Block Caving Mining Method: Transformation and Its Potency in Indonesia

Abstract

:1. Introduction

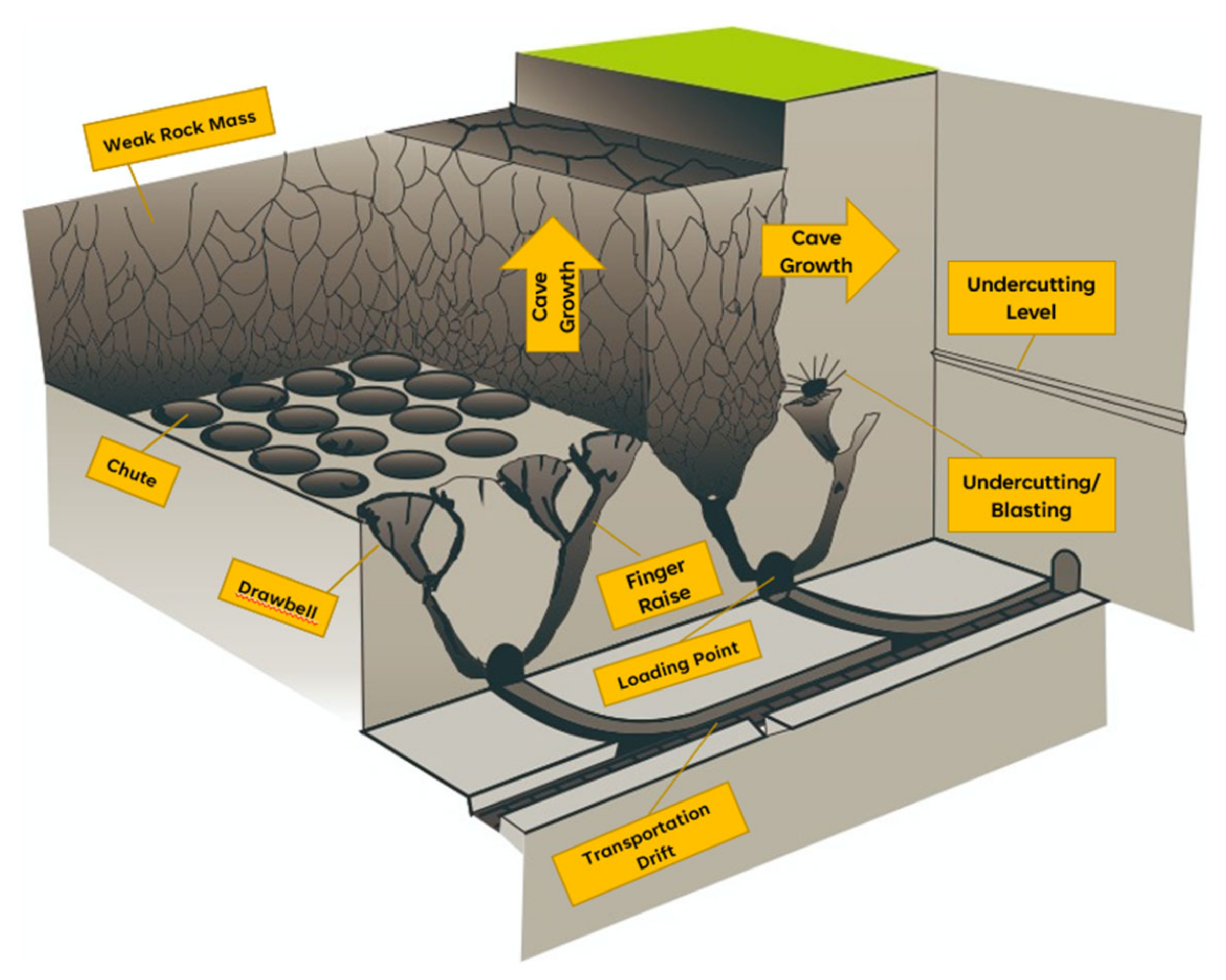

2. Block Caving Method

2.1. Initial Block Caving for Weak to Moderate Rock

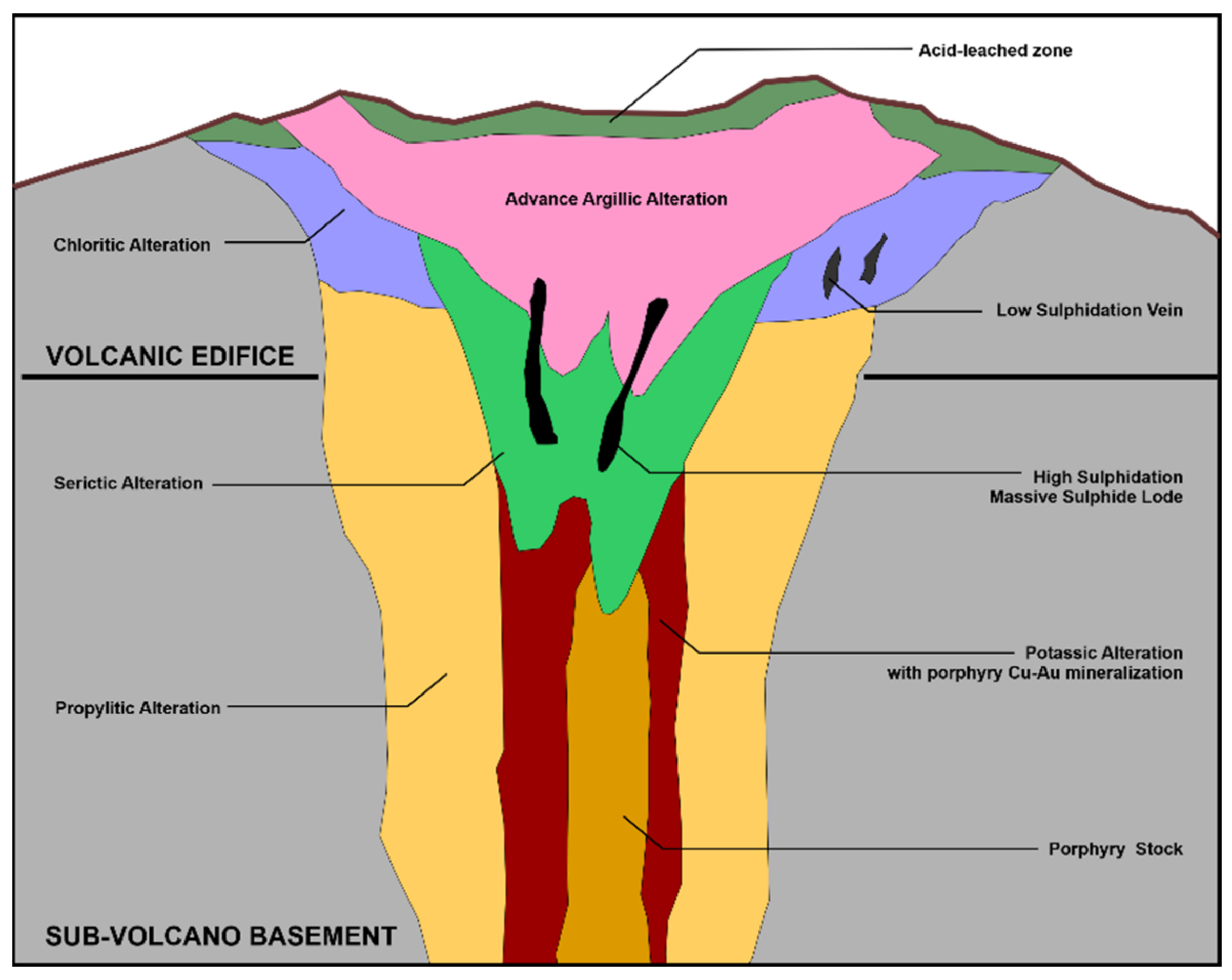

- A weak ore body can easily be fractured or fail and be separated around the block.

- A weak wall rock breaks into bigger boulders than an ore fragment, where the pressure helps to break the ore body below.

- Homogeneous deposit shape is required, as it is impossible to conduct selective mining. Should eye catching characteristics cause physical differentiation between ore body and capping, dilution at the draw point can be avoided. Ore body should be difficult to react with air. Therefore, this method is not appropriate for sulfidation deposits.

- Dip of the deposit is not a problem. However, a dip > 65° is favorable if it is a vein.

- Deposit thickness > 3 m with height > 35 m.

- The grade of ore should not be high.

- The depth is moderate.

- A massive ore body with a thickness of more than 100 m, a dip of more than 55° and depth of more than 100 m.

- Grade distribution is relatively uniform.

- Very low-quality ore body (Rock Mass Rating, RMR = 0–20), wall rock is from very weak to moderate (RMR = 0–60).

- The ore body and wall rock’s uniaxial compressive strength (σc) are very weak. Compared with major principal stress (σ1), the ratio σc/σ1 is lower than 5.

2.2. Transformation to Competent Rock

3. Requirements and Technical Specifications for Block Cave Mines Globally

- 1.

- Ore body dimension

- 2.

- Ore body and rock mass quality

- 3.

- Grade

- 4.

- Depth

- 1.

- Preparation method

- 2.

- Undercutting strategy

- 3.

- Mine Design

- 4.

- Mining equipment

- 5.

