The Influence of Different Operating Conditions on the Support Bracket Stress in Pumped Storage Units

Abstract

:1. Introduction

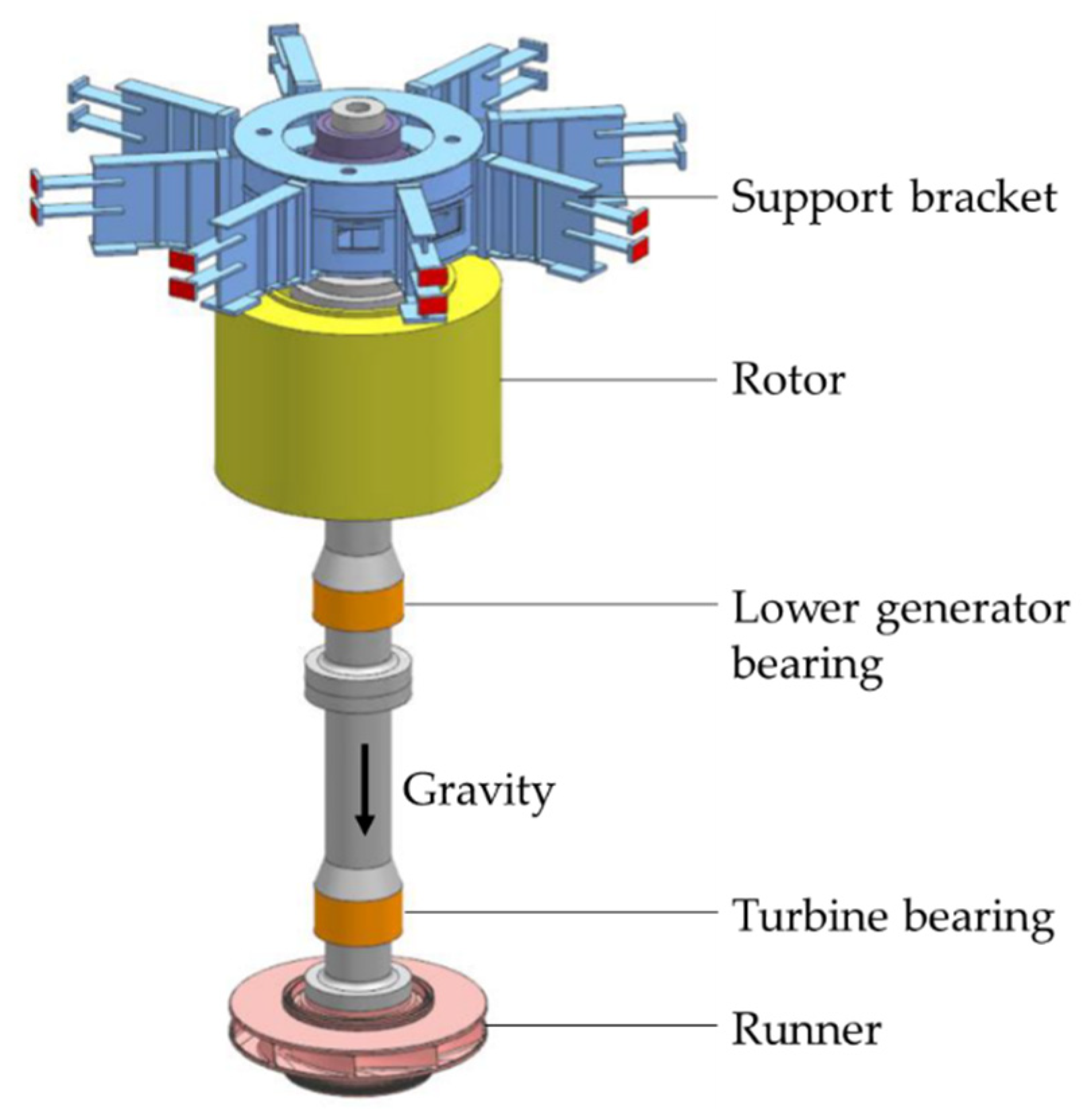

2. Simulation and Experiment Method

2.1. CFD Simulation

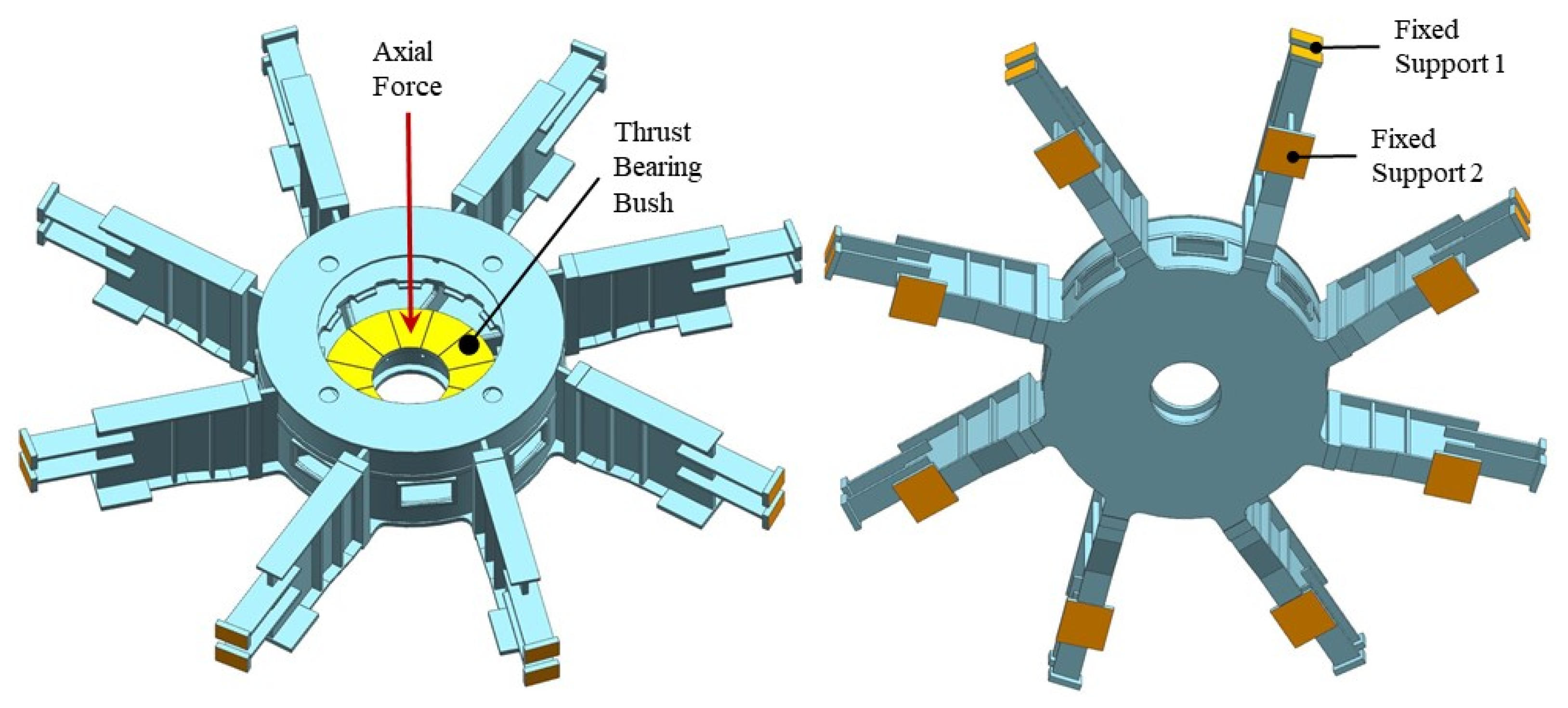

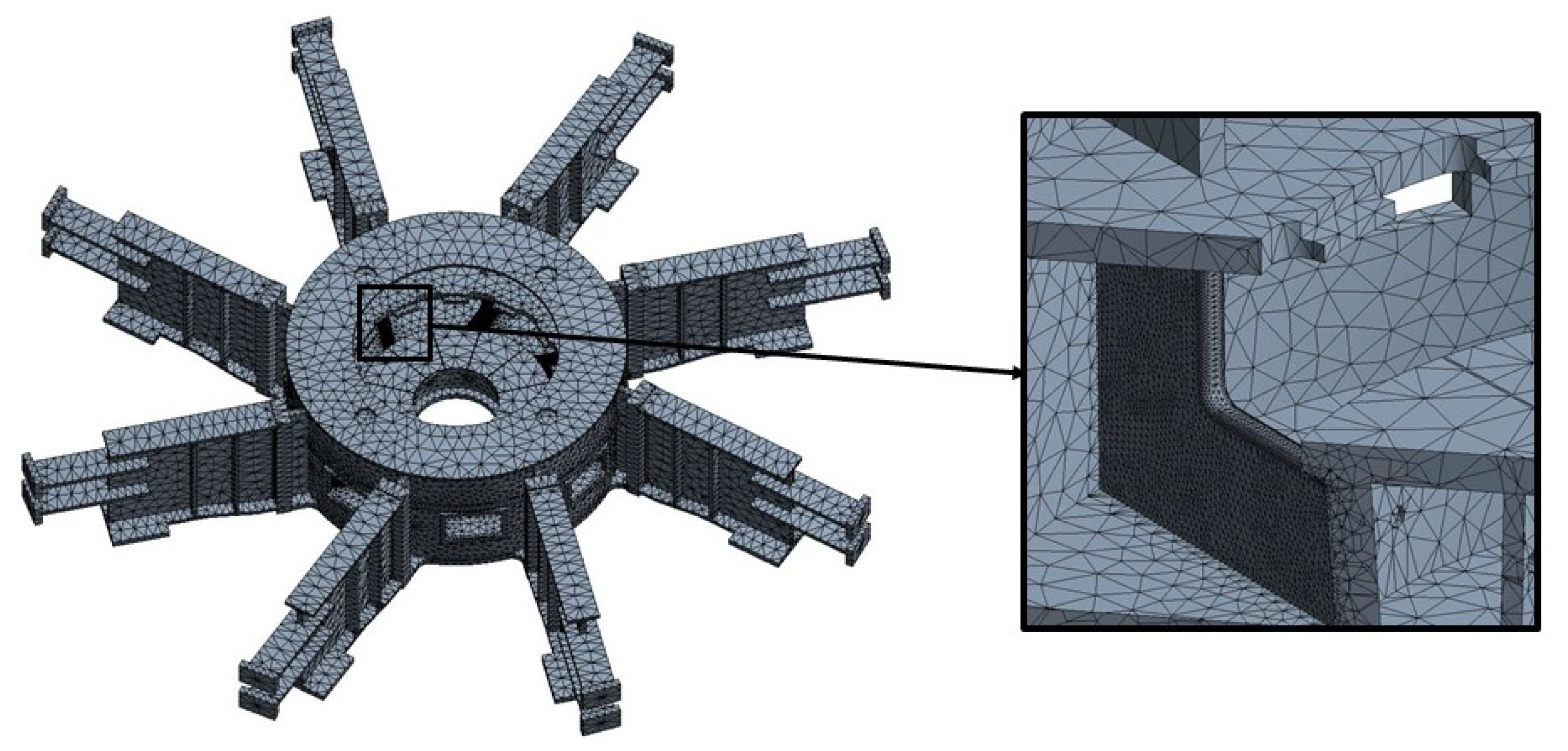

2.2. The Structure Analysis Method

3. Model and Simulation Settings

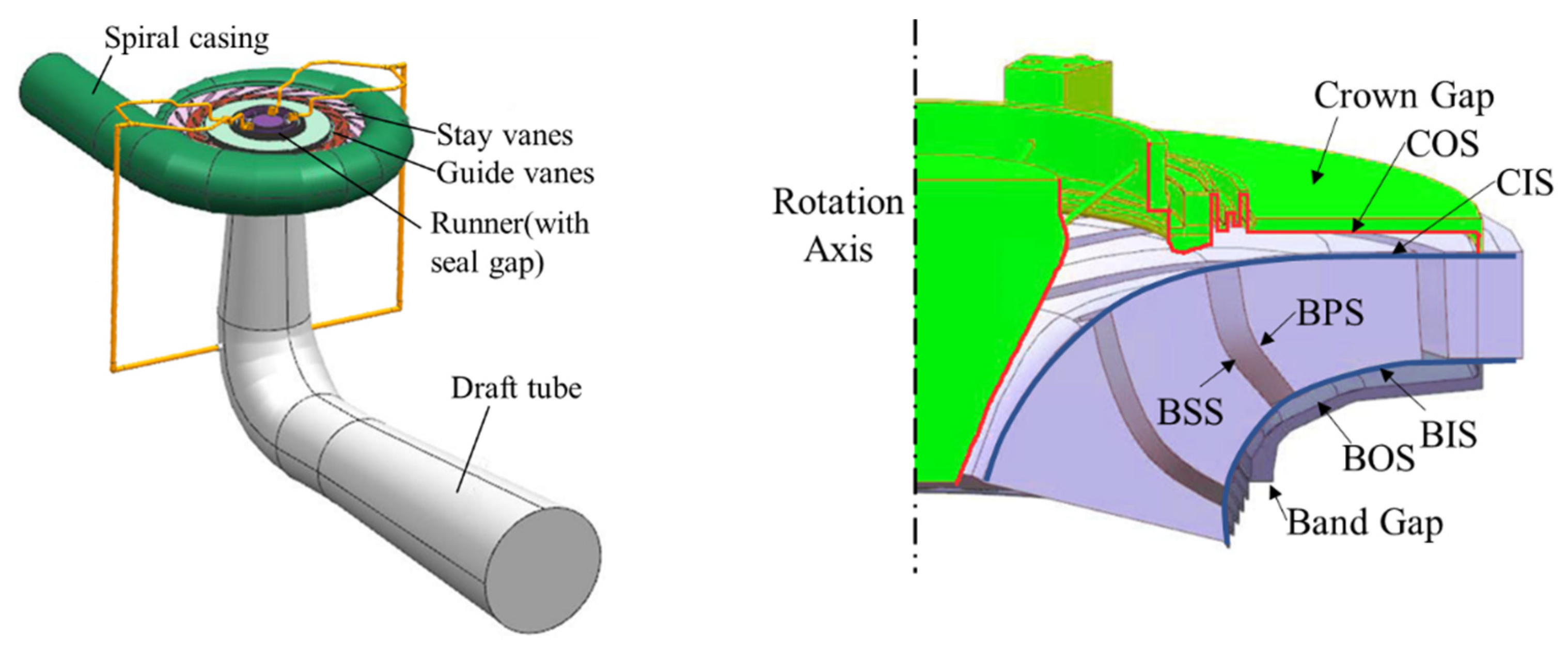

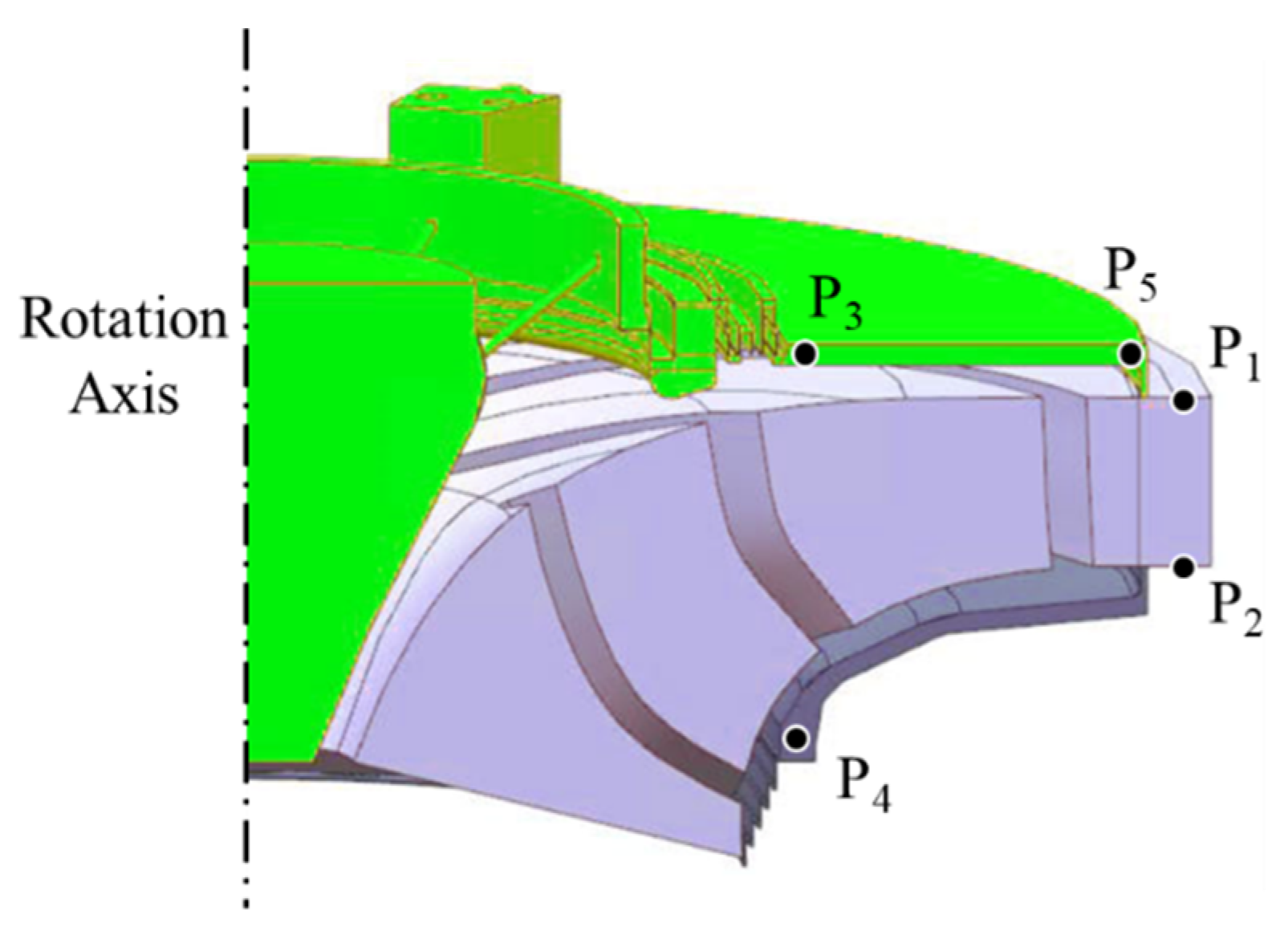

3.1. Model of CFD

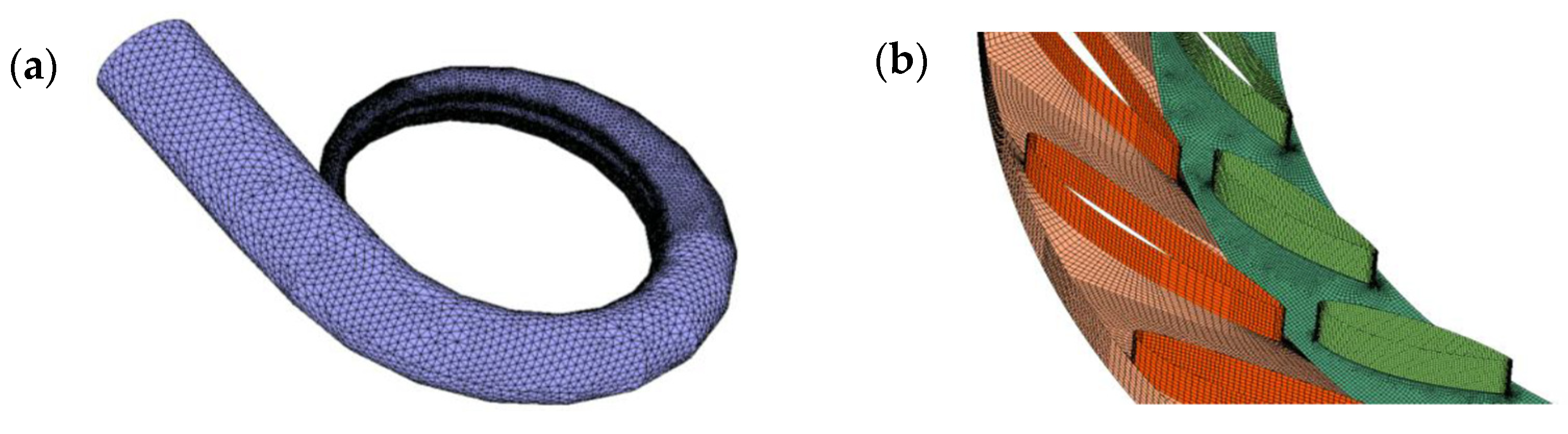

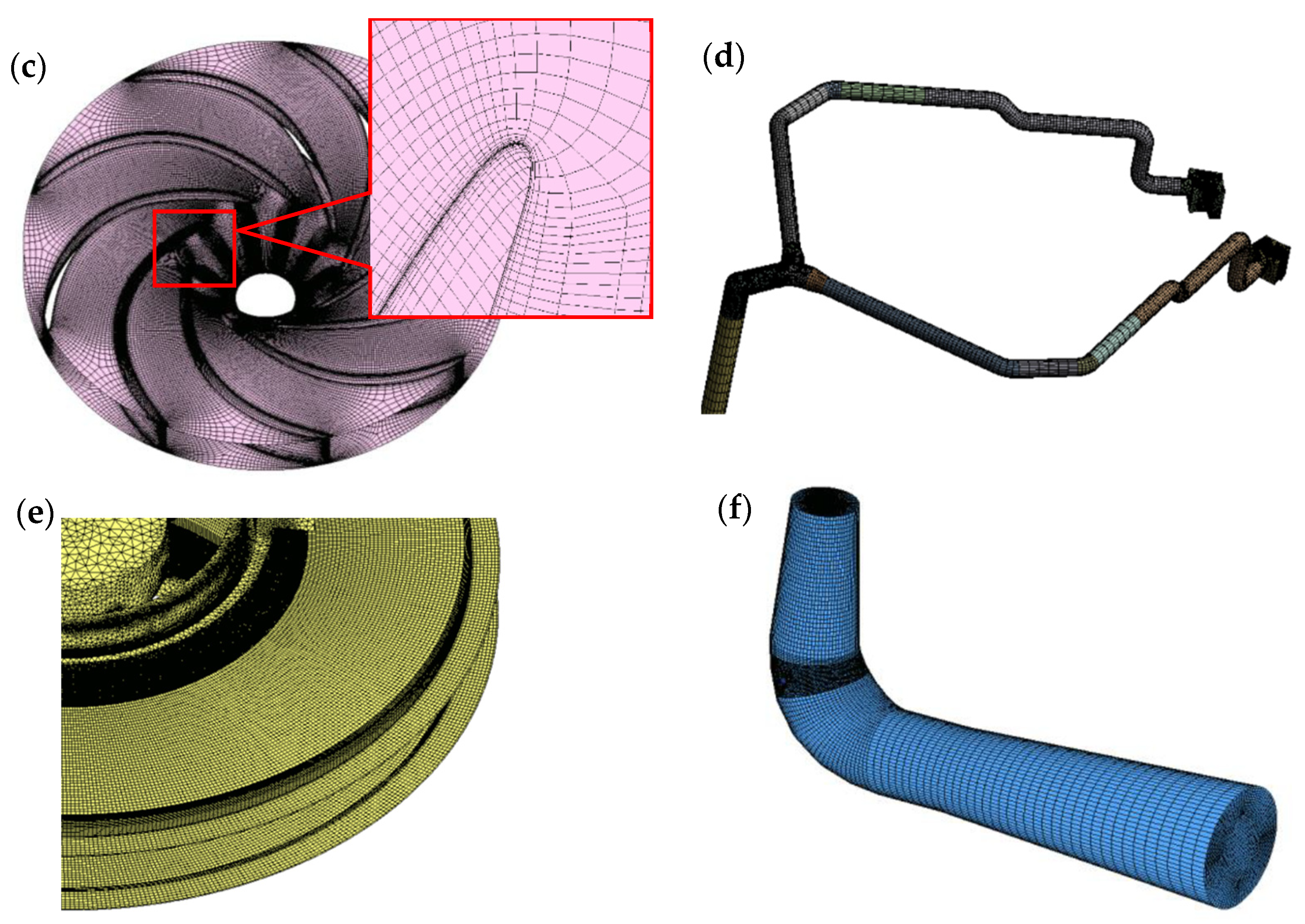

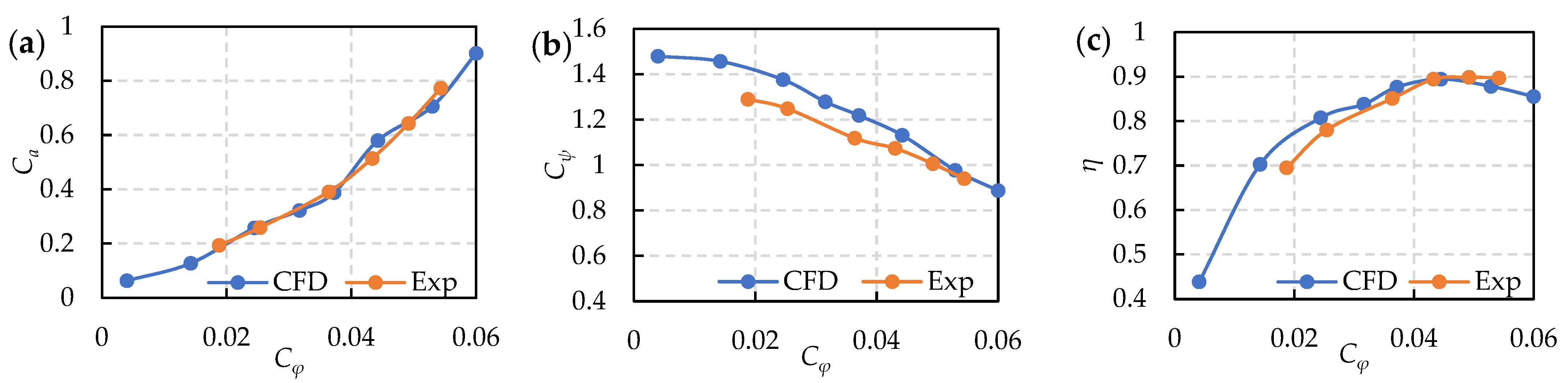

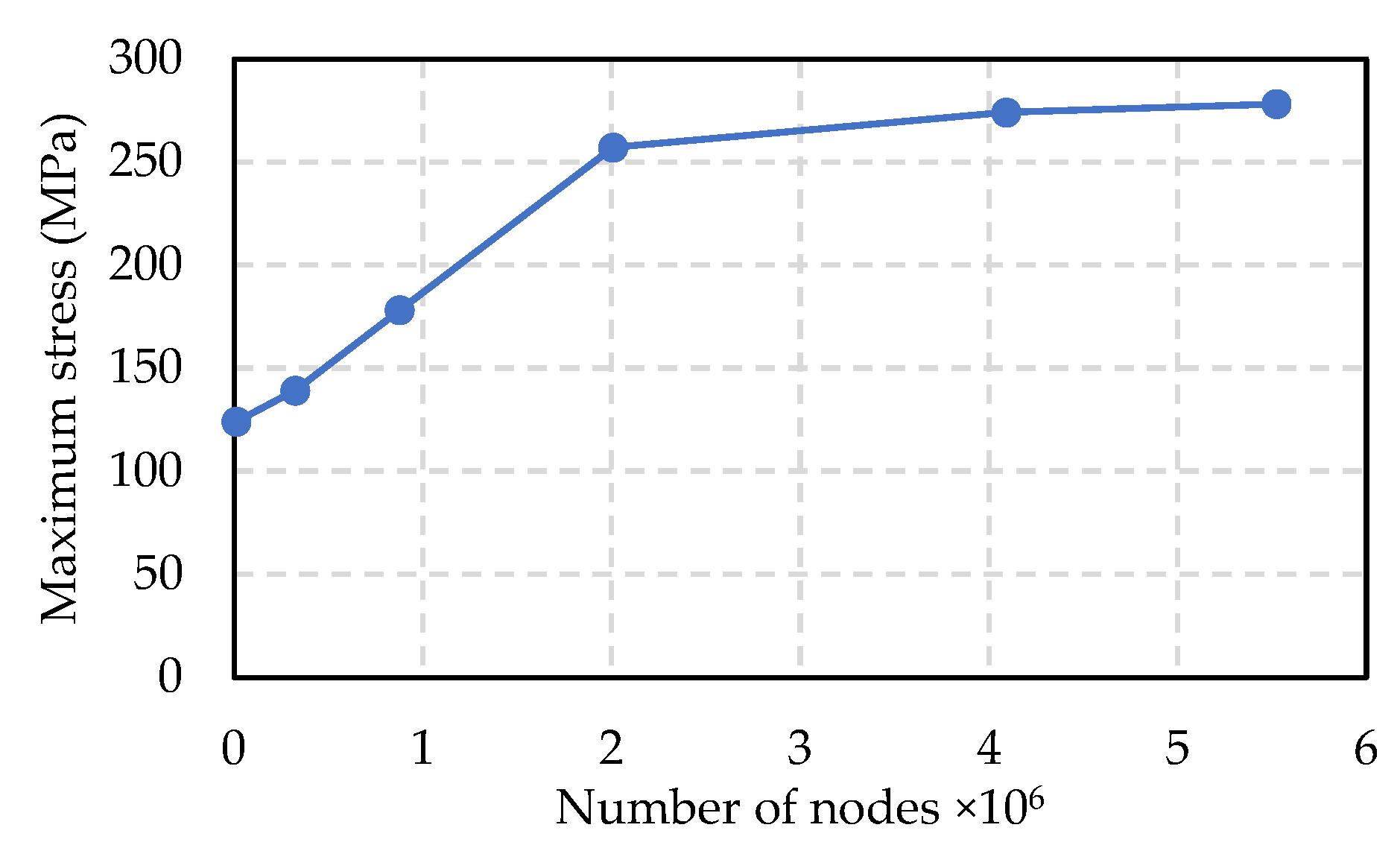

3.1.1. Mesh and Grid Checking

