Characteristics of Deep Coal Reservoir and Key Control Factors of Coalbed Methane Accumulation in Linxing Area

Abstract

:1. Introduction

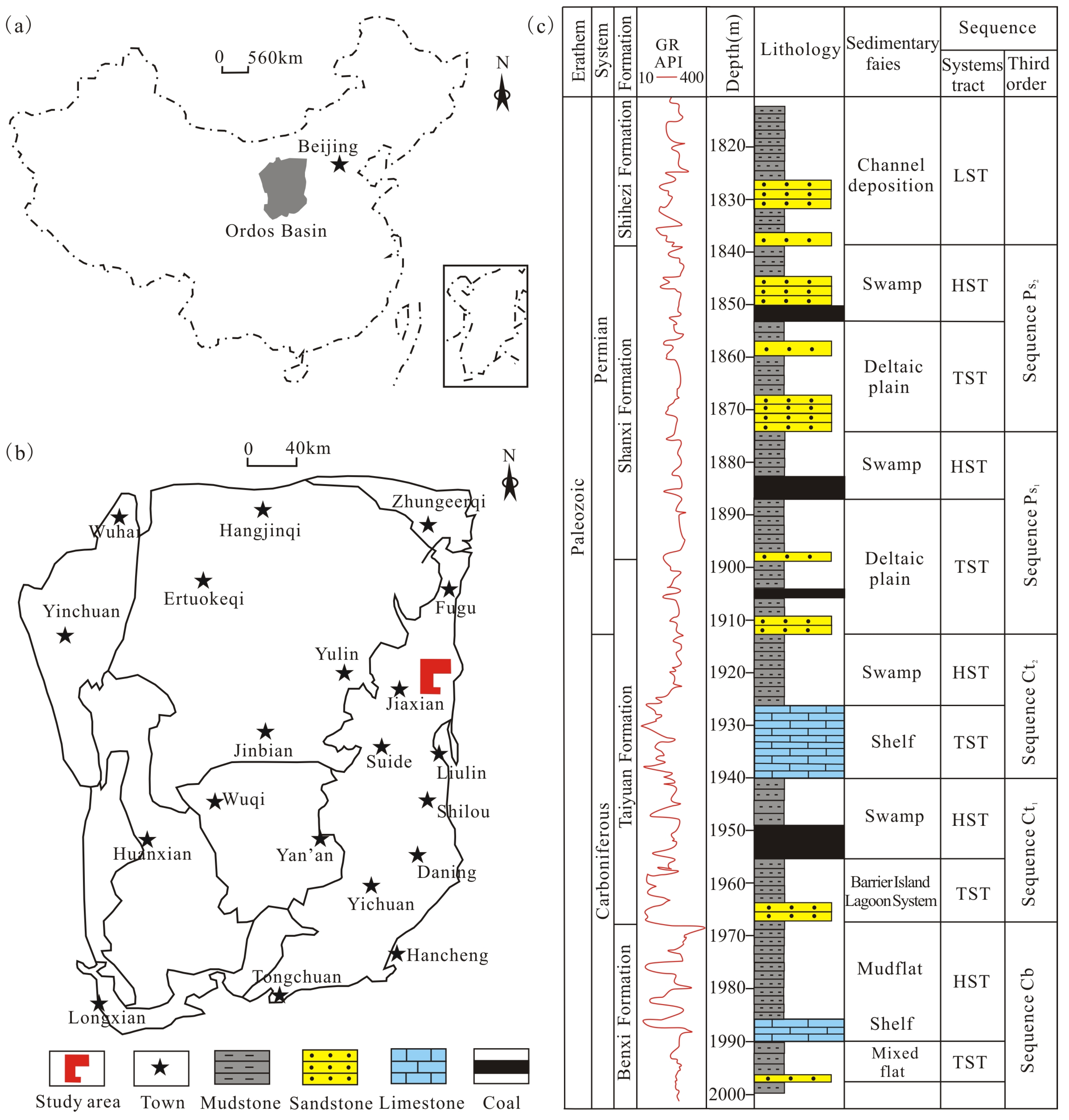

2. Geological Setting

3. Databases and Methods

- (1)

- Maceral composition and vitrinite reflectance of coal

- (2)

- Maximum pyrolysis temperature and proximate analysis of coal

- (3)