- Monitoring system

4. Existing Caving Mine in Indonesia

4.1. Grasberg Caving Complex

4.2. Semi Caving in Pongkor

5. Mineralization Type and Potential Cave Mines in Indonesia

- Onto deposit

- Porphyry deposits on Tambulilato

- Tumpangpitu, Tujuh Bukit porphyry deposit

- Randu Kuning deposit

6. Opportunities and Challenges of Block Caving Method in Indonesia

6.1. Exploration

6.2. Cost

6.3. Operational

6.4. Environment

6.5. Policy

6.6. Social Geology

7. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Mines | Ore Bodies and Types of Mineralization | Rock Mass | Depth | Production Rates and Reserves | Footprint | Mine Design | Equipment | Time | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Argyle, Australia | Diamond pipe. Volcanic vent intrusion of magmatic lamproite and lamproitic tuff. | Granite, dolerite, basalt and metamorphosed quartzite and mudstone. UCS 35–104 MPa, RMR 45–59 | σ1 = 2σv, σ2 = 1.5σv, σ3 = 0.027z | 18,000 tpd (Lift 1). It has produces 800M carats | 75,000 m2 | an advanced undercut technique using a W-incline undercut design | Real-time LHD dispatch | 2008 (undercutting), 2015 (development complete), 2020 (final production) | [142,143] |

| Cadia East, Australia | Monzonite porphyry, Au-Cu porphyry deposits | Andesit, monzonite, quartz. UCS 132–140 MPa, E 65–67 GPa, FF < 15. | 63:42:36 @1200; 72:48:41 @1400; | 26 Mta | Width orebody 700 m | El Teniente, Drawbell Spacing: 32 × 20 m | Load-Haul-Dump (LHD) operation | 2000 (production) | [47,77,99] |

| Carrapateena, South Australia | copper-gold deposit | brecciated granite complex | 500 m | 10,000–120,000 t of copper and 110,000–120,000 oz | 70,000 m2 | El Teniente, draw point spacing of 32 m × 22 | LHD., Jaw Gyratory crusher, crushed-ore-bin, conveyor system | 2020 (Prefeasibility study), 2026 (Production), 2045 (final year) | [132,144,145,146] |

| Cullinan, South Africa | Kimberlite pipe | UCS Kimberlite: 80–130 (Grey), 73–193 (Hypabyssal) Mpa; UCS Country rock: 140–220 (Norite), 60–240 (Metasediments), Hydraulic radius: 30; Mining Rock Mass Rating: 30–50 (grey), 25–35 (contacts, internal dykes and shear zones), 40–60 (Hypabissal) | 630–732 mbs | 3.9 Mt/a; Reserves: 38.6 Mt, grade 38.8, 14.97 Mt | 32 ha | Centenary-Cut; Undercut tunnels 4 m wide and 4 m height, 16 m spacing; Extraction level 4.2 m wide by 4.2 m high, spacing 16–18 m; Tunnel spacing in the production level of 32 m; Drawpoint spacing 18 m | Tamrock Toro–LHD | 1980–2037 (operation) | [147] |

| El Teniente, Chile | copper-molybdenum deposit | Andesite, dacite, diorite, braden pipe; UCS 120, 110, 140, 90 MPa; RMR 53–59, 59–66, 64–66 | 2200 m. σ1 = 0.0328z + 16, σ2 = 0.0283z + 5, σ1 = 0.0265z | Productions 140,000 tons per day. Measured resources 1128 million tons 0.985%Cu | 500–800 m | El Teniente, hydraulic radius 26 m | Load-Haul-Dump (LHD) | 1997 (pre-undercutting), 2032 (planned final production) | [66,148] |

| Grasberg, Indonesia | Cu-Au Porphyry, Skarn | Fair to the very good ground: 80–140 MPa; Poor to fair ground: 5–80 MPa | 1200 m | 60,000–100,000 tpd; 160,000 (planned for 2026) | Area: 700,000 m2 | El Teniente, Drawbell Spacing: 20 × 30 m | Load-Haul-Dump (LHD) operation, rail haulage system | 2004 (construction), 2018 (production) | [59,109,110,112,149,150] |

| Jwaneng, Botswana | diamond-bearing kimberlite complex | Sand, calcrete, laminated shale, carbonaceous shale, quarzitic shale, chert pebble conglomerate-bevets, carbonaceous shale and dolomite. UCS 25 MPa (weak kimberlite), >250 MPa (very competent dolomite) | ~1000 m; σ1 = 0.9–1.1σv, σ2 = 0.5σv, σ3 = 0.027z | No data found | No data found | No data found | No data found | 2032 (construction) | [151,152] |

| Northparkes Mine, Australia | Trachyandesites (Volcanics) and finger-like monzonite porphyry (MP) intrusions, potassic alteration and occurs predominately in stockwork quartz veins. | Gypsum and quartz. MRMR’s in Lift 1 ranged from 33 to 54. | >800 m | 16,000 tpd (E26 Lift 1, Lift 2, Lift 2 N); 18,000 tpd (E48 Lift 1). Reserves 27 million tons of Ore. | Width vein 200 m, height 800 m. 196 meters long by 180 meters wide. | Northparkes layout style, Hydraulic radius 20–25 | Load Haul Dump | 2002 (production) | [48] |

| Oyu Tolgoi, Mongolia | copper-gold-molybdenum mineralization | volcanic and quartz monzo-diorite (QMD); Dacite tuff, breccia (IGN), basalt flows and minor volcaniclastic strata (Va). Dikes: rhyolitic, hornblende biotite andesite, dacite and basalt. MRMR < 20 | 1385 m | 95,000 tpd (Hugo North Lift 1) | Hugo deposit height 900 m, length 1.8 km, width 500 m. | El Teniente draw point layout on 31 × 18 m spacing | underground trucking system, gyratory crushers, conveyor system, concentrator | 2015 (construction), 2020 (production) | [57,153] |

| Padcal, Philippines | Cu-Au Porphyry | 0.18% Cu, 0.27 g/t Au; 56 Mlbs Cu, 166.700 oz Au | No data found | Production 70,000 m2 | No data found | No data found | No data found | 2020 (exploration) | [154] |

| Palabora, South Africa | Magmatic-hydrothermal deposit. | Carbonatite, 139 MPa (intact), 111 MPa (rock mass) | 1200–1800 m. | Production 30,000–82,000 tpd; Reserve 960 Mt | 250 × 650 m | off-set herringbone style, 20 cross-cut | LHD, crusher | 2000–2014 | [50,51,104] |

| Ridgeway Deeps, Australia | Au-Cu porphyry | Cadia Valley Monzonite (93–155 MPa), Forrest Reef Volcaniclastics (87–150 MPa) and Weemalla Sediments (88–144 MPa). Average density 2.85 t/m3 | 1100 m. σ1 = 65 MPa, σ2 = 47 MPa, σ3 = 32 MPa | 101 mt at 1.8g/t Au and, 0.38% Cu for 2.6 Moz Au and 380 kt Cu | 500 × 200 m2 | Offset Herringbone layout and consists of 15 extraction drives, 250 drawpoints | Load haul Dump | 2005–2017 (production) | [50] |

| Shabanie, Zimbabwe | Asbestos | Dunite Sill intruding Precambrian Gneisses | No data found | No data found | No data found | No data found | No data found | 1970 (production) | [146] |

| Stornoway Diamonds’ Renard Mine, Quebec, Canada | Kimberly pipe | Pyroclastic, granitoid and gneissic host rock, UCS 4.5–26 MPa | 600 m. σ1 = 0.9–1.1σv, σ2 = 0.5σv, σ3 = ρ.g.h | 3000–5000 tpd | 225 m | Herringbone. Drawpoints are 5.3 m wide, distance between center 15 m | Load haul Dump | 2018 (production) | [55] |

| Lvivvuhillia SE Mine, and Ukraine | Coal, carbonous formation | Sandstone, Argillite, Aleurite | Sandy shale 23.2–31.1 MPa | 100 ktons per months | its average mining thickness is 1.24 m. | 10.3–10.6 m2 for boundary entry | Coal shearers, Scraper, Oil-pumping station | 2020 (production) | [25,26] |

| the 10th Anniversary of Kazakhstan’s Independence Mine, and Kazakh-stan | Chromite deposits | Peridotite and Serpentinite, UCS 17.1–64.5 MPa | Depth 900 m, σ1 = σ3 = and σz = 24.8 MPa | No data found | 180 m | Undercut-caving system, Drawpoint spacing 12–24 m | No data found | Development (2021) | [155] |

| Location | Ore Genesis | Type | Size, Dip | Grade, Volume | Rock Mass | Mining Method | Status | References |

|---|---|---|---|---|---|---|---|---|

| Awak Mas, Latimojong, South Sulawesi | Hydrothermal | albite-ankerite-pyrite alteration halo | up to ~75 m width | Indicate and inferred resource of 38.4 Mt at 1.41 gr/t Au~1.74 Moz Au | Phyllite and schist. | - | Exploration | [156] |

| Batu Hijau | Epithermal | Porphyry | a zone 300 m × 900 m containing > 0.3 wt % Cu | > 0.1 wt % Cu, > 0.1 wt % Cu, Mo (> 30 ppm) | Diorite, metavolcanic rock | Open Pit, Block Caving (in panning) | Production Planning | [157,158] |

| Beruang Kanan, Kalimantan Tengah | Epithermal | quartz vein, porphyry | vein direction is N 312° E/43° | Not explore yet | Dasite, diorite, silica sand | - | 2017 (Exploration) | [159] |

