Heat Transfer Enhancement of Crossflow Air-to-Water Fin-and-Tube Heat Exchanger by Using Delta-Winglet Type Vortex Generators

Abstract

:1. Introduction

2. Mathematical Modelling

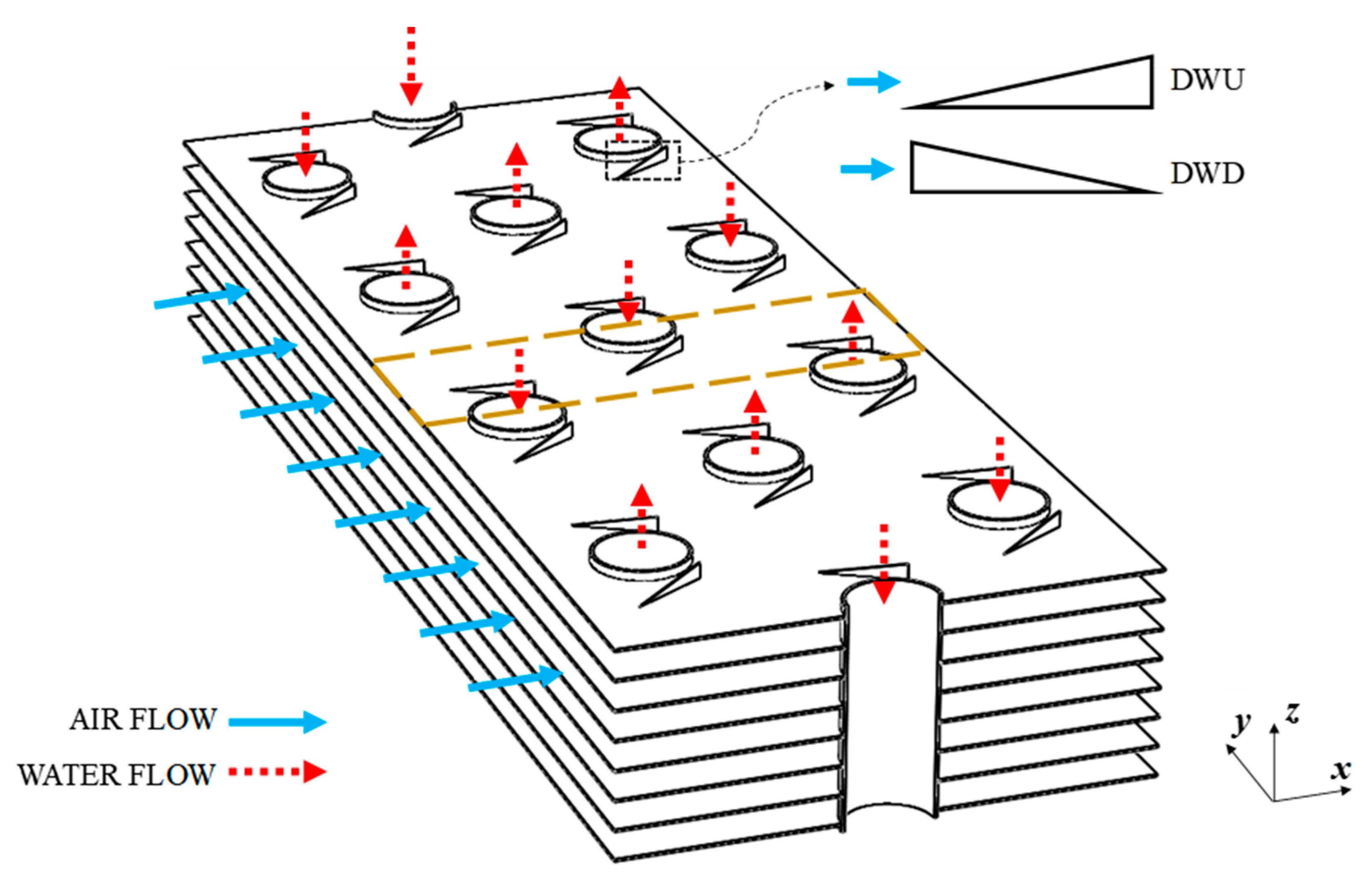

2.1. Problem Description and Computational Domain

2.2. Governing Equations

2.3. Boundary Conditions

3. Numerical Method

- Change in standard deviation of velocity profiles between inlet and outlet water boundaries is less than 0.1%;

