Performance Evaluation of Solar-Powered Atmospheric Water Harvesting Using Different Glazing Materials in the Tropical Built Environment: An Experimental Study

Abstract

:1. Introduction

Solar-Powered Atmospheric Water Harvesting (SPAWH)

2. Experimental Setup and Measurements

2.1. Laboratory Tests

2.2. Experimental Study

2.2.1. Measuring Instruments and Sensor Specifications

2.2.2. Experimental Procedure

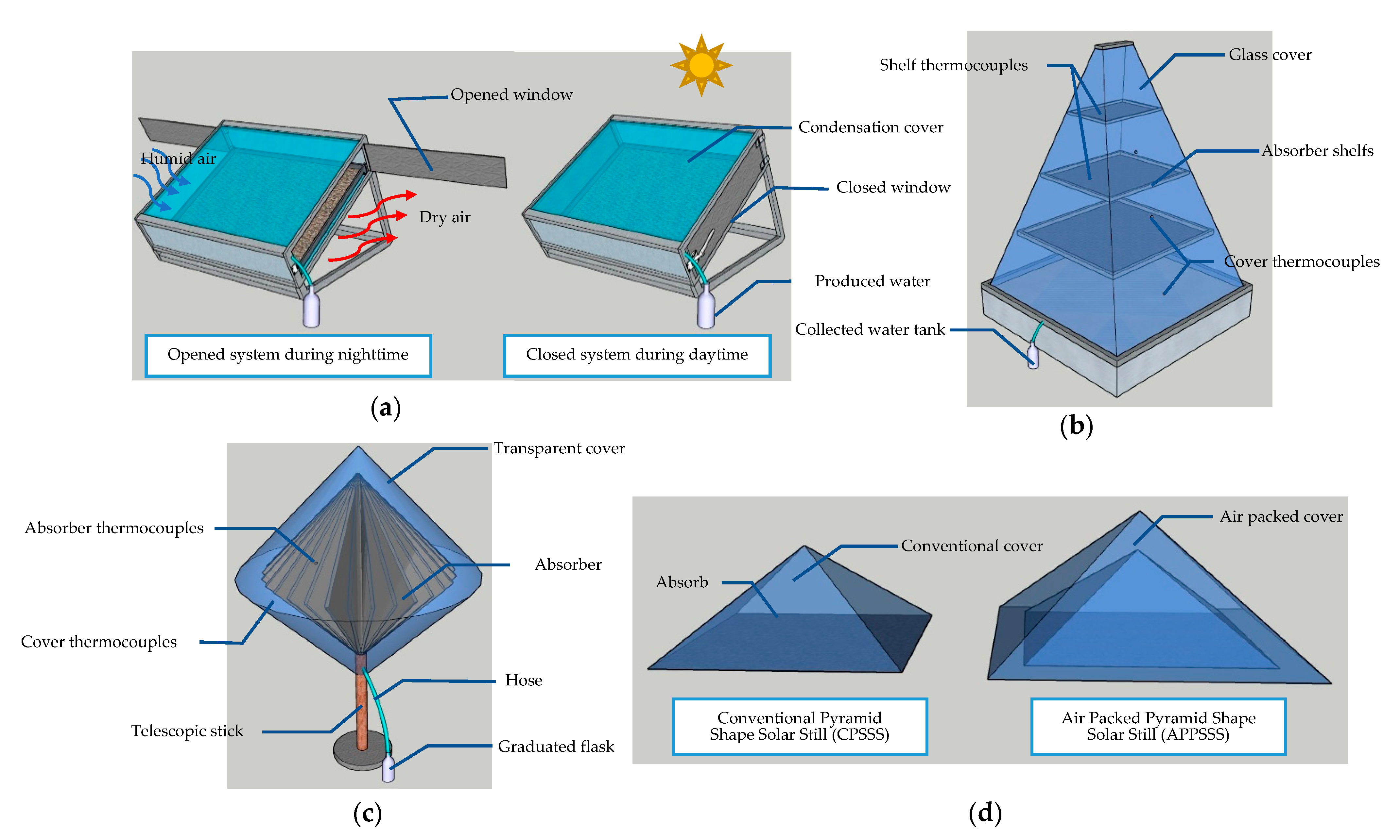

- (a)

- Adsorption process at night. In this step, water vapor is taken up by the adsorbent in contact with ambient air.

- (b)

- Desorption and condensation process on the next day. The desiccant is isolated from the ambient air and the solar heat is applied to desorb the water vapor, which is finally condensed and collected.

