Experimental Study on Temporal and Spatial Evolutions of Temperature Field of Double-Pipe Freezing in Saline Stratum with a High Velocity

Abstract

:1. Introduction

2. Freezing Point Test of Similar Materials in Saline Layer

2.1. Test Method and Scheme

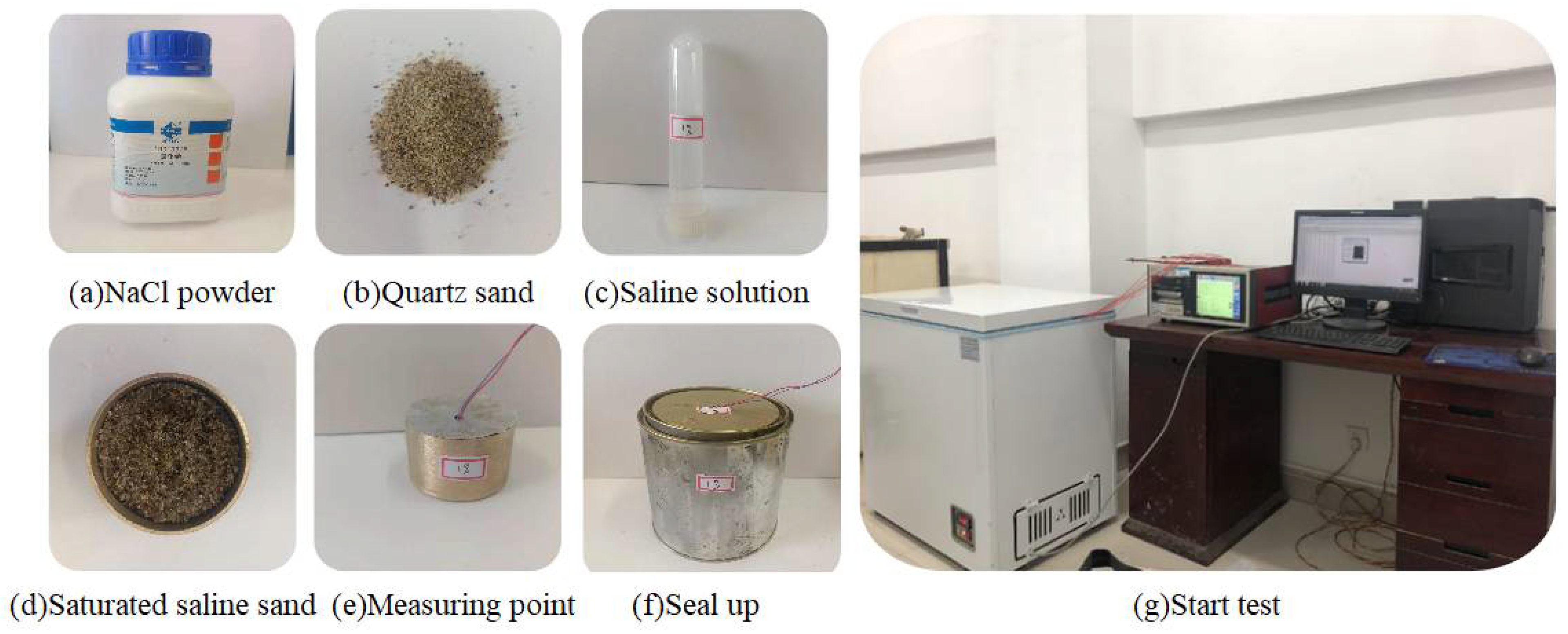

