Large-Scale Ex Situ Tests for CO2 Storage in Coal Beds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coal Properties and Sample Preparation

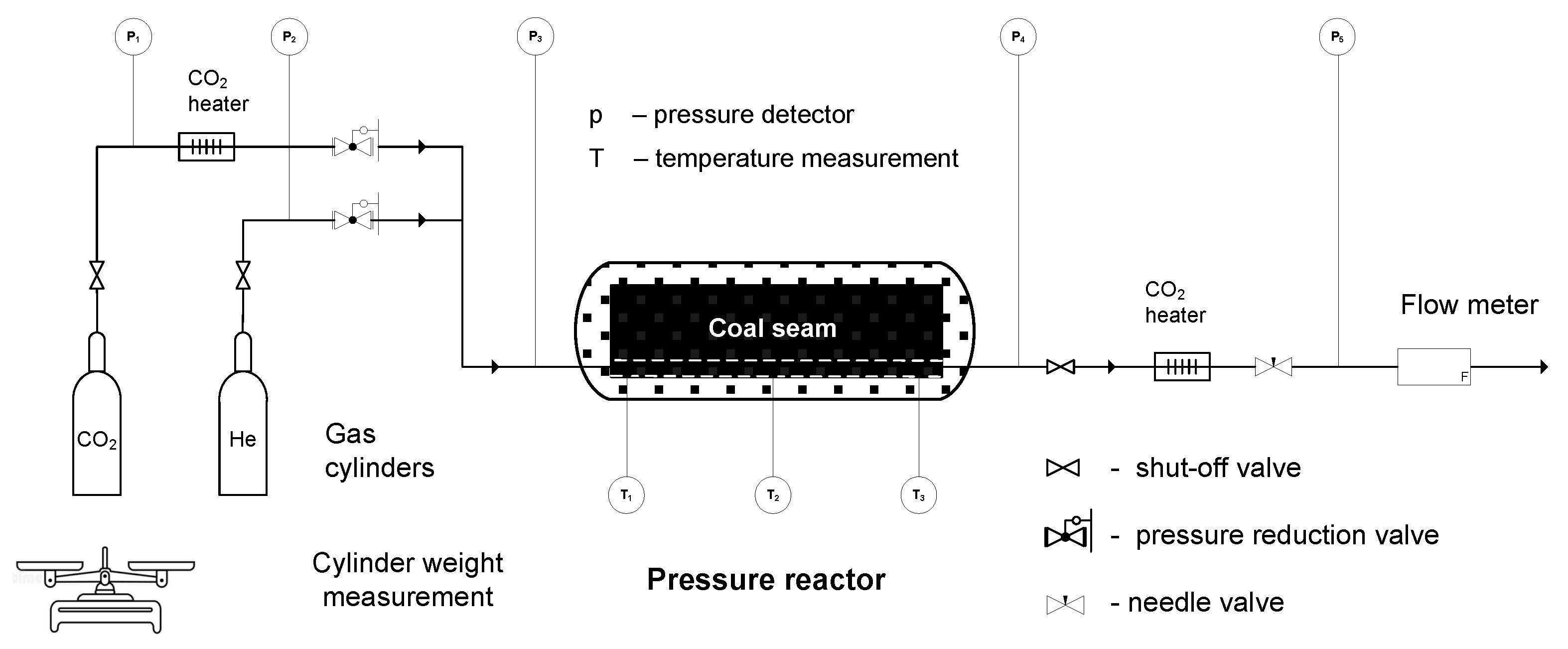

2.2. Experimental Setup

2.3. Experimental Procedure

- Installation of the measurement system and helium filling system (from gas cylinder) to the reactor,

- Measurement of the temperature and pressure prevailing in the gas cylinder before filling the reactor with helium,

- Filling the reactor with helium to a pressure of 3 bar and waiting until the gas pressure in the reactor is established,

- Depressurization of the reactor to atmospheric by opening the outlet and needle valves and releasing helium into the atmosphere,

- Measuring the volume of helium released from the reactor with a flow meter,

- Re-measuring the temperature and pressure of the remaining helium in the gas cylinder,

- Repeating the procedure for a higher pressure of 6 bar.

