Topology Optimization Design of Micro-Channel Heat Sink by Considering the Coupling of Fluid-Solid and Heat Transfer

Abstract

:1. Introduction

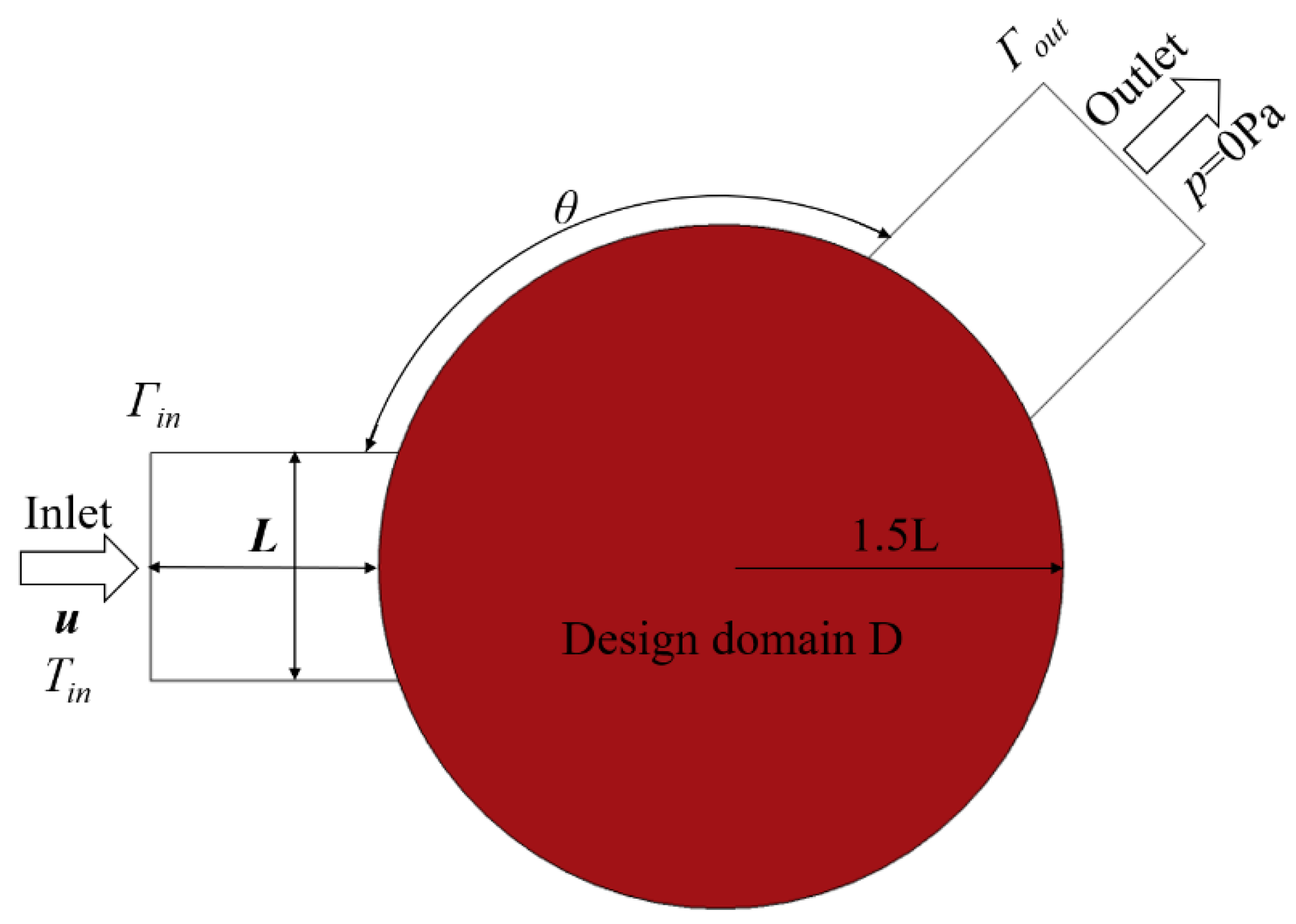

2. Physical Model

2.1. Governing Equations

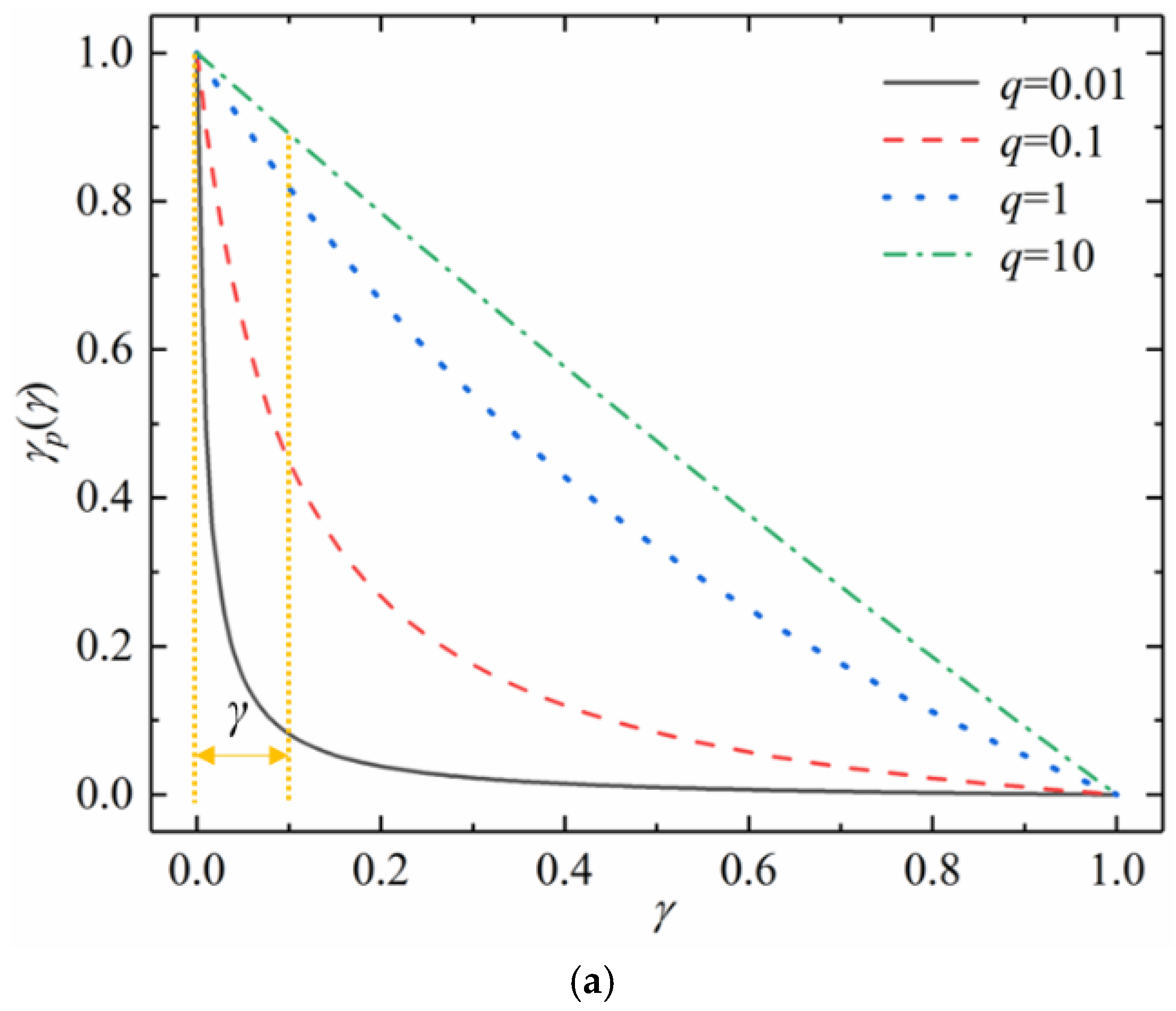

2.2. Topology Optimization Model Based on Variable Density Method

