Flexible Droop Coefficient-Based Inertia and Voltage Cascade Control for Isolated PV-Battery DC Microgrid

Abstract

:1. Introduction

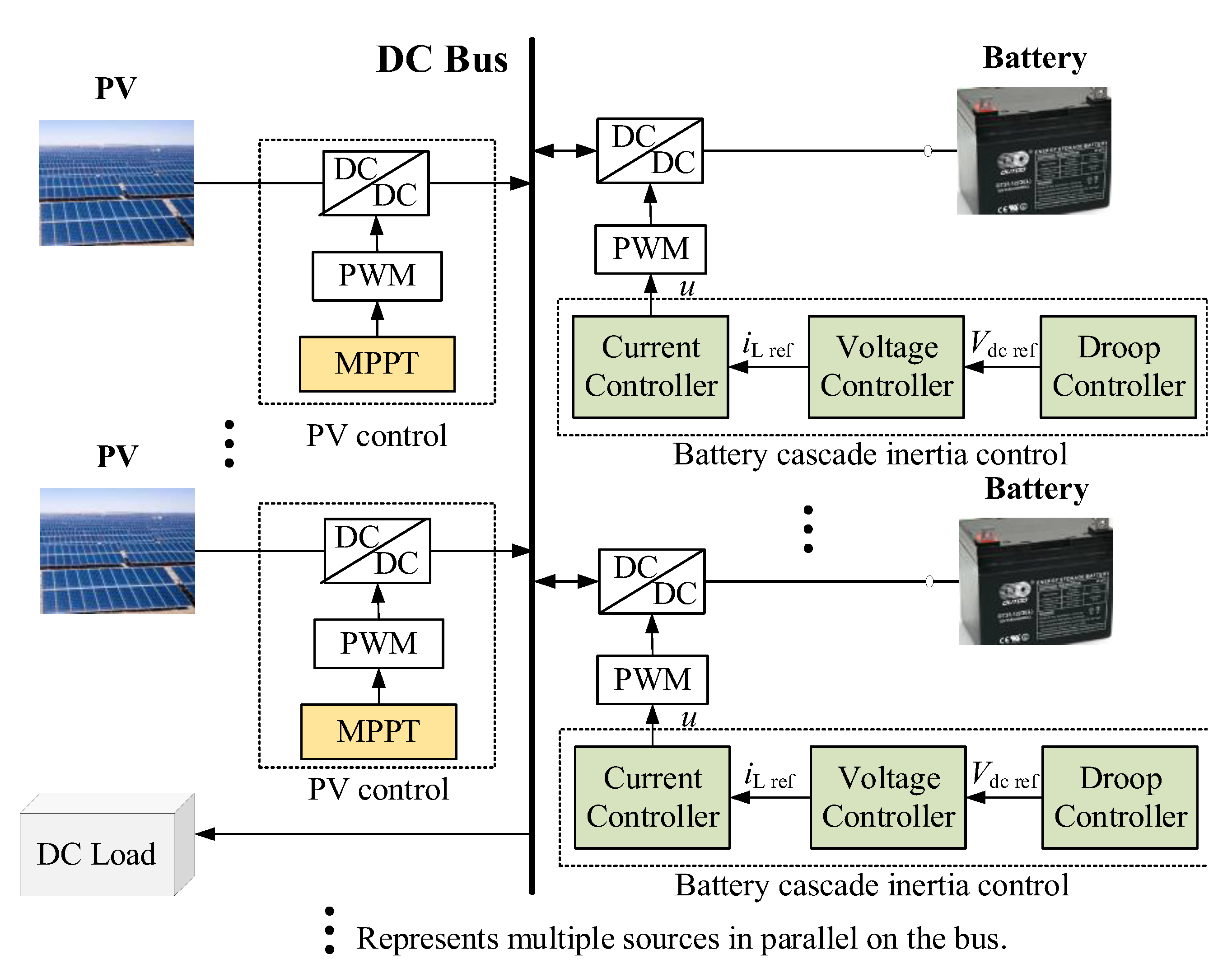

2. Flexible V-P Droop Coefficient-Based Inertia Control

2.1. V-P Characteristic-Based Droop Control

2.2. Inertia Analysis of Battery Converter

2.3. Flexible V-P Droop Coefficient-Based Inertia Control

3. NTSMC for Tracking Voltage and Current References

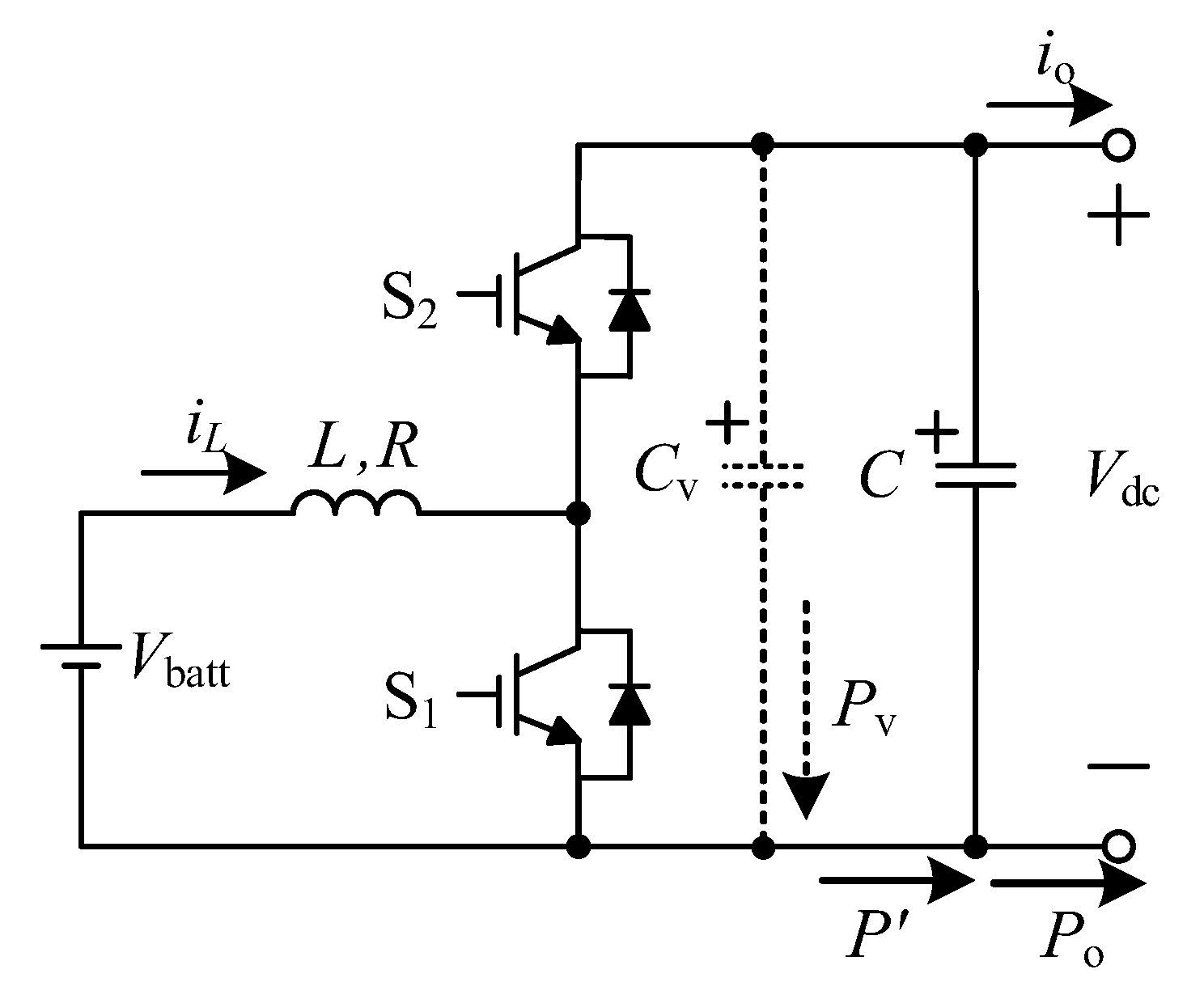

3.1. Model of the Battery Bidirectional DC–DC Converter

3.2. NTSMC for Tracking Voltage and Current References

3.3. NTSMC Performance Analysis for Tracking Voltage and Current References

4. Simulation Results