3.1.2. Simulation Configuration

3.1.3. Pressure Balance Pipeline Blockage Setting

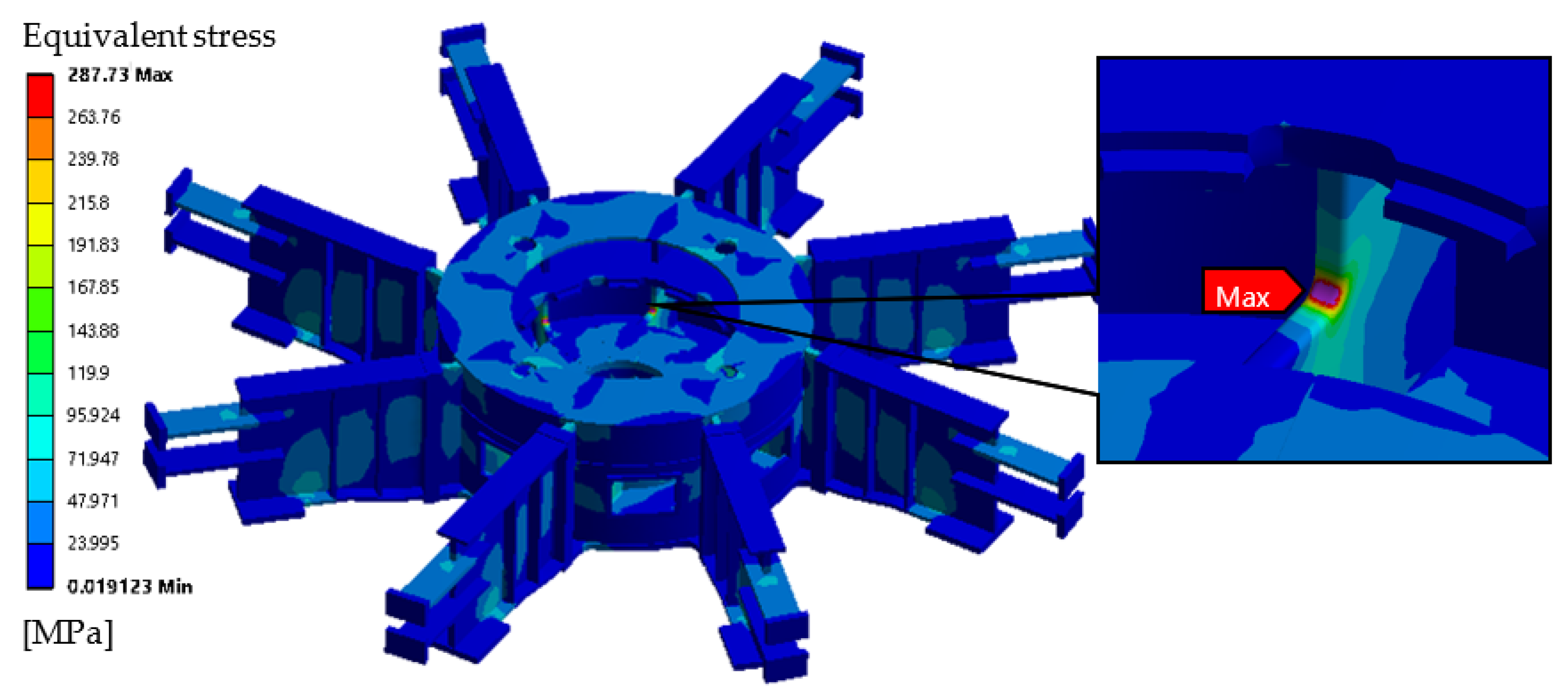

3.2. Support Bracket Stress Calculation

4. Results

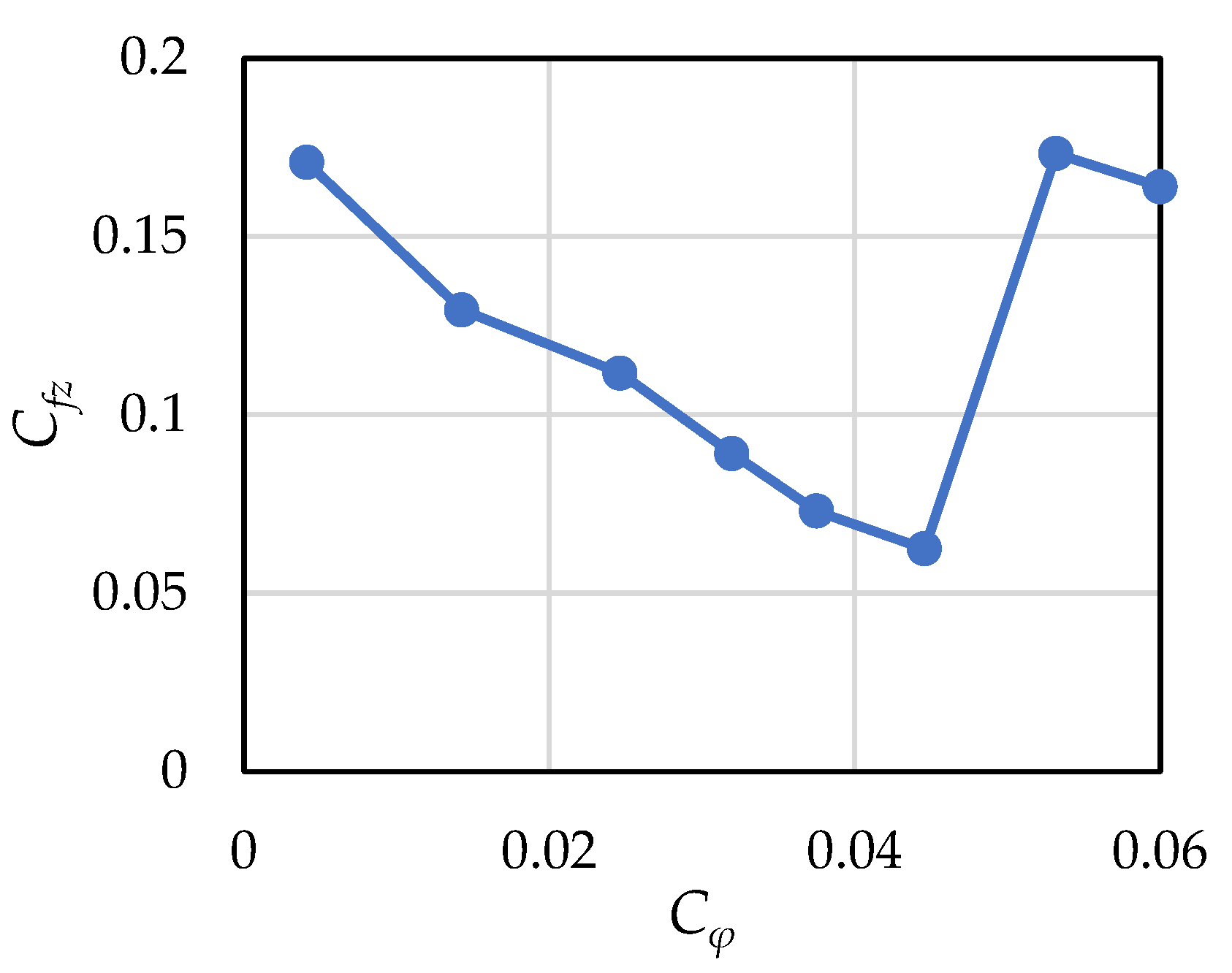

4.1. Axial Forces under Different Operating Conditions

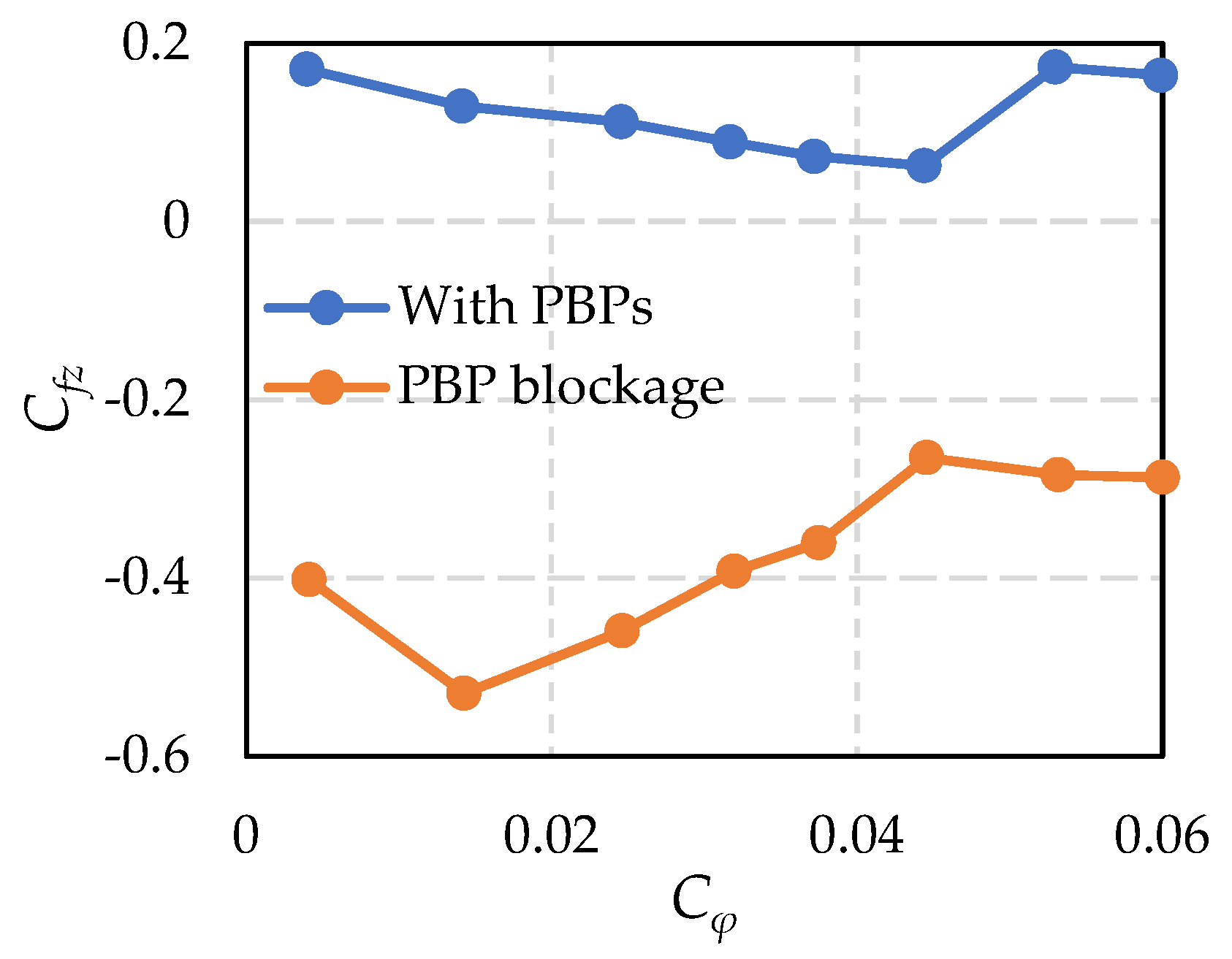

4.2. Axial Force with Pressure Balance Pipelines

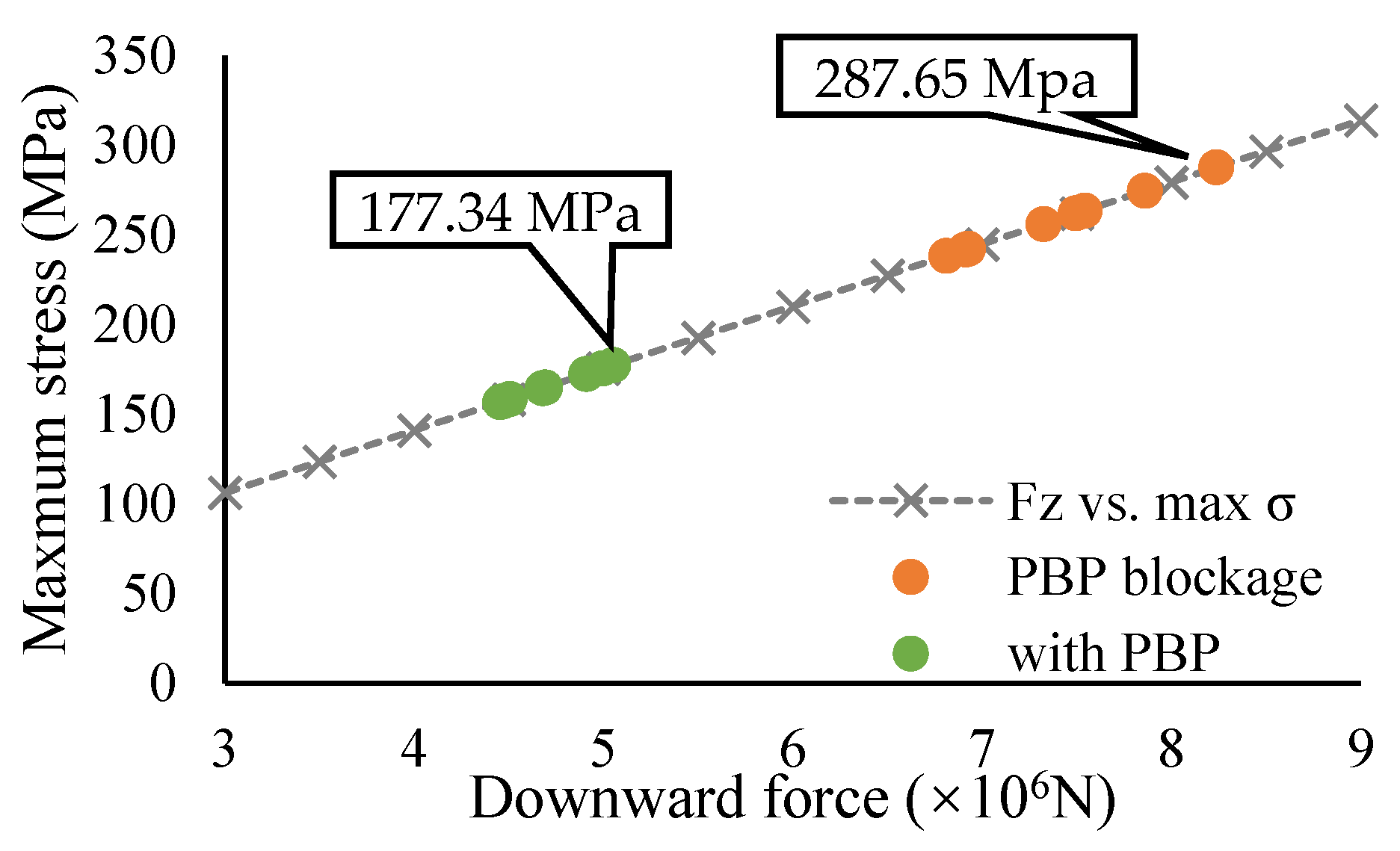

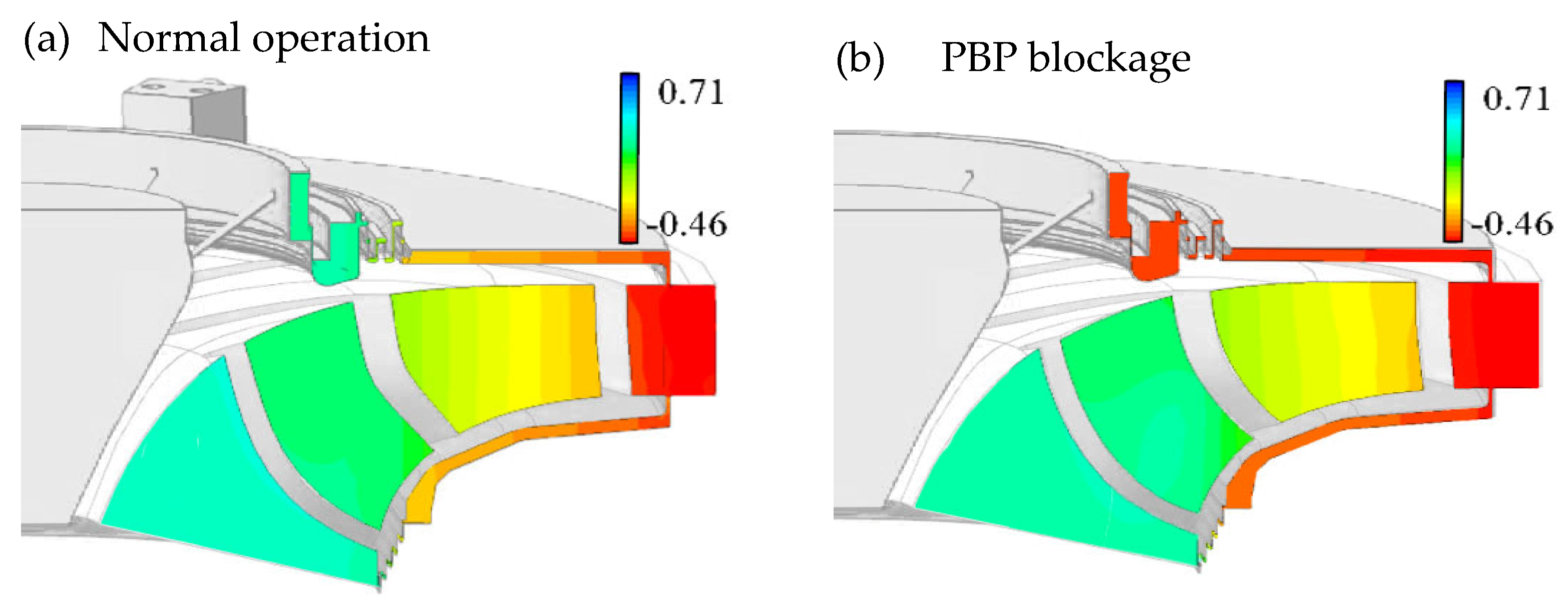

4.3. Effect of PBP Blockage on the Support Bracket

5. Discussion

6. Conclusions

- The CFD simulation revealed that the axial force in pump mode of pump-turbines is mainly caused by the pressure imbalance between the upper and lower gaps and the runner.

