Abstract

The maintenance strategy used in an electric power plant plays a crucial role in its overall performance and operational efficiency. An effective maintenance strategy describes the approach to exploiting various forms of maintenance (corrective, preventive, predictive, proactive, etc.) in an electric power plant. In this paper, the effective and ineffective impacts of maintenance strategies on power plants were examined. Also, the distinction between corrective, preventive, and aggressive maintenance was considered. In terms of effective impacts, a well-designed and executed maintenance strategy enhances the reliability and availability of the electric power plant by minimising unplanned downtime. It extends the lifespan of critical equipment, improves safety measures, increases energy efficiency, and contributes to long-term cost savings. However, in terms of ineffective impacts, poorly planned or executed maintenance strategies can result in increased downtime, higher repair costs, safety risks, decreased efficiency, and regulatory compliance issues. Neglecting maintenance can lead to equipment failures, reduced productivity, and potential environmental incidents.

1. Introduction

An electric power plant is a complex and critical facility that is responsible for the generation and supply of electricity to consumers. To ensure a plant operates efficiently and reliably, implementing an effective maintenance strategy is crucial. Such a strategy should consider both the effective and ineffective impacts of the maintenance activity. By understanding and balancing these impacts, electric power plant operators can optimise performance, minimise downtime, and reduce maintenance costs. On the other hand, a maintenance strategy can be considered a framework in which a wide range of maintenance actions (corrective, preventive, predictive, proactive, etc.) are planned [1]. This research assesses the differences between three distinct maintenance approaches:

- i.

- Corrective maintenance;

- ii.

- Preventive maintenance;

- iii.

- Aggressive maintenance.

The maintenance function, and hence maintenance management, has expanded dramatically in importance within India’s industrial sector in recent years. With today’s ever-changing business climate, upkeep has grown increasingly difficult [2]. The wastefulness and potential shutdown of a manufacturing line are two additional costs associated with defect creation. Effective maintenance plans are required for keeping tabs on machinery, controlling its use, and increasing its efficiency so that it can produce at maximum capacity. As a result, selecting an appropriate maintenance strategy is crucial for ensuring the smooth operation of all equipment and machinery [3]. The major contribution of this research is the development of an enhanced framework for designing an effective maintenance strategy for electric power plants, considering effective and ineffective impacts. Also, the methodology proposed can easily be applied in other institutions, such as healthcare facilities, for the ideal choice of maintenance strategy. A further contribution is that this framework presents different applications of the decision criteria. These criteria can be applied based on the specific circumstances of different institutions.

2. Related Work

This section of the research presents a review of related works based on the effective and ineffective impacts of maintenance strategies adopted by electric power plants. Related works are first presented, followed by the introduction of a summary table to identify the author, contribution, results, and limitations.

Research in [4] present maintenance of electric power plant functionality even when no strategic framework is not implemented. Usually, a framework for maintenance strategy presents a company’s long-term goals and directs upper management and front-line employees toward achieving those goals. Based on the results of the research, there are normally three main components in a company strategy. These are long-term goals, short-term goals, and a plan on how to achieve them. These three components must be included in the plans of electric power plants and any other maintenance plans. However, [4] is limited in conducting extensive presentation for a maintenance framework. The manuscript suggests conducting research on framework for effective and ineffective maintenance strategy.

Ref. [5] presented the need to exploit an existing maintenance technique and adopt its crucial parts when developing new maintenance techniques. The whole organisation must understand and buy into the maintenance plan for it to be effective. It is equally important to obtain the support of upper management. Good maintenance, like successful safety and quality management, requires contributions from all levels of an organisation. In [5], a strategy was presented, but the paper did not specifically indicate the policy framework of the power plant.

The research in [6] indicated that to guarantee electrical production quantity, quality, and maintenance cost goals, there must be a safety, health, and environmental framework to be followed without compromise. In the research, it was noted that maintenance management must consider shift management to effectively plan, organise, and regulate the maintenance resources in the power plant.

The comprehensive research in [7] analysed the importance of the maintenance management team in lessening the frequency of maintenance and enhancing affordable production cost. The paper also assessed how different approaches and strategies affect production and maintenance costs, considering the global economic downturn and its impact. Competition between enterprises and power plants has expanded due to the deregulation of the electricity generation and distribution sector in Southern Africa during the last decade or two. The management of a power plant is under pressure to improve availability and lower production costs when the effective impacts of maintenance costs are not applied.

