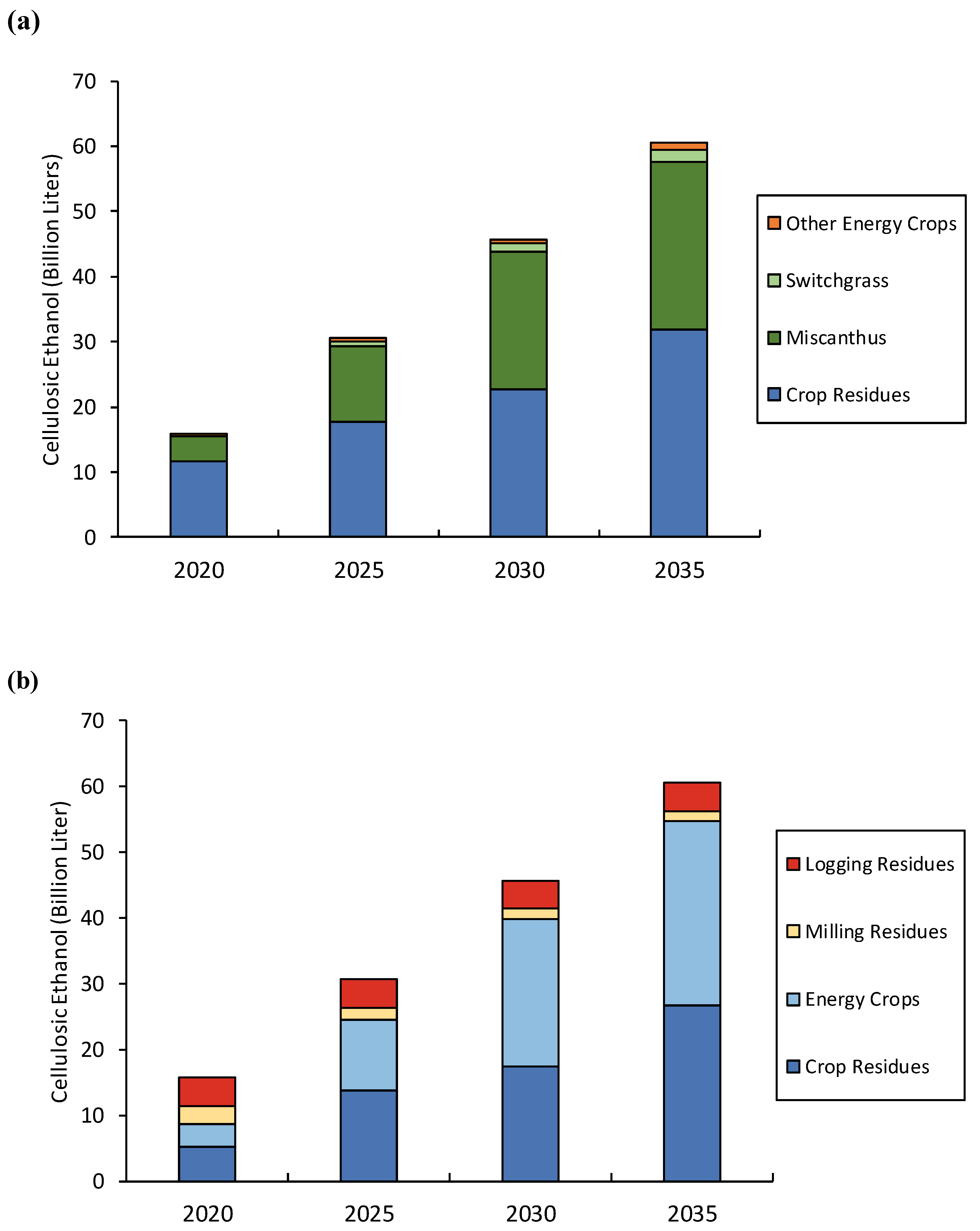

- Ag-only EtOH: Cellulosic ethanol production is assumed to grow linearly from 0.8 BL in 2015 to 60.56 BL in 2035, while corn ethanol and biodiesel production are the same as in the No-cell EtOH scenario; the cellulosic ethanol target is met by agricultural biomass only.

- (c)

- Wood & Ag EtOH: Cellulosic ethanol production is the same as in the Ag-only EtOH scenario, and the total target is met by a mix of forest and agricultural feedstocks; corn ethanol and biodiesel production are the same as in the above scenarios.

