A Critical Review on Geometric Improvements for Heat Transfer Augmentation of Microchannels

Abstract

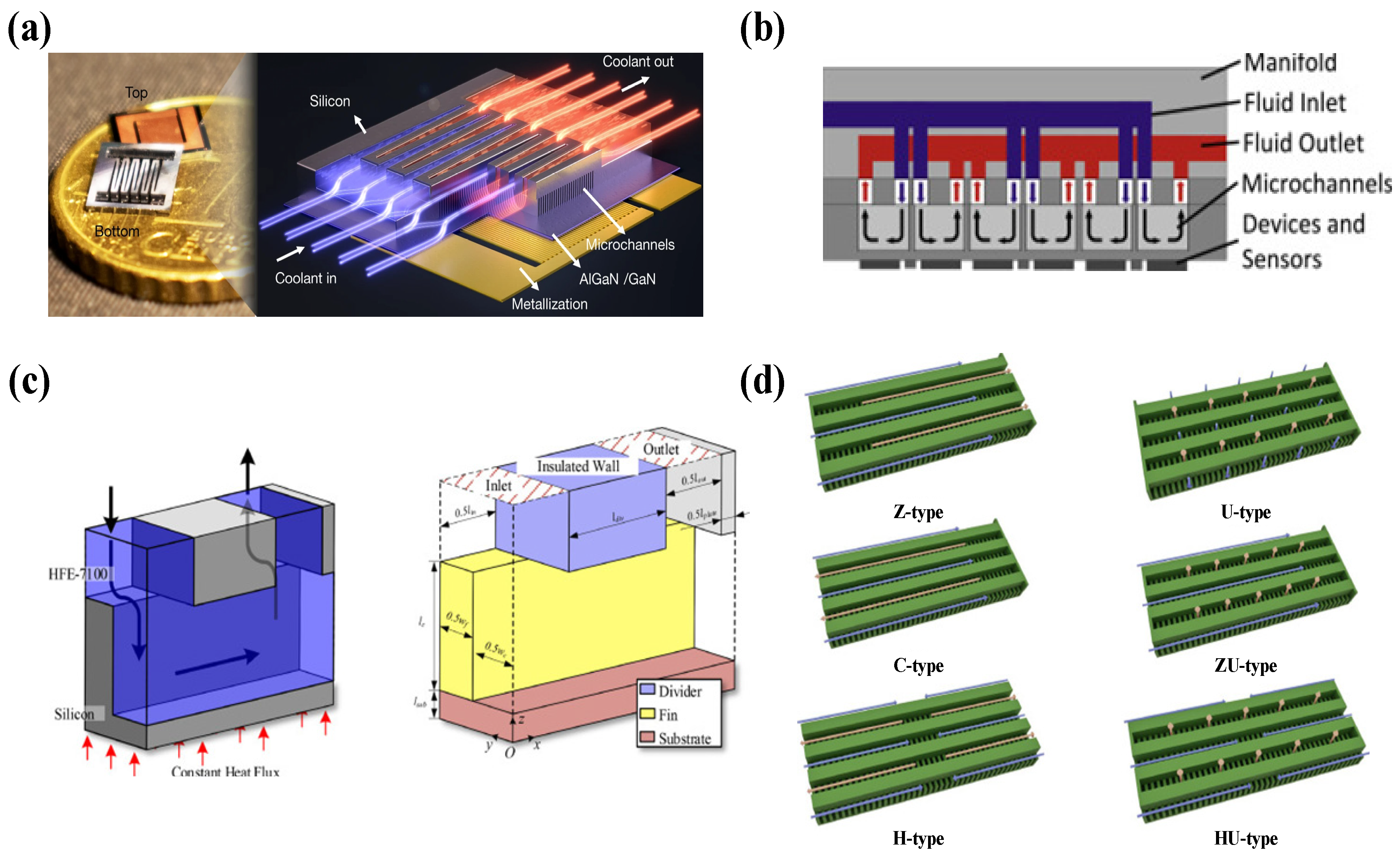

:1. Introduction

2. Fundamentals of Optimizing Geometry Technology for Microchannel Heat Transfer

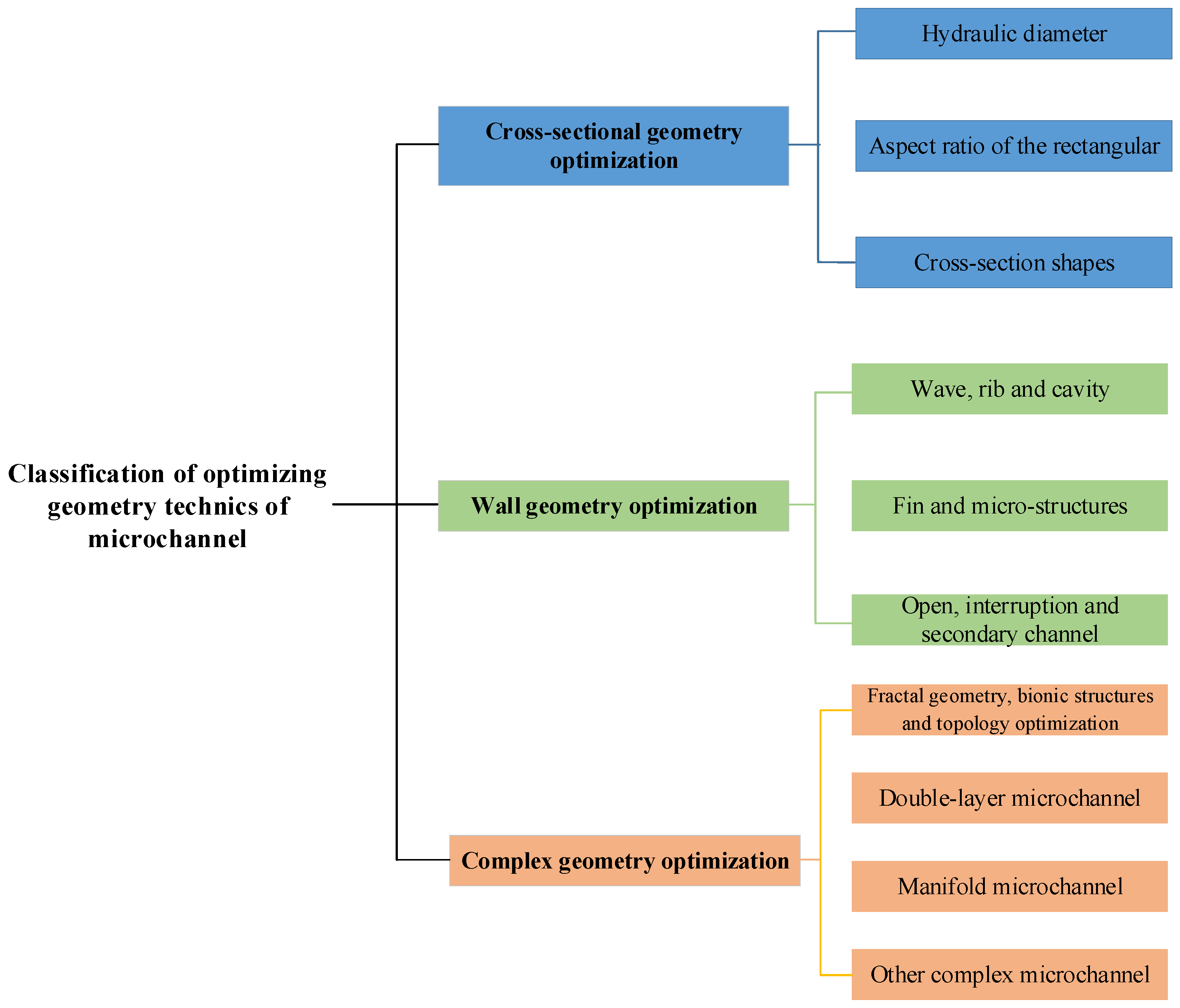

2.1. Classification of Optimizing Geometry Technology

2.2. The Mechanism of Optimizing Geometry Technology for Microchannel Heat Transfer

- The increase of heat transfer surface area. Optimizing the geometric structure can increase a larger surface area to volume ratio. The application of optimized geometric techniques, such as a smaller section size [26], complex section shapes [27], wall ribs [28,29,30], cavities [31], and pin fins [32] can effectively improve the heat transfer surface area.

- The redevelopment of the thermal boundary layer. The conventional straight channel fully develops the thermal boundary layer along with the flow direction. The hot fluid accumulates at the edge of the channel. The heat exchange between the mainstream cold fluid and the wall is limited. The optimized geometry technology interrupts and re-develops the developed thermal boundary layer through ribs [33], pin fins [34], and microstructures [35] to promote the mixing of hot and cold fluids.

- Secondary flow and chaotic mixing [36]. The optimized geometry technology generates secondary flow and fluid mixing locally in the microchannel. This accelerates the fluid flow, enhances the turbulence, reduces laminar stagnation zones, and increases the disturbance to the central mainstream cold fluid.

- Enhanced boiling heat transfer [37]. For the flow-boiling heat transfer, the optimized geometry technology is very important for the control and guidance of bubble behavior, increasing bubble nucleation, controlling the frequency of bubble detachment, and forming a suitable thin liquid film, which is beneficial to heat transfer augmentation.

- The field synergy principle [38]. The optimized geometry technology can improve the synergistic relationship between the fluid velocity field and the temperature gradient field to enhance the overall heat or mass transfer capacity.

