Increasing the Efficiency of Turbine Inlet Air Cooling in Climatic Conditions of China through Rational Designing—Part 1: A Case Study for Subtropical Climate: General Approaches and Criteria

Abstract

1. Introduction

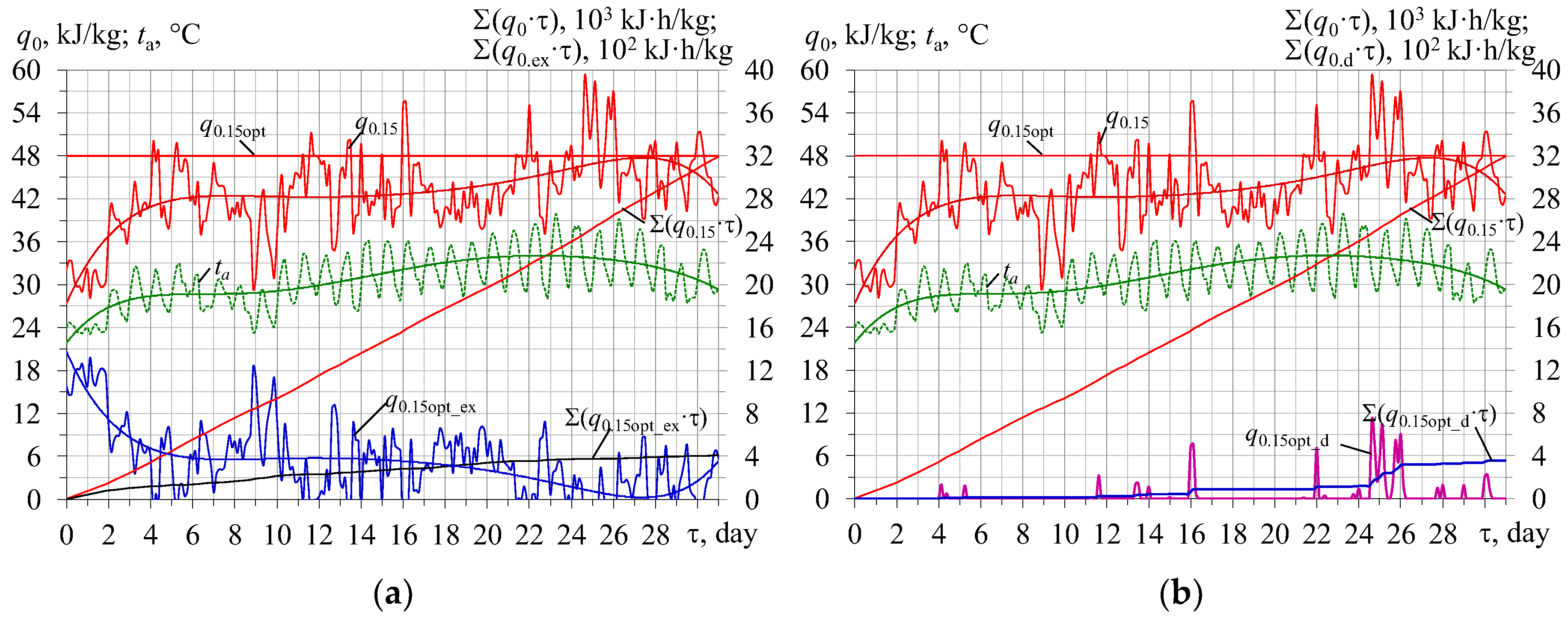

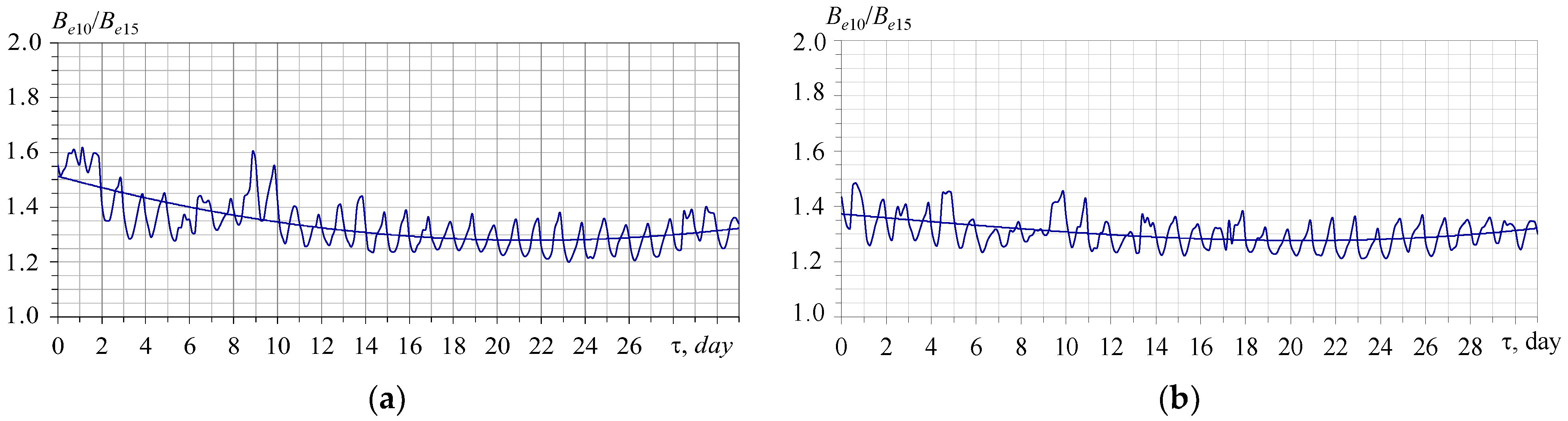

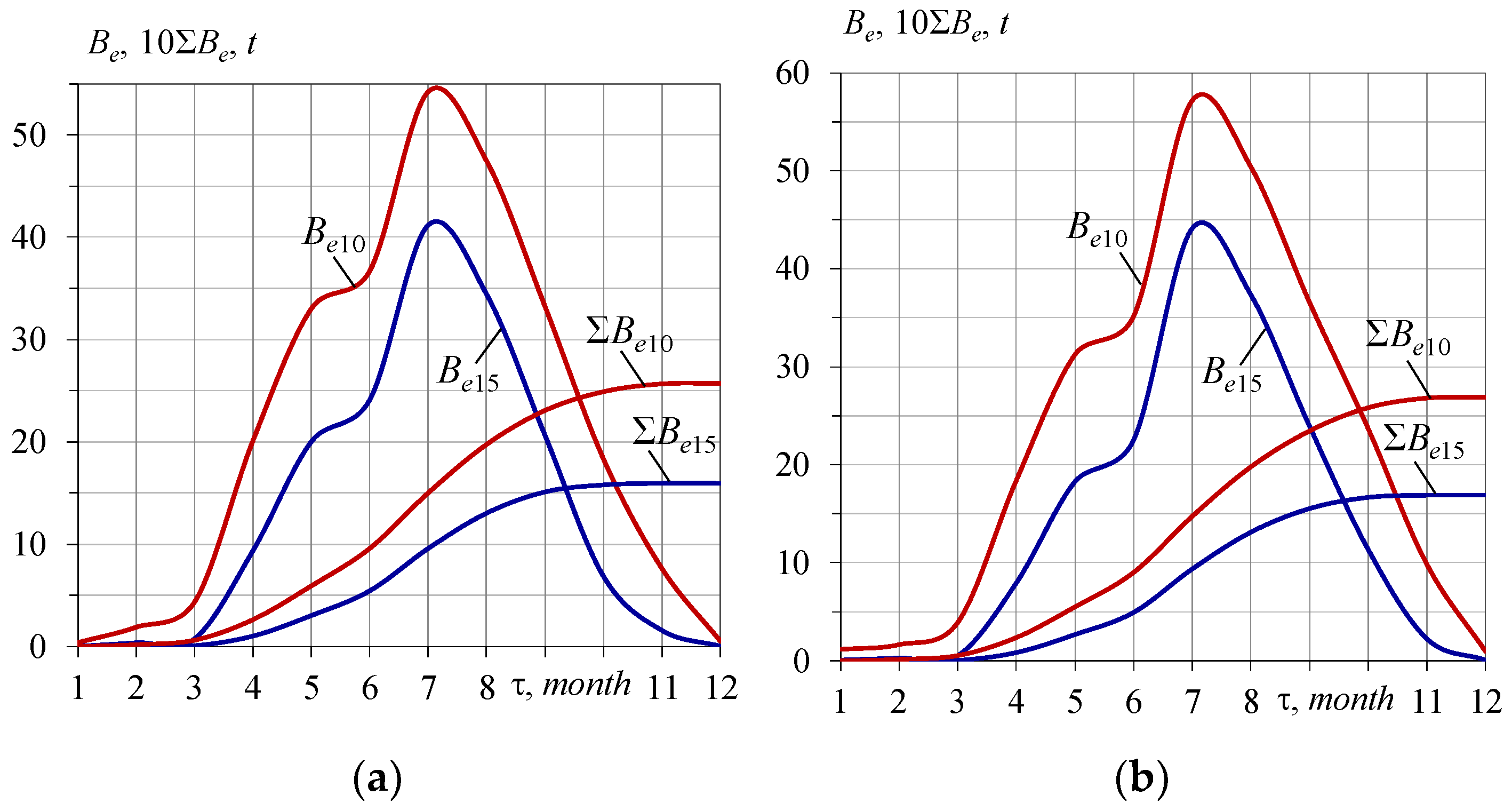

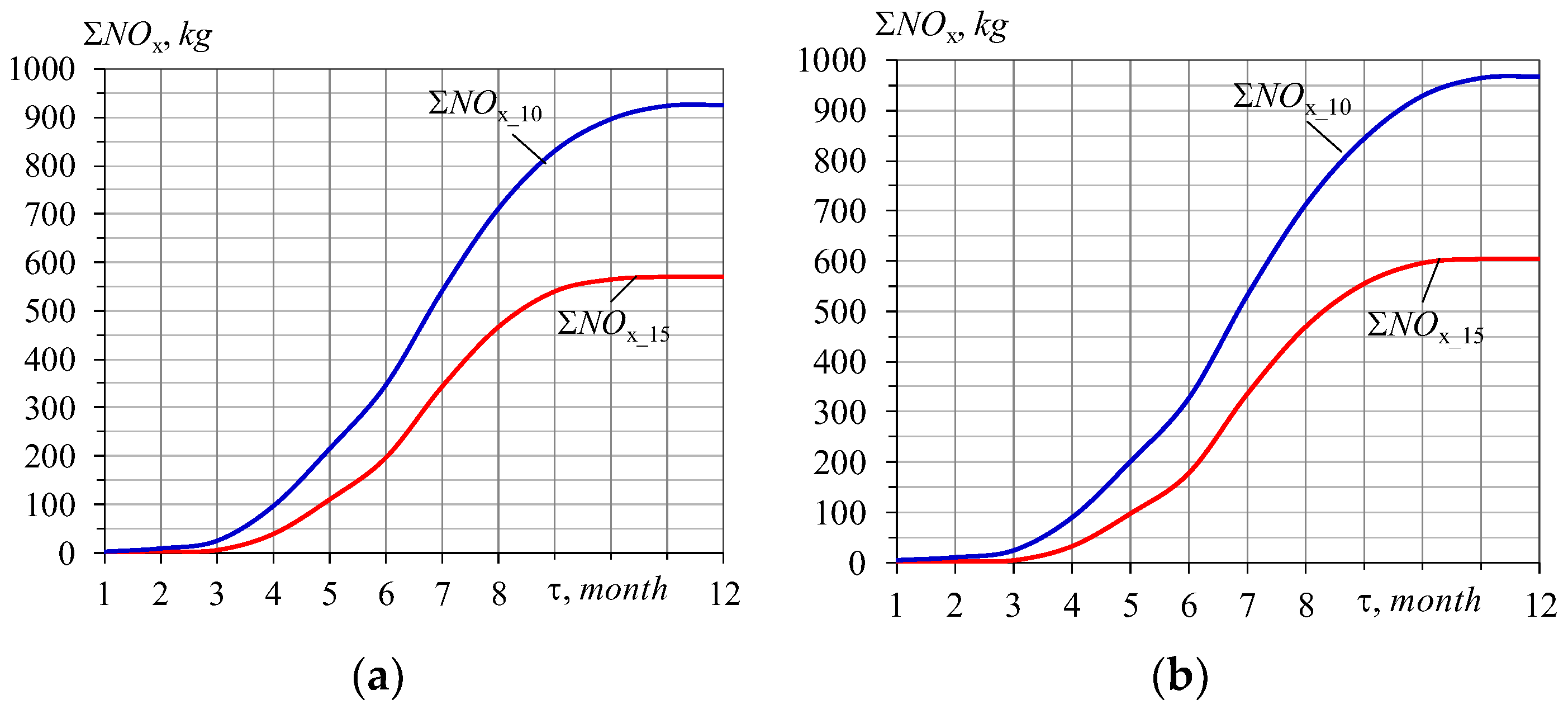