An analysis was conducted in [8] that assessed electricity production costs during World War II. Based on the results, most maintenance processes were performed only when necessary (breakdown maintenance). However, some low-level preventive maintenance was undertaken on weapons systems to maximise mission availability. This included, for example, monitoring oil levels and finding faults in essential equipment. However, the research did not include the effective and ineffective impacts of maintenance.

Recently, ref. [9] stated that increased performance and availability of physical assets require extensive preventive maintenance, which becomes necessary with the introduction of complex systems using increasingly advanced technology. Breakdown maintenance was the primary method of upkeep in older power plants. Thus, proactive maintenance services are conducted even before a breakdown occurs. However, the paper only considered the effective impacts of the maintenance strategy.

According to [10], electrical equipment’s entire lifespan is well utilized effectively, until when failure occured used. As a result, the power supply to clients may be interrupted, and there is a risk of safety, health, and environmental (SHE) impacts due to random breakdowns. If electricity is interrupted, customers like smelting companies might incur substantial material and financial losses. This indicates that ineffective maintenance strategies are adopted from time to time.

Research on condition-based maintenance was conducted in [11], which explored basic condition monitoring methods, such as visual inspections and sound checks. These methods have been used for a long time, being introduced around the early 1970s. Therefore, the results showed that more advanced methods, such as vibration analysis and oil monitoring, have gained widespread acceptance. In condition-based maintenance (CBM), also known as predictive maintenance, the asset is inspected at regular intervals to measure and record data that may be used to assess its health. As a result of using condition-based maintenance during the previous two to three decades, many power plants have seen major performance improvements. However, condition-based maintenance requires consideration of both the effective and ineffective impacts of maintenance strategies for enhancement.

Table 1 below provides a summarised review of the related works, presenting their results, contributions, and limitations.

Table 1.

Summary of related work.

Table 1.

Summary of related work.

| Author | Contributions (Strengths) | Results | Limitations |

|---|---|---|---|

| [1] | This paper reviewed a strategy for maintaining the electric energy transition in terms of production and costs in a power plant. | The results presented the impacts of the social, economic, and environmental pillars of energy sustainability in terms of an effective maintenance strategy. | The research recommends investigation and development of effective and non effective maintenance strategy as a framework. |

| [2] | This paper presented digital twin maintenance as a framework. | The results from applying the framework in an existing electric power plant were presented, with an analysis of how digital twins are currently being applied in maintenance. | The type of research conducted in this paper has not been conducted by many researchers, but it recommended that analyses should be conducted in terms of the effective and ineffective impacts of the maintenance framework. |

| [3] | This paper proposed a conceptual classification framework for assessing maintenance policy optimisation. This includes energy systems and structures such as turbines, foundations, power cables, and electrical substations. | The results presented an existing framework that addresses a wide range of theoretical and practical issues in electric power plants. These include models, methods, and strategies that can be used to optimise maintenance decisions and inspection procedures. | This paper was limited in conducting systematically classified research using numerous criteria and some research directions of potential interest to operational researchers, such as the effective and ineffective impacts of maintenance strategies. |

| [4] | This paper presented a new decision support system that functions based on decision trees (DTs). The DTs guide the decision making for predictive maintenance implementation using direct and indirect maintenance and production costs. The DTs enable different scenarios to be studied to identify strategies where a predictive maintenance policy functions based on a machine learning algorithm. | The DT results presented a simple approach to implementing a tool that supports the decision process by assessing all levels of occurrence and the severity of failures. | The DTs are limited but can be applied in new technologies adopted by electric power plants to enhance performance. |

3. Methodology

This research adopted a mixture of research techniques (qualitative and quantitative) to ensure the development of a functional maintenance strategy framework for electric power plants (effective and ineffective impacts). The maintenance strategy was examined using critical parameters, including preventive maintenance (PM), predictive maintenance (PdM), and corrective maintenance (CM) strategies. Each strategy has its own effective and ineffective impacts, as presented below.

- i.

- Preventive maintenance (PM) involves regularly scheduled inspections, servicing, and component replacements to prevent failures before they occur. The effective impacts of PM are the reduction in equipment breakdowns and increased reliability. However, ineffective impacts may include excessive costs if maintenance tasks are performed too frequently or on non-critical components;

- ii.