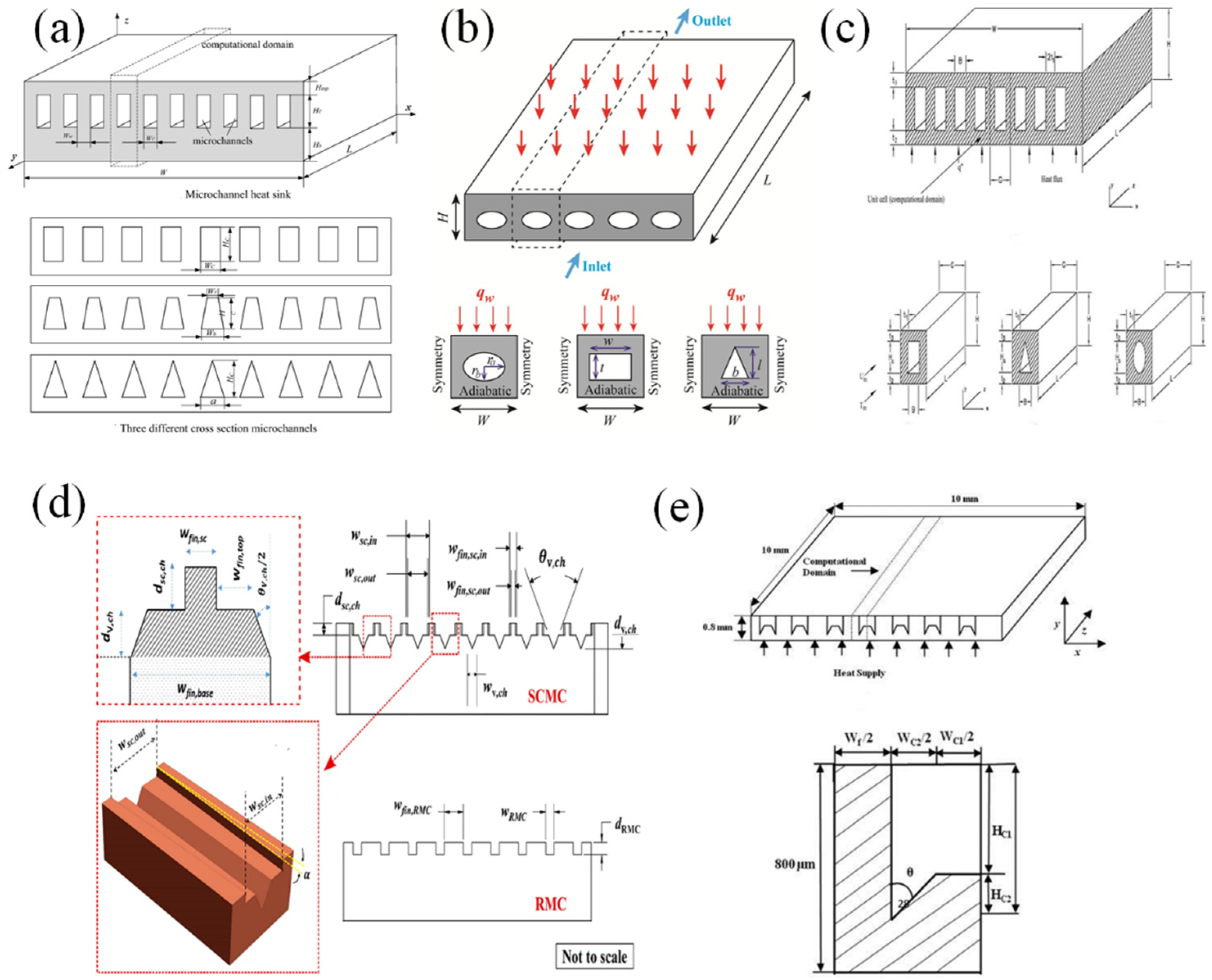

3. Cross-Sectional Geometry Optimization

3.1. Sizes of Cross-Sectional Geometry

3.1.1. Hydraulic Diameter

3.1.2. Aspect Ratio

3.2. Cross-Section Shapes

4. Wall Geometry Optimization

4.1. Wave, Rib, and Cavity on Sidewall

| Reference | Type of Wall Geometry Optimizations | Research Method/ Fluid/ Flow Pattern | Heat Transfer/ Flow Resistance/ Mechanism |

|---|---|---|---|

| Lin et al. [33] | Wave on sidewall | Simulation/ Water/ Single-phase flow | ΔT , Nu , Nu /-/ /-/Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Mohammed et al. [66] | Wave on sidewall | Simulation/ Water/ Single-phase flow | h /ΔP /ΔP / /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Xu et al. [71] | Cavity on bottom wall | Simulation/ Water/ Single-phase flow | Nu 15%/ΔP 15%/ΔP 2%/ 2%/Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Chai et al. [28] | Rib on sidewall | Simulation/ Water/ Single-phase flow | Nu 42~95%/ΔP 42~95%/ΔP / /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Kumar et al. [31] | Cavity on top wall and bottom wall | Simulation and experiment/Water/Single-phase flow | Nu /ΔP /ΔP /Enhanced convection, and increased heat transfer surface area /Enhanced convection, and increased heat transfer surface area |

| Chai et al. [75] | Cavity on sidewall | Simulation/ Water/ Single-phase flow | Nu /ΔP /ΔP / /Enhanced convection, redeveloped boundary layer, and increased heat transfer surface area |

| Li et al. [76] | Cavity on sidewall | Experiment/ Acetone/ Flow boiling | h 155~988%/ 155~988%/ΔP  12.8~50.3%/ 12.8~50.3%/Enhanced convection, and increased heat transfer surface area |

| Chai et al. [77] | Cavity on sidewall | Simulation and experiment/ Water/ Single-phase flow | h 12.5~80.4%, 12.5~80.4%, Nu  180%/ΔP 180%/ΔP / /Enhanced convection, and increased heat transfer surface area |

| Xia et al. [78] | Rib and cavity on sidewall | Simulation/ Water/ Single-phase flow | Nu 167%/- 167%/-/Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Deng et al. [79] | Fin on bottom wall | Experiment/ Water and ethanol/ Flow boiling | h 10~175%/- 10~175%/-/Enhanced chaotic mixing and convection, and redeveloped boundary layer |

| Xie et al. [35] | Micro- structures on bottom wall | Simulation/ Water/ Single-phase flow | h 40~80%, R 40~80%, R 41.02%/ 41.02%/ΔP  /Enhanced convection, redeveloped boundary layer, and increased heat transfer surface area /Enhanced convection, redeveloped boundary layer, and increased heat transfer surface area |

| Rajalingam et al. [80] | Micro- structures on bottom wall | Simulation/ Water/ Single-phase flow | h 161~170%/ΔP 161~170%/ΔP /Enhanced chaotic mixing and convection, and redeveloped boundary layer |

| Ahmadian-Elmi et al. [81] | Fin on bottom wall | Simulation/ Air/ Single-phase flow | h /ΔP /ΔP /Enhanced chaotic mixing and convection, and redeveloped boundary layer |

| Zeng et al. [82] | Fin on bottom wall | Simulation and experiment/ Water/ Single-phase flow | Nu 56~260%/ 56~260%/ΔP  9~27%/ 9~27%/Enhanced chaotic mixing and convection, and redeveloped boundary layer |