- The blockage of pressure balance pipelines increased the pressure difference between the crown gap and the flow passage of the runner. The blockage caused the upward axial force downward, which increases the axial force imposed on the bracket.

- The maximum stresses often concentrate on the corner of support plates. Once there’s a blockage in the PBPs, the maximum stress on the support bracket would increase 62.20%, which causes risk to the operation safety of the support bracket.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ca | Dimensionless guide vane opening |

| Cψ | Head coefficient, flow rate coefficient |

| Cφ | Flow rate coefficient |

| Cp | Relative pressure |

| Cfz | Axial force coefficient |

| Gs | Weight of the shaft system |

| hr | Rated head |

| Ω | Angular velocity of the runner |

| Fz | Axial force |

References

- Zhao, W.; Egusquiza, M.; Valero, C.; Valentín, D.; Presas, A.; Egusquiza, E. On the Use of Artificial Neural Networks for Condition Monitoring of Pump-Turbines with Extended Operation. Measurement 2020, 163, 107952. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped Hydro Energy Storage System: A Technological Review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2020; International Energy Agency: Paris, France, 2020. [Google Scholar]

- International Energy Agency. Global Energy Review 2020; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Valero, C.; Egusquiza, M.; Egusquiza, E.; Presas, A.; Valentin, D.; Bossio, M. Extension of Operating Range in Pump-Turbines. Influence of Head and Load. Energies 2017, 10, 2178. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, Y.; Wu, Y. A Review of Rotating Stall in Reversible Pump Turbine. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 1181–1204. [Google Scholar] [CrossRef] [Green Version]

- Wan, L.; Wang, W.; Gao, H.; Gong, R.; Qian, Z. Numerical Research of Axial Hydraulic Thrust of Runner in Baihetan Hydropower Station. China Rural. Water Hydropower 2014, 12, 161–164. [Google Scholar]