- Connection of the measurement system and CO2 filling system (gas cylinder) to the reactor,

- Measuring the mass of a liquid CO2 cylinder before filling the reactor with carbon dioxide,

- Filling the reactor with CO2 to a starting pressure of 30 bar. Close the gas cylinder valve and wait until the gas pressure in the pressurized reactor is established,

- Calculating, from the difference in the weight of the cylinder, the volume of CO2 let into the reactor at 30 bar. Reducing the pressure in the reactor to atmospheric by opening the outlet needle valve and releasing the CO2 into the atmosphere,

- Measuring the volume of CO2 released into the atmosphere with a flow meter,

- Calculating the difference in the mass of CO2 contained in a full and used gas cylinder and converting the mass to gas volume. The difference in CO2 volume calculated in is the amount of CO2 adsorbed.

3. Results

3.1. Helium Tests

3.1.1. Measurement of the Free Volume of the Reactor without the Coal Block Located Inside

3.1.2. Measurement of the Free Volume of the Reactor with the Coal Block Located Inside

3.1.3. Summary of Reactor Free-Volume Measurement Results

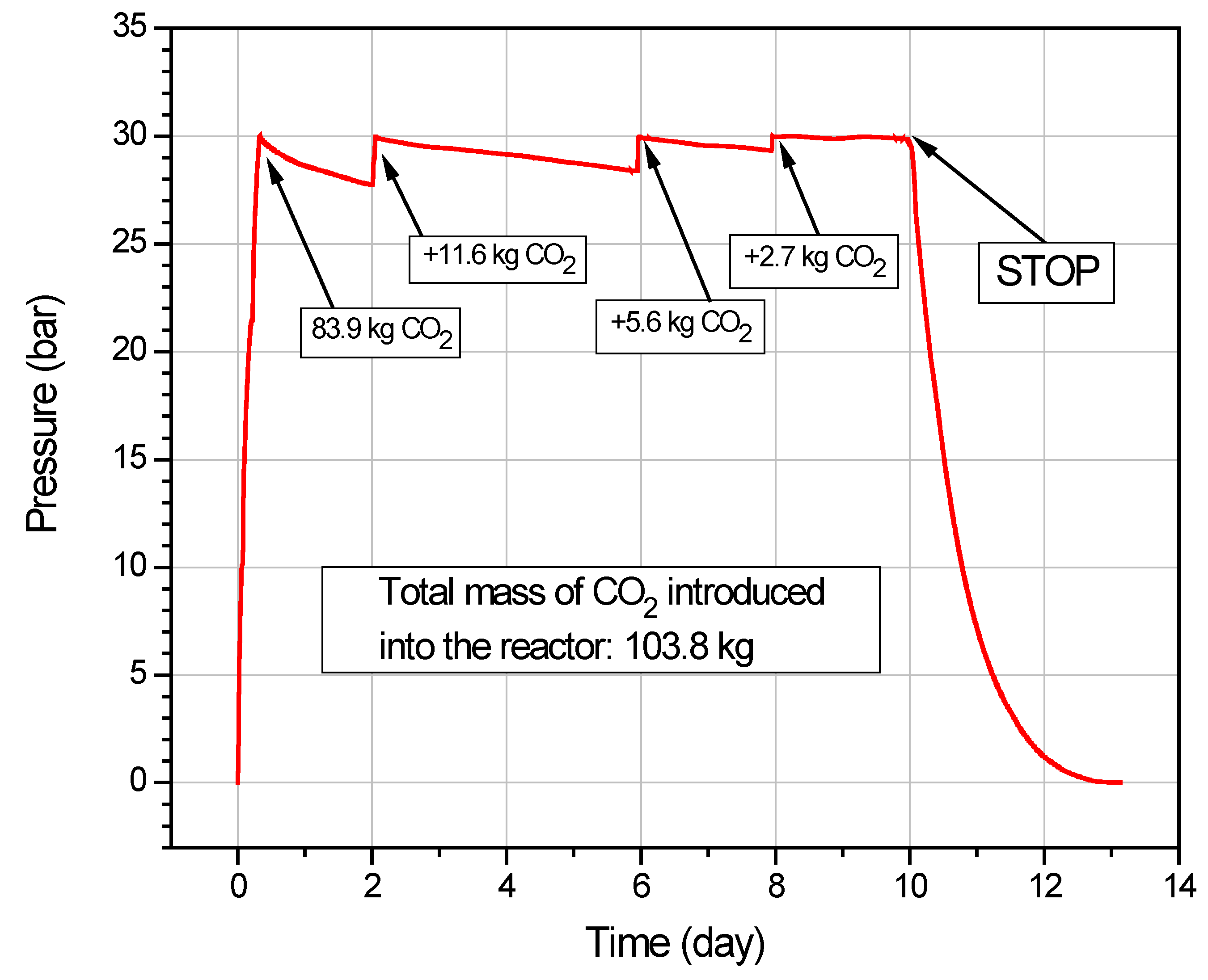

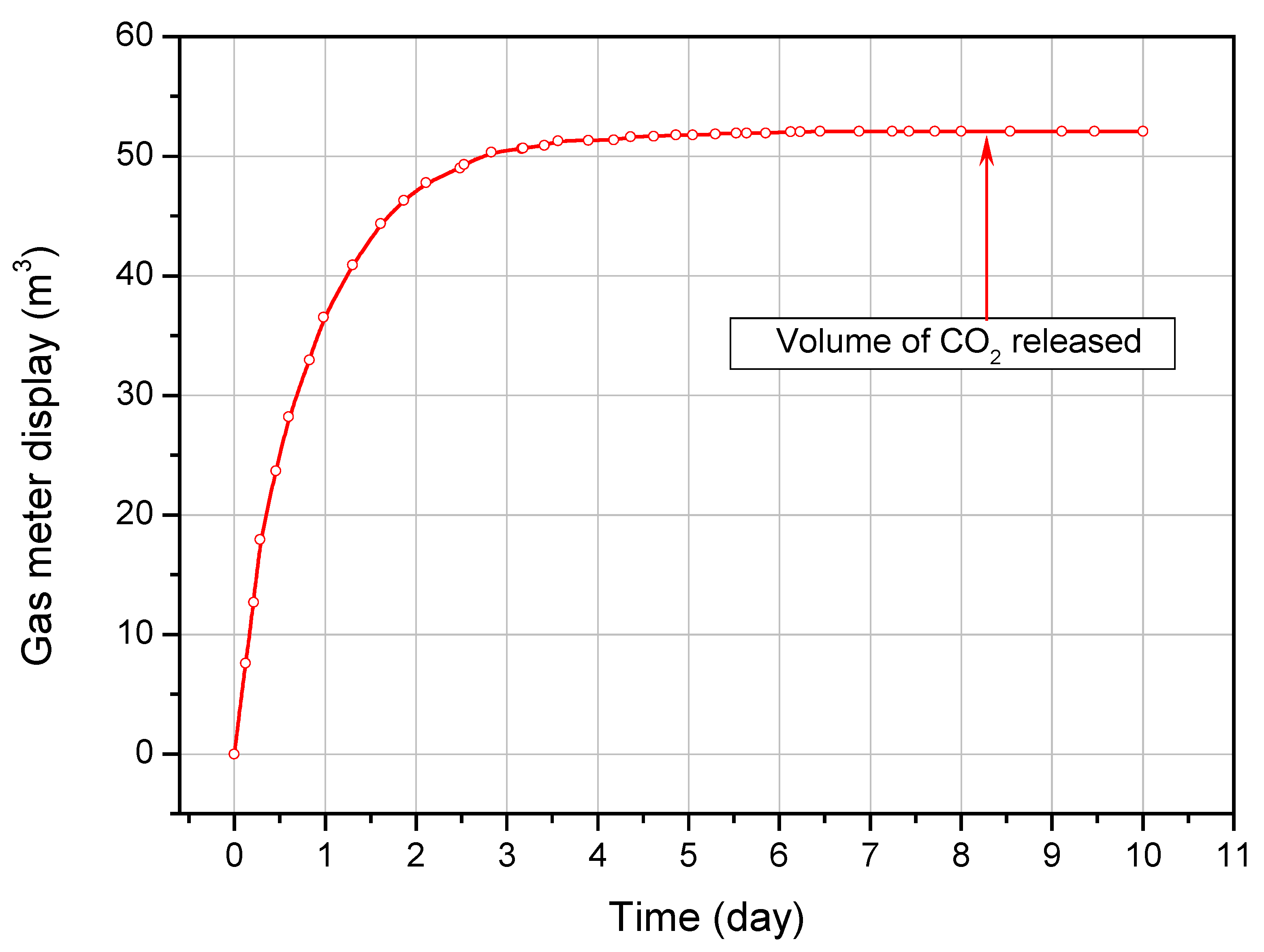

3.2. CO2 Sorption Test

Calculations of the Sorption Capacity of Coal in Relation to the Sorption of Gaseous CO2

4. Discussion and Conclusions