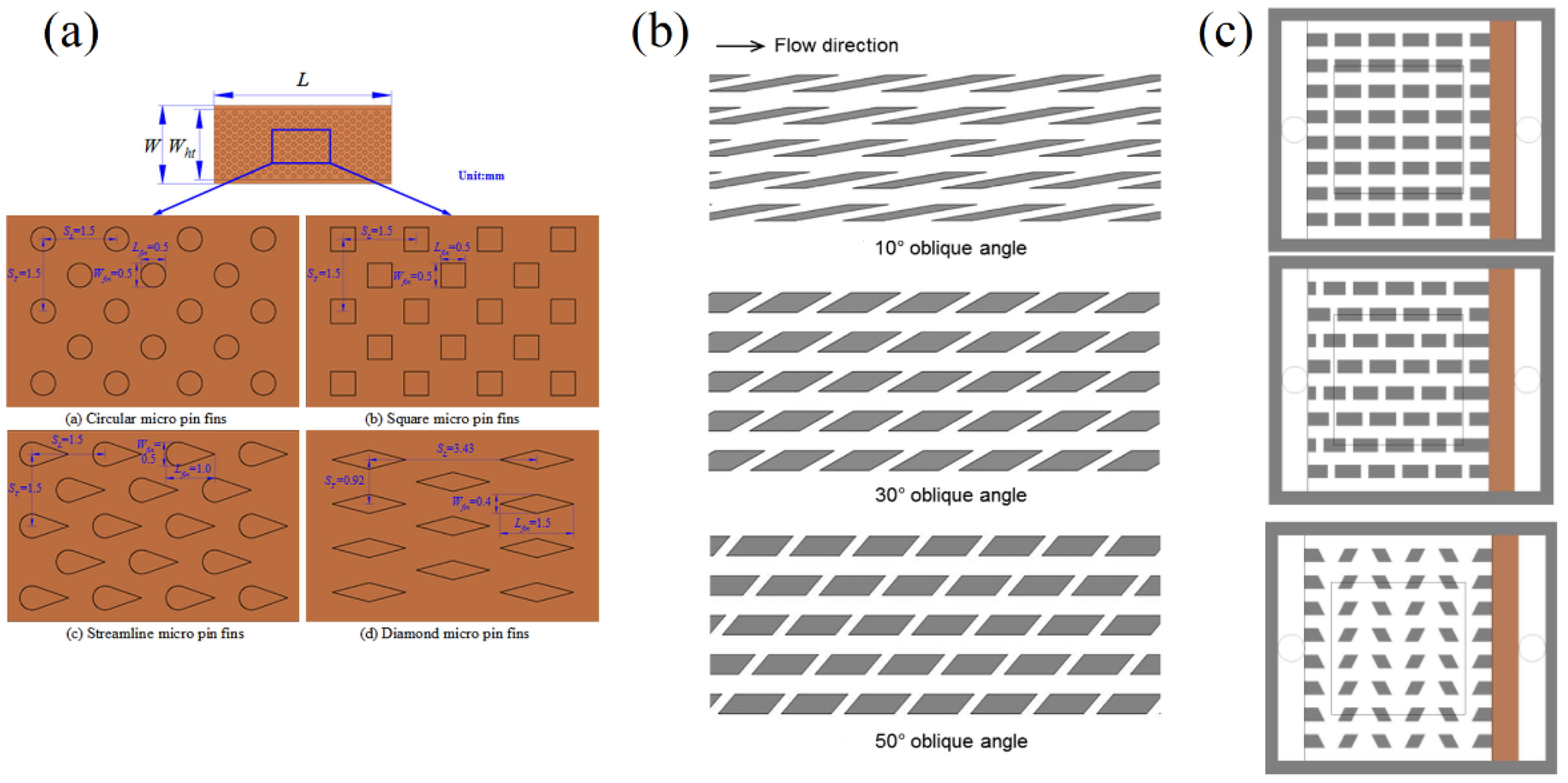

4.2. Fin and Microstructures on Bottom Wall

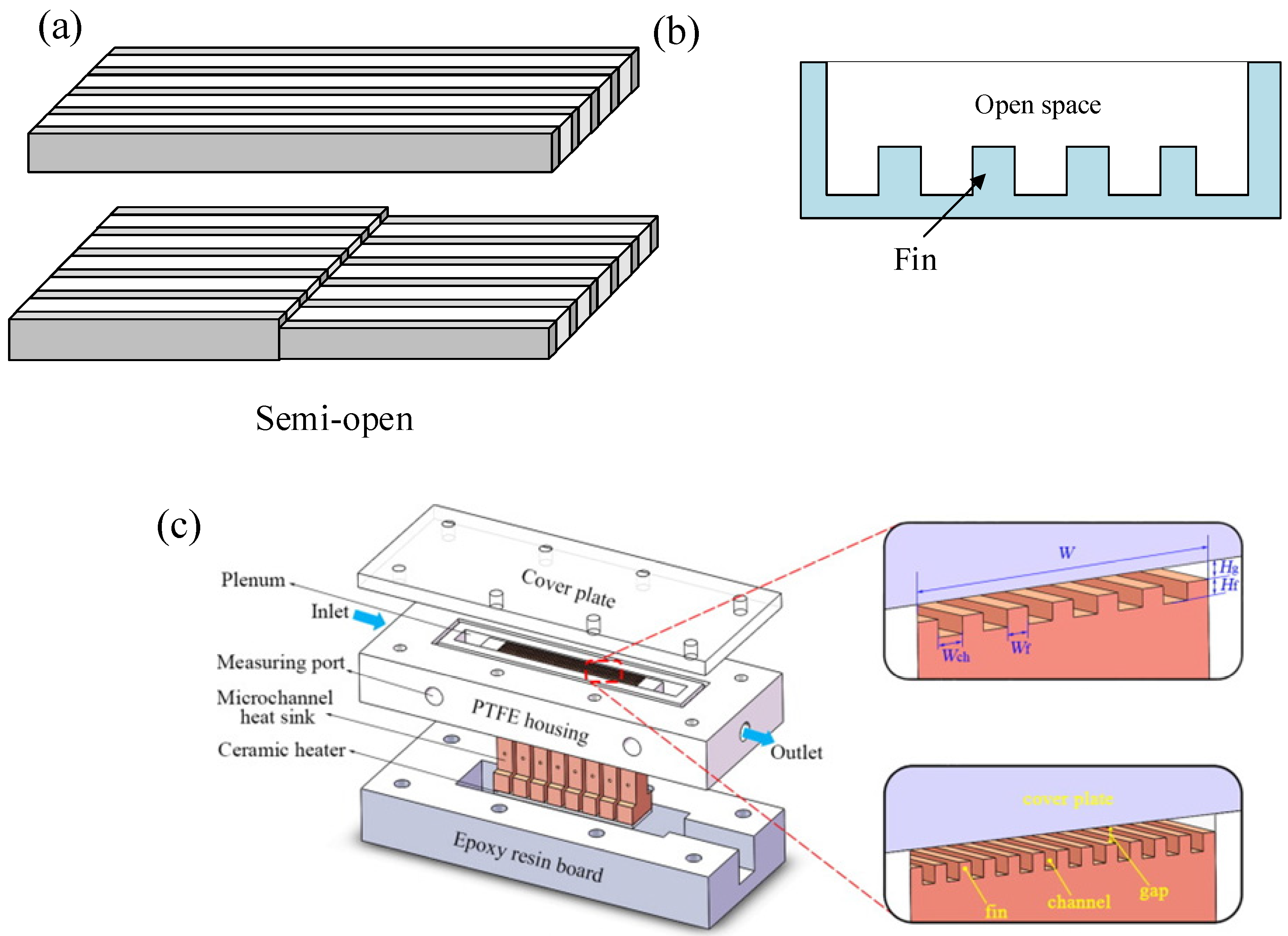

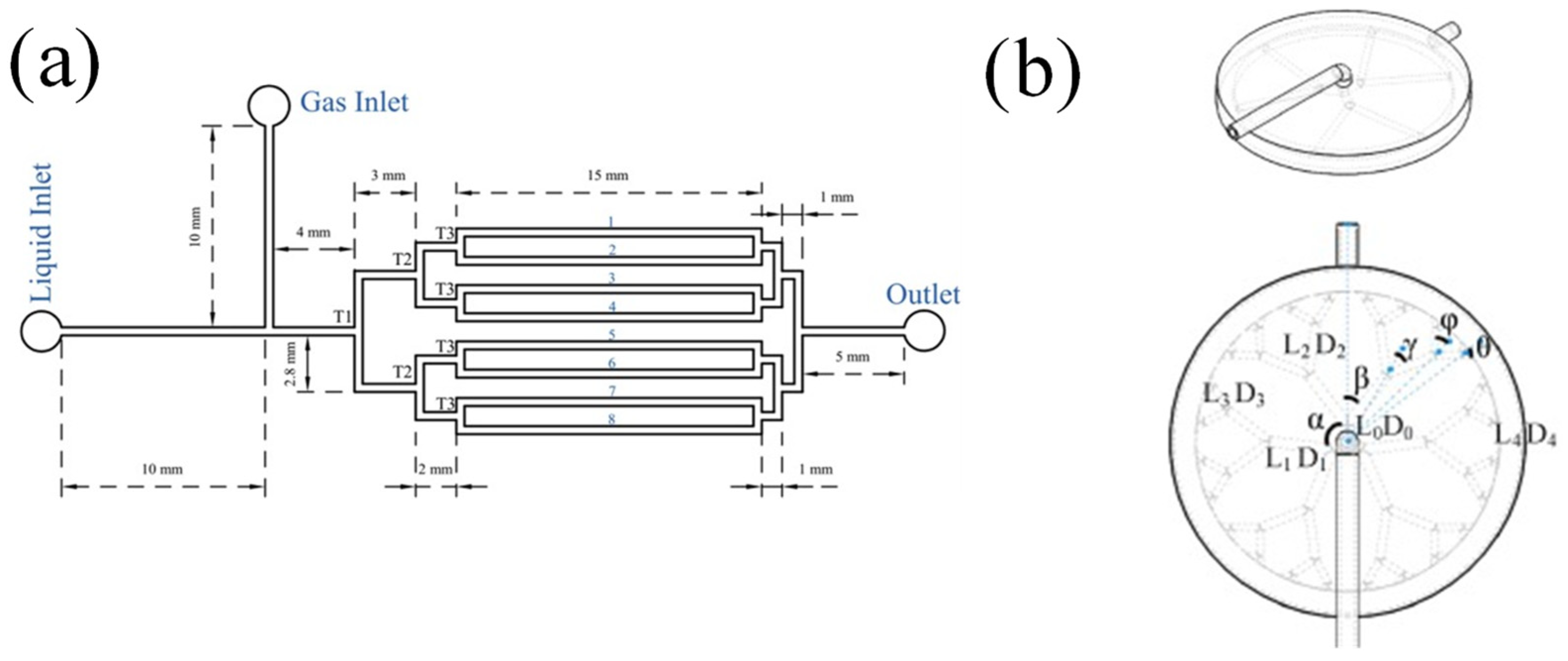

4.3. Open, Interruption, and Secondary Channels

| Reference | Type of Wall Geometry Optimizations | Research Method/ Flow Pattern | Heat Transfer/ Pressure/ Mechanism |

|---|---|---|---|

| Xia et al. [89] | Open channels | Experiment/ Acetone/ Flow boiling | h 36.2%/-/ 36.2%/-/Increased the number of nucleate sites to enhance flow boiling |

| Yin et al. [90] | Open channels | Experiment/ Water/ Flow boiling | h /-/ /-/Increasing area for expanding bubble and increased the number of nucleate sites to enhance flow boiling |

| Balasubramanian et al. [92] | Open channels | Experiment/ Water/ Flow boiling | CHF , h , h /ΔP /ΔP / /Increasing area for expanding bubble to enhance flow boiling |

| Bhandari et al. [93] | Open channels | Simulation/ Water/ Single-phase flow | Nu /ΔP /ΔP / /Increasing area for expanding bubble to enhance flow boiling |

| Xu et al. [94] | Interruption channels | Simulation and experiment/ Water/ Single-phase flow | Nu /ΔP /ΔP / /Enhanced chaotic mixing and convection, and redeveloped boundary layer |

| Chai et al. [95] | Interruption channels | Simulation and experiment/ Water/ Single-phase flow | Nu 18~60%/-/ 18~60%/-/Enhanced chaotic mixing, and redeveloped boundary layer |

| Prajapati et al. [96] | Secondary channels | Experiment/water/ Flow boiling | -/ΔP / /Secondary flow and enhanced flow boiling |

| Law et al. [37] | Secondary channels | Experiment/ FC-72/ Flow boiling | h 120~620%, CHF 120~620%, CHF 250~280%/ΔP 250~280%/ΔP / /Secondary flow and enhanced flow boiling |

| Shi et al. [36] | Secondary channels | Simulation/ Water/ Single-phase flow | R 29.2%/ΔP 29.2%/ΔP 26.4%/ 26.4%/Enhanced chaotic mixing, secondary flow, and redeveloped boundary layer |

| Ghani et al. [97] | Secondary channels | Simulation/ Water/ Single-phase flow | Nu /ΔP /ΔP 50%/ 50%/Enhanced chaotic mixing, secondary flow, and redeveloped boundary layer |

| Law et al. [99] | Secondary channels | Simulation and experiment/FC-72/ Flow boiling | h /ΔP /ΔP / /Enhanced chaotic mixing, secondary flow, and redeveloped boundary layer |

5. Complex Geometry Optimization

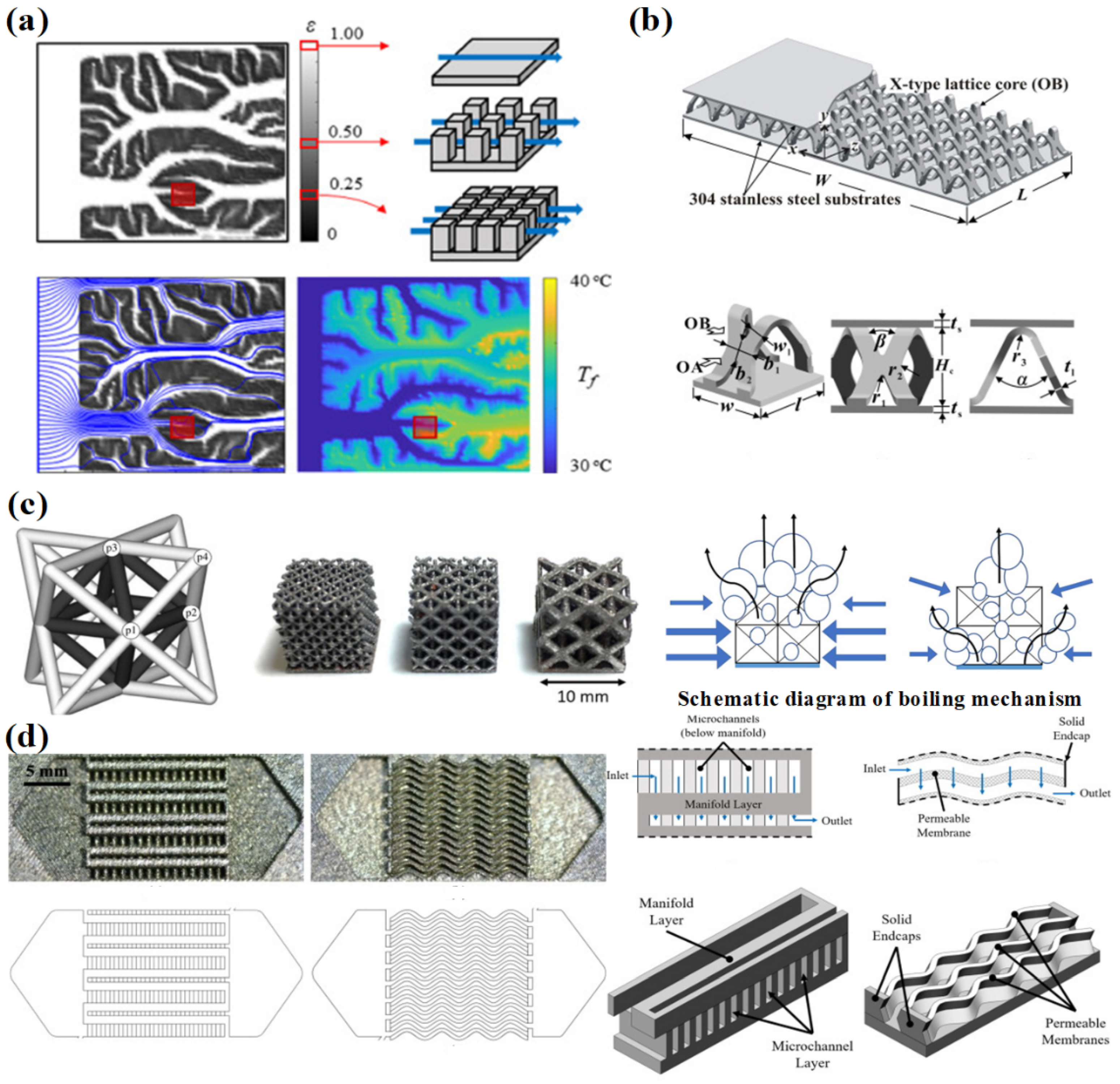

5.1. Fractal Geometry, Bionic Structures, and Topology Optimization

| Reference | Type of Wall Geometry Optimizations | Research Method/ Fluid/ Flow Pattern | Heat Transfer/ Flow Resistance/ Mechanism |