3. Results and Discussion

3.1. Adsorption Rate of Desiccant Materials

3.2. Temperature Variation in the Systems

3.3. Variation in Water Production

3.4. Cost Analysis of the SPAWH

4. Conclusions

- Although acrylic glazing allows more solar transmission compared to glass, a system with acrylic has a low thermal conductivity compared to glass. The data showed that the desiccant material’s temperature of the SPAWHa was higher than SPAWHg at the first two hours of the experimental period; however, the desiccant materials of the SPAWHg recorded higher temperature along with the daytime.

- The power transmission in glass samples (3 mm–8 mm) is reduced from 82–70%, while, for acrylic samples, the percentage was maintained for all samples with different thicknesses and achieved 91%. These findings showed that the SPAWHg desiccant materials maintained higher temperatures along with the daytime with less heat loss, hence, increased system efficiency.

- Water production from SPAWHg was 220 g/day on 21 February 2020 and 180 g/day on 1 August 2020. SPAWHa was 160 g/day on 21 February 2020 and 125 g/day on 1 August 2020. These results showed that during a dry season, when ambient air temperature and solar radiation are high, the system could generate 22% water in SPAWHg and 28% in SPAWHa more than in a wet season because the relative humidity is high and ambient air temperature is low.

- The maximum water produced by SPAWHg and SPAWHa was 0.61 L/m2/day and 0.44 L/m2/day, respectively. That imputes to glass properties that enjoy higher thermal conductivity and mitigate heat loss, hence, increasing the system efficiency.

- The cost analysis shows that the kilogram of produced water costs 0.18 USD/kg and 0.40 USD/kg for glass and acrylic SPAWH, respectively.

- Atmospheric water can be produced using SPAWH in the tropical climate, which enjoys a high percentage of moisture content.

Author Contributions

Funding

Conflicts of Interest

References

- United Nations. Revision of World Population Prospects; UN: New York, NY, USA, 2019. [Google Scholar]

- Zhang, S.; Huang, J.; Chen, Z.; Lai, Y. Bioinspired special wettability surfaces: From fundamental research to water harvesting applications. Small 2017, 13, 1602992. [Google Scholar] [CrossRef] [PubMed]

- Shiklomanov, I.A. World freshwater resources. Water in crisis: A guide to the world’s freshwaterresources. Clim. Chang. 1993, 45, 379–382. [Google Scholar]

- Eslami, M.; Tajeddini, F.; Etaati, N. Thermal analysis and optimization of a system for water harvesting from humid air using thermoelectric coolers. Energy Convers. Manag. 2018, 174, 417–429. [Google Scholar] [CrossRef]

- Claire, S. The Last Drop; Summer Issue; Mazaya: Kabupaten Tasikmalaya, Indonesia, 2002; pp. 22–25. [Google Scholar]

- Lorenzo, T.E.; Kinzig, A.P. Double exposures: Future water security across urban Southeast Asia. Water 2019, 12, 116. [Google Scholar] [CrossRef] [Green Version]

- Al-Duais, H.S.; Ismail, M.A.; Awad, Z.A.; Al-Obaidi, K.M. Methods of harvesting water from air for sustainable buildings in hot and tropical climates. Malays. Constr. Res. J. 2022, 15, 150–168. [Google Scholar]

- Zhou, X.; Lu, H.; Zhao, F.; Yu, G. Atmospheric water harvesting: A review of material and structural designs. ACS Mater. Lett. 2020, 2, 671–684. [Google Scholar] [CrossRef]

- Beysens, D.; Milimouk, I. The case for alternative freshwatersources. [Pour les resources alternatives en eau]. Secheresse 2000, 11, 1–6. [Google Scholar]

- Bergmair, D.; Metz, S.J.; de Lange, H.C.; van Steenhoven, A.A. System analysis of membrane facilitated water generation from air humidity. Desalination 2014, 339, 26–33. [Google Scholar] [CrossRef]

- Wang, J.Y.; Liu, J.Y.; Wang, R.Z.; Wang, L.W. Experimental investigation on two solar-driven sorption based devices to extract freshwaterfrom atmosphere. Appl. Therm. Eng. 2017, 127, 1608–1616. [Google Scholar] [CrossRef]

- Wang, M.; Sun, T.; Wan, D.; Dai, M.; Ling, S.; Wang, J.; Liu, Y.; Fang, Y.; Xu, S.; Yeo, J.; et al. Solar-powered nanostructured biopolymer hygroscopic aerogels for atmospheric water harvesting. Nano Energy 2021, 80, 105569. [Google Scholar] [CrossRef]