- Ex situ experiments allow us to assess the sorption capacity of coal. Such information allows us to quantify CO2 storage capacity when designing commercial-scale installations. For coal from the Polish coal mine “Piast-Ziemowit”, the sorption capacity measured at a pressure of 30 bar was 4.8% by weight relative to the raw coal mass.

- In the research study conducted, CO2 injection followed a multi-stage process where the vessel was repeatedly refilled with gas to achieve a pressure of 30 bar. With each successive CO2 addition, there was a diminishing trend in the reactor’s pressure drop. Concurrently, the amount of CO2 introduced during each cycle decreased. This suggests that, as CO2 migrated and was adsorbed into the coal seam pores, the available sorption capacity progressively diminished.

- Ex situ tests allow simulation of desorption processes following the adsorption phase. Such experiments performed on taken coal samples are essential to determine the total amount of CO2 that remains adsorbed in the coal even after lowering the pressure. This information is crucial, and the method is recommended for risk management. In the event of an emergency leading to leakage, this allows for an estimation of how much of the injected CO2 would remain within the coal seam.

- Based on the known geometry of the artificial seam, it is possible to assess the dynamics of CO2 migration. This knowledge can be transferred to in situ conditions and may prove helpful during an assessment of the feasible injection rates when designing commercial installations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ochedi, F.O.; Liu, Y.; Adewuyi, Y.G. State-of-the-art review on capture of CO2 using adsorbents prepared from waste materials. Process Saf. Environ. Prot. 2020, 139, 1–25. [Google Scholar] [CrossRef]