2. Materials and Methods

2.1. General Assumptions and Hypothesis

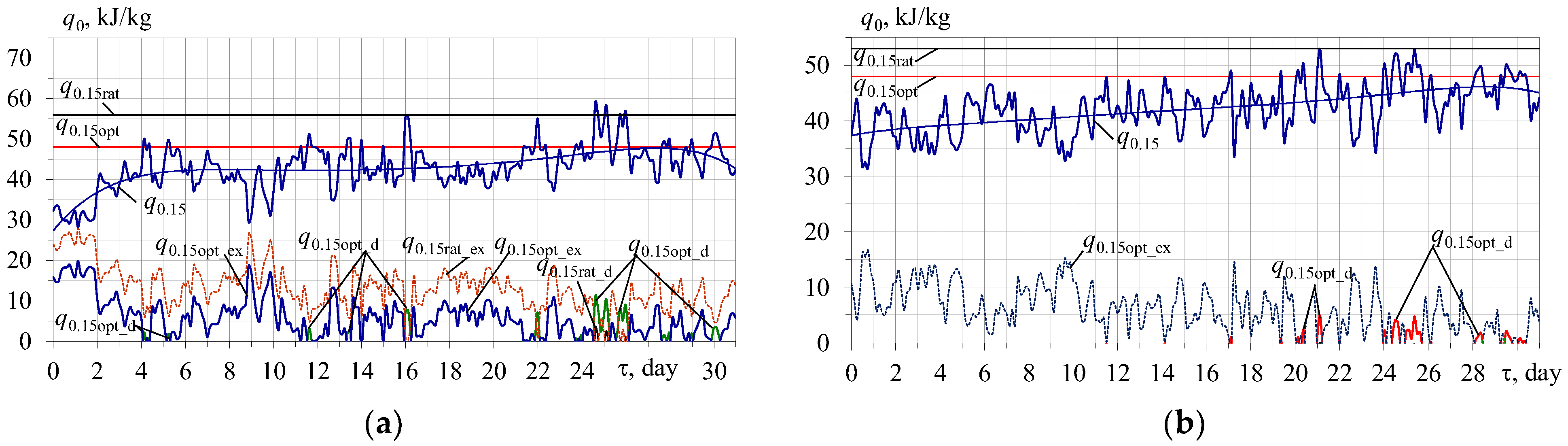

- The values of the TIAC system cooling capacity, which provide the maximum rate of the total increase in annual effect due to TIAC, and provide practically the maximum annual effect, for instance, reduction in fuel consumption, are due to converging dry bulb and wet bulb ambient air temperatures, leading to an increase in actual thermal loading in subtropical climatic conditions.

- Converging the values of cooling capacities, which provide the maximum rate of the total effect increase due to TIAC and maximum annual effect, enables us to design TIAC systems proceeding from the maximum rate of annual effect increase at minimum installed cooling capacity and system sizes accordingly.