- Wang, Q.; Ma, H.; Cao, S.; Chen, B. Structure Optimal Design of Electromagnetic Levitation Load Reduction Device for Hydroturbine Generator Set. Math. Probl. Eng. 2015, 2015, 814084. [Google Scholar] [CrossRef]

- Iliev, H. Failure Analysis of Hydro-Generator Thrust Bearing. Wear 1999, 225, 913–917. [Google Scholar] [CrossRef]

- Liu, D.Y.; You, G.H.; Wang, F.; Zhang, J. Calculation and Analysis of Axial Thrust Acting on Turning Wheel of Flow-Mixing Reversible Hydraulic Turbines. J. Hohai Univ. (Nat. Sci.) 2004, 557–561. [Google Scholar]

- Fořt, I.; Seichter, P.; Pešl, L. Axial Thrust of Axial Flow Impellers. Chem. Eng. Res. Des. 2013, 91, 789–794. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.-W. Computational Fluid Dynamics (CFD)–an Effective and Efficient Design and Analysis Tool for the Food Industry: A Review. Trends Food Sci. Technol. 2006, 17, 600–620. [Google Scholar] [CrossRef]

- Tao, R.; Xiao, R.; Liu, W. Investigation of the Flow Characteristics in a Main Nuclear Power Plant Pump with Eccentric Impeller. Nucl. Eng. Des. 2018, 327, 70–81. [Google Scholar] [CrossRef]

- Anderson, D.; Tannehill, J.C.; Pletcher, R.H. Computational Fluid Mechanics and Heat Transfer; Taylor & Francis: Oxford, UK, 2016; ISBN 1466578300. [Google Scholar]

