Detailing the Pore Structure of Productive Intervals of Oil Wells Using the Color 3D Imaging

Abstract

1. Introduction

2. Materials and Methods

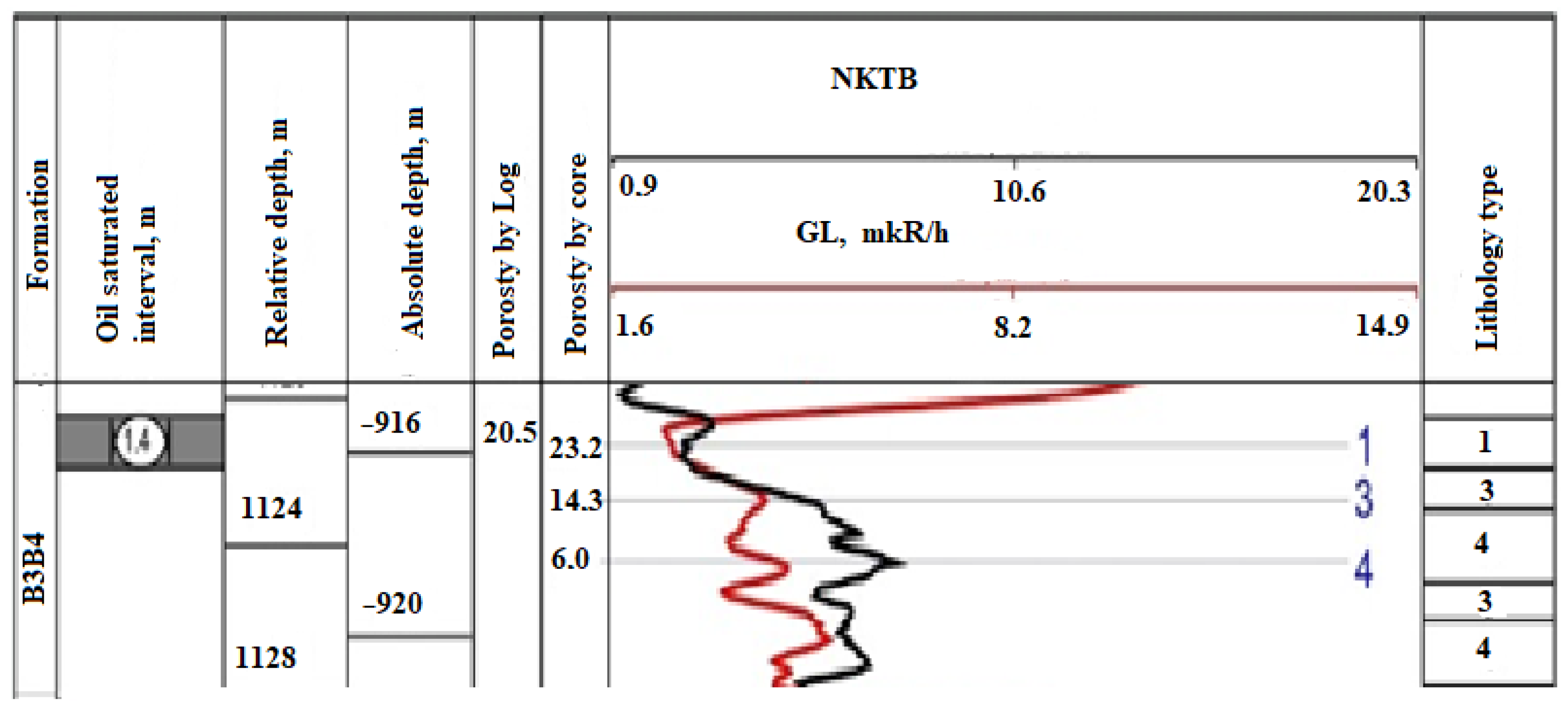

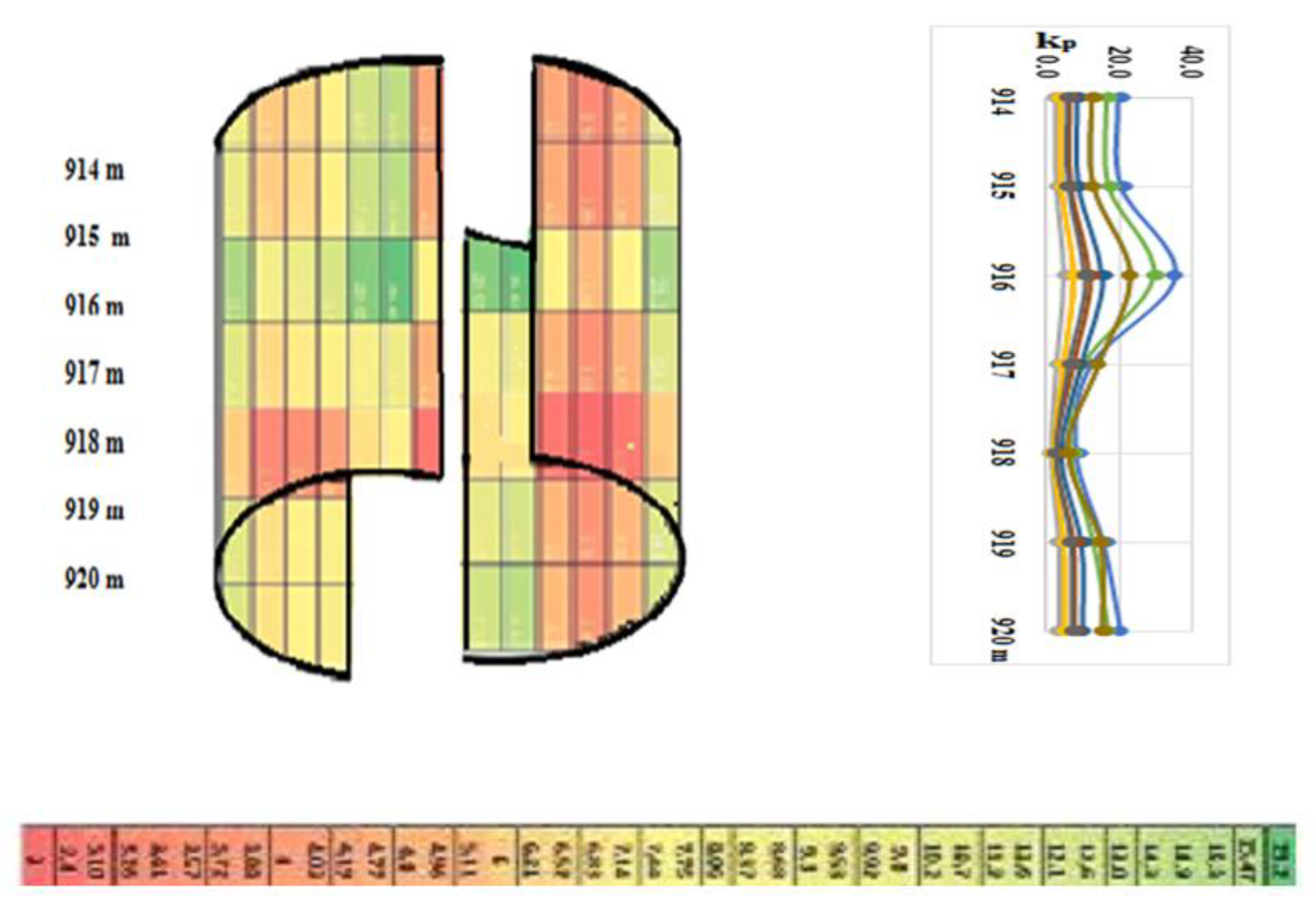

- Lithotype 1 is represented by a highly permeable reservoir with a core and well-logging porosity of more than 20% (Figure 2a).

- Lithotype 2 is interpreted by well logging as a reservoir with porosity in the range of 12–13%. According to core data, lithotype 2 is represented by alternating layers (3–10 cm) of porous and dense varieties of carbonate rocks (Figure 2b).

- Lithotypes 3 (Figure 2c) and 4 (Figure 2d), according to well-logging data, are interpreted as non-reservoirs with porosity values of less than 7%. However, lithotype 3 is characterized by the presence of “traces” of oil, which (with active external influence) can be involved in the production process.

- Lithotype 4 (Figure 2d) is represented by denser limestones; no oil shows were found in it.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gasanov, A.B.; Mamedova, D.N.; Abbasov, E.Y. Geological and Geophysical Knowledge of the PT Section of the South Caspian Depression (Some Issues of Predictive Assessment of the Sedimentary Complex); Lambert Academic Publishing: Moscow, Russia, 2017; Volume 109. (In Russian) [Google Scholar]

- Guliyev, I.S.; Shikhaliev, O.A.; Feyzullaev, A.A.; Kocharli, S.S. To the Concept of Geological Exploration for the Preparation of Hydrocarbon Resources in Azerbaijan; Academy of National Economy: Moscow, Russia, 2014; Volume 9, pp. 8–15, (In Russian). [Google Scholar] [CrossRef]

- Kocharli, S.S. Problematic issues of oil and gas geology of Azerbaijan; Mars Print NPF: Baku, Azerbaijan, 2015; p. 280. [Google Scholar]

- Yusifov, K.M.; Aslanov, B.S. Oil and Gas Bearing Basins in Azerbaijan; Mars Print NPF: Baku, Azerbaijan, 2018; p. 324. (In Russian) [Google Scholar]