|---|---|---|---|

| Wang et al. [103] | Fractal geometry | Simulation/Water/ Single-phase flow | -/ΔP / /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Lu et al. [104] | Fractal geometry | Simulation/Water/ Single-phase flow | Tmax 28.8%, Tave 28.8%, Tave 13.5%/- 13.5%/-/Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Wang et al. [105] | Fractal geometry | Simulation/Water/ Single-phase flow | h /ΔP /ΔP /Enhanced chaotic mixing and convection, and increased heat transfer surface area /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Rubio-Jimenez et al. [106] | Fractal geometry | Simulation/Water/ Single-phase flow | R /ΔP /ΔP /Enhanced chaotic mixing and convection, and increased heat transfer surface area /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Zhang et al. [107] | Fractal geometry | Simulation and experiment/Water/ Single-phase flow | Nu /ΔP /ΔP / /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Hong et al. [108] | Fractal geometry | Simulation/Water/ Single-phase flow | R /ΔP /ΔP / /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Prasenjit et al. [110] | Bionic structures | Simulation and experiment/Water/ Single-phase flow | Nu 14%/ 14%/ΔP  / /Enhanced chaotic mixing and convection, and increased heat transfer surface area |

| Dong et al. [112] | Bionic structures | Experiment/Water/ Single-phase flow | -/ΔP / /Enhanced chaotic mixing and convection |

| Zhang et al. [113] | Bionic structures | Simulation/S-CO2/ Single-phase flow | Nu /ΔP /ΔP 45.83%/ 45.83%/Enhanced chaotic mixing and convection |

| Tan et al. [114] | Topology optimization | Simulation/Water/ Single-phase flow | ΔT 9.9℃/-/ 9.9℃/-/Enhanced chaotic mixing and convection, and redeveloped boundary layer |

| Han et al. [115] | Topology optimization | Simulation/Water/ Single-phase flow | ΔT 57.35%/ΔP 57.35%/ΔP / /Enhanced chaotic mixing and convection, and redeveloped thermal boundary layer |

| Pejman et al. [116] | Topology optimization | Simulation and experiment/Water and ethylene glycol/ Single-phase flow | Tmax /ΔP /ΔP /Enhanced chaotic mixing and convection, and redeveloped thermal boundary layer /Enhanced chaotic mixing and convection, and redeveloped thermal boundary layer |

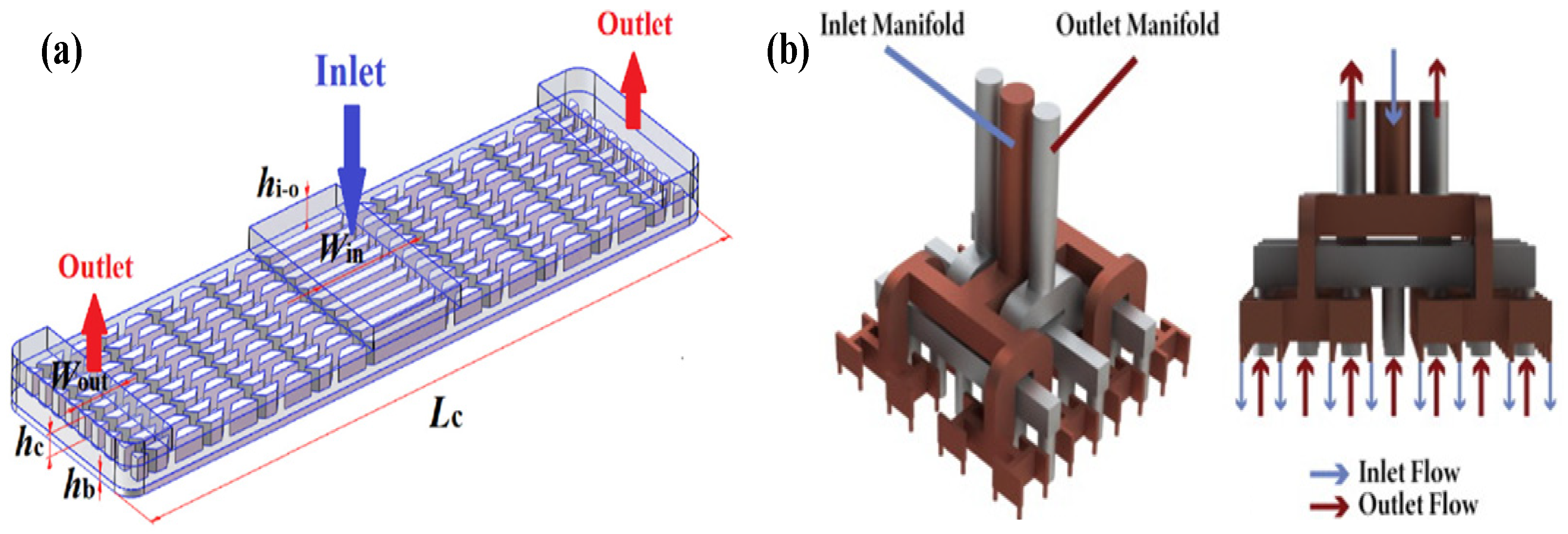

5.2. Double-Layer Microchannel

5.3. Manifold Microchannel

5.4. Other Complex Microchannel

| Reference | Type of Wall Geometry Optimizations | Research Method/ Fluid/ Flow Pattern | Heat Transfer/ Flow Resistance/ Mechanism |

|---|---|---|---|

| Radwan et al. [117] | Double-layer microchannel | Experiment/Ethanol and Novec-7000/ Flow boiling | ΔT /-/ /-/Enhanced chaotic mixing and convection |

| Wong et al. [118] | Double-layer microchannel | Simulation/Water/ Single-phase flow | R /ΔP /ΔP / /Enhanced convection |

| Elbadawy et al. [119] | Double-layer microchannel | Simulation/Water/ Single-phase flow | h 13.12%/ΔP 13.12%/ΔP 10%/ 10%/Enhanced chaotic mixing and convection |

| Hung et al. [121] | Double-layer microchannel | Simulation/Water/ Single-phase flow | R /ΔP /ΔP / /Enhanced convection |

| Hung et al. [122] | Double-layer microchannel | Simulation/Water/ Single-phase flow | R 52.8% 52.8% |

| Debbarma et al. [124] | Double-layer microchannel | Simulation/Water/ Single-phase flow | Nu /ΔP /ΔP / /Provide a larger flow area |

| Srivastava et al. [125] | Double-layer microchannel | Simulation/Water/ Single-phase flow | ΔT 40%, R 40%, R 28%, Nu 28%, Nu / /ΔP  /Enhanced chaotic mixing and convection /Enhanced chaotic mixing and convection |

| Leng et al. [126] | Double-layer microchannel | Simulation/Water/ Single-phase flow | R /ΔP /ΔP / /Provide a larger flow area |

| Shen et al. [127] | Double-layer microchannel | Simulation/Water/ Single-phase flow | Nu , ΔT , ΔT /ΔP /ΔP / /Enhanced chaotic mixing and convection |

| Li et al. [128] | Double-layer microchannel | Simulation/Water/ Single-phase flow | ΔT 58.04%, R 58.04%, R 14.98%/-/ 14.98%/-/Enhanced convection |

| Zhai et al. [129] | Double-layer microchannel | Simulation/Water/ Single-phase flow | ΔT /ΔP /ΔP Provide a larger flow area |

| Erp et al. [130] | Manifold microchannel | Experiment/Water/ Single-phase flow | h , Nu , Nu /-/ /-/Enhanced chaotic mixing and convection, secondary flow, increased heat transfer area, and redeveloped boundary layer |

| Drummond et al. [131] | Manifold microchannel | Experiment/ HFE-7100/ Flow boiling | h /-/Increasing area for expanding /-/Increasing area for expanding bubble, increasing the number of nucleate sites to enhance flow boiling |

| Drummond et al. [133] | Manifold microchannel | Experiment/ HFE-7100/ Flow boiling | h , R , R /-/ /-/Increasing area for expanding bubble, increasing the number of nucleate sites to enhance flow boiling |

| Luo et al. [134] | Manifold microchannel | Simulation/ HFE-7100/ Flow boiling | R /ΔP /ΔP Secondary flow, increased heat transfer area, and enhanced flow boiling |

| Luo et al. [135] | Manifold microchannel | Simulation/ HFE-7100/ Flow boiling | ΔT /ΔP /ΔP / /Increasing area for expanding bubble and the number of nucleate sites to enhance flow boiling |

| Yang et al. [137] | Manifold microchannel | Simulation/Water/ Single-phase flow | R 19.15%/ΔP 19.15%/ΔP 1.91%/ 1.91%/Increasing area for expanding bubble, increasing the number of nucleate sites to enhance flow boiling |

| Ozguc et al. [139] | Other complex microchannel | Simulation/ Water, ethylene/ Single-phase flow | Thermal resistance /ΔP /ΔP Secondary flow, increased heat transfer area, and redeveloped boundary layer |

| Yan et al. [140] | Other complex microchannel | Experiment/ Air/ Single-phase flow | Nu 77%/-/ 77%/-/Increased heat transfer area and redeveloped boundary layer |

| Wong et al. [27] | Other complex microchannel | Experiment/ FC-72/ Flow boiling | h 281%, CHF 281%, CHF /-/ /-/Increasing area for expanding bubble, increasing the number of nucleate sites to enhance flow boiling |

| Collins et al. [141] | Other complex microchannel | Experiment/ Water/ Single-phase flow | R 17%/ΔP 17%/ΔP 50%/ 50%/Enhanced chaotic mixing and convection, secondary flow, increased heat transfer area, and redeveloped boundary layer |

6. Conclusions and Future Works

- The size of the cross section of the microchannel has a profound effect on the flow and heat transfer in the microchannel. Small hydraulic diameter and a narrow and deep aspect ratio usually have better thermal performance for the single-phase flow. However, for flow boiling, the influence of geometry is complex, and bubble behavior and liquid film diffusion are the keys to heat transfer. The restrictive effect of small channels on bubble behavior may lead to greater flow resistance and deterioration of heat transfer. In addition, the cross-sectional area determines the heat transfer mechanism of flow boiling. The area decreases, and the heat transfer increases. The microchannel with the rectangular cross-section aspect ratio of one has a better heat transfer effect. However, the impact of the aspect ratio on microchannel pressure drop is not clear.

- The research on the cross-sectional shape of the microchannel generally includes the comparative study of different cross-sectional shapes and the size optimization of a certain cross-sectional shape. However, there is still a lack of comparative studies on the hydraulic and thermal properties of microchannels of different shapes after size optimization. In addition, the influence of cross-sectional geometry on microchannels is very complex which depends on its operating parameters. This indicates that it is necessary to further study the relationship between geometry and other influencing factors (such as mass flux and heat flux) to achieve the best heat transfer performance.

- The wavy microchannel and the channel geometry modification by adding ribs, cavities, pin fins, and bifurcations on the wall are introduced. These geometric modifications mainly improve the heat transfer in the straight microchannels from two aspects. On the one hand, these geometric modifications have increased the heat transfer surface area inside the microchannel. On the other hand, it can increase fluid disturbance, generate secondary flow, and promote the reconstruction of the thermal boundary layer. However, these geometric modifications increased or did not reduce the pressure drop in the channel to a certain extent compared to straight channels. The same geometric modification still needs optimization to balance pressure drop and heat transfer to meet engineering requirements.