3.5. GHG Emissions Estimation

4. Results

4.1. Biomass Supply

4.2. Land Use Change

4.3. GHG Emissions Implication

4.4. Sensitivity Analysis

5. Discussion

6. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Energy Information Administration. EIA Monthly Energy Review; U.S. Energy Information Administration: Washington, DC, USA, 2022. [Google Scholar]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental Sustainability of Biofuels: A Review. Proc. R. Soc. A 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Khanna, M.; Rajagopal, D.; Zilberman, D. Lessons Learned from US Experience with Biofuels: Comparing the Hype with the Evidence. Rev. Environ. Econ. Policy 2021, 15, 67–86. [Google Scholar] [CrossRef]

- Lark, T.J.; Hendricks, N.P.; Smith, A.; Pates, N.; Spawn-Lee, S.A.; Bougie, M.; Booth, E.G.; Kucharik, C.J.; Gibbs, H.K. Environmental Outcomes of the US Renewable Fuel Standard. Proc. Natl. Acad. Sci. USA 2022, 119, e2101084119. [Google Scholar] [CrossRef] [PubMed]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.-H. Use of U.S. Croplands for Biofuels Increases Greenhouse Gases through Emissions from Land-Use Change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Field, J.L.; Richard, T.L.; Smithwick, E.A.H.; Cai, H.; Laser, M.S.; LeBauer, D.S.; Long, S.P.; Paustian, K.; Qin, Z.; Sheehan, J.J.; et al. Robust Paths to Net Greenhouse Gas Mitigation and Negative Emissions via Advanced Biofuels. Proc. Natl. Acad. Sci. USA 2020, 117, 21968–21977. [Google Scholar] [CrossRef]

- Raud, M.; Kikas, T.; Sippula, O.; Shurpali, N.J. Potentials and Challenges in Lignocellulosic Biofuel Production Technology. Renew. Sustain. Energy Rev. 2019, 111, 44–56. [Google Scholar] [CrossRef]

- Rosales-Calderon, O.; Arantes, V. A Review on Commercial-Scale High-Value Products That Can Be Produced alongside Cellulosic Ethanol. Biotechnol. Biofuels 2019, 12, 240. [Google Scholar] [CrossRef]

- Ghavami, N.; Özdenkçi, K.; Chianese, S.; Musmarra, D.; De Blasio, C. Process Simulation of Hydrothermal Carbonization of Digestate from Energetic Perspectives in Aspen Plus. Energy Convers. Manag. 2022, 270, 116215. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Faaij, A.; de Vries, B.; Turkenburg, W. Exploration of Regional and Global Cost–Supply Curves of Biomass Energy from Short-Rotation Crops at Abandoned Cropland and Rest Land under Four IPCC SRES Land-Use Scenarios. Biomass Bioenergy 2009, 33, 26–43. [Google Scholar] [CrossRef]

- Field, C.; Campbell, J.; Lobell, D. Biomass Energy: The Scale Of The Potential Resource. Trends Ecol. Evol. 2008, 23, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Haberl, H.; Beringer, T.; Bhattacharya, S.C.; Erb, K.-H.; Hoogwijk, M. The Global Technical Potential of Bio-Energy in 2050 Considering Sustainability Constraints. Curr. Opin. Environ. Sustain. 2010, 2, 394–403. [Google Scholar] [CrossRef]

- Batidzirai, B.; Smeets, E.M.W.; Faaij, A.P.C. Harmonising Bioenergy Resource Potentials—Methodological Lessons from Review of State of the Art Bioenergy Potential Assessments. Renew. Sustain. Energy Rev. 2012, 16, 6598–6630. [Google Scholar] [CrossRef]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and Climate Change Mitigation: An Assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef]

- US Department of Energy 2016 Billion-Ton Report, Volume 2: Environmental Sustainability Effects of Select Scenarios from Volume 1. Available online: https://www.energy.gov/sites/default/files/2017/02/f34/2016_billion_ton_report_volume_2_front_cover.pdf (accessed on 12 April 2022).

