Comparison of China’s Biomass Combustion Power Generation with Different Installed Capacities

Abstract

1. Introduction

2. Introduction to the 30 MW and 12 MW BCPG Projects

3. Operation Performance Analysis

4. Techno-Economic Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Calculation of the Internal Rate of Return

References

- Abuelmuor, A.A.A.; Wahid, M.A.; Hosseini, S.E.; Saat, A.; Saqr, K.M.; Sait, H.H.; Osman, M. Characteristics of biomass in flameless combustion: A review. Renew. Sustain. Energy Rev. 2014, 33, 363–370. [Google Scholar] [CrossRef]

- Karpenstein-Machan, M. Sustainable Cultivation Concepts for Domestic Energy Production from Biomass. Crit. Rev. Plant Sci. 2001, 20, 1–14. [Google Scholar] [CrossRef]

- Balat, M.; Ayar, G. Biomass Energy in the World, Use of Biomass and Potential Trends. Energy Source 2005, 27, 931–940. [Google Scholar] [CrossRef]

- Mckendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- He, J.; Zhu, R.; Lin, B. Prospects, obstacles and solutions of biomass power industry in China. J. Clean. Prod. 2019, 237, 117783. [Google Scholar] [CrossRef]

- IPCC (Intergovernmental Panel on Climate Change). Special Report on Global Warming of 1.5 °C; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Huang, X.; Chang, S.; Zheng, D.; Zhang, X. The role of BECCS in deep decarbonization of China's economy: A computable general equilibrium analysis. Energy Econ. 2020, 92, 104968. [Google Scholar] [CrossRef]

- Galazka, A.; Szadkowski, J. Enzymatic hydroplysis of fast-growing poplar wood after pretreatment by steam explosion. Cell. Chem. Technol. 2021, 55, 637–647. [Google Scholar] [CrossRef]

- IRENA (International Renewable Energy Administration). World Energy Transitions Outlook; IRENA: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Pan, X.; Chen, W.; Wang, L.; Lin, L.; Li, N. The role of biomass in China’s long-term mitigation toward the Paris climate goals. Environ. Res. Lett. 2018, 13, 124028. [Google Scholar] [CrossRef]

- Wang, T.; Huang, H.; Yu, C.; Fang, K.; Zheng, M.; Luo, Z. Understanding cost reduction of China's biomass direct combustion power generation—A study based on learning curve model. J. Clean. Prod. 2018, 188, 546–555. [Google Scholar] [CrossRef]

- Zhao, X.; Tan, Z.; Liu, P. Development goal of 30 GW for China’s biomass power generation: Will it be achieved? Renew. Sustain. Energy Rev. 2013, 25, 310–317. [Google Scholar]

- Chen, S.; Feng, H.; Zheng, J.; Ye, J.; Song, Y.; Yang, H.; Zhou, M. Life Cycle Assessment and Economic Analysis of Biomass Energy Technology in China: A Brief Review. Processes 2020, 8, 1112. [Google Scholar] [CrossRef]

- Patzek, T.W.; Pimentel, D. Thermodynamics of Energy Production from Biomass. Crit. Rev. Plant Sci. 2005, 24, 327–364. [Google Scholar] [CrossRef]

- NEA (National Energy Administration). Biomass Energy Development Plan in “The Thirteenth Five-Year”; NEA: Washington, DC, USA, 2016. [Google Scholar]

- Wang, Z.; Wang, Z.; Xu, G.; Ren, J.; Wang, H.; Li, J. Sustainability assessment of straw direct combustion power generation in China: From the environmental and economic perspectives of straw substitute to coal. J. Clean. Prod. 2020, 273, 122890. [Google Scholar] [CrossRef]

- CREEI (China Renewable Energy Engineering Institute). Biomass Power Achievement Statistical Report of China 2020; CREEI: Beijing, China, 2021. [Google Scholar]

- McIlveen-Wright, D.R.; Huang, Y.; Rezvani, S.; Redpath, D.; Anderson, M.; Dave, A.; Hewitt, N.J. A technical and economic analysis of three large scale biomass combustion plants in the UK. Appl. Energy 2013, 112, 396–404. [Google Scholar] [CrossRef]