- The open microchannel changes the flow pattern of the working fluid in the single-layer microchannel so that the working fluid has a broader flow space. Studies have shown that the open form can reduce flow resistance of the microchannel with appropriate geometric optimization. The secondary channel not only retains the advantages of the interrupted channel, the ribs, and the cavity to enhance heat transfer. It also promotes the flow between the channels to reduce the pressure drop. In addition, the geometry of the secondary channel also suppresses the instability of flow boiling. However, the new structure’s design means more adjustment and optimization of geometric parameters, such as the distribution, shape, size, and angle of the fins, etc.

- Fractal geometry and bionic structures is a structure optimized by nature. As long-term evolution, the structure has the best performance in heat and mass transfer. This natural structure is applied to a microchannel heat sink to enhance heat transfer and reduce pressure drop. However, most existing structures in nature are not compatible with microchannel heat sinks. Topology optimization can further improve the adaptability of fractal geometry and bionic structures in microchannel industrial applications.

- The design of the double-layer microchannel adjusts the flow direction of the working fluid in each microchannel layer so that the temperature gradient inside the microchannel is significantly reduced. This alleviates the problem of uneven temperature distribution in the flow field.

- The manifold structure divides the microchannel into many parallel microchannel units, which shortens the flow length of the working fluid and reduces the pressure drop. At the same time, the thermal boundary layer is difficult to develop in the microchannel, which is beneficial to increase the heat transfer coefficient and reduce the total thermal resistance. Furthermore, the temperature distribution of the manifold microchannel heat sink is more uniform.

- With the development of additive manufacturing technology, more complex microstructure microchannels can be fabricated. The manufacturing technology combines the abovementioned multiple geometric optimizations to specifically solve special industrial problems, such as non-uniform heating conditions of local hot spots.

- There are many types of microchannel geometric modification, but simple geometric modification such as hydraulic diameter, cross-sectional shape, and other single geometric factors are rarely studied to ensure that other geometric factors remain constant. In recent years, this kind of weak research on the influence of basic geometric factors has received increasing attention. Many researchers have made a combination of various geometric modifications and have shown their comprehensive advantages. If the influential characteristics of a single geometric factor are clearly studied, the difficulty of combining multiple geometric modifications will be reduced.

- Secondary channels with pin fins, fractal geometry, and bionic structures, manifold microchannels have unique advantages in enhancing heat transfer. However, there are still more geometric parameters that need to be optimized to reduce the thermal resistance and pressure drop.

- The topology optimization method is effective in adjusting the parameters of the flow channel geometric structure in the microchannel. However, the research of topology optimization on the flow and heat transfer of microchannels is basically limited to single-phase flow. Flow-boiling heat transfer has broader prospects and is more complex than single-phase flow. Therefore, more topology optimization work needs to be conducted for flow boiling.

- Due to the complexity of flow-boiling heat transfer, the influence of microchannel geometry on bubbles or flow patterns should be further studied. Since different flow patterns correspond to different heat transfer mechanisms, appropriate geometry should be selected according to different flow patterns to optimize heat transfer technology.

- The geometric characteristics of microchannels are not a single factor affecting flow and heat transfer. Comprehensive consideration of the coordinated working conditions of geometry, mass flux, heat flux, working fluid, and other factors help to achieve the optimal performance of the microchannel. In addition, nanofluids, phase change materials, and other passive cooling methods combined with geometric optimization research can further improve the performance of microchannel heat sinks.

- In recent years, with the continuous advancement of processing technology, such as additive manufacturing technology, microchannels with complex geometries have become possible, and more complex microstructure microchannel experimental research should be carried out. New interesting microstructures and heat transfer mechanisms deserve to be developed. Furthermore, in practical applications, not only the thermal resistance of the microchannel heat sinks is considered, but the thermal resistance between the heat source and the microchannel heat sink is also the key to enhancing heat transfer. Therefore, collaborative design of microdevices and cooling is necessary. The embedded cooling structure may provide a broader idea for the geometric optimization of the microchannel heat sinks overall heat transfer performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| microchannel hydraulic diameter, m | |

| thermal conductivity, W/(m·K) | |

| the Nusselt number | |

| heat transfer coefficient, W/(m2·K) | |

| temperature, °C | |

| pressure drop, Pa | |

| thermal resistance, (K/W) |

Abbreviations

| AR | aspect ratio |

| CHF | critical heat flux |

| MCHS | microchannel heat sink |

| TEC | thermoelectric cooler |

| VLSI | very-large-scale integrated |

Subscripts

| average | |

| maximum |

References

- Dai, X.; Zhou, W.; Yang, S.; Sun, F.; Qian, J.; He, M.; Chen, Q. Microchannel process for phenol production via the cleavage of cumene hydroperoxide. Chem. Eng. Sci. 2019, 199, 398–404. [Google Scholar] [CrossRef]

- Strumpf, H.J.; Mirza, Z. Development of a Microchannel Heat Exchanger for Aerospace Applications. In Proceedings of the ASME 2012 10th International Conference on Nanochannels, Microchannels, and Minichannels (ICNMM), Rio Grande, PR, USA, 8–12 July 2012. [Google Scholar]

- Abo-Zahhad, E.M.; Ookawara, S.; Radwan, A.; Elkady, M.; El-Shazly, A.H. Optimization of stepwise varying width microchannel heat sink for high heat flux applications. Case Stud. Therm. Eng. 2020, 18, 100587. [Google Scholar] [CrossRef]

- Sharma, C.S.; Tiwari, M.K.; Poulikakos, D. A simplified approach to hotspot alleviation in microprocessors. Appl. Therm. Eng. 2016, 93, 1314–1323. [Google Scholar] [CrossRef]

- Li, X.; Xuan, Y. Self-adaptive cooling of chips with unevenly distributed high heat fluxes. Appl. Therm. Eng. 2022, 202, 117913. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, Z.; Gong, Y.; Zhang, T.; Huang, Y.; Niu, F. Optimal study of swordfish fin microchannel heat exchanger for the next generation nuclear power conversion system of lead-based reactor. Ann. Nucl. Energy 2022, 165, 108679. [Google Scholar] [CrossRef]

- Prabhakar, A.; Verma, D.; Dhwaj, A.; Mukherji, S. Microchannel integrated tapered and tapered-bend waveguides, for proficient, evanescent-field absorbance based, on-chip, chemical and biological sensing operations. Sens. Actuators B Chem. 2021, 332, 129455. [Google Scholar] [CrossRef]

- Redo, M.A.; Jeong, J.; Giannetti, N.; Enoki, K.; Yamaguchi, S.; Saito, K.; Kim, H. Characterization of two-phase flow distribution in microchannel heat exchanger header for air-conditioning system. Exp. Therm. Fluid Sci. 2019, 106, 183–193. [Google Scholar] [CrossRef]

- Tuckerman, D.; Pease, R. High-performance heat sinking for VLSI. IEEE Electron. Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Hajialibabaei, M.; Saghir, Z. A Critical Review of the Straight and Wavy Microchannel Heat Sink and the Application in Lithium-Ion Battery Thermal Management. SSRN Electron. J. 2022. preprint article. [Google Scholar] [CrossRef]

- Andhare, R.S.; Shooshtari, A.; Dessiatoun, S.; Ohadi, M. Heat transfer and pressure drop characteristics of a flat plate manifold microchannel heat exchanger in counter flow configuration. Appl. Therm. Eng. 2016, 96, 178–189. [Google Scholar] [CrossRef]

- Hao, X.; Peng, B.; Xie, G.; Chen, Y. Efficient on-chip hotspot removal combined solution of thermoelectric cooler and mini-channel heat sink. Appl. Therm. Eng. 2016, 100, 170–178. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Antao, D.; Chu, K.; Chen, S.; Hendricks, T.; Zhang, T.; Wang, E. Surface Structure Enhanced Microchannel Flow Boiling. J. Heat Transf. 2016, 138, 091501. [Google Scholar] [CrossRef] [Green Version]

- Green, C.E.; Kottke, P.A.; Sarvey, T.E.; Fedorov, A.G.; Joshi, Y.K.; Bakir, M.S. Performance and Integration Implications of Addressing Localized Hotspots Through Two Approaches: Clustering of Micro Pin-Fins and Dedicated Microgap Coolers. In Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Francisco, CA, USA, 6–9 July 2015. [Google Scholar]

- Tang, J.X.; Liu, Y.; Huang, B.; Xu, D. Enhanced heat transfer coefficient of flow boiling in microchannels through expansion areas. Int. J. Therm. Sci. 2022, 177, 107573. [Google Scholar] [CrossRef]

- Ramesh, K.; Sharma, T.K.; Rao, G.A. Latest Advancements in Heat Transfer Enhancement in the Micro-channel Heat Sinks: A Review. Arch. Comput. Methods Eng. 2020, 28, 3135–3165. [Google Scholar] [CrossRef]

- Toghraie, D.; Mashayekhi, R.; Niknejadi, M.; Arasteh, H. Hydrothermal performance analysis of various surface roughness configurations in trapezoidal microchannels at slip flow regime. Chin. J. Chem. Eng. 2020, 28, 1522–1532. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, G.; Sun, J.; Li, H. Investigation of the roughness effect on flow behavior and heat transfer characteristics in microchannels. Int. J. Heat Mass Transf. 2015, 83, 11–20. [Google Scholar] [CrossRef]

- Attalla, M.; Maghrabie, H.M.; Specht, E. An experimental investigation on fluid flow and heat transfer of rough mini-channel with rectangular cross section. Exp. Therm. Fluid Sci. 2016, 75, 199–210. [Google Scholar] [CrossRef]

- Guo, L.; Xu, H.; Gong, L. Influence of wall roughness models on fluid flow and heat transfer in microchannels. Appl. Therm. Eng. 2015, 84, 399–408. [Google Scholar] [CrossRef]

- Wan, Z.; Lin, Q.; Wang, X.; Tang, Y. Flow characteristics and heat transfer performance of half-corrugated microchannels. Appl. Therm. Eng. 2017, 123, 1140–1151. [Google Scholar] [CrossRef]

- Xu, S.; Yang, L.; Li, Y.; Wu, Y.; Hu, X. Experimental and numerical investigation of heat transfer for two-layered microchannel heat sink with non-uniform heat flux conditions. Heat Mass Transf. 2016, 52, 1755–1763. [Google Scholar] [CrossRef]

- Lorenzini, G.; Biserni, C.; Rocha, L. Constructal design of non-uniform X-shaped conductive pathways for cooling. Int. J. Therm. Sci. 2013, 71, 140–147. [Google Scholar] [CrossRef]

- Chamkha, A.; Molana, M.; Rahnama, A.; Ghadami, F. On the nanofluids applications in microchannels: A comprehensive review. Powder Technol. 2018, 332, 287–322. [Google Scholar] [CrossRef]

- Sidik, N.A.; Muhamad, M.N.; Japar, W.M.; Rasid, Z.A. An overview of passive techniques for heat transfer augmentation in microchannel heat sink. Int. Commun. Heat Mass Transf. 2017, 88, 74–83. [Google Scholar] [CrossRef]

- Markal, B.; Aydin, O.; Avci, M. Effect of hydraulic diameter on flow boiling in rectangular microchannels. Heat Mass Transf. 2019, 55, 1033–1044. [Google Scholar] [CrossRef]