- Ochedi, F.O.; Yu, J.; Yu, H.; Liu, Y.; Hussain, A. Carbon dioxide capture using liquid absorption methods: A review. Environ. Chem. Lett. 2021, 19, 77–109. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Yusup, S. An overview of activated carbons utilization for the post-combustion carbon dioxide capture. J. CO2 Util. 2016, 13, 1–16. [Google Scholar] [CrossRef]

- Wang, X.; Liu, H.; Zhang, D.; Yuan, X.; Zeng, P.; Zhang, H. Effects of CO2 adsorption on molecular structure characteristics of coal: Implications for CO2 geological sequestration. Fuel 2022, 321, 124155. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; de Coninck, H.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage; IPPC: Rome, Italy, 2005. [Google Scholar]

- Mukherjee, A.; Okolie, J.A.; Abdelrasoul, A.; Niu, C.; Dalai, A.K. Review of post-combustion carbon dioxide capture technologies using activated carbon. J. Environ. Sci. 2019, 83, 46–63. [Google Scholar] [CrossRef]

- Liu, E.; Lu, X.; Wang, D. A Systematic Review of Carbon Capture, Utilization and Storage: Status, Progress and Challenges. Energies 2023, 16, 2865. [Google Scholar] [CrossRef]

- Vo Thanh, H.; Yasin, Q.; Al-Mudhafar, W.J.; Lee, K.K. Knowledge-based machine learning techniques for accurate prediction of CO2 storage performance in underground saline aquifers. Appl. Energy 2022, 314, 118985. [Google Scholar] [CrossRef]