- Bakos, G.C.; Tsioliaridoua, E.; Potolias, C. Technoeconomic assessment and strategic analysis of heat and power co-generation (CHP) from biomass in Greece. Biomass BioEnergy 2008, 32, 558–567. [Google Scholar] [CrossRef]

- Cardoso, J.; Silva, V.; Eusébio, D. Techno-economic analysis of a biomass gasification power plant dealing with forestry residues blends for electricity production in Portugal. J. Clean. Prod. 2019, 212, 741–753. [Google Scholar] [CrossRef]

- Moon, J.H.; Lee, J.W.; Lee, U.D. Economic analysis of biomass power generation schemes under renewable energy initiative with Renewable Portfolio Standards (RPS) in Korea. Bioresour. Technol. 2011, 102, 9550–9557. [Google Scholar] [CrossRef]

- Wright, D.G.; Dey, P.K.; Brammer, J. A barrier and techno-economic analysis of small-scale bCHP (biomass combined heat and power) schemes in the UK. Energy 2014, 71, 332–345. [Google Scholar] [CrossRef]

- Cui, H.; Wu, R. Feasibility analysis of biomass power generation in China. Energy Procedia 2012, 16, 45–52. [Google Scholar] [CrossRef][Green Version]

- Zhao, Z.; Yan, H. Assessment of the biomass power generation industry in China. Renew. Energy 2012, 37, 53–60. [Google Scholar] [CrossRef]

- Zhao, X.; Feng, T.; Ma, Y.; Yang, Y.; Pan, X. Analysis on investment strategies in China: The case of biomass direct combustion power generation sector. Renew. Sust. Energy Rev. 2015, 42, 760–772. [Google Scholar]

- He, J.; Liu, Y.; Lin, B. Should China support the development of biomass power generation? Energy 2018, 163, 416–425. [Google Scholar] [CrossRef]

- Liu, D.; Liu, M.; Xiao, B.; Guo, X.; Niu, D.; Qin, G.; Jia, H. Exploring biomass power generation’s development under encouraged policies in China. J. Clean. Prod. 2020, 258, 120786. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, D.; Fang, X. Analysis on the policies of biomass power generation in China. Renew. Sust. Energy Rev. 2014, 32, 926–935. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, J.; Liu, X.; Feng, T.; Liu, P. Focus on situation and policies for biomass power generation in China. Renew. Sust. Energy Rev. 2012, 16, 3722–3729. [Google Scholar]

- Student. The probable error of a mean. Biometrika 1908, 6, 1–25. [Google Scholar] [CrossRef]

- Box, J.F. Guinness, Gosset, Fisher, and Small Samples. Stat. Sci. 1987, 2, 45–52. [Google Scholar] [CrossRef]

- Prol, J.L.; Steininger, K.W. Photovoltaic self-consumption is now profitable in Spain: Effects of the new regulation on prosumers’ internal rate of return. Energy Policy 2020, 146, 111793. [Google Scholar] [CrossRef]

- Talavera, D.L.; Aguilera, J.A. The internal rate of return of photovoltaic grid-connected systems: A comprehensive sensitivity analysis. Renew. Energy 2010, 35, 101–111. [Google Scholar] [CrossRef]

- Malek, A.B.M.A.; Hasanuzzaman, M.; Rahim, N.A.; Turki, Y.A.A. Techno-economic analysis and environmental impact assessment of a 10 MW biomass-based power plant in Malaysia. J. Clean. Prod. 2017, 141, 502–513. [Google Scholar] [CrossRef]

- NDRC (National Development and Reform Commission), MOC (Ministry of Construction). Construction Project Economic Evaluation Methods and Parameters, 3rd ed.; China Planning Press: Beijing, China, 2006.