| Bombana, Southeast Sulawesi | Secondary (placer) in Langkolawa in Wumbubangka derived from orogenic gold | Gold-bearing quartz vein | 2 cm–2 m | grades <0.005 g/t to 134 g/t | mica schist, phyllite, metasandstone and marble) | Placer mining -artisanal and small-scale gold mining | 2011 (study) | [160,161] |

| Bulagidun | Hydrothermal | a copper, gold and tourmaline bearing porphyry and breccia system | up to 500 m lateral distance, veins up to 2 m true width, | more than 14.4 Mt at 0.68 ppm Au and 0.61 wt.% Cu | early diorite to quartz diorite to late tonalite and post-mineral andesitic dykes. | - | Geological Study | [162] |

| Cibaliung, Banten | Epithermal | Quartz vein | Dyke 1 to 120 m wide, 20 to >300 m long. | 1.3 Mt 10.42 g/t Au, 60.7 g/t Ag 3 g/t cut-off; 435,000 ounces of Au and 2.54 Mounces Ag | UCS 16.85 MPa, Tensile strength 0.69 MPa | Cut and fill | 2001 (Exploration); 2010 (production | [163,164] |

| Cikidang (Cikotok) | Low sulfidation epithermal adularia | Quartz vein | Thickness 0.7–3 m, dip 60–86° | 74.9 g/t Au, 1.2–225 g/t Ag | Lapilli tuff, breccia andesite, claystone, limestone, Sandstone | Underhand stall-stopping method | 1998 (production), | [165] |

| Elang | Epithermal | Porphyry | undescribed | 300 t Au, >5 Mt Cu | Volcanoclastic and esitic | - | Exploration | [123,129] |

| Ertsberg | Contact metasomatism | Skarn system | length > 1.1 km, 4–60 m thick, depth >700 m | 2.69 percent Cu, 1.02 g/t Au and 16 g/t. | dolomitic sediments | Block Caving | Production | [105] |

| Gosowong, Halmahera | Epithermal | Quartz vein, porphyry | Thickness 30–40 m, dip 35–70° | 0.99 million metric tons (Mt) at 27 g/t Au and 38 g/t Ag | Volcaniclastic and pyroclastic | Open pit | 1996 (exploration) | [118] |

| Grasberg | Contact metasomatism | Porphyry | 1.2 km (pit) | over 32 Mt of Cu and 3 kt of Au | Diorite, limestone | Open Pit, Block Caving | Production | [56,109,110,150] |

| Gunung Subang, West Java | Epithermal | Gold-bearing minerals | 0.01–0.2 m; 40–81° | Au 0.22–14.49 ppm, Ag 17–21.40 ppm, Cu 8.25–34515 ppm, Pb 107.69–2226 ppm, 35.36–7335 ppm | Andesite, tuff, breccia | - | 2018 (Prospection) | [126] |

| Kelian, East Kalimantan | Epithermal | Au-Ag mineralization | 0.25–5 m | 240 t Au | Rhyolite | Open pit | 2003 (Mine closure) | [166] |

| Kencana | Epithermal | Au deposit | Thickness 12 m, 45° | 39 g/ton gold | RMR 25–55 and esite lavas, | Underhand cut and fill | Production | [167] |

| Malala, Northwest Sulawesi | Hydrothermal | fluorine-poor (quartz monzonite or differentiated monzogranite) class of molybdenum deposits | 50 m | estimated resource of 100 Mt at 0.14% MoS. | granites and granodiorites | - | 1993 (Geological study) | [168] |

| Miwah, Aceh | Hydrothermal | high-sulfidation Au–Ag deposit | >60° | inferred total resource of 3.13 million oz (Moz) of Au at a cut-off grade of 0.2 g/t Au | silicified rocks, breccia | - | 2019 (Prospection) | [128] |

| Ojolali, Lampung | Epithermal | Tambang Vein:Ag-Au intermediate sulfidation deposit; Bukit Jambi Vein: low sulfidation Au-Ag deposit | <50 m, ~50° | inferred resource 167 g/t Ag and 0.7 g/t Au, forms a total of 40 Moz Ag and 170,000 oz Au | Basalt and esite | - | 2014 (Geological study) | [127] |

| Pani JV Project, Hulawa, Gorontalo | Hydrothermal | Open vein and breccia | No description | Resources 72.7 mt, 0.98 g/t, 2.3 mlb Au | UCS 21.42 MPa, UTS 2.06 MPa | Breccia, granodiorite and dasite | Conceptual study (2020) | [123,129] |

| Pongkor | Hydrothermal alteration | Vein | Thickness 2–24 m | 2.1 million metric tons at 13.63 ppm gold and 163.24 ppm silver (proven ore reserve) | volcanic breccia, lapilli tuff and esite lava and siltstone | Cut and Fill Stopping, Semi Caving | Production | [115,116,117] |

| Tambulilato: Cabang Kiri, Sungai Mak, Kayubulan and Cabang Kanan | Hydrothermal | Poprhyry (Cabang Kiri, Sungai Mak, Kayu Bulan, Cabang Kanan), high-sulfidation epithermal Au-Ag (Motomboto); low-sulfidation epithermal Au-Ag (Kaidundu) | Various wide of veins and porphyry | 392.3 million tons, 0.49%Cu, 0.43 g/t/Au, 1.65 g/t Ag. | Dacite, vulcanic, diorite | Stopping underground mining | Production (until 2052) | [122] |

| Tangse, North Sumatra | Hydrothermal | Cu-Mo porphyry deposit | Not explored yet | Not explore yet | Diorite | - | 2018 (Prospecting) | [125] |

| Toguraci, Halmahera | Epithermal | Quartz vein, porphyry | - | 0.41 Mt, 27 g/t Au | Andesitic lava, UCS 80 MPa | Under Hand Cut and Fill (UHCF) and Open Stope (Sub Level–Blind Stope) | 1996 (exploration) | [169] |

| Tujuh Bukit | Hydrothermal | Porphyry | described | Inferred resources 1.9 bt, 0.45% Cu, 0.45 g/t, 8.7 mt Cu, 28 mlb Au | sedimentary and andesitic volcanic rocks | Open Pit | Production (2021) | [123,129,170] |

| Tumpangpitu, East Java | Epithermal | Porphyry | Mineralization > 800 m | 1.9 Gt, 0.45% Cu, 0.45 g/t Au | Diorite and esite, breccia | - | Exploration | [123,129,170] |

| Underground Tujuh Bukit | Hydrothermal | Porphyry (high level porphyry copper-gold-molybdenum deposit (sulfide) | Inferred resources 1.9 bt, 0.45% Cu, 0.45 g/t, 8.7 mt Cu, 28 mlb Au | sedimentary and andesitic volcanic rocks | Underground mining (undetermined) | Pre-feasibility study (2021) | [123] | |

| Wetar, Pulau Wetar, Southwestern moluccas | Volcanic- hosted massive sulfide (VMS) | Primarily pyrite | ~150,100.70 m and ~1,209,030 m, | 20 mt, 38% S, 33% Fe, host Cu, Au, Ag, Zn | Basaltic and andesite | Open pit | Production (2010) | [171] |

| Type of Deposit | Characteristic | Recommended Exploration Methods & Tools | Rationalization |

|---|---|---|---|

| Porphyry Cu-Au deposits | Commonly associated with magnetite that can produce strong discrete magnetic anomalies. Strong charge abilities due to sulfides are typically associated with porphyry systems. | High-resolution magnetic survey | Porphyry is usually within a zone of magnetite-destructive alteration. Magnetic surveys are also valuable for defining regional structure and geology in the porphyry environment. |

| Gravity, radio metrics, remote sensing and topography | Mineralization and clay-pyrite alteration can produce strong anomalies and late-stage and post-mineral intrusions can be mapped as low chargeability within the system. These systems may be more conductive than the host rock because of clay-pyrite alteration and sulfide veining and airborne electromagnetic can be helpful in locating and defining their extent. | ||

| High sulfidation epithermal system | Gold is commonly associated with massive silica alteration. | Resistivity and airborne electromagnetic survey | This alteration results in resistivities in the order of thousands of ohmmeters compared with background resistivities of tens of ohm-meters in argillic and propylitic alteration. Alteration in high sulfidation epithermal deposits is magnetite destructive over a large area, although it does not appear to have a large vertical extent as the subdued characterization of the underlying lithologies can be observed. |

| Low sulfidation epi-thermal system | Gold in this deposit is in thin quartz veins associated with major structures. Some deposits are associated with broad zones of magnetite destruction, which is apparent in the regional magnetics. | High-resolution magnetics, resistivity surveying | The alteration associated with the veins is magnetite destructive and high-resolution magnetics can be beneficial and cost-effective technique to map the structures and alteration. Generally, the high resistivity zones are due to silicification are coincident with the structure identified in the magnetics. |

References

- Reichl, C.; Schatz, M. World Mining Data 2022. International Organizing Committee for the World Mining Congresses; Federal Ministry of Agriculture, Regions and Tourism: Vienna, Austria, 2022. [Google Scholar]

- Dong, L.; Sun, D.; Shu, W.; Li, X. Exploration: Safe and clean mining on Earth and asteroids. J. Clean. Prod. 2020, 257, 120899. [Google Scholar] [CrossRef]

- Lurka, A. Spatio-temporal hierarchical cluster analysis of mining-induced seismicity in coal mines using Ward’s minimum variance method. J. Appl. Geophys. 2021, 184, 104249. [Google Scholar]