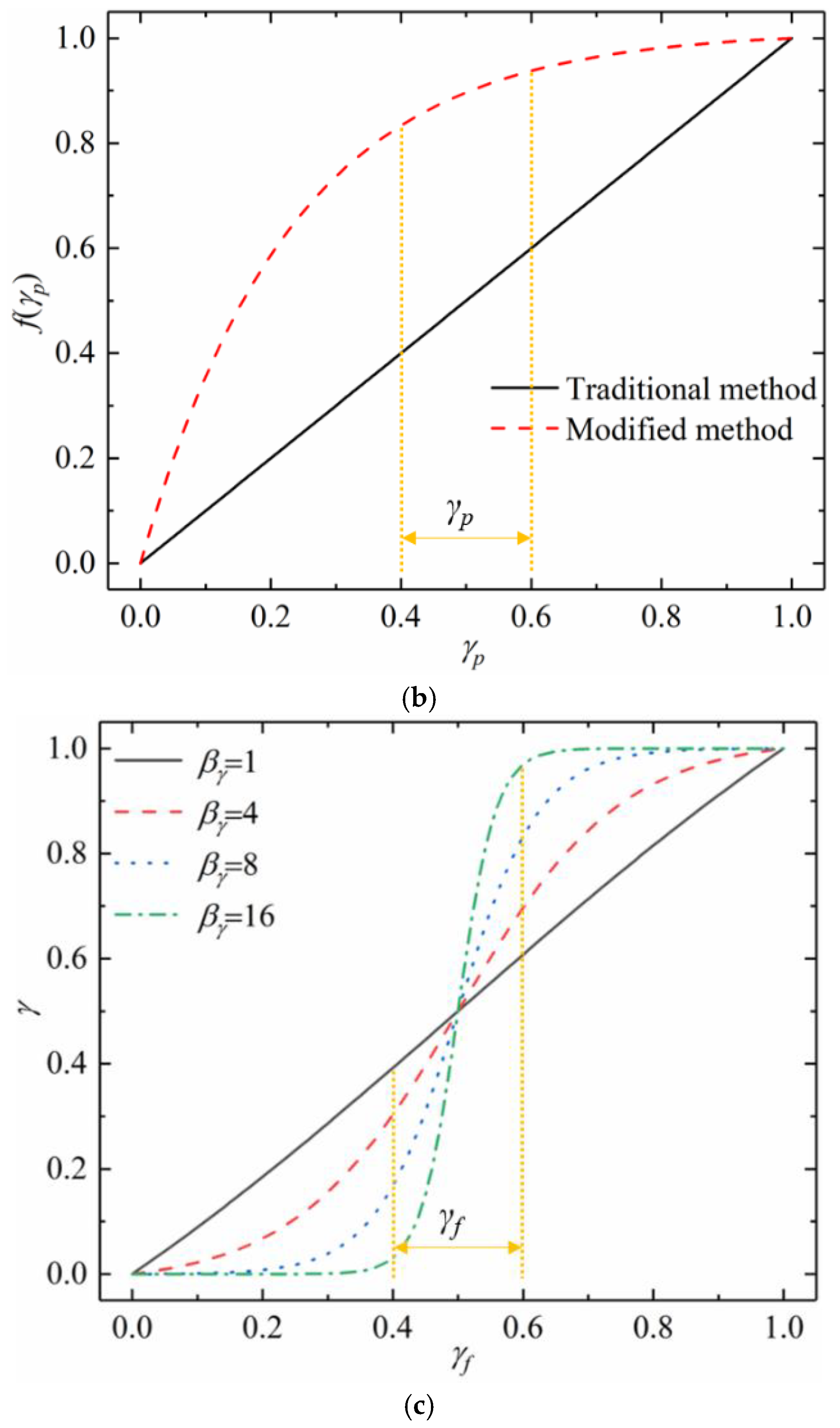

2.3. Filter and Projection

3. Multi-Objective Optimization

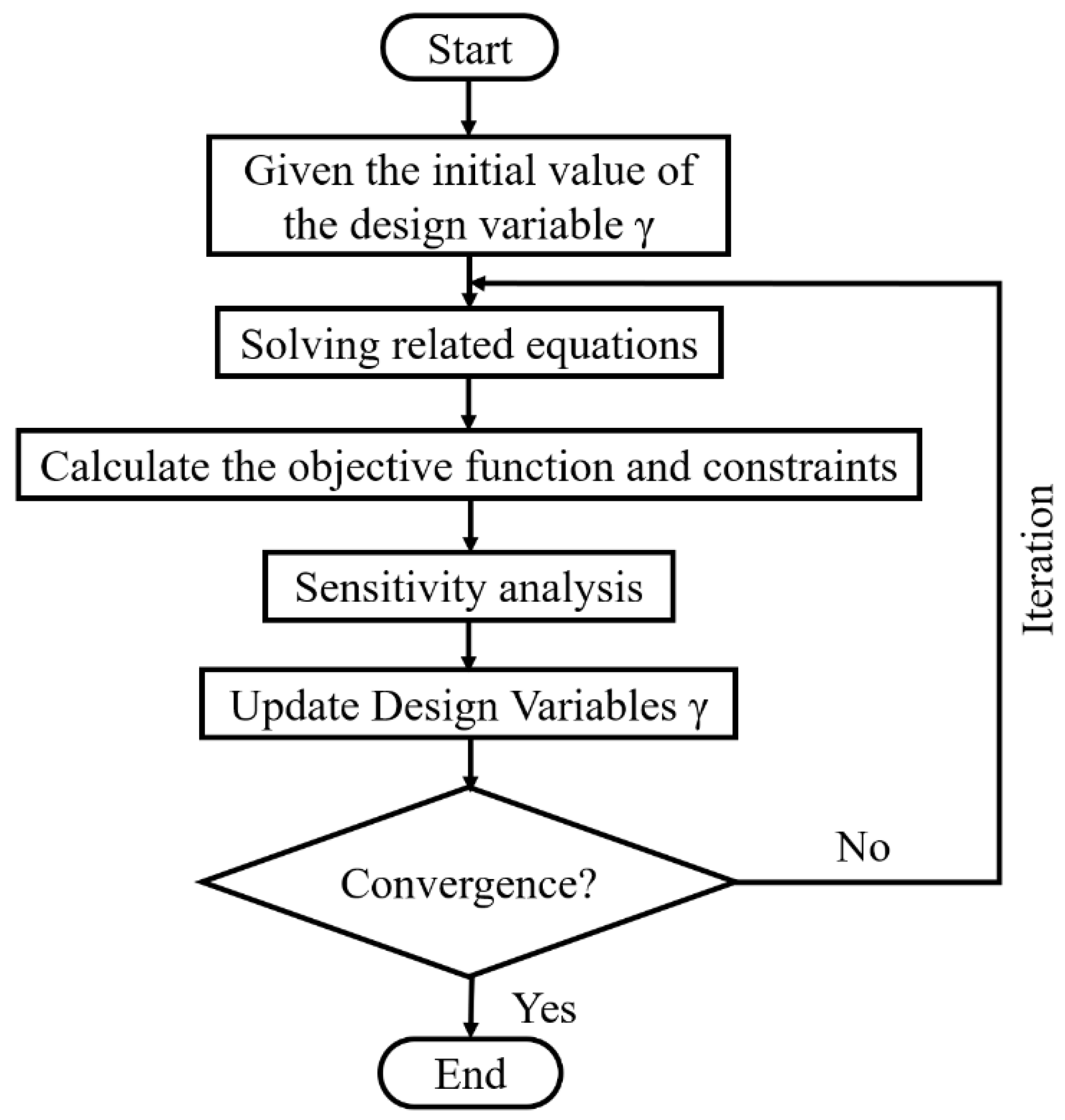

4. The Solution Process of Topology Optimization

- (1)

- Give the initial value of the design variable in the design domain.

- (2)

- Solve equations at various current parameters.

- (3)

- Calculate the objective function and constraints.

- (4)

- Calculate the design sensitivity under the current concomitant variables.

- (5)

- Update the design variable using the Global Convergence Method of Moving Asymptotes (GCMMA).

- (6)

- Loop the above (2)–(5) steps until the iteration termination condition is met.