2.2. Experimental Equipment and Steps

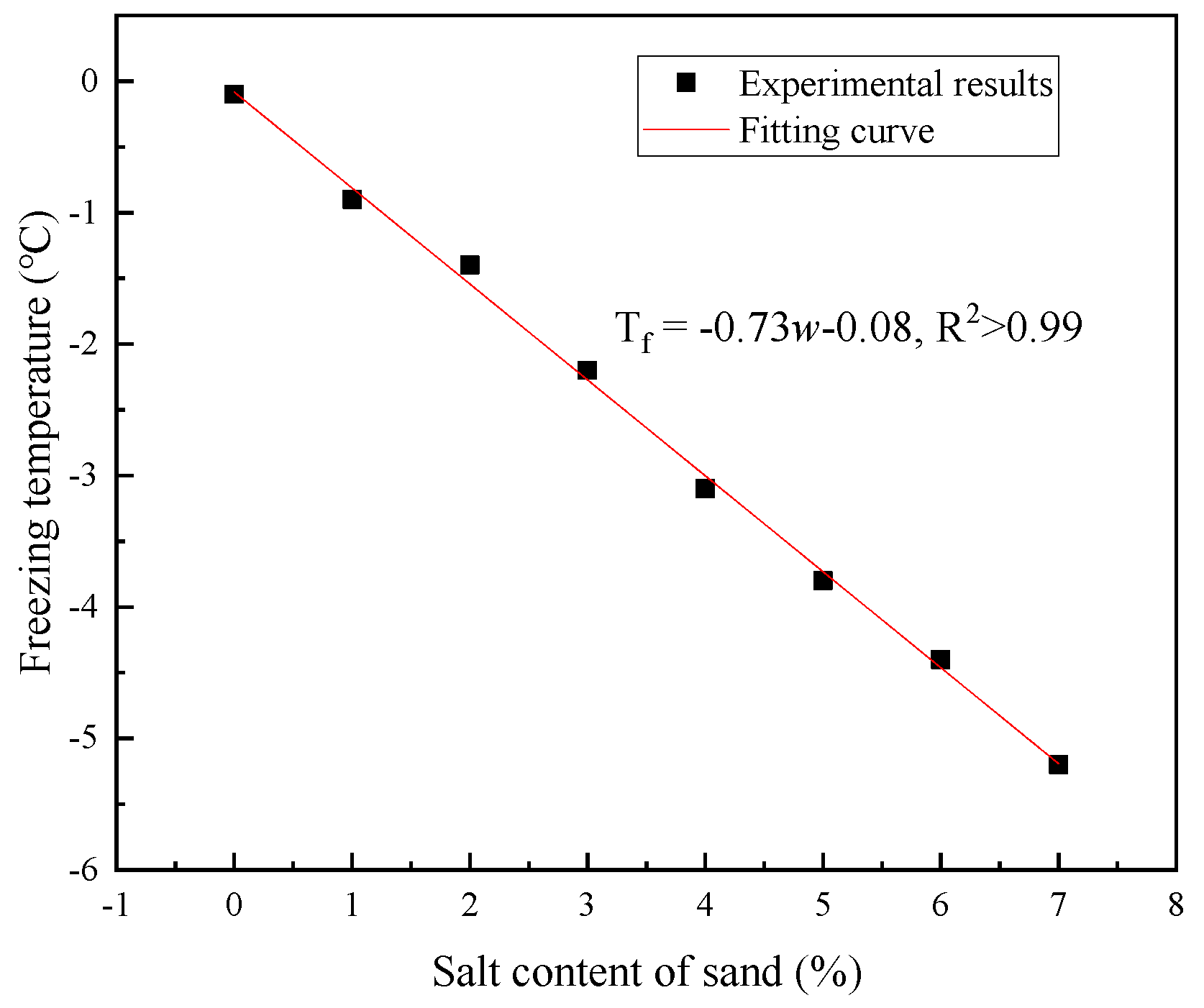

2.3. Analysis of Test Results

3. Model Test of Saline Sand under Different Velocities

3.1. Model Test Scheme

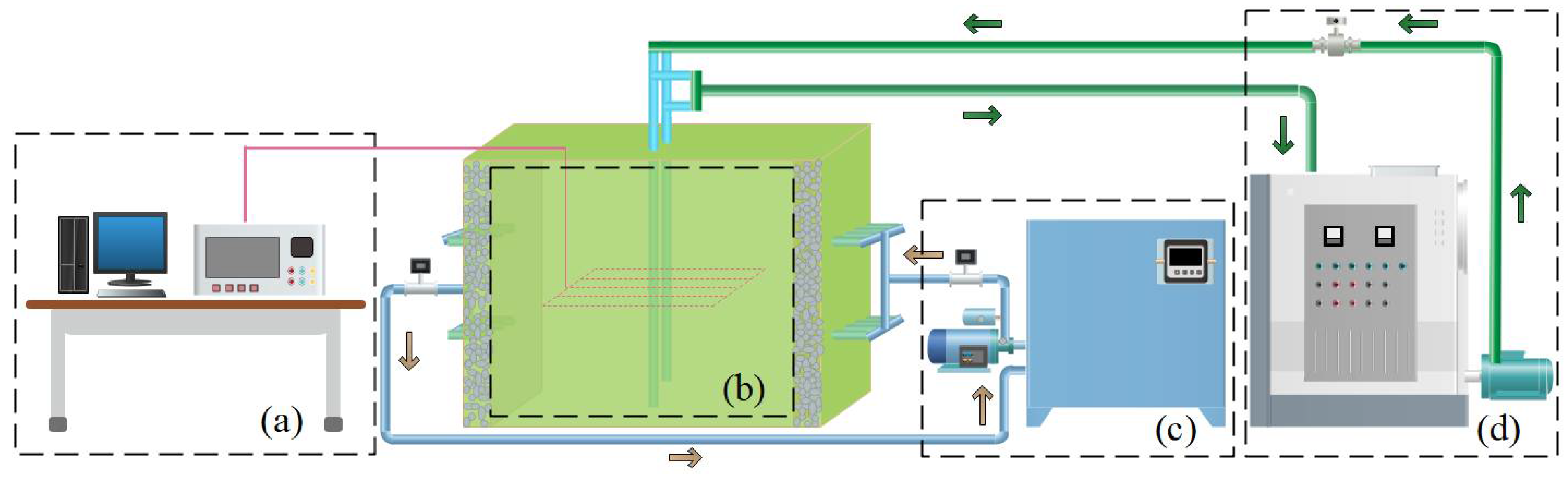

3.2. Design of the Freezing in Saline Sand