- Brodny, J.; Tutak, M. Challenges of the polish coal mining industry on its way to innovative and sustainable development. J. Clean. Prod. 2022, 375, 134061. [Google Scholar] [CrossRef]

- Sahu, H.; Prakash, N.; Jayanthu, S. Underground Mining for Meeting Environmental Concerns–A Strategic Approach for Sustainable Mining in Future. Procedia Earth Planet. Sci. 2015, 11, 232–241. [Google Scholar] [CrossRef] [Green Version]

- Harraz, H. Underground mining. In Mining Methods; Geology Department, Faculty of Science: Tanta, Egypt, 2011. [Google Scholar]

- Orellana, L.; Castro, R.; Hekmat, A.; Arancabia, E. Productivity of a Continuous Mining System for Block Caving. Rock Mech. Rock Eng. 2016, 50, 657–663. [Google Scholar]

- Ibishi, G.; Yavuz, M.; Genis, M. Underground mining method assessment using decision-making techniques in a fuzzy environment: Case study, Trepça mine, Kosovo. Min. Miner. Depos. 2020, 14, 134–140. [Google Scholar] [CrossRef]

- Wu, H.; Yin, Z.; Zhang, Y.; Qi, C.; Liu, X.; Wang, J. Comparizon of underground coal mining methods based on life cycle assessment. Front. Earth Sci. 2022, 10, 933. [Google Scholar] [CrossRef]

- Hartman, H. Introductory Mining Engineering; John Wiley & Sons: New York, NY, USA, 1987. [Google Scholar]

- Adhikary, D.P.; Guo, H. Modelling of longwall mining-induced strata permeability change. Rock Mech. Rock Eng. 2015, 48, 345–359. [Google Scholar] [CrossRef]

- Mitchell, G.W. Longwall Mining; Australasian Coal Mining Practice: Melbourne, Australia, 2009; pp. 340–373. [Google Scholar]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar] [CrossRef]

- Lechner, A.M.; Baumgartl, T.; Matthew, P.; Glenn, V. The impact of underground longwall mining on prime agricultural land: A review and research agenda. Land Degrad. Dev. 2016, 27, 1650–1663. [Google Scholar] [CrossRef]

- Bai, Q.; Tu, S. A general review on longwall mining-induced fractures in near-face regions. Geofluids 2019, 2019, 3089292. [Google Scholar] [CrossRef] [Green Version]

- Mark, C. Coal bursts in the deep longwall mines of the United States. Int. J. Coal Sci. Technol. 2016, 3, 1–9. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int. J. Rock Mech. Min. Sci. 2012, 51, 24–34. [Google Scholar] [CrossRef]

- Islavath, S.R.; Deb, D.; Kumar, H. Numerical analysis of a longwall mining cycle and development of a composite longwall index. Int. J. Rock Mech. Min. Sci. 2016, 89, 43–54. [Google Scholar] [CrossRef]

- Guo, H.; Adhikary, D.P.; Craig, M.S. Simulation of mine water inflow and gas emission during longwall mining. Rock Mech. Rock Eng. 2009, 42, 25–51. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, D.; Zhang, X.; He, M. Analysis and optimization of entry stability in underground longwall mining. Sustainability 2017, 9, 2079. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Pang, Y. Surrounding rock control theory and longwall mining technology innovation. Int. J. Coal Sci. Technol. 2017, 4, 301–309. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.R.; Hayashi, D.; Kamruzzaman, A.B.M. Finite element modeling of stress distributions and problems for multi-slice longwall mining in Bangladesh, with special reference to the Barapukuria coal mine. Int. J. Coal Geol. 2009, 78, 91–109. [Google Scholar] [CrossRef]

- Hoseinie, S.H.; Ataei, M.; Khalokakaie, R.; Ghodrati, B.; Kumar, U. Reliability analysis of drum shearer machine at mechanized longwall mines. J. Qual. Maint. Eng. 2012, 18, 98–119. [Google Scholar] [CrossRef]

- Najafi, A.B.; Saeedi, G.R.; Farsangi, M.A. Risk analysis and prediction of out-of-seam dilution in longwall mining. Int. J. Rock Mech. Min. Sci. 2014, 70, 115–122. [Google Scholar] [CrossRef]

- Shavarskyi, I.; Falshtynskyi, V.; Dychkovskyi, R.; Akimov, O.; Sala, D.; Buketov, V. Management of the longwall face advance on the stress-strain state of rock mass. Min. Miner. Depos. 2022, 16, 78–85. [Google Scholar] [CrossRef]

- Ukrinform. Ukrainians Miners Produces 2.6 Mtonnes of Coal in September. Available online: https://www.ukrinform.net/rubric-economy/3109854-ukrainian-miners-produced-26m-tonnes-of-coal-in-september.html (accessed on 21 October 2022).

- Wojtecki, Ł.; Kurzeja, J.; Knopik, M. The influence of mining factors on seismic activity during longwall mining of a coal seam. Int. J. Min. Sci. Technol. 2021, 31, 429–437. [Google Scholar] [CrossRef]

- He, M.; Gao, Y.; Yang, J.; Gong, W. An innovative approach for gob-side entry retaining in thick coal seam longwall mining. Energies 2017, 10, 1785. [Google Scholar] [CrossRef] [Green Version]

- Pongpanya, P.; Sasaoka, T.; Shimada, H.; Hamanaka, A.; Wahyudi, S. Numerical study on effect of longwall mining on stability of main roadway under weak ground conditions in Indonesia. J. Geol. Resour. Eng. 2017, 3, 93–104. [Google Scholar]

- Sasaoka, T.; Mao, P.; Shimada, H.; Hamanaka, A.; Oya, J. Numerical analysis of longwall gate-entry stability under weak geological condition: A case study of an Indonesian coal mine. Energies 2020, 13, 4710. [Google Scholar] [CrossRef]

- Sasaoka, T.; Takamoto, H.; Shimada, H.; Oya, J.; Hamanaka, A.; Matsui, K. Surface subsidence due to underground mining operation under weak geological condition in Indonesia. J. Rock Mech. Geotech. Eng. 2015, 7, 337–344. [Google Scholar] [CrossRef] [Green Version]

- Sasaoka, T.; Hamanaka, A.; Shimada, H.; Matsui, K.; Lin, N.Z.; Sulistianto, B. Punch multi-slice longwall mining system for thick coal seam under weak geological conditions. J. Geol. Resour. Eng. 2015, 4, 28–36. [Google Scholar]

- Mao, P.; Sasaoka, T.; Shimada, H.; Hamanaka, A.; Wahyudi, S.; Oya, J.; Naung, N. Three-Dimensional Analysis of Gate-Entry Stability in Multiple Seams Longwall Coal Mine under Weak Rock Conditions. Earth Sci. Res. 2020, 9, P72. [Google Scholar] [CrossRef] [Green Version]

- Skawina, B.; Greberg, J.; Salama, A.; Gustafson, A. The effects of orepass loss on loading, hauling, and dumping operations and production rates in a sublevel caving mine. J. S. Afr. Inst. Min. Metall. 2018, 118, 409–418. [Google Scholar] [CrossRef] [Green Version]

- Kosenko, A.V. Improvement of sub-level caving mining methods during high-grade iron ore mining. Natsional’nyi Hirnychyi Universytet. Nauk. Visnyk 2021, 1, 19–25. [Google Scholar]

- Yi, C.; Sjöberg, J.; Johansson, D. Numerical modelling for blast-induced fragmentation in sublevel caving mines. Tunn. Undergr. Space Technol. 2017, 68, 167–173. [Google Scholar] [CrossRef]

- Blachowski, J.; Ellefmo, S. Numerical modelling of rock mass deformation in sublevel caving mining system. Acta Geodyn. Geomater. 2012, 9, 167. [Google Scholar]

- Singh, R.; Singh, T.N. Investigation into the behaviour of a support system and roof strata during sublevel caving of a thick coal seam. Geotech. Geol. Eng. 1999, 17, 21–35. [Google Scholar] [CrossRef]

- Shekhar, G.; Gustafson, A.; Hersinger, A.; Jonsson, K.; Schunnesson, H. Development of a model for economic control of loading in sublevel caving mines. Min. Technol. 2019, 128, 118–128. [Google Scholar] [CrossRef] [Green Version]

- Navarro, J.; Schunnesson, H.; Ghosh, R.; Segarra, P.; Johansson, D.; Sanchidrian, J. Application of drill-monitoring for chargeability assessment in sublevel caving. Int. J. Rock Mech. Min. Sci. 2019, 119, 180–192. [Google Scholar] [CrossRef]

- Abolfazlzadeh, Y.; Hudyma, M. Identifying and describing a seismogenic zone in a sublevel caving mine. Rock Mech. Rock Eng. 2016, 49, 3735–3751. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Wimmer, M. A case study of dividing a single blast into two parts in sublevel caving. Int. J. Rock Mech. Min. Sci. 2018, 104, 84–93. [Google Scholar] [CrossRef]

- Ge, Q.; Fan, W.; Zhu, W.; Chen, X. Application and research of Block Caving in Pulang Copper Mine. In IOP Conference Series: Earth and Environmental Science; ESMA 2017; IOP Publishing: Beijing, China, 2018; pp. 1–8. [Google Scholar]