| Equipment | Designed Parameter | 30 MW | 12 MW |

|---|---|---|---|

| Boiler | Max. continuous steam capacity | 130 t/h | 48 t/h |

| Steam pressure | 9.2 MPa | 9.2 MPa | |

| Steam temperature | 540 °C | 540 °C | |

| Boiler efficiency | 92% | 92% | |

| Steam Turbine | Rated power | 30 MW | 12 MW |

| Rated rotation speed | 3000 r/min | 3000 r/min | |

| Generator | Rated power | 30 MW | 12 MW |

| Rated voltage | 6.3 kV | 10.5 kV | |

| Rated rotation speed | 3000 r/min | 3000 r/min |

| Operation Parameter | 30 MW | 12 MW |

|---|---|---|

| Total power production (million kWh/year) | 231.7 | 93.6 |

| Total power sent into grid (million kWh/year) * | 209.3 | 88.9 |

| Average daily production (104 kWh) | 65.4 | 26.4 |

| Equipment utilization period (h/year) | 7722 | 7798 |

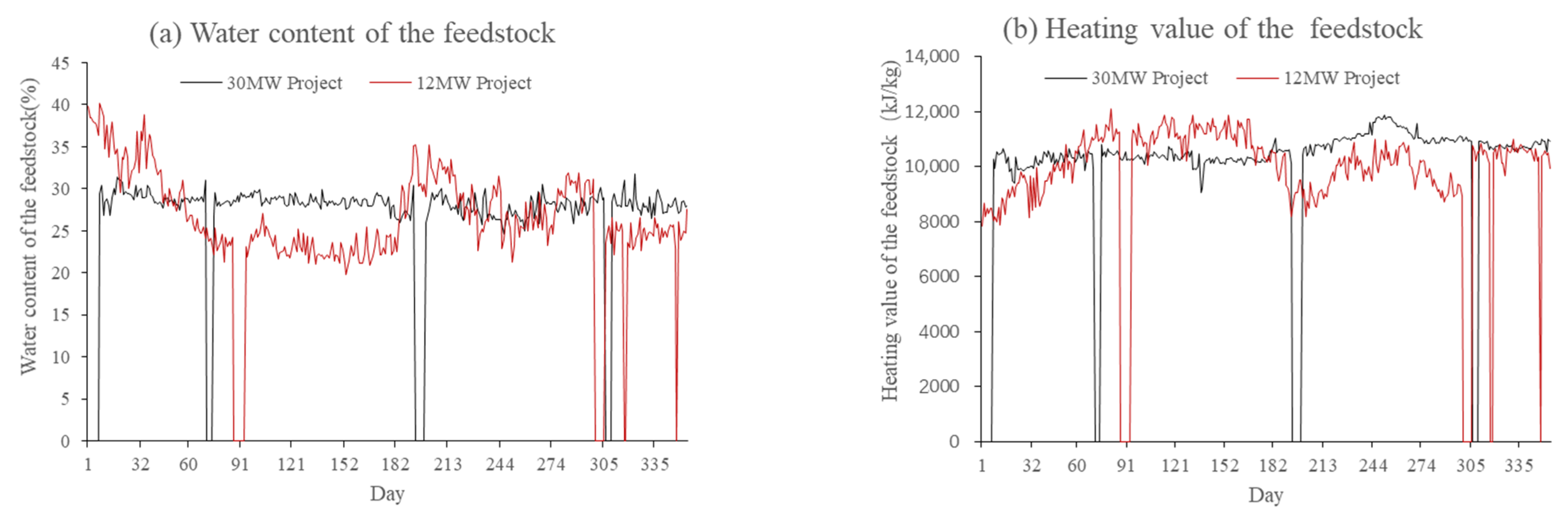

| Heating value of feedstock (kJ/kg) | 10,616 | 10,202 |