- Change in minimum and maximum velocity values between inlet and outlet water boundaries is less than 0.1%;

- Change in air outlet temperature between two separate simulations is less than 0.002 °C.

4. Experimental Validation

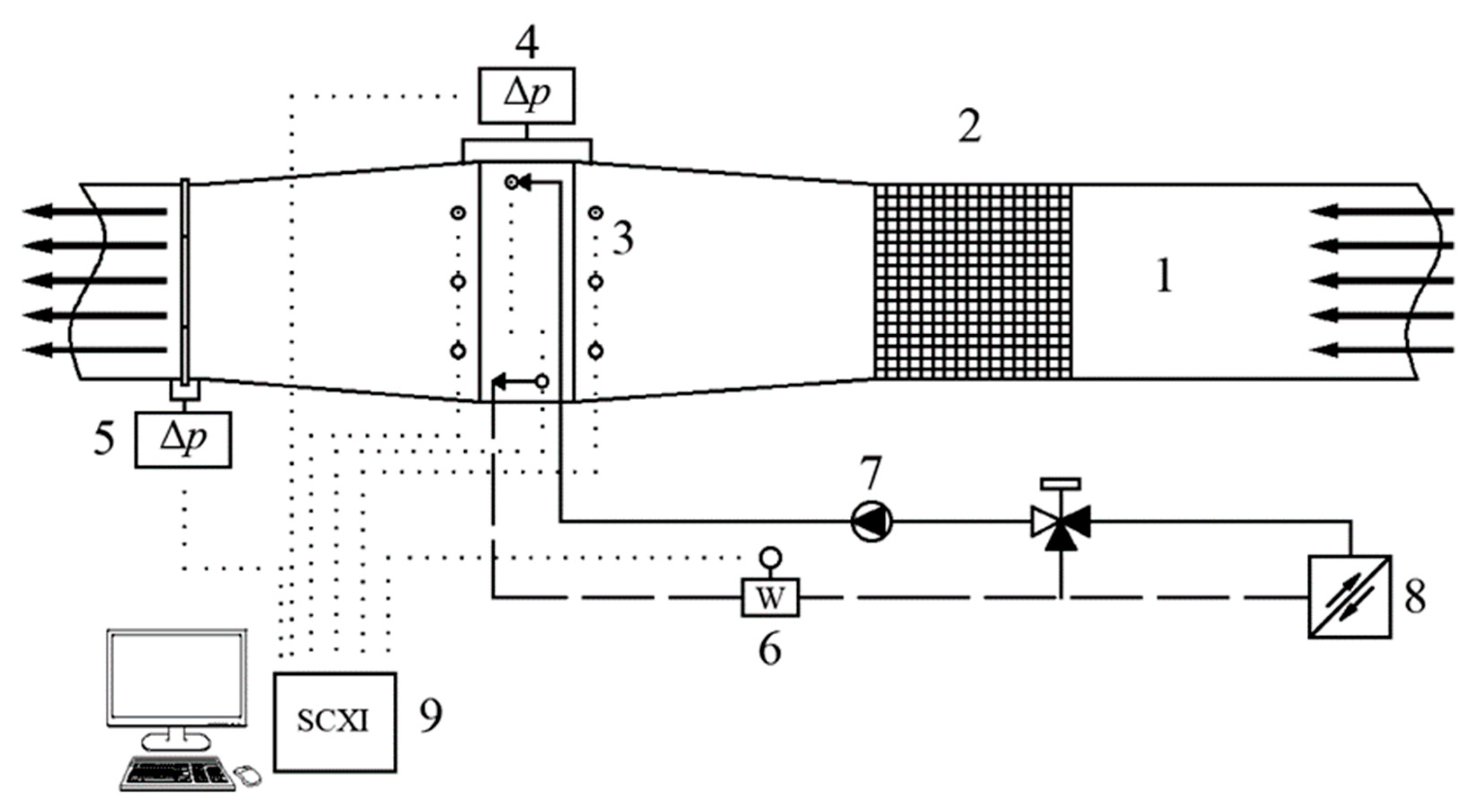

4.1. Experimentally Studied Fin-and-Tube Heat Exchanger and Test Line

4.2. Test Conditions

4.3. Model Validation

5. Results and Discussion