- Eberhardt, E.; Woo, K.; Stead, D.; Elmo, D. Transitioning from open pit to underground mass mining: Meeting the rock engineering challenges of going deeper. In ISRM Congress 2015 Proceedings—International Symposium on Rock Mechanics; International Society for Rock Mechanics: Salzburg, Austria, 2015; ISBN 978-1-926872-25-4. [Google Scholar]

- Potvin, Y.; Jakubec, J. Preface. Caving 2018: Proceedings of the Fourth International symposium on Block and Sublevel Caving; Australian Centre for Geomechanics: Vancouver, BC, Canada, 2018. [Google Scholar]

- Woo, K.-S.; Eberhardt EElmo, D.; Stead, D. Empirical investigation and characterization of surface subsidence related to block cave mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 31–42. [Google Scholar] [CrossRef]

- Sainsbury, B.; Sainsbury, D.; Carroll, D. Back-analysis of PC1 cave propagation and subsidence behaviour at the Cadia East mine. In Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving; Australian Centre for Geomechanics: Vancouver, Australia, 2018; pp. 167–178. [Google Scholar]

- Van As, A.; Jeffrey, R.G. Hydraulic Fracturing as a Cave Inducement Technique at Northparkes Mines. In Proceedings of the MassMin2000 Conference, Brisbane, QLD, Australia, 29 October–2 November 2000. [Google Scholar]

- Cuello, D.; Newcombe, G. Key geotechnical knowledge and practical mine planning guidelines in deep, high stress, hard rock conditions for block and panel cave mining. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving; Australian Centre for Geomechanics: Vancouver, BC, Canada, 2018; pp. 17–35. [Google Scholar]

- Lowther, R.J.; Capes, G.W.; Sharrock, G.B. A deformation monitoring plan for extraction level drives at Ridgeway Deeps block cave mine. In Caving 2010; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2010. [Google Scholar]

- Ferguson, G.; Cuello, D.; Moreno, P.; Potvin, Y.; Valdivia, E. Strategy for research and development in the cave mining industry. In Caving 2018; Potvin, Y., Jakubec, J., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2018. [Google Scholar]

- Westley-Hauta, R.L.; Meyer, S. Characterisation of seismic activity at a kimberlite block caving operation in a complex geological setting in Quebec, Canada. In Caving 2022: Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Australian Centre for Geomechanics: Perth, Australia, 2022; pp. 1101–1120. [Google Scholar]

- Groves, D.I.; Vielreicher, N.M. The Phalabowra (Palabora) carbonatite-hosted magnetite–copper sulfide deposit, South Africa: An end-member of the iron-oxide copper–gold–rare earth element deposit group? Miner. Depos. 2001, 36, 189–194. [Google Scholar] [CrossRef]

- Moss, A.; Dianchenko, S. Townsend, Interaction between the block cave and the pit slopes at Palabora mine. J. S. Afr. Inst. Min. Metall. 2006, 106, 479–484. [Google Scholar]

- Stegman, C.; van As, A.; Peebles, E. Past learning focus innovative solutions to future cave mining. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving; Australian Centre for Geomechanics: Vancouver, BC, Canada, 2018; pp. 37–41. [Google Scholar]

- Campbell, R.; Banda, H.; Fajar, J.; Brannon, C. Optimising for success at the Grasberg Block Cave. In Caving 2018; Australian Centre for Geomechanics: Perth, Australia, 2018; Volume 3–15, pp. 91–106. [Google Scholar]

- Moorcroft, T.H.; Simanjuntak, K.; Dorjsuren, O.; Sanaakhorol, M.; Enkhtaivan, E.; Watt, G.; Eickhoff, V.; Cerny, L.; Deasy, C.; Zimmermann, T. Oyu Tolgoi and Rio Tinto partnership with Palantir Technologies to provide effective geotechnical risk management. In Caving 2022; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2022. [Google Scholar]

- Catalan, A.; Onederra, I.; Chitombo, G. Evaluation of intensive preconditioning in block and panel caving-Part I, quantifying the effect on intact rock. Min. Technol. 2017, 126, 209–220. [Google Scholar] [CrossRef] [Green Version]

- Widodo, S.; Anwar, H.; Syafitri, N.A. Comparative analysis of ANFO and emulsion application on overbreak and underbreak at blasting development activity in underground Deep Mill Level Zone (DMLZ) PT Freeport Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2019, 279, 012001. [Google Scholar] [CrossRef]

- Catalan, A.; Onederra, I.; Chitombo, G. Evaluation of intensive preconditioning in block and panel caving-Part II, quantifying the effect on seismicity and draw rates. Min. Technol. 2017, 126, 221–239. [Google Scholar] [CrossRef]

- Els, F.; Jamasmie, C.; Stutt, A.; Leotaud, V.R.; Chen, J.; Venditti, B. Ranked: World’s 10 Biggest Underground Mines by Tonnes of Ore Milled. 2021. Available online: https://www.mining.com/featured-article/ranked-worlds-10-biggest-underground-mines-by-tonnes-of-ore-milled/ (accessed on 3 September 2022).

- Jacubec, J. Adressing the challenges and future of cave mining. SRK Consulting’s International Newsletter. 2018. Available online: https://www.caveminingforum.com/addressing-challenges-future-cave-mining/ (accessed on 15 September 2022).

- Fernberg, H. Mining in steep orebody. Mining Methods in Underground Mining; Atlas Copco: Nacka Municipality, Sweden, 2007; pp. 33–37. [Google Scholar]

- Peele, R. Mining Engineer’s Handbook, 3rd ed.; John Wiley & Sons: New York, NY, 1941. [Google Scholar]

- Banks, C. Relationships between Geology, Ore-Body Genesis, and Rock Mass Characteristics in Block Caving Mines; The University of British Colombia: Vancouver, BC, Canada, 2009. [Google Scholar]

- United States Geological Survey (USGS). El Teniente: Porphyry Copper (Cu-Mo) Deposit in Libertador General Bernardo O’Higgins, Chile. 2022. Available online: https://mrdata.usgs.gov/sir20105090z/show-sir20105090z.php?id=311 (accessed on 21 October 2022).

- Miller-Tait LPakalnis, R.; Poulin, R. UBC Mining Method Selection. Proc. Mine Planning and Equipment Selection; Balkema: Rotterdam, The Netherlands, 1995. [Google Scholar]

- Wagner, H.; Ladinig, T. Raise Caving Method for Mining an ore from an Ore Body, and a Mining Infrastructure, Monitoring System, Machinery, Control System and Data Medium Therefor. Classification: E21C41/22 92006.01—Methods of Underground Mining; Layouts Therefor for Ores, e.g. Mining Placers. World Intellectual Property Organization (WIPO). Applicant: Luossavaara Kiirunavaara AB. International Patent WO2021236000A1, 25 November 2021. [Google Scholar]

- Ladinig, T. Raise Caving-Cheaper and More Flexible Mining at Great Depths; Mining Engineering and Mineral Economics, Montan Universitat: Leoben, Austria, 2021. [Google Scholar]

- Ladinig, T.; Wagner, H. Raise Caving—A Hybrid Mining Method Addressing Current. Berg Huettenmaenn Mon. 2022, 167, 177–186. [Google Scholar] [CrossRef]

- Ladinig, T.; Wimmer, M.; Wagner, H. Raise caving: A novel mining method for deep mass mining. In Caving 2022: Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Australian Centre for Geomechanics, The University of Western Australia: Perth, Australia, 2022. [Google Scholar]

- Karlsson, M.; Ladinig, T.; Grynienko, M. Test mining with raise caving mining method: One-time chance to prove the concept? In Caving 2022: Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Australian Centre for Geomechanics, The University of Western Australia: Perth, Australia, 2022. [Google Scholar]

- Chacon, E.B. Hydraulic fracturing used to precondition ore and reduce fragment size for block caving. In MassMin; Instituto de Ingenieros de Chile: Santiago, Chile, 2004. [Google Scholar]

- Van As, A.; Jeffrey, R.; Chacon, E.; Barrera, V. Preconditioning by hydraulic fracturing for block caving in a moderately stressed naturally fractured orebody. In MassMin; Instituto de Ingenieros de Chile: Santiago, Chile, 2004. [Google Scholar]

- Rogers, S.E. Understanding hydraulic fracture geometry and interactions in pre-conditioning through DFN and numerical modeling. In Proceedings of the 45th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 26–29 June 2011. [Google Scholar]

- He, Q.S. Review of Hydraulic Fracturing for Preconditioning in Cave Mining. Rock Mech. Rock Eng. 2016, 49, 4893–4910. [Google Scholar] [CrossRef]

- Catalan, A.; Dunstan, G.; Morgan, M.; Green, S.; Jorquera, M.; Thornhill, T.; Onederra, I.; Chitombo, G. How Can an Intensive Preconditioning Concept Be Implemented at Mass Mining Method? Application to Cadia East Panel Caving Project. In Proceedings of the 6th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 23–26 June 2012. [Google Scholar]

- Flores, G.; Catalan, A. A transition from a large open pit into a novel “macroblock variant” block caving geometry at Chuquicamata mine, Codelco Chile. J. Rock Mech. Geotech. Eng. 2019, 11, 549–561. [Google Scholar] [CrossRef]

- Fiscor, S. Problem solvers overcome adversity with advances in equipment and technology: Tracking 150 Years of Mining Engineering. Eng. Min. J. 2016, 217, 110. [Google Scholar]