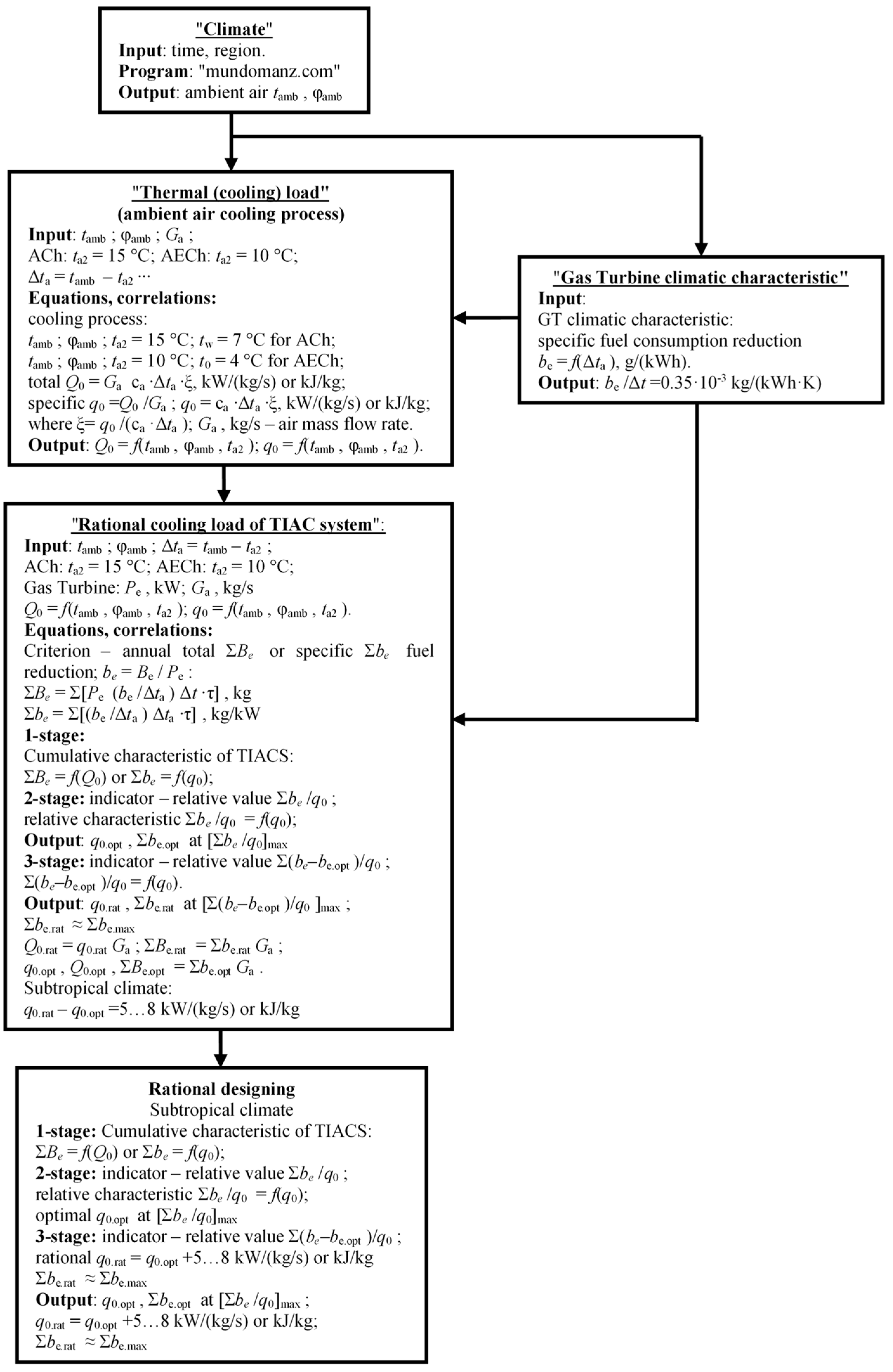

2.2. The Computation Procedure

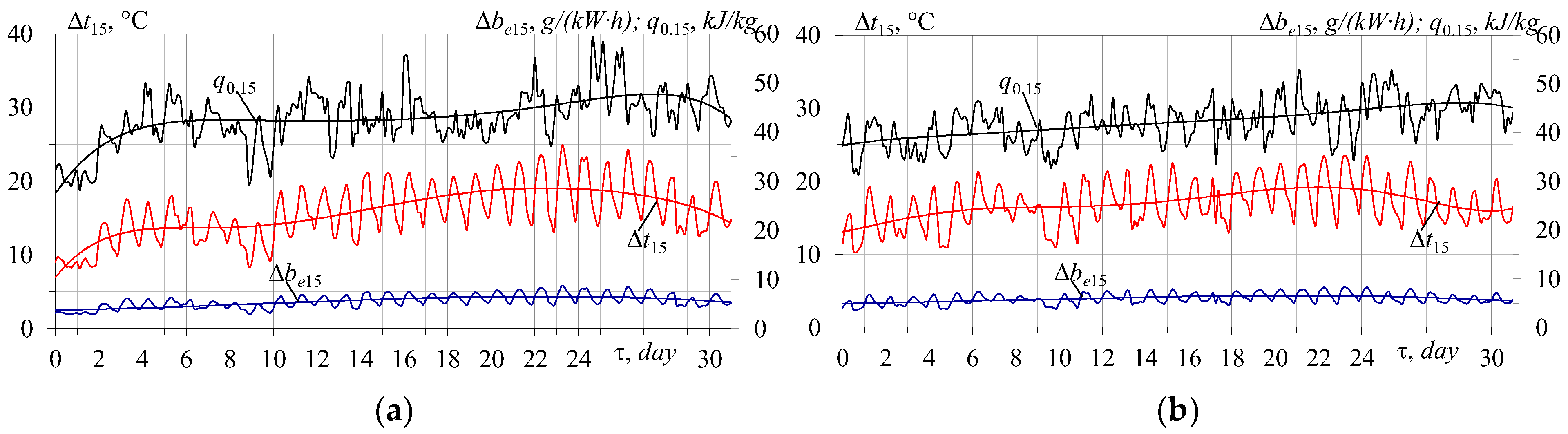

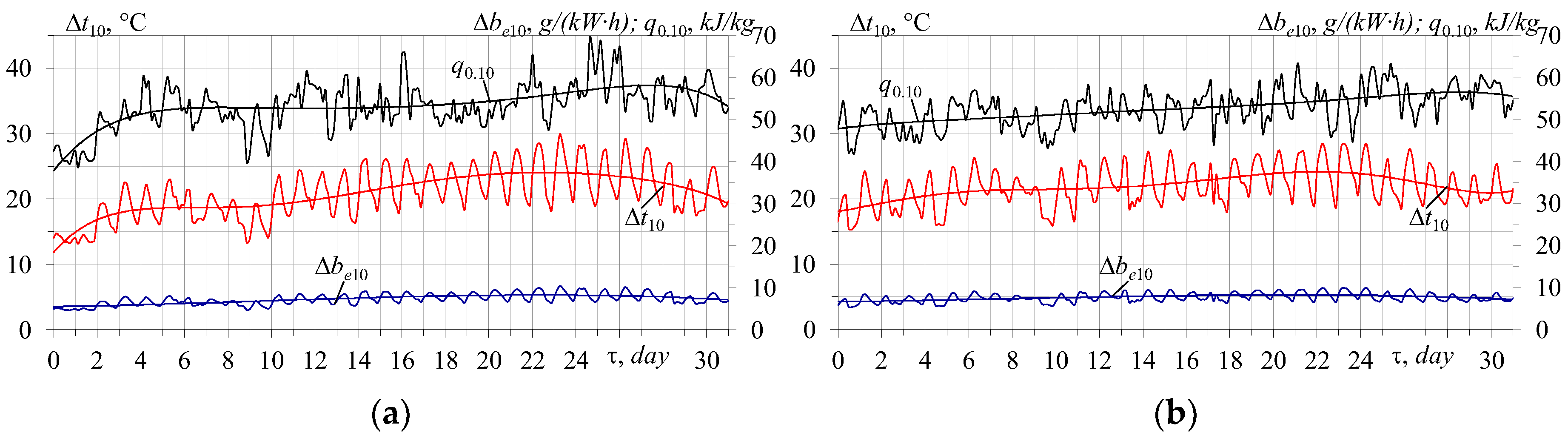

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Nomenclature and units | ||

| ACh | Absorption lithium-bromide chiller | |

| AECh | Absorption–ejector chiller | |

| COP | Coefficient of performance | |

| ECh | Ejector chiller | |

| GT | Gas turbine | |

| TIAC | Turbine intake air cooling | |

| WAC | Water Atomization Cooling | |

| Symbols and units | ||

| a | ambient air | |

| B | fuel reduction | t |

| be | specific fuel consumption | g/kWh |

| cma | air specific heat | kJ/(kg·K) |

| da | absolute humidity | g/kg |

| G | mass flow rate | kg/s |

| Pe | power | kW |

| Q0 | total cooling capacity | kW |

| q0 | specific cooling capacity | kJ/kg; kW/(kg/s) |

| q0.15opt; q0.10opt | optimum values for cooling air to 15 °C and 10 °C | kJ/kg |