- Porosity and permeability of coal

4. Results

4.1. Burial Depth Variations

4.2. Material Composition of Coal

4.2.1. Maceral Composition

4.2.2. Proximate Analysis

4.3. Reservoir Pressure and Temperature

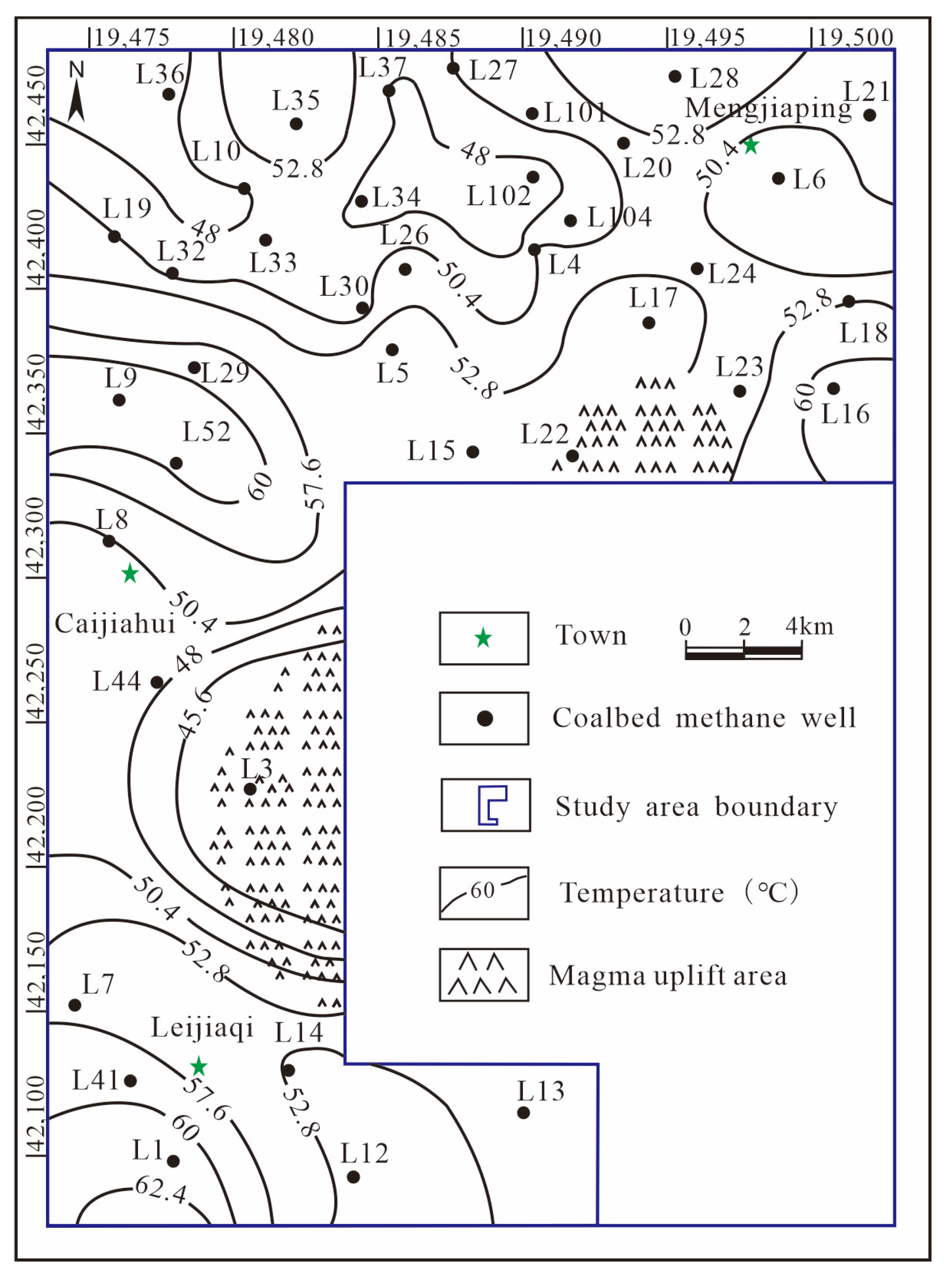

4.3.1. Temperature

4.3.2. Pressure

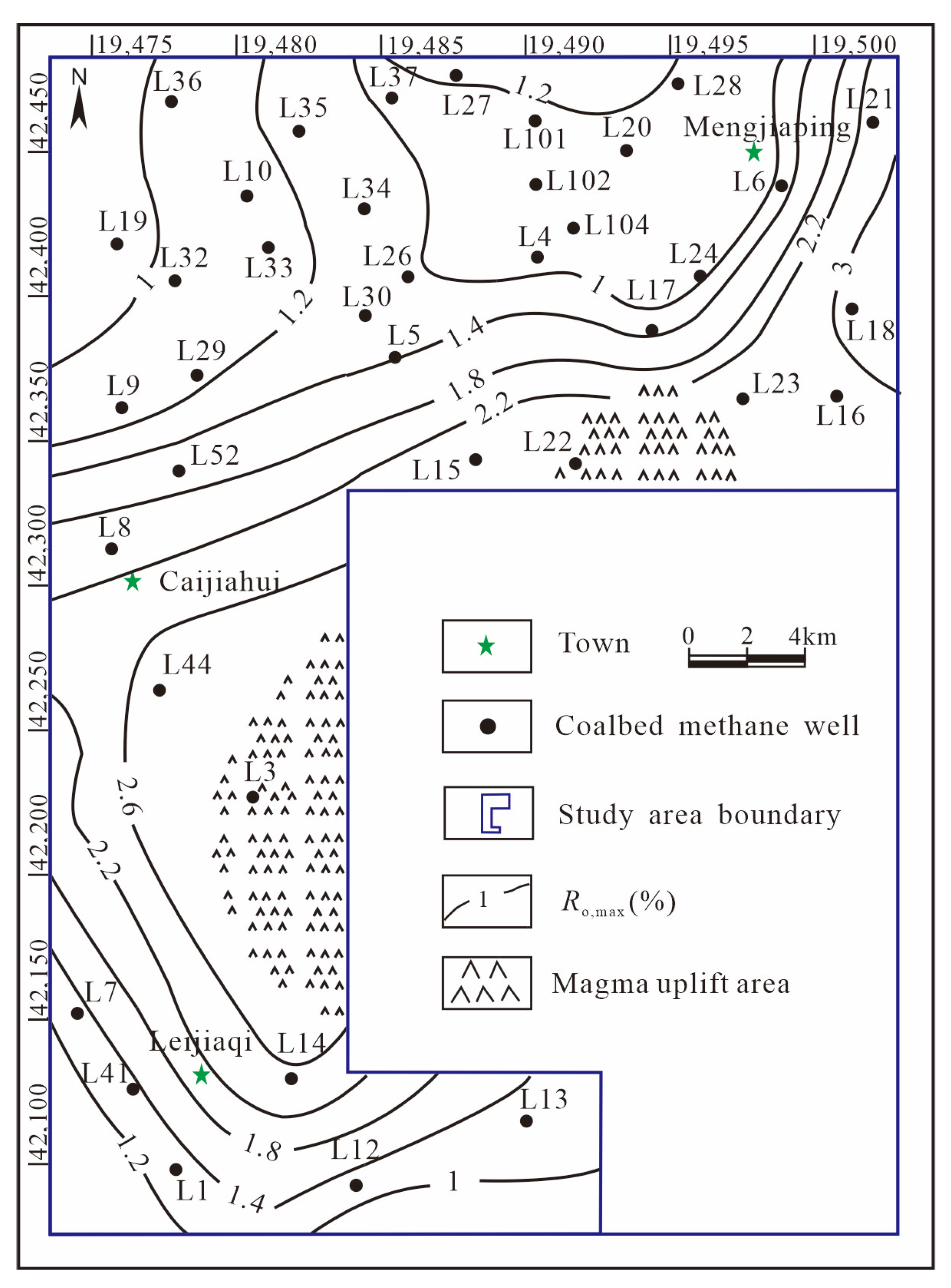

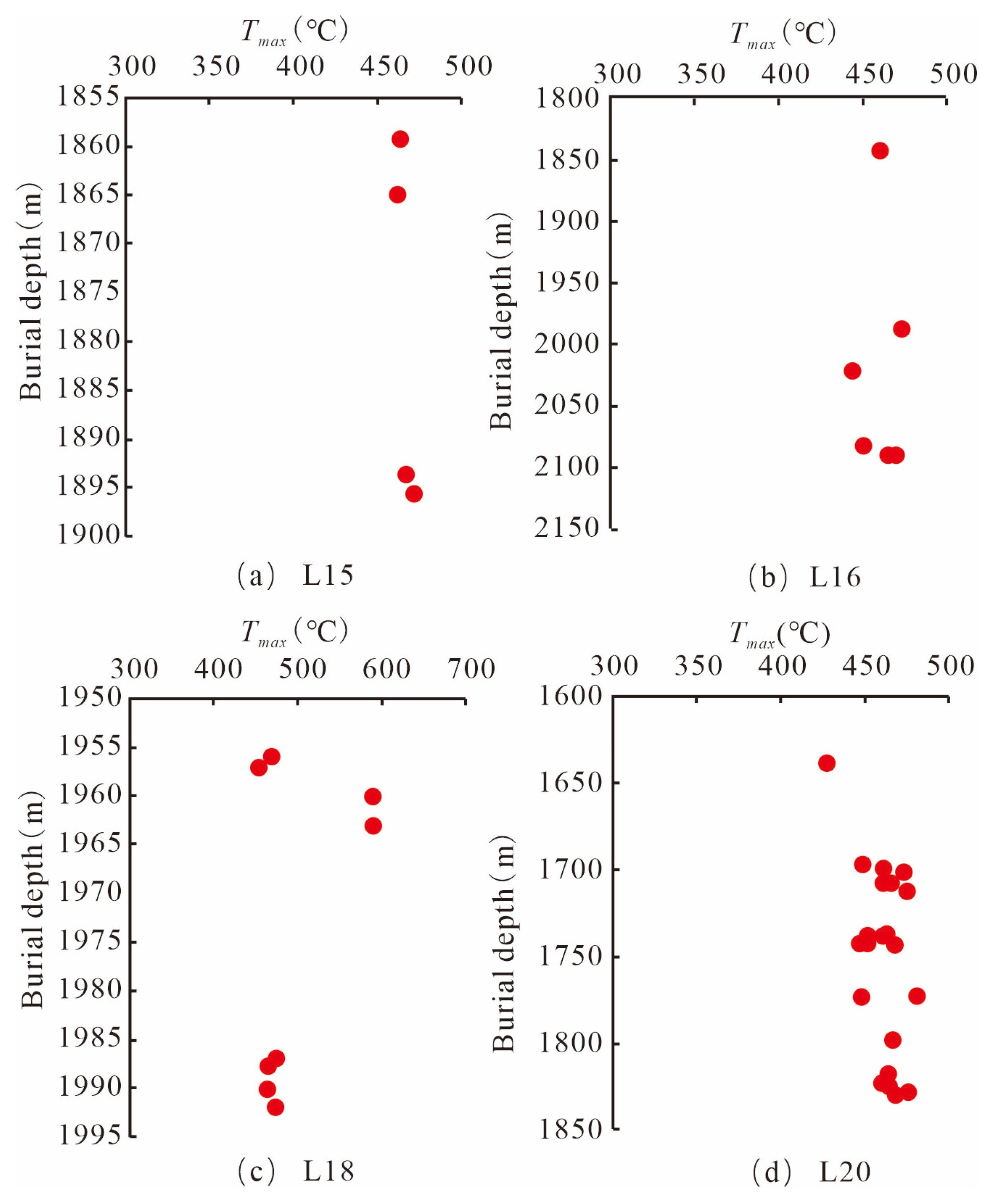

4.4. Thermal Maturity

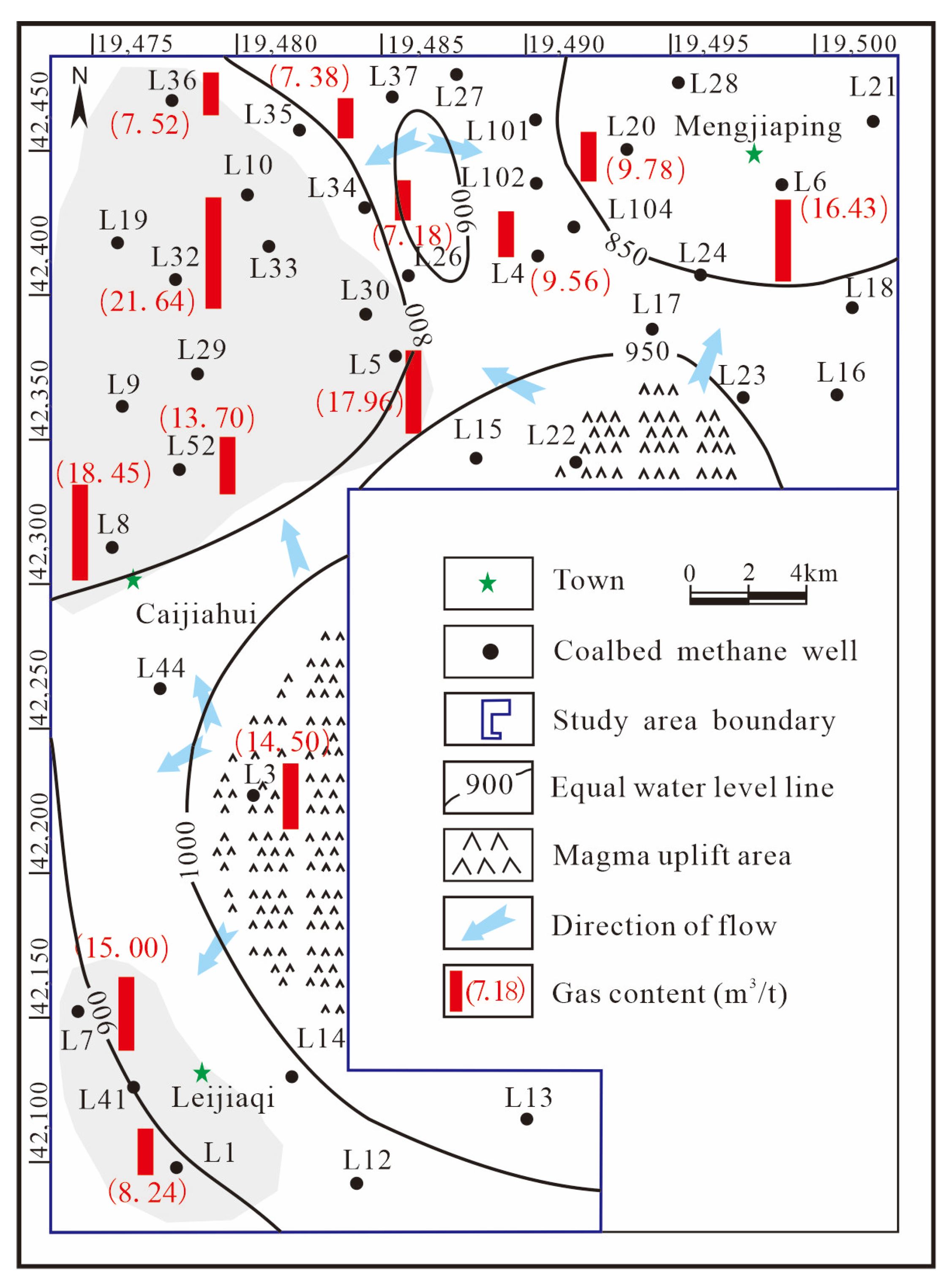

4.5. Gas Content and Coal Thickness

4.6. Characterization of Porosity and Permeability

5. Discussion

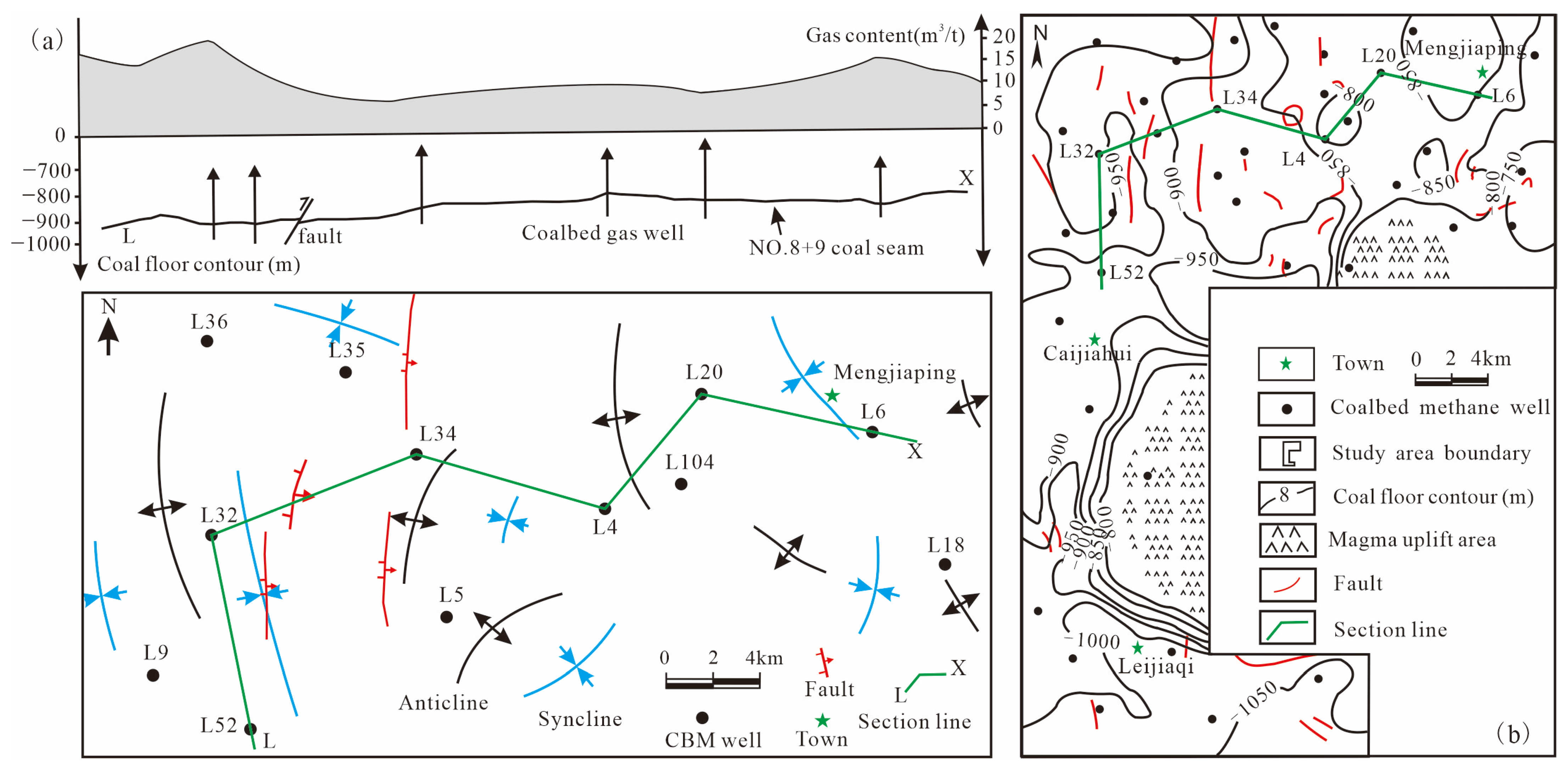

5.1. Influences of Structural Patterns on Gas Content

5.2. Influences of Hydrodynamic on Gas Content