- Rafiee, R.; Ataei, M.; Khalookakaie, R.; Jalali, S.E.; Sereshki, F.; Norrozi, M. Numerical modeling of influence parameters in cavability of rock mass in block caving mines. Int. J. Rock Mech. Min. Sci. 2018, 105, 22–27. [Google Scholar] [CrossRef]

- Bahrani, N.; Kaiser, K.; Corkum, A. Suggested methods for estimation of confined strength of heterogeneous (defected) rocks caving operation in a complex geological setting in Quebec, Canada. In Caving 2022; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2018. [Google Scholar]

- Sainsbury, D.; Carrol, D. Analysis of Caving Behavior Using a Synthetic Rock Mass—Ubiquitous Joint Rock Mass Modelling Technique. In SHIRMS 2018; Australian Centre for Geomechanics: Perth, Australia, 2018. [Google Scholar]

- Cumming-Potvin, D.W. A re-evaluation of the conceptual model of caving mechanics. In Caving 2018; Australian Center for Geomechanics: Perth, Australia, 2018; pp. 179–190. [Google Scholar]

- Cumming-Potvin, D.W.-C. Numerical simulation of a centrifuge model of caving. In Caving 2018; Australian Center for Geomechanics: Perth, Australia, 2018; pp. 191–206. [Google Scholar]

- Fuenzalida, M. REBOP-FLAC3D hybrid approach to cave modelling. In Caving 2018; Australian Center for Geomechanics: Perth, Australia, 2018; p. 297. [Google Scholar]

- Hebert, Y.; Sharrock, G. Three-dimensional simulation of cave initiation, propagation and surface subsidence using a coupled finite difference-cellular automata solusion. In Caving; Australian Center for Geomechanics: Perth, Australia, 2022; pp. 151–166. [Google Scholar]

- Gomez, R.; Castro, R. Stress modelling using cellular automata for block caving applications. Int. J. Rock Mech. Min. Sci. 2022, 154, 105124. [Google Scholar] [CrossRef]

- Arndt, A.B.; Bui, T.; Diering, T.; Austen, I.; Hocking, R. Integrated simulation and optimation tools for production scheduling using finite element analysis caving geomechanics simulation coupled with 3D cellular automata. In Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Center for Geomechanics: Perth, Australia, 2018; pp. 247–260. [Google Scholar]

- Nadolski, S.; Klein, B.; Hart, C.J.R.; Moss, A.; Elmo, D. An approach to evaluating block and panel cave projects for sensor-based sorting applications. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Center for Geomechanics: Perth, Australia, 2018; pp. 133–140. [Google Scholar]

- Henning, M.G. Grade control and segregation at new Gold’s new Afton block cave operation, Kamloops, British Colombia. In Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2022; pp. 141–150. [Google Scholar]

- Moss, A.; Klein, B.; Nadolski, S. Cave to mill: Improving valeu of caving operations. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 119–132. [Google Scholar]

- Hidayat, W.; Sahara, D.; Widiyantoro, S.; Suharsono, S.; Wattimena, R.K.; Melati, S.; Putra, I.R.A.; Prahastudhi, S.; Sitorus, E.; Riyanto, E. Testing the Utilization of a Seismic Network Outside the Main Mining Facility Area for Expanding the Microseismic Monitoring Coverage in a Deep Block Caving. Appl. Sci. 2022, 12, 7265. [Google Scholar] [CrossRef]

- Dong, L.; Zou, W.; Li, X.; Shu, W.; Wang, Z. Collaborative localization method using analytical and iterative solutions for microseismic/acoustic emission sources in the rockmass structure for underground mining. Eng. Fract. Mech. 2019, 210, 95–112. [Google Scholar] [CrossRef]

- Ross, I.T. Bencmarking and its application for caving projects. In Caving 2018: Proceedings of the Foutrh International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Vancouver, BC, Canada, 2018; pp. 473–486. [Google Scholar]

- Thompson, R.; Malekzehtab, H. Underground roadway design consideration for efficient autonomous hauling. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 337–350. [Google Scholar]

- Paredes, P.; Leano, T.; Jauriat, L. Chuquicamata underground mine design: The simplification of the ore handling system of Lift 1. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 385–398. [Google Scholar]

- Rogers, S.; Elmo, D.; Webb, G.; Catalan, A. Volumetric Fracture Intensity Measurement for Improved Rock Mass Characterisation and Fragmentation Assessment in Block Caving Operations. Rock Mech. Rock Eng. 2015, 48, 633–649. [Google Scholar] [CrossRef]

- Liu, Y.; Nadolski, D.; Elmo, D.; Klein, B.; Scoble, M. Use of Digital Imaging Processing Techniques to Characterise Block Caving Secondary Fragmentation and Implications for a Proposed Cave-to-Mill Approach. In Proceedings of the 49th U.S. Rock Mechanics/Geomechanics Symposium, American Rock Mechanics Association (ARMA), San Francisco, CA, USA, 1–25 June 2015. [Google Scholar]

- Castro, R.; Cuello, D. Hang-up analysis and modeling for Cadia East PC1-S1 and PC2-S1. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 233–246. [Google Scholar]

- Dorador, L.; Eberhardt, E.; Elmo, D. Influence of rock mass veining and non-persistent joints on secondary fragmentation during block caving. In Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018. [Google Scholar]

- Parsons, J.; Hamilton, D.B.; Ludwicki, C. Non-vertical cave and dilution modeling at New Gold’s New Afton Mine. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 323–336. [Google Scholar]

- Sánchez, V.; Castro, R.L.; Palma, S. Gravity flow characterization of fine granular material for Block Caving. Int. J. Rock Mech. Min. Sci. 2019, 114, 24–32. [Google Scholar] [CrossRef]

- Castro, R.; Arancibia, L.; Gomez, R. Quantifying fines migration in block caving through 3D experiments. Int. J. Rock Mech. Min. Sci. 2022, 151, 105033. [Google Scholar] [CrossRef]

- Diering, T.; Ngidi, S.N.; Bezuidenhout, J.J.; Paetzold, H.D. Palabora Lift 1 block cave: Understanding the grade behaviour. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018. [Google Scholar]

- Rumbiak, U.; Laim, C.K.; Al Furqan, R.; Rosana, M.; Yuningsih, E.; Tsikoras, B.; Ifandi, E.; Malik Chen, H. Geology, alteration geochemistry, and exploration geochemical mapping of the Erstberg Cu-Au-Mo district in Papua, Indonesia. J. Geochem. Explor. 2022, 232, 106889. [Google Scholar] [CrossRef]

- PT Freeport Indonesia. Block Cave Underground Mine; PT Freeport Indonesia: South Jakarta, Indonesia, 2020. [Google Scholar]

- Sahupala, H.A.; Szwedzicki, T.; Prasetyo, R. Diameter of a draw zone-a case study from a block caving mine, Deep ore Zone, PT Freeport Indonesia. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 633–644. [Google Scholar]

- Ruswanto, M.F.; Fatimah, M.R.; Yuningsih, E.T.; Purwariswanto, B.A. Minegrafi batuan Penyusun Tambang Deep Mill level Zone (DMLZ) PT Freeport Indonesia. Bull. Sci. Contrib. Geol. 2017, 15, 173–180. [Google Scholar]

- Brannon, C.; Beard, D.; Pascoe, N.; Priatna, A. Development of and production update for the Grasberg Block Cave mine–PT Freeport Indonesia. In MassMin 2020: Proceedings of the Eighth International Conference & Exhibition on Mass Mining-University of Chile, Virtual, 4–8 October 2020; University of Chile: Santiago, Chile, 2020; pp. 747–760. [Google Scholar]

- Beard, D.; Brannon, C. Grasberg Block Cave mine: Cave planning and undercut sequencing. In Caving 2018: Proceeding of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 15–17 October 2018; Australian Center for Geomechanics: Perth, Australia, 2018; pp. 373–384. [Google Scholar]

- De Beer, W.; Jalbout, A.; Riyanto, E.; Ginting ASullivan, M.; Colllins, D.S. The design, optimisation, and use of the seismic system at the deep and high-stress block cave Deep Mill Level Zone mine. Undergr. Min. Technol. 2017, 2017, 233–246. [Google Scholar]

- Widijanto, E.; Wattimena, R.K.; Kramadibrata, S.; Rai, M.A. Geometry effects on Slope Stability at Grasberg Mine Through the Transsition from Open Pit to Underground Block Cave Mining. Electron. J. Geotech. Eng. 2017, 22, 1733–1745. [Google Scholar]

- Meinert, L.D.; Hefton, K.K.; Mayes, D.; Tasiran, I. Geology, zonation, and fluid evolution of the Big Gossan Cu-Au skarn deposit, Ertsberg district, Irian Jaya. Econ. Geol. 1997, 92, 509–534. [Google Scholar] [CrossRef]

- Onederra, I.; Chitombo, G. Design methodology for underground ring blasting. Min. Technol. 2007, 116, 180–195. [Google Scholar] [CrossRef]

- Wattimena, R.K.; Sulistianto, B.; Risono; Matsui, K. A semi-caving method applied at level 600 Ciurug vein, Pongkor underground gold mine, PT Aneka Tambang Tbk. In Mine Planning and Equipment Selections; Taylor & Francis Group: London, UK, 2004. [Google Scholar]

- Syafrizal, I.A.; Watanabe, K. Origin of Ore-forming Fluids Responsible for Gold Mineralization of the Pongkor Au-Ag Deposit, West Java, Indonesia: Evidence from Mineralogic, Fluid Inclusion Microthermometry and Stable Isotope Study of the Ciurug–Cikoret Veins. Resour. Geol. 2007, 57, 136–148. [Google Scholar]