- Predictive maintenance (PdM) utilises condition monitoring techniques, such as vibration analysis, thermal imaging, and oil analysis, to detect early signs of equipment deterioration and schedule maintenance accordingly. The effective impacts of PdM are the maximisation of equipment uptime, the optimisation of maintenance schedules, and the minimisation of unnecessary maintenance. Ineffective impacts arise when condition monitoring techniques are not accurate or when maintenance actions are delayed despite clear indications of impending failures;

- iii.

- Corrective maintenance (CM) involves repairing or replacing failed components after a breakdown has occurred. While CM is generally considered reactive, it is still an essential part of a maintenance strategy. The effective impacts of CM include the timely restoration of equipment functionality, the minimisation of downtime, and the reduction in the need for unnecessary preventive tasks. However, the ineffective impacts include higher costs associated with emergency repairs, prolonged downtime, and potential safety hazards.

3.1. Analysis Using Markov Chains

Numerous studies apply the concept of Markov chains to model electric power plant systems in terms of effective reliability, availability, and other safety parameters. The research in [1] determined a maintenance policy for a catalytic cracking unit in a power plant. Ref. [2] used a Markov model to predict the impact of alternative inspection strategies and leak detection on piping system reliability. The paper also evaluated the changes in risks due to changes in the in-service inspection programs and leak detection for electrical components. Ref. [3] applied a Markov chain to model demand uncertainty response resources to minimise power. Therefore, Markov chains can be applied in computing the failure probability of generating units in an electric power plant.

3.2. Effective Impacts of Maintenance Strategies

In an effective maintenance strategy framework, a standard operating procedure to assist in executing the maintenance strategy of the electric power plant can have some beneficial impacts, as stated below.

- i.

- Conducting regular maintenance activities, such as preventive and predictive maintenance, in a power plant can minimise unplanned downtime and enhance the power plant’s reliability and availability. This ensures that the plant operates efficiently and consistently meets the demand for electricity;

- ii.

- Conducting effective maintenance practices, such as routine inspections, cleaning, lubrication, and component replacements, can prolong the lifespan of critical equipment. This maximises the return on investment and lessens the need for frequent capital expenditure;

- iii.

- Maintenance strategies that prioritise safety inspections, training programs, and adherence to standard operational procedures contribute to a safer working environment for electric plant personnel. This lessens the risk of accidents, injuries, and potential hazards, ensuring the well-being of employees;

- iv.

- Regular maintenance optimises the performance of power plant equipment and enhances energy efficiency. Therefore, well-maintained turbines, boilers, generators, and other electric components operate at their peak efficiency, with reduced energy waste and lowered operational costs;

- v.

- Although maintenance activities incur operational costs, an effective strategy provides cost optimisation in the long term. By preventing major breakdowns, minimising repair costs, and optimising equipment performance, maintenance leads to an overall cost reduction and enhanced operational efficiency.

3.3. Ineffective Impacts of Maintenance Strategies

A poorly planned or executed maintenance strategy has adverse impacts on electric power plants. These include the following:

- i.

- Inadequate maintenance practices lead to more frequent breakdowns and failures, leading to increased downtime. This practice disrupts the power generation process, reduces reliability, and inconveniences consumers who rely on a consistent power supply;

- ii.

- Neglecting maintenance can lead to minor issues escalating into major failures. This can lead to costly repairs or equipment replacements. Reactive maintenance that involves fixing power plant issues only after they occur often results in higher repair expenses as compared to proactive maintenance strategies;

- iii.

- Insufficient maintenance highly compromises the safety of plant personnel and the surrounding environment. Therefore, ageing equipment, electrical faults, and malfunctioning systems increase the likelihood of accidents, electrical hazards, and environmental incidents.

- iv.

- Without regular maintenance, power plant equipment will experience reduced efficiency due to wear and tear, dirt accumulation, or inefficient operational procedures. These issues result in higher energy consumption, increased emissions, and decreased overall plant performance.

- v.

- Power plants can have various regulations and environmental standards. Inadequate maintenance practices can lead to non-compliance, potentially resulting in penalties, legal issues, and damage to the plant’s reputation.

According to this research, the major difference between the effective and ineffective impacts of maintenance strategies is their clear distinction in terms of efficiency. Effective impacts provide the best practices for ease of maintenance, and ineffective impacts have several inadequacies.