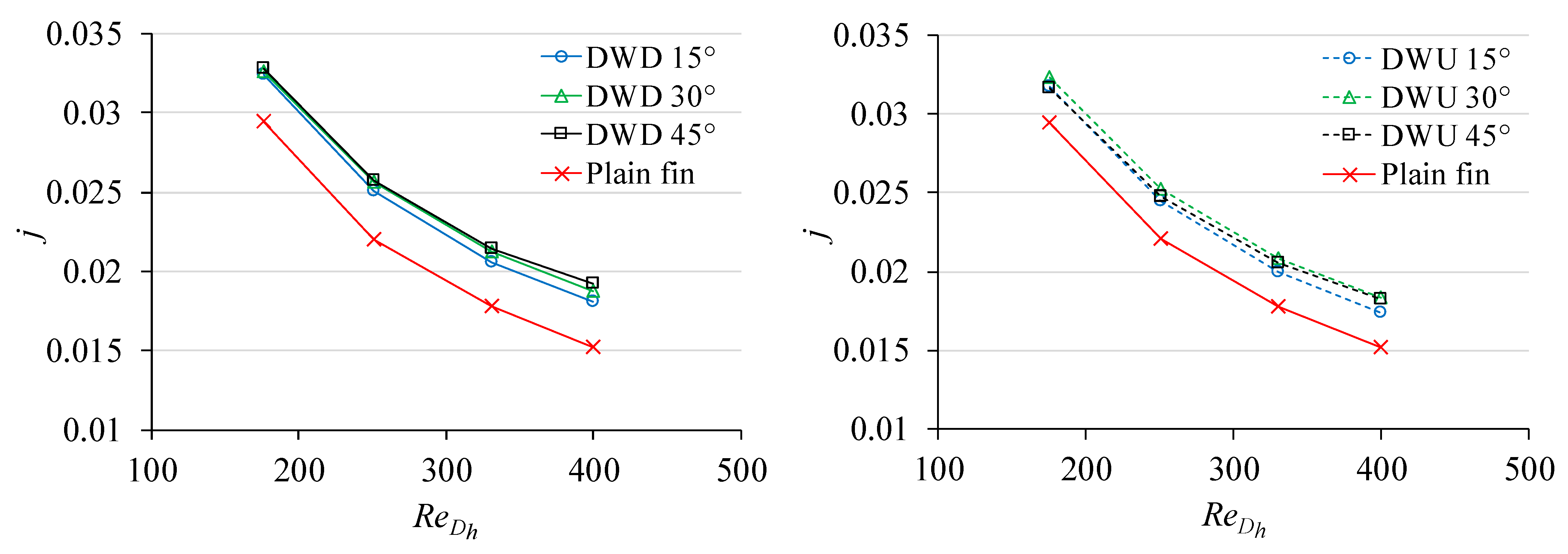

5.1. Comparison of Air-Side Colburn Factors j and Friction Factors f

5.2. Distributions of Temperatures, Velocities and Air-Side Heat Transfer Coefficients

5.3. Comparison of the Air-Side Thermal-Hydraulic Performances

5.4. Comparison of the Overall Heat Transfer Coefficients and Air-Side Thermal Resistance Fractions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | cross-sectional area (m2) |

