Optimal Design of Marine Motors for Joint Efficiency and Economic Optimization

Abstract

:1. Introduction

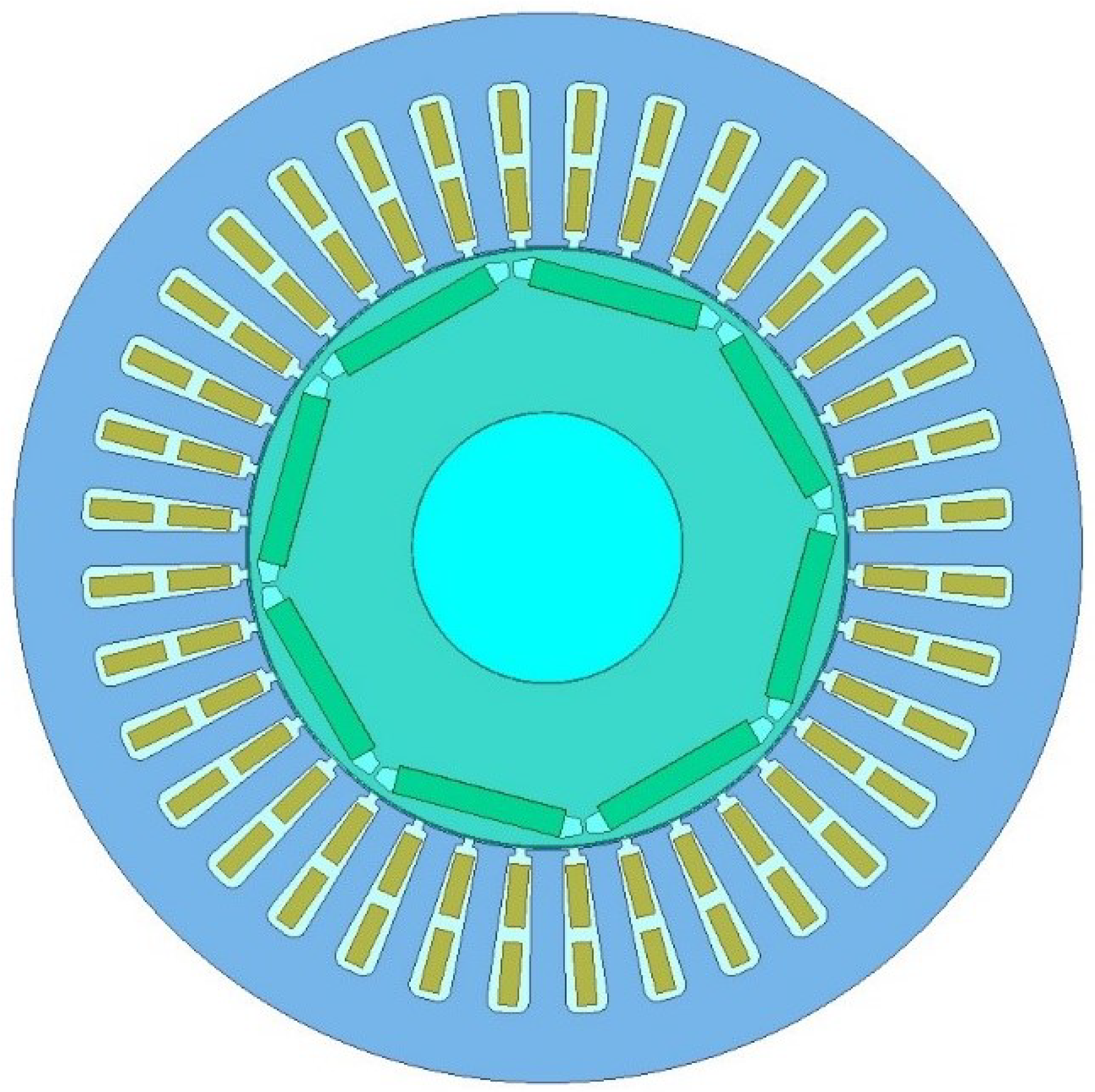

2. Finite Element Model

2.1. Motor Initial Parameter Design

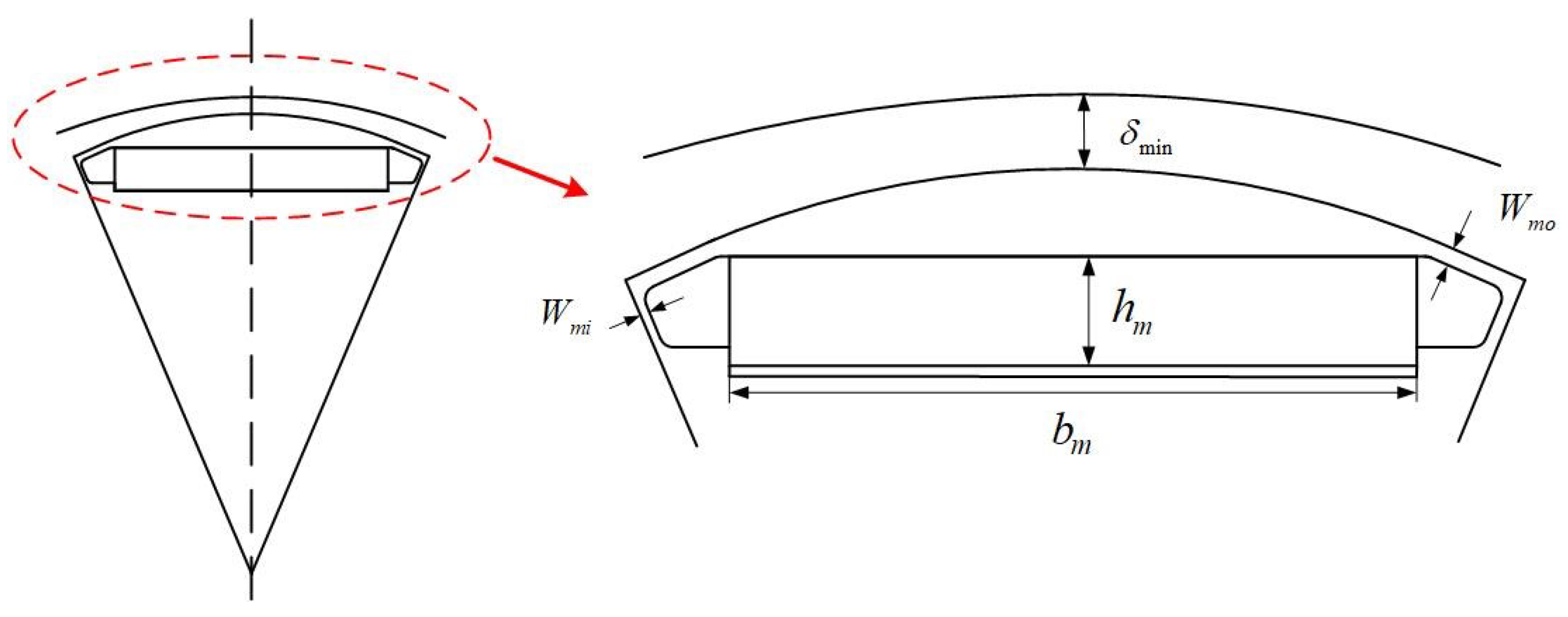

2.2. Rotor Eccentricity Design

3. Parameter Optimization Based on Hybrid Taguchi–Genetic Algorithm

3.1. The Principle of Hybrid Genetic Algorithm

3.2. Establishment of Optimization Model for Electric Motors

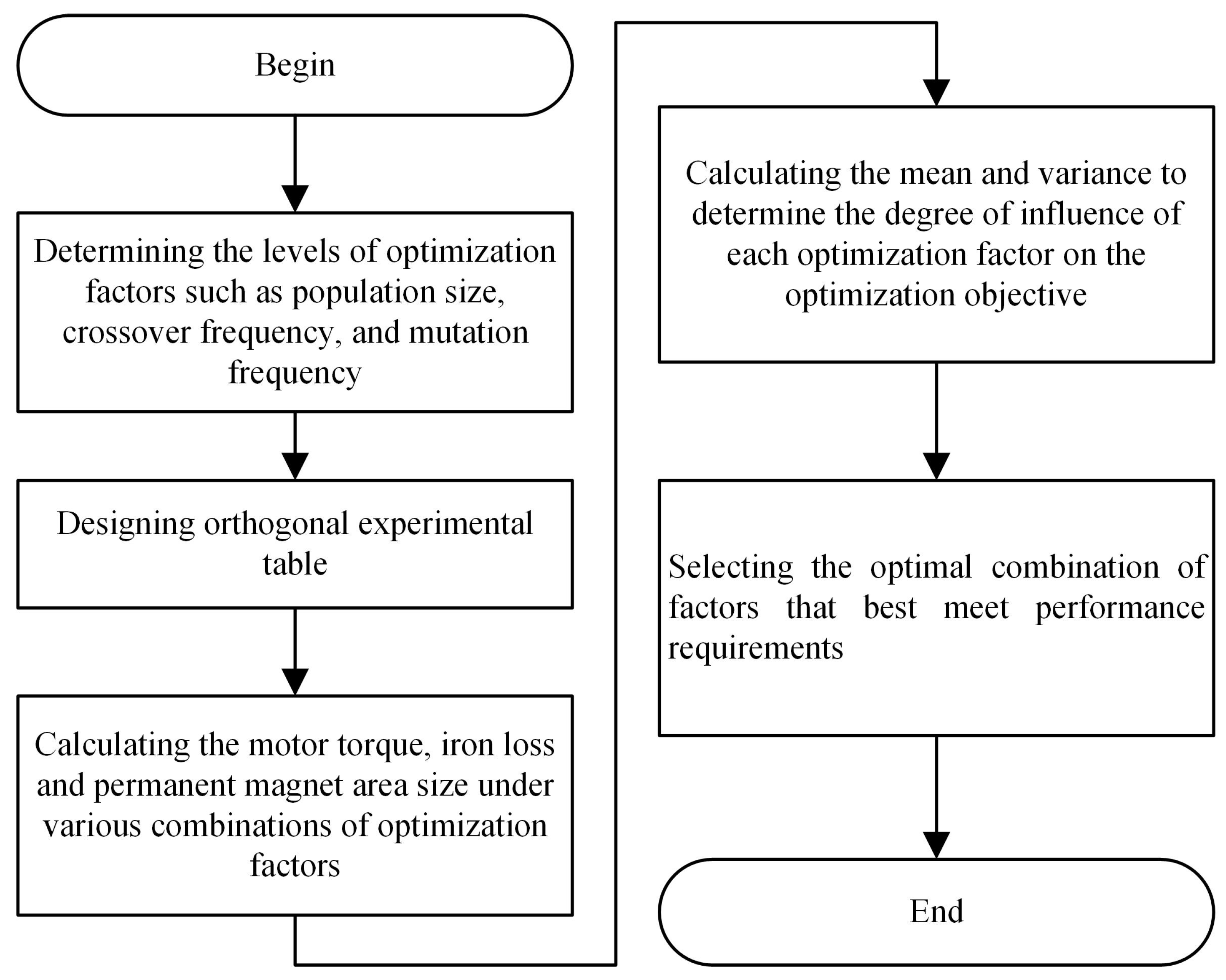

4. The Application of Taguchi Method

4.1. Determining GA Parameters Using the Taguchi Method

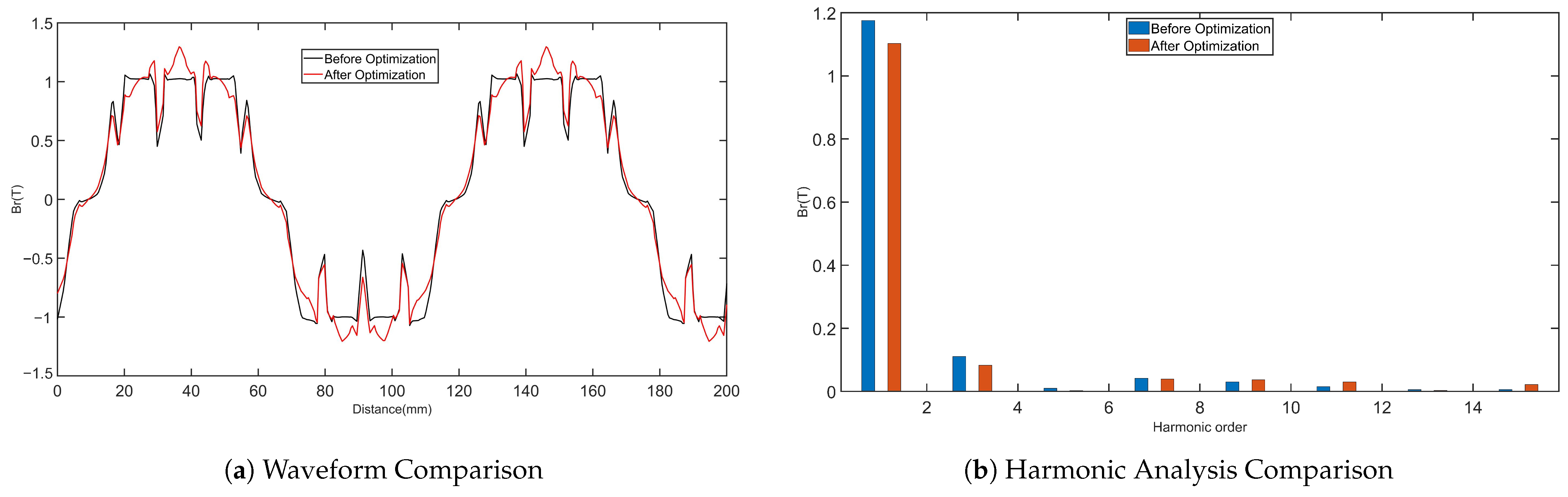

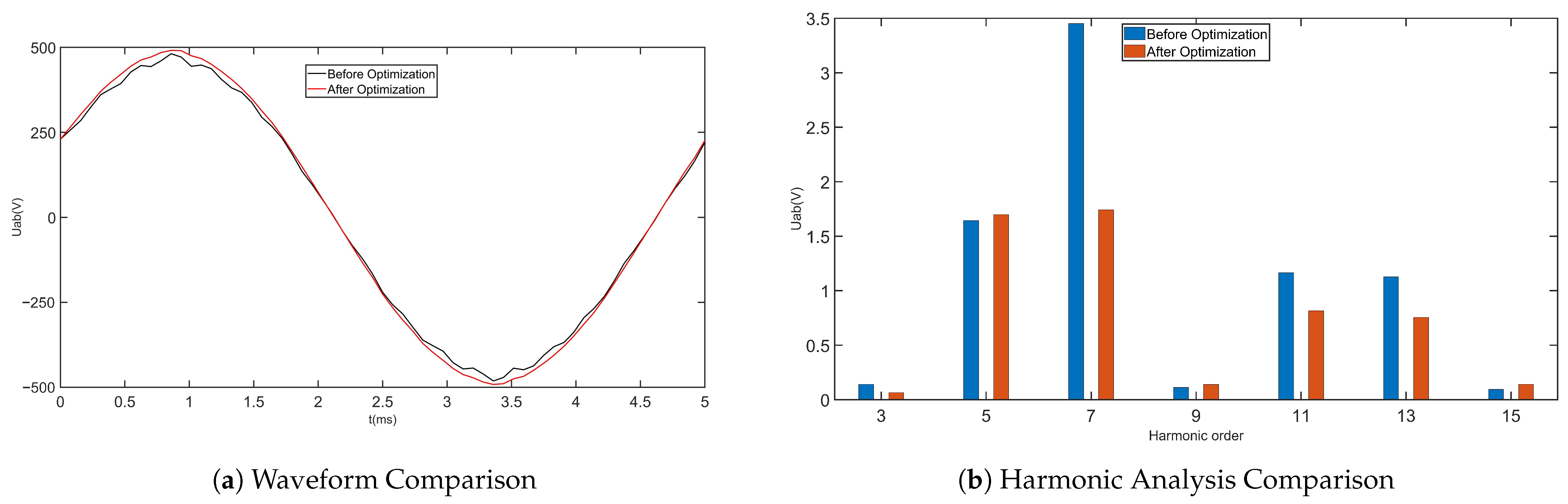

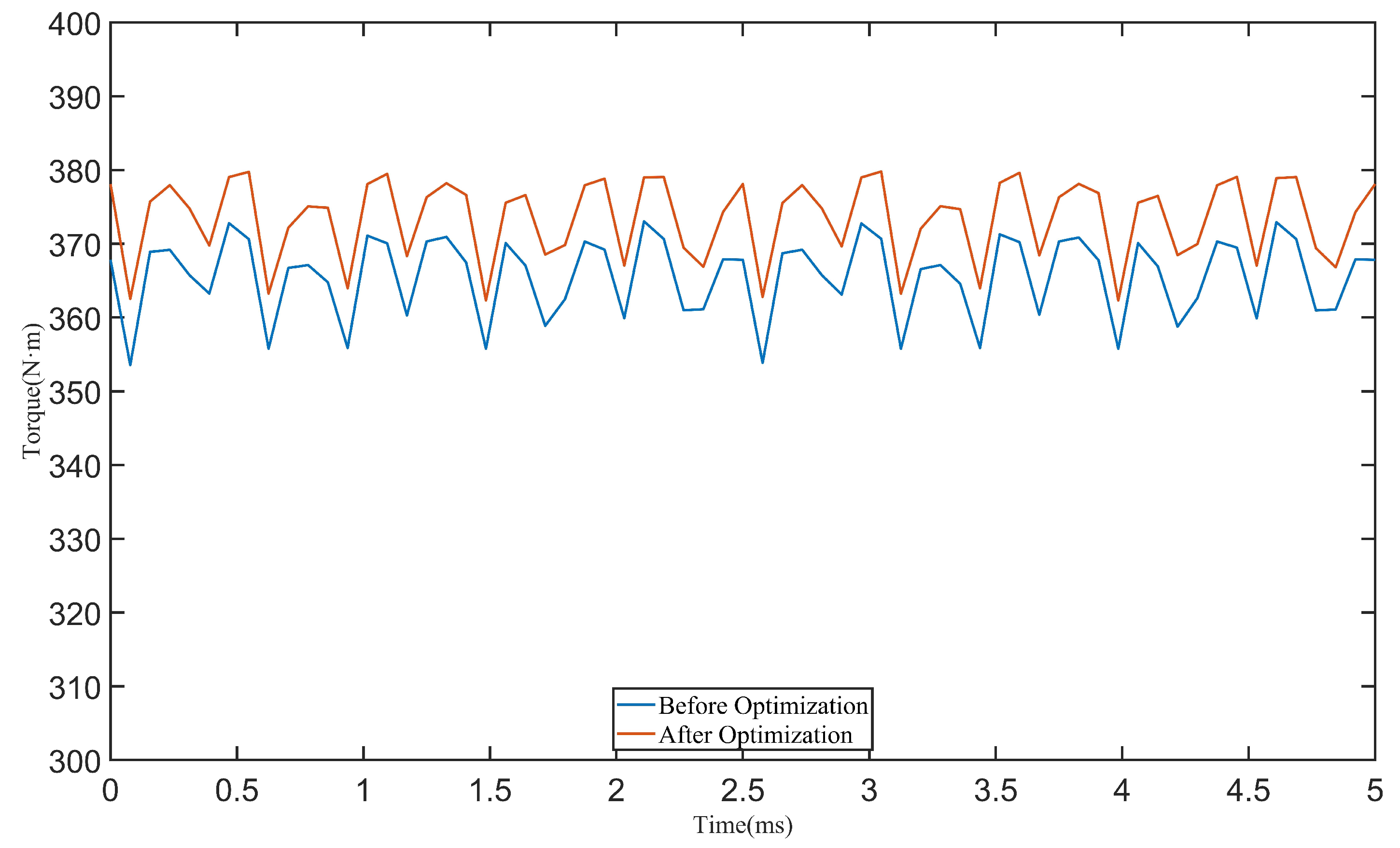