- Zhang, Q. Adsorption mechanism of different coal ranks under variable temperature and pressure conditions. J. China Univ. Min. Technol. 2008, 18, 395–400. [Google Scholar] [CrossRef]

- Lyu, X.; Liu, Q.; Yang, K.; Duan, M.; Fang, J. Experimental study of adsorption characteristics and deformation of coal for different gases. ACS Omega 2022, 7, 11415–11421. [Google Scholar] [CrossRef]

- Jia, L.; Cheng, P.; Yu, Y.; Chen, S.; Wang, C.; He, L.; Nie, H.; Wang, J.; Zhang, J.; Fan, B.; et al. Regeneration mechanism of a novel high-performance biochar mercury adsorbent directionally modified by multimetal multilayer loading. J. Environ. Manag. 2023, 326, 116790. [Google Scholar] [CrossRef]

- Zhao, X.; Liao, X.; He, L. The evaluation methods for CO2 storage in coal beds, in China. J. Energy Inst. 2016, 89, 389–399. [Google Scholar] [CrossRef]

- Hol, S.; Peach, C.J.; Spiers, C.J. A new experimental method to determine the CO2 sorption capacity of coal. Energy Procedia 2011, 4, 3125–3130. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Li, B.; Kong, X.; Xu, J.; Peng, S.; Chen, Y. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam. Energy 2022, 262, 125473. [Google Scholar] [CrossRef]

- Asif, M.; Wang, L.; Wang, R.; Wang, H.; Hazlett, R.D. Mechanisms in CO2-enhanced coalbed methane recovery process. Adv. Geo-Energy Res. 2022, 6, 531–534. [Google Scholar] [CrossRef]

- Shi, J.Q.; Durucan, S. CO2 Storage in Deep Unminable Coal Seams. Oil Gas Sci. Technol. Rev. IFP 2005, 60, 547–558. [Google Scholar] [CrossRef]

- Wen, H.; Hao, J.; Ma, L.; Zheng, X. Experimental Study on Replacing Coal Seam CH4 with CO2 Gas. ACS Omega 2022, 7, 1395–1403. [Google Scholar] [CrossRef]

- Bai, G.; Su, J.; Zhang, Z.; Lan, A.; Zhou, X.; Gao, F.; Zhou, J. Effect of CO2 injection on CH4 desorption rate in poor permeability coal seams: An experimental study. Energy 2021, 238, 121674. [Google Scholar] [CrossRef]

- Kumar, H. Effect of sorption isotherm on CO2 storage capacity in Indian coal seam. Arab. J. Geosci. 2023, 16, 75. [Google Scholar] [CrossRef]

- Wetzel, M.; Otto, C.; Chen, M.; Masum, S.; Thomas, H.; Urych, T.; Bezak, B.; Kempka, T. Hydromechanical Impacts of CO2 Storage in Coal Seams of the Upper Silesian Coal Basin (Poland). Energies 2023, 16, 3279. [Google Scholar] [CrossRef]

- Fujioka, M.; Yamaguchi, S.; Nako, M. CO2-ECBM field tests in the Ishikari Coal Basin of Japan. Int. J. Coal Geol. 2010, 82, 287–298. [Google Scholar] [CrossRef]

- Kahnt, R.; Kutzke, A.; Martin, M.; Eckart, M.; Schlüter, R.; Kempka, T.; Tillner, E.; Hildenbrand, A.; Krooss, B.M.; Gensterblum, Y.; et al. “CO2RINA”—CO2 Storage Risk Integrated Analysis. Geological Storage of CO2—Long Term Security Aspects. GEOTECHNOLOGIEN Sci. Rep. 2015, 22, 139–166. [Google Scholar] [CrossRef]

- van Bergen, F.; Winthaegen, P.; Pagnier, H.; Krzystolik, P.; Jura, B.; Skiba, J.; van Wageningen, N. Assessment of CO2 storage performance of the Enhanced Coalbed Methane pilot site in Kaniow. Energy Procedia 2009, 1, 3407–3414. [Google Scholar] [CrossRef]