- Chaitanya, B.; Bahadur, V.; Thakur, A.D.; Raj, R. Biomass-gasification-based atmospheric water harvesting in India. Energy 2018, 165, 610–621. [Google Scholar] [CrossRef]

- Wikramanayake, E.D.; Ozkan, O.; Bahadur, V. Landfill gas-powered atmospheric water harvesting for oilfield operations in the United States. Energy 2017, 138, 647–658. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Rayegan, S.; Pasdarshahri, H. Dynamic simulation of a solar desiccant cooling system combined with a ground source heat exchanger in humid climates. J. Build. Eng. 2020, 28, 101048. [Google Scholar] [CrossRef]

- Ng, K.C.; Thu, K.; Saha, B.B.; Chakraborty, A. Study on a waste heat-driven adsorption cooling cum desalination cycle. Int. J. Refrig. 2012, 35, 685–693. [Google Scholar] [CrossRef]

- Tan, B.; Luo, Y.; Liang, X.; Wang, S.; Gao, X.; Zhang, Z.; Fang, Y. Composite salt in MIL-101 (Cr) with high water uptake and fast adsorption kinetics for adsorption heat pumps. Microporous Mesoporous Mater. 2019, 286, 141–148. [Google Scholar] [CrossRef]

- Srivastava, S.; Yadav, A. Water generation from atmospheric air by using composite desiccant material through fixed focus concentrating solar thermal power. Sol. Energy 2018, 169, 302–315. [Google Scholar] [CrossRef]

- Cattani, L.; Cattani, P.; Magrini, A. Air to water generator integrated systems: The proposal of a global evaluation index—GEI formulation and application examples. Energies 2021, 14, 8528. [Google Scholar] [CrossRef]

- Kumar, M.; Yadav, A. Experimental investigation of solar powered water production from atmospheric air by using composite desiccant material “CaCl2/saw wood”. Desalination 2015, 367, 216–222. [Google Scholar] [CrossRef]

- William, G.E.; Mohamed, M.H.; Fatouh, M. Desiccant system for water production from humid air using solar energy. Energy 2015, 90, 1707–1720. [Google Scholar] [CrossRef]

- Talaat, M.A.; Awad, M.M.; Zeidan, E.B.; Hamed, A.M. Solar-powered portable apparatus for extracting water from air using desiccant solution. Renew. Energy 2018, 119, 662–674. [Google Scholar] [CrossRef]

- Khechekhouche, A.; Benhaoua, B.; Manokar, A.M.; Kabeel, A.E.; Sathyamurthy, R. Exploitation of an insulated air chamber as a glazed cover of a conventional solar still. Heat Transf. Asian Res. 2019, 48, 1563–1574. [Google Scholar] [CrossRef]

- Kumar, S.A.; Mohan Kumar, P.S.; Sathyamurthy, R.; Manokar, A.M. Experimental investigation on pyramid solar still with single and double collector cover—comparative study. Heat Transf. Asian Res. 2020, 49, 103–119. [Google Scholar] [CrossRef]

- Khalifa, A.J.; Hamood, A.M. Effect of insulation thickness on the productivity of basin type solar stills: An experimental verification under local climate. Energy Convers. Manag. 2009, 50, 2457–2461. [Google Scholar] [CrossRef]

- Elango, T.; Murugavel, K.K. The effect of the water depth on the productivity for single and double basin double slope glass solar stills. Desalination 2015, 359, 82–91. [Google Scholar] [CrossRef]

- Al-Karaghouli, A.A.; Alnaser, W.E. Experimental comparative study of the performances of single and double basin solar-stills. Appl. Energy 2004, 77, 317–325. [Google Scholar] [CrossRef]

- Manokar, A.M.; Winston, D.P.; Kabeel, A.E.; Sathyamurthy, R. Sustainable freshwaterand power production by integrating PV panel in inclined solar still. J. Clean. Prod. 2018, 172, 2711–2719. [Google Scholar] [CrossRef]

- Manokar, A.M.; Winston, D.P.; Mondol, J.D.; Sathyamurthy, R.; Kabeel, A.E.; Panchal, H. Comparative study of an inclined solar panel basin solar still in passive and active mode. Sol. Energy 2018, 169, 206–216. [Google Scholar] [CrossRef]

- Sibie, S.K.; El-Amin, M.F.; Sun, S. Modeling of water generation from air using anhydrous salts. Energies 2021, 14, 3822. [Google Scholar] [CrossRef]