4.2. Optimization Result

5. Simulation and Performance Testing

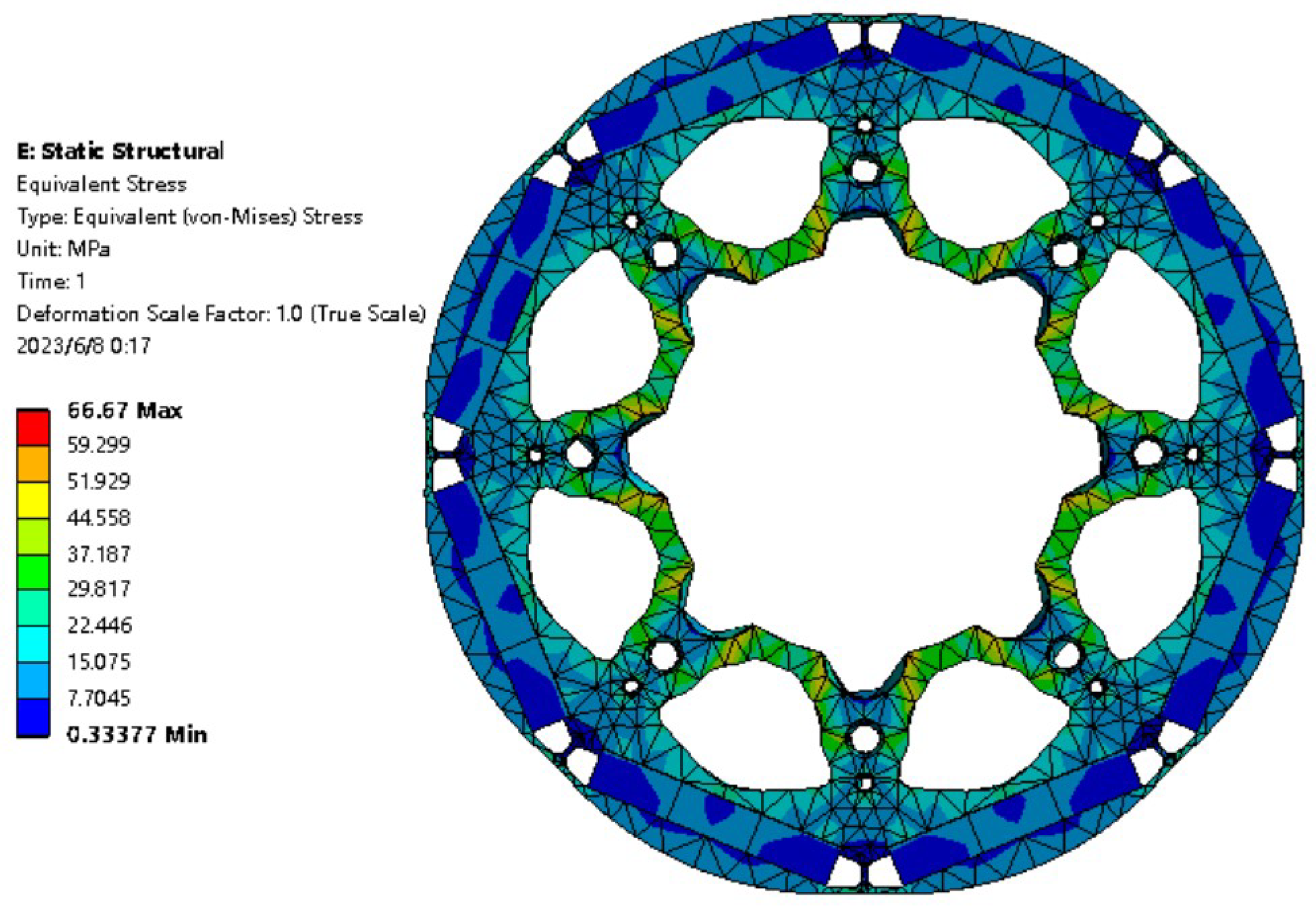

5.1. Design for Weight Reduction in Motors

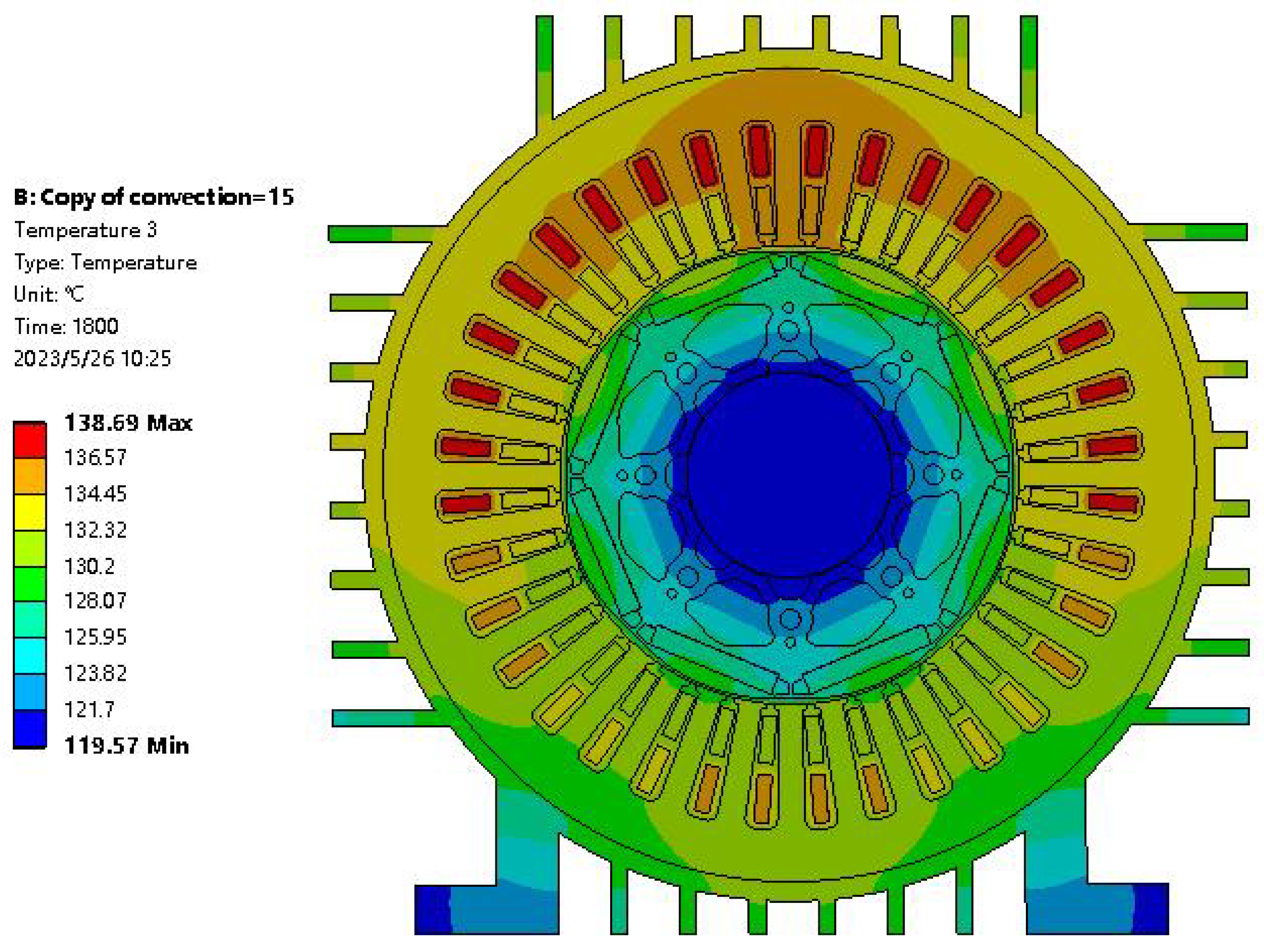

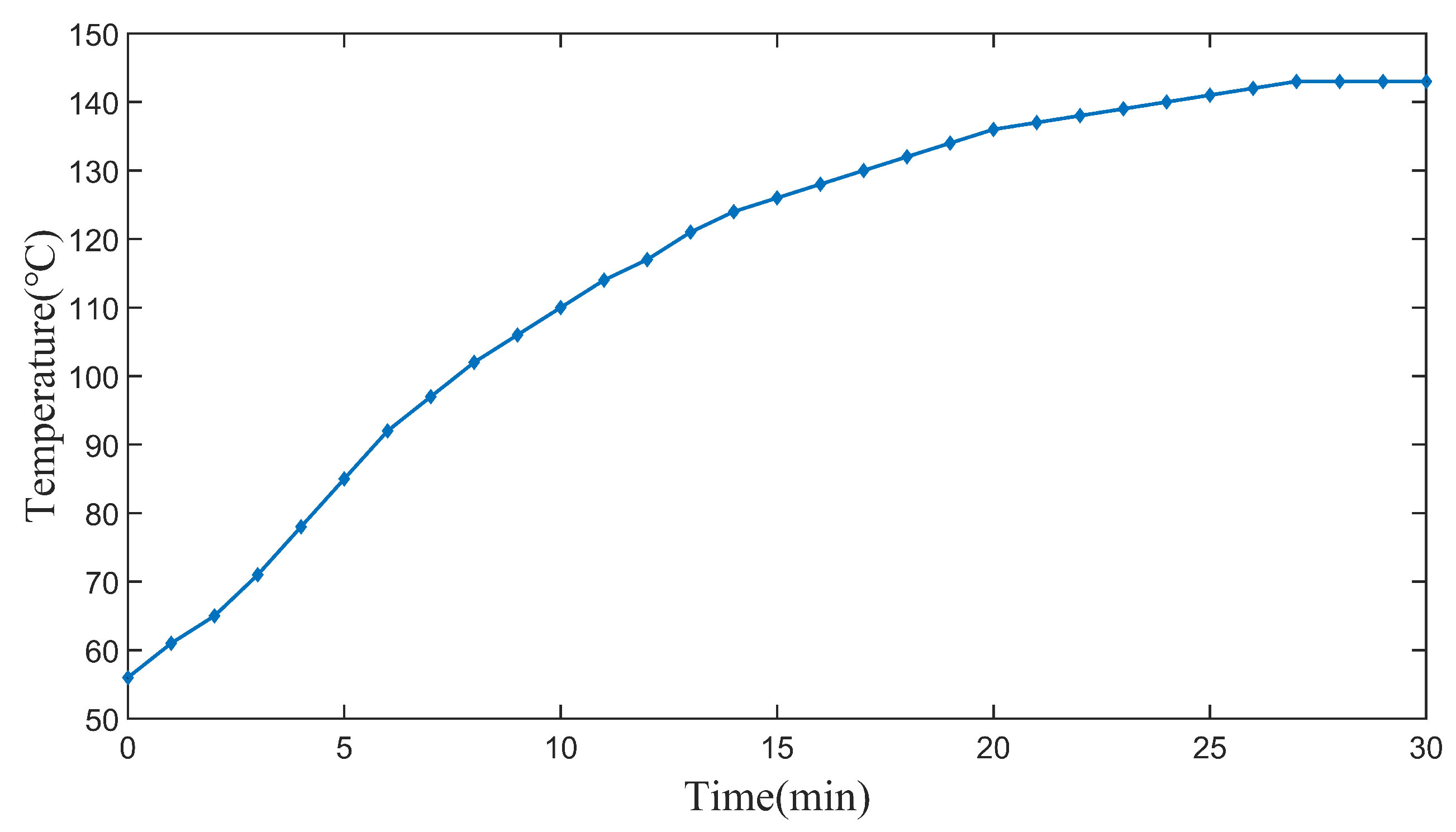

5.2. Simulation of Motor Temperature Rise

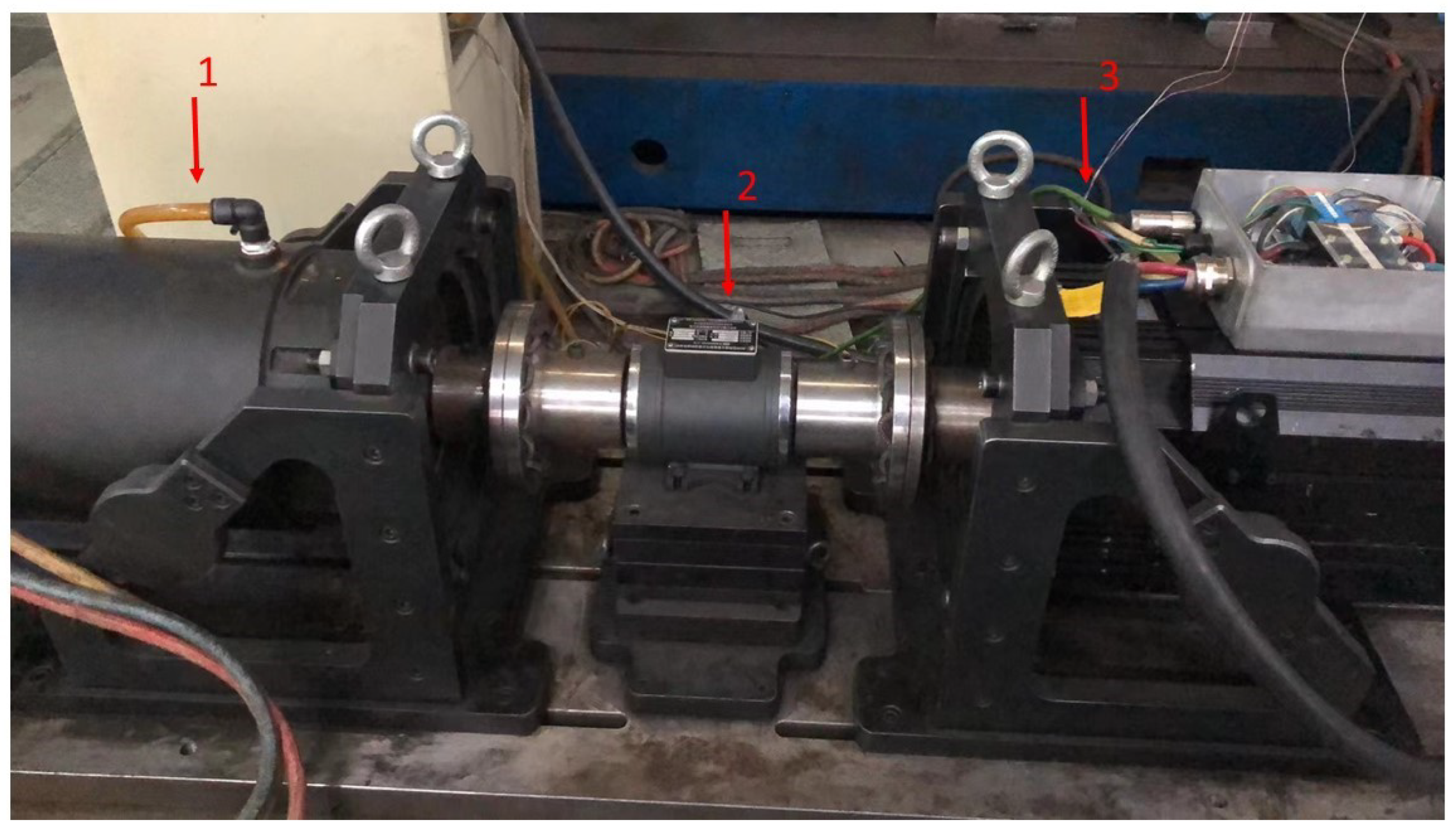

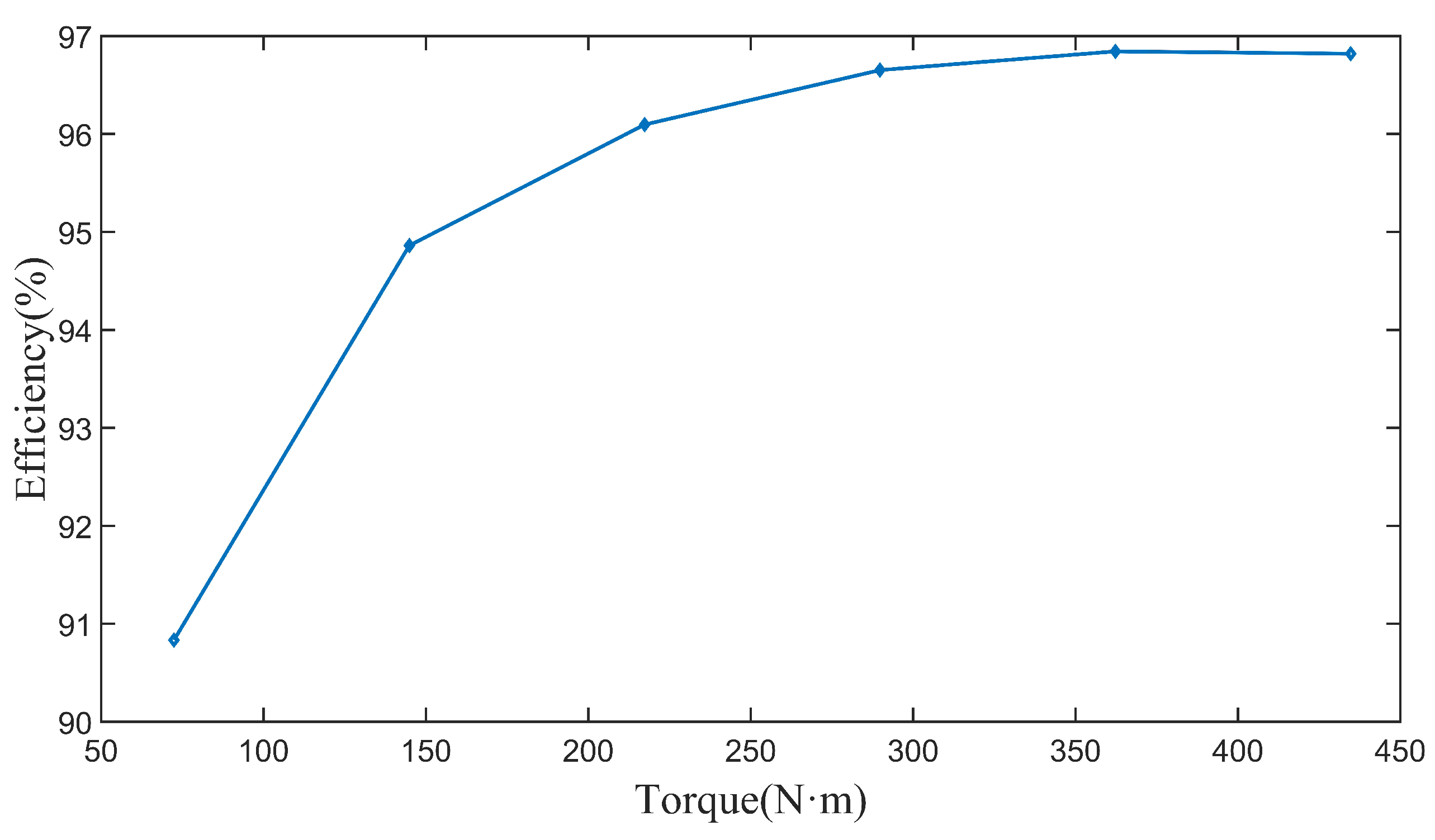

5.3. Prototype Performance Testing

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PMSM | Permanent Magnet Synchronous Motor |

| IPMSM | Interior Permanent Magnet Synchronous Motor |

| SNR | Signal-to-Noise Ratio |

| NSGA-II | Nondominated Sorting Genetic Algorithm II |

| GA | Genetic Algorithm |

| SA | Simulated Annealing |

