Analysis of Core Losses in Transformer Working at Static Var Compensator

Abstract

:1. Introduction

2. Analysis of Magnetic Field and Core Losses

3. Numerical Model of Transformer Core and Winding

4. Results of 3D and 2D Analysis of Power Transformer

5. Conclusions

- The obtained results of core losses calculated using various methods showed an accuracy within a few percent of the results obtained from measurements of the real power transformer in the test field. The Transient 2D calculation method with the J-A core losses model and the Time-Harmonic 3D method with the Steinmetz model proved to be the best. It is supposed that in the case of the second method, such a good result is accidental because the 3D model did not consider the region of overlap; moreover, the hysteresis loop was also not included in the calculations. The important issue is that core loss values calculated using the Steinmetz model are subject to an error resulting from the need to extrapolate the magnetic permeability and iron losses characteristic in the saturation area.

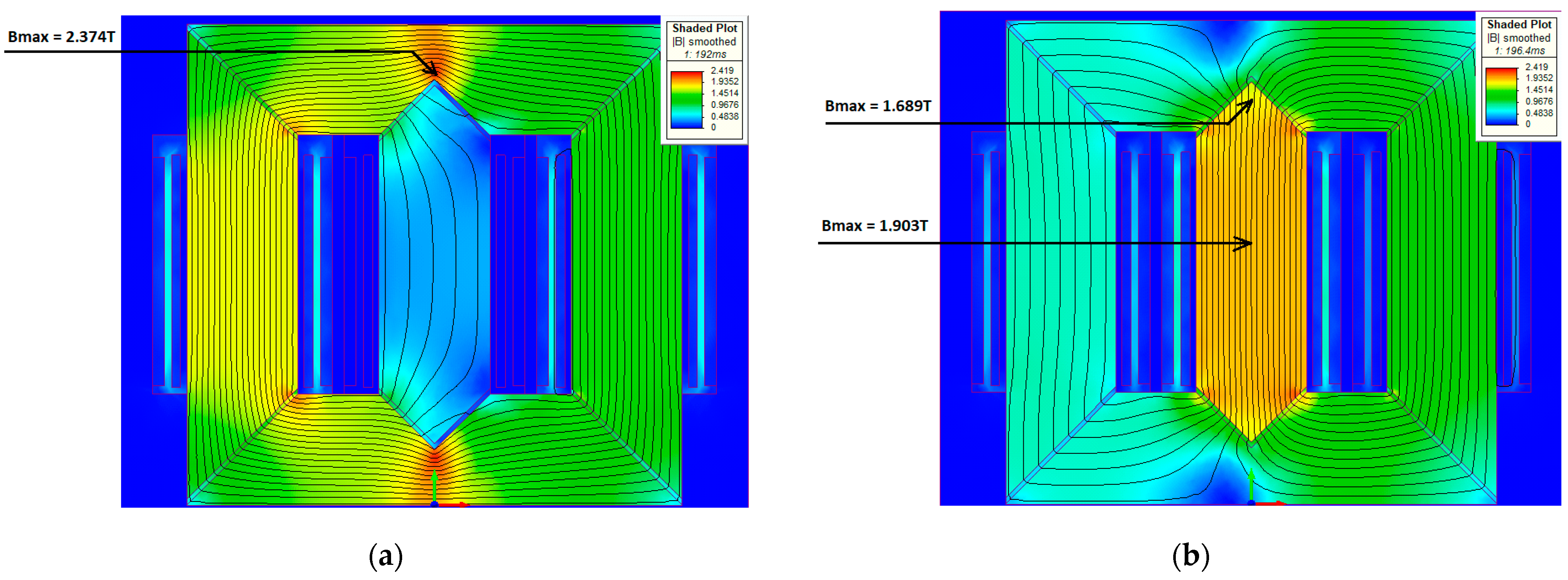

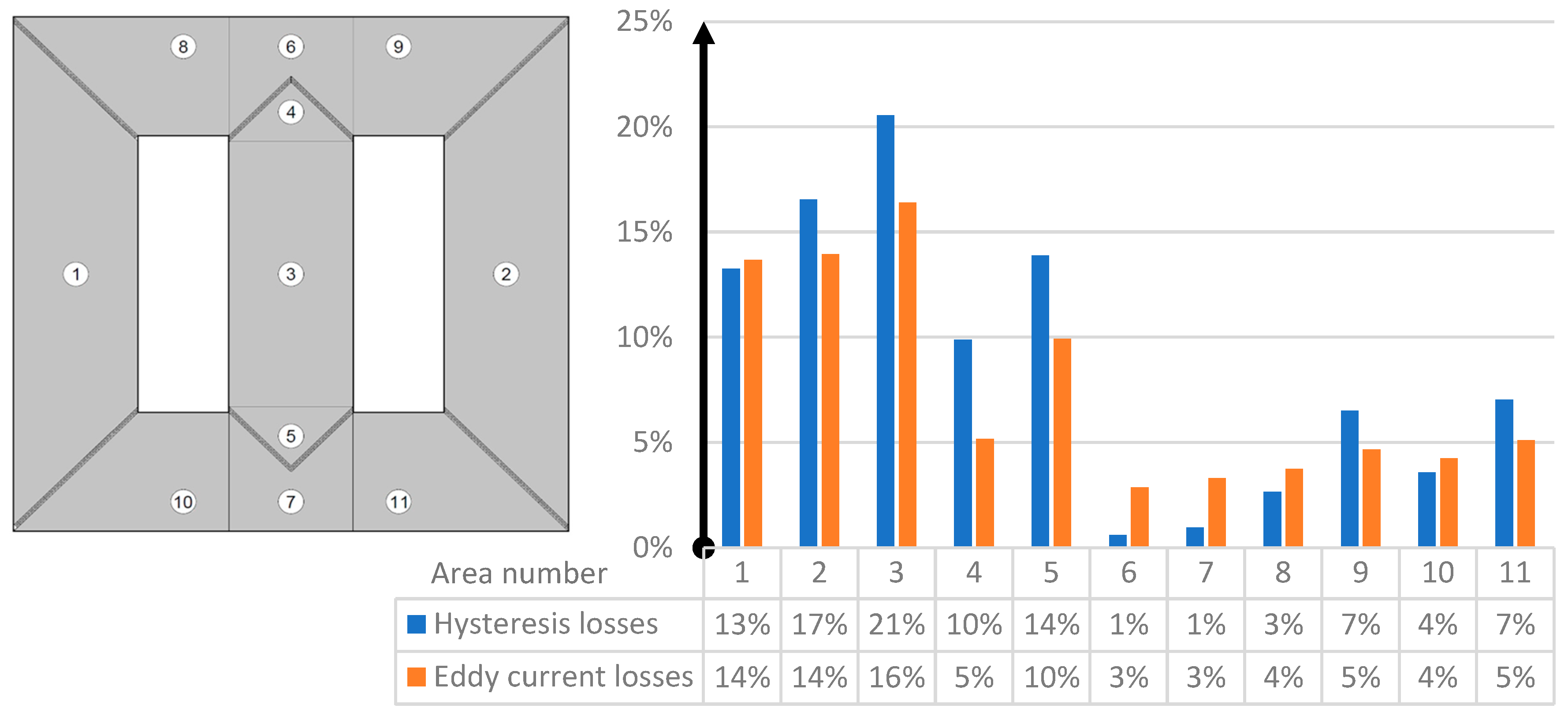

- The presented two-dimensional model of the power transformer was prepared considering the areas where the core sheets overlap. Thanks to this approach, it was possible to obtain a more realistic distribution of flux density in the core as well as the values of phase currents.

- The analysis of the core hot-spot area and the central point of the core limb showed that the capacitive load causes a significant increase in the value of magnetic flux density in the core limb compared to the value obtained in the no-load condition. The change in flux density was particularly noticeable in the limb part of the core. Considering the preparation of the power transformer design for operation in reactive power compensation stations, an increase in the magnetic flux density value results in the