5.3. Influences of High Reservoir Temperature and Pressure

5.3.1. Variations in Deep Buried Strata

5.3.2. Influences from Magma Event

5.4. Partition of CBM Accumulation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuuskraa, V.A.; Wyman, R.E. Deep coal seams: An overlooked source for long-term natural gas supplies. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Calgary, AB, Canada, 3–6 October 1993; Society of Petroleum Engineers: London, UK, 1993; pp. 26–196. [Google Scholar]

- Robert, R.T.; Jennifer, L.M. A conventional Look at an Unconventional Reservoir: Coalbed Methane Production Potential in Deep Environments; AAPG Annual Convention and Exhibition: New Orleans, LA, USA, 2010; pp. 11–14. [Google Scholar]

- Liu, C.L.; Zhu, J.; Che, C.B.; Yang, H.L.; Fan, M.Z. Methodologies and results of the latest assessment of coalbed methane resources in China. Nat. Gas Ind. 2009, 29, 130–132+152. (In Chinese) [Google Scholar]

- Flores, R.M. Coalbed methane in the Powder River Basin, Wyoming and Montana: An assessment of the Tertiary-upper Cretaceous coalbed methane total petroleum system. In U.S. Geological Survey Digital Data Series DDS-69-C, Version 1; Department of the interior and Geological Survey: Reston, VA, USA, 2004; Chapter 2; p. 56. [Google Scholar]

- Stokes, S.M.; Ge, S.M.; Brown, M.R.M.; Menezes, E.A.; Sheehan, A.F.; Tiampo, K.F. Pore Pressure Diffusion and Onset of Induced Seismicity. J. Geophys. Res.-Solid Earth 2023, 128. [Google Scholar] [CrossRef]

- Ayers, W.B. Coalbed gas systems, resources, and production and a review of contrasting cases from the San Juan and Powder River Basins. AAPG Bull. 2002, 86, 1853–1890. [Google Scholar]

- Pependick, S.L.; Downs, K.R.; Vo, K.D.; Hamilton, S.K.; Dawson, G.K.W.; Golding, S.D.; Gilcrease, P.C. Biogenic methane potential for Surat Basin, Queensland coal seams. Int. J. Coal Geol. 2011, 88, 123–134. [Google Scholar] [CrossRef]

- Burra, A.; Esterle, J.S.; Golding, S.D. Horizontal stress anisotropy and effective stress as regulator of coal seam gas zonation in the Sydeny Basin, Australia. Int. J. Coal Geol. 2014, 132, 103–116. [Google Scholar] [CrossRef]