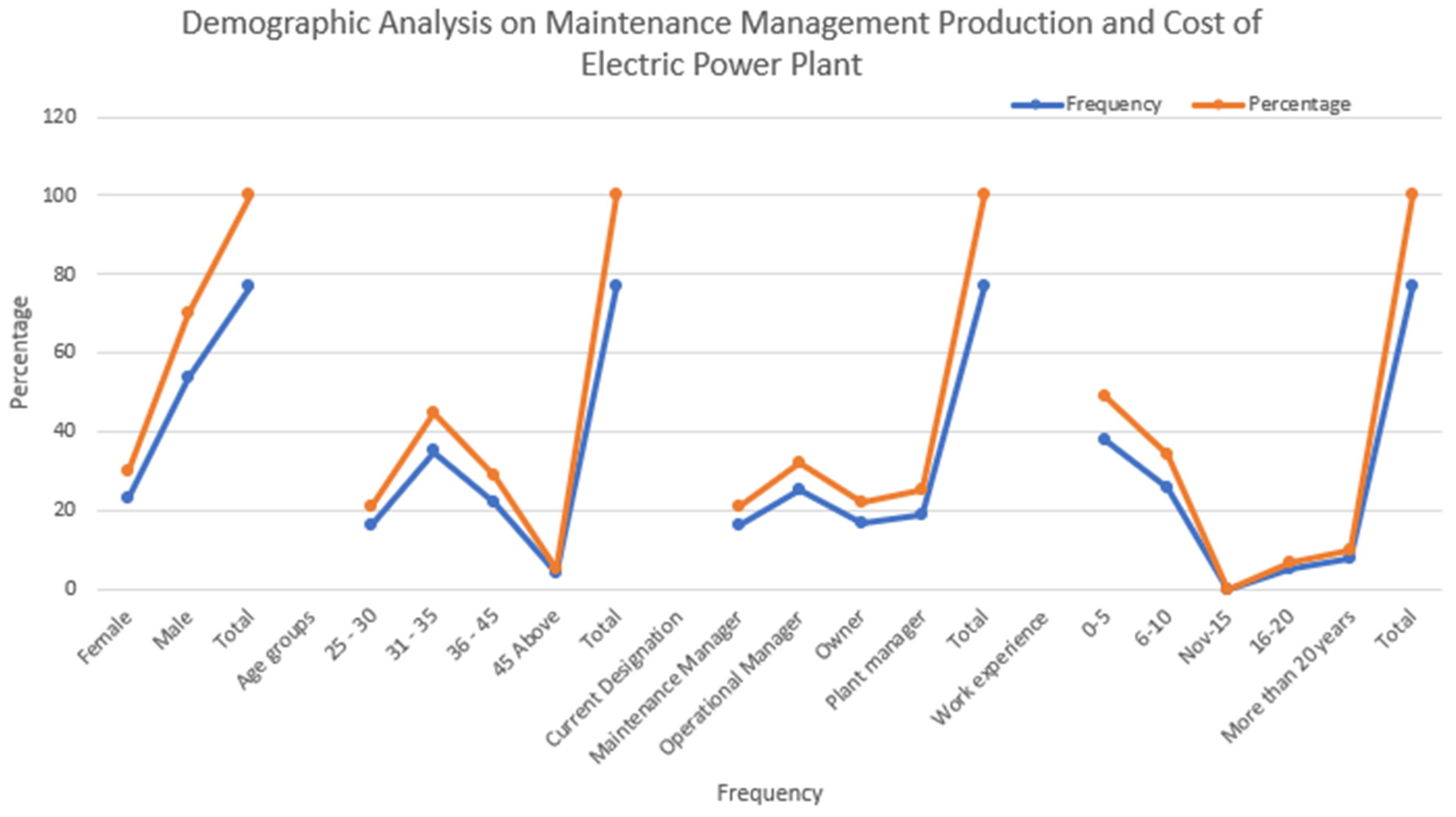

In terms of simulation, the use of a randomised Markov chain model was adopted to examine the demographic data (see Table 2) and present the results in graphical form. A hypothetical approach was used in this research to analyse the methodology of using the effective and ineffective impacts of an electric power plant’s maintenance strategy. The research method followed the rules, procedures, and methods that were used to collect and analyse data. Also, the data generated were efficiently used to draw conclusions from the results of this study.

Demographic analysis was conducted to determine and interpret the data in terms of gender, age group, educational level, current designation, and work experience using frequencies and percentages. Table 2 below presents the demographic analysis.