| PSO | Particle Swarm Optimization |

| FFT | Fast Fourier Transform |

| EMF | Electromotive Force |

Appendix A

| Number | Population Size | Crossover Probability | Mutation Probability | Average Torque (N·m) | Permanent Magnet Area (mm) | Iron Loss of the Motor (kW) | Efficiency (%) |

|---|---|---|---|---|---|---|---|

| 1 | 20 | 0.55 | 0.001 | 380.24 | 302.59 | 1.1597 | 96.39 |

| 2 | 20 | 0.7 | 0.05 | 389.49 | 341.05 | 1.1325 | 96.54 |

| 3 | 20 | 0.85 | 0.1 | 398.33 | 302.97 | 1.1422 | 96.60 |

| 4 | 50 | 0.55 | 0.05 | 400.99 | 302.70 | 1.1455 | 96.62 |

| 5 | 50 | 0.7 | 0.1 | 373.39 | 250.33 | 1.1243 | 96.39 |

| 6 | 50 | 0.85 | 0.001 | 397.39 | 308.90 | 1.1561 | 96.57 |

| 7 | 80 | 0.55 | 0.1 | 403.10 | 390.29 | 1.1447 | 96.64 |

| 8 | 80 | 0.7 | 0.001 | 380.27 | 255.68 | 1.1382 | 96.43 |

| 9 | 80 | 0.85 | 0.05 | 409.50 | 338.65 | 1.1467 | 96.70 |

| Load Torque (N·m) | Motor Input Voltage (V) | Motor Input Current (A) | Motor Input Power (kw) | Power Factor | Efficiency (%) |

|---|---|---|---|---|---|

| 306.19 | 46.62 | 23.93 | 0.94 | 90.833 | |

| 316.88 | 86.99 | 45.73 | 0.92 | 94.861 | |

| 327.16 | 127.23 | 67.73 | 0.9 | 96.096 | |

| 336.32 | 167.38 | 89.73 | 0.88 | 96.652 | |

| 346.47 | 208.16 | 112.031 | 0.86 | 96.843 | |

| 354.54 | 247.58 | 132.951 | 0.84 | 96.819 |

References

- Nuchturee, C.; Li, T.; Xia, H.P. Energy efficiency of integrated electric propulsion for ships—A review. Renew. Sustain. Energy Rev. 2020, 134, 110–145. [Google Scholar] [CrossRef]