- Tonnsen, R.R.; Miskimins, J.L. Simulation of deep coalbed methane permeability and production assuming variable pore volume compressibility. J. Can. Pet. Technol. 2011, 50, 23–31. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Liu, B.; Chang, S.L.; Zhang, S.; Chen, Q.; Zhang, J.Z.; Li, Y.R.; Liu, J. Coalbed methane gas content and its geological controls: Research based on seismic-geological integrated method. J. Nat. Gas Sci. Eng. 2022, 101, 104510. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.B.; Shen, Y.L.; Wang, G. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2018, 60, 777–812. [Google Scholar] [CrossRef]

- Gurdal, G.; Yalcin, M.N. Gas adsorption capacity of carboniferous coals in the Zonguldak Basin (NW Turkey) and its controlling factors. Fuel 2000, 79, 1913–1924. [Google Scholar] [CrossRef]

- Song, Y.; Liu, S.B.; Ma, X.B.; Jiang, L.; Hong, F. Favorable depth distribution of coalbed methane enrichment and high yield zone in slope areas. Acta Geol. Sin. 2017, 99, 371–372. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tang, S.H.; Qian, Z.; Pan, Z.J.; Guo, Q.L. Evaluation of geological features for deep coalbed methane reservoirs in the Dacheng Salient, Jizhong Depression, China. Int. J. Coal Geol. 2014, 133, 60–71. [Google Scholar] [CrossRef]

- Cai, Y.D.; Liu, D.M.; Yao, Y.B.; Li, J.Q.; Qiu, Y.K. Geological controls on prediction of coalbed methane of No. 3 coal seam in Southern Qinshui Basin, North China. Int. J. Coal Geol. 2011, 88, 101–112. [Google Scholar] [CrossRef]

- Wang, B.; Sun, F.J.; Tang, D.Z.; Zhao, Y.; Song, Z.H.; Tao, Y. Hydrological control rule on coalbed methane enrichment and high yield in FZ Block of Qinshui Basin. Fuel 2015, 140, 568–577. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, J.C.; Shan, Y.S.; Xiong, J.Y. Upper Paleozoic coal measures and unconventional natural gas systems of the Ordos Basin, China. Geosci. Front. 2012, 3, 863–873. [Google Scholar] [CrossRef]

- Zhu, X.M.; Zhong, D.K.; Yuan, X.J.; Zhang, H.L.; Zhu, S.F.; Sun, H.T.; Gao, Z.Y.; Xian, B.Z. Development of sedimentary geology of petroliferous basins in China. Pet. Explor. Dev. 2016, 43, 820–829. (In Chinese) [Google Scholar] [CrossRef]

- Xie, Y.G.; Qin, Y.; Meng, S.Z.; Pan, X.Z.; Gao, L.J.; Duan, C.J. Study on occurrence characteristics and controlling factors of permian deep coalbed methane in Linxing block. Fresenius Environ. Bull. 2022, 31, 3408–3414. [Google Scholar]

- Xu, H.; Tang, D.Z.; Zhao, J.L.; Li, S. A precise measurement method for shale porosity with low-field nuclear magnetic resonance: A case study of the Carboniferous-Permian strata in the Linxing area. Fuel 2015, 143, 47–54. [Google Scholar] [CrossRef]

- Shen, J.; Li, K.X.; Zhang, H.W.; Shabbiri, K.; Hu, Q.J.; Zhang, C. The geochemical characteristics, origin, migration and accumulation modes of deep coal-measure gas in the west of Linxing block at the eastern margin of Ordos Basin. J. Nat. Gas Sci. Eng. 2021, 91, 103965. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, C.J.; Qin, Y.; Zhang, B. Effect factors on co-mining of sandstone gas and coalbed methane in coal series and threshold of parameter in Linxing block, Ordos Basin. Nat. Gas Geosci. 2017, 3, 479–487. [Google Scholar]

- Li, J.; Tang, S.H.; Zhang, S.H.; Li, L.; Jiang, G.W.; Xi, Z.; Sun, K. Characterization of unconventional reservoirs and continuous accumulations of natural gas in the Carboniferous-Permian strata, mid-eastern Qinshui Basin, China. J. Nat. Gas Sci. Eng. 2018, 49, 298–316. [Google Scholar] [CrossRef]

- Fu, X.Y.; Meng, Y.J.; Li, Z.C.; Kong, P.; Chang, S.L.; Yan, T.T.; Liu, Y.F. Coalbed Methane Potential Evaluation and Development Sweet Spot Prediction Based on the Analysis of Development Geological Conditions in Yangjiapo Block, Eastern Ordos Basin, China. Geofluids 2021, 2021. [Google Scholar] [CrossRef]

- GB/T19559-2008; Method of Determining Coalbed Gas Content. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 6948-2008; Method of Determining Microscopically the Reflectance of Vitrinite in Coal. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 18602-2001; Rock Pyrolysis Analysis. Standardization Administration of the People’s Republic of China: Beijing, China, 2001.

- GB/T212-2008; Proximate Analysis of Coal. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- SY/T 5336-1996; Method of Core Routine Analysis. China National Petroleum Corporation: Beijing, China, 1996.