In addition, Table 2 can be graphically illustrated, as shown in Figure 1 below.

Table 2.

Demographic analysis.

Table 2.

Demographic analysis.

| Gender | Frequency | Percentage |

|---|---|---|

| Female | 23 | 30 |

| Male | 54 | 70 |

| Total | 77 | 100 |

| Age group | ||

| 25–30 | 16 | 21 |

| 31–35 | 35 | 45 |

| 36–45 | 22 | 29 |

| 45 Above | 4 | 5 |

| Total | 77 | 100 |

| Current Designation | ||

| Maintenance manager | 16 | 21 |

| Operational manager | 25 | 32 |

| Owner | 17 | 22 |

| Plant manager | 19 | 25 |

| Total | 77 | 100 |

| Work experience | ||

| 0–5 | 38 | 49 |

| 6–10 | 26 | 34 |

| 11–15 | 0 | 0 |

| 16–20 | 5 | 7 |

| More than 20 years | 8 | 10 |

| Total | 77 | 100 |

Figure 1.

Graphical representation of the demographic analysis.

To further analyse the hypotheses, Table 3 below presents three hypotheses based on Pearson chi-square tests, likelihood ratios, and N of valid cases with respect to their value, df, and asymptotic significance.

Hypothesis 1.

states that there is a significant relationship between installed capacity and the fact that maintenance of a plant is crucial for the safety and preservation of the longevity of plant assets.

Hypothesis 2.

states that there is a significant relationship between the size of a plant and the fact that equipment and machinery deteriorate if proper plant maintenance practices are not followed. The null hypothesis states that there is not a significant relationship.

Hypothesis 3.

states that there is a significant relationship between accidents and the fact that people who work in poorly maintained plants run the danger of getting hurt. The null hypothesis states that there is not a significant relationship.

Table 3.

Chi-square test for Hypotheses 1–3.

Table 3.

Chi-square test for Hypotheses 1–3.

| Chi-Square Test H1 | Chi-Square Test H2 | Chi-Square Test H3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | |

| Pearson Chi-square | 26.34a | 16 | 0.047 | 13.690a | 6 | 0.33 | 31.469a | 16 | 0.12 |

| Likelihood ratio | 30.061 | 16 | 0.018 | 14.085 | 6 | 0.029 | 29.352 | 16 | 0.022 |

| N of valid Cases | 77 | 77 | 77 | ||||||

Several variables were considered in this analysis. However, the maintenance capacity has an insignificant output in electric power plants as it is crucial for the safety and preservation of the longevity of plant assets. From Table 3 above, we can see that the significance value of the Pearson chi-square test was 0.047, which is less than the p-value of 0.05. Hence, we reject the null hypothesis and conclude that there is a significant relationship between installed capacity and the fact that the maintenance of a plant is crucial for the safety and preservation of the longevity of plant assets. This is applicable to Hypotheses 2 and 3. Hypotheses 4–6 are presented (as in Table 4) below.

Hypothesis 4.

states that there is a significant relationship between the problems of shutdown and the fact that equipment and machinery will deteriorate if proper plant maintenance practices are not followed. The null hypothesis states that there is not a significant relationship.

Hypothesis 5.

states that there is a significant relationship between equipment failure and the fact that maintenance of a plant is crucial for the safety and preservation of the longevity of plant assets. The null hypothesis states that there is not a significant relationship.

Hypothesis 6.

states that there is a significant relationship between regular and scheduled maintenance to minimise risks to employees and the fact that people who work in poorly maintained plants run the danger of getting hurt. The null hypothesis states that there is not a significant relationship.

We considered the following variables: How often do you come across problems of shutdown due to improper maintenance of equipment at your plant? Do you believe that equipment and machinery will deteriorate if proper plant maintenance practices are not followed?

Table 4.

Chi-square test for Hypotheses 4–6.

Table 4.

Chi-square test for Hypotheses 4–6.

| Chi-Square Test H4 | Chi-Square Test H5 | Chi-Square Test H6 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | |

| Pearson Chi-square | 27.262a | 12 | 0.007 | 27.262a | 12 | 0.007 | 33.582a | 16 | 0.006 |

| Likelihood ratio | 29.262 | 12 | 0.004 | 29.262 | 12 | 0.004 | 31.561 | 16 | 0.011 |

| N of valid Cases | 77 | 77 | 77 | ||||||

From Table 4 above, we can see that the significance value of the Pearson chi-square test was 0.007, which is less than the p-value of 0.05. Hence, we reject the null hypothesis and conclude that there is a significant relationship between the problems of shutdown and the fact that equipment and machinery will deteriorate if proper plant maintenance practices are not followed. This is applicable to Hypotheses 5 and 6. Hypotheses 7–9 are presented (as in Table 5) below.