5. Results and Discussions

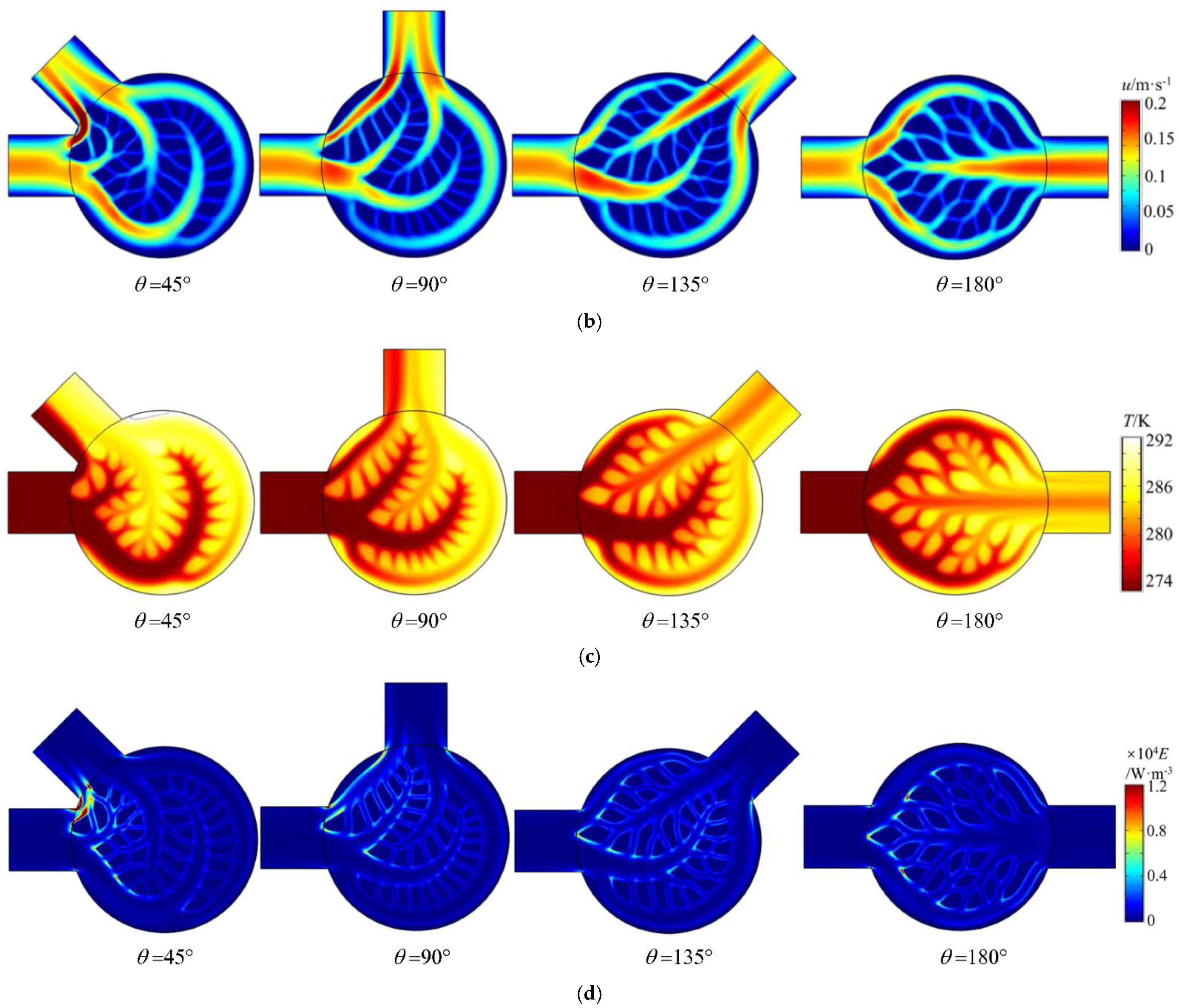

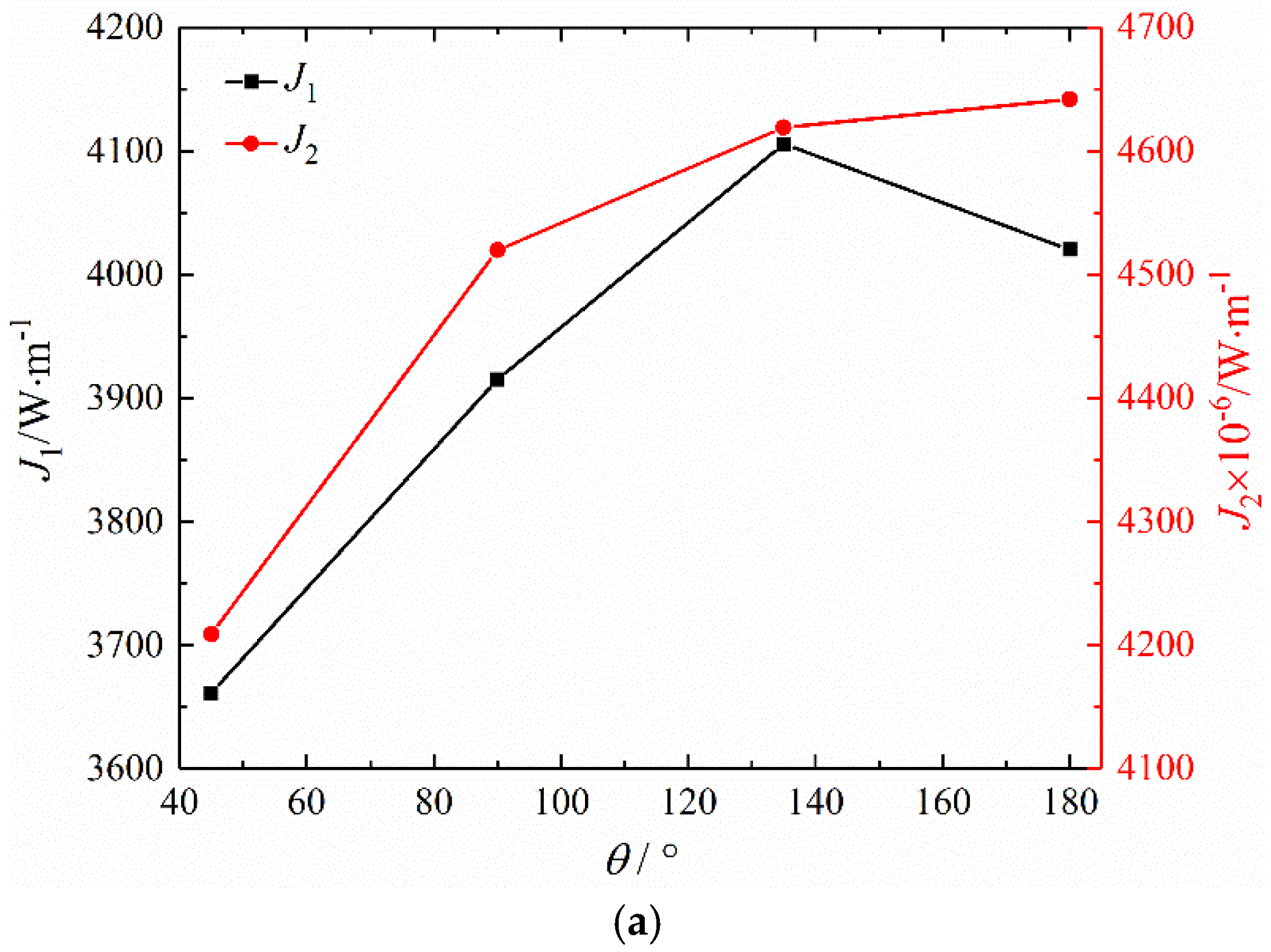

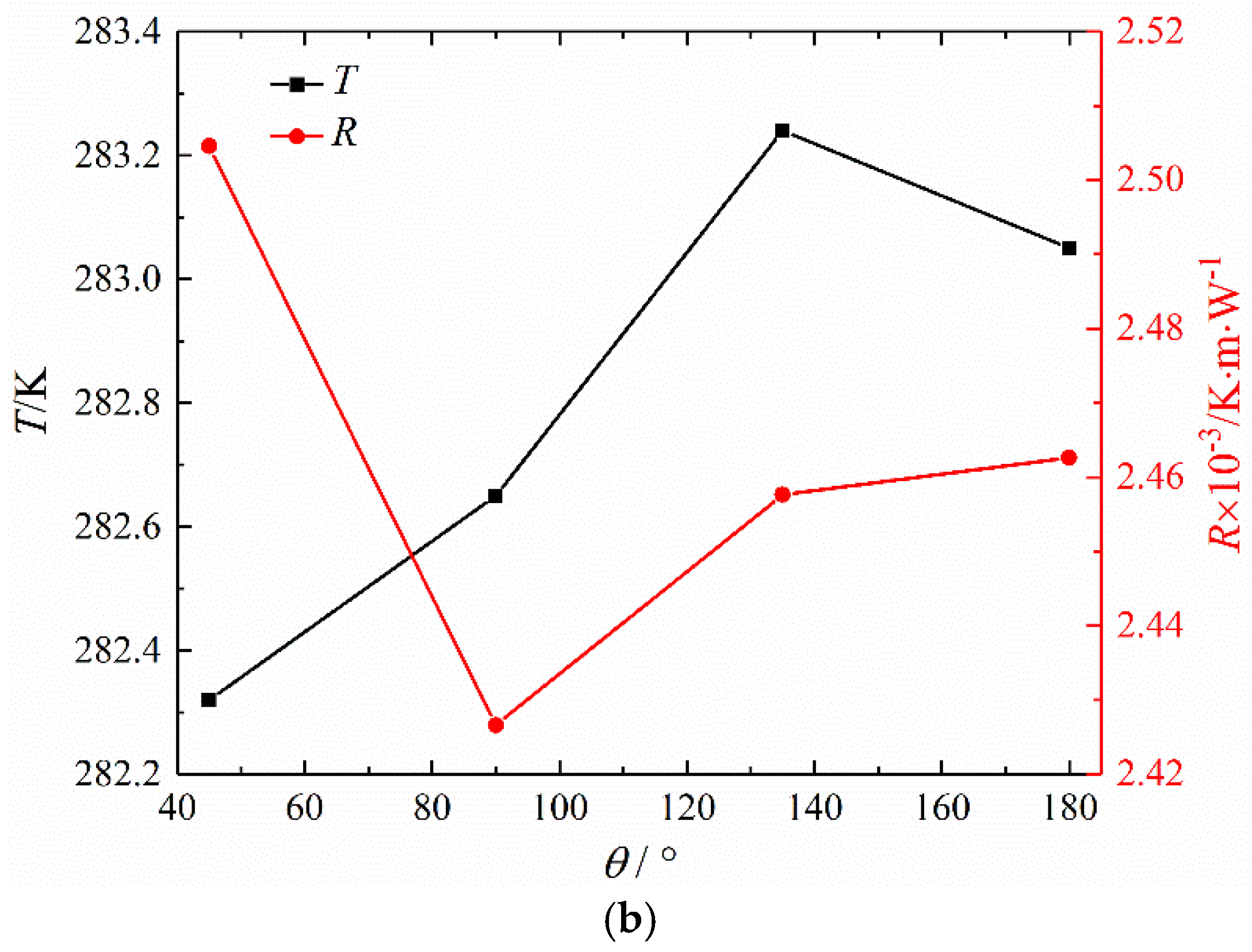

5.1. Micro-Channel Heat Sink Optimization under Different θ

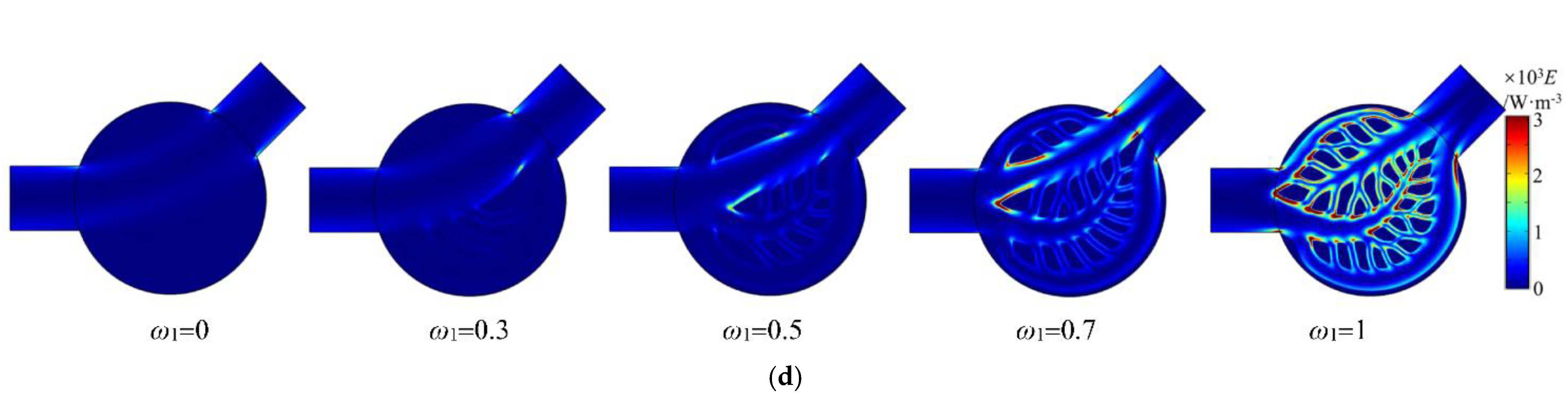

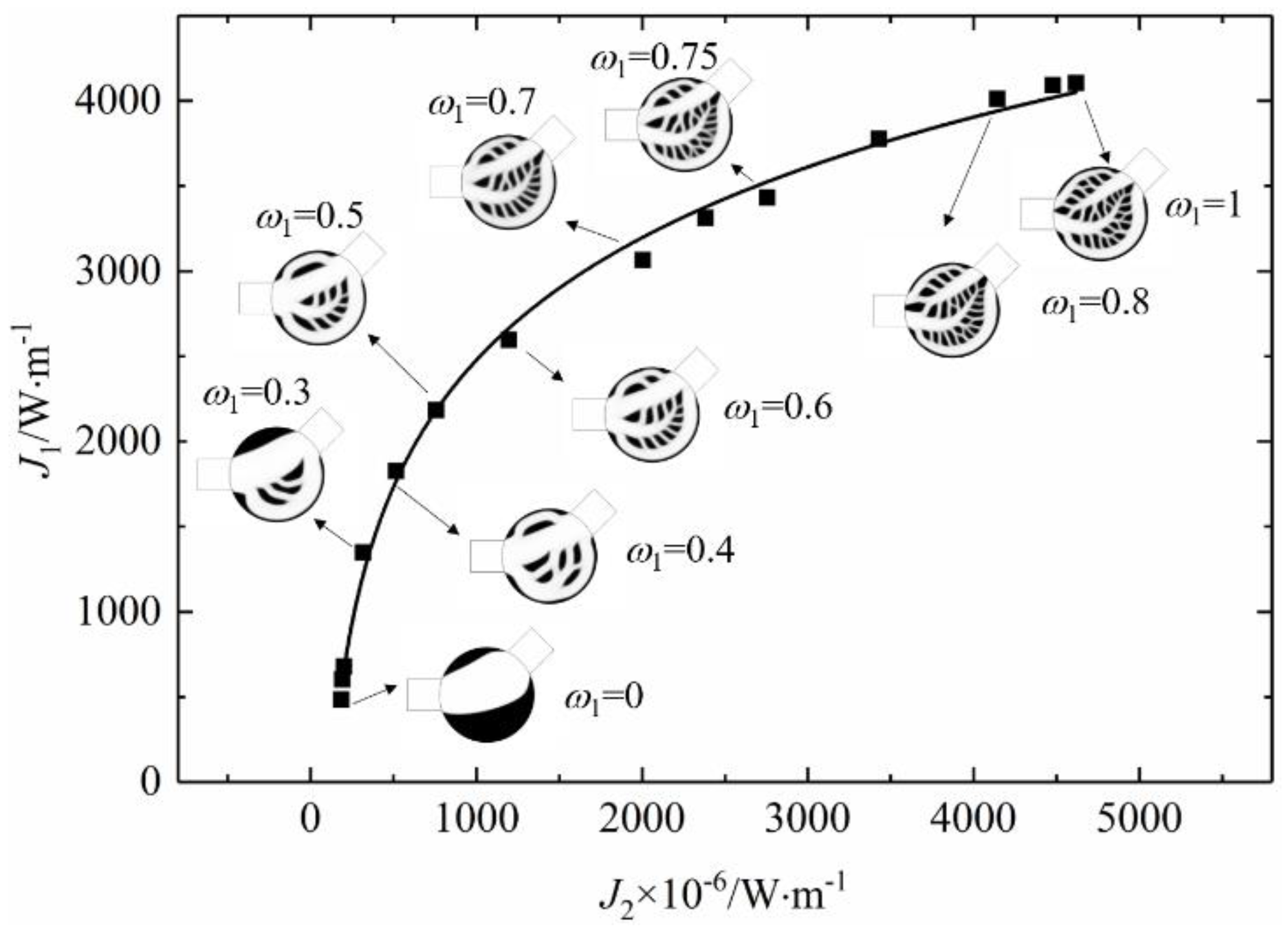

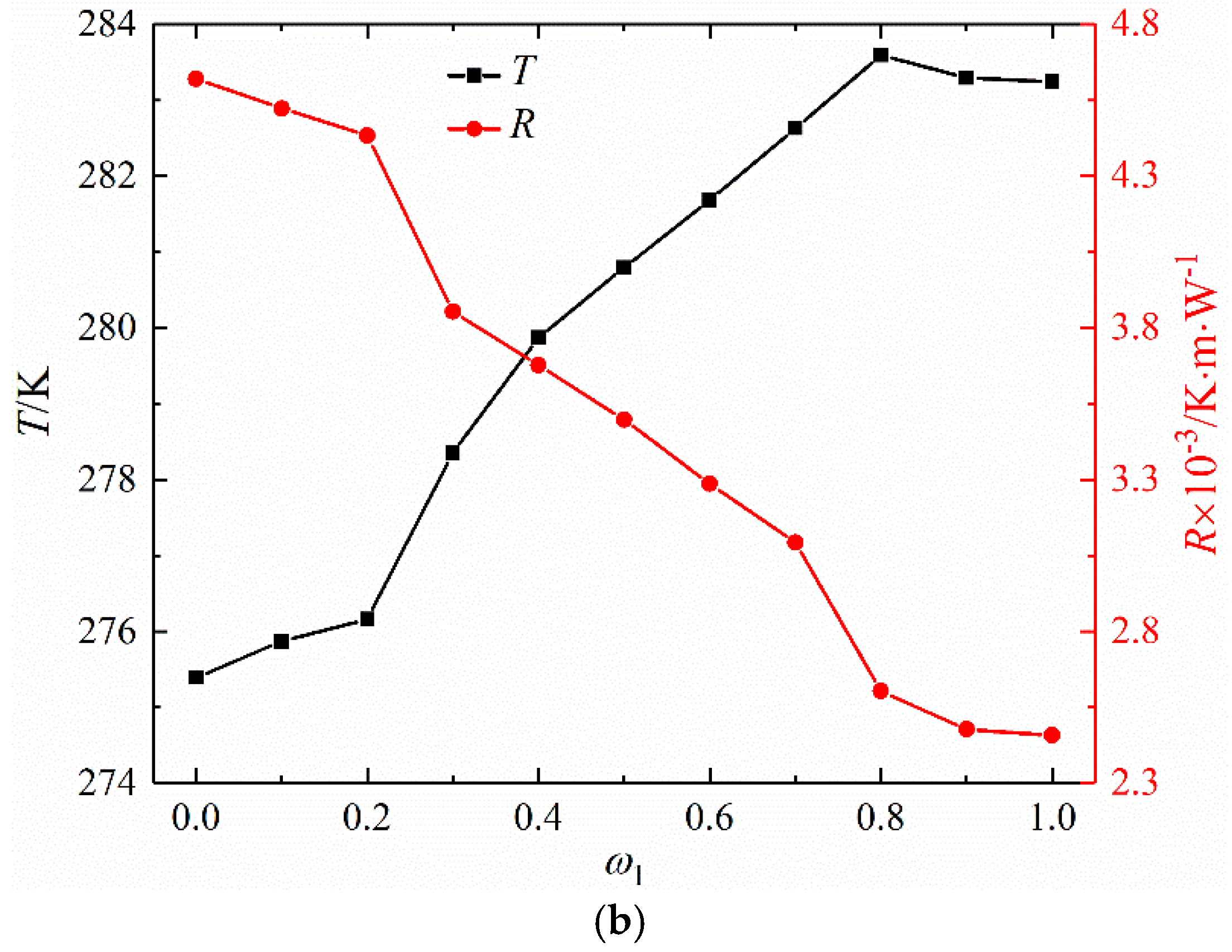

5.2. Micro-Channel Heat Sink Optimization under Different ω1

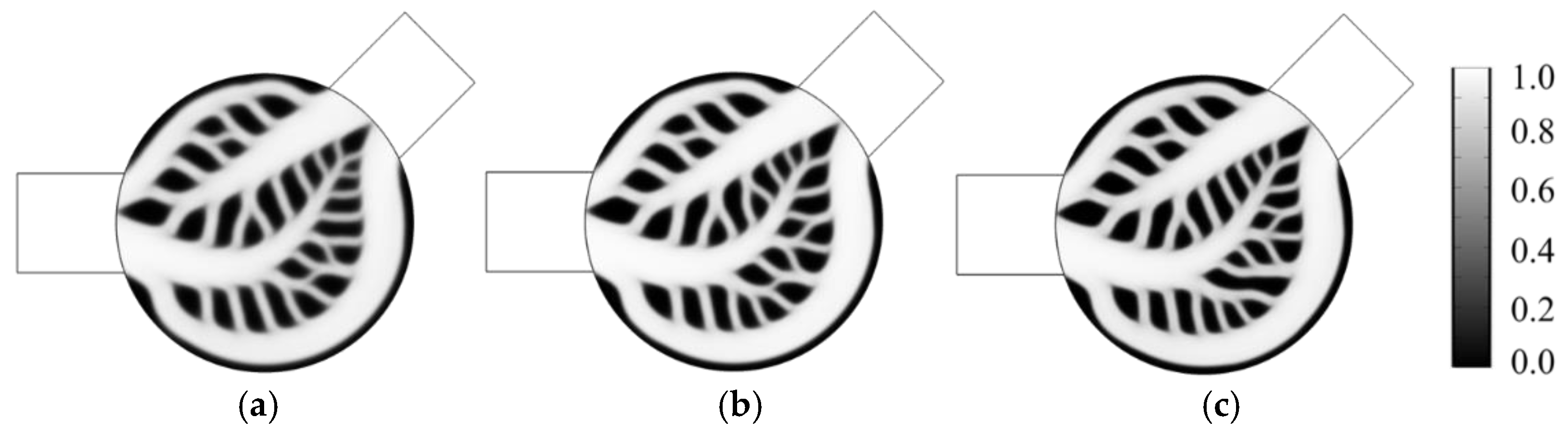

5.3. Mesh Independence Test

6. Conclusions

- In the numerical implementation of topology optimization design, the improved interpolation function, PDE filter, and hyperbolic tangent projection effectively eliminate the gray area of the topology structure and tiny solid particles, which improve the smoothness of the flow channels and avoid checkerboard results.

- The optimal topology of the micro-channel heat sink has obvious regularity with the change of θ. With the increase of θ, the overall performance parameters show a monotonically increasing trend. Among them, the heat exchange and the average outlet temperature reach the maximum value when θ = 135°, and the overall flow energy dissipation is relatively small. Therefore, in the selection of the heat sink, different bifurcation angles can be considered based on the calculation results, rather than the intuitive or empirical selection of θ = 180°.