- Taheripour, F.; Tyner, W.E. Induced Land Use Emissions Due to First and Second Generation Biofuels and Uncertainty in Land Use Emission Factors. Econ. Res. Int. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Hudiburg, T.W.; Wang, W.; Khanna, M.; Long, S.P.; Dwivedi, P.; Parton, W.J.; Hartman, M.; DeLucia, E.H. Impacts of a 32-Billion-Gallon Bioenergy Landscape on Land and Fossil Fuel Use in the US. Nat. Energy 2016, 1, 15005. [Google Scholar] [CrossRef]

- Chen, L.; Debnath, D.; Zhong, J.; Ferin, K.; VanLoocke, A.; Khanna, M. The Economic and Environmental Costs and Benefits of the Renewable Fuel Standard. Environ. Res. Lett. 2021, 16, 034021. [Google Scholar] [CrossRef]

- Sedjo, R.A.; Sohngen, B. Wood as a Major Feedstock for Biofuel Production in the United States: Impacts on Forests and International Trade. J. Sustain. For. 2013, 32, 195–211. [Google Scholar] [CrossRef][Green Version]

- Ince, P.J.; Kramp, A.D.; Skog, K.E.; Yoo, D.; Sample, V.A. Modeling Future U.S. Forest Sector Market and Trade Impacts of Expansion in Wood Energy Consumption. JFE 2011, 17, 142–156. [Google Scholar] [CrossRef]

- Nepal, P.; Abt, K.L.; Skog, K.E.; Prestemon, J.P.; Abt, R.C. Projected Market Competition for Wood Biomass between Traditional Products and Energy: A Simulated Interaction of US Regional, National, and Global Forest Product Markets. For. Sci. 2019, 65, 14–26. [Google Scholar] [CrossRef]

- Abt, K.L.; Abt, R.C.; Galik, C. Effect of Bioenergy Demands and Supply Response on Markets, Carbon, and Land Use. For. Sci. 2012, 58, 523–539. [Google Scholar] [CrossRef]

- Beach, R.H.; Zhang, Y.W.; Mccarl, B.A. Modeling Bioenergy, Land Use, and GHG Emissions with FASOMGHG: Model Overview and Analysis of Storage Cost Implications. Clim. Chang. Econ. 2012, 03, 1250012. [Google Scholar] [CrossRef]

- Latta, G.S.; Baker, J.S.; Beach, R.H.; Rose, S.K.; McCarl, B.A. A Multi-Sector Intertemporal Optimization Approach to Assess the GHG Implications of U.S. Forest and Agricultural Biomass Electricity Expansion. JFE 2013, 19, 361–383. [Google Scholar] [CrossRef]

- Galik, C.S.; Abt, R.C.; Latta, G.; Vegh, T. The Environmental and Economic Effects of Regional Bioenergy Policy in the Southeastern U.S. Energy Policy 2015, 85, 335–346. [Google Scholar] [CrossRef]

- Daioglou, V.; Doelman, J.C.; Stehfest, E.; Müller, C.; Wicke, B.; Faaij, A.; van Vuuren, D.P. Greenhouse Gas Emission Curves for Advanced Biofuel Supply Chains. Nat. Clim. Chang. 2017, 7, 920–924. [Google Scholar] [CrossRef]

- Chen, L.; Blanc-Betes, E.; Hudiburg, T.W.; Hellerstein, D.; Wallander, S.; DeLucia, E.H.; Khanna, M. Assessing the Returns to Land and Greenhouse Gas Savings from Producing Energy Crops on Conservation Reserve Program Land. Environ. Sci. Technol. 2021, 55, 1301–1309. [Google Scholar] [CrossRef] [PubMed]

- Qin, Z.; Dunn, J.B.; Kwon, H.; Mueller, S.; Wander, M.M. Soil Carbon Sequestration and Land Use Change Associated with Biofuel Production: Empirical Evidence. GCB Bioenergy 2016, 8, 66–80. [Google Scholar] [CrossRef]

- DeCicco, J.M.; Schlesinger, W.H. Opinion: Reconsidering Bioenergy given the Urgency of Climate Protection. Proc. Natl. Acad. Sci. USA 2018, 115, 9642–9645. [Google Scholar] [CrossRef] [PubMed]

- Oliver, A.; Khanna, M. Demand for Biomass to Meet Renewable Energy Targets in the United States: Implications for Land Use. GCB Bioenergy 2017, 9, 1476–1488. [Google Scholar] [CrossRef]

- Chen, X.; Önal, H. Modeling Agricultural Supply Response Using Mathematical Programming and Crop Mixes. Am. J. Agric. Econ. 2012, 94, 674–686. [Google Scholar] [CrossRef]