4. Analysis of Freezing Model Test Results in Saline Sand

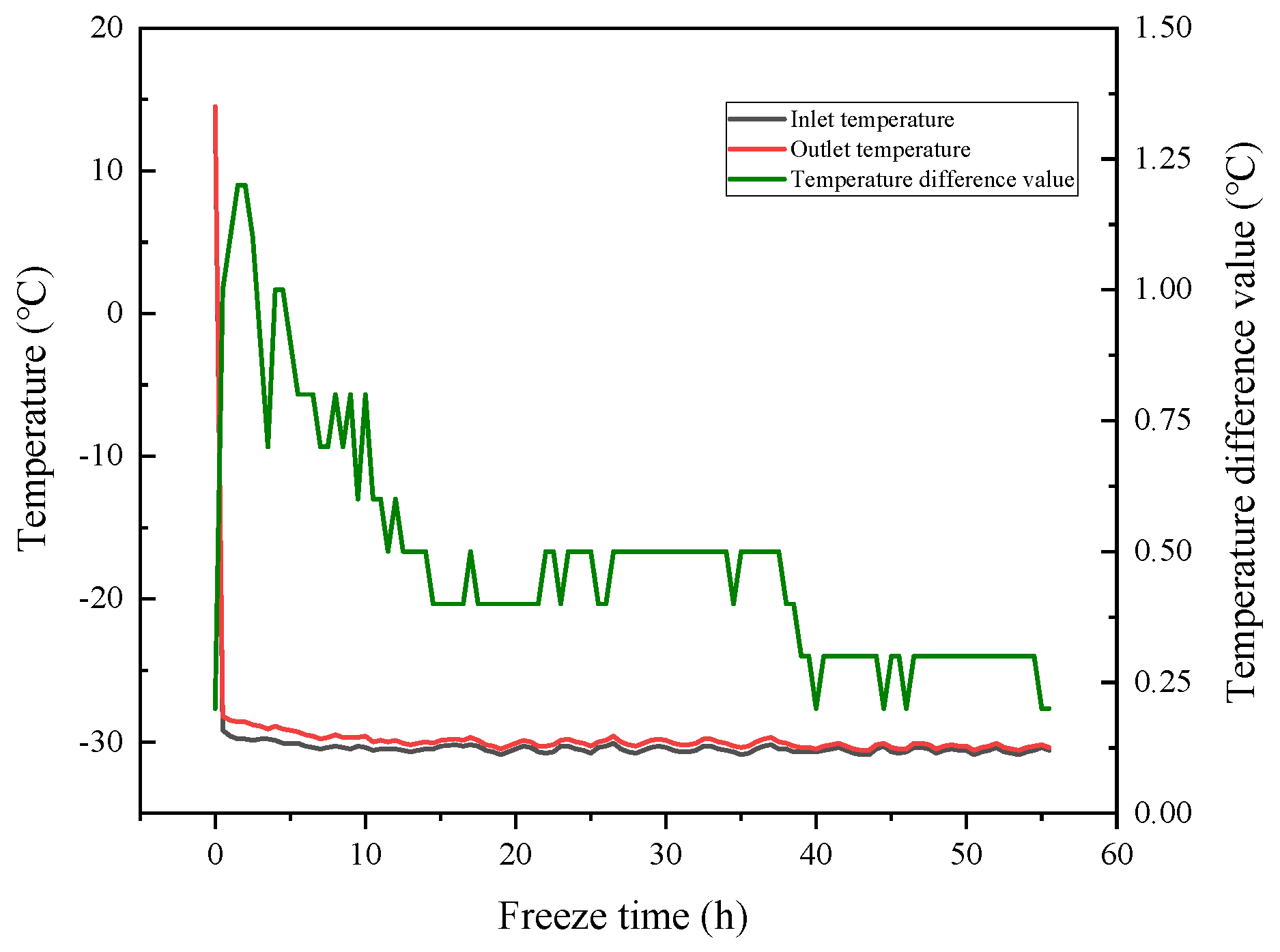

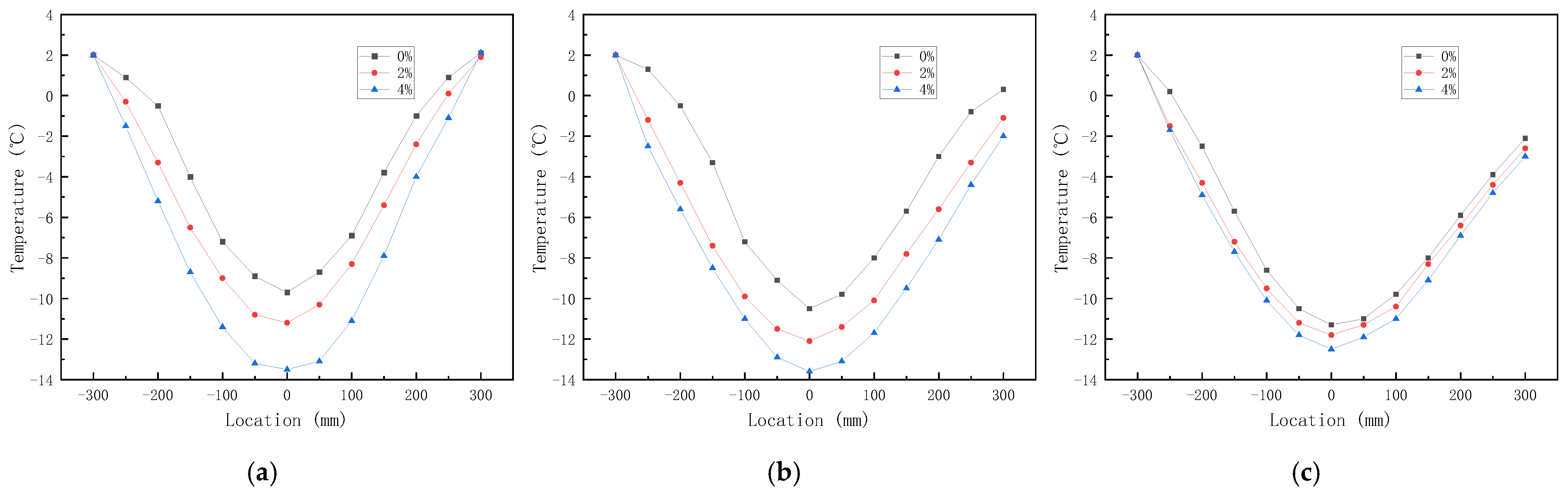

4.1. Temporal and Spatial Development of Freezing Temperature Field in Saline Sand

4.2. The Overlapping Times of the Frozen Curtain under Different Velocities and Salinities