- Jin, X. Research on status, problems and countermeasures of china’s shipping industry development. Product. Res. 2013, 4, 3. [Google Scholar]

- Wang, X.; Li, W.L.; Cheng, S.K. Prospects for development of permanent magnet synchronous motors. Micromotor 2007, 4, 4. [Google Scholar]

- Deng, S.X.; Shen, X. Application and simulation of permanent magnet motor in ship power propulsion. Navig. Technol. 2005, 4, 43–46. [Google Scholar]

- An, Q.; Sun, L.; Li, B. Control system of permanent magnet synchronous motor for submarine lateral thruster without position sensor. J. Dalian Marit. Univ. 2007, 33, 4. [Google Scholar]

- Long, F.; Wang, M.; Yang, J. Research on bow thruster and its application. Ship Electr. Technol. 2005, 2, 6–9. [Google Scholar]

- Chen, J. Characteristics of operation and development trend of marine electric motors. Shandong Sci. Technol. 2021, 5, 42–45. [Google Scholar]

- Dmitrievskii, V.; Prakht, V.; Kazakbaev, V.; Anuchin, A. Comparison of interior permanent magnet and synchronous homopolar motors for a mining dump truck traction drive operated in wide constant power speed range. Mathematics 2022, 10, 1581. [Google Scholar] [CrossRef]

- Nelder, J.A.; Mead, R. A simplex method for function minimization. Comput. J. 1964, 7, 308–313. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Y.; Chen, Q. Multi-objective optimal design of asymmetric V-shaped built-in permanent magnet synchronous motor. J. Electr. Eng. Technol. 2018, 33, 385–393. [Google Scholar]

- Liu, G.; Ren, S. Taguchi Method and Robustness Design. Electrotech. Electr. 2010, 10, 53–57. [Google Scholar]

- Wang, X.; Zhang, L.; Xu, W. Multi-objective Optimization Design of Built-in Permanent Magnet Synchronous Motor Based on Taguchi Method. Micromotor 2016, 49, 1–5. [Google Scholar]

- Qiu, R.L.; Hua, Q.S. Optimization of stator lamination based on taguchi method. Small Spec. Electr. Mach. 2020, 48, 13–16. [Google Scholar]

- Chen, S.; Zhang, Z.; Li, J. Application of Taguchi Method in Multi-Objective Optimization Design of Permanent Magnet Synchronous Motor. Micromotor 2021, 54, 17. [Google Scholar]