Hypothesis 7.

states that there is a significant relationship between maintenance strategy practices and the formulation of a maintenance strategy. The null hypothesis states that there is not a significant relationship.

Hypothesis 8.

states that there is a significant relationship between appropriate manpower management and factors considered while enhancing the maintenance of a plant. The null hypothesis states that there is not a significant relationship.

Hypothesis 9.

states that there is a significant relationship between the condition or nature of a plant and factors considered while enhancing the maintenance of a plant. The null hypothesis states that there is not a significant relationship.

Table 5.

Chi-square test for Hypotheses 7–9.

Table 5.

Chi-square test for Hypotheses 7–9.

| Chi-Square Test H7 | Chi-Square Test H8 | Chi-Square Test H9 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | |

| Pearson Chi-square | 26.490a | 16 | 0.048 | 25.376a | 12 | 0.013 | 31.037a | 16 | 0.013 |

| Likelihood ratio | 29.011 | 16 | 0.024 | 26.474 | 12 | 0.009 | 36.962 | 16 | 0.002 |

| N of valid Cases | 77 | 77 | 77 | ||||||

We considered the following variables: Is it possible for maintenance strategy practices to be conducted in the electric power plant? And how is the maintenance strategy formulated?

From Table 5 above, we can see that the significance value of the Pearson chi-square test was 0.048, which is less than the p-value of 0.05. Hence, we reject the null hypothesis and conclude that there is a significant relationship between maintenance strategy practices and the formulation of a maintenance strategy. This is applicable to Hypotheses 8 and 9.

Hypotheses 10–13 are presented (as in Table 6) below.

Hypothesis 10.

states that there is a significant relationship between the age of a plant and the maintenance strategy. The null hypothesis states that there is not a significant relationship.

Hypothesis 11.

states that there is a significant relationship between the safety measures deployed and the factors considered while enhancing the maintenance of a plant. The null hypothesis states that there is not a significant relationship.

Hypothesis 12.

states that there is a significant relationship between not adopting maintenance and formulating a maintenance strategy. The null hypothesis states that there is not a significant relationship.

Hypothesis 13.

states that there is a significant relationship between companies interested in the maintenance of their plant and factors considered while enhancing the maintenance of the plant. The null hypothesis states that there is not a significant relationship.

Table 6.

Chi-square test for Hypotheses 10–13.

Table 6.

Chi-square test for Hypotheses 10–13.

| Chi-Square Test H10 | Chi-Square Test H11 | Chi-Square Test H12 | Chi-Square Test H13 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | Value | df | Asymptotic Significance (2-Sided) | |

| Pearson chi-square | 20.348a | 12 | 0.61 | 18.439a | 16 | 0.299 | 39.088a | 16 | 0.001 | 23.591a | 12 | 0.023 |

| Likelihood ratio | 21.011 | 12 | 0.050 | 21.910 | 16 | 0.146 | 46.134 | 16 | 0.000 | 24.523 | 12 | 0.017 |

| 77 | 77 | 77 | 77 | |||||||||

We considered the following variables: How old is your power plant? And how do you formulate your plant’s maintenance strategy?

From Table 6 above, we can see that the significance value of the Pearson chi-square square test was 0.061, which is greater than the p-value of 0.05. Hence, we do not reject the null hypothesis and conclude that there is no significant relationship between the age of a plant and the maintenance strategy. This is applicable to Hypotheses 10–13.

4. Results

This section presents the results of the analysis. This includes the hypothesis computation of H1–H5 using Pearson chi-square tests based on the parameters considered in the methodology section. From Hypothesis 1, it was found that installed capacity and the fact that plant maintenance is important for safety and keeping plant assets in good shape for a long time were the most important variables. We can see that the Pearson chi-square test returned a significance value of 0.047, which is less than the 0.05 p-value. Therefore, we do not accept the null hypothesis and conclude that there is a significant link between installed capacity and the fact that plant maintenance is important for safety and keeping plant assets in good shape for a long time. For Hypothesis 2, the variables considered were the size of the plant in terms of employees, and the fact that equipment and machinery will break down if proper plant maintenance practices are not followed. We can see that the Pearson chi-square test returned a significance value of 0.033, which is less than the 0.05 p-value. Therefore, we reject the null hypothesis and conclude that there is a significant relationship between the size of a plant and the fact that equipment and machinery will break down if proper plant maintenance practices are not followed.