core entering the saturation state more quickly. In areas with the worst oil circulation, local overheating may occur, leading to a weakening of the insulation system. The consequence of this may be a significantly accelerated aging of the power transformer, resulting in increased operation costs for the entire power grid. Furthermore, the determination of the core area with the highest density of power losses makes it possible to accurately determine the installation of sensors monitoring the condition of the transformer.

- The paper discusses aspects related only to the core losses in the power transformer, including the effects of magnetic hysteresis, different calculation methods and the impact of capacitive load. The analysis of windings losses was not included. The operation of thyristors in SVC stations causes the appearance of higher current harmonics and increased load losses. The results presented in this paper can serve as a basis for further research on the topic of power transformer total losses in reactive power compensation systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dixon, J.; Rodriguez, J.; Moran, L.; Domke, R. Reactive Power Compensation Technologies: State-of-the-Art Review. Proc. IEEE 2005, 93, 2144–2164. [Google Scholar] [CrossRef]

- Xu, W.; Martinich, T.G.; Sawada, J.H.; Mansour, Y. Harmonics from SVC transformer saturation with direct current offset. IEEE Trans. Power Deliv. 1994, 9, 1502–1509. [Google Scholar] [CrossRef]

- Arslan, E.; Sakar, S.; Balci, M.E. On the No-Load Loss of Power Transformers under Voltages with Sub-harmonics. In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), Dubrovnik, Croatia, 13–16 May 2014. [Google Scholar] [CrossRef]

- Girgis, R.; teNyenhuis, G.E. Hydrogen Gas Generation Due to Moderately Overheated Transformer Cores. In Proceedings of the IEEE Power & Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009. [Google Scholar] [CrossRef]