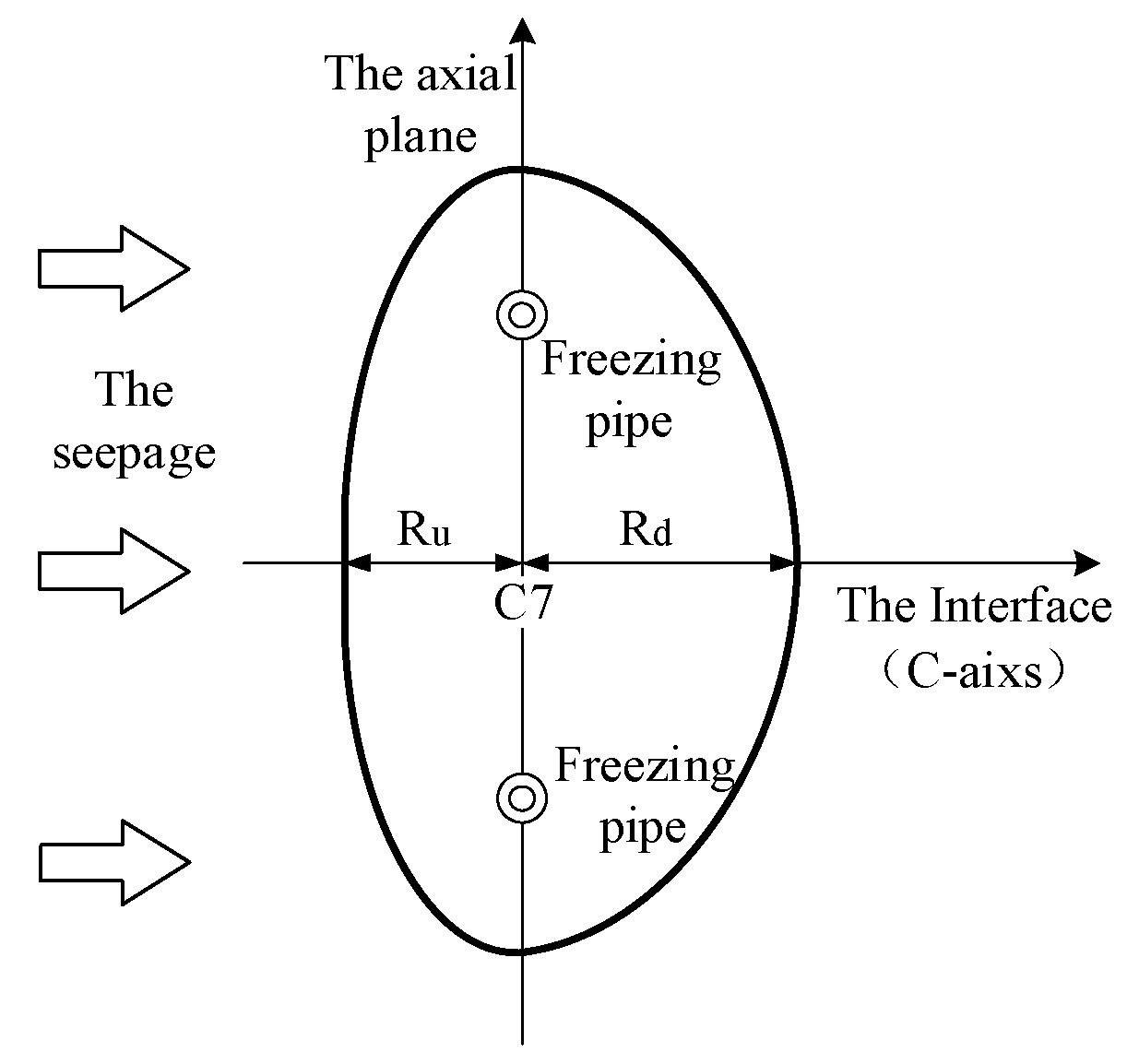

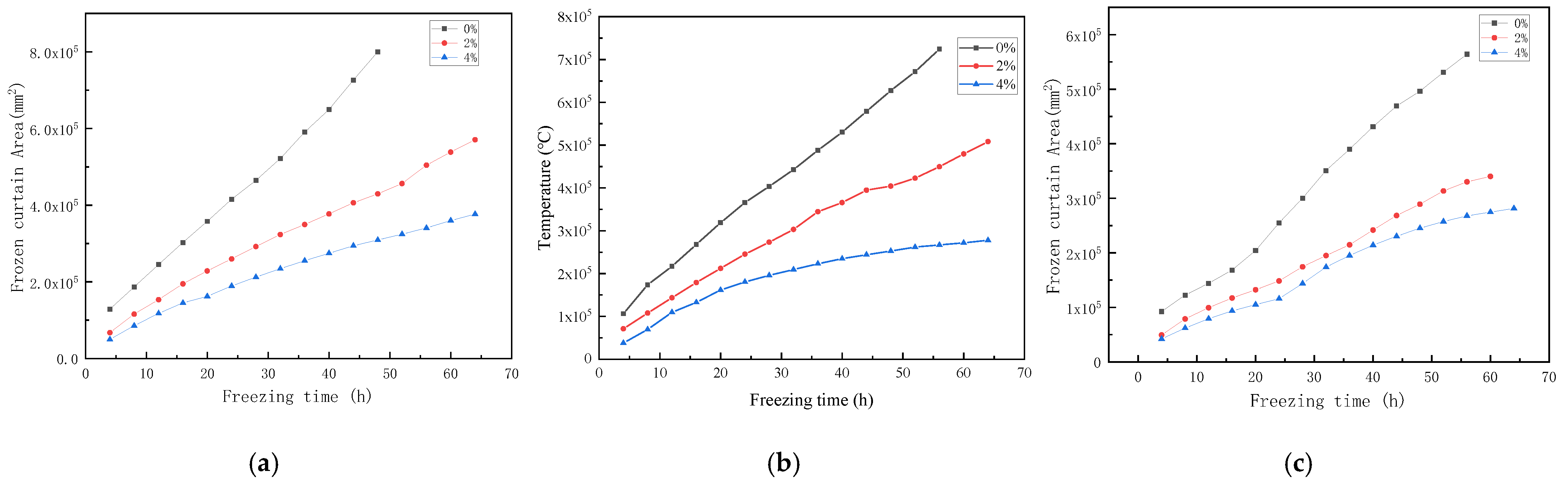

4.3. The Development of the Frozen Curtain under Different Velocities and Salinities

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Construction, PRC. Code for Geotechnical Engineering Investigation (GB50021-2009); Ministry of Construction: Beijing, China, 2009.

- Kalinina, N.V.; Rukhovich, D.I.; Pankova, E.I.; Chernousenko, G.I.; Koroleva, P.V. Cartographic analysis of the distribution of saline soils in Russia depending on some climatic parameters. Eurasian Soil Sci. 2016, 49, 1211–1227. [Google Scholar] [CrossRef]

- Hammam, A.; Mohamed, E. Mapping soil salinity in the East Nile Delta using several methodological approaches of salinity assessment. Egypt J. Remote Sens. Space Sci. 2020, 23, 125–131. [Google Scholar] [CrossRef]