Hypothesis 3 looked at the following variables: Do you think accidents never happen at your plant? Do you think that people who work in plants that are not well-kept are more likely to get hurt? We can see that the significance value of the Pearson chi-square test was 0.012, which is less than the p-value of 0.05. Therefore, we reject the null hypothesis and conclude that there is a significant link between accidents and the fact that people who work in plants that are not well taken care of are more likely to get hurt. Hypothesis 4 looked at the following variables: How often do you have to shut down parts of your plant because of bad maintenance? Do you think that equipment and machinery will break down if proper maintenance practices are not followed? We can see that the Pearson chi-square test returned a significance value of 0.007, which is less than the 0.05 p-value. Therefore, we reject the null hypothesis and conclude that there is a significant relationship between problems with shutting down and the fact that equipment and machinery will break down if proper plant maintenance practices are not followed.

Focusing on Hypothesis 5, it was found that the variables “Why do you think equipment breaks down at the plant?” and “Do you think that plant maintenance is important for the safety and longevity of plant assets?” had a significance value of 0.007, which is less than the 0.05 p-value. Therefore, we do not accept the null hypothesis and conclude that there is a significant link between equipment failure and the fact that plant maintenance is important for safety and keeping plant assets in good shape for a long time. Hypothesis 6 looked at two variables: Do you think that regular and scheduled maintenance reduces risks to both employees and the plant? And do you think that people who work in poorly maintained plants are more likely to get hurt? The Pearson chi-square test showed that the significance value was 0.006, which is less than the p-value of 0.05. Therefore, we reject the null hypothesis and conclude that there is a significant link between regular and scheduled maintenance to reduce risks to employees and the fact that people who work in plants that are not well taken care of are more likely to get hurt. Hypothesis 7 looked at the following variables: Do you think maintenance strategy practices can be carried out easily at your plant? And how do you come up with a maintenance strategy? We can see that the significance value of the Pearson chi-square test was 0.048, which is less than the p-value of 0.05. Therefore, we do not accept the null hypothesis and conclude that there is a significant link between conducting maintenance strategy practices and coming up with a maintenance strategy.

Focusing on Hypothesis 8, it was found that the variables “What percentage of your plant’s workers are trained?” and “What factors do you consider when trying to improve the use of maintenance at your plant?” were important. The significance value of the Pearson chi-square test was found to be 0.013, which is less than the p-value of 0.05. Therefore, we reject the null hypothesis and conclude that there is a significant relationship between the right way to manage people and the things that should be considered when improving plant maintenance. Hypothesis 9 considered the variables “How old is your power plant?” and “What factors do you consider when improving the use of maintenance at the plant?” We can see that the Pearson chi-square test returned a significance value of 0.013, which is less than the p-value of 0.05. Therefore, we reject the null hypothesis and conclude that there is a significant relationship between the condition or nature of a plant and the things considered when trying to improve the use of plant maintenance.

This research considered the age of power plants and how maintenance plans are formulated, as stated in Hypothesis 10. We can see that the Pearson chi-square test returned a significance value of 0.061, which is higher than the p-value of 0.05. Since we agree with the null hypothesis, we can say that there is no significant link between the age of a plant and its maintenance strategy. Hypothesis 11 also looked at the variables “Do you think maintenance is important for keeping plant assets safe and making sure they last as long as possible?” and “What do you think about when trying to improve maintenance at the plant?” We can see that the significance value of the Pearson chi-square test was 0.299, which is higher than the p-value of 0.05. Therefore, we do not reject the null hypothesis and conclude that there is no significant link between the safety measures taken and the things considered when trying to improve how maintenance is used at the plant.