| Moisture content of feedstock (%) | 28.3 | 27.1 |

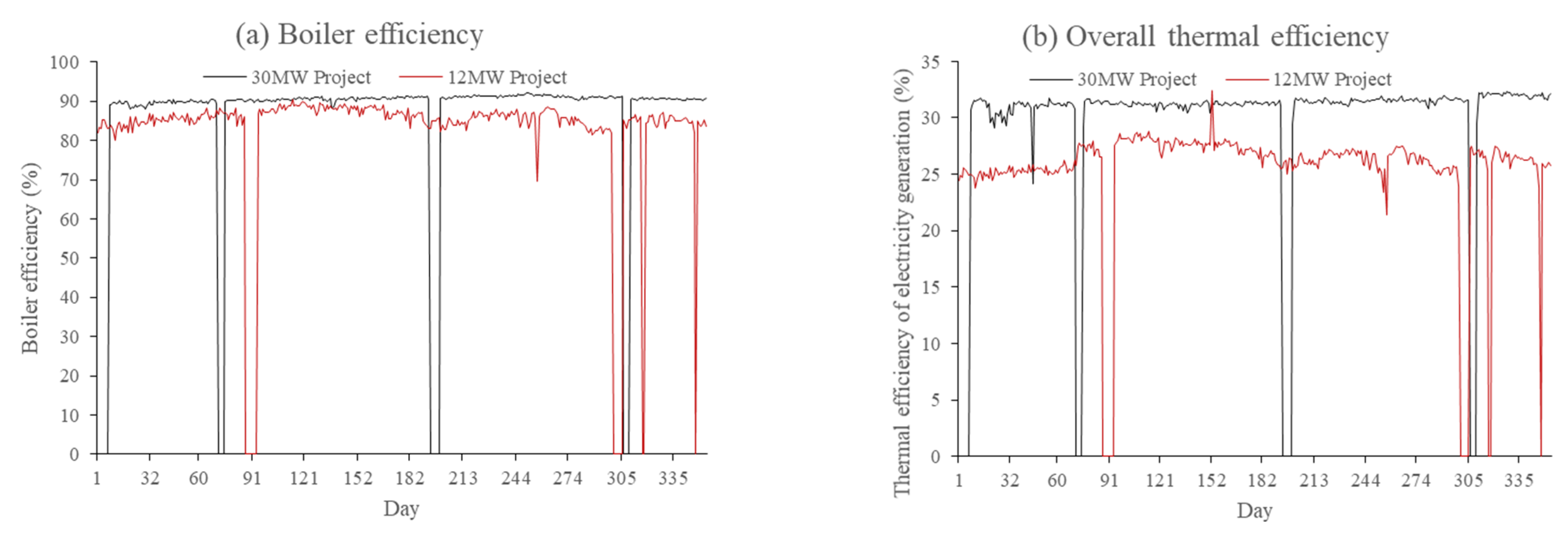

| Boiler efficiency (%) | 90.6 | 85.9 |

| Thermal efficiency (%) | 31.4 | 26.5 |

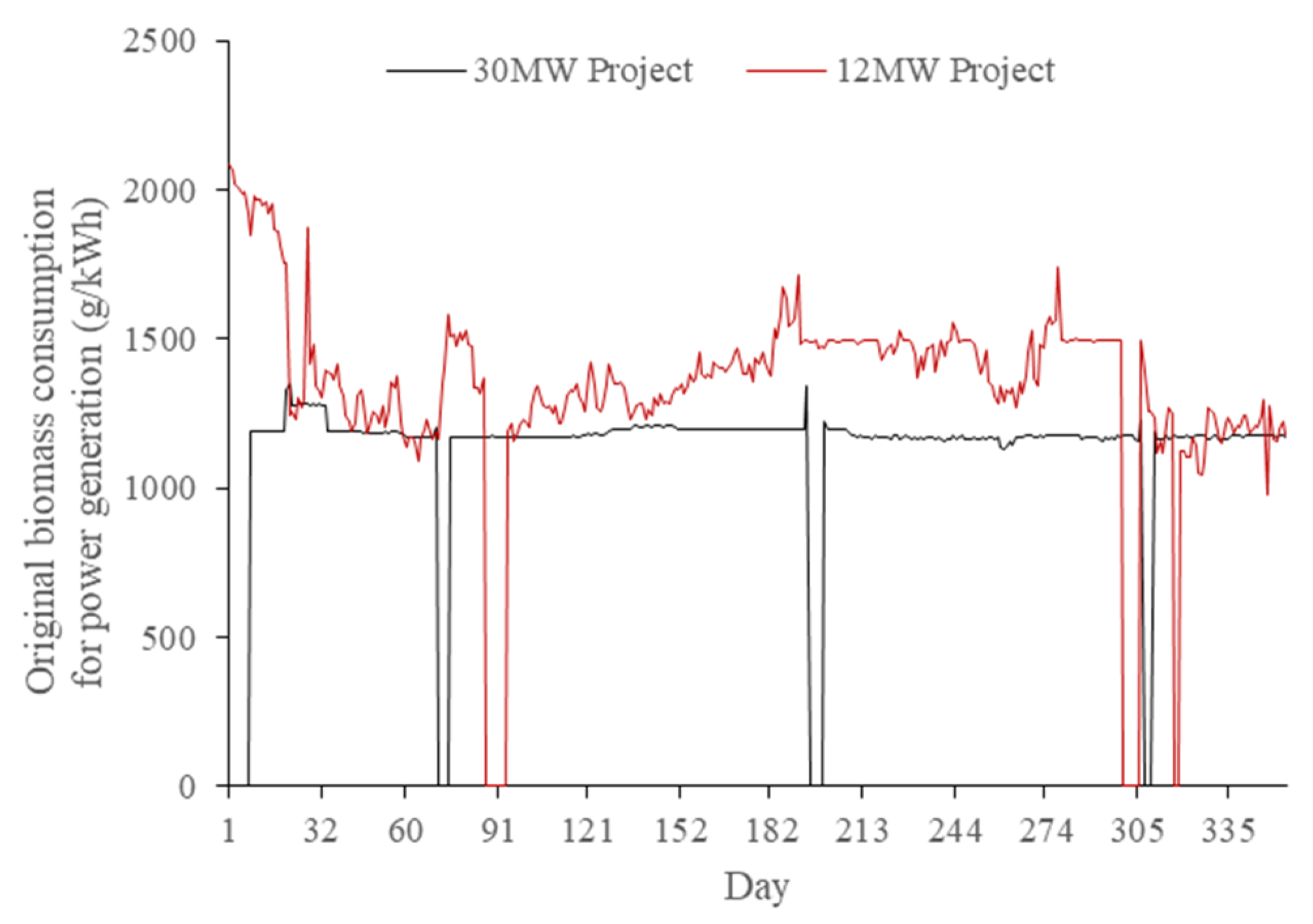

| Original biomass consumption (g/kWh) | 1184 | 1392 |

| Parameter | 30 MW | 12 MW |

|---|---|---|

| Total investment (million CNY) | 304 | 167 |

| Biomass feedstock price (CNY/tonne) | 319 | 249 |

| Biomass feedstock consumption (tonne/year) | 274,397 | 130,228 |

| Cost of feedstock (million CNY/year) | 87.5 | 37.6 |

| Operation cost (million CNY/year) | 29.7 | 16.9 |

| Financial cost (million CNY/year) | 15.9 | 8.8 |

| Total cost (million CNY/year) | 133.2 | 58.1 |

| Output value (million CNY/year) ** | 157.0 | 66.6 |

| Pre-tax net income (million CNY/year) | 23.8 | 8.6 |

| Installed Capacity | Project IRR (Benchmark = 8%) * |

|---|---|

| 30 MW | 11.7% |

| 12 MW | 4.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Zhang, Y.; Wang, Z.; Pan, X. Comparison of China’s Biomass Combustion Power Generation with Different Installed Capacities. Energies 2022, 15, 1535. https://doi.org/10.3390/en15041535

Zhu X, Zhang Y, Wang Z, Pan X. Comparison of China’s Biomass Combustion Power Generation with Different Installed Capacities. Energies. 2022; 15(4):1535. https://doi.org/10.3390/en15041535

Chicago/Turabian StyleZhu, Xiaocheng, Yanru Zhang, Zhenzhong Wang, and Xunzhang Pan. 2022. "Comparison of China’s Biomass Combustion Power Generation with Different Installed Capacities" Energies 15, no. 4: 1535. https://doi.org/10.3390/en15041535

APA StyleZhu, X., Zhang, Y., Wang, Z., & Pan, X. (2022). Comparison of China’s Biomass Combustion Power Generation with Different Installed Capacities. Energies, 15(4), 1535. https://doi.org/10.3390/en15041535