- Önal, H.; McCarl, B.A. Exact Aggregation in Mathematical Programming Sector Models. Can. J. Agric. Econ. 1991, 39, 319–334. [Google Scholar] [CrossRef]

- Chen, X.; Huang, H.; Khanna, M.; Önal, H. Alternative Transportation Fuel Standards: Welfare Effects and Climate Benefits. J. Environ. Econ. Manag. 2014, 67, 241–257. [Google Scholar] [CrossRef]

- Beach, R.H.; McCarl, B.A. Agricultural and Forestry Impacts of the Energy Independence and Security Act: FASOM Results and Model Description; Final Report Prepared for US Environmental Protection Agency; US Environmental Protection Agency: Washington, DC, USA, 2010. [Google Scholar]

- Beach, R.H.; Cai, Y.; Thomson, A.; Zhang, X.; Jones, R.; McCarl, B.A.; Crimmins, A.; Martinich, J.; Cole, J.; Ohrel, S.; et al. Climate Change Impacts on US Agriculture and Forestry: Benefits of Global Climate Stabilization. Environ. Res. Lett. 2015, 10, 095004. [Google Scholar] [CrossRef]

- Wang, W.; Dwivedi, P.; Abt, R.; Khanna, M. Carbon Savings with Transatlantic Trade in Pellets: Accounting for Market-Driven Effects. Environ. Res. Lett. 2015, 10, 114019. [Google Scholar] [CrossRef]

- Beach, R.H.; Zhang, Y.W.; McCarl, B.A. Modeling Bioenergy, Land Use, and GHG Mitigation with FASOMGHG: Implications of Storage Costs and Carbon Policy. In Handbook of Bioenergy Economics and Policy: Volume II; Khanna, M., Zilberman, D., Eds.; Natural Resource Management and Policy; Springer: New York, NY, USA, 2017; Volume 40, pp. 239–271. ISBN 978-1-4939-6904-3. [Google Scholar]

- Thiffault, E.; Béchard, A.; Paré, D.; Allen, D. Recovery Rate of Harvest Residues for Bioenergy in Boreal and Temperate Forests: A Review. WIREs Energy Environ. 2015, 4, 429–451. [Google Scholar] [CrossRef]

- NASS National Agricultural Statistics Service. Census of Agriculture Quick Stats 2.0 Beta, United States Department of Agriculture. 2011. Available online: http://www.Nass.Usda.Gov/Quick_Stats/ (accessed on 10 March 2021).

- Sheehan, J.; Aden, A.; Paustian, K.; Killian, K.; Brenner, J.; Walsh, M.; Nelson, R. Energy and Environmental Aspects of Using Corn Stover for Fuel Ethanol. J. Ind. Ecol. 2003, 7, 117–146. [Google Scholar] [CrossRef]

- Malcolm, S. Weaning off Corn: Crop Residues and the Transition to Cellulosic Ethanol. In The Transition to a BioEconomy: Environmental and Rural Development Impacts; Farm Foundation: St. Louis, MO, USA, 2008. [Google Scholar]

- Salassi, M.E.; Deliberto, M.A. Sugarcane Production in Louisiana. Farm Management Research and Extension. Department of Agriculture Economics & Agribusiness. A.E.A. Information Series No. 282. 2012. Available online: https://www.lsuagcenter.com/~/media/system/8/c/3/6/8c36fdef23a6c1e8558e65256708d712/2012sugarcanebudgetsaea282.pdf (accessed on 20 May 2022).

- Lazarus, W.F. Minnesota Crop Cost and Return Guide for 2011; Department of Applied Economics, University of Minnesota: Minneapolis, MN, USA, 2010. [Google Scholar]

- Davis, S.C.; Boundy, R.G. Transportation Energy Data Book; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2009. [Google Scholar]

- de Wit, M.; Junginger, M.; Lensink, S.; Londo, M.; Faaij, A. Competition between Biofuels: Modeling Technological Learning and Cost Reductions over Time. Biomass Bioenergy 2010, 34, 203–217. [Google Scholar] [CrossRef]

- EIA Annual Energy Outlook 2010: With Projections to 2035; U.S. Energy Information Administration, Office of Integrated Analysis and Forecasting: Washington, DC, USA, 2010.