- Based on the multi-objective topology optimization design, micro-channel heat sinks with different heat transfer weighting coefficients are obtained. When minimizing energy dissipation dominates, the heat sink is occupied by the main channel connecting the inlet and outlet, and the fluid mainly flows out through the main flow channel with few branch flow channels. Its flow energy dissipation is smaller and the heat exchange effect is worse. When the maximum heat exchange is dominant, the main channel of the heat sink is filled with scaly-like distribution of solid heat sources, and the main channel gradually shrinks and is replaced by the upper, middle, and lower branch channels. In addition, the branch flow channels are further refined into many tiny flow channels, which makes the heat exchange effect of the heat sink better and the flow energy consumption larger.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Qu, W.L.; Mudawar, I. Experimental and numerical study of pressure drop and heat transfer in a single-phase micro-channel heat sink. Int. J. Heat Mass Transf. 2002, 45, 2549–2565. [Google Scholar] [CrossRef]

- Afzal, H.; Kwang-Yong, K. Shape optimization of micro-channel heat sink for micro-electronic cooling. IEEE Trans. Compon. Packag. Technol. 2008, 31, 322–330. [Google Scholar] [CrossRef]

- Alperen, Y.; Sertac, C. Multi objective optimization of a micro-channel heat sink through genetic algorithm. Int. J. Heat Mass Transf. 2020, 146, 118847. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, J.G.; Gao, L.M. Topology optimization design of nanofluid-cooled microchannel heat sink with temperature-dependent fluid properties. Appl. Therm. Eng. 2020, 176, 115354. [Google Scholar] [CrossRef]

- Bejan, A.; Errera, M.R. Convective trees of fluid channels for volumetric cooling. Int. J. Heat Mass Transf. 2000, 43, 3105–3118. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhang, F.L.; Sunden, B.; Xie, G. Laminar thermal performance of microchannel heat sinks with constructal vertical Y-shaped bifurcation plates. Appl. Therm. Eng. 2014, 73, 183–193. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, W.Y.; Chen, W.; Wang, N. A conceptual structure for heat transfer imitating the transporting principle of plant leaf. Int. J. Heat Mass Transf. 2014, 71, 79–90. [Google Scholar] [CrossRef]

- Qu, W.L. Comparison of thermal-hydraulic performance of singe-phase micro-pin-fin and micro-channel heat sinks. In Proceedings of the 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 28–31 May 2008. [Google Scholar] [CrossRef]