- Wong, K.K.; Leong, K.C. Saturated pool boiling enhancement using porous lattice structures produced by Selective Laser Melting. Int. J. Heat Mass Transf. 2018, 121, 46–63. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.; Wang, H.S. Numerical study of laminar flow and heat transfer in microchannel heat sink with offset ribs on sidewalls. Appl. Therm. Eng. 2016, 92, 32–41. [Google Scholar] [CrossRef]

- Chai, L.; Wang, L.; Bai, X. Thermohydraulic performance of microchannel heat sinks with triangular ribs on sidewalls—Part 1: Local fluid flow and heat transfer characteristics. Int. J. Heat Mass Transf. 2018, 127, 1124–1137. [Google Scholar] [CrossRef]

- Chai, L.; Wang, L.; Bai, X. Thermohydraulic performance of microchannel heat sinks with triangular ribs on sidewalls—Part 2: Average fluid flow and heat transfer characteristics. Int. J. Heat Mass Transf. 2018, 128, 634–648. [Google Scholar] [CrossRef]

- Kumar, P. Numerical investigation of fluid flow and heat transfer in trapezoidal microchannel with groove structure. Int. J. Therm. Sci. 2019, 136, 33–43. [Google Scholar] [CrossRef]

- Xie, G.; Zhao, L.; Dong, Y.; Li, Y.; Zhang, S.; Yang, C. Hydraulic and Thermal Performance of Microchannel Heat Sink Inserted with Pin Fins. Micromachines 2021, 12, 245. [Google Scholar] [CrossRef]

- Lin, L.; Zhao, J.; Lu, G.; Wang, X.D.; Yan, W.M. Heat transfer enhancement in microchannel heat sink by wavy channel with changing wavelength/amplitude. Int. J. Therm. Sci. 2017, 118, 423–434. [Google Scholar] [CrossRef]

- Shamsi, M.; Akbari, O.A.; Marzban, A.; Toghraie, D.; Mashayekhi, R. Increasing heat transfer of non-Newtonian nanofluid in rectangular microchannel with triangular ribs. Phys. E Low-Dimens. Syst. Nanostructures 2017, 93, 167–178. [Google Scholar] [CrossRef]

- Xie, G.; Shen, H.; Wang, C. Parametric study on thermal performance of microchannel heat sinks with internal vertical Y-shaped bifurcations. Int. J. Heat Mass Transf. 2015, 90, 948–958. [Google Scholar] [CrossRef]

- Shi, X.; Li, S.; Mu, Y.; Yin, B. Geometry parameters optimization for a microchannel heat sink with secondary flow channel. Int. Commun. Heat Mass Transf. 2019, 104, 89–100. [Google Scholar] [CrossRef]

- Law, M.; Lee, P. A comparative study of experimental flow boiling heat transfer and pressure characteristics in straight- and oblique-finned microchannels. Int. J. Heat Mass Transf. 2015, 85, 797–810. [Google Scholar] [CrossRef]

- Zhai, Y.L.; Xia, G.D.; Liu, X.F.; Li, Y.F. Heat transfer in the microchannels with fan-shaped reentrant cavities and different ribs based on field synergy principle and entropy generation analysis. Int. J. Heat Mass Transf. 2014, 68, 224–233. [Google Scholar] [CrossRef]

- Ong, C.L.; Thome, J. Macro-to-microchannel transition in two-phase flow: Part 1—Two-phase flow patterns and film thickness measurements. Exp. Therm. Fluid Sci. 2011, 35, 37–47. [Google Scholar] [CrossRef]

- Kandlikar, S.; Steinke, M.; Tian, S.; Campbell, L. High-Speed photographic observation of flow boiling of water in parallel mini-channels. In Proceedings of the 35th National Heat Transfer Conference, Anaheim, CA, USA, 10–12 June 2001. [Google Scholar]

- Lee, P.S.; Garimella, S.V.; Liu, D. Investigation of heat transfer in rectangular microchannels. Int. J. Heat Mass Transf. 2005, 48, 1688–1704. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, N.; Moharana, M.K. Effect of conjugate heat transfer in single-phase laminar flow through partially heated microtubes. Sādhanā 2021, 46, 28. [Google Scholar] [CrossRef]

- Sadaghiani, A.K.; Koşar, A. Numerical and experimental investigation on the effects of diameter and length on high mass flux subcooled flow boiling in horizontal microtubes. Int. J. Heat Mass Transf. 2016, 92, 824–837. [Google Scholar] [CrossRef]

- Yang, K.; Jeng, Y.; Huang, C.; Wang, C. Heat Transfer and Flow Pattern Characteristics for HFE-7100 within Microchannel Heat Sinks. Heat Transf. Eng. 2011, 32, 697–704. [Google Scholar] [CrossRef]

- Tiwari, N.; Moharana, M.K. Conjugate heat transfer analysis of liquid-vapor two phase flow in a microtube: A numerical investigation. Int. J. Heat Mass Transf. 2019, 142, 118427. [Google Scholar] [CrossRef]

- Matin, M.H.; Moghaddam, S. Thin liquid films formation and evaporation mechanisms around elongated bubbles in rectangular cross-section microchannels. Int. J. Heat Mass Transf. 2020, 163, 120474. [Google Scholar] [CrossRef]

- Naphon, P.; Khonseur, O. Study on the convective heat transfer and pressure drop in the micro-channel heat sink. Int. Commun. Heat Mass Transf. 2009, 36, 39–44. [Google Scholar] [CrossRef]

- Xie, X.; Liu, Z.; He, Y.; Tao, W. Numerical study of laminar heat transfer and pressure drop characteristics in a water-cooled minichannel heat sink. Appl. Therm. Eng. 2009, 29, 64–74. [Google Scholar] [CrossRef]

- Wang, Y.; Sefiane, K. Effects of heat flux, vapour quality, channel hydraulic diameter on flow boiling heat transfer in variable aspect ratio micro-channels using transparent heating. Int. J. Heat Mass Transf. 2012, 55, 2235–2243. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Fluid flow and heat transfer characteristics of low temperature two-phase micro-channel heat sinks—Part 1: Experimental methods and flow visualization results. Int. J. Heat Mass Transf. 2008, 51, 4315–4326. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Fluid flow and heat transfer characteristics of low temperature two-phase micro-channel heat sinks—Part 2. Subcooled boiling pressure drop and heat transfer. Int. J. Heat Mass Transf. 2008, 51, 4327–4341. [Google Scholar] [CrossRef]

- Harirchian, T.; Garimella, S. Microchannel size effects on local flow boiling heat transfer to a dielectric fluid. Int. J. Heat Mass Transf. 2008, 51, 3724–3735. [Google Scholar] [CrossRef] [Green Version]

- Harirchian, T.; Garimella, S.V. The critical role of channel cross-sectional area in microchannel flow boiling heat transfer. Int. J. Multiph. Flow 2009, 35, 904–913. [Google Scholar] [CrossRef]

- Markal, B.; Aydin, O.; Avci, M. Effect of aspect ratio on saturated flow boiling in microchannels. Int. J. Heat Mass Transf. 2016, 93, 130–143. [Google Scholar] [CrossRef]

- Fu, B.R.; Lee, C.Y.; Pan, C. The effect of aspect ratio on flow boiling heat transfer of hfe-7100 in a microchannel heat sink. Int. J. Heat Mass Transf. 2013, 58, 53–61. [Google Scholar] [CrossRef]

- Candan, A.; Markal, B.; Aydin, O.; Avci, M. Saturated flow boiling characteristics in single rectangular minichannels: Effect of aspect ratio. Exp. Heat Transf. 2018, 31, 531–551. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Z.; Gao, J. Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Appl. Therm. Eng. 2016, 107, 870–879. [Google Scholar] [CrossRef]

- Jing, D.; He, L. Numerical studies on the hydraulic and thermal performances of microchannels with different cross-sectional shapes. Int. J. Heat Mass Transf. 2019, 143, 118604. [Google Scholar] [CrossRef]

- Salimpour, M.; Sharifhasan, M.; Shirani, E. Constructal Optimization of Microchannel Heat Sinks with Noncircular Cross Sections. Heat Transf. Eng. 2013, 34, 863–874. [Google Scholar] [CrossRef]

- Luo, W.; He, J.; Luo, B.; Xu, Y.; Lin, M. Numerical Study on the Effect of Cross-Sectional Shape of Microchannels on Flow Boiling. J. Xi’an Jiaotong Univ. 2019, 53, 101–111. (In Chinese) [Google Scholar]

- Sempértegui-Tapia, D.F.; Ribatski, G. The effect of the cross-sectional geometry on saturated flow boiling heat transfer in horizontal micro-scale channels. In Proceedings of the IV Journeys in Multiphase Flows (JEM2015), Campinas, Brazil, 23–27 March 2015. [Google Scholar]

- Goodarzi, M.; Tlili, I.; Tian, Z.; Safaei, M. Efficiency assessment of using graphene nanoplatelets-silver/water nanofluids in microchannel heat sinks with different cross-sections for electronics cooling. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 347–372. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Shi, M.; Wu, J. Three-dimensional numerical simulation of heat and fluid flow in noncircular microchannel heat sinks. Int. Commun. Heat Mass Transf. 2009, 36, 917–920. [Google Scholar] [CrossRef]

- Raj, S.; Shukla, A.; Pathak, M.; Khan, M.K. A novel stepped microchannel for performance enhancement in flow boiling. Int. J. Heat Mass Transf. 2019, 144, 118611. [Google Scholar] [CrossRef]

- Khan, A.; Kim, S.; Kim, K. Multi-Objective Optimization of an Inverse Trapezoidal-Shaped Microchannel. Heat Transf. Eng. 2016, 37, 571–580. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Gunnasegaran, P.; Shuaib, N.H. Numerical simulation of heat transfer enhancement in wavy microchannel heat sink. Int. Commun. Heat Mass Transf. 2011, 38, 63–68. [Google Scholar] [CrossRef]

- Tiwari, N.; Moharana, M.K. Numerical Study of Thermal Enhancement in Modified Raccoon Microchannels. Heat Transf. Res. 2019, 50, 519–543. [Google Scholar] [CrossRef]

- Tiwari, N.; Moharana, M.K. Conjugate effect on flow boiling instability in wavy microchannel. Int. J. Heat Mass Transf. 2021, 166, 120791. [Google Scholar] [CrossRef]

- Bhuva, V.J.; Jani, J.P.; Patel, A.; Tiwari, N. Effect of bubble coalescence on two-phase flow boiling heat transfer in raccoon microchannel—A numerical study. Int. J. Heat Mass Transf. 2022, 182, 121943. [Google Scholar] [CrossRef]

- Sui, Y.; Teo, C.J.; Lee, P.S.; Chew, Y.T.; Shu, C. Fluid flow and heat transfer in wavy microchannels. Int. J. Heat Mass Transf. 2010, 53, 2760–2772. [Google Scholar] [CrossRef]

- Xu, M.; Lu, H.; Gong, L.; Chai, J.; Duan, X. Parametric numerical study of the flow and heat transfer in microchannel with dimples. Int. Commun. Heat Mass Transf. 2016, 76, 348–357. [Google Scholar] [CrossRef] [Green Version]

- Chai, L.; Xia, G.; Wang, H.S. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs on sidewalls—Part 1: Heat transfer. Int. J. Heat Mass Transf. 2016, 97, 1069–1080. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.; Wang, H.S. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs on sidewalls—Part 2: Pressure drop. Int. J. Heat Mass Transf. 2016, 97, 1081–1090. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.; Wang, H.S. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs on sidewalls—Part 3: Performance evaluation. Int. J. Heat Mass Transf. 2016, 97, 1091–1101. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.; Zhou, M.; Li, J. Numerical simulation of fluid flow and heat transfer in a microchannel heat sink with offset fan-shaped reentrant cavities in sidewall. Int. Commun. Heat Mass Transf. 2011, 38, 577–584. [Google Scholar] [CrossRef]