- Coglianese, J.; Davis, L.W.; Kilian, L.; Stock, J.H. Anticipation, Tax Avoidance, and the Price Elasticity of Gasoline Demand: The Price Elasticity of Gasoline Demand. J. Appl. Econ. 2017, 32, 1–15. [Google Scholar] [CrossRef]

- Gillingham, K. Identifying the Elasticity of Driving: Evidence from a Gasoline Price Shock in California. Reg. Sci. Urban Econ. 2014, 47, 13–24. [Google Scholar] [CrossRef]

- Parry, I.W.H.; Small, K.A. Does Britain or the United States Have the Right Gasoline Tax? Am. Econ. Rev. 2005, 95, 1276–1289. [Google Scholar] [CrossRef]

- Bergman, R.; Puettmann, M.; Taylor, A.; Skog, K.E. The Carbon Impacts of Wood Products. For. Prod. J. 2014, 64, 220–231. [Google Scholar] [CrossRef]

- Wang, M.Q.; Han, J.; Haq, Z.; Tyner, W.E.; Wu, M.; Elgowainy, A. Energy and Greenhouse Gas Emission Effects of Corn and Cellulosic Ethanol with Technology Improvements and Land Use Changes. Biomass Bioenergy 2011, 35, 1885–1896. [Google Scholar] [CrossRef]

- Bansal, A.; Illukpitiya, P.; Tegegne, F.; Singh, S.P. Energy Efficiency of Ethanol Production from Cellulosic Feedstock. Renew. Sustain. Energy Rev. 2016, 58, 141–146. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Zhuang, X.S. Conceptual Net Energy Output for Biofuel Production from Lignocellulosic Biomass through Biorefining. Prog. Energy Combust. Sci. 2012, 38, 583–598. [Google Scholar] [CrossRef]

- Austin, K.G.; Jones, J.P.H.; Clark, C.M. A Review of Domestic Land Use Change Attributable to U.S. Biofuel Policy. Renew. Sustain. Energy Rev. 2022, 159, 112181. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. EPA Renewable Fuel Standard Program (RFS2) Regulatory Impact Analysis; EPA-420-R-10-00; US Environmental Protection Agency: Washington, DC, USA, 2010. Available online: http://www.Epa.Gov/Otaq/Fuels/Renewablefuels/Index.Htm (accessed on 15 June 2022).

- Plevin, R.; Mishra, G. Estimates of the Land-Use-Change Carbon Intensity of Ethanol from Switchgrass and Corn Stover Using the GCAM 4.0 Model. Report to Environmental Working Group. 2015. Available online: http://Static.Ewg.Org/Reports/2015/Better-Biofuels-Ahead/Plevinreport.Pdf (accessed on 11 October 2022).

- Valin, H.; Peters, D.; van den Berg, M.; Frank, S.; Havlik, P.; Forsell, N.; Hamelinck, C. The Land Use Change Impact of Biofuels Consumed in the EU: Quantification of Area and Greenhouse Gas Impacts. 2015. Available online: https://Ec.Europa.Eu/Energy/Sites/Ener/Files/Documents/Final%20Report_GLOBIOM_publication.Pdf (accessed on 27 October 2022).

- Pavlenko, N.; Searle, S. White Paper on a Comparison of Induced Land-Use Change Emissions Estimates from Energy Crops; The International Council on Clean Transportation: San Francisco, CA, USA, 2018; Available online: https://Theicct.Org/Publications/Comparison-ILUC-Emissions-Estimatesenergy-Crops (accessed on 5 July 2022).

- Chen, X.; Huang, H.; Khanna, M.; Önal, H. Meeting the Mandate for Biofuels: Implications for Land Use, Food, and Fuel Prices. In The Intended and Unintended Effects of U.S. Agricultural and Biotechnology Policies; University of Chicago Press: Chicago, IL, USA, 2012; ISBN 978-0-226-98803-0. [Google Scholar]

- EPA Inventory of, U.S. Greenhouse Gas Emissions and Sinks 1990–2020. EPA 430-R-22-003. Available online: https://www.Epa.Gov/System/Files/Documents/2022-04/Us-Ghg-Inventory-2022-Main-Text.Pdf (accessed on 28 September 2022).