- Huang, X.; Yao, Z.; Cai, H.; Li, X.; Chen, H. Performance evaluation of coaxial borehole heat exchangers considering ground non-uniformity based on analytical solutions. Int. J. Therm. Sci. 2021, 170, 107162. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, J.; Tang, L. Experimental study on shear strength characteristics of sulfate saline soil in Ningxia region under long-term freeze-thaw cycles. Cold Reg. Sci. Technol. 2019, 160, 48–57. [Google Scholar] [CrossRef]

- Korolyuk, T.V. Specific features of the dynamics of salts in salt-affected soils subjected to long-term seasonal freezing in the south Transbaikal region. Eurasian Soil Sci. 2014, 47, 339–352. [Google Scholar] [CrossRef]

- Li, K.-Q.; Li, D.-Q.; Liu, Y. Meso-scale investigations on the effective thermal conductivity of multi-phase materials using the finite element method. Int. J. Heat Mass Transf. 2020, 151, 119383. [Google Scholar] [CrossRef]

- Wan, X.S.; Zhang, Q.H.; Xue, M.; Fang, J.H. Road disease and treatment in saline soil area. J. Tongji Univ. 2003, 31, 1178–1182. (In Chinese) [Google Scholar]

- Bing, H.; Ma, W. Laboratory investigation of the freezing point of saline soil. Cold Reg. Sci. Technol. 2011, 67, 79–88. [Google Scholar] [CrossRef]

- Wan, X.; Lai, Y.; Wang, C. Experimental Study on the Freezing Temperatures of Saline Silty Soils. Permafr. Periglac. Process. 2015, 26, 175–187. [Google Scholar] [CrossRef]

- Wu, M.; Zhao, Q.; Jansson, P.-E.; Wu, J.; Tan, X.; Duan, Z.; Wang, K.; Chen, P.; Zheng, M.; Huang, J.; et al. Improved soil hydrological modeling with the implementation of salt-induced freezing point depression in CoupModel: Model calibration and validation. J. Hydrol. 2020, 596, 125693. [Google Scholar] [CrossRef]

- Xiao, Z.; Lai, Y.; Zhang, M. Study on the freezing temperature of saline soil. Acta Geotech. 2017, 13, 195–205. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, W.M.; Rahardjo, H.; Satyanaga, A.; Dai, G.L.; Zhao, X.L. Theoretical method for the estimation of vapour con-ductivity for unsaturated soil. Eng. Geol. 2021, 295, 106447. [Google Scholar] [CrossRef]

- Zhai, Q.; Rahardjo, H.; Satyanaga, A.; Priono; Dai, G.-L. Role of the pore-size distribution function on water flow in unsaturated soil. J. Zhejiang Univ. A 2019, 20, 10–20. [Google Scholar] [CrossRef]

- Geng, X.; Boufadel, M.C. Numerical modeling of water flow and salt transport in bare saline soil subjected to evaporation. J. Hydrol. 2015, 524, 427–438. [Google Scholar] [CrossRef]

- Xu, J.; Lan, W.; Li, Y.; Wang, S.; Cheng, W.-C.; Yao, X. Heat, water and solute transfer in saline loess under uniaxial freezing condition. Comput. Geotech. 2020, 118, 20. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Zhai, E.; Ye, P. Coupling analysis of the heat-water dynamics and frozen depth in a seasonally frozen zone. J. Hydrol. 2020, 593, 125603. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y.; Xiao, F.; Chen, W. Large-Scale Model Testing of High-Speed Railway Subgrade under Freeze-Thaw and Precipitation Conditions. Adv. Civ. Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- Ye, C.; Li, Z.C.; Liang, R.Z.; Xiao, M.Z.; Cai, B.H.; Wu, W.B. Analysis of the influence of groundwater salt content on the effect of artificial freezing. Hydro-Sci. Eng. 2021, 2, 78–86. (In Chinese) [Google Scholar]

- Zhang, T.; Yang, P. Effect of different factors on the freezing temperature of shallow top soil. J. Nanjing For. Univ. 2009, 33, 132–134. (In Chinese) [Google Scholar]