- Li, Y.; Xia, G.; Jia, Y.; Cheng, Y.; Wang, J. Experimental investigation of flow boiling performance in microchannels with and without triangular cavities—A comparative study. Int. J. Heat Mass Transf. 2017, 108, 1511–1526. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.; Wang, L.; Zhou, M.; Cui, Z. Heat transfer enhancement in microchannel heat sinks with periodic expansion–constriction cross-sections. Int. J. Heat Mass Transf. 2013, 62, 741–751. [Google Scholar] [CrossRef]

- Xia, G.; Zhai, Y.; Cui, Z. Numerical investigation of thermal enhancement in a micro heat sink with fan-shaped reentrant cavities and internal ribs. Appl. Therm. Eng. 2013, 58, 52–60. [Google Scholar] [CrossRef]

- Deng, D.; Wan, W.; Qin, Y.; Zhang, J.; Chu, X. Flow boiling enhancement of structured microchannels with micro pin fins. Int. J. Heat Mass Transf. 2017, 105, 338–349. [Google Scholar] [CrossRef]

- Rajalingam, A.; Chakraborty, S. Effect of shape and arrangement of micro-structures in a microchannel heat sink on the thermo-hydraulic performance. Appl. Therm. Eng. 2021, 190, 116755. [Google Scholar]

- Ahmadian-Elmi, M.; Mashayekhi, A.; Nourazar, S.S.; Vafai, K. A comprehensive study on parametric optimization of the pin-fin heat sink to improve its thermal and hydraulic characteristics. Int. J. Heat Mass Transf. 2021, 180, 121797. [Google Scholar] [CrossRef]

- Zeng, L.; Deng, D.; Zhong, N.; Zheng, G. Heat transfer and flow characteristics in microchannel heat sink with open-ring pin fins. Int. J. Mech. Sci. 2021, 200, 106445. [Google Scholar] [CrossRef]

- Xia, G.; Jia, Y.; Li, Y.; Ma, D.; Cai, B. Numerical simulation and multiobjective optimization of a microchannel heat sink with arc-shaped grooves and ribs. Numer. Heat Transf. Part A Appl. 2016, 70, 1041–1055. [Google Scholar] [CrossRef]

- Xia, G.; Chai, L.; Wang, H.; Zhou, M.; Cui, Z. Optimum thermal design of microchannel heat sink with triangular reentrant cavities. Appl. Therm. Eng. 2011, 31, 1208–1219. [Google Scholar] [CrossRef]

- Beng, S.W.; Japar, W.A. Numerical analysis of heat and fluid flow in microchannel heat sink with triangular cavities. J. Adv. Res. Fluid Mech. Therm. Sci. 2017, 34, 1–8. [Google Scholar]

- Tiwari, N.; Moharana, M.K. Comparative study of conjugate heat transfer in a single-phase flow in wavy and raccoon microchannels. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 3791–3825. [Google Scholar] [CrossRef]

- Doshi, S.; Kashyap, G.; Tiwari, N. Thermo-hydraulic and entropy generation investigation of nano-encapsulated phase change material (NEPCM) slurry in hybrid wavy microchannel. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 3161–3190. [Google Scholar] [CrossRef]

- Foong, A.; Ramesh, N.; Chandratilleke, T. Laminar convective heat transfer in a microchannel with internal longitudinal fins. Int. J. Therm. Sci. 2009, 48, 1908–1913. [Google Scholar] [CrossRef]

- Xia, G.; Cheng, Y.; Cheng, L.; Li, Y. Heat Transfer Characteristics and Flow Visualization during Flow Boiling of Acetone in Semi-Open Multi-Microchannels. Heat Transf. Eng. 2019, 40, 1349–1362. [Google Scholar] [CrossRef] [Green Version]

- Yin, L.; Jiang, P.; Xu, R.; Wang, W.; Jia, L. Visualization of flow patterns and bubble behavior during flow boiling in open microchannels. Int. Commun. Heat Mass Transf. 2017, 85, 131–138. [Google Scholar] [CrossRef]

- Yin, L.; Jiang, P.; Xu, R.; Hu, H.; Jia, L. Heat transfer and pressure drop characteristics of water flow boiling in open microchannels. Int. J. Heat Mass Transf. 2019, 137, 204–215. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Krishnan, R.; Suresh, S. Spatial orientation effects on flow boiling performances in open microchannels heat sink configuration under a wide range of mass fluxes. Exp. Therm. Fluid Sci. 2018, 99, 392–406. [Google Scholar] [CrossRef]

- Bhandari, P.; Prajapati, Y. Thermal performance of open microchannel heat sink with variable pin fin height. Int. J. Therm. Sci. 2021, 159, 106609. [Google Scholar] [CrossRef]

- Xu, J.; Song, Y.; Zhang, W.; Zhang, H.; Gan, Y. Numerical simulations of interrupted and conventional microchannel heat sinks. Int. J. Heat Mass Transf. 2008, 51, 5906–5917. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.; Zhou, M.; Li, J.; Qi, J. Optimum thermal design of interrupted microchannel heat sink with rectangular ribs in the transverse microchambers. Appl. Therm. Eng. 2013, 51, 880–889. [Google Scholar] [CrossRef]

- Prajapati, Y.; Pathak, M.; Khan, M.K. Bubble dynamics and flow boiling characteristics in three different microchannel configurations. Int. J. Therm. Sci. 2017, 112, 371–382. [Google Scholar] [CrossRef]

- Ghani, I.A.; Sidik, N.; Mamat, R.; Najafi, G.; Ken, T.; Asako, Y.; Japar, W.A. Heat Transfer Enhancement in Microchannel Heat Sink Using Hybrid Technique of Ribs and Secondary Channels. Int. J. Heat Mass Transf. 2017, 114, 640–655. [Google Scholar] [CrossRef]

- Wan, W.; Deng, D.; Huang, Q.; Zeng, T.; Huang, Y. Experimental study and optimization of pin fin shapes in flow boiling of micro pin fin heat sinks. Appl. Therm. Eng. 2017, 114, 436–449. [Google Scholar] [CrossRef]

- Law, M.; Kanargi, O.B.; Lee, P.S. Effects of varying oblique angles on flow boiling heat transfer and pressure characteristics in oblique-finned microchannels. Int. J. Heat Mass Transf. 2016, 100, 646–660. [Google Scholar] [CrossRef]

- Huang, S.; Jin, Z.; Liang, G.; Duan, X. Thermal performance and structure optimization for slotted microchannel heat sink. Appl. Therm. Eng. 2017, 115, 1266–1276. [Google Scholar] [CrossRef]

- Guo, R.; Fu, T.; Zhu, C.; Yin, Y.; Ma, Y. Hydrodynamics and mass transfer of gas-liquid flow in a tree-shaped parallel microchannel with T-type bifurcations. Chem. Eng. J. 2019, 373, 1203–1211. [Google Scholar] [CrossRef]

- Yu, X. Experimental and Numerical Study on Fractal Tree-like Microchannels. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2012. (In Chinese). [Google Scholar]

- Wang, X.; Mujumdar, A.; Yap, C. Thermal characteristics of tree-shaped microchannel nets for cooling of a rectangular heat sink. Int. J. Therm. Sci. 2006, 45, 1103–1112. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, K.; Liu, J.; Li, F. Effect of branching level on the performance of constructal theory based Y-shaped liquid cooling heat sink. Appl. Therm. Eng. 2020, 168, 114824. [Google Scholar] [CrossRef]

- Wang, X.; Mujumdar, A.S.; Yap, C. Effect of bifurcation angle in tree-shaped microchannel networks. J. Appl. Phys. 2007, 102, 73530. [Google Scholar] [CrossRef]

- Rubio-Jimenez, C.; Hernández-Guerrero, A.; Cervantes, J.; Lorenzini-Gutierrez, D.; Gonzalez-Valle, C.U. CFD study of constructal microchannel networks for liquid-cooling of electronic devices. Appl. Therm. Eng. 2016, 95, 374–381. [Google Scholar] [CrossRef]

- Zhang, C.; Lian, Y.; Yu, X.; Liu, W.; Teng, J.; Xu, T.; Hsu, C.; Chang, Y.; Greif, R. Numerical and experimental studies on laminar hydrodynamic and thermal characteristics in fractal-like microchannel networks. Part B: Investigations on the performances of pressure drop and heat transfer. Int. J. Heat Mass Transf. 2013, 66, 939–947. [Google Scholar] [CrossRef]

- Hong, F.; Cheng, P.; Ge, H.; Joo, G.T. Conjugate heat transfer in fractal-shaped microchannel network heat sink for integrated microelectronic cooling application. Int. J. Heat Mass Transf. 2007, 50, 4986–4998. [Google Scholar] [CrossRef]

- Guo, D.Z.; Huang, X.Y.; Li, P. Flow structure and heat transfer characteristics of microchannel heat sinks with split protrusion. Chin. Sci. Bull. 2019, 64, 1526–1534. (In Chinese) [Google Scholar] [CrossRef]

- Dey, P.; Hedau, G.; Saha, S.K. Experimental and numerical investigations of fluid flow and heat transfer in a bioinspired surface enriched microchannel. Int. J. Therm. Sci. 2019, 135, 44–60. [Google Scholar] [CrossRef]

- Tan, H.; Chen, J.; Wang, M.; Du, P. Experimental Study of Flow Boiling Heat Transfer in Spider Netted Microchannel for Chip Cooling. In Proceedings of the World Congress on Engineering (WCE), London, UK, 4–6 July 2018. [Google Scholar]

- Dong, T.; Chen, Y.S.; Yang, Z.C.; Bi, Q.C.; Wu, H.L.; Zheng, G.P. Flow and heat transfer in comby fractal microchannel network. J. Chem. Ind. Eng. 2005, 56, 1619–1625. (In Chinese) [Google Scholar]

- Zhang, T.Y.; Guo, Z.P.; Niu, F.L.; Huang, Y.P. Heat Transfer Characteristic of Airfoil Microchannel Efficient and Compact Heat Exchanger. At. Energy Sci. Technol. 2020, 54, 1780–1786. (In Chinese) [Google Scholar]

- Tan, H.; Wu, L.; Wang, M.; Yang, Z.; Du, P. Heat transfer improvement in microchannel heat sink by topology design and optimization for high heat flux chip cooling. Int. J. Heat Mass Transf. 2019, 129, 681–689. [Google Scholar] [CrossRef]

- Han, X.; Liu, H.; Xie, G.; Sang, L.; Zhou, J. Topology optimization for spider web heat sinks for electronic cooling. Appl. Therm. Eng. 2021, 195, 117154. [Google Scholar] [CrossRef]

- Pejman, R.; Aboubakr, S.H.; Martin, W.H.; Devi, U.; Tan, M.H.; Patrick, J.F.; Najafi, A.R. Gradient-based hybrid topology/shape optimization of bioinspired microvascular composites. Int. J. Heat Mass Transf. 2019, 144, 118606. [Google Scholar] [CrossRef]