- Chein, R.; Huang, G. Analysis of microchannel heat sink performance using nanofluids. Appl. Therm. Eng. 2005, 25, 3104–3114. [Google Scholar] [CrossRef]

- Rahbarshahlan, S.; Esmaeilzadeh, E.; Khosroshahi, A.R.; Bakhshayesh, A.G. Numerical simulation of fluid flow and heat transfer in microchannels with patterns of hydrophobic/hydrophilic walls. Eur. Phys. J. Plus 2020, 135, 157. [Google Scholar] [CrossRef]

- Rostamzadeh, A.; Razavi, S.E.; Mirsajedi, S.M. Towards Multidimensional Artificially Characteristic-Based Scheme for Incompressible Thermo-Fluid Problems. Mechanika 2017, 23, 826–834. [Google Scholar] [CrossRef] [Green Version]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Borrvall, T.; Petersson, J. Topology optimization of fluids in Stokes flow. Int. J. Numer. Methods Fluids 2003, 41, 77–107. [Google Scholar] [CrossRef]

- Yoon, G.H. Topological design of heat dissipating structure with forced convective heat transfer. J. Mech. Sci. Technol. 2010, 24, 1225–1233. [Google Scholar] [CrossRef]

- Koga, A.A.; Lopes, E.C.C.; Villa Nova, H.F.; de Lima, C.R.; Silva, E.C.N. Development of heat sink device by using topology optimization. Int. J. Heat Mass Transf. 2013, 64, 759–772. [Google Scholar] [CrossRef]