- Aliyarov, R.Y.; Hasanov, A.B.; Ibrahimli, M.S.; Ismayilova, Z.E.; Jabiyeva, A.J. Forecasting of qualitative characteristics of oil reservoirs. In Proceedings of the Materials of the Republican Scientific-Practical Conference devoted to the 95th Anniversary of H. Aliyev: Unity of Science, Education and Production at the Present Stage of Development, Lenkaran, Azerbaijan, 20 April 2018; pp. 22–31. [Google Scholar]

- Aliyarov, R.Y.; Ramazanov, R.A. Prediction of multivariable properties of reservoir rocks byusing fuzzy clustering. In Proceedings of the 12th International Conference on Application of Fuzzy Systems and Soft Computing, ICAFS 2016, Vienna, Austria, 29–30 August 2016; pp. 424–431. [Google Scholar] [CrossRef][Green Version]

- Buryakovsky, L.A.; Chilingar, G.V.; Aminzadeh, F. Petroleum Geology of the South Caspian Basin; Gulf Professional Publishing: Houston, TX, USA, 2001; p. 341. [Google Scholar] [CrossRef]

- Anifowose, F.; Abdulraheem, A. Prediction of porosity and permeability of oil and gas reservoirs using hybrid computational intelligence models. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 14–17 February 2010; p. 126649. [Google Scholar] [CrossRef]

- Cuddy, S. The Application of the mathematics of fuzzy logic to petrophysics. In Proceedings of the 38th Annual Logging Symposium SPWLA, Houston, TX, USA, 15–18 June 1997; p. 125959936. [Google Scholar]

- Votinov, A.S.; Drozdov, S.A.; Malysheva, V.L.; Mordvinov, V.A. Recovery and increase of the productivity of wells of Kashirskiy and Podolskiy reservoirs of the certain Perm region oil field. Perm J. Pet. Min. Eng. 2018, 18, 140–148. [Google Scholar] [CrossRef]

- Kochnev, A.A.; Zotikov, V.I.; Galkin, S.V. Analysis of the influence of geological and technological indicators on the efficiency of radial drilling technology on the example of production facilities in the Perm Territory. Izv. TPU Georesour. Eng. 2018, 329, 20–29. (In Russian) [Google Scholar]

- Chi, H.; Li, G.; Huang, Z.; Tian, S.; Song, X. Maximum drillable length of the radial horizontal micro-hole drilled with multiple high-pressure water jets. J. Nat. Gas Sci. Eng. 2015, 26, 1042–1049. [Google Scholar] [CrossRef]

- Penny, G.S.; Canway, M.L.; Wellington, L. Control and modeling of fluid leakoff during hydraulic fracturing. J. Pet. Technol. 1985, 37, 1071–1081. [Google Scholar] [CrossRef]

- Kanevskaya, R.D. Foreign and Russian Experience in the Use of Hydraulic Fracturing; JSC VNIIOENG: Moscow, Russia, 1998; p. 37, (In Russian). [Google Scholar] [CrossRef]

- Zdolnik, S.E.; Nekipelov, Y.V.; Gaponov, M.A. Implementation of new hydraulic fracturing technologies at the carbonate objects of the fields of PJSC ANK Bashneft. Oil Ind. 2016, 7, 92–95. (In Russian) [Google Scholar]

- Topal, A.Y.; Usmanov, T.S.; Zorin, A.M.; Khaidar, A.M.; Gorin, A.N. Application of acid-proppant hydraulic fracturing at the fields of OJSC Udmurtneft. Oil Ind. 2018, 3, 34–37. (In Russian) [Google Scholar] [CrossRef]

- Economides, M.J.; Nolte, K.G. Reservoir Stimulation; J. Wiley and Sons: New York, NY, USA, 2006; p. 856. [Google Scholar]

- Wright, R.; Muma, R.D. High Volume Hydralic Fracturing and Human Health Outcomes: A Scoping Review. J. Occup. Environ. Med. 2018, 60, 424–429. [Google Scholar] [CrossRef]

- Muther, T.; Nizamani, A.A.; Ismail, A.R. Analysis on the effect of different fracture geometries on the productivity of tight gas reservoirs. Malays. J. Fundam. Appl. Sci. 2020, 16, 201–211. [Google Scholar] [CrossRef]

- Aliyeva, E.; Mustafayev, K. Petrographic and filtration-volume features of Miocene deposits of the western flank of the South Caspian basin. ANAS Trans. Earth Sci. 2021, 1, 3–15. [Google Scholar] [CrossRef]