- Bustin, R.M.; Clarkson, C.R. Geological controls on coalbed methane reservoir capacity and gas content. Int. J. Coal Geol. 1998, 38, 3–26. [Google Scholar] [CrossRef]

- Xie, X.Y. Provenance and sediment dispersal of the Triassic Yanchang Formation, southwest Ordos Basin, China, and its implications. Sediment. Geol. 2016, 335, 1–16. [Google Scholar] [CrossRef]

- Jiang, Z.X.; Xu, J.; Wang, G.T. The discovery and significance of a sedimentary hiatus within the Carboniferous Taiyuan Formation, northeastern Ordos Basin, China. AAPG Bull. 2012, 96, 1173–1195. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Kitano, K.; Vassileva, C.G. Relations between ash yield and chemical and mineral composition of coals. Fuel 1997, 76, 3–8. [Google Scholar] [CrossRef]

- Zhou, D.; Feng, Z.C.; Zhao, D.; Zhao, Y.S.; Cai, T.T. Uniformity of temperature variation in coal during methane adsorption. J. Nat. Gas Sci. Eng. 2016, 33, 954–960. [Google Scholar] [CrossRef]

- Pashin, J.C. Stratigraphy and structure of coalbed methane reservoirs in the United States: An overview. Int. J. Coal Geol. 1998, 35, 207–238. [Google Scholar] [CrossRef]

- Tian, L.; Cao, Y.X.; Chai, X.Z.; Liu, T.J.; Feng, P.W.; Feng, H.M.; Zhou, D.; Shi, B.; Oestreich, R.; Rodvelt, G. Best practices for the determination of low-pressure/permeability coalbed methane reservoirs, Yuwu Coal Mine, Luan mining area, China. Fuel 2015, 160, 100–107. [Google Scholar] [CrossRef]

- Scott, S.; Anderson, B.; Crosdale, P.; Dingwall, J.; Leblang, G. Coal petrology and coal seam gas contents of the Walloon Subgroup Surat Basin, Queensland, Australia. Int. J. Coal Geol. 2007, 70, 209–222. [Google Scholar] [CrossRef]

- Zhao, J.L.; Tang, D.Z.; Xu, H.; Li, Y.; Li, S.; Tao, S.; Liu, W.J.; Liu, Z.X. Characteristic of In Situ Stress and Its Control on the Coalbed Methane Reservoir Permeability in the Eastern Margin of the Ordos Basin, China. Rock Mech. Rock Eng. 2016, 49, 3307–3322. [Google Scholar] [CrossRef]

- Li, Y.; Tang, D.Z.; Xu, H.; Yu, T.X. In-situ stress distribution and its implication on coalbed methane development in Liulin area, eastern Ordos Basin, China. J. Pet. Sci. Eng. 2014, 122, 488–496. [Google Scholar] [CrossRef]

- Li, M.; Jiang, B.; Miao, Q.; Wang, G.; You, Z.J.; Lan, F.J. Multi-Phase Tectonic Movements and Their Controls on Coalbed Methane: A Case Study of No. 9 Coal Seam from Eastern Yunnan, SW China. Energies 2020, 13, 6003. [Google Scholar] [CrossRef]

- Chen, S.D.; Tao, S.; Tian, W.G.; Tang, D.Z.; Zhang, B.; Liu, P.C. Hydrogeological control on the accumulation and production of coalbed methane in the Anze Block, southern Qinshui Basin, China. J. Pet. Sci. Eng. 2021, 198, 108138. [Google Scholar] [CrossRef]

- Yang, M.; Jia, G.N.; Gao, J.L.; Liu, J.J.; Zhang, X.B.; Lu, F.C.; Liu, L.; Pathak, A. Experimental study on the influence of aerated gas pressure and confining pressure on low-rank coal gas adsorption process. Energy Explor. Exploit. 2022, 40, 381–399. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Y.M.; Liu, S.M.; Li, W.; Tang, X. Temperature effect on gas adsorption capacity in different sized pores of coal: Experiment and numerical modeling. J. Pet. Sci. Eng. 2018, 165, 821–830. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Cai, J.H.; Yan, G.H.; Zhou, W.W.; Yan, Z.J. SHRIMP zircon U-Pb age, geochemistry and Sr-Nd-Hf isotopic characteristics of the Zijinshan alkaline complex in Linxian County, Shanxi Province. Acta Petrol. MIneralogica 2014, 33, 1052–1072, (In Chinese with English Abstract). [Google Scholar]

- Li, K.J.; Chen, G.; Li, W.; Wu, X.L.; Tan, J.C.; Qu, J.W. A comparative evaluation of coal specific surface area by CO2 and N2 adsorption and its influence on CH4 adsorption capacity at different pore sizes. Fuel 2016, 183, 420–431. [Google Scholar]

- Yang, X.K.; Chao, H.X.; Zhang, Z.F.; Yao, W.H.; Dong, M. Characteristics of the Zijinshan complex and its dynamic environment in the east of the Ordos Basin-Analysis of a classic example on the deep processes of the magma activity in the basin. Geotecton. Metallog. 2010, 34, 269–281. [Google Scholar]

- Yao, Y.B.; Liu, D.M.; Yan, T.T. Geological and hydrogeological controls on the accumulation of coalbed methane in the Weibei field, southeastern Ordos Basin. Int. J. Coal Geol. 2014, 121, 148–159. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Qin, Y.; You, Z.J.; Yang, Z.B. Distribution characteristics of in-situ stress field and vertical development unit division of CBM in western Guizhou, China. Nat. Resour. Res. 2021, 30, 3659–3671. [Google Scholar] [CrossRef]