- van Bergen, F.; Krzystolik, P.; van Wageningen, N.; Pagnier, H.; Jura, B.; Skiba, J.; Winthaegen, P.; Kobiela, Z. Production of gas from coal seams in the Upper Silesian Coal Basin in Poland in the post-injection period of an ECBM pilot site. Int. J. Coal Geol. 2009, 77, 175–187. [Google Scholar] [CrossRef]

- Alves Dias, P.; Kanellopoulos, K.; Medarac, H.; Kapetaki, Z.; Miranda Barbosa, E.; Shortall, R.; Czako, V.; Telsnig, T.; Vazquez Hernandez, C.; Lacal Arantegui, R.; et al. EU Coal Regions: Opportunities and Challenges Ahead; Report number: JRC112593; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-89884-6 (online), 978-92-79-89883-9 (print). doi: 10.2760/064809 (online), 10.2760/668092 (print). [Google Scholar]

- Vangkilde-Pedersen, T.; Anthonsen, K.L.; Smith, N.; Kirk, K.; Neele, F.; van der Meer, B.; Le Gallo, Y.; Bossie-Codreanu, D.; Wojcicki, A.; Le Nindre, Y.-M.; et al. Assessing European capacity for geological storage of carbon dioxide–the EU GeoCapacity project. Energy Procedia 2009, 1, 2663–2670. [Google Scholar] [CrossRef]

- Kumar, H. An overview of characterization and sorption capacity of coal for CO2 sequestration. Arab. J. Geosci. 2022, 15, 1364. [Google Scholar] [CrossRef]

- Zheng, S.; Sang, S.; Liu, S.; Wang, M.; Cao, L.; Jin, X.; Feng, G.; Yang, Y. Measurement of CO2 adsorption capacity with respect to different pressure and temperature in sub-bituminous: Implication for CO2 geological sequestration. Front. Earth Sci. 2023. [Google Scholar] [CrossRef]

- Huy, P.Q.; Sasaki, K.; Sugai, Y.; Kiga, T.; Fujioka, M.; Adachi, T. Effects of SO2 and pH Concentration on CO2 Adsorption Capacity in Coal Seams for CO2 Sequestration with Considerations for Flue Gas from Coal-Fired Power Plants. J. Can. Pet. Technol. 2009, 48, 58–63. [Google Scholar] [CrossRef]

- PN-EN ISO/IEC 17025:2018-2; Ogólne Wymagania Dotyczące Kompetencji Laboratoriów Badawczych i Wzorcujących. General Requirements for the Competence of Testing and Calibration Laboratories. ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/files/live/sites/isoorg/files/store/en/PUB100424.pdf (accessed on 27 August 2023).

- PN-G-04560:1998 Standard; Paliwa Stałe—Oznaczanie Zawartości Wilgoci, Części Lotnych Oraz Popiołu Analizatorem Automatycznym. Solid Fuels—Determination of Moisture, Volatile Matter and Ash by Automatic Analyzer. Polish Committee for Standardization: Warsaw, Poland, 1998. (In Polish)

- PN-G-04516:1998 Standard; Paliwa Stałe—Oznaczanie Zawartości Części Lotnych Metodą Wagową. Solid Fuels—Gravimetric Determination of Volatile Matter. Polish Committee for Standardization: Warsaw, Poland, 1998. (In Polish)

- PN-G-04584:2001 Standard; Paliwa Stałe—Oznaczanie Zawartości Siarki Całkowitej i Popiołowej Automatycznymi Analizatorami. Solid Fuels—Determination of Total and Ash Sulfur Content with Automatic Analyzers. Polish Committee for Standardization: Warsaw, Poland, 2001. (In Polish)

- PN-G-04513:1981 Standard; Paliwa Stałe—Oznaczanie Ciepła Spalania i Obliczanie Wartości Opałowej. Solid Fuels—Determination of the Calorific Value and Calorific Value Calculation. Polish Committee for Standardization: Warsaw, Poland, 1991. (In Polish)