- Catapano, F.; Costa, M.; Marseglia, G.; Sementa, P.; Sorge, U.; Vaglieco, B.M. An Experimental and Numerical Investigation of GDI Spray Impact over Walls at Different Temperatures. In Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2016. [Google Scholar]

- Costa, M.; Sementa, P.; Sorge, U.; Catapano, F.; Marseglia, G.; Vaglieco, B.M. Split Injection in a GDI Engine under Knock Conditions: An Experimental and Numerical Investigation. In Proceedings of the 12th International Conference on Engines & Vehicles, Capri Napoli, Italy, 13–17 September 2015. [Google Scholar]

- Li, X.; Mao, Z.; Lin, W.; Bi, H.; Tao, R.; Wang, Z. Prediction and Analysis of the Axial Force of Pump-Turbine during Load-Rejection Process. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Changchun, China, 21–23 August 2020; Volume 440, p. 052081. [Google Scholar]

- Li, J.; Zhang, Y.; Liu, K.; Xian, H.; Yu, J. Numerical Simulation of Hydraulic Force on the Impeller of Reversible Pump Turbines in Generating Mode. J. Hydrodyn. Ser. B 2017, 29, 603–609. [Google Scholar] [CrossRef]

- Shi, W.; Li, Q.; Lu, W.; Zhang, D. Estimation and Experiment of Axial Thrust in Centrifugal Pump Based on CFD. Trans. Chin. Soc. Agric. Mach. 2009, 40, 60–63. [Google Scholar]

- Zhu, D.; Xiao, R.; Liu, W. Influence of Leading-Edge Cavitation on Impeller Blade Axial Force in the Pump Mode of Reversible Pump-Turbine. Renew. Energy 2021, 163, 939–949. [Google Scholar] [CrossRef]

- Kong, L.; Cao, J.; Li, X.; Zhou, X.; Hu, H.; Wang, T.; Gui, S.; Lai, W.; Zhu, Z.; Wang, Z. Numerical Analysis on the Hydraulic Thrust and Dynamic Response Characteristics of a Turbine Pump. Energies 2022, 15, 1580. [Google Scholar] [CrossRef]

- Kalinichenko, P.; Suprun, A. Effective Modes of Axial Balancing of Centrifugal Pump Rotor. Procedia Eng. 2012, 39, 111–118. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Wang, Q.; Ju, P. Study of the Load Reduction for Hydro-Generator Bearing by Hybrid Magnetic Levitation. Int. J. Appl. Electromagn. Mech. 2013, 43, 215–226. [Google Scholar] [CrossRef]

- Zhou, L.; Shi, W.; Li, W.; Agarwal, R. Numerical and Experimental Study of Axial Force and Hydraulic Performance in a Deep-Well Centrifugal Pump with Different Impeller Rear Shroud Radius. J. Fluids Eng. 2013, 135, 104501. [Google Scholar] [CrossRef]

- Xi, C. Mechanical Design of 300 MW Pump-Turbine for Heimifeng Pumped Storage Power Station. Dongfang Electr. Rev. 2011, 25, 27–33. [Google Scholar]

- Zhang, F.; Lv, Y.; Gui, Z.; Wang, Z. Effect of the Diameter of Pressure-Balance Pipe on Axial Hydraulic Thrust. J. Mar. Sci. Eng. 2021, 9, 724. [Google Scholar] [CrossRef]

- Tanaka, H. Vibration Behavior and Dynamic Stress of Runners of Very High Head Reversible Pump-Turbines. Int. J. Fluid Mach. Syst. 2011, 4, 289–306. [Google Scholar] [CrossRef]

- He, L.Y.; Wang, Z.W.; Kurosawa, S.; Nakahara, Y. Resonance Investigation of Pump-Turbine during Startup Process. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Jakarta, Indonesia, 23–24 January 2014; Volume 22, p. 32024. [Google Scholar]

- He, L.; Zhou, L.; Ahn, S.-H.; Wang, Z.; Nakahara, Y.; Kurosawa, S. Evaluation of Gap Influence on the Dynamic Response Behavior of Pump-Turbine Runner. Eng. Comput. 2019, 36, 491–508. [Google Scholar] [CrossRef]

- Mao, Z.; Tao, R.; Chen, F.; Bi, H.; Cao, J.; Luo, Y.; Fan, H.; Wang, Z. Investigation of the Starting-Up Axial Hydraulic Force and Structure Characteristics of Pump Turbine in Pump Mode. J. Mar. Sci. Eng. 2021, 9, 158. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten Years of Industrial Experience with the SST Turbulence Model. In Turbulence, Heat, and Mass Transfer 1; Begell House: Danbury, CT, USA, 2003; Volume 4, pp. 625–632. [Google Scholar]

- Menter, F. Zonal Two Equation Kw Turbulence Models for Aerodynamic Flows. In Proceedings of the 23rd fluid dynamics, plasmadynamics, and lasers conference, Orlando, FL, USA, 6–9 July 1993; p. 2906. [Google Scholar]

- Xiao, R.; Wang, Z.; Luo, Y. Dynamic Stresses in a Francis Turbine Runner Based on Fluid-Structure Interaction Analysis. Tsinghua Sci. Technol. 2008, 13, 587–592. [Google Scholar] [CrossRef]

- Presas, A.; Luo, Y.; Wang, Z.; Guo, B. Fatigue Life Estimation of Francis Turbines Based on Experimental Strain Measurements: Review of the Actual Data and Future Trends. Renew. Sustain. Energy Rev. 2019, 102, 96–110. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Rated head Hr | 430 | m |

| Rated speed nr | 428.6 | rpm |

| Rated output Pr | 300 | MW |

| Runner diameter D | 4.16 | m |

| Number of the blades zb | 9 | |

| Number of the guide vanes zg | 20 | |

| Number of the stay vanes zs | 20 |

| Component | Number of the Nodes |

|---|---|

| Draft tube | 348,822 |

| Runner | 3,663,918 |

| Runner seal and gap | 5,894,860 |

| Guide vane | 1,957,000 |

| Stay vane | 834,840 |

| Spiral casing | 301,592 |

| Total | 13,001,032 |

| Plane | Boundary Condition | Value |

|---|---|---|

| Draft tube inlet | Speed inlet | Speed value depends on the discharge Cφ |

| Pressure outlet | Pressure outlet | Average pressure is set as 1 atm |

| Wall boundaries | Non-slip wall surfaces | |

| Connection of the parts | Junction surface model |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, B.; Zhao, W.; Lin, W.; Mao, Z.; Tao, R.; Wang, Z. The Influence of Different Operating Conditions on the Support Bracket Stress in Pumped Storage Units. Energies 2022, 15, 2195. https://doi.org/10.3390/en15062195

Xu B, Zhao W, Lin W, Mao Z, Tao R, Wang Z. The Influence of Different Operating Conditions on the Support Bracket Stress in Pumped Storage Units. Energies. 2022; 15(6):2195. https://doi.org/10.3390/en15062195

Chicago/Turabian StyleXu, Buchao, Weiqiang Zhao, Wenhua Lin, Zhongyu Mao, Ran Tao, and Zhengwei Wang. 2022. "The Influence of Different Operating Conditions on the Support Bracket Stress in Pumped Storage Units" Energies 15, no. 6: 2195. https://doi.org/10.3390/en15062195

APA StyleXu, B., Zhao, W., Lin, W., Mao, Z., Tao, R., & Wang, Z. (2022). The Influence of Different Operating Conditions on the Support Bracket Stress in Pumped Storage Units. Energies, 15(6), 2195. https://doi.org/10.3390/en15062195