| q0.15rat; q0.10rat | rational values for cooling air to 15 °C and 10 °C | kJ/kg |

| q0.15rat_ex | excess of rational design value when cooling air to 15 °C | kJ/kg |

| q0.15opt_d | deficit of optimum design value when cooling air to 15 °C | kJ/kg |

| ta | air temperature | °C; K |

| φ | relative humidity | % |

| τ | time | h |

| Δt | temperature drop | °C; K |

| ΣB | annual, monthly fuel reduction | t |

| ξ | specific heat ratio | |

| Subscripts | ||

| 10, 15 | set temperature 10 °C and 15 °C | |

| a | ambient air | |

| d | deficit | |

| ex | excess | |

| f | fuel | |

| max | maximum | |

| opt | optimum | |

| rat | rational | |

Appendix A

References

- Patel, V.R.; Chaudhari, K.V.; Pathak, B.C.; Shekh, A.A. Evaluation of output and heat rate of the simple cycle gas turbine during the base load condition. Int. J. Adv. Res. Eng. Sci. Technol. (IJAREST) 2015, 2, 2394–2444. [Google Scholar]

- Yang, Z.; Radchenko, R.; Radchenko, M.; Radchenko, A.; Kornienko, V. Cooling potential of ship engine intake air cooling and its realization on the route line. Sustainability 2022, 14, 15058. [Google Scholar] [CrossRef]

- Radchenko, M.; Mikielewicz, D.; Andreev, A.; Vanyeyev, S.; Savenkov, O. Efficient ship engine cyclic air cooling by turboexpander chiller for tropical climatic conditions. In Integrated Computer Technologies in Mechanical Engineering (ICTM 2020); Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2021; Volume 188, pp. 498–507. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Radchenko, M.; Radchenko, A.; Pavlenko, A.; Konovalov, D. Cooling cyclic air of marine engine with water-fuel emulsion combustion by exhaust heat recovery chiller. Energies 2022, 15, 248. [Google Scholar] [CrossRef]

- Maravera, D.; Sina, A.; Royob, J.; Sebastián, F. Assessment of CCHP systems based on biomass combustion for small-scale applications through a review of the technology and analysis of energy efficiency parameters. Appl. Energy 2013, 102, 1303–1313. [Google Scholar] [CrossRef]

- Radchenko, A.; Scurtu, I.-C.; Radchenko, M.; Forduy, S.; Zubarev, A. Monitoring the efficiency of cooling air at the inlet of gas engine in integrated energy system. Therm. Sci. 2022, 26 Pt A, 185–194. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, Z.; Hao, H.; Chang, L.J. Application research of intake-air cooling technologies in gas-steam combined cycle power plants in China. Power Energy Eng. 2014, 2, 304–311. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, N.; Tsoy, A.; Portnoi, B.; Kantor, S. Increasing the efficiency of gas turbine inlet air cooling in actual climatic conditions of Kazakhstan and Ukraine. In Proceedings of the AIP Conference Proceedings, Nur-Sultan, Kazakhstan, 26–29 February 2020; Volume 2285, p. 030071. [Google Scholar] [CrossRef]

- Mohapatra, A.K. Comparative analysis of inlet air cooling techniques integrated to cooled gas turbine plant. J. Energy Inst. 2015, 88, 344–358. [Google Scholar] [CrossRef]

- Kamal, S.N.O.; Salim, D.A.; Fouzi, M.S.M.; Khai, D.T.H.; Yusof, M.K.Y. Feasibility Study of Turbine Inlet Air Cooling using Mechanical Chillers in Malaysia Climate. Energy Procedia 2017, 138, 558–563. [Google Scholar] [CrossRef]

- Popli, S.; Rodgers, P.; Eveloy, V. Trigeneration scheme for energy efficiency enhancement in a natural gas processing plant through turbine exhaust gas waste heat utilization. Appl. Energy 2012, 93, 623–636. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, M.; Mikielewicz, D.; Pavlenko, A.; Radchenko, R.; Forduy, S. Energy saving in trigeneration plant for food industries. Energies 2022, 15, 1163. [Google Scholar] [CrossRef]

- Liang, X.; He, G.; Zhou, S.; Hao, Z.; Cai, D. Absorption characteristics of NH3/NaSCN working pair in an adiabatic absorber with structured packing. Appl. Therm. Eng. 2021, 185, 116325. [Google Scholar] [CrossRef]

- Al-Tahaineh, H.A. Cooling of compressor air inlet of a gas turbine power plant using ammonia-water vapor absorption system. Int. J. Energy Eng. 2013, 3, 267–271. [Google Scholar]

- Radchenko, R.; Radchenko, N.; Tsoy, A.; Forduy, S.; Zybarev, A.; Kalinichenko, I. Utilizing the heat of gas module by an absorption lithium-bromide chiller with an ejector booster stage. In Proceedings of the AIP Conference Proceedings, Nur-Sultan, Kazakhstan, 26–29 February 2020; Volume 2285, p. 030084. [Google Scholar] [CrossRef]

- Elberry, M.F.; Elsayed, A.; Teamah, M.; Abdel-Rahman, A.; Elsafty, A. Performance improvement of power plants using absorption cooling system. Alex. Eng. J. 2018, 57, 2679–2686. [Google Scholar] [CrossRef]

- Umberto, L. Adsorber efficiency in adsorption refrigeration. Renew. Sustain. Energy Rev. 2013, 20, 570–575. [Google Scholar]