- PN-G-04571:1998 Standard; Paliwa Stałe—Oznaczanie Zawartości Węgla, Wodoru i Azotu Automatycznymi Analizatorami—Metoda Makro. Solid Fuels—Determination of Carbon, Hydrogen and Nitrogen Content with Automatic Analyzers—Macro Method. Polish Committee for Standardization: Warsaw, Poland, 1998. (In Polish)

| Parameter | Symbol | Unit | Value | Standard b | |

|---|---|---|---|---|---|

| As received | Total moisture | Wtr | (%) | 8.50 | PN-G-04560:1998 [31] |

| Ash | Ar | (%) | 7.56 | PN-G-04560:1998 | |

| Volatile matter | Vr | (%) | 30.15 | PN-G-04516:1998 [32] | |

| S total | Str | (%) | 0.98 | PN-G-04584:2001 [33] | |

| Lower heating value | Qr | (kJ/kg) | 25,786 | PN-G-04513:1981 [34] | |

| Analytical | Moisture | Wa | (%) | 7.47 | PN-G-04560:1998 |

| Ash | Aa | (%) | 7.64 | PN-G-04560:1998 | |

| Volatile matter | Va | (%) | 30.49 | PN-G-04516:1998 | |

| Lower heating value | Qa | (kJ/kg) | 26,103 | PN-G-04513:1981 | |

| Sta total | (%) | 0.99 | PN-G-04584:2001 | ||

| Ca | (%) | 68.62 | PN-G-04571:1998 [35] | ||

| Ha | (%) | 4.30 | PN-G-04571:1998 | ||

| Na | (%) | 1.08 | PN-G-04571:1998 | ||

| Oa * | (%) | 10.20 |

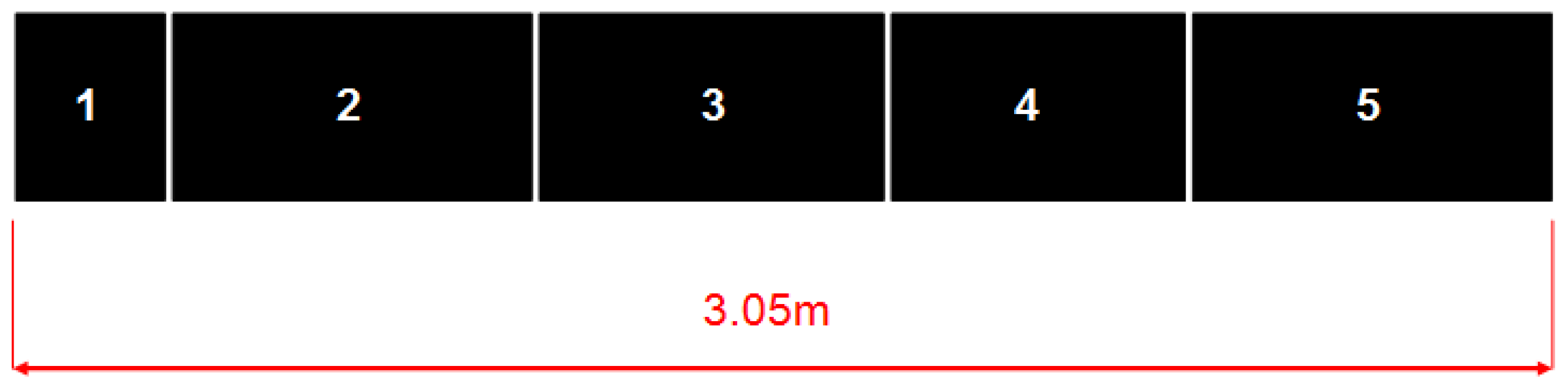

| Coal Block | Width (cm) | Height (cm) | Length (cm) | Weight (kg) | Volume of a Coal Block (dm3) |

|---|---|---|---|---|---|

| 1 | 40 | 40 | 31 | 58 | 47.4 |

| 2 | 40 | 40 | 74 | 139 | 108.0 |

| 3 | 40 | 40 | 70 | 184 | 101.3 |

| 4 | 40 | 40 | 60 | 106 | 96.2 |

| 5 | 40 | 40 | 70 | 144 | 105.1 |

| TOTAL | 631 | 458.0 | |||

| Test No. | Initial Pressure in the Helium Cylinder | Final Pressure in the Helium Cylinder | Helium Cylinder Volume | Average Helium Cylinder Temperature | Amount of Helium Taken from the Gas Cylinder | |