- Syafrizal, I.A.; Motomura, Y.; Watanabe, K. Characteristics of gold mineralization at the Ciurug vein, Pongkor gold-silver deposit, West Java, Indonesia. Resour. Geol. 2005, 55, 225–238. [Google Scholar] [CrossRef]

- Carlile, J.C.; Davey, G.R.; Kadir, I.; Langmead, R.; Rafferty, W.J. Discovery and exploration of the Gosowong epithermal gold deposit, Halmahera, Indonesia. J. Geochem. Explor. 1998, 60, 207–227. [Google Scholar] [CrossRef]

- Dilles, J.H.; John, D.A. Porphyry and Epithermal Mineral Deposits. In Encyclopedia of Geology, 2nd ed.; Alderton, D., Elias, S.A., Eds.; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Hoschke, T.G. Geophysical Signatures of Copper-Gold Porphyry and Epithermal Gold Deposits, and Implications for Exploration. Ph.D. Thesis, University of Tasmania, Hobart, Australia, 2011. [Google Scholar]

- Burrows, D.R.; Rennison, M.; Burt., D.; Davies, D. The Onto Cu-Au Discovery, Eastern Sumbawa, Indonesia: A Large, Middle. Soc. Econ. Geol. 2020, 115, 1385–1412. [Google Scholar] [CrossRef]

- PT Bumi Resources Mineral. PT Gorontalo Minerals (Copper & Gold). PT Bumi Resources Minerals Tbk. 2020. Available online: https://www.bumiresourcesminerals.com/pt-gorontalo-minerals-copper-gold/ (accessed on 3 September 2022).

- Merdeka Copper Gold. wetar Porhyry Project. 2019. Available online: https://merdekacoppergold.com/en/operations/tujuh-bukit-porphyry-project/ (accessed on 1 September 2022).

- Sutarto, I.A.; Harjoko ASetijadji, L.D.; Meyer, F.M.; Sindern, S. Mineralization style of the Randu Kuning porphyry Cu-Au and intermediate sulphidation epithermal Au-base metals deposits at Selogiri area, Central Java Indonesia. AIP Conf. Proc. 2020, 2245, 080006. [Google Scholar]

- Hu, P.; Cao, L.; Zhang, H.; Yang, Q.; Armin, T.; Cheng, X. Late miocene adakites with the Tangse porphyry Cu-Mo deposit within the Sunda arch, North Sumatera, Indonesia. Ore Geol. Rev. 2019, 111, 102983. [Google Scholar] [CrossRef]

- Li, X.-Y.; Zhang, Z.-W.; Wu, C.-Q.; Xu, J.-H.; Jin, Z.-R. Geology and geochemistry of Gunung Subang gold deposit, Tanggeung, Cianjur, West Java, Indonesia. Ore Geol. Rev. 2019, 113, 103060. [Google Scholar] [CrossRef]

- McCarrol, R.J.; Graham, I.T.; Fountain, R.; Privat, K.; Woodhead, J. The Ojolali region, Sumatera, Indonesia: Epithermal gold-silver mineralisation within the Sunda Arch. Gondwana Res. 2014, 26, 218–240. [Google Scholar] [CrossRef]

- Mulja, T.; Heriawan, M.N.; Supomo, B.D.H. The Miwah high-sulphidation epithermal Au-Ag deposit, Aceh, Indonesia: Geology and spatial relationships of gold with associated metals and structures. Ore Geol. Rev. 2020, 123, 103564. [Google Scholar] [CrossRef]

- PT Merdeka Copper Gold, Tbk. Quarterly Report: March 2020; Merdeka Copper Gold: Jakarta, Indonesia, 2020. [Google Scholar]

- Walker, S. Block Caving: Mining Specialization. Eng. Min. J. 2014, 215, 32. [Google Scholar]

- Mining Technology. Ridgeway Gold and Copper Mine, New South Wales. 2008. Available online: https://www.mining-technology.com/projects/cadiavalley/ (accessed on 23 March 2022).

- Mining Weekly. Oz Minerals gives the go-ahead at Carrapateena. Mining Weekly, Creamer Media’s. 2022. Available online: https://www.miningweekly.com/article/oz-minerals-gives-the-go-ahead-at-carrapateena-2021-01-29/rep_id:3650/ (accessed on 17 September 2022).

- Chung, J.; Asad, M.W.A.; Topal, E. Timing of transition from open-pit to underground mining: A simultaneous optimisation model for open-pit and underground mine production schedules. Resour. Policy 2022, 77, 102632. [Google Scholar] [CrossRef]

- Tegachouang, N.C.; Bowa, V.M.; Li, X.; Luo, Y.; Gong, W. Study of the Influence of Block Caving Underground Mining on the Stability of the Overlying Open Pit Mine. Geotech. Geol. Eng. 2022, 40, 165–173. [Google Scholar] [CrossRef]

- Ding, K.; Li, H. Monitoring analysis and environmental assessment of mine subsidence based on surface displacement monitoring. J. Comput. Methods Sci. Eng. 2022, 22, 399–410. [Google Scholar] [CrossRef]

- Xia, Z.Y.; Tan, Z.Y.; Zhang, L. Instability Mechanism of Extraction Structure in Whole Life Cycle in Block Caving Mine. Geofluids 2021, 2021, 9932932. [Google Scholar] [CrossRef]

- Vallejos, J.; Basaure, K.; Palma, S.; Castro, R.L. Methodology for evaluation of mud rush risk in block caving mining. J. S. Afr. Inst. Min. Metall. 2017, 117, 491–497. [Google Scholar] [CrossRef]

- Ajayi, K.; Tukkaraja, P.; Shahbazi, K.; Katzenstein, K.; Loring, D. Computational fluid dynamics study of radon gas migration in a block caving mine. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015; pp. 341–348. [Google Scholar]

- Erb, M.; Mucek, A.E.; Robinson, K. Exploring a social geology approach in eastern Indonesia: What are mining territories? Extr. Ind. Soc. 2021, 8, 89–103. [Google Scholar] [CrossRef]

- Mata-Perello, J.M.; Mata-Lleonart, R.; Vintro-Sanchez, C.; Restrepo-Martinez, C. Social Geology: A new perspective on geology. Dyna 2012, 79, 158–166. [Google Scholar]

- Stewart, I.S.; Gill, J.C. Social geology—Integrating sustainability concepts into Earth sciences. Proc. Geol. Assoc. 2017, 128, 165–172. [Google Scholar] [CrossRef] [Green Version]

- Donaldson, S.N.; Harney, W.; Cox, T. Operational and real-time LHD dispatch at Rio Tinto’s Argyle Diamond Mine. In MassMin 2020: Proceedings of the Eighth International Conference & Exhibition on Mass Mining, Santiago, Chile, 9–12 December 2020; University of Chile: Santiago, Chile, 2020; pp. 693–702. [Google Scholar]

- Fernandez, F.; Evans, P.; Gelosn, R. Design and implementation of a damage assessment system at Argyle Diamond’s block cave project. In Caving 2010; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2010. [Google Scholar]

- Glesson, D. OZ Minerals eyes up block cave opportunities at Carrapateena underground mine. Available online: https://im-mining.com/2020/06/23/oz-minerals-eyes-block-cave-opportunities-carrapateena-underground-mine/ (accessed on 5 September 2022).

- Pitcher, A.; Hocking, R.J. Assessing the risk of a sublevel cave–block cave transition using dynamic decision tree analysis overlain with Monte Carlo analysis. In Caving 2022, Proceedings of the Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Australian Centre for Geomechanics: Perth, Australia, 2022; pp. 815–824. [Google Scholar]

- Poulter, M.; Ormerod, T.; Balog, G.; Cox, D. Geotechnical monitoring of the Carrapateena cave. In Caving 2022, Proceedings of the Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2022. [Google Scholar]

- Tukker, H.; Holder, A.; Swarts, B.; van Strijp, T.; Grobler, E. The CCUT block cave design for Cullinan Diamond Mine. J. S. Afr. Inst. Min. Metall. 2016, 116, 715. [Google Scholar] [CrossRef] [Green Version]

- Brzovic, A. Characterisation of Primary Copper Ore for Block Caving at The El Teniente Mine, Chile; Curtin University of Technology: Perth, Australia, 2010. [Google Scholar]

- Sieber, M.J.; Brink, F.J.; Leys, C.; King, L.; Henley, R.W. Prograde and retrograde metasomatic reactions in mineralised magnesium-silicate skarn in the Cu-Au Ertsberg East Skarn System, Ertsberg, Papua Province, Indonesia. Ore Geol. Rev. 2020, 125, 103697. [Google Scholar] [CrossRef]

- Mernagh, T.; Leys, C.; Henley, R.W. Fluid inclusion systematics in porphyry copper deposits: The super-giant Grasberg deposit, Indonesia, as a case study. Ore Geol. Rev. 2020, 123, 103570. [Google Scholar] [CrossRef]

- Debswana. Jwaneng Mine Goes Underground. 2022. Available online: http://www.debswana.com/Our-Projects/Pages/Jwaneng_underground.aspx (accessed on 21 April 2022).