- Sur, A.; Das, R.K.; Sah, R.P. Influence of Initial Bed Temperature on Bed Performance of an Adsorption Refrigeration System. Therm. Sci. 2018, 22, 2583–2595. [Google Scholar] [CrossRef]

- Barreto, D.; Fajardo, J.; Caballero, G.C.; Escorcia, Y.C. Innovative exergy and exergoeconomic analysis of a gas power system with steam injection and air cooling with a compression refrigeration machine. Energy Technol. 2021, 9, 2000993. [Google Scholar] [CrossRef]

- Yang, Z.; Korobko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R. Improving thermoacoustic low temperature heat recovery systems. Sustainability 2022, 14, 12306. [Google Scholar] [CrossRef]

- Pourhedayat, S.; Hu, E.; Chen, L. An improved semi-analytical model for evaluating performance of gas turbine power plants. Energy 2022, 267, 126583. [Google Scholar] [CrossRef]

- Serbin, S.I.; Kozlovskyi, A.V.; Burunsuz, K.S. Investigations of Nonstationary Processes in Low Emissive Gas Turbine Combustor with Plasma Assistance. IEEE Trans. Plasma Sci. 2016, 44, 2960–2964. [Google Scholar] [CrossRef]

- Anoop, K.S.; Oskar, S. Performance evaluation of steam injected gas turbine based power plant with inlet evaporative cooling. Appl. Therm. Eng. 2016, 102, 454–464. [Google Scholar]

- Dizaji, H.S.; Hu, E.J.; Chen, L.; Pourhedayat, S. Using novel integrated Maisotsenko cooler and absorption chiller for cooling of gas turbine inlet air. Energy Convers. Manag. 2019, 195, 1067–1078. [Google Scholar] [CrossRef]

- Baakeem, S.S.; Orfi, J.; Al-Ansary, H. Performance improvement of gas turbine power plants by utilizing turbine inlet air-cooling (TIAC) technologies in Riyadh, Saudi Arabia. Appl. Therm. Eng. 2018, 138, 417–432. [Google Scholar] [CrossRef]

- Kwon, H.M.; Kim, T.S.; Sohn, J.L. Performance improvement of gas turbine combined cycle power plant by dual cooling of the inlet air and turbine coolant using an absorption chiller. Energy 2018, 163, 1050–1061. [Google Scholar] [CrossRef]

- Forsyth, J.L. Gas turbine inlet air chilling for LNG. IGT Int. Liq. Nat. Gas Conf. Proc. 2013, 3, 1763–1778. [Google Scholar]

- Kalhori, S.B.; Rabiei, H.; Mansoori, Z. Mashad trigeneration potential—An opportunity for CO2 abatement in Iran. Energy Conv. Manag. 2012, 60, 106–114. [Google Scholar] [CrossRef]

- Chen, G.; Volovyk, O.; Zhu, D.; Ierin, V.; Shestopalov, K. Theoretical analysis and optimization of a hybrid CO2 transcritical mechanical compression–ejector cooling cycle. Int. J. Refrig. 2017, 74, 84–92. [Google Scholar] [CrossRef]

- Chen, G.; Ierin, V.; Volovyk, O.; Shestopalov, K. An improved cascade mechanical compression–ejector cooling cycle. Energy 2019, 170, 459–470. [Google Scholar] [CrossRef]

- Konovalov, D.; Radchenko, M.; Kobalava, H.; Kornienko, V.; Maksymov, V.; Radchenko, A.; Radchenko, R. Research of characteristics of the flow part of an aerothermopressor for gas turbine intercooling air. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 634–646. [Google Scholar] [CrossRef]

- Yang, Z.; Konovalov, D.; Radchenko, M.; Radchenko, R.; Kobalava, H.; Radchenko, A.; Kornienko, V. Analyzing the efficiency of thermopressor application for combustion engine cyclic air cooling. Energies 2022, 15, 2250. [Google Scholar] [CrossRef]

- Ierin, V.; Chen, G.; Volovyk, O.; Shestopalov, K. Hybrid two–stage CO2 transcritical mechanical compression–ejector cooling cycle: Thermodynamic analysis and optimization. Int. J. Refrig. 2021, 132, 45–55. [Google Scholar] [CrossRef]

- Chen, G.; Zhelezny, V.; Khliyeva, O.; Shestopalov, K.; Ierin, V. Ecological and energy efficiency analysis of ejector and vapor compression air conditioners. Int. J. Refrig. 2017, 74, 127–135. [Google Scholar] [CrossRef]

- Ghatos, S.; Taha-Janan, M.; Mehdari, A. Thermodynamic model of a single stage H2O-LiBr absorption cooling. In Proceedings of the E3S Web of Conferences, Kenitra, Morocco, 25–27 December 2020; Volume 234, p. 00091. [Google Scholar]

- Radchenko, M.; Portnoi, B.; Kantor, S.; Forduy, S.; Konovalov, D. Rational Thermal Loading the Engine Inlet Air Chilling Complex with Cooling Towers. In Advanced Manufacturing Processes II; InterPartner 2020; Lecture Notes in Mechanical, Engineering; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Grabchenko, A., Pavlenko, I., Edl, M., Kuric, I., Dasic, P., Eds.; Springer: Cham, Switzerland, 2021; pp. 724–733. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Bohdal, T.; Radchenko, M.; Andreev, A. Thermal characteristics of the wet pollution layer on condensing heating surfaces of exhaust gas boilers. In Advances in Design, Simulation and Manufacturing IV; DSMIE 2021; Lecture Notes in Mechanical Engineering; Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M., Eds.; Springer: Cham, Switzerland, 2021; pp. 339–348. [Google Scholar] [CrossRef]

- Yang, Z.; Kornienko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R.; Pavlenko, A. Capture of pollutants from exhaust gases by low-temperature heating surfaces. Energies 2022, 15, 120. [Google Scholar] [CrossRef]

- Radchenko, N. A concept of the design and operation of heat exchangers with change of phase. Arch. Thermodyn. 2004, 25, 3–19. [Google Scholar]

- Nikulin, A.; Khliyeva, O.; Zhelezny, V.; Semenyuk, Y.; Lukianov, N.; Moreira, A.L.N. How does change of the bulk concentration affect the pool boiling of the refrigerant oil solutions and their mixtures with surfactant and nanoparticles? Int. J. Heat Mass Transf. 2019, 137, 868–875. [Google Scholar] [CrossRef]