- Xu, Y.; Tang, R. Application of Simulated Annealing Algorithm in Optimization Design of Permanent Magnet Synchronous Motor. Electr. Eng. 2000, 2, 8–10. [Google Scholar]

- Chen, D.; Sun, C.; Liu, Z. Optimization Design of Micro Permanent Magnet Motor Based on Hybrid Algorithm of Chaotic Particle Swarm. J. Shenyang Univ. Technol. 2006, 6, 614–618. [Google Scholar]

- Wei, H.; Jiao, L.; Cheng, Z. Optimization Design of Permanent Magnet Linear Motor Based on Improved Particle Swarm Algorithm. Micromotor 2012, 45, 1–3. [Google Scholar]

- Yang, S.M.; Ma, Q. Multi-objective optimization of rotor structure of permanent magnet synchronous motor based on hierarchical optimization strategy. J. Shanghai Univ. Eng. Technol. 2022, 36, 369–377. [Google Scholar]

- Khoshoo, B.; Blank, J.; Pham, T.; Deb, K.; Foster, S. Optimized Electric Machine Design Solutions with Efficient Handling of Constraints. In Proceedings of the 2021 IEEE Symposium Series on Computational Intelligence (SSCI), Orlando, FL, USA, 5–7 December 2021; pp. 1–8. [Google Scholar]

- Chuprin, A.D.; Batchelor, J.C.; Paker, E.A. Design of convoluted wire antennas using a genetic algorithm. IEEE Proc. Microwaves Antennas Propag. 2001, 148, 323–326. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, Z.; Xu, Y. Multi-Objective Optimization Design of Permanent Magnet Synchronous Motor Based on Genetic Algorithm. In Proceedings of the 2020 2nd International Conference on Machine Learning, Big Data and Business Intelligence (MLBDBI), Shanghai, China, 23–25 October 2020; pp. 405–409. [Google Scholar]

- Zhang, Y.; Du, R.; Zhao, X.; Ye, Q. Optimization of motor noise based on multi-objective genetic algorithm. Microtechnology 2020, 48, 21–25. [Google Scholar]

| Properties | Value | Units |

|---|---|---|

| Stator outer diameter | 248 | mm |

| Stator inner diameter | 140 | mm |

| Core length | 280 | mm |

| Air gap | 0.8 | mm |

| Permanent magnet width | 40 | mm |

| Magnetization direction length | 6.4 | mm |

| Wire size | 1 | mm |

| Number of turns | 21 | – |

| Conductors per slot | 14 | – |

| Coil pitch | 4 | – |

| Winding layers | 2 | – |

| Permanent magnet grade | N48UH | – |

| Silicon steel sheet grade | 50WW470 | – |

| Insulation class | F | – |

| Properties | Before Optimization | After Optimization | Units |

|---|---|---|---|

| Rated torque | 353.73 | 367.33 | N·m |

| Torque ripple | 7.92 | 5.35 | % |

| Efficiency | 91.78 | 92.03 | % |

| Core loss | 1.2005 | 1.112 | kW |

| Motor Parameters | Parameter Range | Units |

|---|---|---|

| 37.5 ≤ ≤ 40.5 | mm | |

| 2.4 ≤ ≤ 10.4 | mm | |

| 0.6 ≤ ≤ 1 | mm | |

| 0.365 ≤ ≤ 1.235 | mm | |

| 0.505 ≤ ≤ 1.505 | mm |

| Optimization Factor | Average Torque | Permanent Magnet Area | Core Loss | |||

|---|---|---|---|---|---|---|

| Variance | Weight | Variance | Weight | Variance | Weight | |

| Population size | 10,837.066 | 73.68 | 2160 | 94.24 | 2.22 | 2.09 |

| Crossover probability | 48.126 | 0.33 | 83 | 3.62 | 6.84 | 64.47 |

| Mutation probability | 21.616 | 0.2 | 49.2 | 2.14 | 3.55 | 33.44 |

| Motor Structure and Performance Parameters | Before Optimization | After Optimization | Unit |

|---|---|---|---|

| Minimum air gap length | 0.8 | 0.827 | mm |

| Permanent magnet thickness | 6.4 | 6.34 | mm |

| Permanent magnet width | 40 | 39.485 | mm |

| Internal magnetic bridge width | 0.73 | 0.39291881 | mm |

| Edge magnetic bridge width | 1.005 | 0.668979 | mm |

| Efficiency | 92.03 | 96.39 | % |

| Permanent magnet area | 256 | 250.3349 | mm |

| Core loss | 1.112 | 1.0868 | kW |

| Torque | 367.33 | 373.3949 | N·m |

| Motor Performance Parameters | Before Weight Reduction Design | After Weight Reduction Design | Unit |

|---|---|---|---|

| Efficiency | 96.39 | 96.54 | % |

| Weight of rotor | 19.71 | 11.18 | kg |

| Motor back electromotive | 315 | 314.85 | V |

| Torque | 373.39 | 370.64 | N·m |

| Motor Performance Parameters | The Simulated Data | The Data Measured in Reality | Unit |

|---|---|---|---|

| Efficiency | 96.54 | 96.84 | % |

| Motor back electromotive | 314.85 | 314.63 | V |

| Torque | 370.64 | 346 | N·m |

| The initial temperature of the motor | 56 | 56.1 | °C |

| The temperature of the motor after running for 30 min | 138.69 | 143 | °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Fang, Y.; Zhang, Q.; Liu, Q. Optimal Design of Marine Motors for Joint Efficiency and Economic Optimization. Energies 2023, 16, 4588. https://doi.org/10.3390/en16124588

Sun Y, Fang Y, Zhang Q, Liu Q. Optimal Design of Marine Motors for Joint Efficiency and Economic Optimization. Energies. 2023; 16(12):4588. https://doi.org/10.3390/en16124588

Chicago/Turabian StyleSun, Yingshui, Yuxuan Fang, Qiao Zhang, and Qing Liu. 2023. "Optimal Design of Marine Motors for Joint Efficiency and Economic Optimization" Energies 16, no. 12: 4588. https://doi.org/10.3390/en16124588

APA StyleSun, Y., Fang, Y., Zhang, Q., & Liu, Q. (2023). Optimal Design of Marine Motors for Joint Efficiency and Economic Optimization. Energies, 16(12), 4588. https://doi.org/10.3390/en16124588