4.1. Scheme I: Condition Involving Sudden Changes in Load Power

4.2. Scheme II: Condition Involving Out-of-Operation PV Failure

4.3. Scheme III: Condition Involving Continuous Load Fluctuation

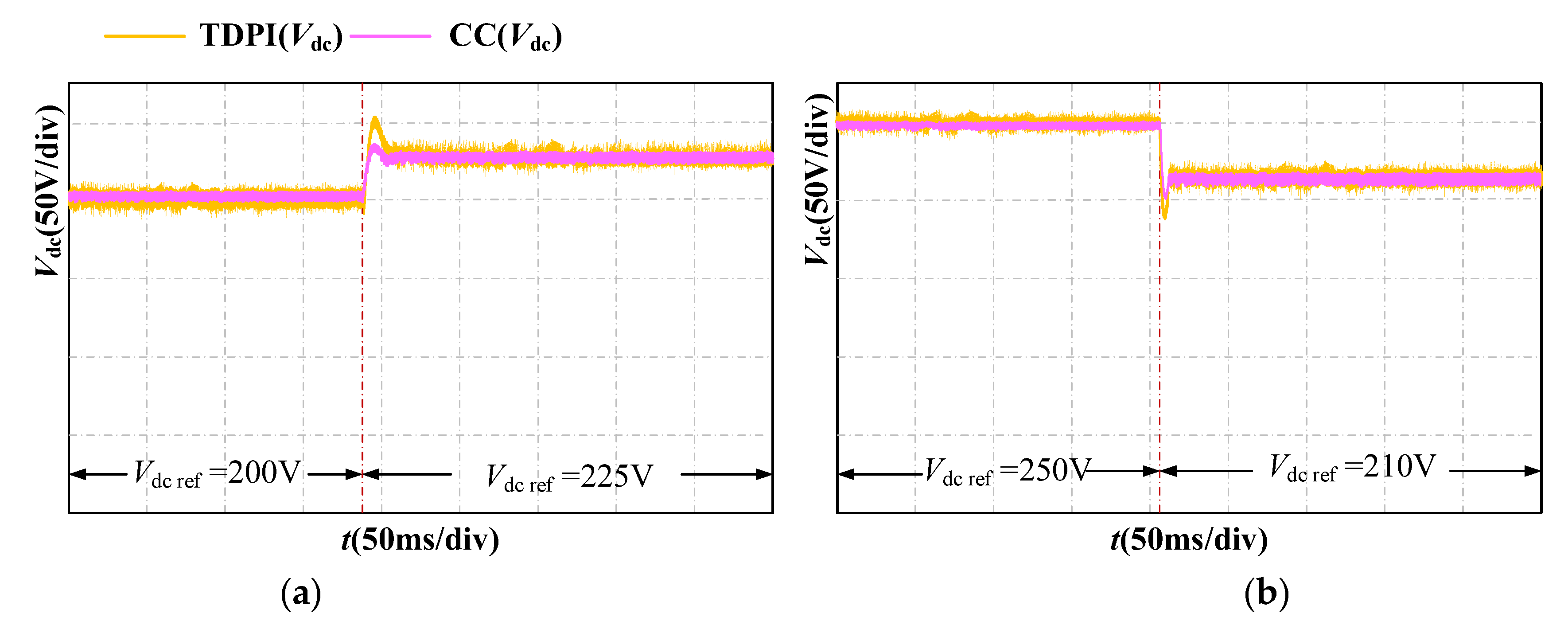

5. Experimental Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Vdc | Battery converter output voltage | u | Drive signal with a duty cycle |

| Vdc ref | Reference value of the battery converter output voltage | L0 | Nominal values of L |

| P | Battery converter output active power | R0 | Nominal values of R |

| Pref | Rated value of the battery converter output active power | C0 | Nominal values of C |

| Vbatt | Terminal voltage of the battery | zV | Deviations of actual and reference values of the voltage loop |

| io | Battery converter output current | zi | Deviations of actual and reference values of the current loop |

| iL | Terminal current of the battery | iLref | Output current reference value of the voltage controller |

| L | Filter inductance | sV | NTSMC switching functions of the voltage loop |

| R | Internal resistance | si | NTSMC switching functions of the current loop |

| C | Inherent filter capacitor | VV | Lyapunov functions of the voltage-loop control laws |

| Cv | Virtual capacitor | Vi | Lyapunov functions of the current-loop control laws |

| Wo | Electric energy provided by the capacitor C to the DC bus | Vo | DC bus voltage |