- Wang, D.; Nong, C.G.; Zhu, Q.Q.; Wang, P.; Wu, D.; Liu, Z. Study on Geological main controlling factors of CBM enrichment in medium-high rank coal. Fresenius Environ. Bull. 2022, 31, 8088–8096. [Google Scholar]

| Basin | Ordos | Qinshui | Piceance | San Juan | Black Warrior | Powder River | Bowen | Sydney |

|---|---|---|---|---|---|---|---|---|

| Country | China | China | America | America | America | America | Australian | Australian |

| Depth (m) | 100–1500 | 200–2000 | 1560–2561 | 169–1220 | 152–1375 | 55–975 | 300~1400 | 650–850 |

| Coal rank | Low-volatile bituminous | Semianthracite to anthracite | Low | Subbituminous A to low-volatile bituminous | Medium–high volatile bituminous | Subbituminous C-A | Medium–high volatile bituminous | High rank (bituminous) |

| Sample No. | Depth(m) | Coal Maceral Composition (%) | Priximate Analysis (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| V | I | E | M | Ad | Vdaf | Mad | FCad | ||

| L1-1 | 2086.61 | 86.2 | 6.8 | 0 | 7.0 | 12.36 | 23.34 | 0.20 | 64.10 |

| L1-2 | 2088.16 | 88.6 | 8.1 | 0 | 3.3 | 9.73 | 23.39 | 0.30 | 66.58 |

| L1-3 | 2088.23 | 86.6 | 4.1 | 0 | 9.3 | 14.47 | 23.85 | 0.25 | 61.43 |

| L3-1 | 1068.29 | - | - | - | - | 31.77 | 5.99 | 0.95 | 61.29 |

| L3-2 | 1090.14 | - | - | - | - | 23.81 | 6.56 | 0.81 | 68.82 |

| L4-1 | 1825.50 | 75.9 | 9.8 | 0 | 14.3 | 38.55 | 24.17 | 0.40 | 36.88 |

| L5-1 | 1769.51 | 72.9 | 16.1 | 0.2 | 10.8 | 14.25 | 27.06 | 0.40 | 58.29 |

| L5-2 | 1770.51 | 83.6 | 9.2 | 0 | 7.2 | 11.22 | 25.79 | 0.40 | 62.59 |

| L6-1 | 1855.64 | 71.9 | 17.9 | 0.2 | 10.0 | 23.48 | 33.67 | 0.30 | 42.55 |

| L8-1 | 1961.80 | 85.4 | 5.4 | 0 | 9.2 | 33.17 | 22.35 | 0.20 | 44.28 |

| L18-1 | 1955.60 | - | - | - | - | 29.64 | 7.23 | 0.26 | 62.87 |

| L32-1 | 1936.22 | 63.7 | 28.8 | 0 | 7.5 | 21.41 | 24.36 | 0.61 | 53.62 |

| L36-1 | 1846.29 | 54.9 | 31.2 | 0 | 13.9 | 20.26 | 22.79 | 1.34 | 55.61 |

| L36-2 | 1848.26 | 62.7 | 20.7 | 0 | 16.6 | 25.07 | 25.58 | 1.50 | 47.85 |

| L41-1 | 2158.05 | 85.2 | 9.2 | 0 | 5.6 | 18.30 | 22.50 | 0.80 | 58.40 |

| Sample No. | Depth (m) | Length (cm) | Diameter (cm) | Pore Volume (cm3) | Porosity (%) | Permeability (mD) |

|---|---|---|---|---|---|---|

| L4 | 1823.0 | 5.28 | 2.45 | 1.25 | 5.02 | 0.08 |

| L5-1 | 1769.2 | 4.80 | 2.46 | 1.24 | 5.44 | 2.90 |

| L5-2 | 1786.0 | 5.19 | 2.45 | 1.41 | 5.78 | 0.52 |

| L8 | 1886.9 | 3.58 | 2.44 | 0.64 | 4.01 | 1.95 |

| L10-1 | 1635.2 | 4.82 | 2.43 | 0.98 | 4.58 | 0.26 |

| L10-2 | 1635.6 | 5.34 | 2.39 | 1.17 | 4.86 | 0.20 |

| L15 | 1895.0 | 4.54 | 2.44 | 1.37 | 6.50 | 5.70 |

| L17 | 1899.0 | 4.15 | 2.44 | 0.96 | 3.35 | 1.35 |

| L20 | 1738.7 | 4.47 | 2.44 | 0.70 | 4.68 | 2.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, C.; Li, Y.; Wang, Y.; Ni, X.; Wu, X.; Zhao, S. Characteristics of Deep Coal Reservoir and Key Control Factors of Coalbed Methane Accumulation in Linxing Area. Energies 2023, 16, 6085. https://doi.org/10.3390/en16166085

Tao C, Li Y, Wang Y, Ni X, Wu X, Zhao S. Characteristics of Deep Coal Reservoir and Key Control Factors of Coalbed Methane Accumulation in Linxing Area. Energies. 2023; 16(16):6085. https://doi.org/10.3390/en16166085

Chicago/Turabian StyleTao, Chuanqi, Yong Li, Yanbin Wang, Xiaoming Ni, Xiang Wu, and Shihu Zhao. 2023. "Characteristics of Deep Coal Reservoir and Key Control Factors of Coalbed Methane Accumulation in Linxing Area" Energies 16, no. 16: 6085. https://doi.org/10.3390/en16166085