| Ao | total outside surface area of the finned tube (m2) |

| Amin | minimal flow cross-sectional area (m2) |

| C | heat capacity rate (W/K) |

| C* | Cmin/Cmax heat capacity rate ratio |

| c | specific heat capacity (J/kgK) |

| Dh | 4∙Amin∙Lx/Ao, hydraulic diameter (m) |

| d | tube diameter (m) |

| Fp | fin pitch (m) |

| f | friction factor |

| Hvg | height of vortex generator (m) |

| h | heat transfer coefficient (W/m2K) |

| j | Colburn factor |

| k | turbulence kinetic energy (m2/s2) |

| Lx | fin length (m) |

| Lvg | length of vortex generator (m) |

| Lz | tube length (m) |

| mass flow rate (kg/s) | |

| Nt | number of tubes |

| p | pressure (Pa) |

| Pr | Prandtl number |

| specific heat flux (W/m2) | |

| exchanged heat flux (W) | |

| R | thermal resistance (K/W) |

| ReDh | ρDhwc/μ, Reynolds number based on hydraulic diameter |

| Redi | ρdiw/μ, Reynolds number based on inner tube diameter |

| r | tube radius (m) |

| T | temperature (K) |

| TPF | thermal performance factor |

| U | overall heat transfer coefficient (W/m2K) |

| wc | centreline velocity (m/s) |

| wcore | velocity at minimal flow cross-sectional area (m/s) |

| wx, wy, wz | velocity components in x, y, and z-directions (m/s) |

| x, y, z | Cartesian coordinates (m) |

| XL | longitudinal tube pitch (m) |

| XT | transverse tube pitch (m) |

| y+ | ∆ynρ(τwallρ)0.5/μ dimensionless distance from the wall |

| Greek symbols | |

| α | attack angle (°) |

| δ | thickness (m) |

| ∆p | pressure drop (Pa) |

| ∆T | temperature difference (K) |

| ∆x | distance between tube and winglet in airflow direction (m) |

| ∆y | distance between tube and winglet in spanwise direction (m) |

| ∆yn | distance of the near-wall node to the solid surface (m) |

| ηf | fin efficiency |

| ηo | overall surface efficiency |

| λ | thermal conductivity (W/mK) |

| μ | dynamic viscosity (Pa∙s) |

| ρ | density (kg/m3) |

| σk | turbulent Prandtl number for kinetic energy |

| σω | turbulent Prandtl number for energy dissipation rate |

| τwall | wall shear stress (kg/s2m) |

| ω | turbulence frequency (1/s) |

| Subscripts | |

| air | air side |

| avg | average |

| DWD | delta-winglet downstream |

| DWU | delta-winglet upstream |

| f | fin |

| i | tube side |

| in | inlet |

| LMTD | logarithmic mean temperature difference |

| min | minimum value |

| max | maximum value |

| o | total outside surface |

| out | outlet |

| red | reduced |

| ref | baseline case |

| vg | vortex generator |

| water | water side |

References

- Shah, R.K. Fundamentals of Heat Exchanger Design; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Wu, J.; Liu, P.; Yu, M.; Liu, Z.; Liu, W. Thermo-hydraulic performance and exergy analysis of a fin-and-tube heat exchanger with sinusoidal wavy winglet type vortex generators. Int. J. Therm. Sci. 2022, 172, 107274. [Google Scholar] [CrossRef]

- Alison, C.B.; Dally, B.B. Effect of a delta-winglet vortex pair on the performance of a tube-fin heat exchanger. Int. J. Heat Mass Transf. 2007, 50, 5065–5072. [Google Scholar] [CrossRef]

- Fiebig, M. Vortex generators for compact heat exchangers. J. Enh. Heat Transf. 1995, 2, 43–61. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wu, X.; Wang, L.B.; Song, K.W.; Dong, Y.X.; Liu, S. Comparison of heat transfer performance of tube bank with mounted vortex generators to tube bank fin with punched vortex generators. Exp. Therm. Fluid Sci. 2008, 33, 58–66. [Google Scholar] [CrossRef]