- Khliyeva, O.; Zhelezny, V.; Lukianov, T.; Lukianov, N.; Semenyuk, Y.; Moreir, A.L.N.; Murshed, S.M.S.; Palomo del Barrio, E.; Nikulin, A. A new approach for predicting the pool boiling heat transfer coefficient of refrigerant R141b and its mixtures with surfactant and nanoparticles using experimental data. J. Therm. Anal. Calorim. 2020, 142, 2327–2339. [Google Scholar] [CrossRef]

- Kruzel, M.; Bohdal, T.; Dutkowski, K.; Radchenko, M. The Effect of Microencapsulated PCM Slurry Coolant on the Efficiency of a Shell and Tube Heat Exchanger. Energies 2022, 15, 5142. [Google Scholar] [CrossRef]

- Yu, Z.; Løvås, T.; Konovalov, D.; Trushliakov, E.; Radchenko, M.; Kobalava, H.; Radchenko, R.; Radchenko, A. Investigation of thermopressor with incomplete evaporation for gas turbine intercooling systems. Energies 2022, 15, 20. [Google Scholar] [CrossRef]

- Zhelezny, V.; Khliyeva, O.; Lukianov, M.; Motovoy, I.; Ivchenko, D.A.; Faik, A.; Grosu Ya Nikulin, A.; Moreira, A.L.N. Thermodynamic properties of isobutane/mineral compressor oil and isobutane/mineral compressor oil/fullerenes C60 solutions. Int. J. Refrig. 2019, 106, 153–162. [Google Scholar] [CrossRef]

- Shevchenko, S.; Shevchenko, O.; Vynnychuk, S. Mathematical Modelling of Dynamic System Rotor-Groove Seals for the Purposes of Increasing the Vibration Reliability of NPP Pumps. Nucl. Radiat. Saf. 2021, 1, 80–87. [Google Scholar] [CrossRef]

- Shevchenko, S.; Shevchenko, O. Improvement of Reliability and Ecological Safety of NPP Reactor Coolant Pump Seals. Nucl. Radiat. Saf. 2020, 4, 47–55. [Google Scholar] [CrossRef]

- Blecich, P. Experimental investigation of the effects of airflow nonuniformity on performance of a fin-and-tube heat exchanger. Int. J. Refrig. 2015, 59, 65–74. [Google Scholar] [CrossRef]

- Pourhedayat, S.; Hu, E.; Chen, L. A comparative and critical review on gas turbine intake air pre-cooling strategies. Therm. Sci. Eng. Prog. 2023, 41, 101828. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, G.; Mikielewicz, D. A New Approach for the Mitigating of Flow Maldistribution in Parallel Microchannel Heat Sink. J. Heat Transf. 2018, 140, 72401–72410. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, G.; Mikielewicz, D. Numerical Study on Mitigation of Flow Maldistribution in Parallel Microchannel Heat Sink: Channels Variable Width Versus Variable Height Approach. J. Electron. Packag. 2019, 141, 21009–21011. [Google Scholar] [CrossRef]

- Dąbrowski, P.; Klugmann, M.; Mikielewicz, D. Channel Blockage and Flow Maldistribution during Unsteady Flow in a Model Microchannel Plate heat Exchanger. J. Appl. Fluid Mech. 2019, 12, 1023–1035. [Google Scholar] [CrossRef]

- Dąbrowski, P.; Klugmann, M.; Mikielewicz, D. Selected studies of flow maldistribution in a minichannel plate heat exchanger. Arch. Thermodyn. 2017, 38, 135–148. [Google Scholar] [CrossRef][Green Version]

- Konovalov, D.; Trushliakov, E.; Radchenko, M.; Kobalava, G.; Maksymov, V. Research of the aerothermopresor cooling system of charge air of a marine internal combustion engine under variable climatic conditions of operation. In Grabchenko’s International Conference on Advanced Manufacturing Processes; InterPartner-2019; Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Grabchenko, A., Pavlenko, I., Edl, M., Kuric, I., Dasic, P., Eds.; Springer: Cham, Switzerland, 2020; pp. 520–529. [Google Scholar] [CrossRef]

- Radchenko, N.; Radchenko, A.; Tsoy, A.; Mikielewicz, D.; Kantor, S.; Tkachenko, V. Improving the efficiency of railway conditioners in actual climatic conditions of operation. In Proceedings of the AIP Conference Proceedings, Nur-Sultan, Kazakhstan, 26–29 February 2020; Volume 2285, p. 030072. [Google Scholar] [CrossRef]

- Radchenko, N.; Trushliakov, E.; Radchenko, A.; Tsoy, A.; Shchesiuk, O. Methods to determine a design cooling capacity of ambient air conditioning systems in climatic conditions of Ukraine and Kazakhstan. In Proceedings of the AIP Conference Proceedings, Nur-Sultan, Kazakhstan, 26–29 February 2020; Volume 2285, p. 030074. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Q.; Gong, L.; Lei, J. Application of a mid-/low-temperature solar thermochemical technology in the distributed energy system with cooling, heating and power production. Appl. Energy 2019, 253, 113491. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Mikielewicz, D.; Radchenko, R.; Andreev, A. A novel degree-hour method for rational design loading. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 237, 570–579. [Google Scholar] [CrossRef]

- Coskun, C.; Demiral, D.; Ertürk, M.; Oktay, Z. Modified Degree-Hour Calculation Method. In Solar Power; Radu, R., Ed.; InTech: London, UK, 2012; ISBN 978-953-51-0014-0. Available online: http://www.intechopen.com/books/solar-power/modified-degree-hour-calculation-method (accessed on 22 June 2021).