- Zhou, J.Z.; Tan, L.; Wei, C.F.; Wei, H.Z. Experimental study on freezing temperature and supercooling temperature of soil. Geotech. Mech. 2015, 36, 777–785. (In Chinese) [Google Scholar]

- Kozlowski, T. Some factors affecting supercooling and the equilibrium freezing point in soil–water systems. Cold Reg. Sci. Technol. 2009, 59, 25–33. [Google Scholar] [CrossRef]

- Sun, S.C.; Rong, C.X.; Chen, H.; Wang, B. Experimental Study of the Space-Time Effect of a Double-Pipe Frozen Curtain For-mation with Different Groundwater Velocities. Energies 2021, 14, 17. [Google Scholar]

- Li, Z.X. Research of Salt Migration Rule in Saline Soil; Hefei University of Technology: Hefei, China, 2012. [Google Scholar]

- Su, W.D. Application of freezing method in the construction of subway connecting aisle under the enriched seawater stratum. J. Water Resour. Archit. Eng. 2019, 17, 181–186. (In Chinese) [Google Scholar]

- Wang, B.; Rong, C.; Cheng, H.; Cai, H.; Dong, Y.; Yang, F. Temporal and spatial evolution of temperature field of single freezing pipe in large velocity infiltration configuration. Cold Reg. Sci. Technol. 2020, 175, 5902184. [Google Scholar] [CrossRef]

| Particle Size (mm) | Dry Density (kg/m3) | Porosity | Saturated Moisture Content | Permeability Coefficient (m/s) |

|---|---|---|---|---|

| 0.5 ± 0.15 | 1612 | 0.32 | 20% | 2.28 × 10−4 |

| Salinities of the Solution | 0% | 1% | 2% | 3% | 4% | 5% | 6% | 7% |

|---|---|---|---|---|---|---|---|---|

| salinities of saline sand | 0% | 0.216% | 0.435% | 0.660% | 0.889% | 1.122% | 1.362% | 1.605% |

| Geometric Similarity Ratio | Temperature Similarity Ratio | Time Similarity Ratio | Model Test Size | Freezing Pipe Radius | Freezing Pipe Spacing |

|---|---|---|---|---|---|

| 1/3 | 1 | 1/3 | 1.5 m × 2 m × 1 m | 0.02 m | 0.4 m |

| The Velocity | The Salinity | ||

|---|---|---|---|

| 0 | 2% | 4% | |

| 0 m/d | 0 | 0 | 0.1 |

| 3 m/d | 2.1 | 3.6 | 4.6 |

| 6 m/d | 3.6 | 4.5 | 5.9 |

| The Velocity | The Salinity | ||

|---|---|---|---|

| 0 | 2% | 4% | |

| 0 m/d | 450 | 304 | 227 |

| 3 m/d | 395 | 254 | 196 |

| 6 m/d | 280 | 192 | 175 |

| The Velocity | The Salinity | ||

|---|---|---|---|

| 0 | 2% | 4% | |

| 0 m/d | 15,246 | 8387 | 5443 |

| 3 m/d | 12,366 | 7284 | 4116 |

| 6 m/d | 9434 | 5191 | 3987 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, C.; Sun, S.; Cheng, H.; Duan, Y.; Yang, F. Experimental Study on Temporal and Spatial Evolutions of Temperature Field of Double-Pipe Freezing in Saline Stratum with a High Velocity. Energies 2022, 15, 1308. https://doi.org/10.3390/en15041308

Rong C, Sun S, Cheng H, Duan Y, Yang F. Experimental Study on Temporal and Spatial Evolutions of Temperature Field of Double-Pipe Freezing in Saline Stratum with a High Velocity. Energies. 2022; 15(4):1308. https://doi.org/10.3390/en15041308

Chicago/Turabian StyleRong, Chuanxin, Shicheng Sun, Hua Cheng, Yin Duan, and Fan Yang. 2022. "Experimental Study on Temporal and Spatial Evolutions of Temperature Field of Double-Pipe Freezing in Saline Stratum with a High Velocity" Energies 15, no. 4: 1308. https://doi.org/10.3390/en15041308