| G1 | Droop coefficient when the microgrid is in a steady state | Si | Power switch |

| G2 | Dynamic coefficient | P′ | Active power of the converter flowing to the capacitor C when the battery adopts flexible V-P droop coefficient-based inertia control |

| Gmax | Upper limit of the dynamic coefficient | Po | Active power flowing from the capacitor C to the DC bus |

| Gmin | Lower limit of the dynamic coefficient | Pv | Introduced inertia power |

| dVdc/dt | Voltage variation rate | W | Electric energy provided by the battery converter to the capacitor C side |

| Abbreviation | |||

| TSMC | Terminal sliding mode control | TDPI | Traditional droop control and PI control method |

| NTSMC | Nonsingular terminal sliding mode control | CC | The cascade control proposed in this paper |

References

- Okwako, O.E.; Lin, Z.-H.; Xin, M.; Premkumar, K.; Rodgers, A.J. Neural Network Controlled Solar PV Battery Powered Unified Power Quality Conditioner for Grid Connected Operation. Energies 2022, 15, 6825. [Google Scholar] [CrossRef]

- Pranith, S.; Kumar, S.; Singh, B.; Bhatti, T.S. Improved Gaussian Filter Based Solar PV-BES Microgrid With PLL Based Islanding Detection and Seamless Transfer Control. IEEE Trans. Ind. Electron. 2022, 69, 5815–5825. [Google Scholar] [CrossRef]

- Alramlawi, M.; Li, P. Design Optimization of a Residential PV-Battery Microgrid with a Detailed Battery Lifetime Estimation Model. IEEE Trans. Ind. Appl. 2020, 56, 2020–2030. [Google Scholar] [CrossRef]

- Valibeygi, A.; Konakalla, S.A.R.; Callafon, R.D. Predictive Hierarchical Control of Power Flow in Large-Scale PV Microgrids With Energy Storage. IEEE Trans. Sustain. Energy 2021, 12, 412–419. [Google Scholar] [CrossRef]

- Shubhra, S.; Singh, B. Three-Phase Grid-Interactive Solar PV-Battery Microgrid Control Based on Normalized Gradient Adaptive Regularization Factor Neural Filter. IEEE Trans. Ind. Inform. 2020, 16, 2301–2314. [Google Scholar] [CrossRef]

- Li, D.; Ho, C.N.M. Decentralized PV–BES Coordination Control with Improved Dynamic Performance for Islanded Plug-n-Play DC Microgrid. IEEE Trans. J. Emerg. Sel. Topics Power Electron. 2021, 9, 4992–5001. [Google Scholar] [CrossRef]

- Oliver, J.S.; David, P.W.; Balachandran, P.K.; Mihet-Popa, L. Analysis of Grid-Interactive PV-Fed BLDC Pump Using Optimized MPPT in DC–DC Converters. Sustainability 2022, 14, 7205. [Google Scholar] [CrossRef]

- Dragičević, T.; Guerrero, J.M.; Vasquez, J.C.; Škrlec, D. Supervisory Control of an Adaptive-Droop Regulated DC Microgrid With Battery Management Capability. IEEE Trans. Power Electron. 2014, 29, 695–706. [Google Scholar] [CrossRef] [Green Version]

- Beerten, J.; Belmans, R. Analysis of Power Sharing and Voltage Deviations in Droop-Controlled DC Grids. IEEE Trans. Power Syst. 2013, 28, 4588–4597. [Google Scholar] [CrossRef] [Green Version]

- Shi, M.; Chen, X.; Zhou, J.; Chen, Y.; Wen, J.; He, H. Advanced Secondary Voltage Recovery Control for Multiple HESSs in a Droop-Controlled DC Microgrid. IEEE Trans. Smart Grid. 2019, 10, 3828–3839. [Google Scholar] [CrossRef]

- Wang, W.; Li, Y.; Cao, Y.; Häger, U.; Rehtanz, C. Adaptive Droop Control of VSC-MTDC System for Frequency Support and Power Sharing. IEEE Trans. Power Syst. 2018, 33, 1264–1274. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, M.; Li, G. Applying power margin tracking droop control to flexible operation in multi-terminal DC collector systems of renewable generation. CSEE J. Power Energy Syst. 2021, 7, 1176–1186. [Google Scholar]