- Xie, J.; Lee, H.M. Thermo-Hydraulic Performance of a Fin-and-Tube Heat Exchanger with Differently Configured Curved-Rectangular Vortex Generators. Heat Transf. Eng. 2022, 43, 63–82. [Google Scholar] [CrossRef]

- Torii, K.; Kwak, K.M.; Nishino, K. Heat transfer enhancement accompanying pressure-loss reduction with winglet-type vortex generators for fin-tube heat exchanger. Int. J. Heat Mass Transf. 2002, 45, 3795–3801. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Impact of delta winglet vortex generators on the performance of a novel fin-tube surfaces with two row of tubes in different diameters. Energy Convers. Manag. 2011, 52, 2895–2901. [Google Scholar] [CrossRef]

- Arora, A.; Subbarao, P.M.V.; Agarwal, R.S. Development of parametric space for the vortex generator location for improving thermal compactness of an existing inline fin and tube heat exchanger. Appl. Therm. Eng. 2016, 98, 727–742. [Google Scholar] [CrossRef]

- Qian, Z.; Wang, Q.; Cheng, J. Analysis of heat and resistance performance of plate fin-and-tube heat exchanger with rectangle-winglet vortex generator. Int. J. Heat Mass Transf. 2018, 124, 1191–1211. [Google Scholar] [CrossRef]

- Naik, H.; Tiwari, S. Thermal performance analysis of fin-tube heat exchanger with staggered tube arrangement in presence of rectangular winglet pairs. Int. J. Therm. Sci. 2021, 161, 106723. [Google Scholar] [CrossRef]

- Awais, M.; Bhuiyan, A.A. Enhancement of thermal and hydraulic performance of compact finned-tube heat exchanger using vortex generators (VGs): A parametric study. Int. J. Therm. Sci. 2019, 140, 154–166. [Google Scholar] [CrossRef]

- Wang, Q.; Qian, Z.; Cheng, J.; Ren, J.; Huang, W. Investigation on Heat Transfer Performance and Flow Resistance Characteristics in Finned-Tube Heat Exchangers with Different Vortex Generator Positions. J. Heat Transf. 2019, 141, 091804. [Google Scholar] [CrossRef]

- Delac, B.; Trp, A.; Lenic, K. Numerical investigation of heat transfer enhancement in a fin and tube heat exchanger using vortex generators. Int. J. Heat Mass Transf. 2014, 78, 662–669. [Google Scholar] [CrossRef]

- Sarangi, S.K.; Mishra, D.P. Effect of winglet location on heat transfer of a fin-and-tube heat exchanger. Appl. Therm. Eng. 2017, 116, 528–540. [Google Scholar] [CrossRef]

- Modi, A.J.; Kalel, N.A.; Rathod, M.K. Thermal performance augmentation of fin-and-tube heat exchanger using rectangular winglet vortex generators having circular punched holes. Int. J. Heat Mass Transf. 2020, 158, 119724. [Google Scholar] [CrossRef]

- Shi, W.; Liu, T.; Song, K.; Zhang, Q.; Hu, W.; Wang, L. The optimal longitudinal location of curved winglets for better thermal performance of a finned-tube heat exchanger. Int. J. Therm. Sci. 2021, 167, 107035. [Google Scholar] [CrossRef]

- Modi, A.J.; Rathod, M.K. Comparative study of heat transfer enhancement and pressure drop for fin-and-circular tube compact heat exchangers with sinusoidal wavy and elliptical curved rectangular winglet vortex generator. Int. J. Heat Mass Transf. 2019, 141, 310–326. [Google Scholar] [CrossRef]

- Xie, J.; Lee, H.M. Flow and Heat Transfer performances of Directly Printed Curved-rectangular Vortex Generators in a Compact Fin-Tube Heat Exchanger. Appl. Therm. Eng. 2020, 180, 115830. [Google Scholar] [CrossRef]