- Girgis, R.; teNyenhuis, G.E. Characteristics of Inrush Current of Present Designs of Power Transformers. In Proceedings of the IEEE Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007. [Google Scholar] [CrossRef]

- Jain, S.A.; Pandya, A.A. Three Phase Power Transformer Modeling Using FEM for Accurate Prediction of Core and Winding Loss. Kalpa Publ. Eng. 2017, 1, 75–80. [Google Scholar]

- Krings, A.; Soulard, J. Overview and comparison of iron loss models for electrical machines. J. Electr. Eng. Elektrotech. Cas. 2010, 10, 162–169. [Google Scholar]

- Tekgun, B. Analysis, Measurement and Estimation of the Core Losses in Electrical Machines. Master’s Thesis, The University of Akron, Akron, OH, USA, 2016. [Google Scholar]

- Steinmetz, C.P. On the law of hysteresis. Trans. Am. Inst. Electr. Eng. 1984, 72, 197–221. [Google Scholar] [CrossRef]

- Jiles, D.; Atherton, D. Theory of ferromagnetic hysteresis. J. Magn. Magn. Mater. 1986, 61, 48–60. [Google Scholar] [CrossRef]

- Guerin, C.; Jacques, K.; Sabariego, R.V.; Dular, P.; Geuzaine, C.; Gyselinck, J. Using a vector Jiles-Atherton hysteresis model for isotropic magnetic materials with the FEM, Newton-Raphson method and relaxation procedure. Int. J. Numer. Model. Electron. Netw. Devices Fields 2016, 30, e2189. [Google Scholar] [CrossRef]

- Zakrzewski, K.; Tomczuk, B. Magnetic Field Analysis and Leakage Inductance Calculation in Current Transformers by Means of 3-D Integral Methods. IEEE Trans. Magn. 1996, 32, 1637–1640. [Google Scholar] [CrossRef]

- Constantin, D.; Nicolae, P.M.; Nitu, C.M. 3D Finite Element Analysis of a Three Phase Power Transformer. In Proceedings of the EuroCon 2013, Zagreb, Croatia, 1–4 July 2013. [Google Scholar] [CrossRef]

- Xing, J.; Dai, Z.; Song, Y.; Wang, D.; Yu, W.; Zhang, Y.F. Finite Element Calculation Loss Analysis of Large Transformers under the Influence of GIC. In Proceedings of the 10th International Conference on Power Science and Engineering, Istanbul, Turkey, 21–23 October 2021. [Google Scholar] [CrossRef]

- Mousavi, S.; Shamei, M.; Siadatan, A.; Nabizadeh, F.; Mirimani, S.H. Calculation of Power Transformer Losses by Finite Element Method. In Proceedings of the IEEE Electrical Power and Energy Conference (EPEC), Toronto, ON, Canada, 10–11 October 2018. [Google Scholar] [CrossRef]

- Nakata, T.; Takahasi, N.; Fujiwara, K.; Okada, Y. Improvements of the T-Omega method for 3-D Eddy current analysis. IEEE Trans. Magn. 1988, 24, 94–97. [Google Scholar] [CrossRef]

- Hussain, S.; Chang, K. Effects of Incorporating Hysteresis in the Simulation of Electromagnetic Devices, Siemens. Technical Report. 2019. Available online: https://www.researchgate.net/publication/325943830_Effects_of_Incorporating_Hysteresis_in_the_Simulation_of_Electromagnetic_Devices (accessed on 7 May 2023).

- Ciesielski, M.; Witczak, P. The Equivalence Conditions of 2D and 3D Models of Phase Shifting Transformer. In Proceedings of the 7th International Advanced Research Workshop on Transformers (ARWtr), Baiona, Spain, 2–26 October 2022. [Google Scholar] [CrossRef]

- Ciesielski, M.; Witczak, P. The use if FEM modeling to analyze phase shifting transformer in steady-state service conditions. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2022, 41, 1214–1222. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osinski, P.; Witczak, P. Analysis of Core Losses in Transformer Working at Static Var Compensator. Energies 2023, 16, 4584. https://doi.org/10.3390/en16124584

Osinski P, Witczak P. Analysis of Core Losses in Transformer Working at Static Var Compensator. Energies. 2023; 16(12):4584. https://doi.org/10.3390/en16124584

Chicago/Turabian StyleOsinski, Piotr, and Pawel Witczak. 2023. "Analysis of Core Losses in Transformer Working at Static Var Compensator" Energies 16, no. 12: 4584. https://doi.org/10.3390/en16124584

APA StyleOsinski, P., & Witczak, P. (2023). Analysis of Core Losses in Transformer Working at Static Var Compensator. Energies, 16(12), 4584. https://doi.org/10.3390/en16124584