- Dunn, M.J.; Harris, R.O.; Boitshepo, B.; Chiwaye, H.T. Assessing the stress field for the Jwaneng underground project. In Caving 2022, Proceedings of the Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2022. [Google Scholar]

- Stegman, C.L.; Togtokhbayar, O.; Herselman, S.; Altankhuu, B. Oyu Tolgoi: Engineering a Mongolian caving dynasty. In Caving 2022, Proceedings of the Fifth International Conference on Block and Sublevel Caving, Adelaide, Australia, 30 August–1 September 2022; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2022. [Google Scholar]

- Philex Mining Corporation n.d. Philex Mining. A Brave New Day, 2020 Annual and Sustainability Report. 2020. Available online: http://www.philexmining.com.ph/zimbabwe/ (accessed on 23 February 2022).

- Matayev, A.; Kainazarova, A.; Arystan, I.; Abeuov, Y.; Kainazarov, A.; Baizbayev, M.; Demin, V.; Sultanov, M. Research into rock mass geomechanical situation in the zone of stope operations influence at the 10th Anniversary of Kazakhstan’s Independence mine. Min. Miner. Depos. 2021, 15, 103–111. [Google Scholar] [CrossRef]

- Ernowo, E.; Meyer, F.M.; Idrus, A. Hydrothermal alteration and gold mineralization of the Awak Mas metasedimentary rock-hosted gold deposit, Sulawesi, Indonesia. Ore Geol. 2019, 113, 103083. [Google Scholar] [CrossRef]

- Meldrum, S.J.; Aquino, R.S.; Gonzales, R.I.; Burke, R.J.; Suyadi, A.; Irianto, B.; Clarke, D.S. The Batu Hijau porphyry copper-gold deposit, Sumbawa Island, Indonesia. J. Geochem. Explor. 1994, 50, 203–220. [Google Scholar] [CrossRef]

- Idrus, A.; Kolb, J.; Meyer, F.M. Chemical Composition of Rock-Forming Minerals in Copper–Gold-Bearing Tonalite Porphyries at the Batu Hijau Deposit, Sumbawa Island, Indonesia: Implications for Crystallization Conditions and Fluorine–Chlorine Fugacity. Resour. Geol. 2007, 57, 102–113. [Google Scholar] [CrossRef]

- Anjarwati, R.; Idrus, A.; Setijadji, L.D. Geology at Beruang Kanan, Central Kalimantan, Indonesia. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 212. [Google Scholar]

- Idrus AFadlin Prihatmoko, S.; Warmada, I.W.; Nur, I.; Meyer, F.M. The Metamorphic Rock-Hosted Gold Mineralization At Bombana, Southeast Ulawesi: A New Exploration Target In Indonesia (Mineralisasi Emas Pada Batuan Metamorf Di Bombana, Sulawesi Tenggara: Target Baru Eksplorasi Di Indonesia). Proc. Sulawesi Miner. Resour. 2011 Semin. MGEI-IAGI 2011, 22, 35–48. [Google Scholar]

- Basri; Sakakibara, M.; Sera, K. Current Mercury Exposure from Artisanal and Small-Scale Gold Mining in Bombana, Southeast Sulawesi, Indonesia—Future Significant Health Risks. Toxics 2017, 5, 7. [Google Scholar] [CrossRef] [PubMed]

- Lubis, H.; Prihatmoko, S.; James, L. Bulagidun prospect: A copper, gold and tourmaline bearing porphyry and breccia system in northern Sulawesi, Indonesia. J. Geochem. Explor. 1994, 50, 257–278. [Google Scholar] [CrossRef]

- Angeles, C.A.; Prohatmoko, S.; Walker, J.S. Geology and alteration-mineralization characteristic of the cibaliung epithermal gold deposit, Banten, Indonesia. Resour. Geol. 2002, 52, 329–339. [Google Scholar] [CrossRef]

- Ambarini, E.; Hirnawan, F.; Guntoro, D. Sistem stabilitas lubang bukaan pengembangan dengan menggunakan baut batuan (rockbolt) dan beton tembak (shortcrete) di blok Cikoneng PT Cibaliung Sumberdaya, Kab. Pandeglang, Prov. Banten. Pros. Tek. Pertamb. 2015, 6, 168–177. [Google Scholar]

- Rosana, M.F.; Matsueda, H. Cikidang hydrothermal gold deposit in wetern java, Indonesia. Resour. Geol. 2002, 52, 341–352. [Google Scholar] [CrossRef]

- Davies, A.G.; Cooke, D.R.; Gemmell, J.B.; van Leeuwen, T.; Cesare, P.; Hartshorn, G. Hydrothermal breccias and veins at the Kelian gold mine, Kalimantan, Indonesia: Genesis of a large epithermal gold deposit. Econ. Geol. 2008, 103, 717–757. [Google Scholar] [CrossRef]

- Febrian, I.; Wahyudin, A.; Gunadi, C.; Peterson, D.; Mah, P.; Pakalnis, R. Mining within a weak rock mass-Kencana Underground Mine case study-PT Nusa Halmahera Minerals (Newcrest Mining Ltd.), Indonesia. In Proceedings of the 1st Canada-US Rock Mechanics Symposium, Vancouver, BC, Canada, 27–31 May 2007. [Google Scholar]

- Van Leeuwen, T.M.; Taylor, R.; Coote, A.; Longstaffe, F.J. Porphyry molybdenum mineralization in a continental collision setting at Malala, northwest Sulawesi, Indonesia. J. Geochem. Explor. 1994, 50, 279–315. [Google Scholar] [CrossRef]

- Umar, T.W.; Maryanto, Y. Evaluating Stope Design Based on Equivalent Linear Overbreak/Slough (Elos) on Damar Vein Unit Gold Mining Toguraci Underground Mining. In Prosiding Teknik Pertambangan; Universitas Islam Bandung: Bandung, Indonesia, 2018. [Google Scholar]

- Harrison, R.L.; Maryono, A.; Norris, M.S.; Rohrlach, B.D.; Cooke, D.R.; Thompson, J.M.; Creaser, R.A.; Thiede, D.S. Geochronology of the tumpangpitu porphyry Au-Cu-Mo and high-sulfidation epithermal Au-Ag-Cu deposit: Evidence for pre- and postmineralization diatremes in the Tujuh Bukit District, Southeast Java, Indonesia. Econ. Geol. 2018, 113, 163–192. [Google Scholar] [CrossRef]

- Scotney, M.; Roberts, S.; Herrington, R.J.; Boyce, A.J.; Burgess, R. The development of volcanic hosted massive sulfide and barite-gold orebodies on Wetar Island, Indonesia. In Mineralium Deposita; Springer: Berlin/Heidelberg, Germany, 2005; Volume 40, pp. 76–79. [Google Scholar]

| Underground Method | Unsupported | Supported | Caving | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Factors | Shrinkage stoping | Sublevel stoping | Stope and pillar | Room and pillar | Cut and fill stoping | Square set stoping | Longwall | Sublevel caving | Block caving |

| Ore strength | Strong | Moderate/ strong | Moderate/strong | Moderate/ strong | Moderate/ strong | Weak | Any | Moderate/ strong | Weak/ moderate |

| Rock strength | Strong | Fairly strong | Moderate/strong | Moderate/ strong | Weak | Weak | Weak/moderate | Weak | Weak/ moderate |

| Deposit shape | Tabular/ lenticular | Tabular/ lenticular | Tabular/lenticular | Tabular | Tabular/ lenticular | Any | Tabular | Tabular/ massive | Tabular/ thick |

| Deposit dip | Fairly steep | Fairly steep | Low/moderate | Low/flat | Fairly steep | Any | Low/flat | Fairly steep | Fairly steep |

| Deposit size | Thin/ moderate | Thick/ moderate | Any | Large/thin | Thin/ moderate | Usually, small | Thin/wide | Large thick | Very thick |

| Ore grade | Fairly high | Moderate | Low/moderate | Moderate | Fairly high | High | Moderate | Moderate | Low |

| Ore uniformity | Uniform | Uniform | Variable | Uniform | Variable | Variable | Uniform | Moderate | Uniform |

| Depth | Shallow/ moderate | Moderate | Shallow/moderate | Shallow/ moderate | Moderate/deep | Deep | Moderate/ deep | Moderate | Moderate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melati, S.; Wattimena, R.K.; Sahara, D.P.; Syafrizal; Simangunsong, G.M.; Hidayat, W.; Riyanto, E.; Felisia, R.R.S. Block Caving Mining Method: Transformation and Its Potency in Indonesia. Energies 2023, 16, 9. https://doi.org/10.3390/en16010009

Melati S, Wattimena RK, Sahara DP, Syafrizal, Simangunsong GM, Hidayat W, Riyanto E, Felisia RRS. Block Caving Mining Method: Transformation and Its Potency in Indonesia. Energies. 2023; 16(1):9. https://doi.org/10.3390/en16010009

Chicago/Turabian StyleMelati, Sari, Ridho Kresna Wattimena, David Prambudi Sahara, Syafrizal, Ganda Marihot Simangunsong, Wahyu Hidayat, Erwin Riyanto, and Raden Roro Shinta Felisia. 2023. "Block Caving Mining Method: Transformation and Its Potency in Indonesia" Energies 16, no. 1: 9. https://doi.org/10.3390/en16010009

APA StyleMelati, S., Wattimena, R. K., Sahara, D. P., Syafrizal, Simangunsong, G. M., Hidayat, W., Riyanto, E., & Felisia, R. R. S. (2023). Block Caving Mining Method: Transformation and Its Potency in Indonesia. Energies, 16(1), 9. https://doi.org/10.3390/en16010009