- Oktay, Z.; Coskun, C.; Dincer, I. A new approach for predicting cooling degree-hours and energy requirements in buildings. Energy 2011, 36, 4855–4863. [Google Scholar] [CrossRef]

- Coskun, C. A novel approach to degree-hour calculation: Indoor and outdoor reference temperature based degree-hour calculation. Energy 2010, 35, 2455–2460. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, M.; Koshlak, H.; Radchenko, R.; Forduy, S. Enhancing the efficiency of integrated trigeneration system by redistribution of heat flows on the base of monitoring data. Energies 2020, 15, 8774. [Google Scholar] [CrossRef]

- Lozano, M.A.; Ramos, J.C.; Serra, L.M. Cost Optimization of the Design of CHCP (Combined Heat, Cooling and Power) Sys-tems under Legal Constraints. Energy 2010, 35, 794–805. [Google Scholar] [CrossRef]

- Pavlenko, A. Energy conversion in heat and mass transfer processes in boiling emulsions. Therm. Sci. Eng. Prog. 2020, 15, 00439. [Google Scholar] [CrossRef]

- Kavvadias, K.C.; Tosios, A.P.; Maroulis, Z.B. Design of a combined heating, cooling and power system: Sizing, operation strategy selection and parametric analysis. Energy Convers. Manag. 2010, 51, 833–845. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A. A methodology for sizing a trigeneration plant in mediterranean areas. Appl. Therm. Eng. 2003, 23, 15. [Google Scholar] [CrossRef]

- Shevchenko, S.; Chernov, A. Development of pulse mechanical seal calculation methods on the basis of its physical model construction. East.-Eur. J. Enterp. Technol. 2020, 3, 58–69. [Google Scholar] [CrossRef]

- Freschi, F.; Giaccone, L.; Lazzeroni, P.; Repetto, M. Economic and environmental analysis of a trigeneration system for food-industry: A case study. Appl. Energy 2013, 107, 157–172. [Google Scholar] [CrossRef]

- Ortiga, J.; Bruno, J.C.; Coronas, A. Operational optimization of a complex trigeneration system connected to a district heating and cooling network. Appl. Therm. Eng. 2013, 50, 1536–1542. [Google Scholar] [CrossRef]

- Rodriguez-Aumente, P.A.; Rodriguez-Hidalgo, M.C.; Nogueira, J.I.; Lecuona, A.; Veneg, M.C. District heating and cooling for business buildings in Madrid. Appl. Therm. Eng. 2013, 50, 1496–1503. [Google Scholar] [CrossRef]

- Khliyeva, O.; Shestopalov, K.; Ierin, V.; Zhelezny, V.; Chen, G.; Gao, N. Environmental and energy comparative analysis of expediency of heat-driven and electrically-driven refrigerators for air conditioning application. Appl. Therm. Eng. 2022, 219 Pt. B, 119533. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Trushliakov, E.; Pavlenko, A.M.; Radchenko, R. Advanced method of variable refrigerant flow (VRF) systems designing to forecast on site operation–Part 1: General approaches and criteria. Energies 2023, 16, 1381. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Trushliakov, E.; Koshlak, H.; Radchenko, R. Advanced method of variable refrigerant flow (VRF) systems designing to forecast on site operation—Part 2: Phenomenological simulation to recuperate refrigeration energy. Energies 2023, 16, 1922. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Trushliakov, E.; Pavlenko, A.; Radchenko, R. Advanced Method of Variable Refrigerant Flow (VRF) System Design to Forecast on Site Operation—Part 3: Optimal Solutions to Minimize Sizes. Energies 2023, 16, 2417. [Google Scholar] [CrossRef]

- Khliyeva, O. New indicator for life cycle greenhouse gases emission assessment of household refrigerating appliances. Environ. Probl. 2019, 4, 39–44. [Google Scholar] [CrossRef]

- Yang, Z.; Radchenko, M.; Radchenko, A.; Mikielewicz, D.; Radchenko, R. Gas turbine intake air hybrid cooling systems and a new approach to their rational designing. Energies 2022, 15, 1474. [Google Scholar] [CrossRef]

- Pavlenko, A.M.; Koshlak, H. Application of thermal and cavitation effects for heat and mass transfer process intensification in multicomponent liquid media. Energies 2021, 14, 7996. [Google Scholar] [CrossRef]

- Shubenko, A.; Babak, M.; Senetskyi, O.; Tarasova, V.; Goloshchapov, V.; Senetska, D. Economic assessment of the modernization perspectives of a steam turbine power unit to the ultra-supercritical operation conditions. Int. J. Energy Res. 2022, 46, 23530–23537. [Google Scholar] [CrossRef]

- Naeim, K.A.; Hegazi, A.A.; Awad, M.M.; El-Emam, S.H. Inlet air fogging strategy using natural gas fuel cooling potential for gas turbine power plants. Case Stud. Therm. Eng. 2022, 37, 102235. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radchenko, M.; Yang, Z.; Pavlenko, A.; Radchenko, A.; Radchenko, R.; Koshlak, H.; Bao, G. Increasing the Efficiency of Turbine Inlet Air Cooling in Climatic Conditions of China through Rational Designing—Part 1: A Case Study for Subtropical Climate: General Approaches and Criteria. Energies 2023, 16, 6105. https://doi.org/10.3390/en16176105

Radchenko M, Yang Z, Pavlenko A, Radchenko A, Radchenko R, Koshlak H, Bao G. Increasing the Efficiency of Turbine Inlet Air Cooling in Climatic Conditions of China through Rational Designing—Part 1: A Case Study for Subtropical Climate: General Approaches and Criteria. Energies. 2023; 16(17):6105. https://doi.org/10.3390/en16176105

Chicago/Turabian StyleRadchenko, Mykola, Zongming Yang, Anatoliy Pavlenko, Andrii Radchenko, Roman Radchenko, Hanna Koshlak, and Guozhi Bao. 2023. "Increasing the Efficiency of Turbine Inlet Air Cooling in Climatic Conditions of China through Rational Designing—Part 1: A Case Study for Subtropical Climate: General Approaches and Criteria" Energies 16, no. 17: 6105. https://doi.org/10.3390/en16176105

APA StyleRadchenko, M., Yang, Z., Pavlenko, A., Radchenko, A., Radchenko, R., Koshlak, H., & Bao, G. (2023). Increasing the Efficiency of Turbine Inlet Air Cooling in Climatic Conditions of China through Rational Designing—Part 1: A Case Study for Subtropical Climate: General Approaches and Criteria. Energies, 16(17), 6105. https://doi.org/10.3390/en16176105