|---|---|---|---|---|---|---|

| bar | bar | dm3 | °C | mol | Ndm3 | |

| 1 (3 bar) | 198 | 89 | 50 | 5.5 | 235.23 | 5269.3 |

| 2 (5 bar) | 181 | 5.0 | 50 | 2.9 | 382.16 | 8560.4 |

| Test No. | Pressure Inside the Reactor | Average Temperature Inside the Reactor | Amount of Helium Inserted to the Reactor | Free Volume in the Reactor (under Standard Conditions) |

|---|---|---|---|---|

| bar | °C | mol | Ndm3 | |

| 1 | 3.0 | 11.7 | 235.23 | 1857.0 |

| 2 | 5.0 | 10.5 | 382.16 | 1802.6 |

| Reactor Final Pressure | Atmospheric Pressure | Ambient Temperature | Amount of Helium Released from the Reactor | Free Volume in the Reactor (under Standard Conditions) | |

|---|---|---|---|---|---|

| bar | hPa | °C | dm3 | mol | Ndm3 |

| 3.0 | 965 | 15.1 | 5807 | 230.82 | 1723.5 |

| 5.0 | 975 | 1.5 | 9342 | 377.27 | 1690.2 |

| Test No. | Initial Pressure in the Helium Cylinder | Final Pressure in the Helium Cylinder | Helium Cylinder Volume | Helium Cylinder Temperature | Amount of Helium Taken from the Gas Cylinder | |

|---|---|---|---|---|---|---|

| bar | bar | dm3 | °C | mol | Ndm3 | |

| 3 (3 bar) | 92 | 11 | 50 | 11.3 | 171.25 | 3836 |

| 4 (6 bar) | 187 | 28 | 50 | 11.9 | 335.44 | 7514 |

| Test No. | Pressure Inside the Reactor | Average Temperature Inside the Reactor | Amount of Helium Inserted to the Reactor | Free Volume in the Reactor (under Standard Conditions) |

|---|---|---|---|---|

| bar | °C | mol | Ndm3 | |

| 3 | 3.0 | 8.5 | 171.25 | 1337 |

| 4 | 6.0 | 8.7 | 335.44 | 1310 |

| Reactor Final Pressure | Atmospheric Pressure | Ambient Temperature | Volume of Helium Released from the Reactor | Free Volume in the Reactor (under Standard Conditions) | |

|---|---|---|---|---|---|

| bar | hPa | °C | dm3 | Ndm3 | Ndm3 |

| 2.95 | 1018 | 10.6 | 3861 | 3733 | 1324 |

| 5.89 | 1025 | 11.2 | 7442 | 7235 | 1285 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiatowski, M.; Kapusta, K.; Stańczyk, K.; Szyja, M.; Masum, S.; Sadasivam, S.; Thomas, H.R. Large-Scale Ex Situ Tests for CO2 Storage in Coal Beds. Energies 2023, 16, 6326. https://doi.org/10.3390/en16176326

Wiatowski M, Kapusta K, Stańczyk K, Szyja M, Masum S, Sadasivam S, Thomas HR. Large-Scale Ex Situ Tests for CO2 Storage in Coal Beds. Energies. 2023; 16(17):6326. https://doi.org/10.3390/en16176326

Chicago/Turabian StyleWiatowski, Marian, Krzysztof Kapusta, Kamil Stańczyk, Marcin Szyja, Shakil Masum, Sivachidambaram Sadasivam, and Hywel Rhys Thomas. 2023. "Large-Scale Ex Situ Tests for CO2 Storage in Coal Beds" Energies 16, no. 17: 6326. https://doi.org/10.3390/en16176326

APA StyleWiatowski, M., Kapusta, K., Stańczyk, K., Szyja, M., Masum, S., Sadasivam, S., & Thomas, H. R. (2023). Large-Scale Ex Situ Tests for CO2 Storage in Coal Beds. Energies, 16(17), 6326. https://doi.org/10.3390/en16176326