- Salleh, M.F.M.; Mohammed, H.A.; Wahid, M.A. Thermal and Hydraulic Characteristics of Trapezoidal Winglet across Fin-and-Tube Heat Exchanger (FTHE). Appl. Therm. Eng. 2019, 149, 1379–1393. [Google Scholar] [CrossRef]

- Sarangi, S.K.; Mishra, D.P.; Ramachandran, H.; Anand, N.; Masih, V.; Brar, L.S. Analysis and optimization of the curved trapezoidal winglet geometry in a compact heat exchanger. Appl. Therm. Eng. 2021, 182, 116088. [Google Scholar] [CrossRef]

- Välikangas, T.; Karvinen, R. Conjugated heat transfer simulation of a fin-and-tube heat exchanger. Heat Transf. Eng. 2017, 39, 1192–1200. [Google Scholar] [CrossRef]

- Wu, H.L.; Gong, Y.; Zhu, X. Air Flow and Heat Transfer in Louver-Fin Round-Tube Heat Exchangers. J. Heat Transf. 2007, 129, 200–210. [Google Scholar] [CrossRef]

- Borrajo-Peláez, R.; Ortega-Casanova, J.; Cejudo-López, J.M. A three-dimensional numerical study and comparison between the air side model and the air/water side model of a plain fin-and-tube heat exchanger. Appl. Therm. Eng. 2010, 30, 1608–1615. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.C.; Lin, Z.M.; Yao, Y.H.; Wang, L.B. The condition requiring conjugate numerical method in study of heat transfer characteristics of tube bank fin heat exchanger. Int. J. Heat Mass Transf. 2012, 55, 2353–2364. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Jiang, J.; Li, S.; Luo, X.; Wang, S.; Zhao, W. An investigation of influence factor including different tube bundles on inclined elliptical fin-tube heat exchanger. Int. J. Heat Mass Transf. 2019, 142, 118448. [Google Scholar] [CrossRef]

- Lotfi, B.; Sundén, B. Development of new finned tube heat exchanger: Innovative tube-bank design and thermohydraulic performance. Heat Transf. Eng. 2020, 14, 1209–1231. [Google Scholar] [CrossRef] [Green Version]

- Oh, Y.; Kim, K. Effects of position and geometry of curved vortex generators on fin-tube heat-exchanger performance characteristics. Appl. Therm. Eng. 2021, 189, 116736. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, K.; Li, W.; Chen, Q.; Zheng, N. Investigations of the turbulent thermal-hydraulic performance in circular heat exchanger tubes with multiple rectangular winglet vortex generators. Appl. Therm. Eng. 2020, 168, 114838. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method, 2nd ed.; Pearson: Harlow, UK, 2007. [Google Scholar]

- Farhan, M.; Omar, Z.; Mebarek-Oudina, F.; Raza, J.; Shah, Z.; Choudhari, R.V.; Makinde, O.D. Implementation of the one-step one-hybrid block method on the nonlinear equation of a circular sector oscillator. Comput. Math. Model. 2020, 31, 116–132. [Google Scholar] [CrossRef]

- Alkasassbeh, M.; Omar. Z.; Mebarek-Oudina, F.; Raza, J.; Chamkha, A. Heat transfer study of convective fin with temperature-dependent internal heat generation by hybrid block method. Heat Transf. 2019, 48, 1225–1244. [Google Scholar] [CrossRef]

- Ansys Inc. Fluent, version 18.2; Southpointe: Canonsburg, PA, USA, 2017. [Google Scholar]

- Fan, A.W.; Deng, J.J.; Nakayama, A.; Liu, W. Parametric study on turbulent heat transfer and flow characteristics in a circular tube fitted with louvered strip inserts. Int. J. Heat Mass Transf. 2012, 55, 5205–5213. [Google Scholar] [CrossRef]