- Thakur, A.K.; Sathyamurthy, R.; Velraj, R.; Saidur, R.; Hwang, J.Y. Augmented performance of solar desalination unit by utilization of nano-silicon coated glass cover for promoting drop-wise condensation. Desalination 2021, 515, 115191. [Google Scholar] [CrossRef]

- Zanganeh, P.; Goharrizi, A.S.; Ayatollahi, S.; Feilizadeh, M.; Dashti, H. Efficiency improvement of solar stills through wettability alteration of the condensation surface: An experimental study. Appl. Energy 2020, 268, 114923. [Google Scholar] [CrossRef]

- Tu, Y.; Wang, R.; Zhang, Y.; Wang, J. Progress and expectation of atmospheric water harvesting. Joule 2018, 2, 1452–1475. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Wang, L.; Wu, J. Adsorption Refrigeration Technology: Theory and Application; John Wiley & Sons: New York, NY, USA, 2014. [Google Scholar]

- Kaviti, A.K.; Yadav, A.; Shukla, A. Inclined solar still designs: A review. Renew. Sustain. Energy Rev. 2016, 54, 429–451. [Google Scholar] [CrossRef]

- Selvaraj, K.; Natarajan, A. Factors influencing the performance and productivity of solar stills—A review. Desalination 2018, 435, 181–187. [Google Scholar] [CrossRef]

- Kabeel, A.E. Application of sandy bed solar collector system for water extraction from air. Int. J. Energy Res. 2006, 30, 381–394. [Google Scholar] [CrossRef]

- Kabeel, A.E. Water production from air using multi-shelves solar glass pyramid system. Renew. Energy 2007, 32, 157–172. [Google Scholar] [CrossRef]

- Ji, J.G.; Wang, R.Z.; Li, L.X. New composite adsorbent for solar-driven freshwaterproduction from the atmosphere. Desalination 2007, 212, 176–182. [Google Scholar] [CrossRef]

- Hamed, A.M.; Aly, A.A.; Zeidan, E.S. Application of solar energy for recovery of water from atmospheric air in climatic zones of Saudi Arabia. Nat. Resour. 2011, 2, 8. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Yadav, A. Experimental investigation of design parameters of solar glass desiccant box type system for water production from atmospheric air. J. Renew. Sustain. Energy 2015, 7, 033122. [Google Scholar] [CrossRef]

- Kumar, M.; Yadav, A. Composite desiccant material “CaCl2/Vermiculite/Saw wood”: A new material for freshwaterproduction from atmospheric air. Appl. Water Sci. 2017, 7, 2103–2111. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.Y.; Wang, R.Z.; Wang, L.W.; Liu, J.Y. A high efficient semi-open system for freshwaterproduction from atmosphere. Energy 2017, 138, 542–551. [Google Scholar] [CrossRef]

- Gad, H.E.; Hamed, A.M.; El-Sharkawy, I.I. Application of a solar desiccant/collector system for water recovery from atmospheric air. Renew. Energy 2001, 22, 541–556. [Google Scholar] [CrossRef]

- Elashmawy, M.; Alshammari, F. Atmospheric water harvesting from low humid regions using tubular solar still powered by a parabolic concentrator system. J. Clean. Prod. 2020, 256, 120329. [Google Scholar] [CrossRef]

- EnergyPlus. Weather Data by Region-Southwest Pacific WMO Region 5—Malaysia; 2021. Available online: https://energyplus.net/weather-region/southwest_pacific_wmo_region_5/MYS (accessed on 10 April 2022).

- Kumar, A.; Chaudhary, A.; Yadav, A. The regeneration of various solid desiccants by using a parabolic dish collector and adsorption rate: An experimental investigation. Int. J. Green Energy 2014, 11, 936–953. [Google Scholar] [CrossRef]

- IMPAK. Desiccant Chart Comparisons, Sorbent Systems. 2020. Available online: https://bit.ly/3xBT8xY (accessed on 10 April 2022).