Focusing on Hypothesis 12, the following variables were considered: Which of the following results from not carrying out maintenance at your plant? And how do you come up with a maintenance plan? We can see that the significance value of the Pearson chi-square test was 0.001, which is less than the p-value of 0.05. Therefore, we do not accept the null hypothesis and conclude that there is a significant link between not adopting maintenance practices and coming up with a maintenance strategy. Finally, Hypothesis 13 looked at the following variables: Why do you think companies care about plant maintenance? What factors do you consider when trying to improve the use of plant maintenance? We can see that the significance value of the Pearson chi-square test was 0.023, which is less than the p-value of 0.05. Therefore, we do not accept the null hypothesis and conclude that there is a significant relationship between companies that want to keep their plants in good shape and the things considered when trying to improve the use of plant maintenance.

Furthermore, the hypothesis results present varying metrics using different parameters, as used in the benchmarked research work.

5. Conclusions

In conclusion, an ineffective maintenance strategy in an electric power plant can lead to various challenges with a significant impact on operations and the wider community. These problems include broken equipment, safety risks, long periods of downtime, and high repair costs. To ensure the effective functionality of a power plant, it is crucial to have an enhanced strategy for optimum maintenance. Therefore, being proactive in ensuring an effective maintenance strategy is implemented can limit issues and reduce the accident rate. Ensuring that employees have the right training and tools can ensure the maintenance strategy is effectively implemented. However, this framework considers reviewing the power plants maintenance strategy. This means maintenance issues with high priority will be considered first. The interval for carrying out the changeover to the solution provided in this framework is effective. Therefore, there is no requirement to invest heavily in electrical equipment because predictive maintenance can be outsourced. There will also be an increase in annual maintenance costs per electrical component, but the improvements in the maintenance of the system will be very significant. There will also be improvements in safety, both for facilities and maintenance professionals. The development of a framework that can ensure the implementation of an effective strategy for employees is recommended in future research. Also, a framework for periodic updates is required to enhance decision making, which should be easily adaptable in electric power plants and other institutions using effective maintenance strategies.

Author Contributions

Writing—original draft, T.A.A.A.; Supervision, M.N.A.R. and N.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mahmood, W.H.W.; Ab Rahman, M.N.; Deros, B.M.; Mazli, H. Maintenance management system for upstream operations in oil and gas industry: A case study. Int. J. Ind. Syst. Eng. 2011, 9, 317–329. [Google Scholar] [CrossRef]

- Carpitella, S.; Mzougui, I.; Benítez, J.; Carpitella, F.; Certa, A.; Izquierdo, J.; La Cascia, M. A risk evaluation framework for the best maintenance strategy: The case of a marine salt manufacture firm. Reliab. Eng. Syst. Saf. 2021, 205, 107265. [Google Scholar] [CrossRef]

- Aoudia, M.; Belmokhtar, O.; Zwingelstein, G. Economic impact of maintenance management ineffectiveness of an oil and gas company. J. Qual. Maint. Eng. 2008, 14, 237–261. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Pinho, B. Maintenance Strategy Choice Supported by the Failure Rate Function: Application in a Serial Manufacturing Line. Period. Polytech. Soc. Manag. Sci. 2023, 31, 38–51. [Google Scholar] [CrossRef]

- Zhang, N.; Zhao, Y.; Wang, N. Is China’s energy policy effective for power plants? Evidence from the 12th Five-Year Plan energy saving targets. Energy Econ. 2022, 112, 106143. [Google Scholar] [CrossRef]

- Saihi, A.; Ben-Daya, M.; As’Ad, R.A. Maintenance and sustainability: A systematic review of modeling-based literature. J. Qual. Maint. Eng. 2022, 29, 155–187. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Oke, S.A. A multi-criteria decision-making framework for selecting a suitable maintenance strategy for public buildings using sustainability criteria. J. Build. Eng. 2019, 24, 100753. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Pourarshad, M.; Noorollahi, Y.; Atabi, F.; Panahi, M. Reducing energy and environmental challenges by modeling clean electricity generation in oil-rich regions. Energy Environ. 2022, 0958305X221135056. [Google Scholar] [CrossRef]

- Salarkheili, S.; Nazar, M.S.; Wozabal, D.; Jabari, F. Capacity withholding of GenCos in electricity markets using security-constrained generation maintenance scheduling. Int. J. Electr. Power Energy Syst. 2023, 146, 108771. [Google Scholar] [CrossRef]

- Li, H.; Huang, C.G.; Soares, C.G. A real-time inspection and opportunistic maintenance strategies for floating offshore wind turbines. Ocean. Eng. 2022, 256, 111433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).