- Wang, L.B.; Tao, W.Q. Numerical analysis on heat transfer and fluid flow for arrays of non-uniform plate length aligned at angles to the flow direction. Int. J. Num. Meth. Heat Fluid Flow 1997, 7, 479–496. [Google Scholar] [CrossRef]

- Xie, G.; Wang, Q.; Sundén, B. Parametric study and multiple correlations on air-side heat transfer and friction characteristics of fin-and-tube heat exchangers with large number of large-diameter tube rows. Appl. Therm. Eng. 2009, 29, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Zhang, W.; Gou, Q.; Luo, Z.; Lu, Y. Numerical simulation of heat transfer and fluid flow characteristics of composite fin. Int. J. Heat Mass Transf. 2014, 75, 414–424. [Google Scholar] [CrossRef]

- Hu, W.; Wang, L.; Guan, Y.; Hu, W. The effect of shape of winglet vortex generator on the thermal–hydrodynamic performance of a circular tube bank fin heat exchanger. Heat Mass Transf. 2017, 53, 2961–2973. [Google Scholar] [CrossRef]

- Mangrulkar, C.K.; Abraham, J.D.; Dhoble, A.S. Numerical studies on the near wall y+ effect on heat and flow characteristics of the cross flow tube bank. J. Phys. Conf. Ser. 2019, 1240, 012110. [Google Scholar] [CrossRef]

- LabVIEW, version 2015; National Instruments: Austin, TX, USA, 2015.

- Schmidt, T.E. Heat transfer calculations for extended surfaces. Refrig. Eng. 1949, 4, 351–357. [Google Scholar]

- Tang, L.H.; Zeng, M.; Wang, Q.W. Experimental and numerical investigation on air-side performance of fin-and-tube heat exchangers with various fin patterns. Exp. Therm. Fluid Sci. 2009, 33, 818–827. [Google Scholar] [CrossRef]

- Lotfi, B.; Sundén, B. Thermo-Hydraulic Performance Enhancement of Finned Elliptical Tube Heat Exchangers by Utilizing Innovative Dimple Turbulators. Heat Transf. Eng. 2020, 41, 1117–1142. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Yu, J.; Yan, G. A numerical study on the air-side heat transfer of perforated finned-tube heat exchangers with large fin pitches. Int. J. Heat Mass Transf. 2016, 100, 199–207. [Google Scholar] [CrossRef]

- Tian, L.; He, Y.; Chu, P.; Tao, W. Numerical Study of Flow and Heat Transfer Enhancement by Using Delta Winglets in a Triangular Wavy Fin-and-Tube Heat Exchanger. J. Heat Transf. 2009, 131, 091901. [Google Scholar] [CrossRef]

- Yun, J.Y.; Lee, K.S. Influence of design parameters on the heat transfer and flow friction characteristics of the heat transfer with slit fins. Int. J. Heat Mass Transf. 2000, 43, 2529–2539. [Google Scholar] [CrossRef]

- Ahmed, S.A.E.S.; Mesalhy, O.M.; Abdelatief, M.A. Flow and heat transfer enhancement in tube heat exchangers. Int. J. Heat Mass Transf. 2015, 51, 1607–1630. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batista, J.; Trp, A.; Lenic, K. Heat Transfer Enhancement of Crossflow Air-to-Water Fin-and-Tube Heat Exchanger by Using Delta-Winglet Type Vortex Generators. Energies 2022, 15, 2070. https://doi.org/10.3390/en15062070

Batista J, Trp A, Lenic K. Heat Transfer Enhancement of Crossflow Air-to-Water Fin-and-Tube Heat Exchanger by Using Delta-Winglet Type Vortex Generators. Energies. 2022; 15(6):2070. https://doi.org/10.3390/en15062070

Chicago/Turabian StyleBatista, Josip, Anica Trp, and Kristian Lenic. 2022. "Heat Transfer Enhancement of Crossflow Air-to-Water Fin-and-Tube Heat Exchanger by Using Delta-Winglet Type Vortex Generators" Energies 15, no. 6: 2070. https://doi.org/10.3390/en15062070