- Tu, Y.D.; Wang, R.Z.; Ge, T.S.; Zheng, X. Comfortable, high-efficiency heat pump with desiccant-coated, water-sorbing heat exchangers. Sci. Rep. 2017, 7, 40437. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hanikel, N.; Prévot, M.S.; Fathieh, F.; Kapustin, E.A.; Lyu, H.; Wang, H.; Diercks, N.J.; Glover, T.G.; Yaghi, O.M. Rapid cycling and exceptional yield in a metal-organic framework water harvester. ACS Cent. Sci. 2019, 5, 1699–1706. [Google Scholar] [CrossRef] [PubMed]

- Mitra, S.; Thu, K.; Saha, B.B.; Srinivasan, K.; Dutta, P. Modeling study of two-stage, multi-bed air cooled silica gel+ water adsorption cooling cum desalination system. Appl. Therm. Eng. 2017, 114, 704–712. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Hamed, A.M.; El-Agouz, S.A. Cost analysis of different solar still configurations. Energy 2010, 35, 2901–2908. [Google Scholar] [CrossRef]

| Ref | Location | Procedure | Desiccant | Water Production | Efficiency (%) |

|---|---|---|---|---|---|

| [37] | Egypt | Experimental and theoretical | CaCl2/sand | 1.2 L/m2/day | - |

| [38] | Egypt | Experimental | CaCl2/saw wood and cloth | 2.5 L/m2/day | 90–95% |

| [39] | China | Experimental | CaCl2/MCM-41 | 1.2 kg/m2/day | - |

| [40] | Saudi Arabia | Experimental | CaCl2/sand | 1.0 L/m2/day | - |

| [41] | India | Experimental | Silica gel | 200 mL/kg/day | - |

| [20] | India | Experimental | CaCl2/saw wood | 180 mL/kg/day | - |

| [42] | India | Experimental | CaCl2/vermiculite/saw wood | 195 mL/kg/day | - |

| [21] | Egypt | Experimental | CaCl2/cloth | Cloth = 2320 gm/m2 Sand = 1235 gm/m2 | Cloth = 29.3% Sand = 17.76% |

| [43] | China | Experimental | LiCl/consolidated active carbon | 14.5 kg/40.8 dry sorbent/day | - |

| [18] | India | Experimental | LiCl, CaCl2 and LiBr | LiCl = 90 mL/1.54 m2/day CaCl2 = 115 mL/1.54 m2/day LiBr = 73 mL/1.54 m2/day | - |

| [22] | Egypt | Experimental and theoretical | CaCl2/cloth | 0.33–0.63 kg/m2/day | 22.56% |

| [44] | Egypt | Experimental and mathematical | CaCl2/cloth | 1.5 L/m2/day | 17% |

| [45] | Saudi Arabia | Experimental and theoretical | CaCl2/Cotton cloth | 0.51 L/kg (dry sorbent)/day | 24.61% |

| Properties of Glass (G) vs. Acrylic (A) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| EDTM-SS2450 | EDTM-SP2065 | |||||||||

| Thickness> | UV (315–380 nm) % | Visible (380–780 nm) % | IR (780–1700 nm) % | Damage Weight % | Transmission Power % | |||||

| Glazing | G | A | G | A | G | A | G | A | G | A |

| 3 mm | 59 | 74 | 89 | 91 | 80 | 90 | 84 | 88 | 82 | 91 |

| 4 mm | 59 | 17 | 89 | 92 | 77 | 91 | 85 | 78 | 78 | 91 |

| 5 mm | 59 | 15 | 89 | 93 | 73 | 91 | 85 | 78 | 74 | 91 |

| 6 mm | 59 | 7 | 90 | 94 | 73 | 92 | 86 | 76 | 72 | 91 |

| 8 mm | 57 | 5 | 90 | 95 | 70 | 92 | 86 | 77 | 70 | 91 |

| SPAWH Parts | Description |

|---|---|

| Main container | Two containers of glass and acrylic were used due to their sufficient strength and long life. The size of each SPAWH is 0.6 m × 0.6 m × 0.3 m. The top cover was modified so that it can be removed for the nighttime absorption process. A water pipe with a slight slope was fitted on the front side to collect droplets from the glass/acrylic after condensation. |

| Glazing | The first container used a glass of 3 mm thickness for glazing, while the second container used a clear Perspex acrylic of 3 mm as glazing. This glazing also acted as a condenser during the process of regeneration. The sunlight of shorter wavelengths can enter the SPAWH by the glass and clear acrylic and captured radiation of longer wavelength after heating the desiccant material. The greenhouse effect was generated within the SPAWH. |

| Wire mesh tray | Inside SPAWH, the desiccant material was stored on the wire mesh of steel wire. The wire mesh is 3 mm × 3 mm in dimensions. The aluminum L shape frame was fastened with a wire mesh. |

| Connecting pipe | Between the container and the measuring cylinder, the connection pipe was attached. This pipe provided a path to flow water droplets. |