- Davis, S.C.; Parton, W.J.; Grosso, S.J.D.; Keough, C.; Marx, E.; Adler, P.R.; DeLucia, E.H. Impact of Second-generation Biofuel Agriculture on Greenhouse-gas Emissions in the Corn-growing Regions of the US. Front. Ecol. Environ. 2012, 10, 69–74. [Google Scholar] [CrossRef]

- Fargione, J.E.; Bassett, S.; Boucher, T.; Bridgham, S.D.; Conant, R.T.; Cook-Patton, S.C.; Ellis, P.W.; Falcucci, A.; Fourqurean, J.W.; Gopalakrishna, T.; et al. Natural Climate Solutions for the United States. Sci. Adv. 2018, 4, eaat1869. [Google Scholar] [CrossRef]

- Searchinger, T.D.; Beringer, T.; Strong, A. Does the World Have Low-Carbon Bioenergy Potential from the Dedicated Use of Land? Energy Policy 2017, 110, 434–446. [Google Scholar] [CrossRef]

- Chen, X.; Khanna, M.; Yeh, S. Stimulating learning-by-doing in advanced biofuels: Effectiveness of alternative policies. Environ. Res. Lett. 2012, 7, 045907. [Google Scholar] [CrossRef]

- Adams, D.M.; Alig, R.J.; McCarl, B.A.; Murray, B.C. FASOMGHG Conceptual Structure and Specification: Documentation. Available online: http://agecon2.tamu.edu/people/faculty/mccarl-bruce/papers/1212FASOMGHG_doc.pdf (accessed on 3 August 2022).

- Argonne National Laboratory. GREET Model. Available online: https://greet.es.anl.gov (accessed on 1 August 2021).

- Wang, D.; Jaiswal, D.; Lebauer, D.S.; Wertin, T.M.; Bollero, G.A.; Leakey, A.D.B.; Long, S.P. A Physiological and Biophysical Model of Coppice Willow (Salix Spp.) Production Yields for the Contiguous USA in Current and Future Climate Scenarios. Plant Cell Environ. 2015, 38, 1850–1865. [Google Scholar] [CrossRef]

- Wang, D.; LeBauer, D.; Dietze, M. Predicting Yields of Short-Rotation Hybrid Poplar (Populus Spp.) for the United States through Model–Data Synthesis. Ecol. Appl. 2013, 23, 944–958. [Google Scholar] [CrossRef]

- Duval, B.D.; Anderson-Teixeira, K.J.; Davis, S.C.; Keogh, C.; Long, S.P.; Parton, W.J.; DeLucia, E.H. Predicting Greenhouse Gas Emissions and Soil Carbon from Changing Pasture to an Energy Crop. PLoS ONE 2013, 8, e72019. [Google Scholar] [CrossRef] [PubMed]

| (B Mg CO2e) | Ag-only EtOH | Wood & Ag EtOH |

|---|---|---|

| GHG Emissions Due to | ||

| Aboveground Agricultural Production | 0.091 | 0.080 |

| Conventional Wood Products Production | 0.000 | −0.009 |

| Soil Carbon Accumulation | −0.003 | −0.032 |

| Carbon Stored in Forest | 0.295 | 0.138 |

| Domestic ILUC | 0.126 | 0.118 |

| Feedstock Transportation and Ethanol Production | 0.066 | 0.068 |

| Coproduct Credits | −0.039 | −0.039 |

| Net GHG Emissions | 0.536 | 0.324 |

| Net GHG Savings from Displacing Gasoline | 0.611 | 0.822 |

| LUC emission factors (Mg CO2e ha−1 yr−1) | 1.135 | 0.870 |

| GHG mitigation rate (Mg CO2e ha−1 yr−1) | 7.205 | 10.098 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W. Agricultural and Forestry Biomass for Meeting the Renewable Fuel Standard: Implications for Land Use and GHG Emissions. Energies 2022, 15, 8796. https://doi.org/10.3390/en15238796

Wang W. Agricultural and Forestry Biomass for Meeting the Renewable Fuel Standard: Implications for Land Use and GHG Emissions. Energies. 2022; 15(23):8796. https://doi.org/10.3390/en15238796

Chicago/Turabian StyleWang, Weiwei. 2022. "Agricultural and Forestry Biomass for Meeting the Renewable Fuel Standard: Implications for Land Use and GHG Emissions" Energies 15, no. 23: 8796. https://doi.org/10.3390/en15238796

APA StyleWang, W. (2022). Agricultural and Forestry Biomass for Meeting the Renewable Fuel Standard: Implications for Land Use and GHG Emissions. Energies, 15(23), 8796. https://doi.org/10.3390/en15238796