- Radwan, A.; Ookawara, S.; Ahmed, M. Thermal management of concentrator photovoltaic systems using two-phase flow boiling in double-layer microchannel heat sinks. Appl. Energy 2019, 241, 404–419. [Google Scholar] [CrossRef]

- Wong, K.; Muezzin, F.N. Heat transfer of a parallel flow two-layered microchannel heat sink. Int. Commun. Heat Mass Transf. 2013, 49, 136–140. [Google Scholar] [CrossRef]

- Elbadawy, I.; Fayed, M. Reliability of Al2O3 nanofluid concentration on the heat transfer augmentation and resizing for single and double stack microchannels. Alex. Eng. J. 2020, 59, 1771–1785. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, J.; Tseng, K. Parametric study on the performance of double-layered microchannels heat sink. Energy Convers. Manag. 2014, 80, 550–560. [Google Scholar] [CrossRef]

- Hung, T.; Yan, W.; Li, W. Analysis of heat transfer characteristics of double-layered microchannel heat sink. Int. J. Heat Mass Transf. 2012, 55, 3090–3099. [Google Scholar] [CrossRef]

- Hung, T.; Yan, W.; Wang, X.; Huang, Y. Optimal design of geometric parameters of double-layered microchannel heat sinks. Int. J. Heat Mass Transf. 2012, 55, 3262–3272. [Google Scholar] [CrossRef]

- Lin, L.; Chen, Y.; Zhang, X.; Wang, X. Optimization of geometry and flow rate distribution for double-layer microchannel heat sink. Int. J. Therm. Sci. 2014, 78, 158–168. [Google Scholar] [CrossRef]

- Debbarma, D.; Pandey, K.M.; Paul, A. Numerical study on double layered micro channel heat sink with partly diverged channel in top layer. Mater. Today Proc. 2020, 45, 6542–6546. [Google Scholar] [CrossRef]

- Srivastava, P.; Patel, R.I.; Dewan, A. A study on thermal characteristics of double-layered microchannel heat sink: Effects of bifurcation and flow configuration. Int. J. Therm. Sci. 2021, 162, 106791. [Google Scholar] [CrossRef]

- Leng, C.; Wang, X.; Wang, T. An improved design of double-layered microchannel heat sink with truncated top channels. Appl. Therm. Eng. 2015, 79, 54–62. [Google Scholar] [CrossRef]

- Shen, H.; Xie, G.; Wang, C. Thermal performance and entropy generation of novel X-structured double layered microchannel heat sinks. J. Taiwan Inst. Chem. Eng. 2020, 111, 90–104. [Google Scholar] [CrossRef]

- Li, X.Y.; Wang, S.L.; Wang, X.D.; Wang, T.H. Selected porous-ribs design for performance improvement in double-layered microchannel heat sinks. Int. J. Therm. Sci. 2019, 137, 616–626. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Z.; Wang, H.; Xu, J. Thermodynamic analysis of the effect of channel geometry on heat transfer in double-layered microchannel heat sinks. Energy Convers. Manag. 2017, 143, 431–439. [Google Scholar] [CrossRef]

- Erp, R.V.; Soleimanzadeh, R.; Nela, L.; Kampitsis, G.; Matioli, E. Co-designing electronics with microfluidics for more sustainable cooling. Nature 2020, 585, 211–216. [Google Scholar] [CrossRef]

- Drummond, K.P.; Weibel, J.A.; Garimella, S. Two-phase flow morphology and local wall temperatures in high-aspect-ratio manifold microchannels. Int. J. Heat Mass Transf. 2020, 153, 119551. [Google Scholar]

- Pan, Y.; Zhao, R.; Fan, X.; Nian, Y.; Cheng, W. Study on the effect of varying channel aspect ratio on heat transfer performance of manifold microchannel heat sink. Int. J. Heat Mass Transf. 2020, 163, 120461. [Google Scholar] [CrossRef]

- Drummond, K.P.; Back, D.; Sinanis, M.; Janes, D.; Peroulis, D.; Weibel, J.A.; Garimella, S. A Hierarchical Manifold Microchannel Heat Sink Array for High-Heat-Flux Two-Phase Cooling of Electronics. Int. J. Heat Mass Transf. 2018, 117, 319–330. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Li, W.; Zhang, J.; Minkowycz, W.J. Analysis of thermal performance and pressure loss of subcooled flow boiling in manifold microchannel heat sink. Int. J. Heat Mass Transf. 2020, 162, 120362. [Google Scholar]

- Luo, Y.; Zhang, J.; Li, W. A comparative numerical study on two-phase boiling fluid flow and heat transfer in the microchannel heat sink with different manifold arrangements. Int. J. Heat Mass Transf. 2020, 156, 119864. [Google Scholar] [CrossRef]

- Lin, Y.; Luo, Y.; Li, W.; Cao, Y.; Tao, Z.; Shih, T. Single-phase and Two-phase Flow and Heat Transfer in Microchannel Heat Sink with Various Manifold Arrangements. Int. J. Heat Mass Transf. 2021, 171, 121118. [Google Scholar] [CrossRef]

- Yang, M.; Cao, B. Numerical study on flow and heat transfer of a hybrid microchannel cooling scheme using manifold arrangement and secondary channels. Appl. Therm. Eng. 2019, 159, 113896. [Google Scholar] [CrossRef]

- Paniagua-Guerra, L.E.; Sehgal, S.; Gonzalez-Valle, C.U.; Ramos-Alvarado, B. Fractal channel manifolds for microjet liquid-cooled heat sinks. Int. J. Heat Mass Transf. 2019, 138, 257–266. [Google Scholar] [CrossRef]

- Ozguc, S.; Pan, L.; Weibel, J.A. Topology optimization of microchannel heat sinks using a homogenization approach. Int. J. Heat Mass Transf. 2021, 169, 120896. [Google Scholar] [CrossRef]

- Yan, H.; Yang, X.; Lu, T.J.; Xie, G. Convective heat transfer in a lightweight multifunctional sandwich panel with X-type metallic lattice core. Appl. Therm. Eng. 2017, 127, 1293–1304. [Google Scholar] [CrossRef]

- Collins, I.L.; Weibel, J.A.; Pan, L.; Garimella, S.V. A permeable-membrane microchannel heat sink made by additive manufacturing. Int. J. Heat Mass Transf. 2019, 131, 1174–1183. [Google Scholar] [CrossRef]

| Reference | Channel Size (Hydraulic Diameter/ Aspect Ratio) | Fluid/ Variable Parameter/ Heat Flux | Research Method/ Flow Pattern/ Remarks |

|---|---|---|---|

| Lee et al. [41] | 318~903 μm/aspect ratio: 4.56~5.45 | Deionized water/ Reynolds number: 300~3500/ - | Experiment/ Single-phase flow/ The heat transfer coefficient increases as the size decreases. |

| Markal et al. [26] | 100~250 μm/ aspect ratio: 1 | Deionized water/ Mass flux: 51~93 kg m−2s−1/ 35.9~105.6 kW/m2 | Experiment/ Flow boiling/ The influence of hydraulic diameter on heat transfer performance is complicated. |

| Sadaghiani et al. [43] | 600~900 μm/ Round tube | Deionized water/ Mass flux: 2600~8000 kg m−2s−1/ 3000~6000 kW/m2 | Experiment/ Flow boiling/ The relationship between the heat transfer and the hydraulic diameter is affected by the flow conditions. |

| Yang et al. [44] | 480~790 μm/aspect ratio: 0.25~0.95 | HFE-7100/ Mass flux: 200~400 kg m−2s−1/ 25~37.5 kW/m2 | Experiment/ Flow boiling/ The heat transfer is related to the corresponding two-phase flow patterns under different sizes. |

| Reference | Channel Size (Hydraulic Diameter/ Aspect Ratio) | Fluid/ Variable Parameter/ Heat Flux | Research Method/ Flow Pattern/ Remarks |

|---|---|---|---|

| Naphon et al. [47] | -/ aspect ratio: 3.33~7.50 | Air/ Reynolds number: 200 to 1000/ Heat flux: 1.8 to 5.4 kW m−2 | Experiment/ Single-phase flow/ Microchannels with large aspect ratio have good thermal performance. |

| Xie et al. [48] | 800~1412 μm/ aspect ratio: 4.00~7.50 | Deionized water/ Inlet velocity: 0.1–1.5 m/s/ Heat flux: 1.8 to 2560 kW m−2 | Experiment/ Single-phase flow/ The narrow and deep microchannel has a higher heat transfer coefficient with a higher pressure drop. |

| Wang et al. [49] | 571~1454 μm/aspect ratio: 10~20 | FC-72/ Mass flux: 11.2–44.8 kg m−2s−1/ Heat flux: 0 to 18.6 kW m−2 | Experiment/ Flow boiling/ The critical heat flux (CHF) increases as the hydraulic diameter increases. However, the heat transfer performance deteriorates. |

| Lee and Mudawar [50,51] | 175.7~415.9 μm/aspect ratio: 2.47~4.01 | HFE-7100/ Mass flux: 670–6730 kg m−2s−1/ Heat flux: 0 to 7500 kW m−2 | Experiment/ Flow boiling/ The aspect ratio affects the heat transfer by affecting the transition of the two-phase flow pattern. |

| Harirchian et al. [52,53] | 96 to 707 μm/aspect ratio: 1.05~15.55 | FC-77/ Mass flux: 250–1600 kg m−2s−1/ Heat flux: 0 to 280 kW m−2 | Experiment/ Flow boiling/ The cross-sectional area of the microchannel determines the boiling mechanism and heat transfer. |

| Markal et al. [54] | 100 μm/ aspect ratio: 0.37~5.00 | FC-72/ Mass flux: 11.2–44.8 kg m−2s−1/ Heat flux: 0 to 18.6 kW m−2 | Experiment/ Flow boiling/ When the aspect ratio is 3.54, the heat transfer coefficient reaches its peak in flow boiling. |

| Fu et al. [55] | about 112 μm/aspect ratio: 0.83~6.06 | HFE-7100/ Mass flux: 39–180 kg m−2s−1/ Heat flux: 100 to 1140 kW/m−2 | Experiment/ Flow boiling/ When the aspect ratio is 0.99, the critical heat flux (CHF)reaches its peak in flow boiling. |

| Markal et al. [56] | 112 μm/aspect ratio: 0.25~4.00 | Deionized water/ Mass flux: 70–310 kg m−2s−1/ Heat flux: 108 to 296 kW/m−2 | Experiment/ Flow boiling/ The aspect ratio is 1 shows the best heat transfer coefficient. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Li, T.; Zeng, X.; He, T.; Mao, N. A Critical Review on Geometric Improvements for Heat Transfer Augmentation of Microchannels. Energies 2022, 15, 9474. https://doi.org/10.3390/en15249474

Yu H, Li T, Zeng X, He T, Mao N. A Critical Review on Geometric Improvements for Heat Transfer Augmentation of Microchannels. Energies. 2022; 15(24):9474. https://doi.org/10.3390/en15249474

Chicago/Turabian StyleYu, Hao, Tongling Li, Xiaoxin Zeng, Tianbiao He, and Ning Mao. 2022. "A Critical Review on Geometric Improvements for Heat Transfer Augmentation of Microchannels" Energies 15, no. 24: 9474. https://doi.org/10.3390/en15249474

APA StyleYu, H., Li, T., Zeng, X., He, T., & Mao, N. (2022). A Critical Review on Geometric Improvements for Heat Transfer Augmentation of Microchannels. Energies, 15(24), 9474. https://doi.org/10.3390/en15249474