- Prabhakaran, P.; Goyal, Y.; Agarwal, V. Novel nonlinear droop control techniques to overcome the load sharing and voltage regulation issues in DC microgrid. IEEE Trans. Power Electron. 2018, 33, 4477–4487. [Google Scholar] [CrossRef]

- Lu, X.; Guerrero, J.M.; Sun, K.; Vasquez, J.C. An improved droop control method for DC microgrids based on low bandwidth communication with DC bus voltage restoration and enhanced current sharing accuracy. IEEE Trans. Power Electron. 2014, 29, 1800–1811. [Google Scholar] [CrossRef] [Green Version]

- Vu, T.V.; Perkins, D.; Diaz, F.; Gonsoulin, D.; Edrington, C.S.; El-Mezyani, T. Robust adaptive droop control for DC microgrids. Electr. Power Syst. Res. 2017, 146, 95–106. [Google Scholar] [CrossRef] [Green Version]

- Ratnam, K.S.; Palanisamy, K.; Yang, G. Future low-inertia power systems: Requirements, issues, and solutions—A review. Renew. Sust. Energy Rev. 2020, 124, 109773. [Google Scholar] [CrossRef]

- Saxena, P.; Singh, N.; Pandey, A.K. Enhancing the dynamic performance of microgrid using derivative controlled solar and energy storage based virtual inertia system. J. Energy Storage 2020, 31, 101613. [Google Scholar] [CrossRef]

- Jami, M.; Shafiee, Q.; Gholami, M.; Bevrani, H. Control of a super-capacitor energy storage system to mimic inertia and transient response improvement of a direct current micro-grid. J. Energy Storage 2020, 32, 101788. [Google Scholar] [CrossRef]

- Mi, Y.; Zhang, H.; Fu, Y.; Wang, C.; Loh, P.C.; Wang, P. Intelligent power sharing of DC isolated microgrid based on fuzzy sliding mode droop control. IEEE Trans. Smart Grid. 2019, 10, 2396–2406. [Google Scholar] [CrossRef]

- Mohammadzadeh, A.; Kayacan, E. A novel fractional-order type-2 fuzzy control method for online frequency regulation in ac microgrid. Eng. Appl. Artif. Intell. 2020, 90, 103483. [Google Scholar] [CrossRef]

- Cucuzzella, M.; Lazzari, R.; Trip, S.; Rosti, S.; Sandroni, C.; Ferrara, A. Sliding mode voltage control of boost converters in DC microgrids. Control. Eng. Pract. 2018, 73, 161–170. [Google Scholar] [CrossRef]

- Chen, S.Y.; Lin, F.J. Robust Nonsingular Terminal Sliding-Mode Control for Nonlinear Magnetic Bearing System. IEEE Trans. Control. Syst. Technol. 2011, 19, 636–643. [Google Scholar] [CrossRef]

| Vdc ref Change from 200 V to 400 V | Vdc ref Change from 400 V to 300 V | |||

|---|---|---|---|---|

| Overshoot | Response Time/s | Overshoot | Response Time/s | |

| PI | 6.25% | 0.4 | 4% | 0.4 |

| NTSMC | 5% | 0.3 | 2.67% | 0.3 |

| Voltage Loop | Numerical Values | Current Loop | Numerical Values |

|---|---|---|---|

| βV | 0.00035 | βi | 0.00028 |

| pV | 13 | pi | 11 |

| qV | 9 | qi | 9 |

| λV | 1 | λi | 1 |

| ηV | 32,000 | ηi | 43,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Xue, S.; Wang, Z.; Yu, F.; Chen, H. Flexible Droop Coefficient-Based Inertia and Voltage Cascade Control for Isolated PV-Battery DC Microgrid. Energies 2022, 15, 9318. https://doi.org/10.3390/en15249318

Yin Z, Xue S, Wang Z, Yu F, Chen H. Flexible Droop Coefficient-Based Inertia and Voltage Cascade Control for Isolated PV-Battery DC Microgrid. Energies. 2022; 15(24):9318. https://doi.org/10.3390/en15249318

Chicago/Turabian StyleYin, Zhilong, Shuilian Xue, Zhiguo Wang, Feng Yu, and Hailiang Chen. 2022. "Flexible Droop Coefficient-Based Inertia and Voltage Cascade Control for Isolated PV-Battery DC Microgrid" Energies 15, no. 24: 9318. https://doi.org/10.3390/en15249318