- Yaji, K.; Yamada, T.; Yoshino, M.; Matsumoto, T.; Izui, K.; Nishiwaki, S. Topology optimization in thermal-fluid flow using the lattice Boltzmann method. J. Comput. Phys. 2016, 307, 355–377. [Google Scholar] [CrossRef]

- Dong, X.; Liu, X.M. Multi-objective optimal design of microchannel cooling heat sink using topology optimization method. Numer. Heat Transf. A Appl. 2020, 77, 90–104. [Google Scholar] [CrossRef]

- Alexandersen, J.; Aage, N.; Andreasen, C.S.; Sigmund, O. Topology optimisation for natural convection problems. Int. J. Numer. Methods Fluids 2014, 76, 699–721. [Google Scholar] [CrossRef] [Green Version]

- Alexandersen, J.; Sigmund, O.; Aage, N. Large scale three-dimensional topology optimisation of heat sinks cooled by natural convection. Int. J. Heat Mass Transf. 2016, 100, 876–891. [Google Scholar] [CrossRef]

- Dede, E.M. Multiphysics topology optimization of heat transfer and fluid flow systems. In Proceedings of the COMSOL Users Conference, Boston, MA, USA, 30 March 2009; Available online: https://www.comsol.com/paper/download/44388/Dede.pdf (accessed on 5 June 2021).

- Zhang, B.; Zhu, J.H.; Xiang, G.X.; Gao, L. Design of nanofluid-cooled heat sink using topology optimization. Chin. J. Aeronaut. 2021, 34, 301–317. [Google Scholar] [CrossRef]

- Yaji, K.; Yamada, T.; Kubo, S.; Izui, K.; Nishiwaki, S. A topology optimization method for a coupled thermal-fluid problem using level set boundary expressions. Int. J. Heat Mass Transf. 2015, 81, 878–888. [Google Scholar] [CrossRef]

- Łaniewski-Wołłk, Ł.; Rokicki, J. Adjoint Lattice Boltzmann for topology optimization on multi-GPU architecture. Comput. Math. Appl. 2016, 71, 833–848. [Google Scholar] [CrossRef]

- Sato, Y.; Yaji, L.; Izui, K.; Yamada, T.; Nishiwaki, S. An optimum design method for a thermal-fluid device incorporating multiobjective topology optimization with an adaptive weighting scheme. J. Mech. Des. 2018, 140, 31402. [Google Scholar] [CrossRef]

- Guirguis, D.; Hamza, K.; Aly, M.; Hegazi, H.; Saitou, K. Multi-objective topology optimization of multi-component continuum structures via a Kriging-interpolated level set approach. Struct. Multidiscip. Optim. 2015, 51, 733–748. [Google Scholar] [CrossRef]

- Lv, Y.; Liu, S. Topology optimization and heat dissipation performance analysis of a micro-channel heat sink. Meccanica 2018, 53, 3693–3708. [Google Scholar] [CrossRef]

- Ghasemi, A.; Elham, A. Multi-objective topology optimization of pin-fin heat exchangers using spectral and finite-element methods. Struct. Multidiscip. Optim. 2021, 64, 2075–2095. [Google Scholar] [CrossRef]

- Lazarov, B.S.; Sigmund, O. Filters in topology optimization based on Helmholtz-type differential equations. Int. J. Numer. Methods Eng. 2011, 86, 765–781. [Google Scholar] [CrossRef]

- Kawamoto, A.; Matsumori, T.; Yamasaki, S.; Nomura, T.; Kondoh, T.; Nishiwaki, S. Heaviside projection based topology optimization by a PDE-filtered scalar function. Struct. Multidiscip. Optim. 2011, 44, 19–24. [Google Scholar] [CrossRef]

- Li, H.; Ding, X.H.; Meng, F.Z.; Jing, D.; Xiong, M. Optimal design and thermal modelling for liquid-cooled heat sink based on multi-objective topology optimization: An experimental and numerical study. Int. J. Heat Mass Transf. 2019, 144, 118638. [Google Scholar] [CrossRef]

- Available online: https://www.comsol.com/ (accessed on 5 June 2021).

- Available online: https://www.mathworks.com/ (accessed on 5 June 2021).

- Tezduyar, T.E.; Mittal, S.; Ray, S.E.; Shih, R. Incompressible flow computations with stabilized bilinear and linear equal-order-interpolation velocity-pressure elements. Comput. Methods Appl. Mech. Eng. 1992, 95, 221–242. [Google Scholar] [CrossRef]

- Timothy, W.A.; Panos, Y.P. A note on weighted criteria methods for compromise solutions in multi-objective optimization. Eng. Optim. 1996, 27, 155–176. [Google Scholar] [CrossRef]

| Material | k (W/m/K) | cp (J/kg/K) | |

|---|---|---|---|

| Fluid | 0.6 | 4180 | 1000 |

| Solid | 238 | 900 | 2700 |

| Mesh Number | J1/W∙m−1 | Relative Former Difference (J1) | J2/W∙m−1 (×10−6) | Relative Former Difference (J2) | T/K | Relative Former Difference (T) |

|---|---|---|---|---|---|---|

| (a) 68,250 | 4033.1 | × | 4614.6 | × | 283.07 | × |

| (b) 97,386 | 4105.6 | 1.80% | 4619.1 | 0.10% | 283.24 | 0.06% |

| (c) 131,815 | 4149.1 | 1.06% | 4608.9 | −0.22% | 283.35 | 0.04% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, J.; Liu, X. Topology Optimization Design of Micro-Channel Heat Sink by Considering the Coupling of Fluid-Solid and Heat Transfer. Energies 2022, 15, 8827. https://doi.org/10.3390/en15238827

Wang Y, Wang J, Liu X. Topology Optimization Design of Micro-Channel Heat Sink by Considering the Coupling of Fluid-Solid and Heat Transfer. Energies. 2022; 15(23):8827. https://doi.org/10.3390/en15238827

Chicago/Turabian StyleWang, Yue, Jiahao Wang, and Xiaomin Liu. 2022. "Topology Optimization Design of Micro-Channel Heat Sink by Considering the Coupling of Fluid-Solid and Heat Transfer" Energies 15, no. 23: 8827. https://doi.org/10.3390/en15238827

APA StyleWang, Y., Wang, J., & Liu, X. (2022). Topology Optimization Design of Micro-Channel Heat Sink by Considering the Coupling of Fluid-Solid and Heat Transfer. Energies, 15(23), 8827. https://doi.org/10.3390/en15238827