| Water measuring cylinder | A water measuring cylinder for water collection was used outside the SPAWH. The water was collected directly through the connecting tube to the measuring cylinder. There were measuring marks on the bottle that indicate the amount of water collected. The minimum quantity of water measurable was 5 mL. |

| Desiccant material | For atmospheric water extraction, silica gel was used as a desiccant material. To this end, for each SPAWH, 2 kg of silica gel was used. In regenerated form, the color of silica gel was blue, whereas it turned to a rose color in a saturation state. This color transformation is due to cobalt chloride (Figure 6 and Figure 7). |

| Instruments/ Sensors | Models | Accuracy | Ranges | Characteristics | |

|---|---|---|---|---|---|

| Lab tests | Solar spectrum transmission | EDTM-SS2450 | ±3% | 315 nm–1700 nm | Accurate solar spectrum transmission and damage weight. Application: Measuring glass and acrylic samples (3, 4, 5, 6 and 8 mm). |

| Solar power meter | EDTM-SP2065 | N/A | N/A | Measures the power of incident solar radiation per unit area entering the sensing zone of the meter. Application: measuring glass and acrylic samples (3, 4, 5, 6 and 8 mm). | |

| Experimental sensors | Weather station data logger | H21-USB | - | - | A weatherproof data logger for multi-channel monitoring of microclimates. It includes five smart sensor inputs. |

| 4-Channel Thermocouple Data Logger | UX120-014M | ±0.21 °C | −260 °C to 1820 °C | To measure the surface temperature of the desiccant material, the inner and outer side of the glass/acrylic top cover and the inner side of the SPAWH. | |

| Thermocouple probes | Type J 6 ft Beaded | ±2.2 °C | 0 °C to 250 °C | It contains 1.8 m (6′) of isolated 30-AWG cable wound for a built-in spool caddy/subminiature connector. Application: stick on the glazing surface and connect with the thermocouple data logger. | |

| Outdoor relative humidity | S-THB-M002 | ±0.1% RH | 0–100% | Highly precise measurement of relative humidity. Long-term humidity stability. | |

| Outdoor air temperature | S-THB-M002 | ±0.21 °C | −40 °C to 75 °C | Accurate measurement of ambient air temperature. | |

| Solar radiation intensity | S-LIB-M003 | ±10 W/m2 (±5%) | 0 to 1280 W/m2 | To measure light intensity. This sensor has a measurement range of 0 to 1280 W/m2 over wavelengths from 300 to 1100 nm. | |

| Solar radiation shield | RS3-B | - | - | To improve the precision of temperature measurements, use the RS3-B Solar Radiation Shield with HOBO external sensors in places exposed to sunlight. | |

| Electronic balance | AJ-12KE | ±0.1 g | 0 g–12,000 g | Quick response and stable indication balance. Applications: (1) To measure the desiccant material before experiments. (2) To measure the absorption rate during nighttime. (3) To measure the desiccant material after the regeneration process. |

| Parameter | Cost of Glass AWH System (USD) | Cost of Acrylic AWH System (USD) |

|---|---|---|

| Glazing | 22 | 28 |

| Wire mesh tray | 5 | 5 |

| Desiccant materials (2 kg) | 14 | 14 |

| Wood table | 15 | 15 |

| Paint | 2.5 | 2.5 |

| Water collecting cylinder | 1.25 | 1.25 |

| Connecting pipe | 0.4 | 0.4 |

| Production | 15 | 15 |

| Total cost | 75.15 | 81.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Duais, H.S.; Ismail, M.A.; Awad, Z.A.M.; Al-Obaidi, K.M. Performance Evaluation of Solar-Powered Atmospheric Water Harvesting Using Different Glazing Materials in the Tropical Built Environment: An Experimental Study. Energies 2022, 15, 3026. https://doi.org/10.3390/en15093026

Al-Duais HS, Ismail MA, Awad ZAM, Al-Obaidi KM. Performance Evaluation of Solar-Powered Atmospheric Water Harvesting Using Different Glazing Materials in the Tropical Built Environment: An Experimental Study. Energies. 2022; 15(9):3026. https://doi.org/10.3390/en15093026

Chicago/Turabian StyleAl-Duais, Husam S., Muhammad Azzam Ismail, Zakaria Alcheikh Mahmoud Awad, and Karam M. Al-Obaidi. 2022. "Performance Evaluation of Solar-Powered Atmospheric Water Harvesting Using Different Glazing Materials in the Tropical Built Environment: An Experimental Study" Energies 15, no. 9: 3026. https://doi.org/10.3390/en15093026