- Gurbanov, V.S.; Hasanov, A.B.; Abbasova, G.G. Depth Distribution of Petrophysical Properties of Mesozoic Sediments of Khizi Tectonic Zone; European Association of Geoscientists & Engineers: Moscow, Russia, 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Gurbanov, V.S.; Narimanov, N.R.; Nasibova, G.J.; Mukhtarova, K.Z.; Narimanov, R.N.; Huseynova, S.M. Qualitative assessment of compressional stresses within the South Caspian Megadepression and their impact upon structure formation and hydrocarbon generation. ANAS Trans. Earth Sci. 2021, 2, 39–49. [Google Scholar] [CrossRef]

- Kaushansky, D.A.; Bakirov, N.R.; Demyanovsky, V.B. Studies of the strength characteristics of the core, as an indicator of the distribution of the polymer-gel system “Temposcreen-plus” by volume. SOCAR Proc. Spec. Issue 2021, 2, 12–16. [Google Scholar] [CrossRef]

- Efimov, A.A.; Galkin, S.V.; Savitckiy, I.V.; Galkin, V.I. Estimation of heterogeneity of oil & gas field carbonate reservoirs by means of computer simulation of core X-ray tomography data. Ecol. Environ. Conserv. Spec. Issue 2015, 21, 79–85. [Google Scholar]

- Pakzad, A.; Iacoviello, F.; Ramsey, A.; Speller, R.; Griffiths, J.; Freeth, T.; Gibson, A. Improved X-ray computed tomography reconstruction of the largest fragment of the Antikythera Mechanism, an ancient Greek astronomical calculator. PLoS ONE 2018, 13, e0207430. [Google Scholar] [CrossRef] [PubMed]

- Laubach, S.E.; Reed, R.M.; Olson, J.E.; Lander, R.H.; Bonnel, L.M. Coevolution of crack-seal texture and fracture porosity in sedimentary rocks: Cathodoluminescence observations of regional fractures. J. Struct. Geol. 2004, 26, 967–982. [Google Scholar] [CrossRef]

- Fjær, E.; Holt, R.; Horsrud, P.; Raaen, A. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2008; p. 491. [Google Scholar] [CrossRef]

- Ibatullin, R.R.; Salimov, V.G.; Nasybullin, S.V.; Salimov, O.V. Experimental study of rock crackness. Neft. Khozyastvo 2009, 6, 54–57. (In Russian) [Google Scholar]

- Galkin, S.V.; Savitsky, Y.V.; Kolychev, I.Y.; Votinov, A.S. Prospects for the use of proppant hydraulic fracturing at the Kashiro-Vereisk production facilities of the Volga-Ural oil and gas province. SOCAR Proc. Spec. Issue 2021, 2, 257–265. [Google Scholar] [CrossRef]

- Karev, V.I.; Klimov, D.M.; Kovalenko, Y.F.; Ustinov, K.B. Fracture of sedimentary rocks under a complex triaxial stress state. Mech. Solids 2016, 51, 522–526. [Google Scholar] [CrossRef]

- Karev, V.I.; Kovalenko, Y.F.; Ustinov, K.B. Modeling deformation and failure of anisotropic rocks nearby a horizontal well. J. Min. Sci. 2017, 53, 425–433. [Google Scholar] [CrossRef]

- Galkin, S.V.; Savitskiy, Y.V.; Osovetski, B.M.; Kazımov, K.P.; Gurbanov, V.Ş.; Abbasova, Q.Q.; Kazımov, R.R. Detailed study of hydraulic fracturing of Kashiro-Verey rocks by electron microscopy. ANAS Trans. Earth Sci. 2022, 17–27. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaalishvili, V.B.; Hasanov, A.B.; Abbasov, E.Y.; Mammadova, D.N. Detailing the Pore Structure of Productive Intervals of Oil Wells Using the Color 3D Imaging. Energies 2023, 16, 217. https://doi.org/10.3390/en16010217

Zaalishvili VB, Hasanov AB, Abbasov EY, Mammadova DN. Detailing the Pore Structure of Productive Intervals of Oil Wells Using the Color 3D Imaging. Energies. 2023; 16(1):217. https://doi.org/10.3390/en16010217

Chicago/Turabian StyleZaalishvili, Vladislav B., Adalat B. Hasanov, Elmeddin Y. Abbasov, and Dildar N. Mammadova. 2023. "Detailing the Pore Structure of Productive Intervals of Oil Wells Using the Color 3D Imaging" Energies 16, no. 1: 217. https://doi.org/10.3390/en16010217

APA StyleZaalishvili, V. B., Hasanov, A. B., Abbasov, E. Y., & Mammadova, D. N. (2023). Detailing the Pore Structure of Productive Intervals of Oil Wells Using the Color 3D Imaging. Energies, 16(1), 217. https://doi.org/10.3390/en16010217